Analysis of Machinability and Crack Occurrence of Steels 1.2363 and 1.2343ESR Machined by Die-Sinking EDM

Abstract

1. Introduction

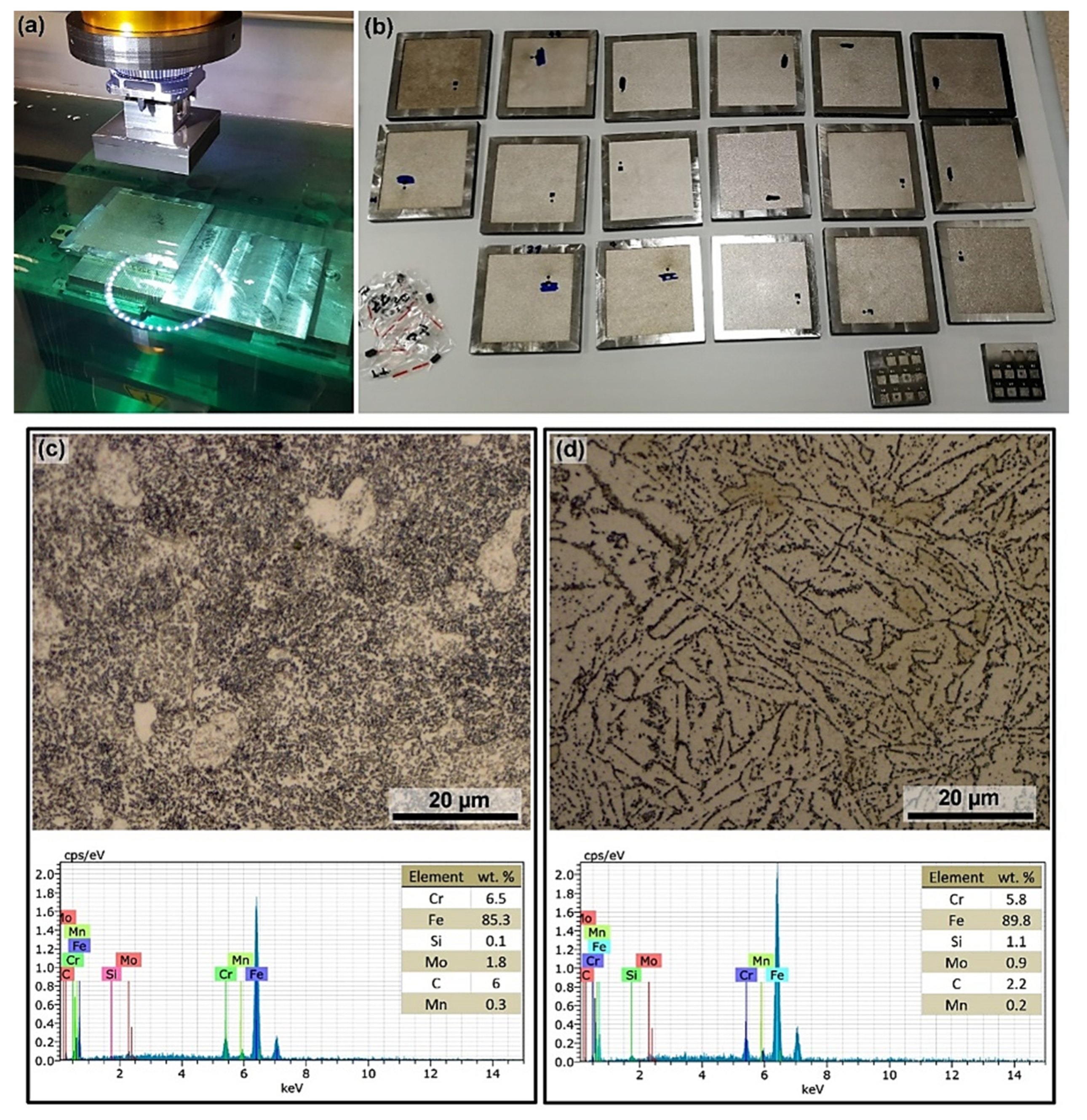

2. Experimental Setup and Material

2.1. Experimental Material

2.2. Electric Discharge Machining (EDM) Machine Setup

