Granulation Effect Analysis of Gas Quenching Blast Furnace Slag with Different Basicities

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Flow Diagram

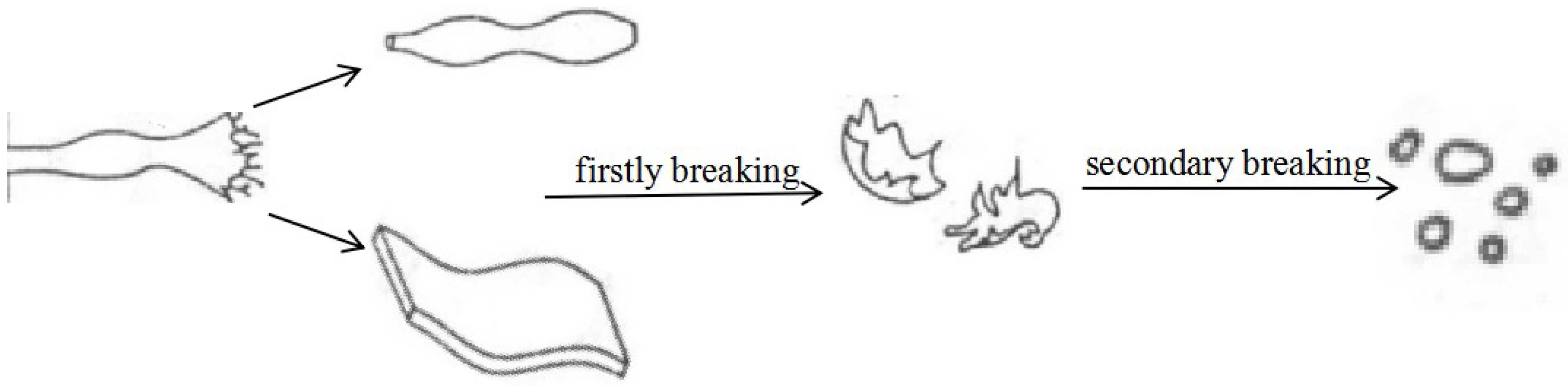

2.3. Gas Quenching Mechanism

2.4. Spherical Degree Analysis

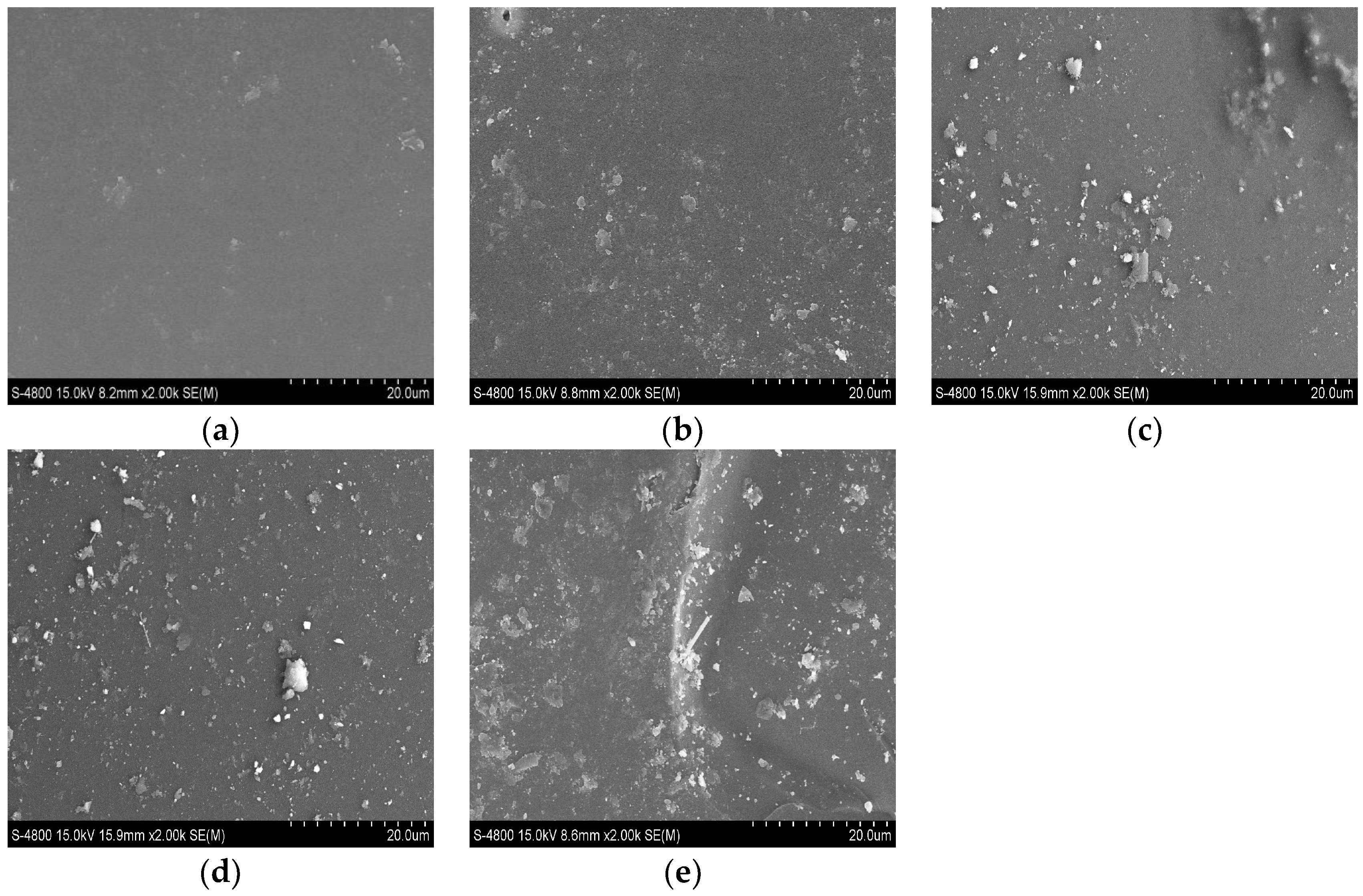

2.5. Amorphous Content Analysis

2.6. Method for Determination of Viscosity and Surface Tension

2.7. DSC Experiment

2.8. Microscopic Morphology Observation

3. Results and Discussion

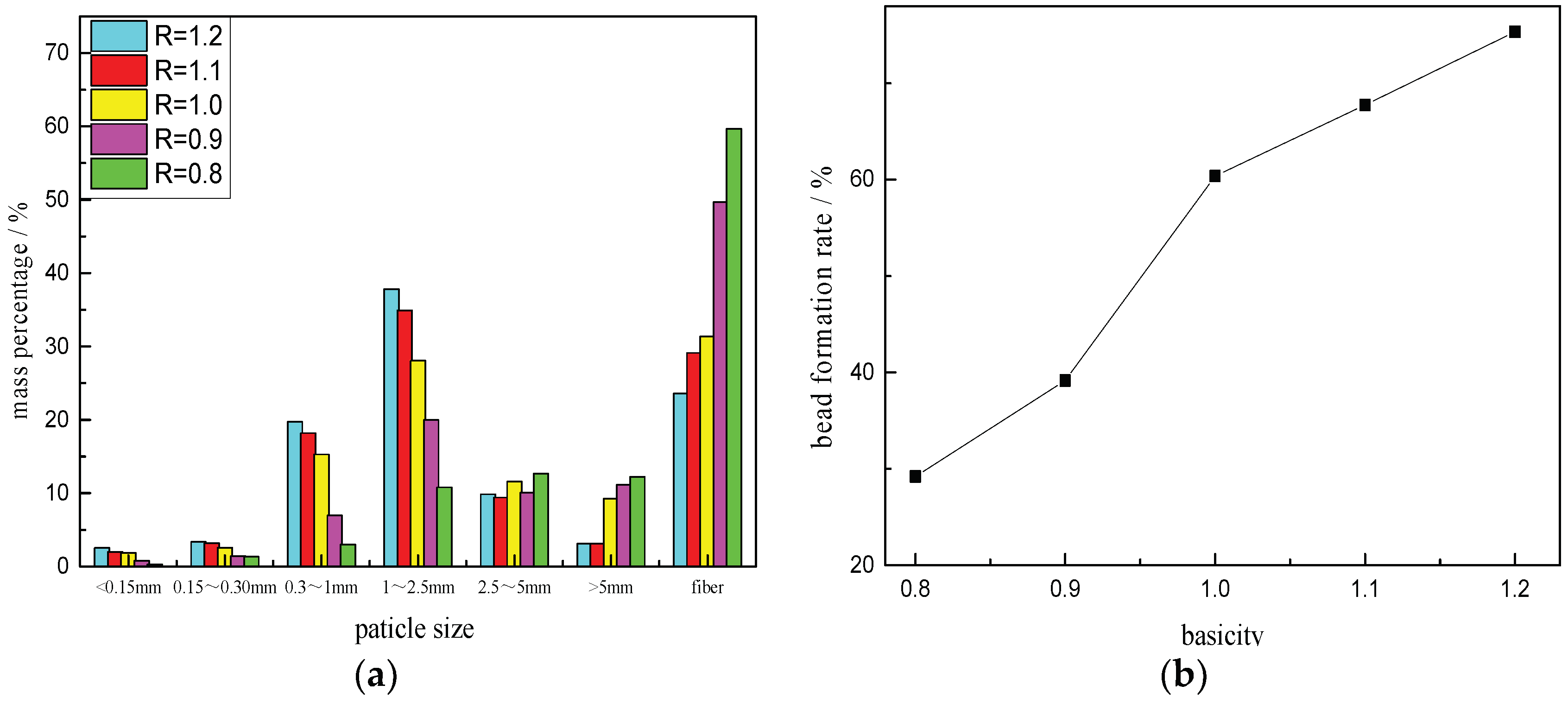

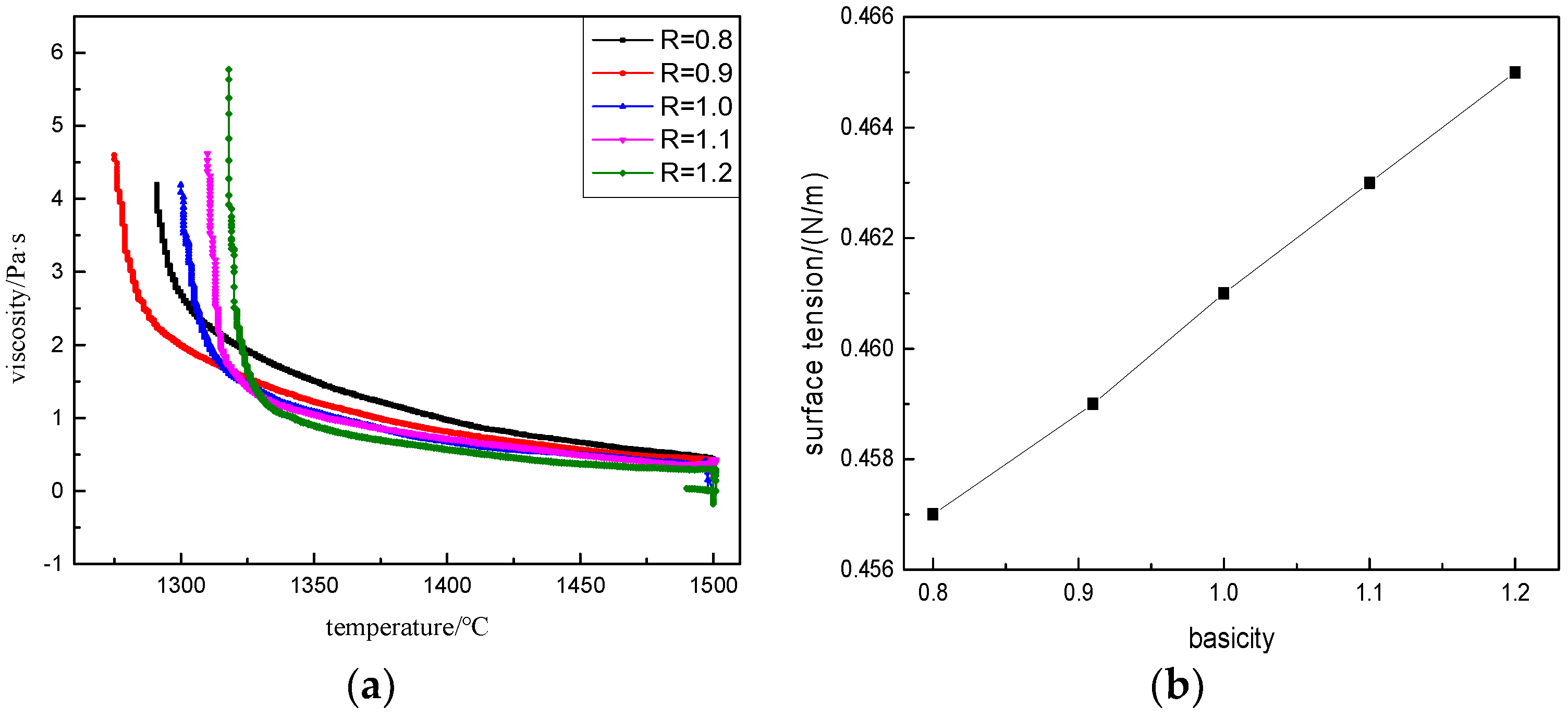

