The Properties of an Aluminum/UV-Curable, Infrared, Low-Emissivity Coating Modified by Nano-Silica Slurry

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Preparation of Coatings

2.3. Testing and Characterization

3. Results and Discussion

3.1. Analysis of Orthogonal Analysis of Aluminum/UV-Curable Coating

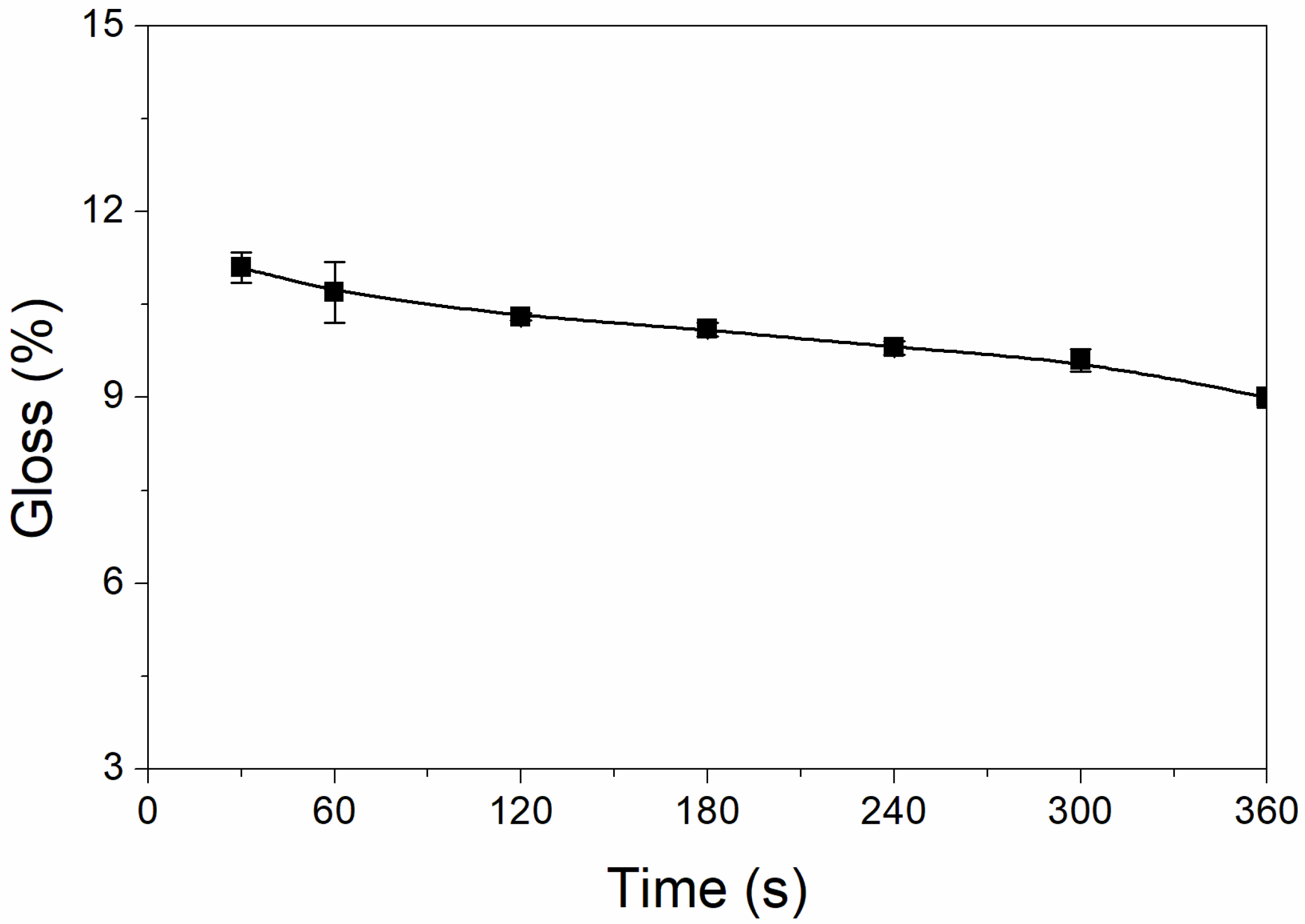

3.2. The Effect of UV-Curing Time on Glossiness

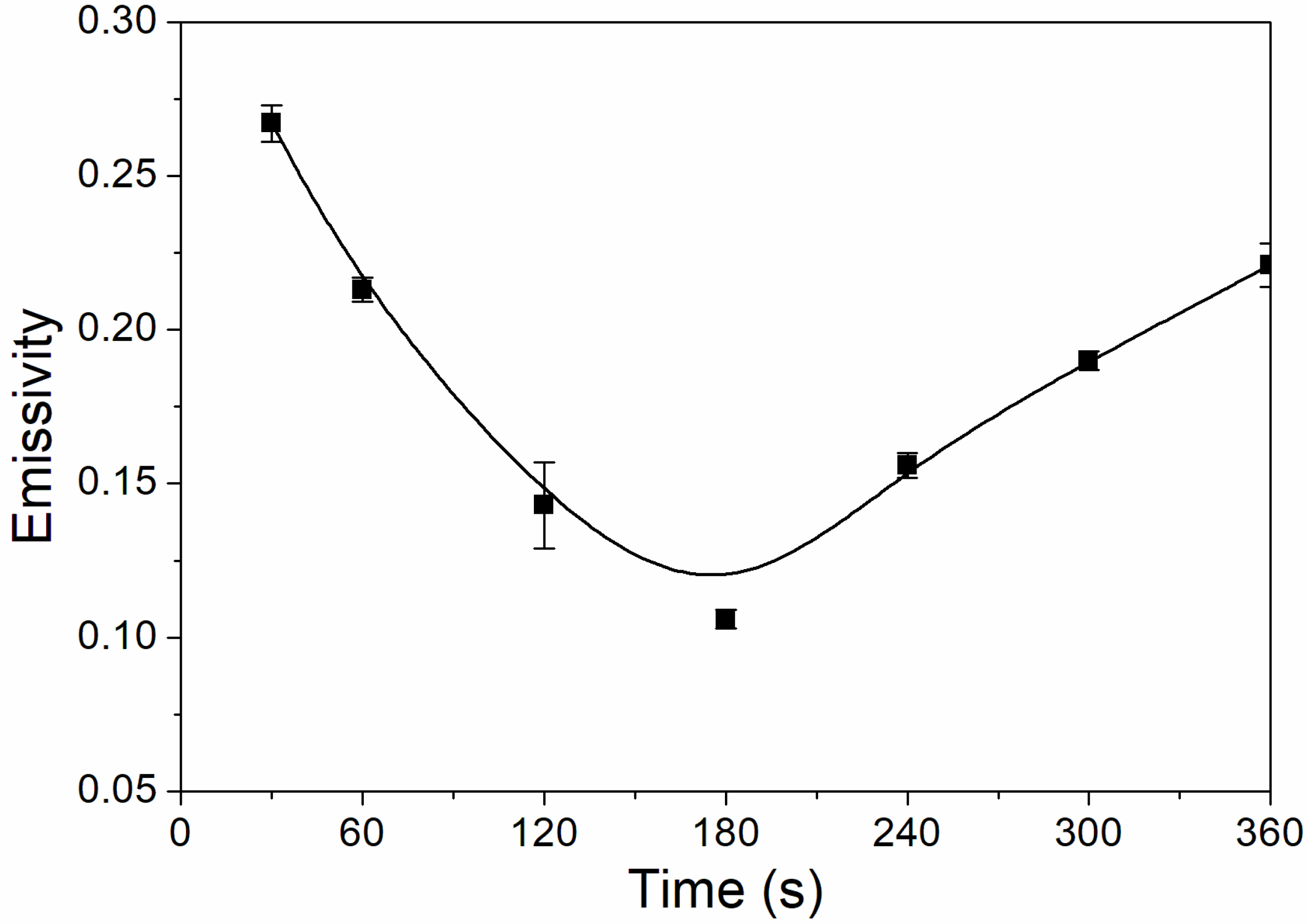

3.3. The Influence of UV-Curing Time on the Infrared Emissivity

3.4. The Influence of UV-Curing Time on the Color Difference

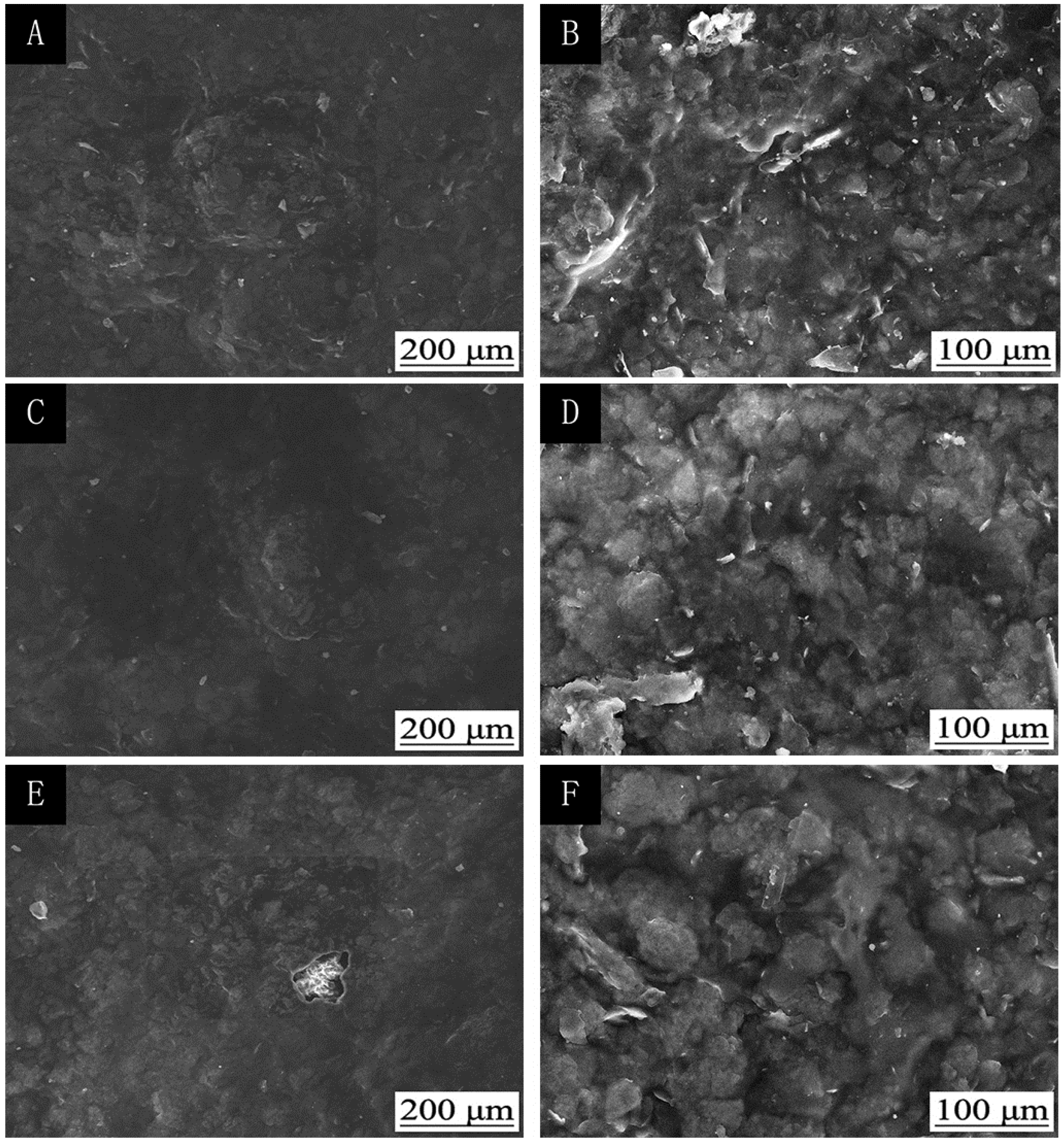

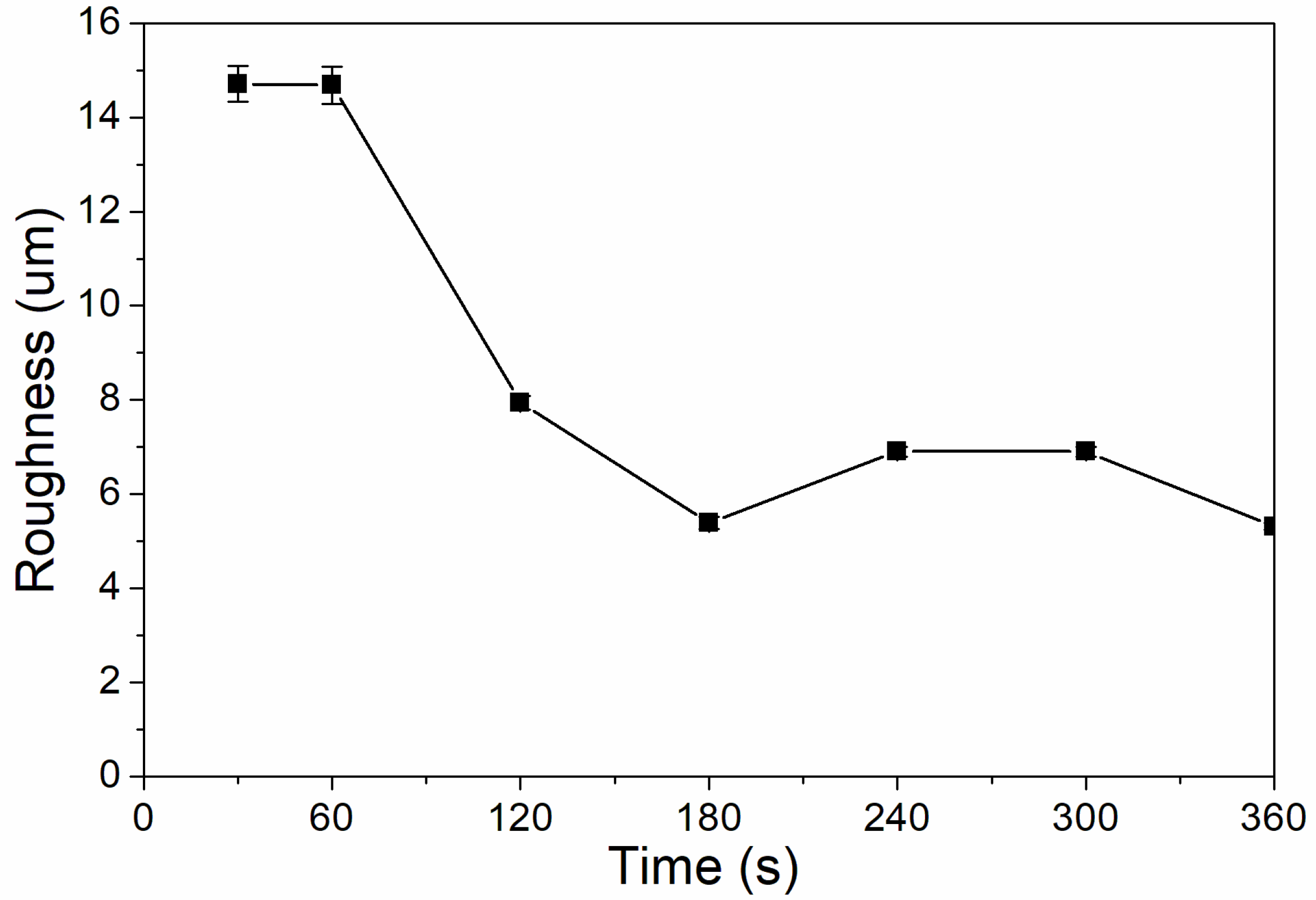