3. Results and Discussion

3.1. Experimental Methods

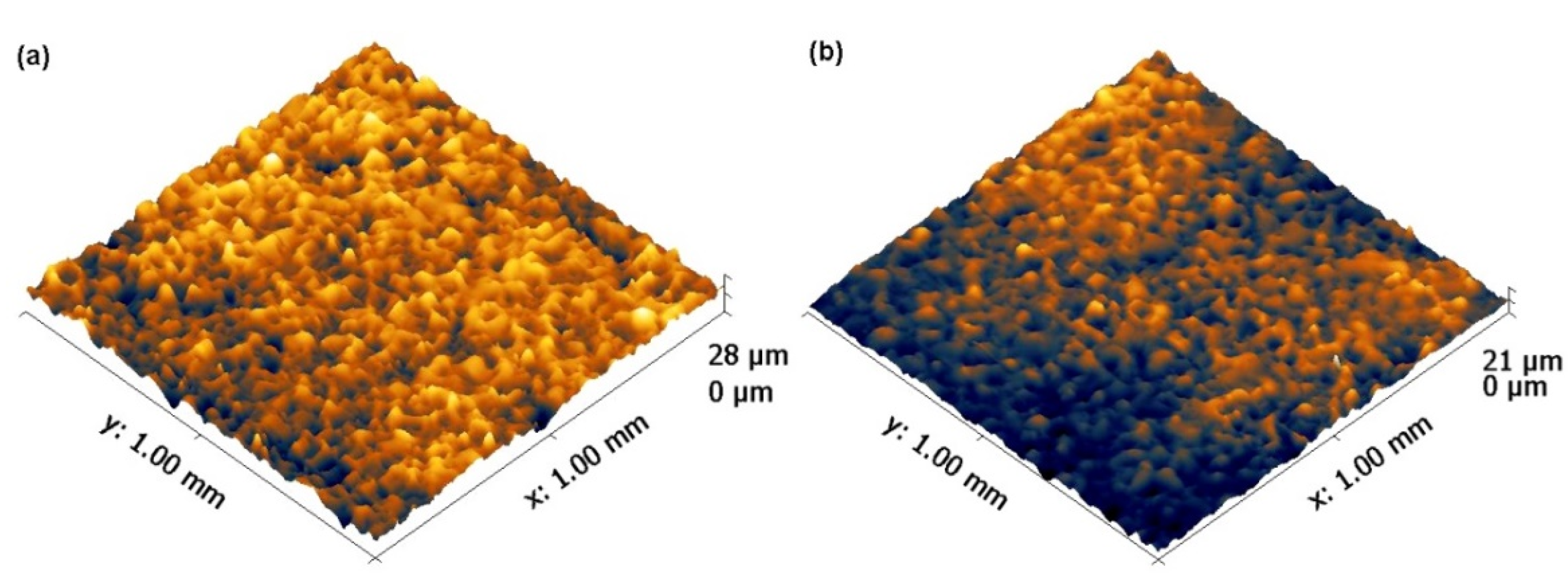

3.2. Surface Topography

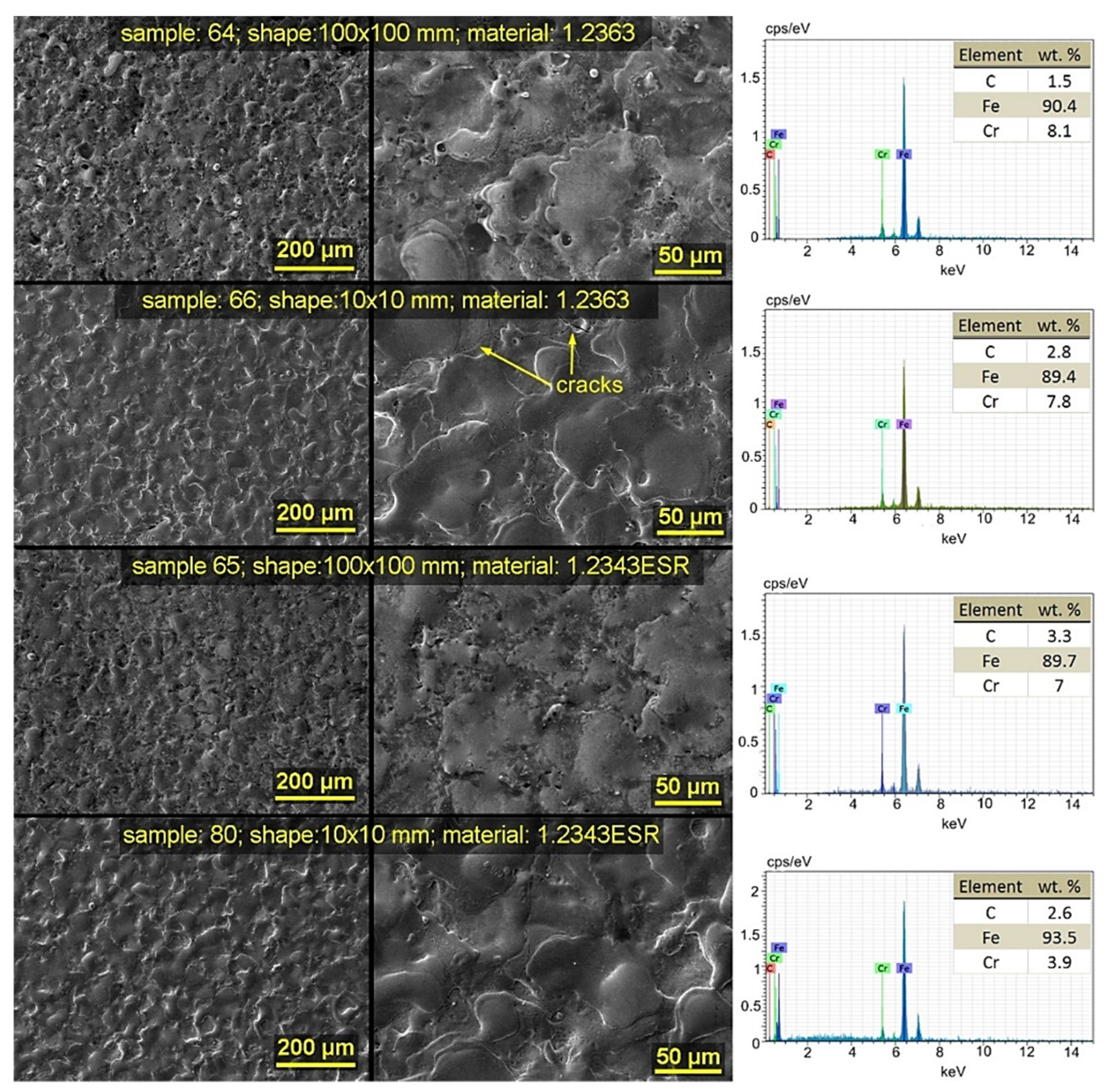

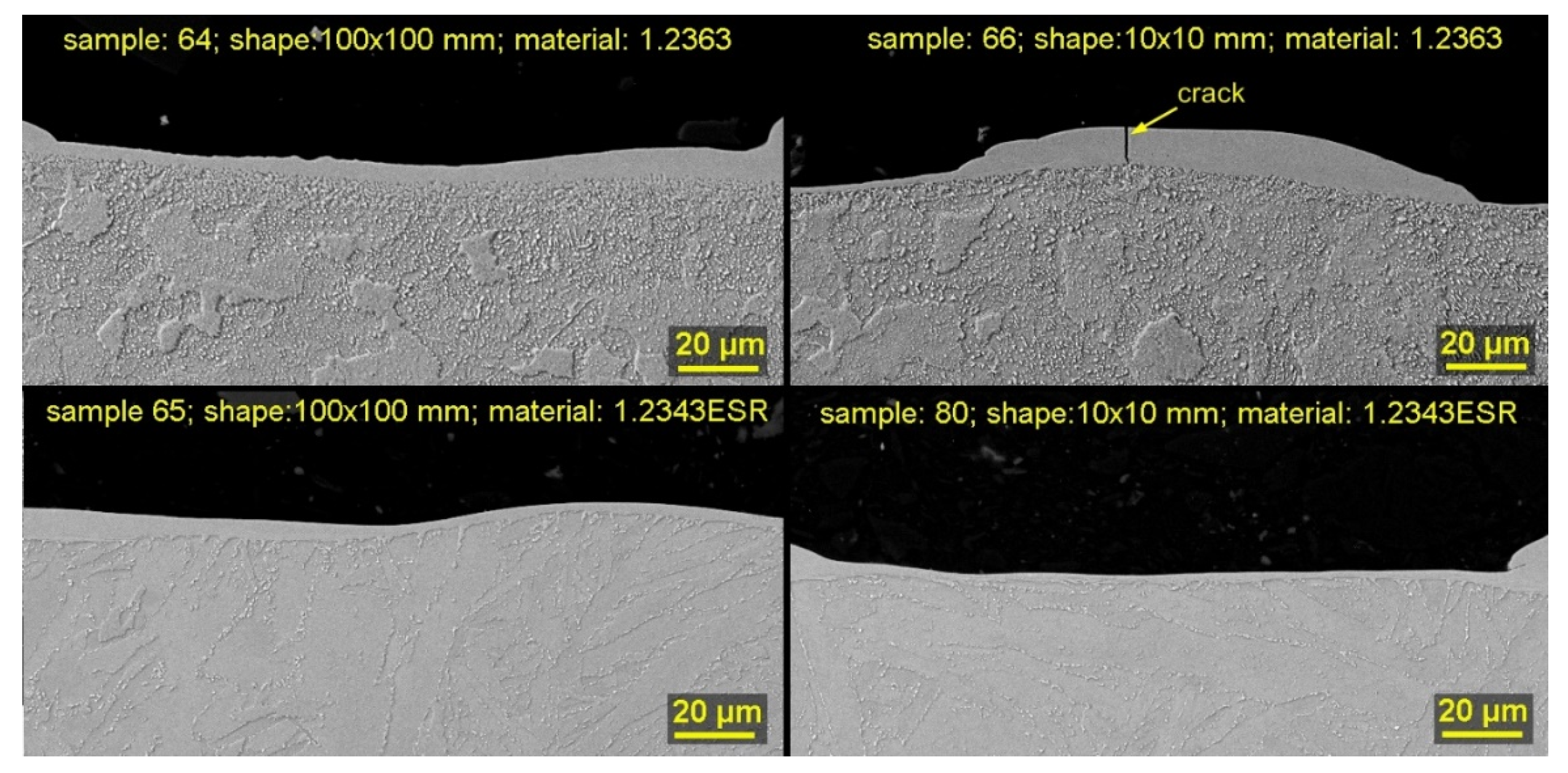

3.3. The Morphology Analysis of the Surface and Subsurface Area Including Defects

