Study on Microstructure and Tribological Performance of Diamond/Cu Composite Coating via Supersonic Laser Deposition

Abstract

1. Introduction

2. Materials and Methods

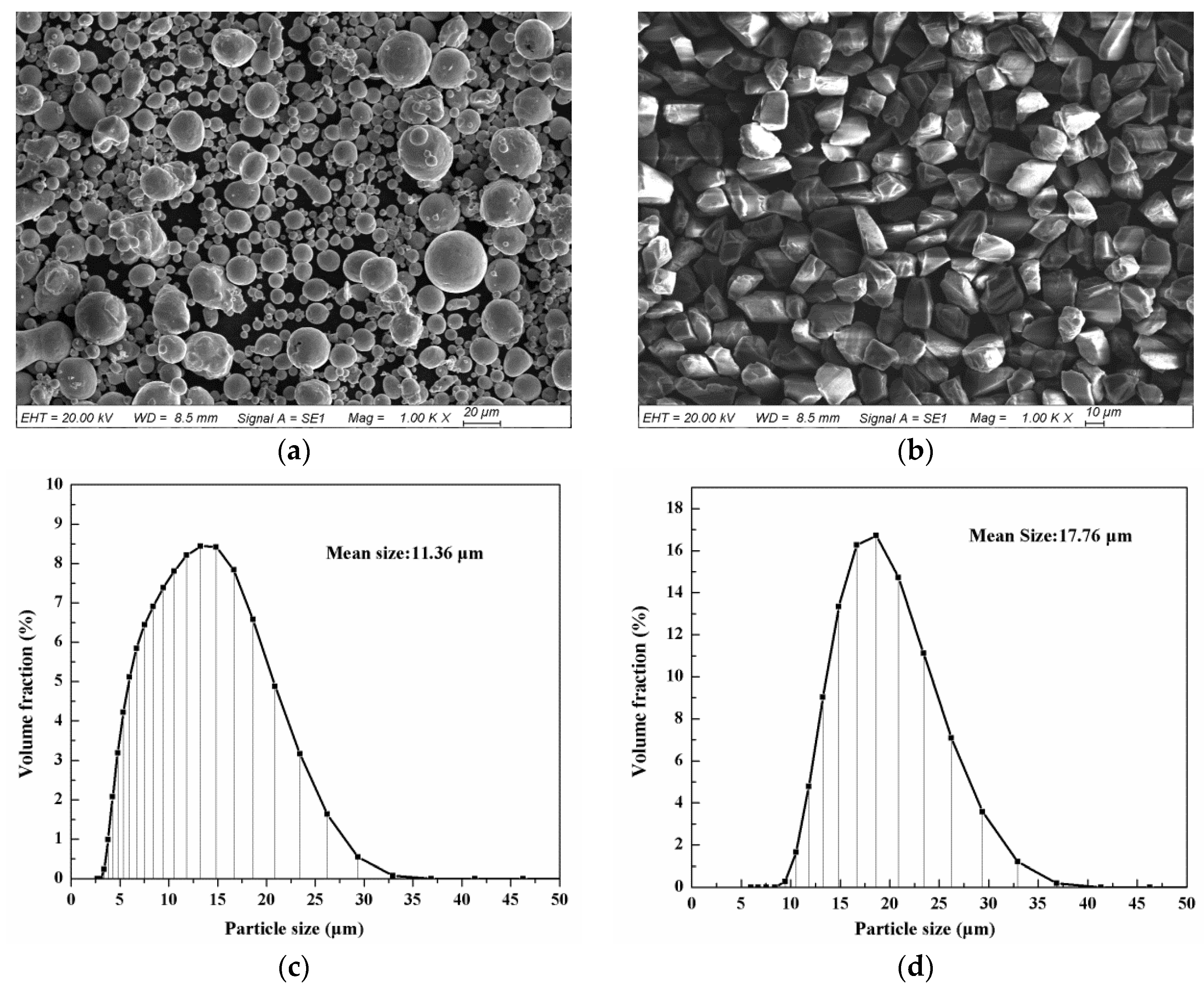

