Effect of Carbon Content and Elements Mo and V on the Microstructure and Properties of Stainless Steel Powder Surfacing Layer

Abstract

1. Introduction

2. Experimental

2.1. Experimental Materials

2.2. Scheme of Surfacing Technology

2.3. Test Methods and Equipment

3. Test Results and Analysis

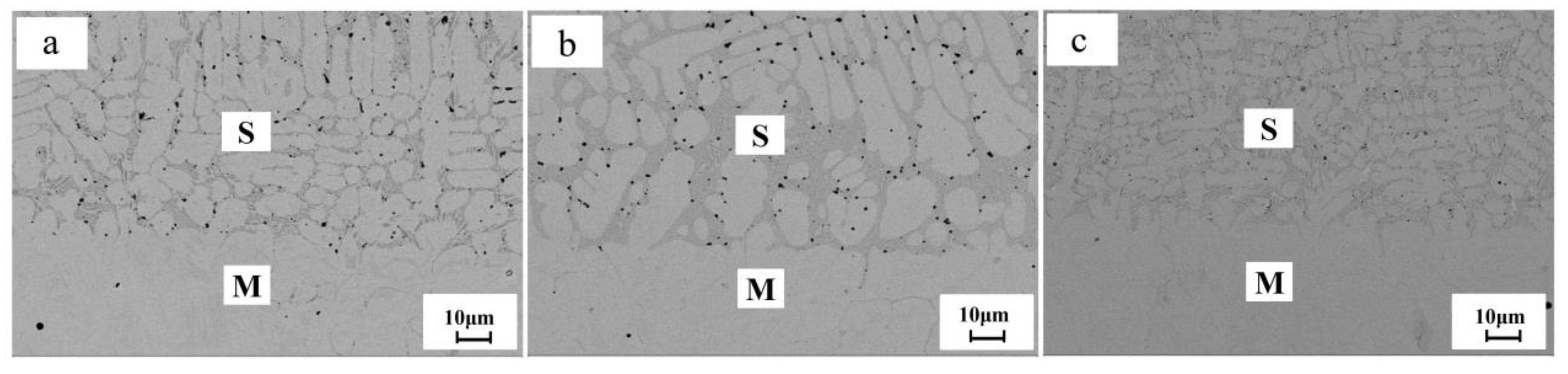

3.1. Effect of Carbon Content and Elements Mo and V on the Microstructure of the Surfacing Layer

3.2. Effect of Carbon Content and the Elements Mo and V on Carbide Distribution in the Surfacing Layer

3.3. Effect of Carbon Content and Elements Mo and V on the Comprehensive Properties of the Surfacing Layer

3.3.1. Comprehensive Hardness

3.3.2. Wear Resistance

3.3.3. Impact Toughness

3.3.4. Corrosion Resistance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Deng, D. Present status and development tendency of plasma transferred arc welding. Chin. J. Mech. Eng. 2013, 49, 106–112. [Google Scholar] [CrossRef]

- Lindner, T.; Kutschmann, P.; Löbel, M.; Lampke, T. Hardening of HVOF-sprayed austenitic stainless-steel coatings by gas nitriding. Coatings 2018, 8, 348. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Y.; Li, B.; Zhang, Z.; Qiu, C. Effects of low-temperature tempering on microstructure and properties of the laser-cladded AISI 420 martensitic stainless steel coating. Coatings 2018, 8, 451. [Google Scholar] [CrossRef]

- Pfender, E. Thermal plasma technology: Where do we stand and where are we going? Plasma Chem. Plasma Process. 1999, 19, 1–31. [Google Scholar] [CrossRef]

- Deuis, R.L.; Yellup, J.M.; Subramanian, C. Metal-matrix composite coatings by PTA surfacing. Compos. Sci. Technol. 1998, 58, 299–309. [Google Scholar] [CrossRef]

- Kuroda, S.; Fukushima, T.; Kitahara, S. Simultaneous measurement of coating thickness and deposition stress during thermal spraying. Thin Solid Films 1988, 164, 157–163. [Google Scholar] [CrossRef]

- Gérard, B. Application of thermal spraying in the automobile industry. Surf. Coat. Technol. 2006, 201, 2028–2031. [Google Scholar] [CrossRef]

- Grozdanov, I. Electroless chemical deposition technique for Cu2O thin films. Mater. Lett. 1994, 19, 281–285. [Google Scholar] [CrossRef]