3.4. The Hardness Analysis of a Subsurface Layer

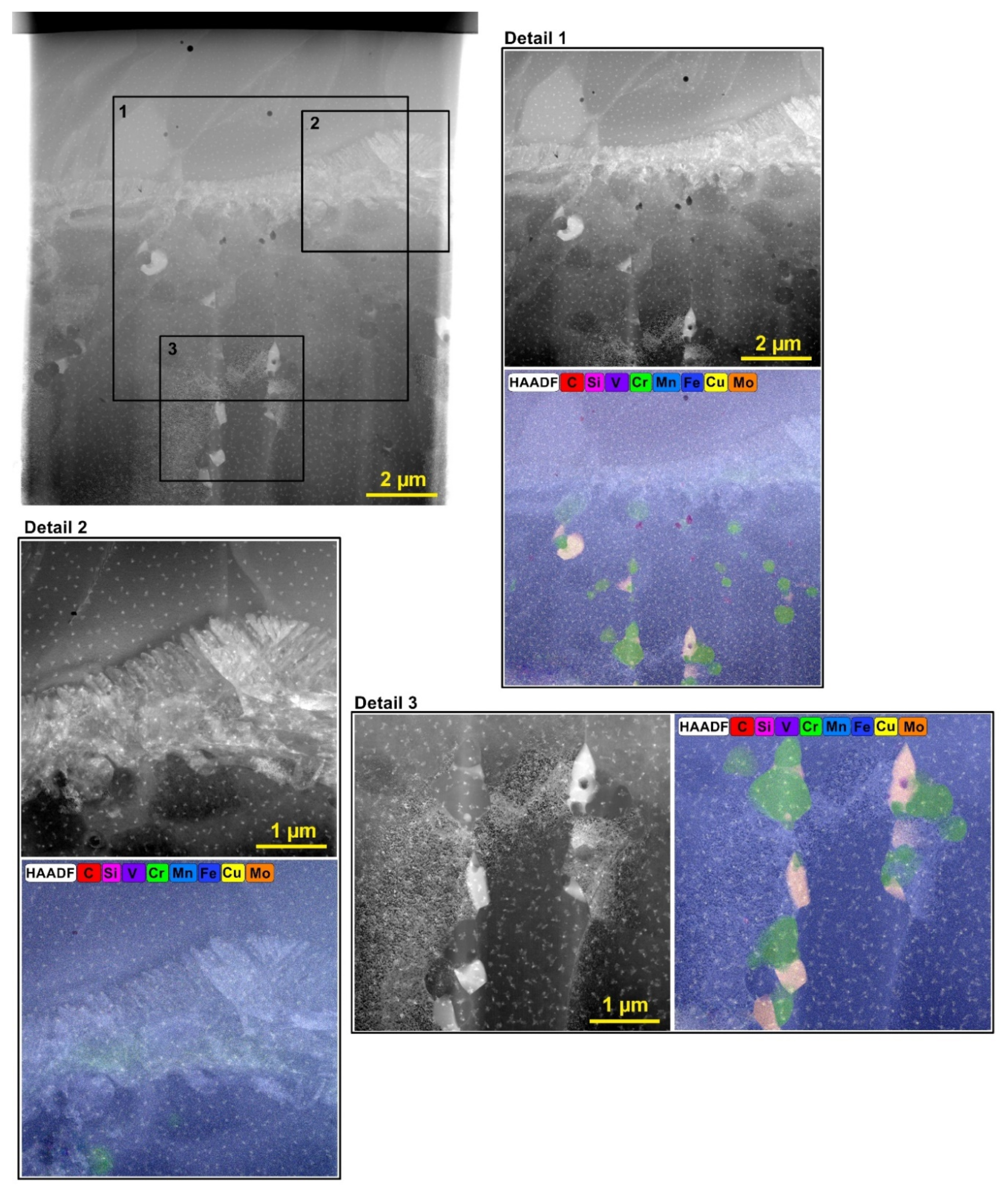

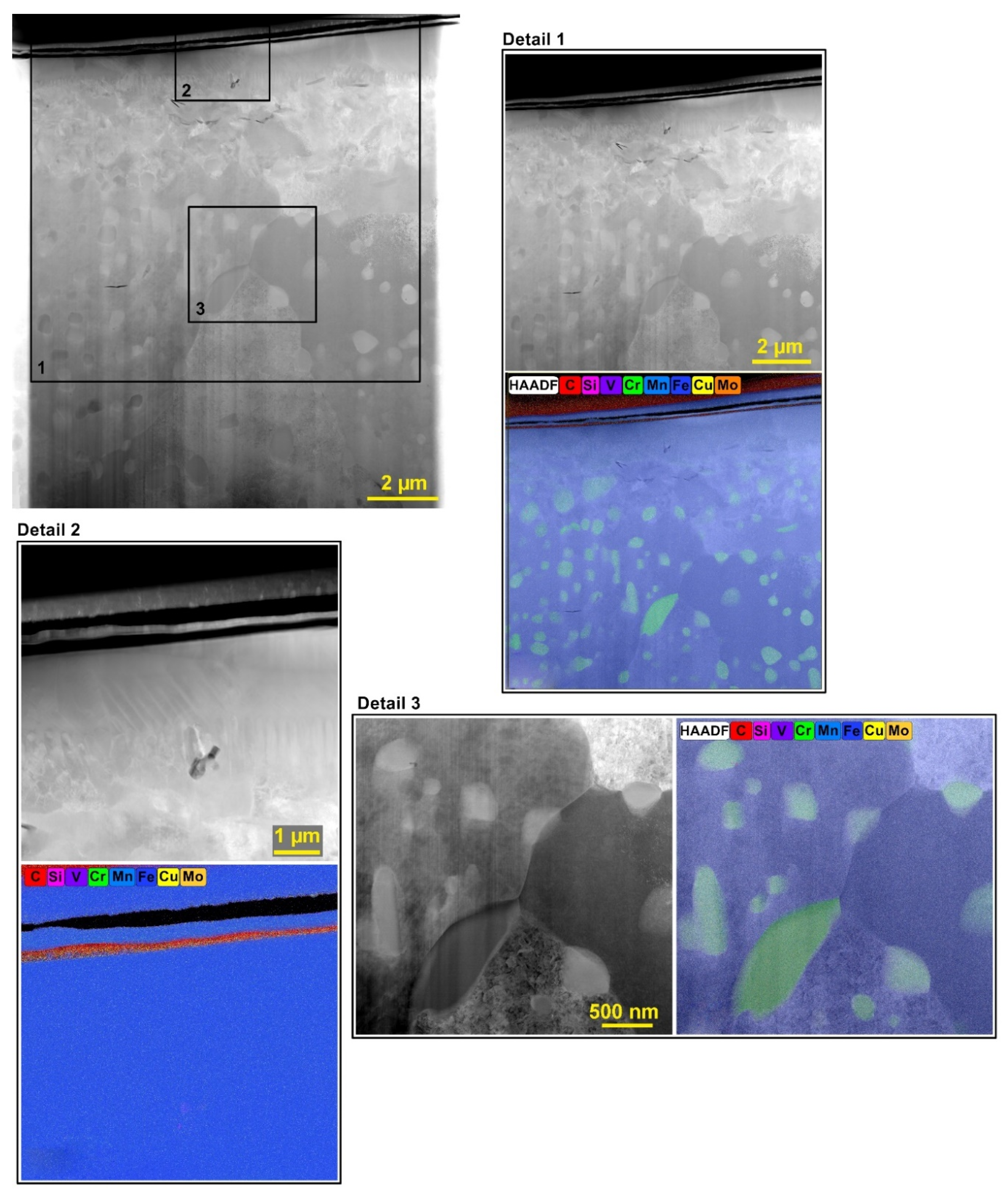

3.5. TEM Lamella Analysis

4. Conclusions

- The morphology of the individual samples was very different and closely correlated with the surface topography analysis, with cracks being studied on some samples, that were further assessed cross-sectioned and statistically analyzed for their occurrence.

- The cross-section analysis of all samples showed cracks in some samples, but these were always in the recast layer only and did not interfere with the base material.

