Investigation and Prediction on Regulation of Hydrophobicity of Polymethyl Methacrylate (PMMA) Surface by Femtosecond Laser Irradiation

Abstract

1. Introduction

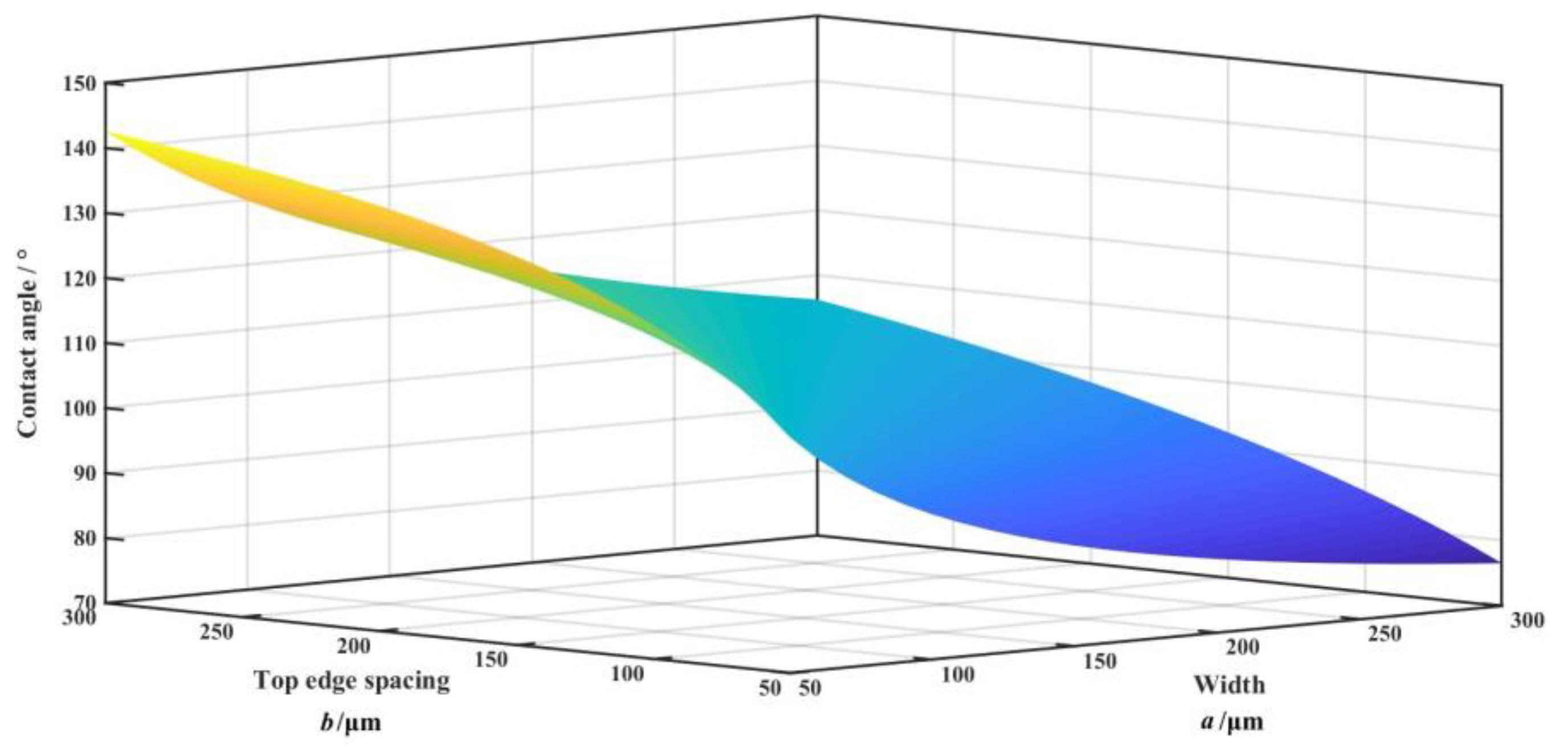

2. Construction of Theoretical Contact Angle Prediction Model Based on Femtosecond Laser