3.5. The Influences of UV-Curing Time on Hardness and Roughness

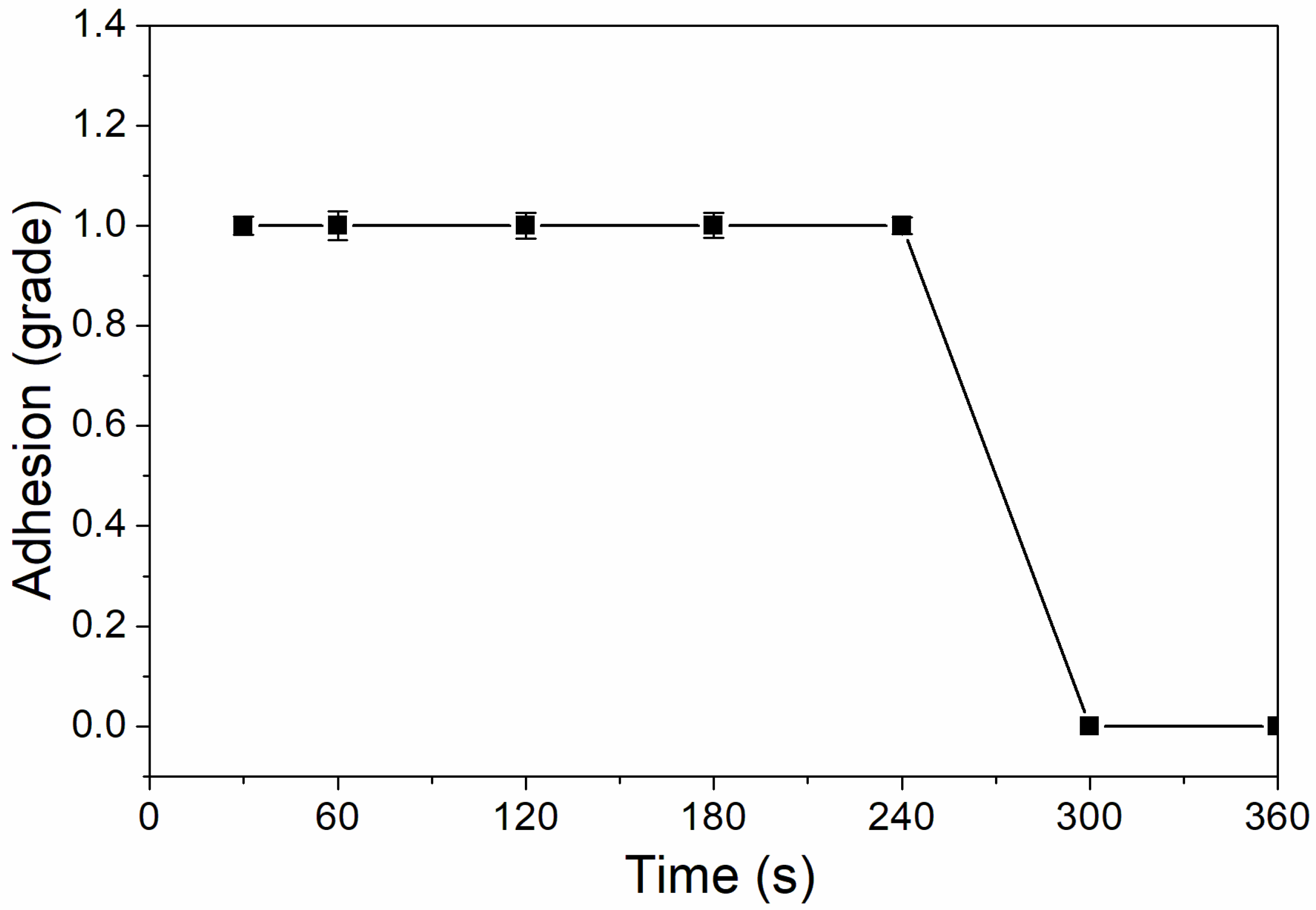

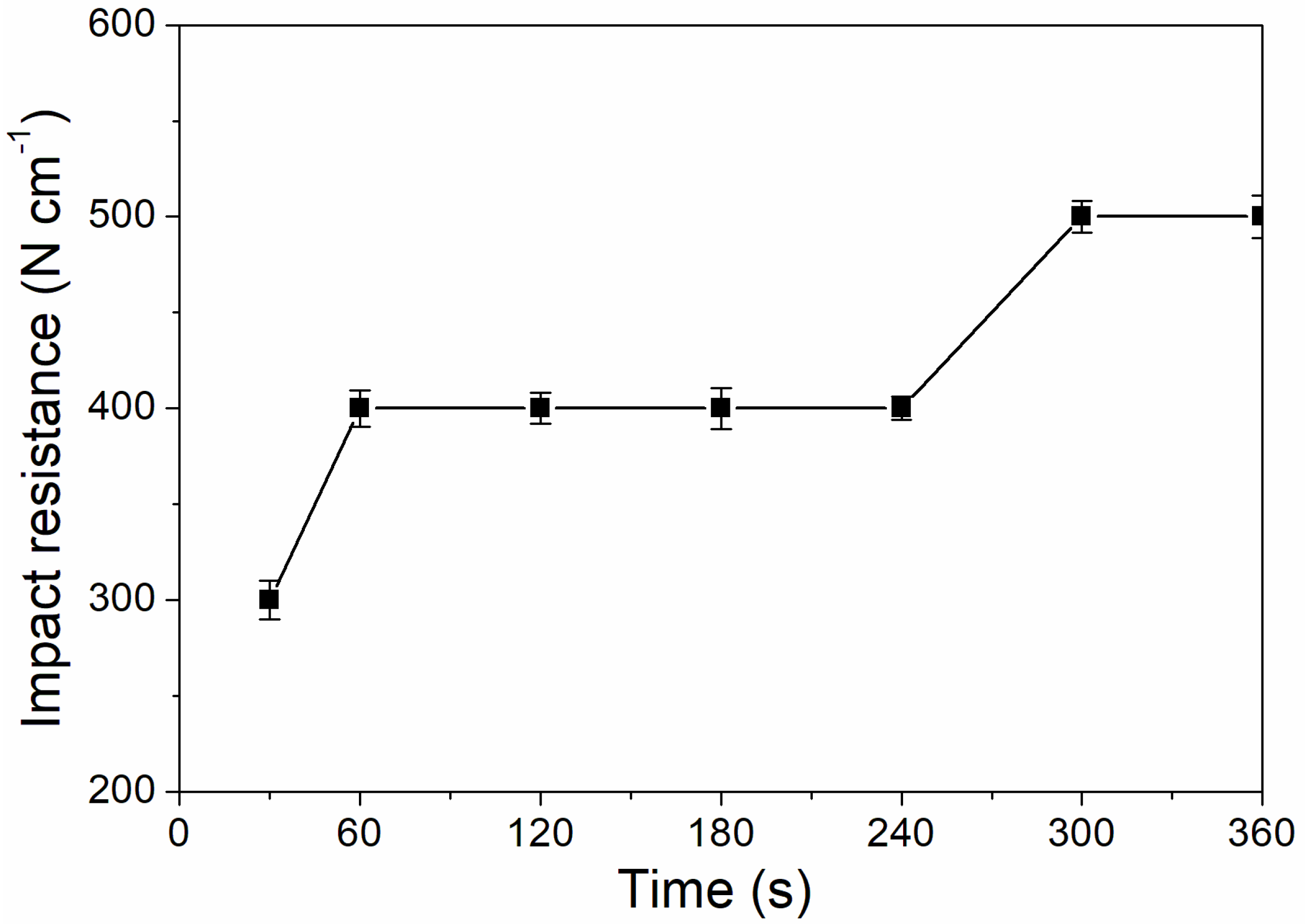

3.6. The Influences of UV-Curing Time on Adhesion and Impact Strength

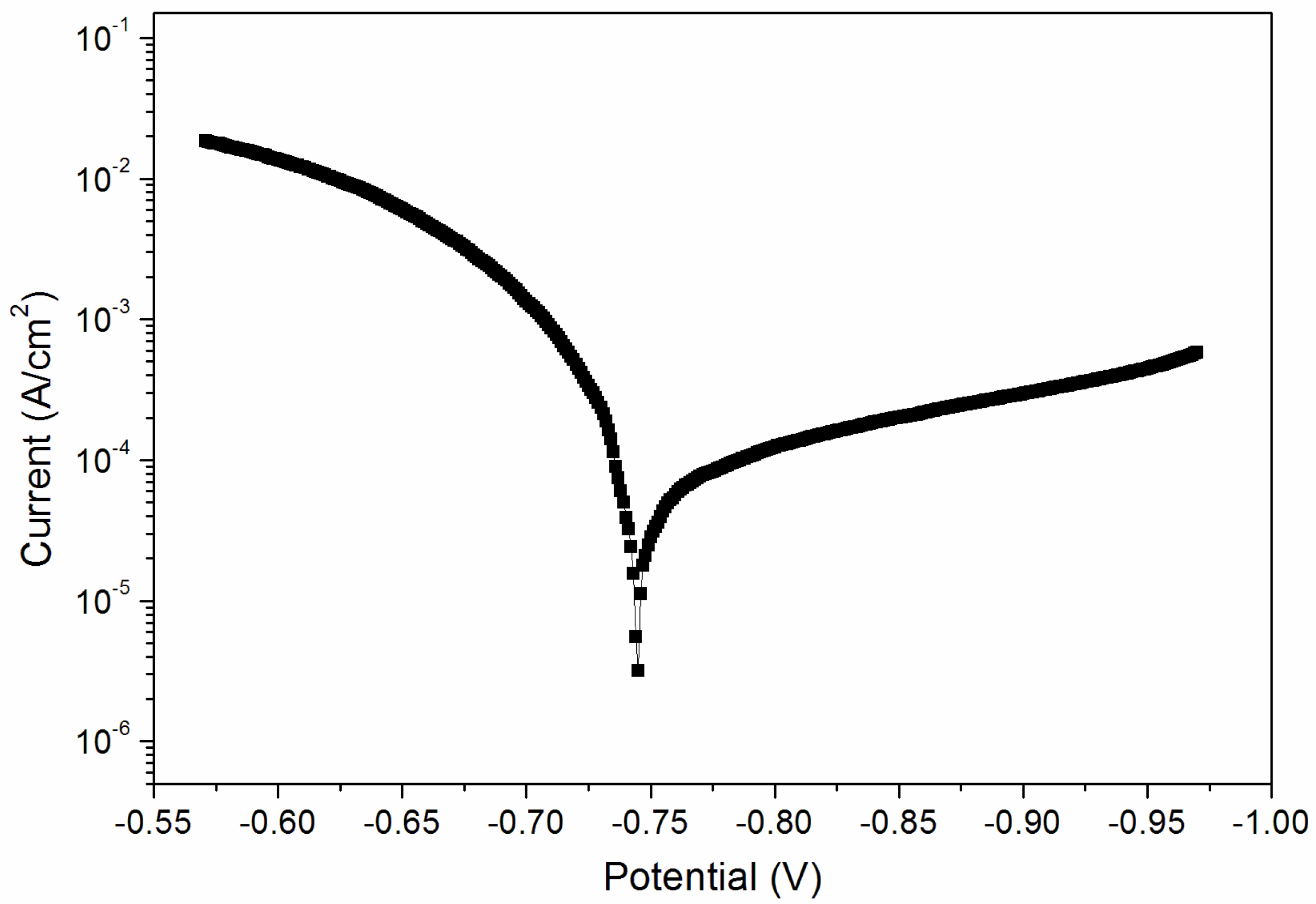

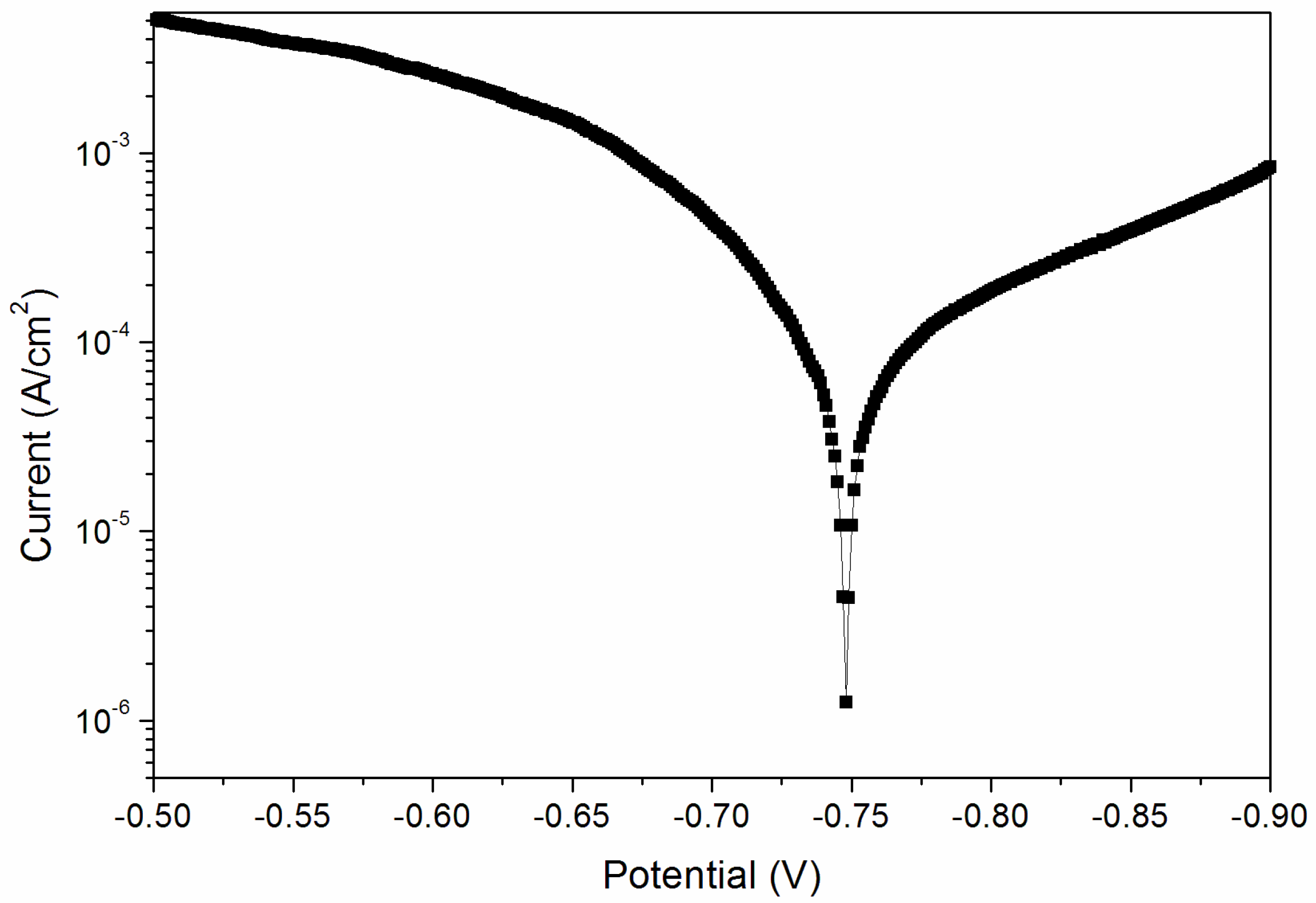

3.7. The Effect of UV-Curing Time on Corrosion Resistance

3.8. The Effect of Al Powder Concentration on the Property

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vishnevetsky, I.; Rotenberg, E.; Kribus, A.; Yakir, D. Method for accurate measurement of infrared emissivity for opaque low-reflectance materials. Appl. Opt. 2019, 58, 4599–4609. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Zhang, X.J.; Huang, S.X.; Shan, D.Y.; Deng, L.W.; He, L.H.; He, J.; Xu, Y.C.; Chen, H.; Liao, C.W. Infrared emissivity and microwave transmission behavior of flaky aluminum functionalized pyramidal-frustum shaped periodic structure. Infrared Phys. Tech. 2019, 99, 123–128. [Google Scholar] [CrossRef]