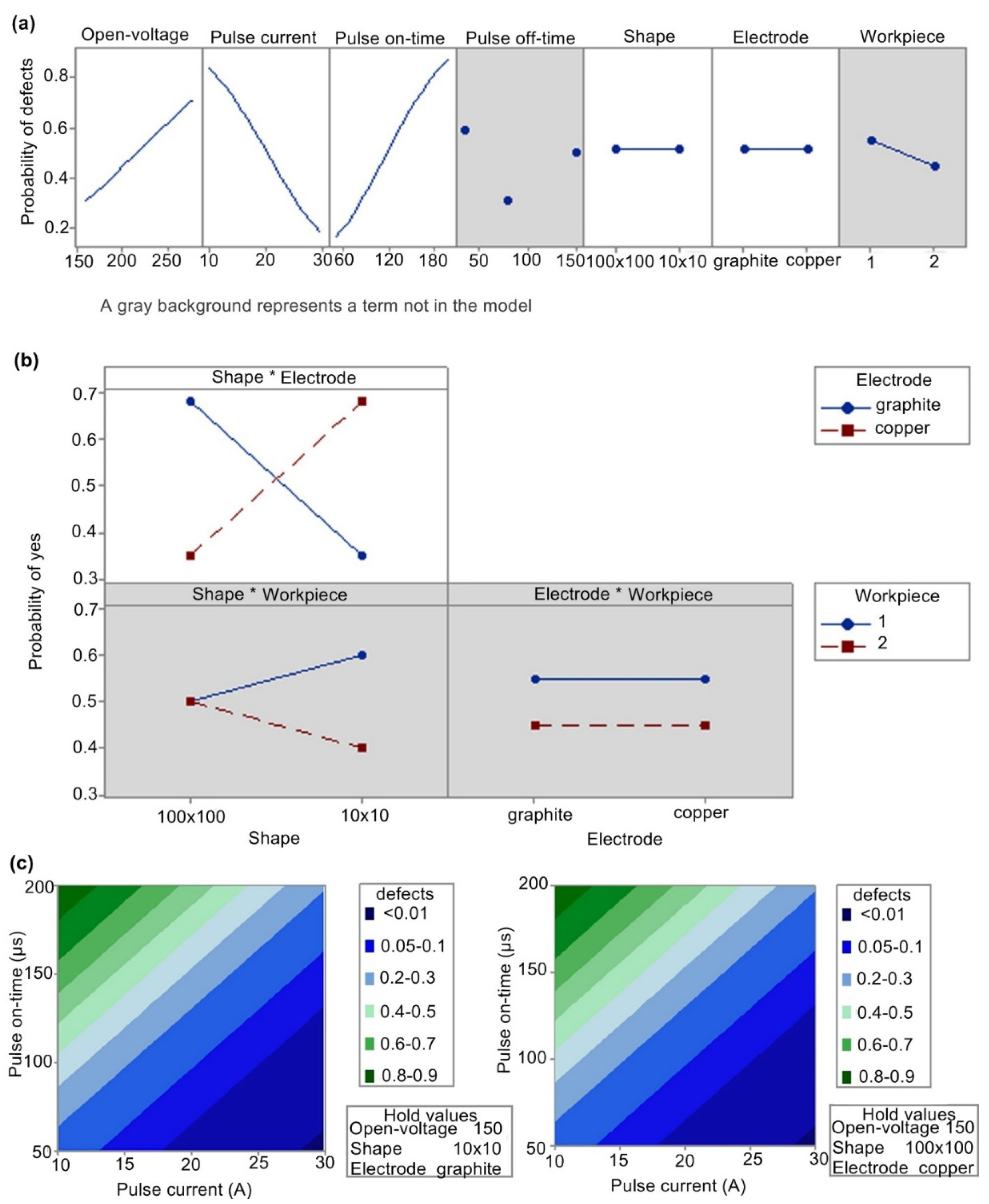

- The occurrence of defects was modelled using binary logistic regression, which made it possible to predict the probability of the occurrence of defects on the surface of samples based on input variables and to create regression equations describing the probability of crack occurrence.

- Based on the measurement of the local hardness development in the subsurface layer of the samples, hardening of the material after EDM was found, but only to a depth of 8–12 µm, with no further impact on the material; and

- The TEM lamellae produced allowed for a detailed study of the microstructure of materials and their changes caused by a die-sinking EDM.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McGeough, J.A. Advanced Methods of Machining; Springer Science & Business Media: New York, NY, USA, 1988. [Google Scholar]

- Ho, K.H.; Newman, S.T. State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Garg, R.K.; Singh, K.K.; Sachdeva, A.; Sharma, V.S.; Ojha, K.; Singh, S. Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int. J. Adv. Manuf. Technol. 2010, 50, 611–624. [Google Scholar] [CrossRef]

- Muthuramalingam, T.; Mohan, B. A review on influence of electrical process parameters in EDM process. Arch. Civ. Mech. Eng. 2015, 15, 87–94. [Google Scholar] [CrossRef]

- Meshram, D.B.; Puri, Y.M. Review of research work in die sinking EDM for machining curved hole. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2593–2605. [Google Scholar] [CrossRef]

- Nikalje, A.M.; Kumar, A.; Srinadh, K.S. Influence of parameters and optimization of EDM performance measures on MDN 300 steel using Taguchi method. Int. J. Adv. Manuf. Technol. 2013, 69, 41–49. [Google Scholar] [CrossRef]

- Rajendran, S.; Marimuthu, K.; Sakthivel, M. Study of crack formation and resolidified layer in EDM process on T90Mn2W50Cr45 tool steel. Mat. Manuf. Proc. 2013, 28, 664–669. [Google Scholar]

- Majumder, A. Process parameter optimization during EDM of AISI 316 LN stainless steel by using fuzzy based multi-objective PSO. J. Mech. Sci. Technol. 2013, 27, 2143–2151. [Google Scholar] [CrossRef]

- Gill, A.S.; Kumar, S. Surface alloying of H11 die steel by tungsten using EDM process. Int. J. Adv. Manuf. Technol. 2015, 78, 1585–1593. [Google Scholar] [CrossRef]

- Corný, I.; Pitel, J.; Hašová, S. Statistical approach to optimize the process parameters of HAZ of tool steel EN X32CrMoV12-28 after die-sinking EDM with SF-Cu electrode. Metals 2017, 7, 35. [Google Scholar]

- Santos, R.F.; Silva, E.R.; Sales, W.F.; Raslan, A.A. Analysis of the surface integrity when nitriding AISI 4140 steel by the sink electrical discharge machining (EDM) process. Procedia CIRP 2016, 45, 303–306. [Google Scholar] [CrossRef][Green Version]

- Sidhom, H.; Ghanem, F.; Amadou, T.; Gonzalez, G.; Braham, C. Effect of electro discharge machining (EDM) on the AISI316L SS white layer microstructure and corrosion resistance. Int. J. Adv. Manuf. Technol. 2013, 65, 141–153. [Google Scholar] [CrossRef]

- Dewangan, S.; Gangopadhyay, S.; Biswas, C.K. Multi-response optimization of surface integrity characteristics of EDM process using grey-fuzzy logic-based hybrid approach. Eng. Sci. Technol. Int. J. 2015, 18, 361–368. [Google Scholar] [CrossRef]

- Dewangan, S.; Biswas, C.K.; Gangopadhyay, S. Influence of different tool electrode materials on EDMed surface integrity of AISI P20 tool steel. Mat. Manuf. Proc. 2014, 29, 1387–1394. [Google Scholar] [CrossRef]

- D’Urso, G.; Giardini, C.; Quarto, M. Characterization of surfaces obtained by micro-EDM milling on steel and ceramic components. Int. J. Adv. Manuf. Technol. 2018, 97, 2077–2085. [Google Scholar] [CrossRef]

- Valentinčič, J.; Kušer, D.; Smrkolj, S.; Blatnik, O.; Junkar, M. Machining parameters selection for varying surface in EDM. Int. J. Mat. Prod. Technol. 2007, 29, 344. [Google Scholar] [CrossRef]

- Debnath, T.; Baroi, B.K.; Patowari, P.K. Machinability study of 430 stainless steel using tap water in EDM. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Jarosz, K.; Nieslony, P.; Löschner, P. Investigation of the effect of process parameters on surface roughness in EDM machining of ORVAR® supreme die steel. In Advances in Manufacturing Engineering and Materials; Springer: Cham, Switzerland, 2019; pp. 333–340. [Google Scholar]

- Valarmathi, T.N.; Sekar, S.; Anthony, G.; Suresh, R.; Balan, K.N. Experimental studies on surface roughness of H12 tool steel in EDM using different tool materials. In Innovative Design, Analysis and Development Practices in Aerospace and Automotive Engineering (I-DAD 2018); Springer: Singapore, 2019; pp. 241–247. [Google Scholar]

- Jiang, X.J.; Whitehouse, D.J. Technological shifts in surface metrology. CIRP Ann. Manuf. Technol. 2012, 61, 815–836. [Google Scholar] [CrossRef]