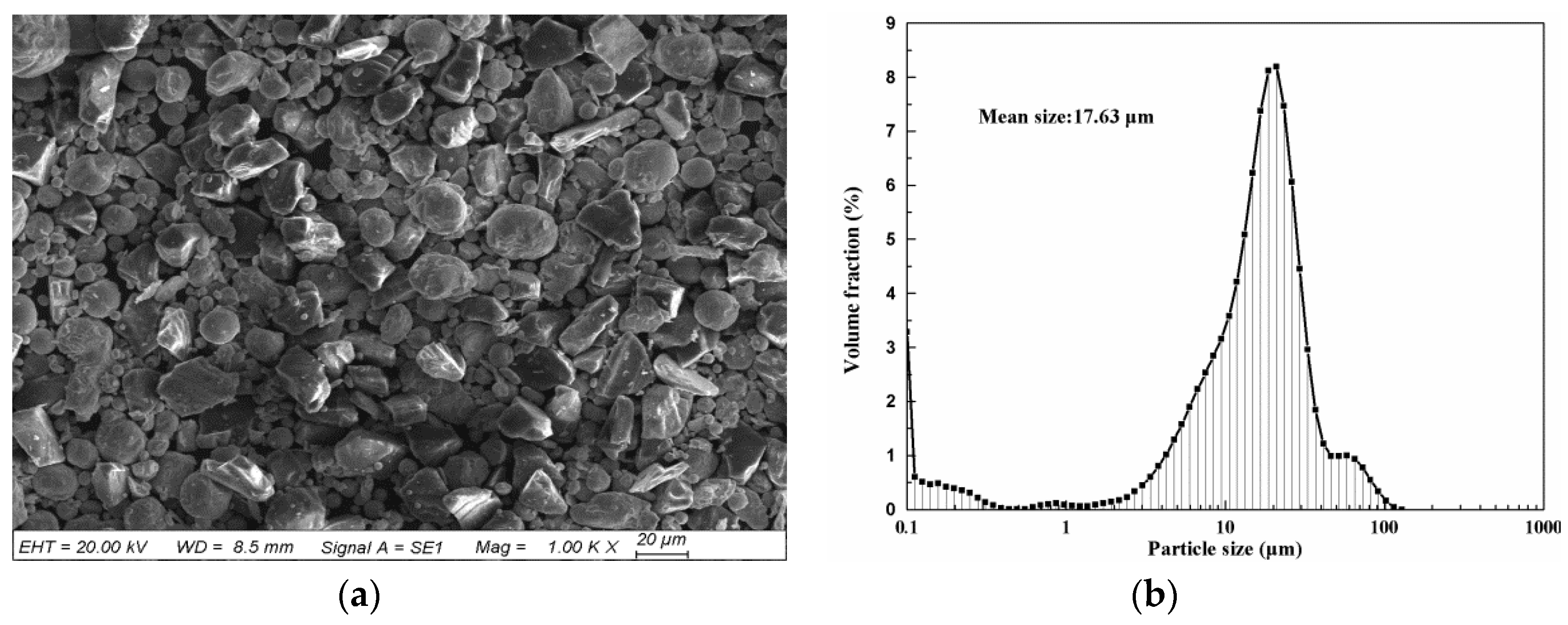

2.1. Feedstock Materials

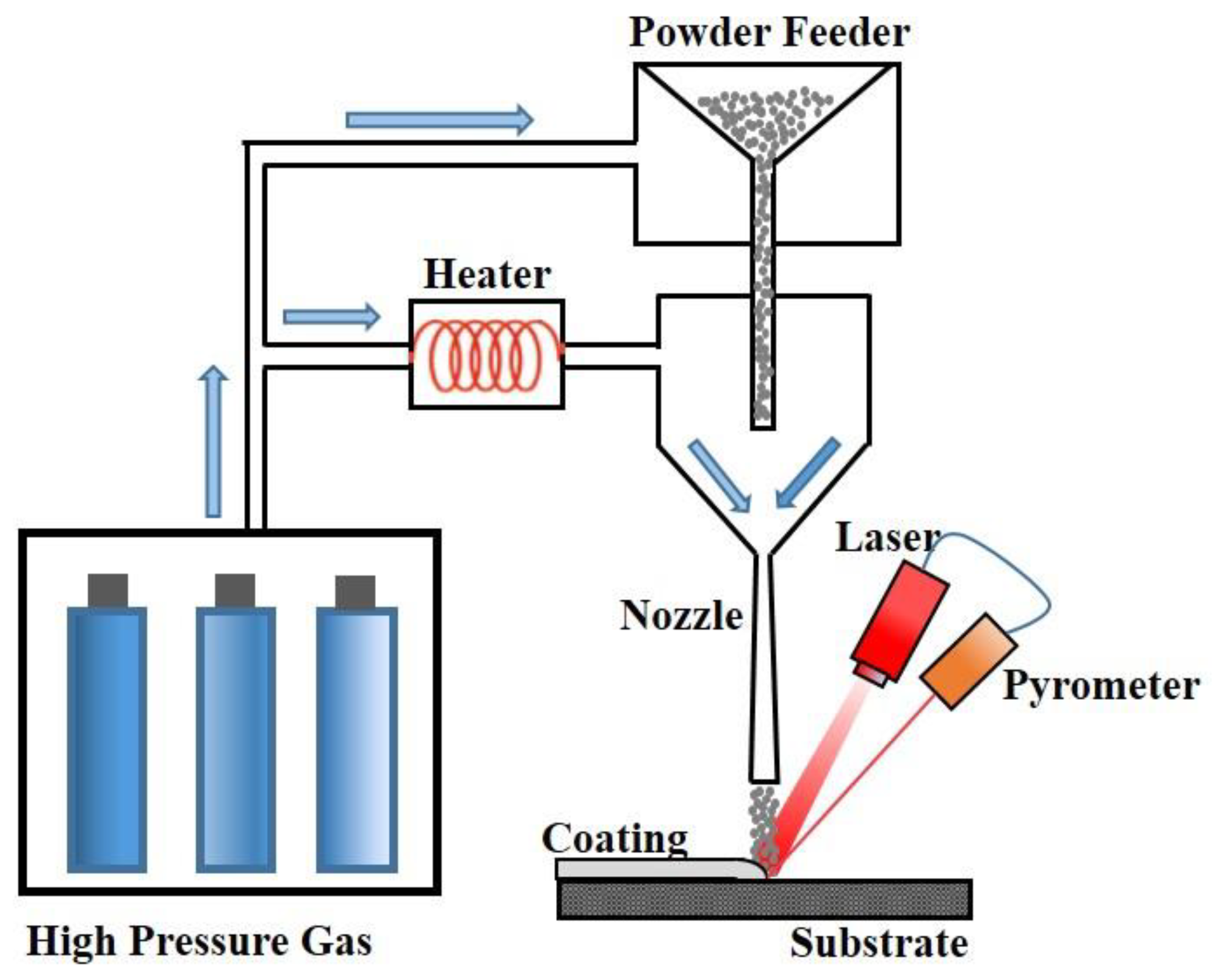

2.2. Coating Fabrication