- Guo, M.Z.; Cao, B.; Fan, W.J.; Ren, H.Z.; Cui, Y.K.; Du, Y.M.; Liu, Q.H. Scattering effect contributions to the directional canopy emissivity and brightness temperature based on CE-P and CBT-P models. IEEE Geosci. Remote. Sens. Lett. 2018, 16, 957–961. [Google Scholar] [CrossRef]

- Coll, C.; Niclos, R.; Puchades, J.; Garcia-Santos, V.; Galve, J.M.; Perez-Planells, L.; Valor, E.; Theocharous, E. Laboratory calibration and field measurement of land surface temperature and emissivity using thermal infrared multiband radiometers. Int. J appl. Earth. Obs. 2019, 78, 227–239. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.Y.; Han, J.T.; Wu, Z.H.; Zhang, J.L. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber. Science 2020, 52, 28–43. [Google Scholar] [CrossRef]

- Qin, Y.S.; Zhang, M.J.; Guan, Y.; Huang, X.G. Laser absorption and infrared stealth properties of Al/ATO composites. Ceram. Int. 2019, 45, 14312–14315. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, X.; Yang, F.; Ye, J. Preparation and characterization of waterborne UV lacquer product modified by zinc oxide with flower shape. Polymers 2020, 12, 668. [Google Scholar] [CrossRef]

- Wang, L.; Xu, G.Y.; Liu, C.Y.; Hou, H.L.; Tan, S.J. Surface-modified CeO2 coating with excellent thermal shock resistance performance and low infrared emissivity at high-temperature. Surf. Coat. Tech. 2019, 357, 559–566. [Google Scholar] [CrossRef]

- Liu, Y.F.; Xie, J.L.; Luo, M.; Peng, B.; Xu, C.; Deng, L.J. The synthesis and optical properties of Al/MnO2 composite pigments by ball-milling for low infrared emissivity and low lightness. Prog. Org. Coat. 2017, 108, 30–35. [Google Scholar] [CrossRef]

- Yuan, L.; Weng, X.L.; Xie, J.L.; Deng, L.J. Effects of shape, size and solid content of Al pigments on the low-infrared emissivity coating. Mater. Res. Innov. 2015, 19 (Suppl. 1), S325–S330. [Google Scholar] [CrossRef]

- He, L.H.; Zhao, Y.; Xing, L.Y.; Liu, P.G.; Zhang, Y.W.; Wang, Z.Y. Low infrared emissivity coating based on graphene surface-modified flaky aluminum. Materials 2018, 11, 1502. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Li, W.; Xu, G.Y.; Meng, X.; Liu, K.; Tan, S.J. Preparation and characterization of the colored coating with low infrared emissivity based on nanometer pigment. Prog. Org. Coat. 2018, 115, 74–78. [Google Scholar] [CrossRef]

- Li, Q.Y.; Cheng, X.D.; Gong, D.Q.; Ye, W.P. Effect of N2 flow rate on structural and infrared properties of multi-layer AlCrN/Cr/AlCrN coatings deposited by cathodic arc ion plating for low emissivity applications. Thin Solid Film. 2019, 675, 74–85. [Google Scholar] [CrossRef]

- Di Carolo, F.; Savino, L.; Palumbo, D.; Del Vecchio, A.; Galietti, U.; De Cesare, M. Standard thermography vs free emissivity dual color novel CIRA physics technique in the near-mid IR ranges: Studies for different emissivity class materials from low to high temperatures typical of aerospace re-entry. Int. J. Therm. Sci. 2020, 147, 106123. [Google Scholar] [CrossRef]

- Guinneton, F.; Sauques, L.; Valmalette, J.C.; Cros, F.; Gavarri, J.R. Role of surface defects and microstructure in infrared optical properties of thermochromic VO2 materials. J. Phys. Chem. Solids 2005, 66, 63–73. [Google Scholar] [CrossRef]

- Qi, D.; Wang, X.; Chen, F.; Cheng, Y.Z.; Gong, R.Z. Metal-based graphical SiO2/Ag/ZnS/Ag hetero-structure for visible-infrared compatible camouflage. Materials 2018, 11, 1594. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.F.; Xie, J.L.; Luo, M.; Jian, S.; Peng, B.; Deng, L.J. Preparation and angle-dependent optical properties of brown Al/MnO2 composite pigments in visible and infrared region. Nanoscale Res. Lett. 2017, 12, 266. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L.; Qian, X.Y. Preparation and characterization of low infrared emissive aluminum/waterborne acrylic coatings. Coatings 2020, 10, 35. [Google Scholar] [CrossRef]

- GB/T 6739-2006 Paints and Varnishes—Determination of Film Hardness by Pencil Test; Standardization Administration of the People’s Republic of China: Beijing, China, 1998; pp. 1–3. (In Chinese)

- Xiong, X.Q.; Yuan, Y.Y.; Niu, Y.T.; Zhang, L.T. Research on the effects of roughness on the tactile properties of rice straw particleboard surface. Sci. Adv. Mater. 2020, 12, 795–801. [Google Scholar] [CrossRef]

- ASTM B117-16 Standard Practice for Operating Salt Spray (Fog) Apparatus; ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Simpson, C.H.; Ray, C.J.; Skerry, B.S. Accelerated corrosion testing of industrial maintenance paints using a cyclic corrosion weatherin method. J. Prot. Coat. Linings 1991, 8, 28–36. [Google Scholar]

- Yan, X.X.; Qian, X.Y.; Lu, R.; Miyakoshi, T. Comparison and optimization of reactive dyes and coating performance on Fraxinus mandshurica veneer. Polymers 2018, 10, 1302. [Google Scholar] [CrossRef] [PubMed]

- Labukas, J.P.; Escarsega, J.A.; Crawford, D.M. Accelerated drying of water-dispersible polyurethane blends. J. Coat. Technol. Res. 2014, 11, 217–229. [Google Scholar] [CrossRef]