- Mouralova, K.; Klakurkova, L.; Matousek, R.; Prokes, T.; Hrdy, R.; Kana, V. Influence of the cut direction through the semi-finished product on the occurrence of cracks for X210Cr12 steel using WEDM. Arch. Civ. Mech. Eng. 2018, 18, 1318–1331. [Google Scholar] [CrossRef]

- Mouralova, K.; Benes, L.; Bednar, J.; Zahradnicek, R.; Prokes, T.; Matousek, R.; Fiserova, Z.; Otoupalik, J. Using a DoE for a comprehensive analysis of the surface quality and cutting speed in WED-machined hadfield steel. J. Mech. Sci. Technol. 2019, 33, 2371–2386. [Google Scholar] [CrossRef]

- Mouralova, K.; Prokes, T.; Benes, L.; Sliwkova, P. Analysis of subsurface defects occurrence in abrasion resistant Creusabro steel after WEDM including the study of morphology and surface topography. Mach. Sci. Technol. 2020, 24, 274–290. [Google Scholar] [CrossRef]

- Mouralova, K.; Prokes, T.; Benes, L.; Bednar, J. The influence of WEDM parameters setup on the occurrence of defects when machining hardox 400 steel. Materials 2019, 12, 3758. [Google Scholar] [CrossRef]

- Mouralova, K.; Prokes, T.; Benes, L. Surface and subsurface layers defects analysis after WEDM affecting the subsequent lifetime of produced components. Arab. J. Sci. Eng. 2019, 44, 7723–7735. [Google Scholar] [CrossRef]

- Geometrical Product Specifications (GPS). Surface Texture: Areal. Part 2: Terms, Definitions and Surface Texture Parameters; ISO 25178-2; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Geometrical Product Specifications (GPS). Surface Texture: Profile Method. Terms, Definitions and Surface Texture Parameters; ISO 4287; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- Lee, H.T.; Rehbach, W.P.; Tai, T.Y.; Hsu, F.C. Relationship between electrode size and surface cracking in the EDM machining process. J. Mater. Sci. 2004, 39, 6981–6986. [Google Scholar] [CrossRef]

- Ekmekci, B. White layer composition, heat treatment, and crack formation in electric discharge machining process. Metall. Mater. Trans. B 2009, 40, 70–81. [Google Scholar] [CrossRef]

- Keskin, Y.; Halkacı, H.S.; Kizil, M. An experimental study for determination of the effects of machining parameters on surface roughness in electrical discharge machining (EDM). Int. J. Adv. Manuf. Technol. 2006, 28, 1118–1121. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Q.; Zhu, G.; Wang, K.; Zhang, J.; Dong, C. Effect of electrode size on the performances of micro-EDM. Mater. Manuf. Proc. 2016, 31, 391–396. [Google Scholar] [CrossRef]

- Yan, B.H.; Tsai, H.C.; Huang, F.Y. The effect in EDM of a dielectric of a urea solution in water on modifying the surface of titanium. Int. J. Mach. Tools Manuf. 2005, 45, 194–200. [Google Scholar] [CrossRef]

- Guu, Y.H. AFM surface imaging of AISI D2 tool steel machined by the EDM process. Appl. Surf. Sci. 2005, 242, 245–250. [Google Scholar] [CrossRef]

- Lee, S.H.; Li, X. Study of the surface integrity of the machined workpiece in the EDM of tungsten carbide. J. Mat. Proc. Technol. 2003, 139, 315–321. [Google Scholar] [CrossRef]

- Kumar, K.L.; Rao, C.S.; Sateesh, B.; Viswanath, M.S.R. Analysis of Micro-cracks and Micro-hardness in White Layer Formation on Machined Surfaces in EDM Process. In Advances in Applied Mechanical Engineering; Springer: Singapore, 2020; pp. 955–963. [Google Scholar]

- Wang, C.C.; Chow, H.M.; Yang, L.D.; Lu, C.T. Recast layer removal after electrical discharge machining via Taguchi analysis: A feasibility study. J. Mater. Proc. Technol. 2009, 209, 4134–4140. [Google Scholar] [CrossRef]

- Mahdieh, M.S.; Mahdavinejad, R. Recast layer and micro-cracks in electrical discharge machining of ultra-fine-grained aluminum. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 428–437. [Google Scholar] [CrossRef]

- Muttamara, A. Comparison performances of EDM on Ti6Al4V with two graphite grades. Int. J. Chem. Eng. Appl. 2015, 6, 250–253. [Google Scholar] [CrossRef]

- Phan, N.H. Analysis of surface layers of hot–forging dies of SKD61 steel fabricated by die–sinking electrical discharge machining using copper and titanium electrodes. Vietnam J. Sci. Technol. 2016, 54, 19–26. [Google Scholar] [CrossRef]

- Matin, R.; Rahmani, R.; Shabgard, M.R. Effect of input parameters on the depth of heat affected zone (HAZ) AISI H13 steel electrical discharge machining process (EDM). Int. J. Mater. Eng. Technol. 2019, 2, 33–38. [Google Scholar]

- Abu Qudeiri, J.E.; Saleh, A.; Ziout, A.; Mourad, A.H.I.; Abidi, M.H.; Elkaseer, A. Advanced electric discharge machining of stainless steels: Assessment of the state of the art, gaps and future prospect. Materials 2019, 12, 907. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Sethi, B.L. Comparison of material transfer in electrical discharge machining of AISI H13 die steel. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2009, 223, 1733–1740. [Google Scholar] [CrossRef]

- Mandal, P.; Mondal, S.C. Surface characteristics of mild steel using EDM with Cu-MWCNT composite electrode. Mater. Manuf. Proc. 2019, 34, 1326–1332. [Google Scholar] [CrossRef]