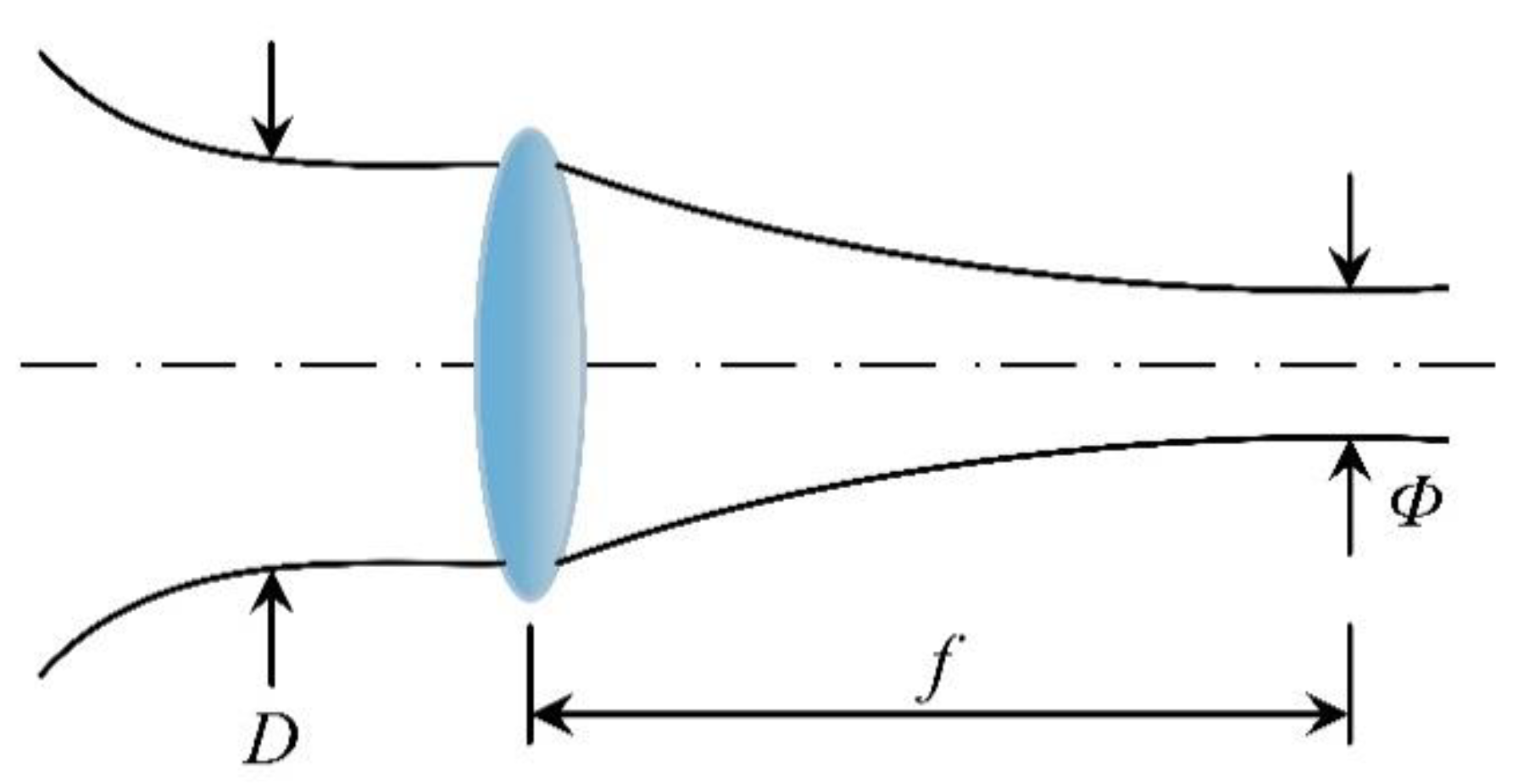

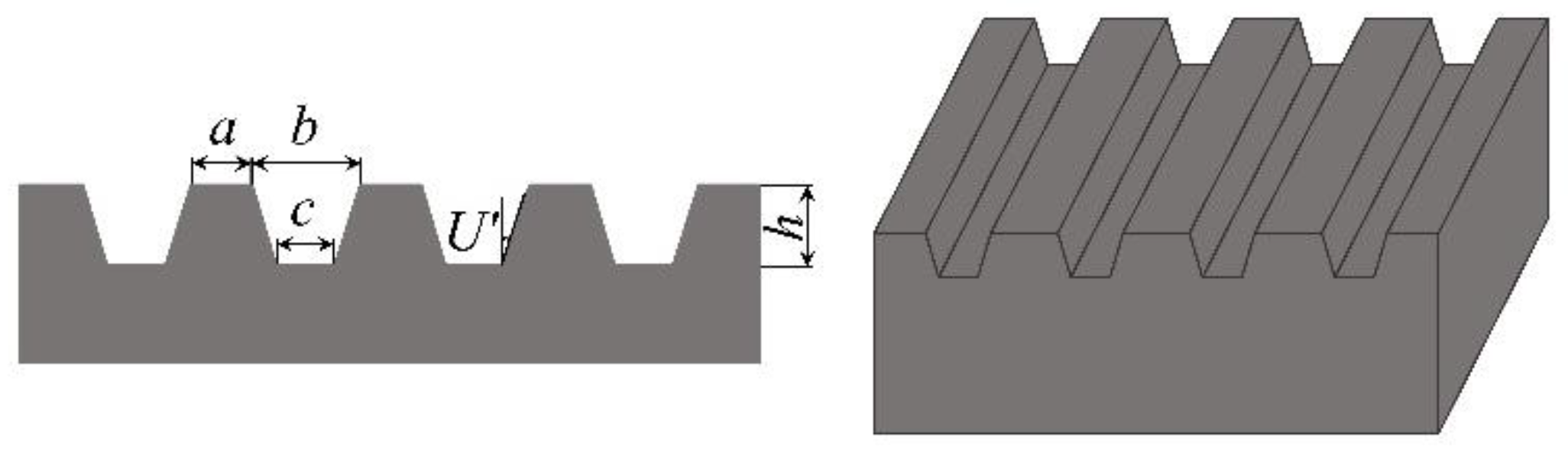

2.1. The Parameters of Models

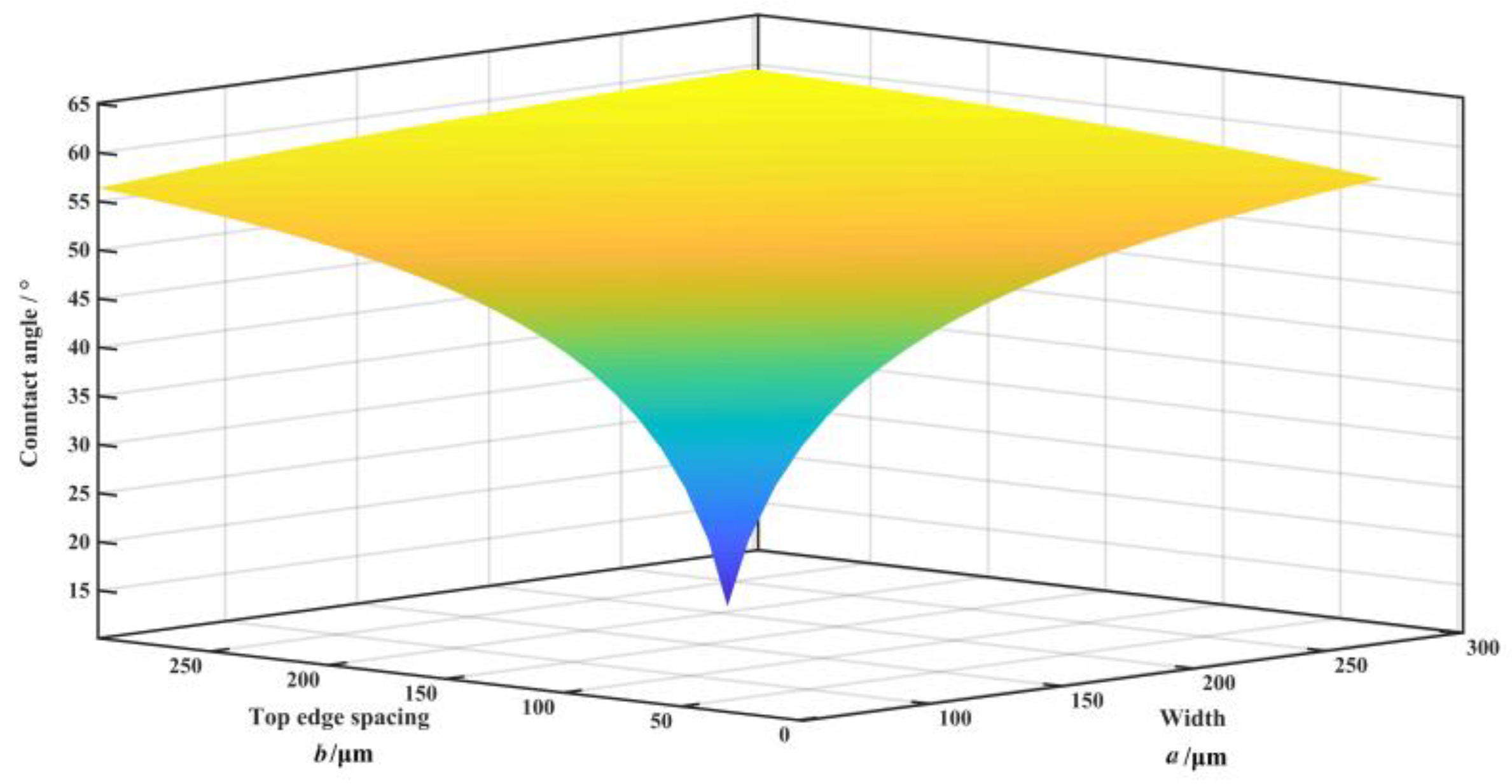

2.2. Establishment of Complete Wetting Prediction Model

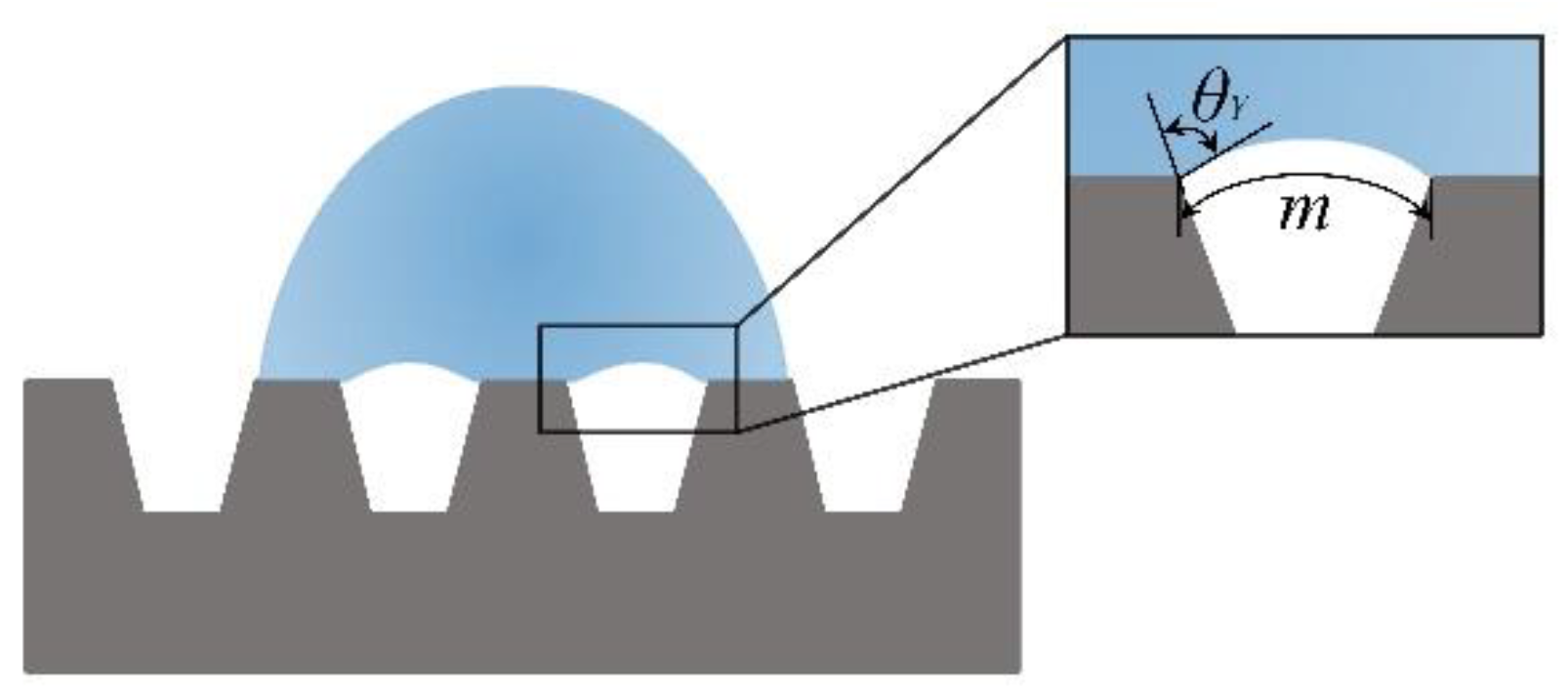