- Li, N.; Bao, M.Z.; Rao, F.; Shu, Y.; Huang, C.J.; Huang, Z.H.; Chen, Y.H.; Bao, Y.J.; Guo, R.C.; Xiu, C.M. Improvement of surface photostability of bamboo scrimber by application of organic UV absorber coatings. J. Wood. Sci. 2019, 65, 7. [Google Scholar] [CrossRef]

- Yan, X.X.; Qian, X.Y.; Lu, R.; Miyakoshi, T. Synergistic effect of addition of fillers on properties of interior waterborne UV-curing wood coatings. Coatings 2018, 8, 9. [Google Scholar] [CrossRef]

- Malm, V.; Straat, M.; Walkenstrom, P. Effects of surface structure and substrate color on color differences in textile coatings containing effect pigments. Text. Res. J. 2014, 84, 125–139. [Google Scholar] [CrossRef]

- Zhou, X.; Mao, J.; Qiao, Z. Electroless plating of copper layer on surfaces of urea-formaldehyde microcapsule particles containing paraffin for low infrared emissivity. Particuology 2016, 24, 159–163. [Google Scholar] [CrossRef]

- Ye, X.Y.; Zheng, C.; Xiao, X.Q.; Cai, S.G. Synthesis, characterization and infrared emissivity study of SiO2/Ag/TiO2 “sandwich” core-shell composites. Mater. Lett. 2015, 141, 191–193. [Google Scholar] [CrossRef]

- Banerjee, S.; Santra, S. Remarkable catalytic activity of silica nanoparticle in the bis-Michael addition of active methylene compounds to conjugated alkenes. Tetrahedron Lett. 2009, 50, 2037–2040. [Google Scholar] [CrossRef]

- Guo, L.; Jing, L.Z.; Liu, Y.; Zou, B.J.; Hua, S.C.; Zhang, J.P.; Yu, D.Y.; Wang, S.C.; Wang, S.R.; Wang, L.D.; et al. Enhanced dispersion of graphene in epoxy-acrylic waterborne anticorrosion coating: Bifunctional ligands linking graphene to SiO2. Int. J. Electrochem. Sci. 2018, 13, 11867–11881. [Google Scholar] [CrossRef]

- Liu, N.; Xu, G.Y.; Guo, T.C.; Meng, X.; Tan, S.J. Effect of Co-60 gamma ray irradiation on adhesion of LIE coatings. Surf. Eng. 2017, 33, 820–826. [Google Scholar] [CrossRef]

- Yan, X.X.; Xu, G.Y. Effect of surface modification of Cu with Ag by ball-milling on the corrosion resistance of low infrared emissivity coating. Mater. Sci. Eng. B Adv. 2010, 166, 152–157. [Google Scholar] [CrossRef]

- Yan, X.X.; Xu, G.Y. Influence of silane coupling agent on corrosion-resistant property in low infrared emissivity Cu/polyurethane coating. Prog. Org. Coat. 2012, 73, 232–238. [Google Scholar] [CrossRef]

- Yan, X.X.; Xu, G.Y. Corrosion and mechanical properties of polyurethane/Al composite coatings with low infrared emissivity. J. Alloys Compd. 2010, 491, 649–653. [Google Scholar] [CrossRef]

- Yan, X.X.; Cai, Y.T.; Lu, R.; Miyakoshi, T. Development and characterization of new coating material of blended epoxy-lacquer with aluminum. Int. J. Polym. Sci. 2017, 5017356. [Google Scholar] [CrossRef]

| Sample | Al (%) | Nano-Silica Slurry (%) | UV-Curing Time (s) |

|---|---|---|---|

| 1# | 20.0 | 2.0 | 120.0 |

| 2# | 20.0 | 10.0 | 360.0 |

| 3# | 40.0 | 2.0 | 360.0 |

| 4# | 40.0 | 10.0 | 120.0 |

| Sample | Al (g) | Nano-Silica Slurry (g) | KH560 (g) | UV-Curable Varnish (g) | UV-Curing Time (s) |

|---|---|---|---|---|---|

| 1# | 20.0 | 2.0 | 2.0 | 76.0 | 120.0 |

| 2# | 20.0 | 10.0 | 2.0 | 68.0 | 360.0 |

| 3# | 40.0 | 2.0 | 2.0 | 56.0 | 360.0 |

| 4# | 40.0 | 10.0 | 2.0 | 48.0 | 120.0 |

| 5# | 10.0 | 2.0 | 2.0 | 86.0 | 180.0 |

| 6# | 20.0 | 2.0 | 2.0 | 76.0 | 180.0 |

| 7# | 30.0 | 2.0 | 2.0 | 66.0 | 180.0 |

| 8# | 40.0 | 0 | 0 | 60.0 | 180.0 |

| 9# | 40.0 | 2.0 | 2.0 | 56.0 | 30.0 |

| 10# | 40.0 | 2.0 | 2.0 | 56.0 | 60.0 |

| 11# | 40.0 | 2.0 | 2.0 | 56.0 | 120.0 |

| 12# | 40.0 | 2.0 | 2.0 | 56.0 | 180.0 |

| 13# | 40.0 | 2.0 | 2.0 | 56.0 | 240.0 |

| 14# | 40.0 | 2.0 | 2.0 | 56.0 | 300.0 |

| Sample | Al (%) | Nano-Silica Slurry (%) | UV-Curing Time (s) | Glossiness (%) |

|---|---|---|---|---|

| 1# | 20.0 | 2.0 | 120.0 | 12.0 ± 0.3 |

| 2# | 20.0 | 10.0 | 360.0 | 9.0 ± 0.3 |

| 3# | 40.0 | 2.0 | 360.0 | 9.0 ± 0.2 |

| 4# | 40.0 | 10.0 | 120.0 | 10.0 ± 0.1 |

| K1 | 10.5 ± 0.1 | 10.5 ± 0.3 | 11.0 ± 0 | - |

| K2 | 9.5 ± 0.2 | 9.5 ± 0.3 | 9.0 ± 0.2 | - |

| R | 1.0 ± 0 | 1.0 ± 0 | 2.0 ± 0 | - |

| Sample | Al (%) | Nano-Silica Slurry (%) | UV-Curing Time (s) | Infrared Emissivity |