- Stráský, J.; Janeček, M.; Harcuba, P.; Bukovina, M.; Wagner, L. The effect of microstructure on fatigue performance of Ti–6Al–4V alloy after EDM surface treatment for application in orthopaedics. J. Mech. Behav. Biomed. Mater. 2011, 4, 1955–1962. [Google Scholar] [CrossRef]

| Parameter | Shape of Electrode | Material of Electrode | Material of Workpiece | Open-Voltage (V) | Pulse Current (A) | Pulse On Time (µs) | Pulse Off Time (µs) |

|---|---|---|---|---|---|---|---|

| Lower level | 10 × 10 | copper | 1.2363 (1) | 160 | 10 | 50 | 35 |

| Central level | – | – | – | 220 | 20 | 100 * | 80 * |

| Higher level | 100 × 100 | graphite | 1.2343ESR (2) | 280 | 30 | 200 | 150 |

| Sample Number | Shape of Electrode | Material of Electrode | Material of Workpiece | Open-Voltage (V) | Pulse Current (A) | Pulse on Time (µs) | Pulse off Time (µs) |

|---|---|---|---|---|---|---|---|

| 1 | 10 × 10 | graphite | 1 | 220 | 20 | 100 | 80 |

| 2 | 100 × 100 | copper | 1 | 280 | 30 | 50 | 35 |

| 3 | 100 × 100 | graphite | 1 | 280 | 10 | 50 | 35 |

| 4 | 10 × 10 | graphite | 2 | 280 | 30 | 200 | 35 |

| 5 | 100 × 100 | graphite | 1 | 280 | 30 | 200 | 35 |

| 6 | 10 × 10 | graphite | 2 | 160 | 10 | 50 | 150 |

| 7 | 100 × 100 | copper | 1 | 160 | 30 | 50 | 150 |

| 8 | 10 × 10 | graphite | 1 | 160 | 10 | 200 | 150 |

| 9 | 10 × 10 | copper | 1 | 160 | 10 | 200 | 35 |

| 10 | 10 × 10 | copper | 1 | 220 | 20 | 100 | 80 |

| 11 | 100 × 100 | copper | 2 | 280 | 30 | 50 | 150 |

| 12 | 10 × 10 | copper | 1 | 220 | 20 | 100 | 80 |

| 13 | 10 × 10 | graphite | 2 | 160 | 30 | 50 | 35 |

| 14 | 100 × 100 | copper | 1 | 220 | 20 | 100 | 80 |

| 15 | 10 × 10 | copper | 2 | 280 | 30 | 200 | 150 |

| 16 | 100 × 100 | graphite | 2 | 220 | 20 | 100 | 80 |

| 17 | 10 × 10 | copper | 1 | 160 | 30 | 200 | 150 |

| 18 | 10 × 10 | copper | 1 | 280 | 10 | 50 | 35 |

| 19 | 10 × 10 | copper | 2 | 280 | 10 | 50 | 150 |

| 20 | 100 × 100 | copper | 2 | 220 | 20 | 100 | 80 |

| 21 | 100 × 100 | graphite | 1 | 220 | 20 | 100 | 80 |

| 22 | 10 × 10 | copper | 2 | 160 | 10 | 200 | 150 |

| 23 | 10 × 10 | graphite | 2 | 160 | 30 | 200 | 150 |

| 24 | 100 × 100 | graphite | 2 | 280 | 10 | 200 | 35 |

| 25 | 100 × 100 | graphite | 2 | 160 | 30 | 50 | 150 |

| 26 | 100 × 100 | copper | 2 | 160 | 30 | 50 | 35 |

| 27 | 100 × 100 | copper | 2 | 220 | 20 | 100 | 80 |

| 28 | 100 × 100 | graphite | 1 | 160 | 10 | 200 | 35 |

| 29 | 10 × 10 | graphite | 1 | 280 | 10 | 200 | 35 |

| 30 | 10 × 10 | copper | 1 | 160 | 30 | 50 | 35 |

| 31 | 100 × 100 | copper | 1 | 160 | 10 | 200 | 150 |

| 32 | 10 × 10 | copper | 2 | 280 | 10 | 200 | 35 |

| 33 | 10 × 10 | graphite | 2 | 220 | 20 | 100 | 80 |

| 34 | 10 × 10 | graphite | 1 | 160 | 10 | 50 | 35 |

| 35 | 100 × 100 | copper | 1 | 280 | 30 | 200 | 150 |

| 36 | 100 × 100 | copper | 2 | 280 | 10 | 200 | 150 |

| 37 | 10 × 10 | graphite | 1 | 280 | 30 | 50 | 35 |

| 38 | 10 × 10 | copper | 2 | 280 | 30 | 50 | 35 |

| 39 | 10 × 10 | copper | 2 | 160 | 30 | 200 | 35 |

| 40 | 10 × 10 | copper | 1 | 280 | 10 | 200 | 150 |

| 41 | 100 × 100 | graphite | 1 | 220 | 20 | 100 | 80 |

| 42 | 10 × 10 | copper | 1 | 280 | 30 | 200 | 35 |

| 43 | 100 × 100 | graphite | 1 | 280 | 10 | 200 | 150 |

| 44 | 100 × 100 | copper | 1 | 160 | 10 | 50 | 35 |

| 45 | 100 × 100 | graphite | 2 | 160 | 30 | 200 | 35 |

| 46 | 100 × 100 | copper | 2 | 160 | 30 | 200 | 150 |

| 47 | 100 × 100 | graphite | 2 | 280 | 10 | 50 | 150 |

| 48 | 10 × 10 | graphite | 1 | 280 | 10 | 50 | 150 |

| 49 | 10 × 10 | copper | 2 | 220 | 20 | 100 | 80 |

| 50 | 100 × 100 | graphite | 2 | 160 | 10 | 50 | 35 |

| 51 | 100 × 100 | graphite | 2 | 280 | 30 | 200 | 150 |

| 52 | 100 × 100 | graphite | 1 | 160 | 30 | 50 | 35 |

| 53 | 10 × 10 | copper | 1 | 280 | 30 | 50 | 150 |

| 54 | 10 × 10 | graphite | 1 | 280 | 30 | 200 | 150 |

| 55 | 100 × 100 | graphite | 1 | 160 | 10 | 50 | 150 |

| 56 | 10 × 10 | graphite | 2 | 280 | 10 | 50 | 35 |

| 57 | 10 × x10 | graphite | 2 | 160 | 10 | 200 | 35 |

| 58 | 100 × 100 | graphite | 2 | 280 | 30 | 50 | 35 |

| 59 | 100 × 100 | graphite | 1 | 160 | 30 | 200 | 150 |

| 60 | 100 × 100 | copper | 1 | 280 | 10 | 50 | 150 |

| 61 | 100 × 100 | graphite | 1 | 280 | 30 | 50 | 150 |

| 62 | 100 × 100 | copper | 1 | 280 | 10 | 200 | 35 |