2.3. Coating Characterization

3. Results and Discussion

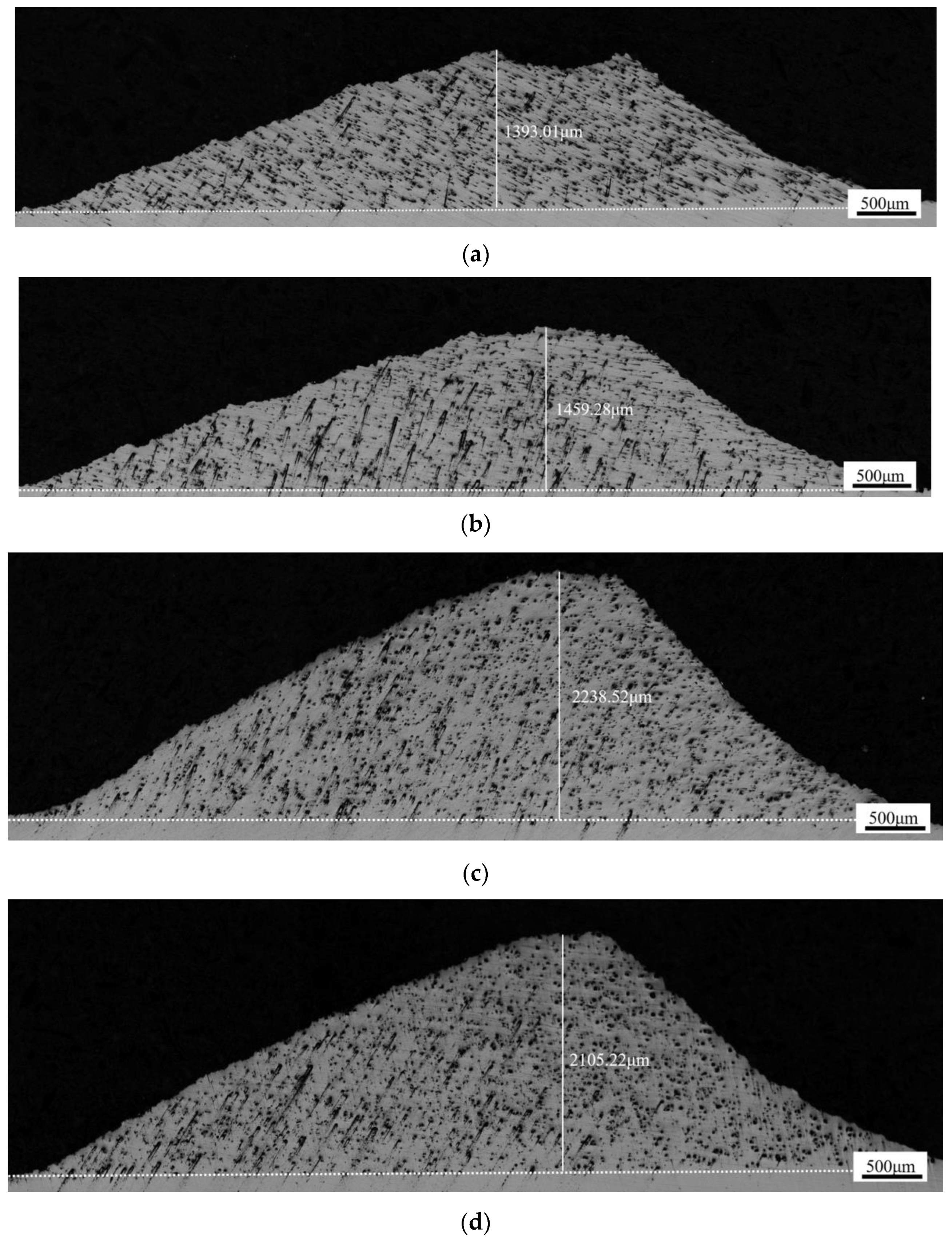