- Kyzioł, K.; Oczkowska, J.; Kottfer, D.; Klich, M.; Kaczmarek, Ł.; Kyzioł, A.; Grzesik, Z. Physicochemical and biological activity analysis of low-density polyethylene substrate modified by multi-layer coatings based on DLC structures, obtained using RF CVD method. Coatings 2018, 8, 135. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering physical vapour deposition (PVD) coatings: A critical review on process improvement and market trend demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing; William Andrew: Burlington, VT, USA, 2010; pp. 1–9. [Google Scholar]

- Wang, X.B.; Wang, X.F.; Shi, Z.Q. The composite Fe–Ti–B–C Coatings by PTA powder surfacing process. Surf. Coat. Technol. 2005, 192, 257–262. [Google Scholar]

- Liu, Y.F.; Xia, Z.Y.; Han, J.M.; Zhang, G.L.; Yang, S.Z. Microstructure and wear behavior of (Cr, Fe)7C3 reinforced composite coating produced by plasma transferred arc weld-surfacing process. Surf. Coat. Technol. 2006, 201, 863–867. [Google Scholar] [CrossRef]

- Xie, G.Z.; Song, X.L.; Zhang, D.J.; Wu, Y.P.; Lin, P.H. Microstructure and corrosion properties of thick WC composite coating formed by plasma cladding. Appl. Surf. Sci. 2010, 256, 6354–6358. [Google Scholar]

- Kim, Y.J. Wear and corrosion resistance of PTA weld surfaced Ni and Co based alloy layers. Surf. Eng. 1999, 15, 495–501. [Google Scholar] [CrossRef]

- Yükse, N.; Şahin, S. Wear behavior–hardness–microstructure relation of Fe–Cr–C and Fe–Cr–C–B based hardfacing alloys. Mater. Des. 2014, 58, 491–498. [Google Scholar] [CrossRef]

- Liu, R.M.; Yao, M.X.; Patnaik, P.C.; Wu, X.J. An improved wear-resistant PTA hardfacing: VWC/Stellite 21. J. Compos. Mater. 2006, 40, 2203–2215. [Google Scholar] [CrossRef]

- Azimi, G.; Shamanian, M. Effects of silicon content on the microstructure and corrosion behavior of Fe–Cr–C hardfacing alloys. J. Alloys Compd. 2010, 505, 598–603. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Yang, J.; Hao, F.; Dan, T.; Yang, Y.; Yang, Q. Effect of La2O3 on granular bainite microstructure and wear resistance of hardfacing layer metal. J. Rare Earths 2014, 32, 83–89. [Google Scholar] [CrossRef]

- Klimpel, A.; Dobrzański, L.A.; Lisiecki, A.; Janicki, D. The study of the technology of laser and plasma surfacing of engine valves face made of X40CrSiMo10-2 steel using cobalt-based powders. J. Mater. Process. Technol. 2006, 175, 251–256. [Google Scholar] [CrossRef]

- Gladkii, P.V.; Perepletchikov, E.F.; Ryabtsev, I.A. Plasma surfacing. Weld. Int. 2007, 21, 685–693. [Google Scholar] [CrossRef]

- Bogolyubskii, S.D.; Guk, V.V.; Shlyamnev, A.P. Corrosion resistance of knife steels. J. Mater. Process. Technol. 2001, 43, 267–269. [Google Scholar]

- Udod, K.A.; Rodionova, I.G.; Knyazev, A.V.; Stukalin, S.V. Study of the effect of chemical composition and heat treatment on corrosion resistance indices for martensitic class stainless steels alloyed with nitrogen. Metallurgist 2016, 59, 1096–1100. [Google Scholar] [CrossRef]

- Prieto, G.; Tuckart, W.R. Influence of cryogenic treatments on the wear behavior of AISI 420 martensitic stainless steel. J. Mater. Eng. Perform. 2017, 26, 5262–5271. [Google Scholar] [CrossRef]

- Qiuli, Z.; Hong, S.; Haiyan, W.; Erwei, C. Brief introduction to metallic materials charpy impact testing method of GB/T 229–2007. Phys. Test. Chem. Anal. 2010, 46, 190–192. [Google Scholar]

- Jiaxiang, C. Data Sheets for Common Steelmaking Charts; Metallurgical Industry Press: Beijing, China, 1984; pp. 155–162. [Google Scholar]

- Gulyaev, A.P.; Sergienko, L.P. Effect of molybdenum and vanadium on the structure and properties of tungstenless high-speed powder steel. Met. Sci. Heat Treat. 1986, 28, 112–118. [Google Scholar] [CrossRef]

- Todić, A.; Čikara, D.; Todić, T.; Pejović, B.; Mišić, M.; Čamagić, I. The effect of vanadium content on mechanical properties and structure of self-hardening steel X160CrMo12-1. J. Mech. Eng. Autom. 2013, 3, 168–172. [Google Scholar]