| 63 | 10 × 10 | graphite | 2 | 280 | 30 | 50 | 150 |

| 64 | 100 × 100 | copper | 1 | 220 | 20 | 100 | 80 |

| 65 | 100 × 100 | graphite | 2 | 220 | 20 | 100 | 80 |

| 66 | 10 × 10 | graphite | 1 | 220 | 20 | 100 | 80 |

| 67 | 10 × 10 | copper | 2 | 160 | 30 | 50 | 150 |

| 68 | 100 × 100 | copper | 2 | 280 | 30 | 200 | 35 |

| 69 | 10 × 10 | graphite | 1 | 160 | 30 | 50 | 150 |

| 70 | 10 × 10 | copper | 1 | 160 | 10 | 50 | 150 |

| 71 | 100 × 100 | copper | 2 | 280 | 10 | 50 | 35 |

| 72 | 10 × 10 | copper | 2 | 220 | 20 | 100 | 80 |

| 73 | 100 × 100 | graphite | 2 | 160 | 10 | 200 | 150 |

| 74 | 10 × 10 | graphite | 2 | 280 | 10 | 200 | 150 |

| 75 | 100 × 100 | copper | 2 | 160 | 10 | 50 | 150 |

| 76 | 100 × 100 | copper | 1 | 160 | 30 | 200 | 35 |

| 77 | 100 × 100 | copper | 2 | 160 | 10 | 200 | 35 |

| 78 | 10 × 10 | copper | 2 | 160 | 10 | 50 | 35 |

| 79 | 10 × 10 | graphite | 1 | 160 | 30 | 200 | 35 |

| 80 | 10 × 10 | graphite | 2 | 220 | 20 | 100 | 80 |

| Sample No. | Defects | Sample No. | Defects | Sample No. | Defects | Sample No. | Defects | Sample No. | Defects |

|---|---|---|---|---|---|---|---|---|---|

| 1 | No | 17 | Yes | 33 | No | 49 | No | 65 | No |

| 2 | No | 18 | Yes | 34 | Yes | 50 | Yes | 66 | Yes |

| 3 | Yes | 19 | No | 35 | Yes | 51 | Yes | 67 | No |

| 4 | No | 20 | No | 36 | Yes | 52 | No | 68 | Yes |

| 5 | Yes | 21 | No | 37 | No | 53 | No | 69 | No |

| 6 | No | 22 | Yes | 38 | Yes | 54 | No | 70 | No |

| 7 | No | 23 | No | 39 | Yes | 55 | No | 71 | No |

| 8 | Yes | 24 | Yes | 40 | Yes | 56 | Yes | 72 | No |

| 9 | Yes | 25 | No | 41 | Yes | 57 | Yes | 73 | Yes |

| 10 | Yes | 26 | No | 42 | Yes | 58 | No | 74 | Yes |

| 11 | No | 27 | Yes | 43 | Yes | 59 | Yes | 75 | No |

| 12 | No | 28 | Yes | 44 | No | 60 | Yes | 76 | No |

| 13 | No | 29 | Yes | 45 | No | 61 | No | 77 | Yes |

| 14 | No | 30 | Yes | 46 | No | 62 | Yes | 78 | No |

| 15 | Yes | 31 | Yes | 47 | Yes | 63 | No | 79 | No |

| 16 | Yes | 32 | Yes | 48 | Yes | 64 | No | 80 | No |

| Element | Detail 1 | Detail 2 | Detail 3 | |||

|---|---|---|---|---|---|---|

| Atomic Fraction (%) | Fit Error (%) | Atomic Fraction (%) | Fit Error (%) | Atomic Fraction (%) | Fit Error (%) | |

| C | 1.74 | 0.17 | 1.72 | 1.64 | 2.85 | 0.66 |

| Si | 1.65 | 0.27 | 1.43 | 0.17 | 2.05 | 0.36 |

| V | 0.49 | 0.13 | 0.40 | 0.03 | 0.69 | 0.20 |

| Cr | 5.65 | 0.17 | 5.35 | 0.21 | 7.83 | 0.11 |

| Mn | 0.45 | 2.96 | 0.46 | 2.10 | 0.44 | 2.91 |

| Fe | 85.27 | 0.05 | 86.35 | 0.05 | 79.88 | 0.03 |

| Cu | 4.10 | 0.00 | 3.73 | 0.01 | 5.00 | 0.02 |

| Mo | 0.64 | 0.31 | 0.58 | 0.24 | 1.26 | 0.08 |

| Element | Detail 1 | Detail 2 | Detail 3 | |||

|---|---|---|---|---|---|---|

| Atomic Fraction (%) | Fit Error (%) | Atomic Fraction (%) | Fit Error (%) | Atomic Fraction (%) | Fit Error (%) | |

| C | 3.69 | 2.01 | 5.96 | 0.10 | 2.53 | 0.73 |

| Si | 0.56 | 0.26 | 0.55 | 0.26 | 0.59 | 0.91 |

| V | 0.09 | 0.03 | 0.10 | 0.16 | 0.19 | 0.05 |

| Cr | 4.30 | 0.15 | 4.00 | 0.03 | 5.48 | 0.27 |

| Mn | 0.63 | 1.45 | 0.59 | 3.20 | 0.58 | 2.18 |

| Fe | 86.23 | 0.08 | 84.39 | 0.05 | 86.20 | 0.12 |

| Cu | 4.17 | 0.02 | 4.11 | 0.02 | 4.09 | 0.01 |

| Mo | 0.33 | 0.30 | 0.29 | 0.09 | 0.34 | 0.29 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mouralova, K.; Benes, L.; Bednar, J.; Zahradnicek, R.; Prokes, T.; Fries, J. Analysis of Machinability and Crack Occurrence of Steels 1.2363 and 1.2343ESR Machined by Die-Sinking EDM. Coatings 2020, 10, 406. https://doi.org/10.3390/coatings10040406

Mouralova K, Benes L, Bednar J, Zahradnicek R, Prokes T, Fries J. Analysis of Machinability and Crack Occurrence of Steels 1.2363 and 1.2343ESR Machined by Die-Sinking EDM. Coatings. 2020; 10(4):406. https://doi.org/10.3390/coatings10040406

Chicago/Turabian StyleMouralova, Katerina, Libor Benes, Josef Bednar, Radim Zahradnicek, Tomas Prokes, and Jiří Fries. 2020. "Analysis of Machinability and Crack Occurrence of Steels 1.2363 and 1.2343ESR Machined by Die-Sinking EDM" Coatings 10, no. 4: 406. https://doi.org/10.3390/coatings10040406

APA StyleMouralova, K., Benes, L., Bednar, J., Zahradnicek, R., Prokes, T., & Fries, J. (2020). Analysis of Machinability and Crack Occurrence of Steels 1.2363 and 1.2343ESR Machined by Die-Sinking EDM. Coatings, 10(4), 406. https://doi.org/10.3390/coatings10040406