3.1. Influence of Different Basicities on the Granulation Effect of Gas Quenching BFS

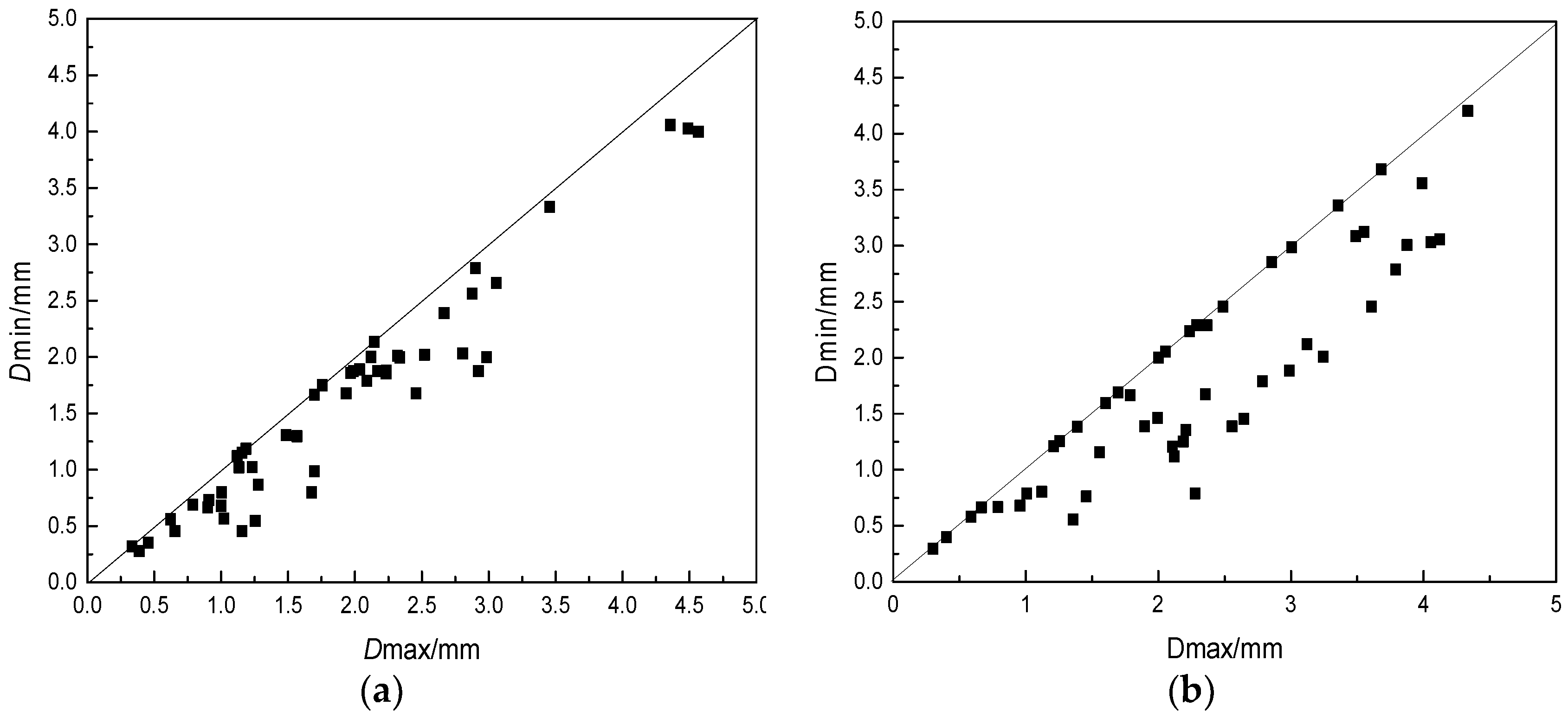

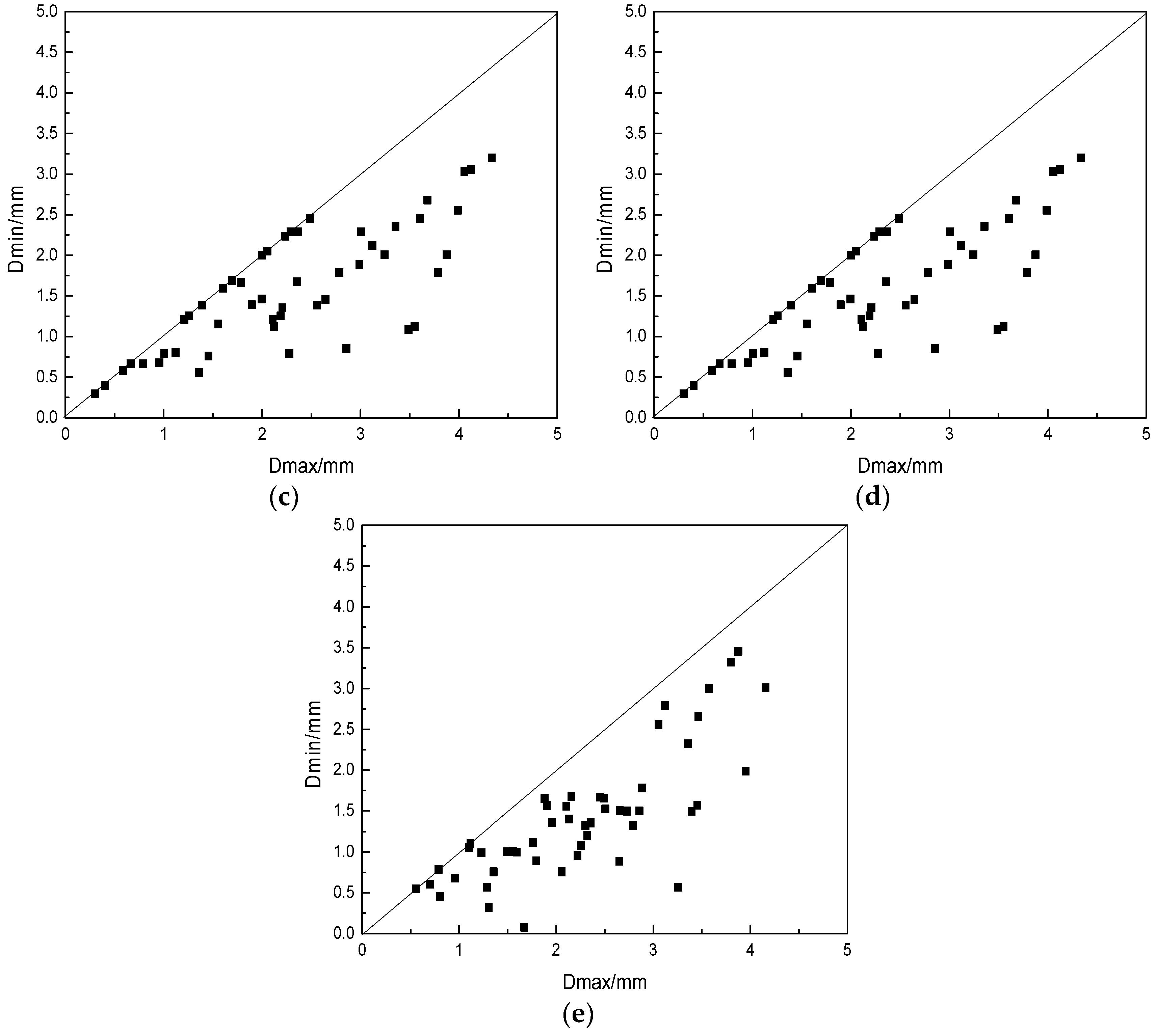

3.2. Influence of Different Basicities on Spherical Degree

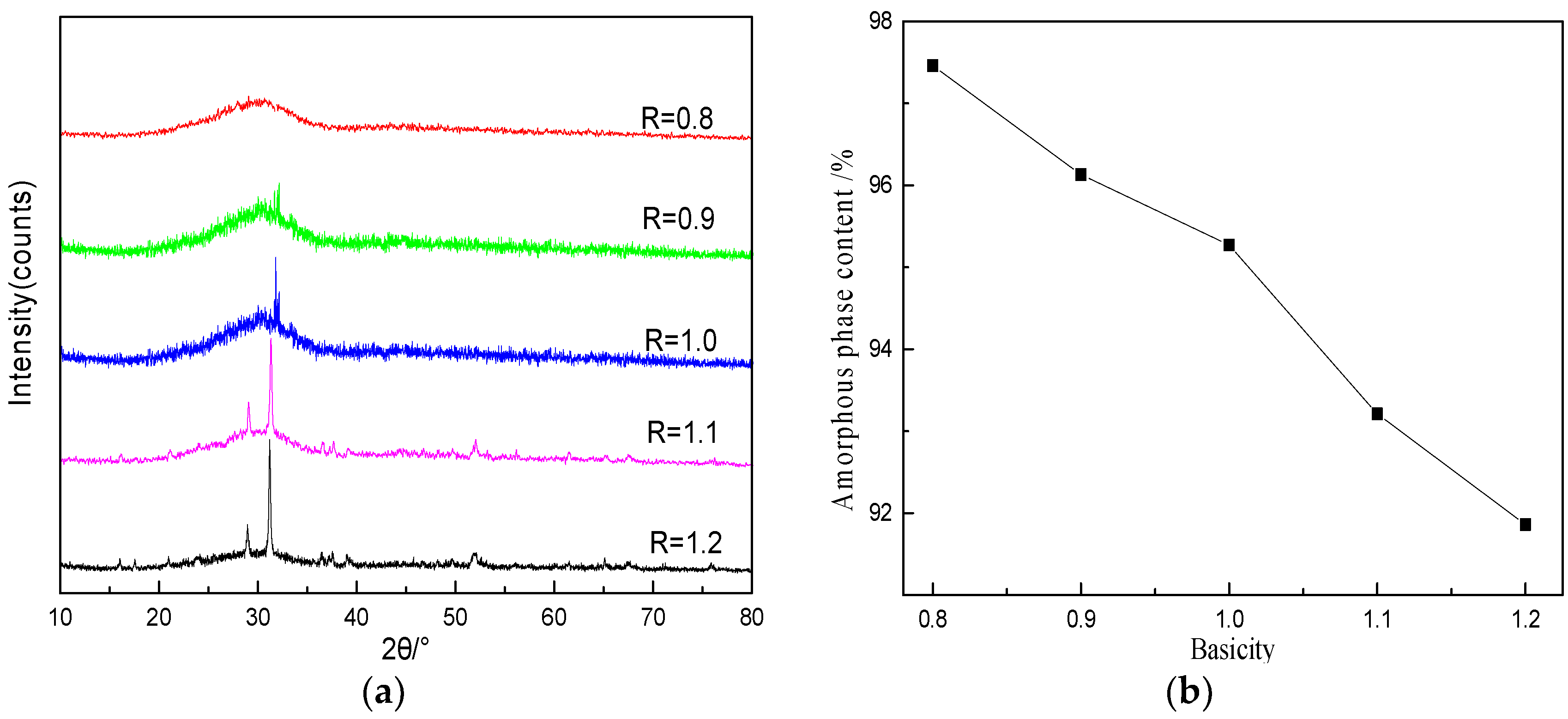

3.3. Analysis of Amorphous Content of Slag Beads

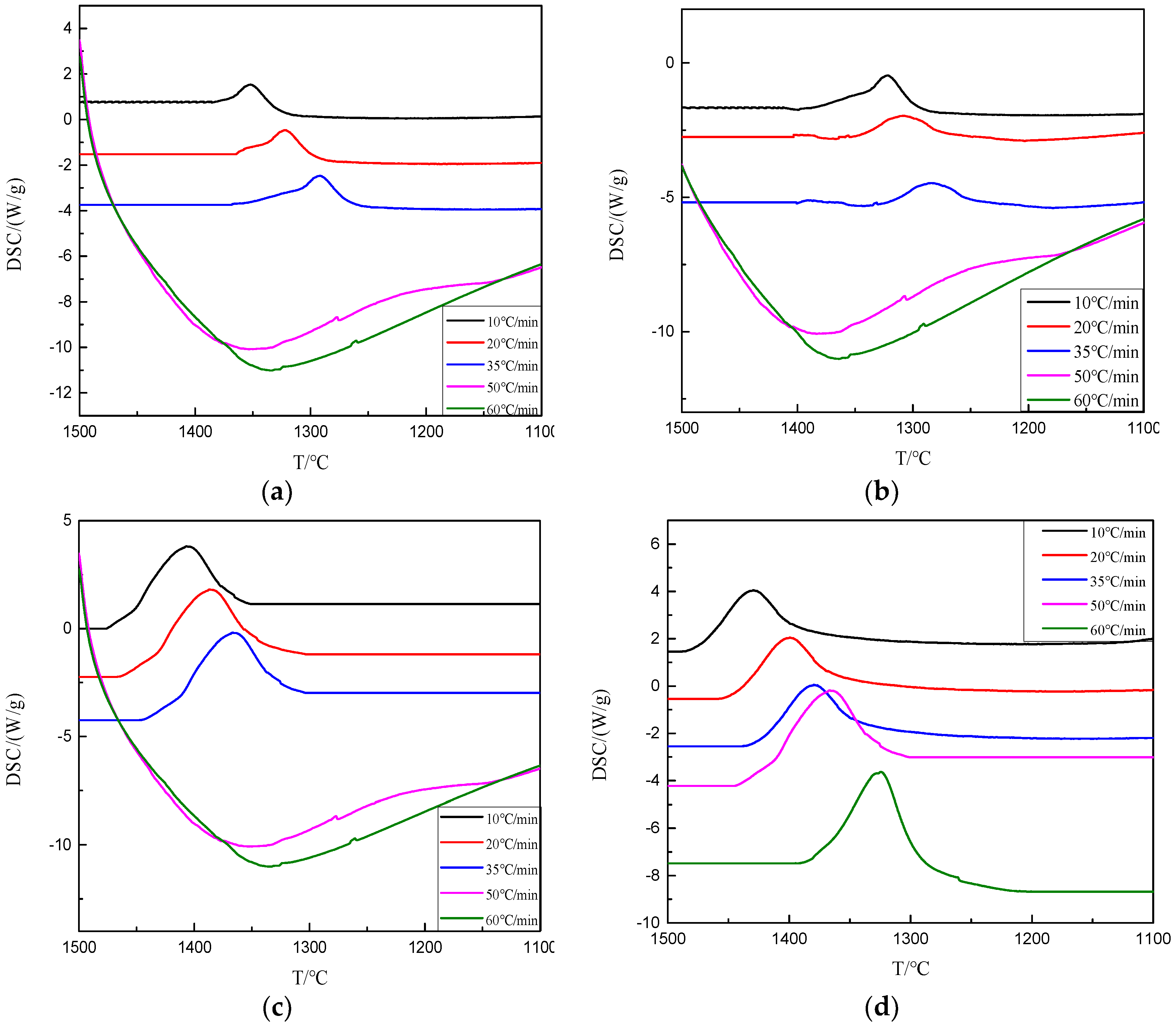

3.4. Crystallization Mechanism of BFS under Different Basicities

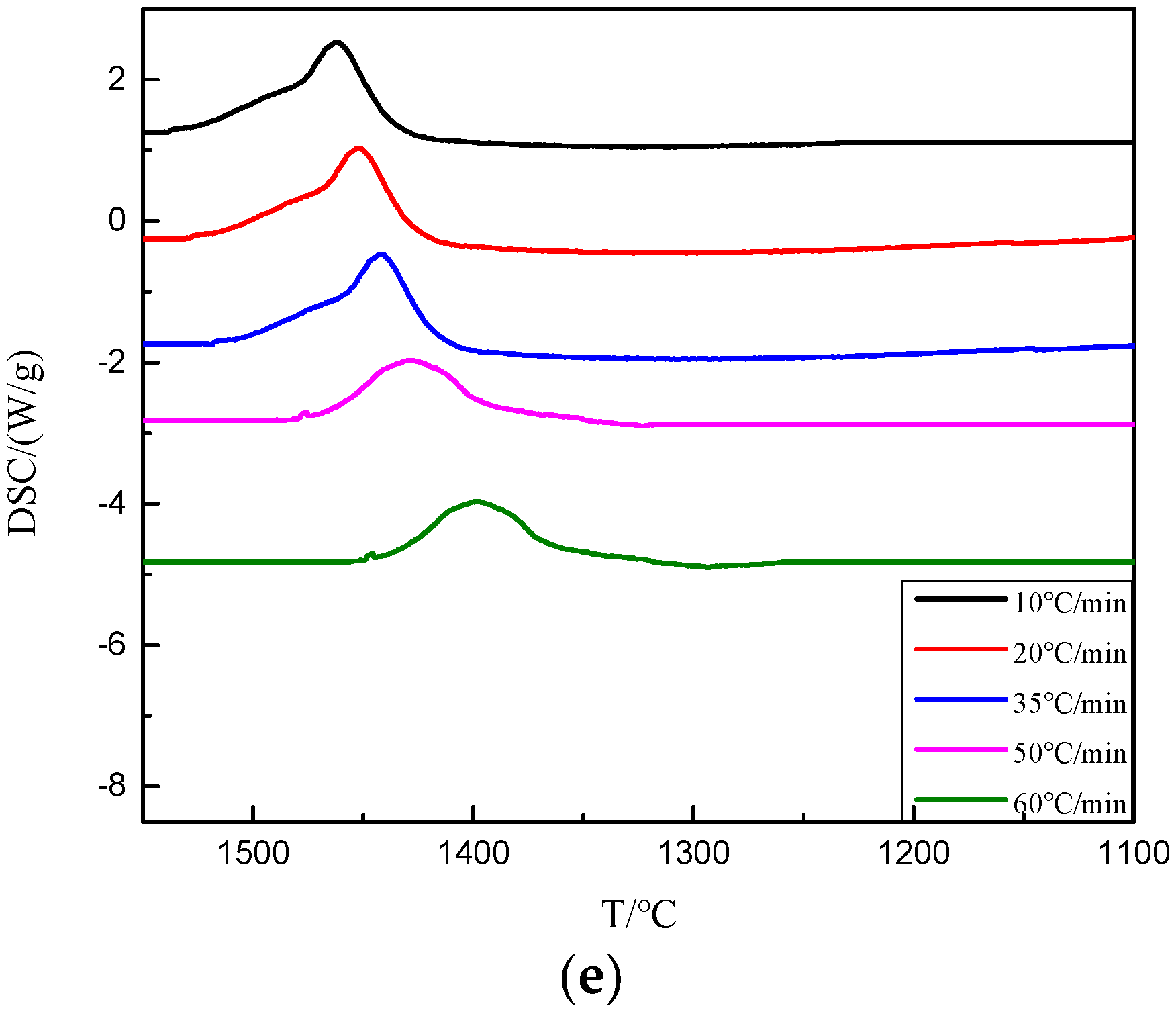

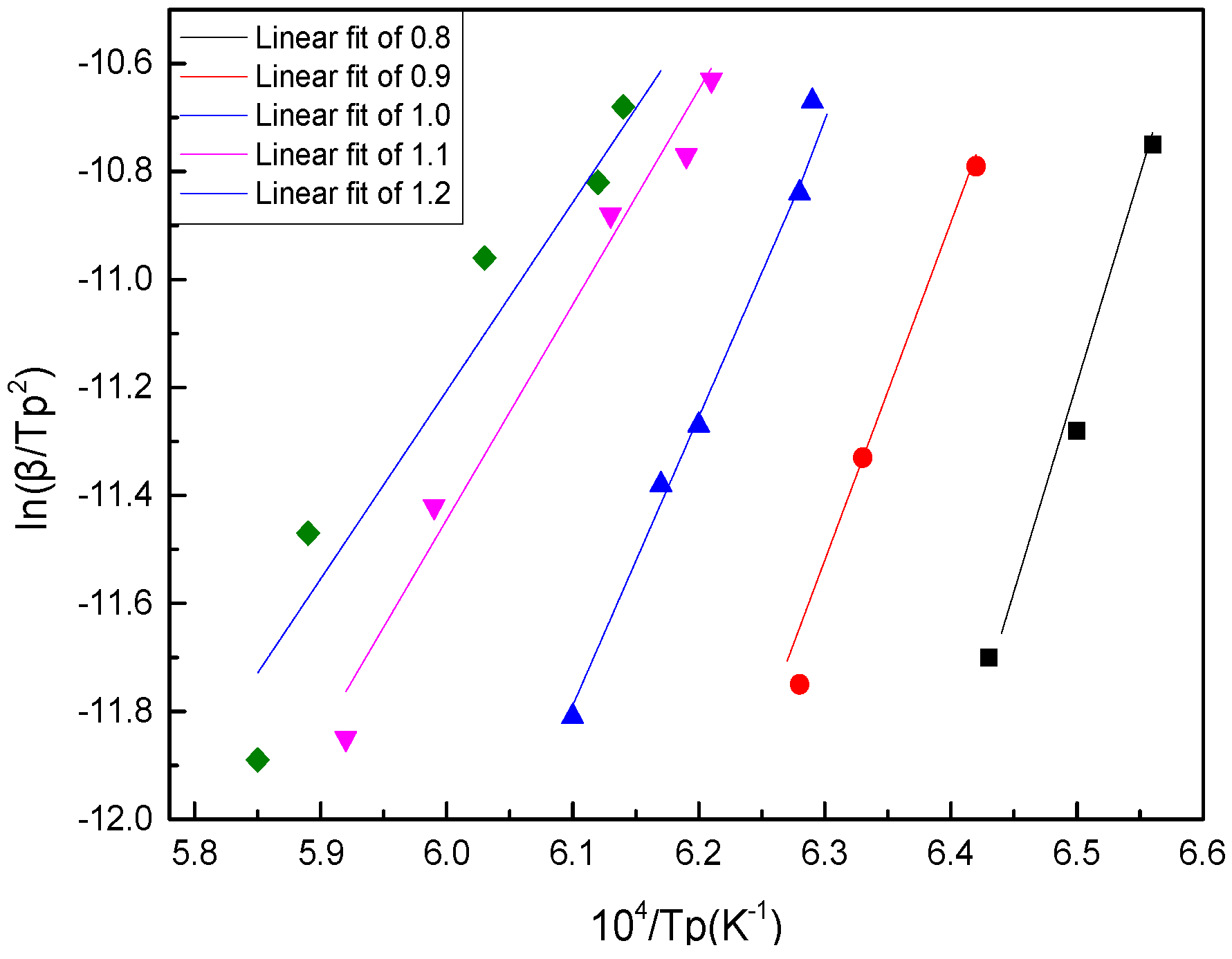

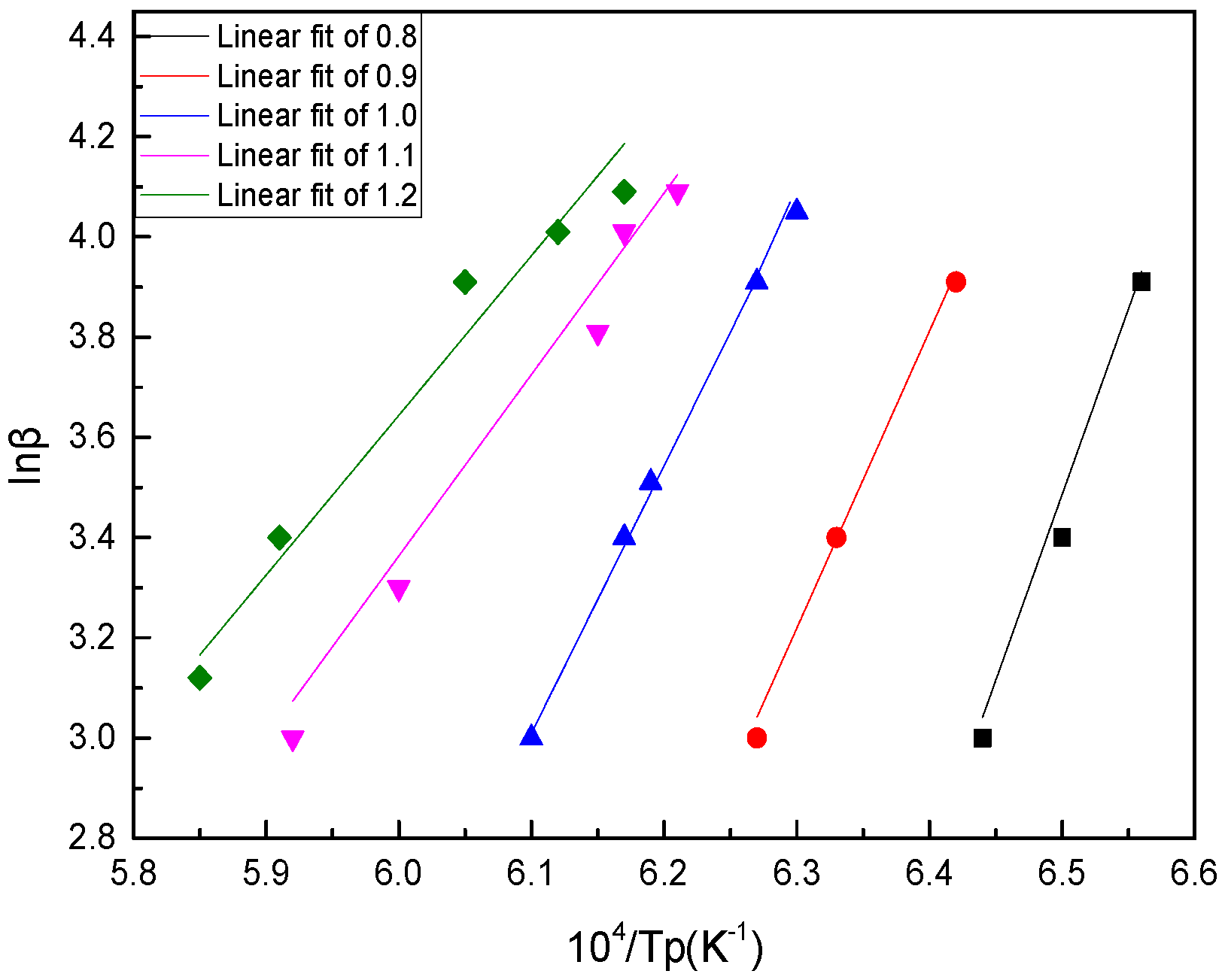