- Dilawary, S.A.; Motallebzadeh, A.; Houdková, Š.; Medlin, R.; Haviar, S.; Lukáč, F.; Afzal, M.; Cimenoglu, H. Modification of M2 hardfacing: Effect of molybdenum alloying and laser surface melting on microstructure and wear performance. Wear 2018, 404, 111–121. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, Q.; Xu, J.Y.; Liao, H.Y. Morphology and composition of plasma alloying of Cr–Mo layer. Surf. Coat. Technol. 2007, 201, 5526–5528. [Google Scholar] [CrossRef]

- Hajihashemi, M.; Shamanian, M.; Azimi, G. Physical, Mechanical, and dry sliding wear properties of Fe-Cr-W-C hardfacing alloys under different tungsten addition. Metall. Mater. Trans. B 2015, 46, 919–927. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; De Hosson, J.T.M. Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys. Mater. Lett. 2012, 84, 69–72. [Google Scholar] [CrossRef]

- Liljedahl, C.D.; Zanellato, O.; Fitzpatrick, M.E.; Lin, J.; Edwards, L. The effect of weld residual stresses and their re-distribution with crack growth during fatigue under constant amplitude loading. Int. J. Fatigue 2010, 32, 735–743. [Google Scholar] [CrossRef]

- Labeas, G.; Diamantakos, I. Numerical investigation of through crack behaviour under welding residual stresses. Eng. Fract. Mech. 2009, 76, 1691–1702. [Google Scholar] [CrossRef]

- Sevim, I.; Eryurek, I.B. Effect of fracture toughness on abrasive wear resistance of steels. Mater. Des. 2006, 27, 911–919. [Google Scholar] [CrossRef]

- Modi, O.P.; Mondal, D.P.; Prasad, B.K.; Singh, M.; Khaira, H.K. Abrasive wear behaviour of a high carbon steel: Effects of microstructure and experimental parameters and correlation with mechanical properties. Mater. Sci. Eng. A 2003, 343, 235–242. [Google Scholar] [CrossRef]

- Su, Y.L.; Chen, K.Y. The influence of niobium, chromium, molybdenum and carbon on the sliding wear behavior of nickel-base hardfacing alloys. Wear 1997, 209, 160–170. [Google Scholar] [CrossRef]

- Qi, X.; Jia, Z.; Yang, Q.; Yang, Y. Effects of vanadium additive on structure property and tribological performance of high chromium cast iron hardfacing metal. Surf. Coat. Technol. 2011, 205, 5510–5514. [Google Scholar] [CrossRef]

- Fang, X.; Cao, R.; Li, G.; Jiang, F.; Chen, J. Effects of grain sizes and second phase sizes of 16MnR steel on its low temperature impact toughness. Chin. J. Mech. Eng. 2011, 47, 40–44. [Google Scholar] [CrossRef]

- Wu, M.W.; Tsao, L.C.; Shu, G.J.; Lin, B.H. The effects of alloying elements and microstructure on the impact toughness of powder metal steels. Mater. Sci. Eng. A 2012, 538, 135–144. [Google Scholar] [CrossRef]

- Kong, J.H.; Zhen, L.; Guo, B.; Li, P.H.; Wang, A.H.; Xie, C.S. Influence of Mo content on microstructure and mechanical properties of high strength pipeline steel. Mater. Des. 2004, 25, 723–728. [Google Scholar]

- Ranganatha, S.; Venkatesha, T.V.; Vathsala, K. Electrochemical studies on Zn/nano-CeO2 electrodeposited composite coatings. Surf. Coat. Technol. 2012, 208, 64–72. [Google Scholar] [CrossRef]

- Cui, Z.Q.; Liu, B.X. Principles of Metallurgy and Heat Treatment; Harbin Institute of Technology: Harbin, China, 2004; pp. 56–99. [Google Scholar]

- Calliari, I.; Zanesco, M.; Dabala, M.; Brunelli, K.; Ramous, E. Investigation of microstructure and properties of a Ni–Mo martensitic stainless steel. Mater. Des. 2008, 29, 246–250. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Arrabal, R.; Matykina, E. Effect of Mo and Mn additions on the corrosion behaviour of AISI 304 and 316 stainless steels in H2SO4. Corros. Sci. 2008, 50, 780–794. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Arrabal, R.; Matykina, E.J. Pitting corrosion behaviour of austenitic stainless steels–combining effects of Mn and Mo additions. Corros. Sci. 2008, 50, 1796–1806. [Google Scholar] [CrossRef]

| C | Si | Mn | P | Ni | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.20 | 0.40 | 0.25 | 0.025 | 0.12 | 13.00 | - | - | Bal. |