2.3. Establishment of Incomplete Wetting Prediction Model

3. Experiment and Verification

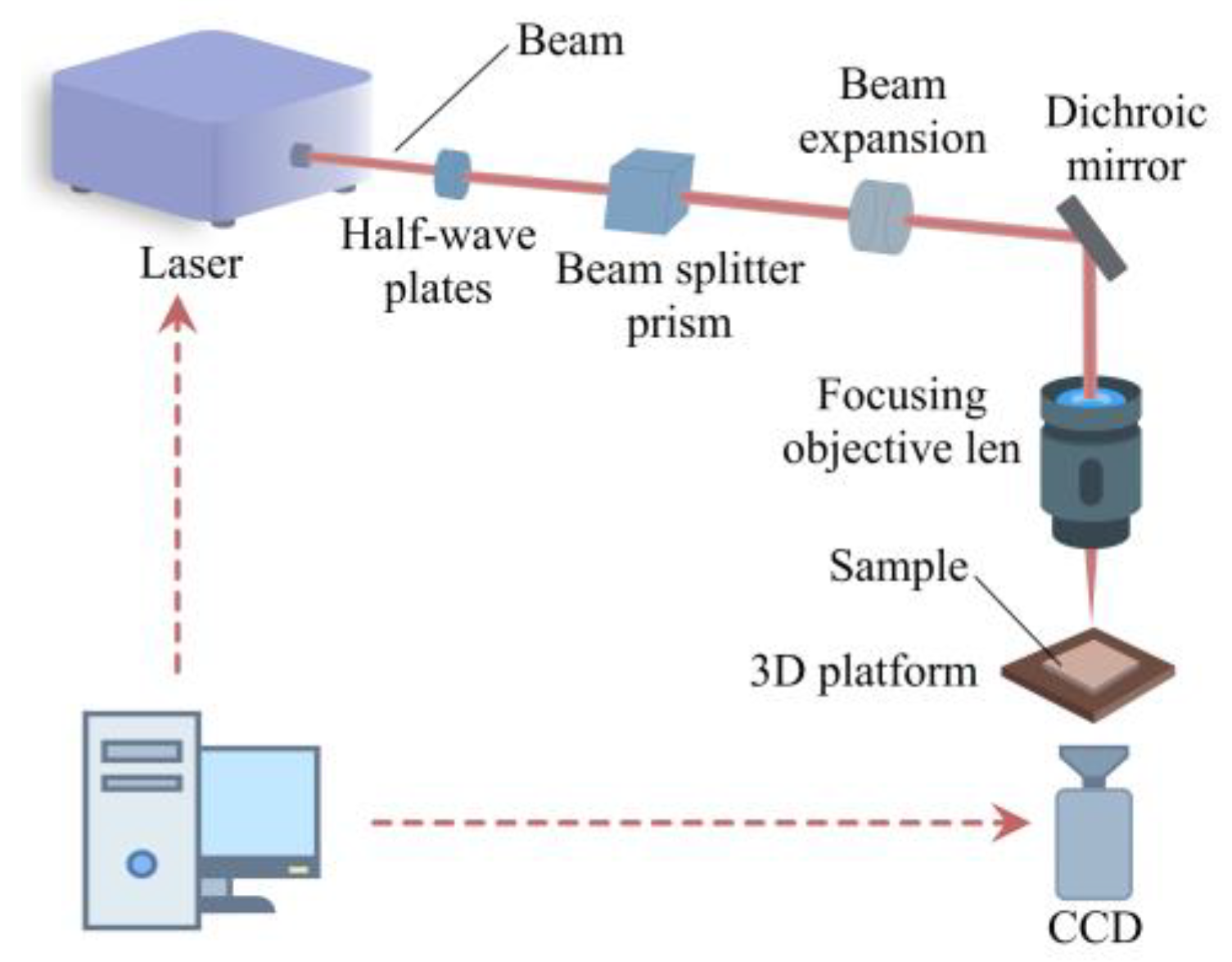

3.1. Experimental Equipment and Processing Parameters

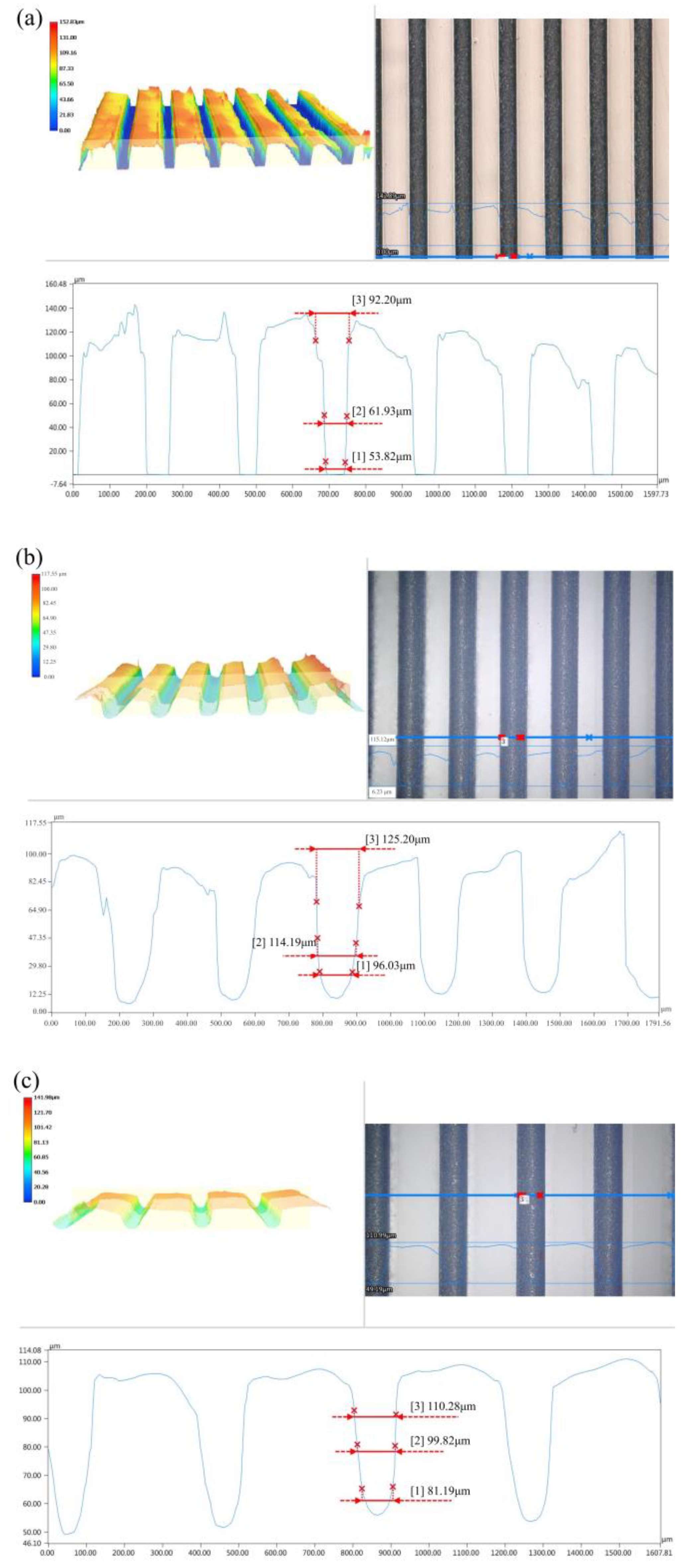

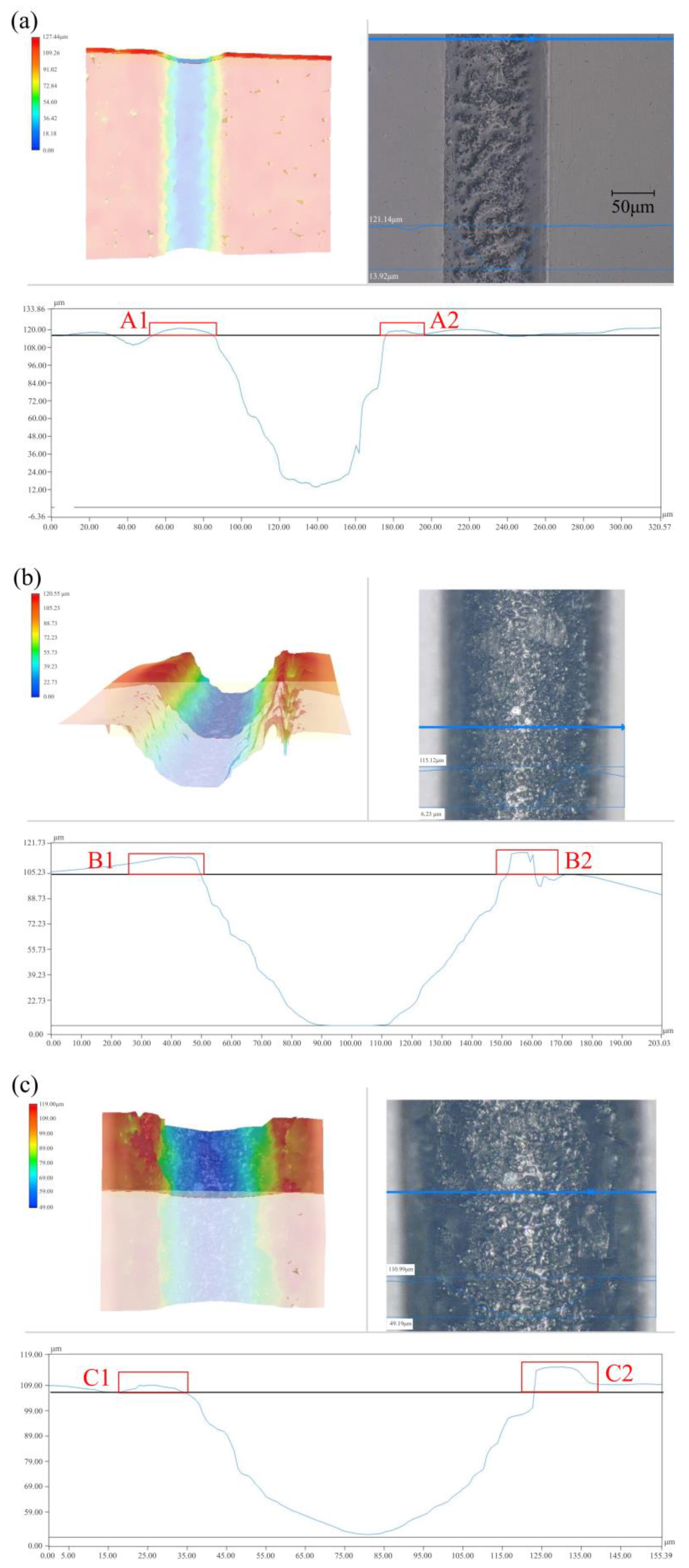

3.2. Observation of Processed Samples