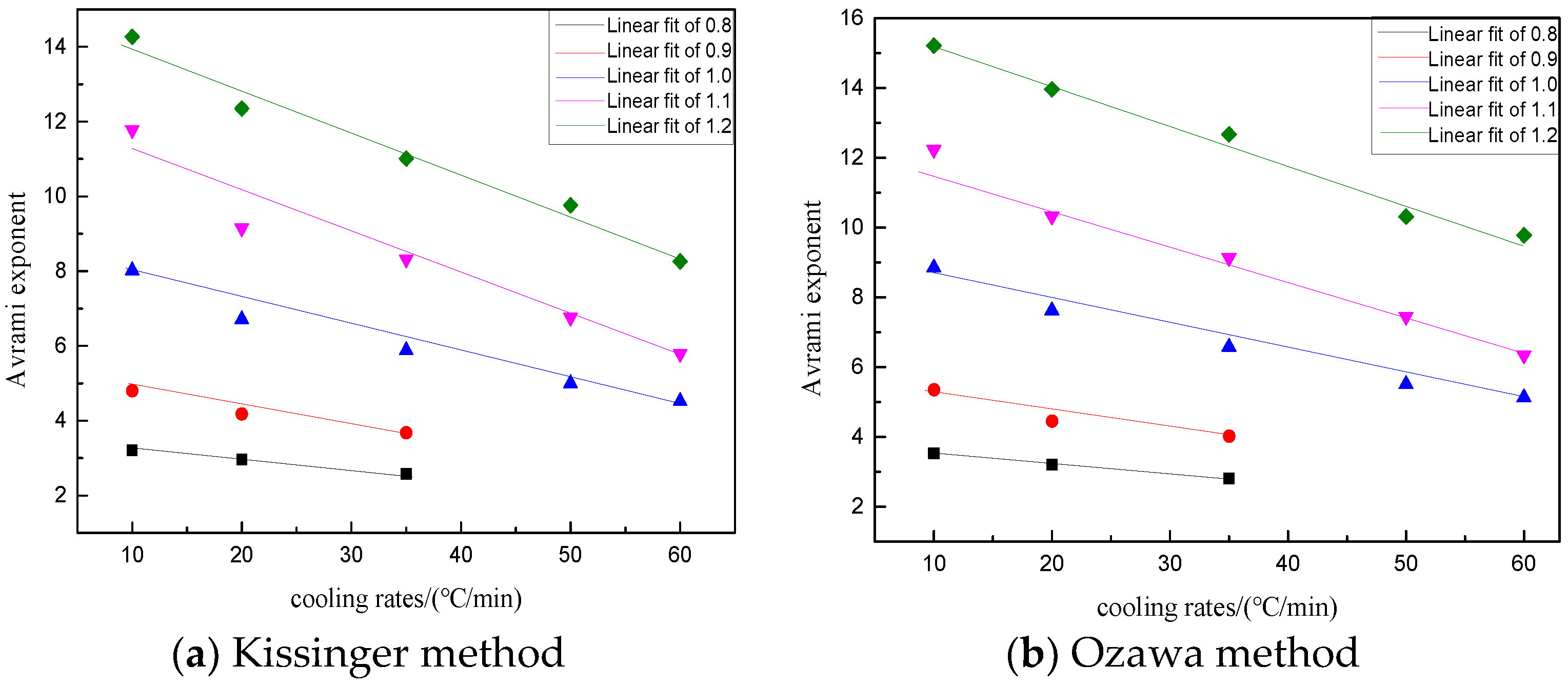

3.5. Calculation of Crystallization Activation Energy and Avrami Exponent

3.5.1. Calculation of Crystallization Activation Energy

3.5.2. Calculation of Avrami Exponent

4. Conclusions

- The BFS granulation products were slag beads with different particle sizes and fibers. The particle size distribution was mainly concentrated in 1~2.5 mm, which was basically a normal distribution, and the particle size distribution was more uniform. With the increase of basicity, the bead formation rate