| Grade | C | Si | Mn | P | Ni | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 5Cr13 | 0.52 | 0.60 | 1.00 | 0.035 | 0.60 | 13.00 | - | - | Bal. |

| 8Cr13 | 0.80 | 1.00 | 1.00 | 0.045 | 0.15 | 13.00 | - | - | Bal. |

| 8Cr13MoV | 0.80 | 1.00 | 1.00 | 0.045 | 0.15 | 13.00 | 0.20 | 0.20 | Bal. |

| Current A | Voltage V | Powder Feeding Rate g/min | Distance of Surfacing mm | Stepping Width mm/min | Plasma Torch Speed, mm/min | Shielding | Plasma Gas |

|---|---|---|---|---|---|---|---|

| 140–160 | 30–40 | 50–70 | 15–25 | 3–7 | 260–290 | Argon | Argon |

| Sample Types | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Matrix (2Cr13) | 42.3 | 44.5 | 44.8 | 45.3 | 41.4 | 40.0 | 42.1 | 42.1 | 43.5 | 42.5 | 42.85 |

| 5Cr13 | 41.5 | 43.2 | 41.5 | 45.2 | 44.2 | 42.2 | 43.5 | 43.2 | 44.5 | 43.0 | 43.20 |

| 8Cr13 | 56.5 | 55.5 | 54.3 | 53.7 | 57.2 | 54.2 | 55.3 | 55.0 | 56.2 | 55.1 | 55.30 |

| 8Cr13MoV | 55.6 | 56.5 | 57.5 | 57.2 | 57.0 | 56.5 | 58.5 | 55.2 | 56.5 | 56.5 | 56.70 |

| Sample Types | 1 | 2 | 3 | Average |

|---|---|---|---|---|

| Matrix (2Cr13) | 7.4 | 7.9 | 7.5 | 7.6 |

| 5Cr13 | 7.1 | 7.5 | 7.6 | 7.4 |

| 8Cr13 | 3.1 | 3.3 | 3.5 | 3.3 |

| 8Cr13MoV | 2.2 | 1.9 | 1.9 | 2.0 |

| Grade | Carbide Content/% | Tl | TS | ΔT |

|---|---|---|---|---|

| 5Cr13 | 0.52 | 1457.66 | 1307.85 | 149.81 |

| 8Cr13 | 0.80 | 1477.81 | 1250.19 | 227.62 |

| Number | 1 | 2 | 3 | Average Impact Energy |

|---|---|---|---|---|

| #1 | 6.8 | 6.6 | 7.0 | 6.8 |

| #2 | 6.9 | 6.8 | 7.0 | 6.9 |

| #3 | 7.7 | 7.7 | 8.0 | 7.8 |

| #4 | 7.1 | 6.9 | 7.0 | 7.0 |

| Sample Type | Ecorr, mV | icoor, μA | βa, mV/dec | βc, mV/dec | Rp, kΩ/cm2 |

|---|---|---|---|---|---|

| Matrix(2Cr13) | −445.62 | 16.30 | 252.79 | 499.01 | 4.47 |

| 5Cr13 | −455.22 | 57.20 | 466.81 | −2679.53 | 4.29 |

| 8Cr13 | −255.46 | 28.85 | 332.83 | 276.70 | 2.27 |

| 8Cr13MoV | −476.73 | 42.18 | 332.53 | −1412.30 | 4.48 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, T.; Wei, C.; Han, X.; Liu, J.; He, Z.; Lü, N. Effect of Carbon Content and Elements Mo and V on the Microstructure and Properties of Stainless Steel Powder Surfacing Layer. Coatings 2020, 10, 371. https://doi.org/10.3390/coatings10040371

Xu T, Wei C, Han X, Liu J, He Z, Lü N. Effect of Carbon Content and Elements Mo and V on the Microstructure and Properties of Stainless Steel Powder Surfacing Layer. Coatings. 2020; 10(4):371. https://doi.org/10.3390/coatings10040371

Chicago/Turabian StyleXu, Taixu, Chongyi Wei, Xiao Han, Jihui Liu, Zhijun He, and Nan Lü. 2020. "Effect of Carbon Content and Elements Mo and V on the Microstructure and Properties of Stainless Steel Powder Surfacing Layer" Coatings 10, no. 4: 371. https://doi.org/10.3390/coatings10040371

APA StyleXu, T., Wei, C., Han, X., Liu, J., He, Z., & Lü, N. (2020). Effect of Carbon Content and Elements Mo and V on the Microstructure and Properties of Stainless Steel Powder Surfacing Layer. Coatings, 10(4), 371. https://doi.org/10.3390/coatings10040371