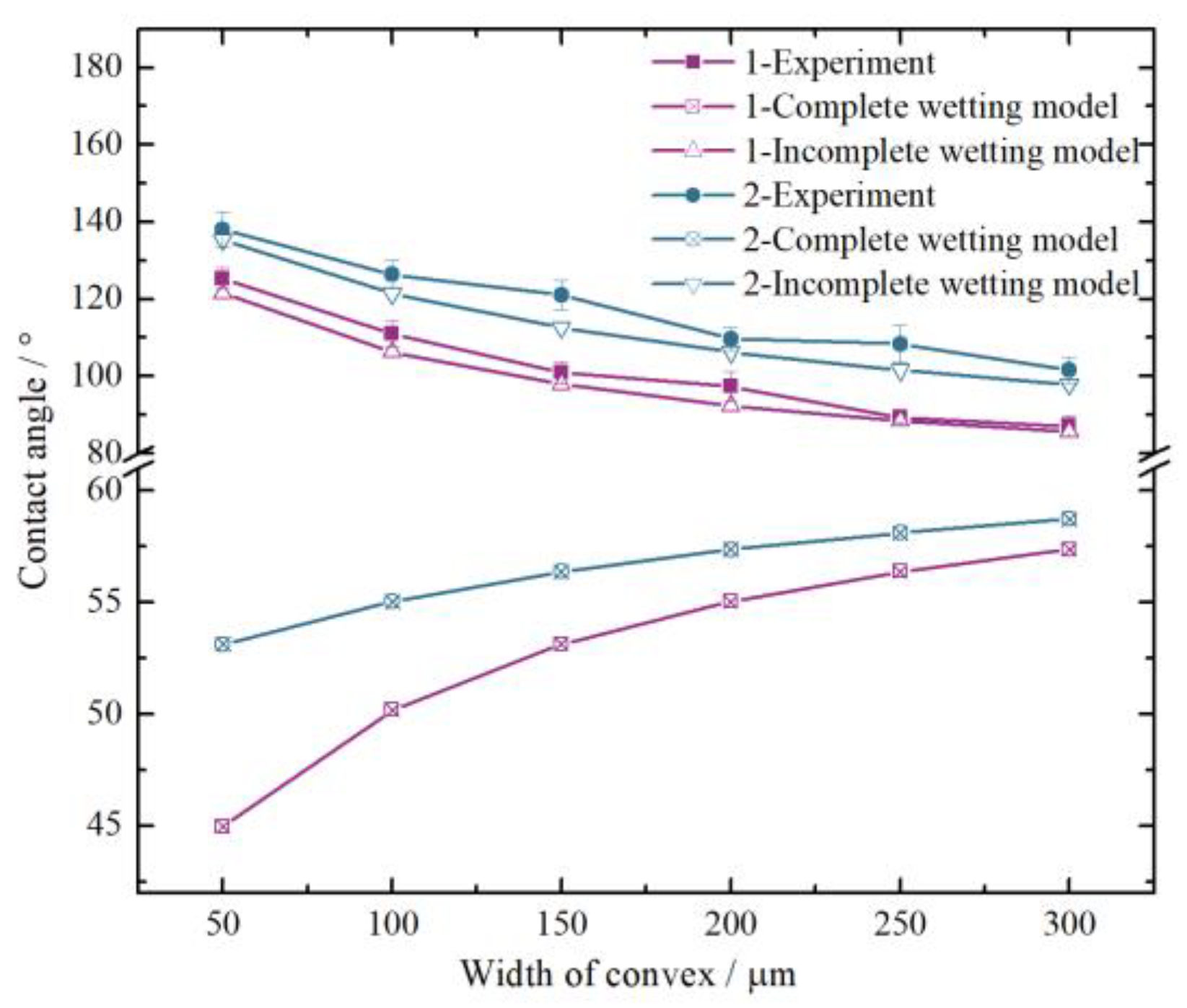

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yan, Y.Y.; Gao, N.; Barthlott, W. Mimicking natural superhydrophobic surfaces and grasping the wetting process: A review on recent progress in preparing superhydrophobic surfaces. Adv. Colloid Interface Sci. 2011, 169, 80–105. [Google Scholar] [CrossRef]

- Cui, C.; Duan, X.; Collier, B.; Poduska, K.M. Fabrication and wettability analysis of hydrophobic stainless steel surfaces with microscale structures from nanosecond laser machining. J. Micro Nano-Manuf. 2018, 6, 031006. [Google Scholar] [CrossRef]

- Cao, Z.; Ding, W.; Ma, Z.; Wang, B.; Wang, Z. Research on the hydrophobicity of square column structures on monocrystalline silicon fabricated using micro-machining. Micromachines 2019, 10, 763. [Google Scholar] [CrossRef]