increased gradually, the number of small size slag beads increased gradually, and the shape changed more regularly. The amorphous degree of slag beads could be improved by decreasing the slag beads basicity and particle size. The amorphous degree of slag beads with a basicity lower than 0.8 and a diameter less than 50 mesh could reach 100%.

- Decreasing basicity could make BFS have higher crystallization activation energy and smaller Avrami exponent, which was not conducive to crystal nucleation and growth. An increasing cooling rate could increase the undercooling degree and inhibit crystal growth. The critical cooling rate required for the amorphization increased when the basicity increased. Overall, the analysis showed that the decrease of basicity and the increase of cooling rate were beneficial to the preparation of amorphous slag beads. The slag with bigger basicity needed a larger cooling rate than that of smaller basicity to obtain a high content of amorphous phase slag beads.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Min, Y.; Huang, J.; Liu, C.J.; Jiang, M.F.; Yu, X.Q. Physical simulation of molten slag granulation by rotary disk. J. Iron Steel Res. Int. 2013, 20, 26–32. [Google Scholar] [CrossRef]

- Ta, Y.; Zhu, X.; He, X.; Ding, B.; Wang, H.; Liao, Q.; Li, H. Granulation characteristics of molten blast furnace slag by hybrid centrifugal-air blast technique. Powder Technol. 2018, 323, 176. [Google Scholar]

- Peng, H.; Shan, X.; Kang, J.; Ling, X.; Wang, D. Influence of rotary disk configurations on droplets characteristics in molten slag granulation for waste heat recovery. Appl. Therm. Eng. 2018, 135, 269. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.; Zhu, X.; Qiu, Y.; Li, K.; Chen, R.; Liao, Q. A review of waste heat recovery technologies towards molten slag in steel industry. Appl. Energy 2013, 112, 956. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Duan, W.; Qin, Q. Experimental investigation of glass content of blast furnace slag by dry granulation. Environ. Prog. Sustain. 2015, 34, 485. [Google Scholar] [CrossRef]

- Purwanto Akiyama, T. Hydrogen production from biogas using hot slag. Int. J. Hydrog. Energy 2006, 31, 491. [Google Scholar] [CrossRef]