|---|---|---|---|---|

| 1# | 20.0 | 2.0 | 120.0 | 0.203 ± 0.003 |

| 2# | 20.0 | 10.0 | 360.0 | 0.257 ± 0.007 |

| 3# | 40.0 | 2.0 | 360.0 | 0.221 ± 0.008 |

| 4# | 40.0 | 10.0 | 120.0 | 0.185 ± 0.006 |

| K1 | 0.230 ± 0.008 | 0.212 ± 0.009 | 0.194 ± 0.007 | - |

| K2 | 0.203 ± 0.006 | 0.221 ± 0.003 | 0.239 ± 0.007 | - |

| R | 0.027 ± 0.006 | 0.009 ± 0 | 0.045 ± 0.001 | - |

| Curing Time (s) | L | a* | b* | L’ | a*’ | b*’ | ΔE |

|---|---|---|---|---|---|---|---|

| 30 | 25.9 ± 0.6 | 5.2 ± 0.3 | −3.1 ± 0 | 78.6 ± 2.9 | 2.5 ± 0.2 | −4.3 ± 0.1 | 52.8 ± 1.0 |

| 60 | 25.9 ± 0.6 | 5.2 ± 0.3 | −3.1 ± 0 | 77.2 ± 1.0 | 2.2 ± 0.2 | −4.3 ± 0.1 | 51.4 ± 1.6 |

| 120 | 25.9 ± 0.6 | 5.2 ± 0.3 | −3.1 ± 0 | 76.3 ± 2.4 | 2.5 ± 0.2 | −4.4 ± 0.1 | 50.5 ± 1.5 |

| 180 | 25.9 ± 0.6 | 5.2 ± 0.3 | −3.1 ± 0 | 76.1 ± 1.8 | 2.5 ± 0.2 | −1.5 ± 0 | 50.3 ± 1.4 |

| 240 | 25.9 ± 0.6 | 5.2 ± 0.3 | −3.1 ± 0 | 75.8 ± 1.9 | 2.3 ± 0.2 | −5.3 ± 0.2 | 50.0 ± 1.4 |

| 300 | 25.9 ± 0.6 | 5.2 ± 0.3 | −3.1 ± 0 | 75.7 ± 1.8 | 2.3 ± 0.2 | −0.6 ± 0 | 49.9 ± 1.2 |

| 360 | 25.9 ± 0.6 | 5.2 ± 0.3 | −3.1 ± 0 | 75.0 ± 1.7 | 1.4 ± 0.2 | −3.9 ± 0.1 | 49.3 ± 1.1 |

| Curing Time (s) | Ecorr (V) | Rp (Ω·cm2) | Icorr (A·cm−2) | βa (mV·dec−1) | βc (mV·dec−1) |

|---|---|---|---|---|---|

| 30 | −0.745 ± 0 | 133.2 ± 2.4 | 2.337 × 10−4 ± 0 | 99.69 ± 3.1 | 254.26 ± 8.4 |

| 180 | −0.748 ± 0 | 171.1 ± 4.6 | 1.802 × 10−4 ± 0 | 124.86 ± 4.0 | 164.07 ± 5.6 |

| Curing Time (s) | L | a* | b* | L’ | a*’ | b*’ | ΔE | Glossiness before Test (%) | Glossiness after Test (%) | Loss of Glossiness (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 78.6 ± 2.9 | 2.5 ± 0.2 | −4.3 ± 0.1 | 72.6 ± 2.5 | 2.4 ± 0.1 | −0.9 ± 0 | 6.9 ± 0.3 | 11.1 ± 0.2 | 3.4 ± 0.1 | 7.7 ± 0.2 |

| 180 | 76.1 ± 1.8 | 2.5 ± 0.2 | −1.5 ± 0 | 75.4 ± 2.1 | 2.1 ± 0 | −0.9 ± 0 | 1.0 ± 0 | 10.1 ± 0.1 | 3.6 ± 0.1 | 6.5 ± 0.2 |

| Al (%) | Nano-Silica Slurry (%) | UV-Curing Time (s) | Glossiness (%) | Infrared Emissivity |

|---|---|---|---|---|

| 10.0 | 2.0 | 180.0 | 13.0 ± 0.2 | 0.468 ± 0 |

| 20.0 | 2.0 | 180.0 | 11.8 ± 0.5 | 0.310 ± 0 |

| 30.0 | 2.0 | 180.0 | 11.2 ± 0.3 | 0.275 ± 0 |

| 40.0 | 2.0 | 180.0 | 10.1 ± 0.1 | 0.106 ± 0 |

| 40.0 | 0 | 180.0 | 54.0 ± 1.6 | 0.118 ± 0 |

| Coating | Filler Mass Fraction (%) | Emissivity | Glossiness (%) | Adhesion (Level) | Impact Resistance (N·cm−1) |

|---|---|---|---|---|---|

| Epoxy-lacquer/Al | 30 | 0.065 | 5.7 | 1 | 500 |

| PU/Cu | 50 | 0.100 | 45.2 | 3 | 200 |

| PU/(ball-milled Ag–Cu) | 50 | 0.129 | 35.6 | 3 | 200 |

| PU/Al | 40 | 0.068 | 38.3 | 1 | 400 |

| Al/waterborne arcylic coating | 30 | 0.113 | 7.7 | 0 | 150 |

| Al/UV modified by nano-silica slurry | 40 | 0.106 | 10.1 | 1 | 400 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Chang, Y.; Qian, X. The Properties of an Aluminum/UV-Curable, Infrared, Low-Emissivity Coating Modified by Nano-Silica Slurry. Coatings 2020, 10, 382. https://doi.org/10.3390/coatings10040382

Yan X, Chang Y, Qian X. The Properties of an Aluminum/UV-Curable, Infrared, Low-Emissivity Coating Modified by Nano-Silica Slurry. Coatings. 2020; 10(4):382. https://doi.org/10.3390/coatings10040382

Chicago/Turabian StyleYan, Xiaoxing, Yijuan Chang, and Xingyu Qian. 2020. "The Properties of an Aluminum/UV-Curable, Infrared, Low-Emissivity Coating Modified by Nano-Silica Slurry" Coatings 10, no. 4: 382. https://doi.org/10.3390/coatings10040382

APA StyleYan, X., Chang, Y., & Qian, X. (2020). The Properties of an Aluminum/UV-Curable, Infrared, Low-Emissivity Coating Modified by Nano-Silica Slurry. Coatings, 10(4), 382. https://doi.org/10.3390/coatings10040382