- Hu, L.; Zhang, L.; Wang, D.; Lin, X.; Chen, Y. Fabrication of biomimetic superhydrophobic surface based on nanosecond laser-treated titanium alloy surface and organic polysilazane composite coating. Colloids Surf. A 2018, 555, 515–524. [Google Scholar] [CrossRef]

- Ding, W.; Cao, Z.; Wang, B.; Xu, S.; Wang, Z. Research on hydrophobic properties of grating structure on monocrystalline silicon fabricated using micromachining. Adv. Mater. Sci. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Sun, T.; Feng, L.; Gao, X.; Jiang, L. Bioinspired surfaces with special wettability. Acc. Chem. Res. 2005, 38, 644–652. [Google Scholar] [CrossRef]

- Razavi Seyed Mohammad, R.; Oh, J.; Sett, S.; Feng, L.; Yan, X.; Hoque, M.J.; Liu, A.; Haasch, R.T.; Masoomi, M.; Bagheri, R.; et al. Superhydrophobic surfaces made from naturally derived hydrophobic materials. ACS Sustain. Chem. Eng. 2017, 5, 11362–11370. [Google Scholar] [CrossRef]

- Song, H.; Liu, Z.; Shi, Z.; Cai, Y. Model of contact angle of hydrophobic surface based on minimum Gibbs free energy. J. Shandong Univ. (Eng. Sci.) 2015, 45, 56–61. [Google Scholar]

- Wu, F.; Shi, G.; Xu, H.; Liu, L.; Wang, Y.; Qi, D.; Lu, N. Fabrication of antireflective compound eyes by imprinting. ACS Appl. Mater. Interfaces 2013, 5, 12799–12803. [Google Scholar] [CrossRef]

- Wang, J.; Liu, F.; Chen, H.; Chen, D. Superhydrophobic behavior achieved from hydrophilic surfaces. Appl. Phys. Lett. 2009, 95, 084104. [Google Scholar] [CrossRef]

- Chen, Z.; Hao, L.; Chen, A.; Song, Q.; Chen, C. A rapid one-step process for fabrication of superhydrophobic surface by electrodeposition method. Electrochim. Acta. 2012, 59, 168–171. [Google Scholar] [CrossRef]

- Hu, Y.; Lao, Z.; Cumming, B.P.; Wu, D.; Li, J.; Liang, H.; Chu, J.; Huang, W.; Gu, M. Laser printing hierarchical structures with the aid of controlled capillary-driven self-assembly. Proc. Natl. Acad. Sci. USA 2015, 112, 6876–6881. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Zorba, V.; Stratakis, E.; Barberoglou, M.; Spanakis, E.; Tzanetakis, P.; Fotakis, C. Tailoring the wetting response of silicon surfaces via fs laser structuring. Appl. Phys. A 2008, 93, 819–825. [Google Scholar] [CrossRef]

- Zhu, D.; Hu, J. Experimental study on picosecond pulsed laser machining of carbon fiber reinforced plastics. Aeronaut. Manuf. Technol. 2017, 20, 54–59. [Google Scholar]

- Zhang, H.Z.; Wang, H.Y.; Liu, F.F.; Wang, L. Investigation on femtosecond laser ablative processing of SiCp/AA2024 composites. J. Manuf. Process. 2020, 49, 227–233. [Google Scholar] [CrossRef]

- Riveiro, A.; Abalde, T.; Pou, P.; Soto, R.; del Val, J.; Comesaña, R.; Badaoui, A.; Boutinguiza, M.; Pou, J. Influence of laser texturing on the wettability of PTFE. Appl. Surf. Sci. 2020, 515, 145984. [Google Scholar] [CrossRef]

- Qin, Z.; Ai, J.; Du, Q.; Liu, J.; Zeng, X. Superhydrophobic polytetrafluoroethylene surfaces with accurately and continuously tunable water adhesion fabricated by picosecond laser direct ablation. Mater. Des. 2019, 173, 107782. [Google Scholar] [CrossRef]

- Farshchian, B.; Gatabi, J.R.; Bernick, S.M.; Lee, G.H.; Droopad, R.; Kim, N. Scaling and mechanism of droplet array formation on a laser-ablated superhydrophobic grid. Colloids Surf. A 2018, 547, 49–55. [Google Scholar] [CrossRef]

- Waugh, D.; Lawrence, J. On the use of CO2 laser induced surface patterns to modify the wettability of Poly (methyl methacrylate) (PMMA). Opt. Lasers Eng. 2010, 48, 707–715. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, M.; Ma, H.; Yu, C.; Li, K.; Yu, C.; Jiang, L. Morphology-control strategy of the superhydrophobic poly (methyl methacrylate) surface for efficient bubble adhesion and wastewater remediation. Adv. Funct. Mater. 2017, 27, 1702020. [Google Scholar] [CrossRef]

- Li, J.; Wang, W.; Mei, X.; Pan, A.; Sun, X.; Liu, B.; Cui, J. Artificial compound eyes prepared by a combination of air-assisted deformation, modified laser swelling, and controlled crystal growth. ACS Nano 2019, 13, 114–124. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Bittoun, E.; Marmur, A. Optimizing super-hydrophobic surfaces: Criteria for comparison of surface topographies. J. Adhes. Sci. Technol. 2009, 23, 401–411. [Google Scholar] [CrossRef]

- Zhenyu, S.; Zhanqiang, L.; Hao, S.; Xianzhi, Z. Prediction of contact angle for hydrophobic surface fabricated with micro-machining based on minimum Gibbs free energy. Appl. Surf. Sci. 2016, 364, 597–603. [Google Scholar] [CrossRef]