- Yoshinaga, M.; Fujii, K.; Shigematsu, T.; Nakata, T. Method of dry granulation and solidification of molten blast furnace slag. ISIJ Int. 1982, 22, 823. [Google Scholar] [CrossRef]

- Kashiwaya, Y.; In Nami, Y.; Akiyama, T. Development of a rotary cylinder atomizing method of slag for the production of amorphous slag particles. ISIJ Int. 2010, 50, 1245. [Google Scholar] [CrossRef]

- Ren, Q.; Zhang, Y.; Long, Y.; Zou, Z.; Pei, J. Crystallisation behaviour of blast furnace slag modified by adding fly ash. Ceram Int. 2018, 44, 11628–11634. [Google Scholar] [CrossRef]

- Dai, B.; Zhang, J.L. The research of blast furnace slag fluidity by viscosity experiment and phase diagram analysis. Am. Soc. Met. 2020, 17, 25–29. [Google Scholar]

- Geng, M.; Zhang, Y.; Xiang, L.; Yin, J.; Tao, W. Influence of MgO content and basicity on viscosity of blast furnace slag. Henan Metall. 2005, 13, 7–8. [Google Scholar]

- Zhao, Y.C.; Xiao, H.N.; Tan, W. Study on compositions and crystallization character of the glass-ceramics with good abrasion resistance. J. Chin. Ceram. Soc. 2003, 31, 406. [Google Scholar]

- Kissinger, H.E.; Mcmurdie, H.F.; Simpson, B.S. Thermal Decomposition of Manganous and Ferrous Carbonates, J. Am. Ceram. Soc. 1956, 39, 168.

- Ozawa, T. Kinetic analysis of derivative curves in thermal analysis. J. Therm. Anal. 1970, 2, 301. [Google Scholar] [CrossRef]

| Components | SiO2 | CaO | MgO | Al2O3 | Fe2O3 | TiO2 | K2O | Na2O | MnO |

|---|---|---|---|---|---|---|---|---|---|

| BFS | 33.53 | 36.25 | 8.64 | 15.82 | 1.57 | 1.38 | 0.54 | 0.32 | 0.17 |

| Fly ash | 51.87 | 3.37 | 0.011 | 33.34 | 3.6 | 0.82 | 0.78 | 0.10 | 0.044 |

| Limestone | 2.08 | 52.04 | 2.85 | 1.22 | - | - | - | - | - |

| No. | BFS/kg | Limestone/kg | Fly Ash/kg | Components | R | |||

|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | |||||

| 1 | 24.06 | - | 5.94 | 29.74 | 37.16 | 1.71 | 19.29 | 0.8 |

| 2 | 26.31 | - | 3.69 | 32.20 | 35.79 | 7.58 | 17.97 | 0.9 |

| 3 | 28.41 | - | 1.59 | 34.51 | 34.50 | 8.18 | 16.75 | 1.0 |

| 4 | 29.62 | 0.38 | - | 36.25 | 32.96 | 8.64 | 15.82 | 1.1 |

| 5 | 27.77 | 2.23 | - | 37.56 | 31.33 | 8.25 | 14.80 | 1.2 |

| R | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 |

|---|---|---|---|---|---|

| <0.15 mm | 100.00 | 99.87 | 99.66 | 98.59 | 97.79 |

| 0.15~0.30 mm | 100.00 | 98.91 | 98.25 | 97.16 | 96.79 |

| 0.30~1 mm | 99.87 | 97.45 | 96.43 | 95.32 | 94.32 |

| 1~2.5 mm | 97.46 | 96.13 | 95.27 | 93.21 | 91.86 |

| 2.5~5 mm | 95.51 | 94.57 | 93.31 | 91.06 | 89.17 |

| β/°C·min−1 | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 |

|---|---|---|---|---|---|

| 10 | 1319.8 | 1356.6 | 1400.2 | 1438.0 | 1457.7 |

| 20 | 1309.2 | 1335.2 | 1378.0 | 1423.2 | 1432.2 |

| 35 | 1290.1 | 1316.1 | 1355.3 | 1419.3 | 1430.6 |

| 50 | - | - | 1342.1 | 1383.5 | 1421.1 |

| 60 | - | - | 1309.6 | 1342.8 | 1389.3 |

| R | Kissinger | Ozawa |

|---|---|---|

| 0.8 | 518 ± 59 | 490 ± 50 |

| 0.9 | 437 ± 17 | 429 ± 33 |

| 1.0 | 327 ± 33 | 297 ± 27 |

| 1.1 | 280 ± 41 | 265 ± 51 |

| 1.2 | 193 ± 35 | 172 ± 48 |

| Basicities | β/°C·min−1 | 10 | 20 | 35 | 50 | 60 |

|---|---|---|---|---|---|---|

| 0.8 | Kissinger | 3.21 | 2.96 | 2.58 | - | - |

| Ozawa | 3.53 | 3.21 | 2.81 | - | - | |

| 0.9 | Kissinger | 4.80 | 4.18 | 3.68 | - | - |

| Ozawa | 5.35 | 4.45 | 4.02 | - | - | |

| 1.0 | Kissinger | 8.02 | 6.71 | 5.88 | 5.00 | 4.52 |

| Ozawa | 8.85 | 7.62 | 6.58 | 5.51 | 5.13 | |

| 1.1 | Kissinger | 11.78 | 9.15 | 8.32 | 6.76 | 5.79 |

| Ozawa | 12.23 | 10.32 | 9.13 | 7.45 | 6.34 | |

| 1.2 | Kissinger | 14.27 | 12.35 | 11.01 | 9.76 | 8.26 |

| Ozawa | 15.21 | 13.96 | 12.67 | 10.31 | 9.78 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Kang, Y.; Zhang, Y.; Xing, H. Granulation Effect Analysis of Gas Quenching Blast Furnace Slag with Different Basicities. Coatings 2020, 10, 372. https://doi.org/10.3390/coatings10040372

Liu C, Kang Y, Zhang Y, Xing H. Granulation Effect Analysis of Gas Quenching Blast Furnace Slag with Different Basicities. Coatings. 2020; 10(4):372. https://doi.org/10.3390/coatings10040372

Chicago/Turabian StyleLiu, Chao, Yue Kang, Yuzhu Zhang, and Hongwei Xing. 2020. "Granulation Effect Analysis of Gas Quenching Blast Furnace Slag with Different Basicities" Coatings 10, no. 4: 372. https://doi.org/10.3390/coatings10040372

APA StyleLiu, C., Kang, Y., Zhang, Y., & Xing, H. (2020). Granulation Effect Analysis of Gas Quenching Blast Furnace Slag with Different Basicities. Coatings, 10(4), 372. https://doi.org/10.3390/coatings10040372