- Drelich, J.W.; Boinovich, L.; Chibowski, E.; Della Volpe, C.; Hołysz, L.; Marmur, A.; Siboni, S. Contact angles: History of over 200 years of open questions. Surf. Innov. 2020, 8, 3–27. [Google Scholar] [CrossRef]

- Shirtcliffe, N.J.; McHale, G.; Atherton, S.; Newton, M.I. An introduction to superhydrophobicity. Adv. Colloid Interface Sci. 2010, 161, 124–138. [Google Scholar] [CrossRef]

- Kwon, M.; Shin, H.; Chu, C. Fabrication of a super-hydrophobic surface on metal using laser ablation and electrodeposition. Appl. Surf. Sci. 2014, 288, 222–228. [Google Scholar] [CrossRef]

- Peng, D.; Li, P.; Hou, R. Effect of aperture in femtosecond laser optical path on machining of microholes. Laser Infrared. 2019, 49, 1201–1205. [Google Scholar]

- Cai, Y.; He, S. Propagation of hollow Gaussian beams through apertured paraxial optical systems. J. Opt. Soc. Am. A Opt. Image Sci. Vis. 2006, 23, 1410–1418. [Google Scholar] [CrossRef]

- Sola, D.; Cases, R. High-repetition-rate femtosecond laser processing of acrylic intra-ocular lenses. Polymers 2020, 12, 242. [Google Scholar] [CrossRef]

- Misawa, H.; Juodkazis, S. 3D Laser Microfabrication: Principles and Applications; Wiley-VCH: Weinheim, Germany, 2006. [Google Scholar]

- Luo, Y.; Jia, W.; Song, Y.; Liu, B.; Hu, M.; Chai, L.; Wang, C. High-repetition-rate femtosecond laser micromachining of poly(methyl methacrylate). Chin. Opt. Lett. 2015, 13, 070003. [Google Scholar]

- Li, J.; Wang, W.; Mei, X.; Sun, X.; Pan, A. The formation of convex microstructures by laser irradiation of dual-layer polymethylmethacrylate (PMMA). Opt. Laser Technol. 2018, 106, 461–468. [Google Scholar] [CrossRef]

- Meunier, T.; Villafranca, A.B.; Bhardwaj, R.; Weck, A. Mechanism for spherical dome and microvoid formation in polycarbonate using nanojoule femtosecond laser pulses. Opt. Lett. 2012, 37, 3168–3170. [Google Scholar] [CrossRef]

| Sample Number | Depth h/μm | Top Edge Length of Spacing b/μm | Width of Convex a/μm |

|---|---|---|---|

| 1-1 | 100 | 100 | 50 |

| 1-2 | 100 | 100 | |

| 1-3 | 100 | 150 | |

| 1-4 | 100 | 200 | |

| 1-5 | 100 | 250 | |

| 1-6 | 100 | 300 | |

| 2-1 | 100 | 200 | 50 |

| 2-1 | 200 | 100 | |

| 2-2 | 200 | 150 | |

| 2-3 | 200 | 200 | |

| 2-5 | 200 | 250 | |

| 2-6 | 200 | 300 |

| Sample Number | Experiment | Complete Wetting Prediction Model | Incomplete Wetting Prediction Model |

|---|---|---|---|

| 1-1 | 125.30 ± 2.8 | 44.96 | 121.4 |

| 1-2 | 111.02 ± 3.29 | 50.19 | 106.3 |

| 1-3 | 100.86 ± 2.7 | 53.14 | 97.87 |

| 1-4 | 97.35 ± 3.9 | 55.04 | 92.35 |

| 1-5 | 89.35 ± 1.3 | 56.38 | 88.43 |

| 1-6 | 87.08 ± 2.67 | 57.36 | 85.48 |

| 2-1 | 138.09 ± 4.63 | 53.14 | 135.4 |

| 2-2 | 126.34 ± 3.62 | 55.04 | 121.4 |

| 2-3 | 121.07 ± 3.8 | 56.38 | 112.6 |

| 2-4 | 109.75 ± 2.91 | 57.36 | 106.3 |

| 2-5 | 108.40 ± 4.86 | 58.12 | 101.6 |

| 2-6 | 101.57 ± 3.29 | 58.73 | 97.87 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Zhang, Y.; Song, J.; Wang, Z. Investigation and Prediction on Regulation of Hydrophobicity of Polymethyl Methacrylate (PMMA) Surface by Femtosecond Laser Irradiation. Coatings 2020, 10, 386. https://doi.org/10.3390/coatings10040386

Wang B, Zhang Y, Song J, Wang Z. Investigation and Prediction on Regulation of Hydrophobicity of Polymethyl Methacrylate (PMMA) Surface by Femtosecond Laser Irradiation. Coatings. 2020; 10(4):386. https://doi.org/10.3390/coatings10040386

Chicago/Turabian StyleWang, Bangfu, Yongkang Zhang, Juan Song, and Zhongwang Wang. 2020. "Investigation and Prediction on Regulation of Hydrophobicity of Polymethyl Methacrylate (PMMA) Surface by Femtosecond Laser Irradiation" Coatings 10, no. 4: 386. https://doi.org/10.3390/coatings10040386

APA StyleWang, B., Zhang, Y., Song, J., & Wang, Z. (2020). Investigation and Prediction on Regulation of Hydrophobicity of Polymethyl Methacrylate (PMMA) Surface by Femtosecond Laser Irradiation. Coatings, 10(4), 386. https://doi.org/10.3390/coatings10040386