3.1. Deposition Efficiency

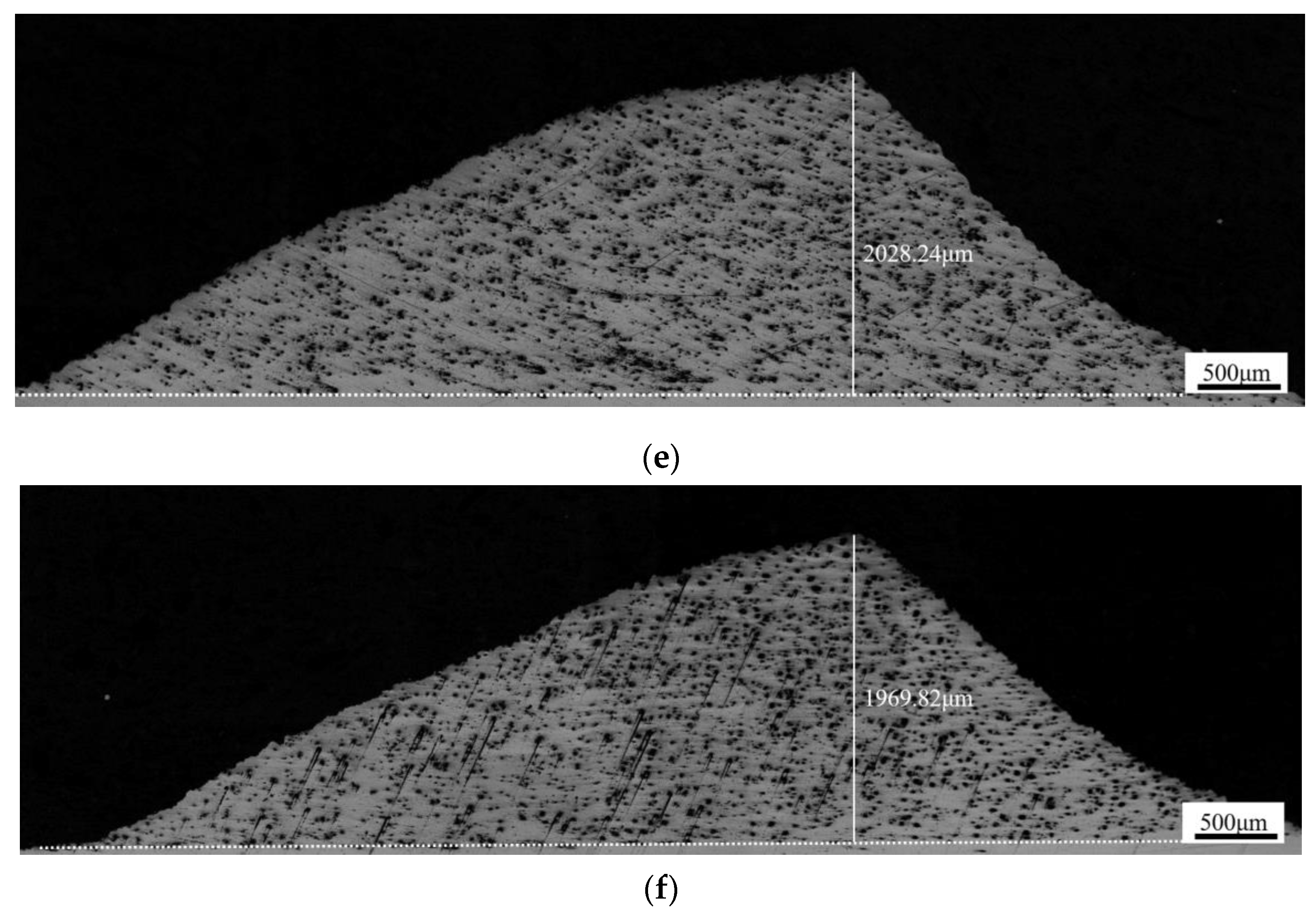

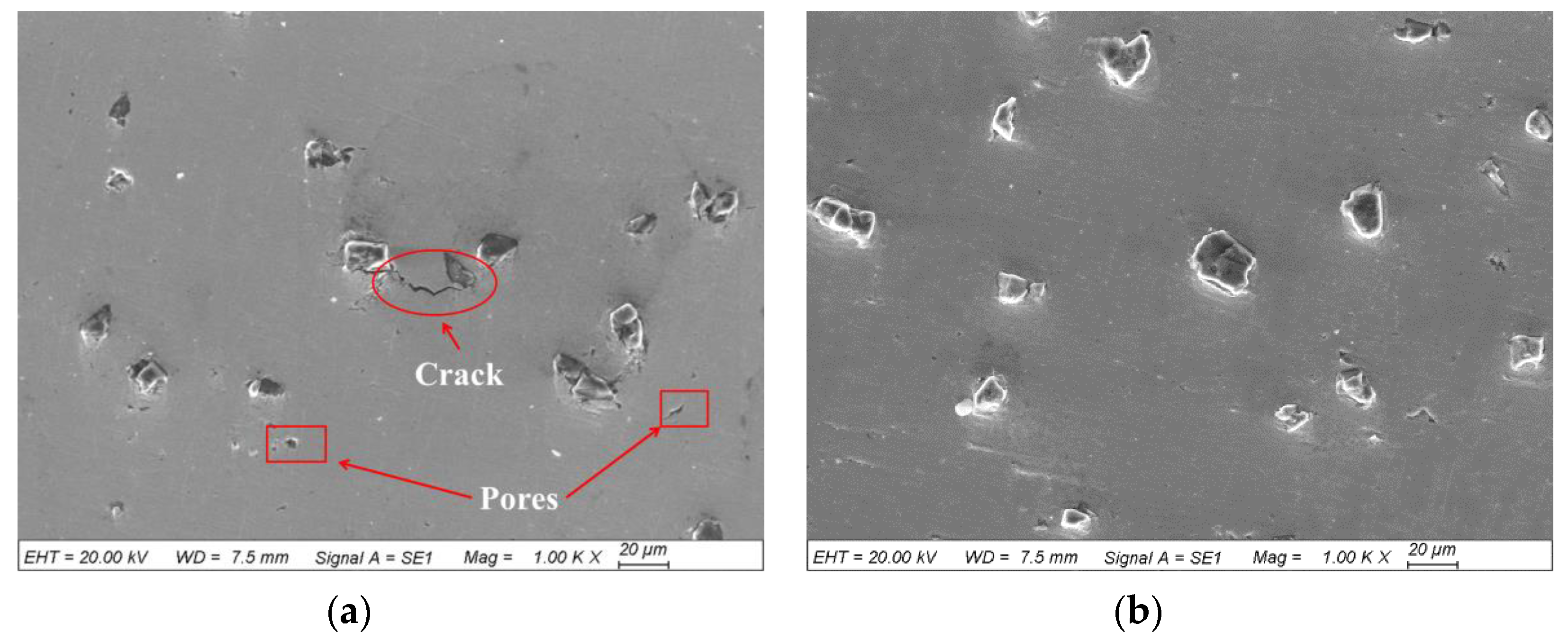

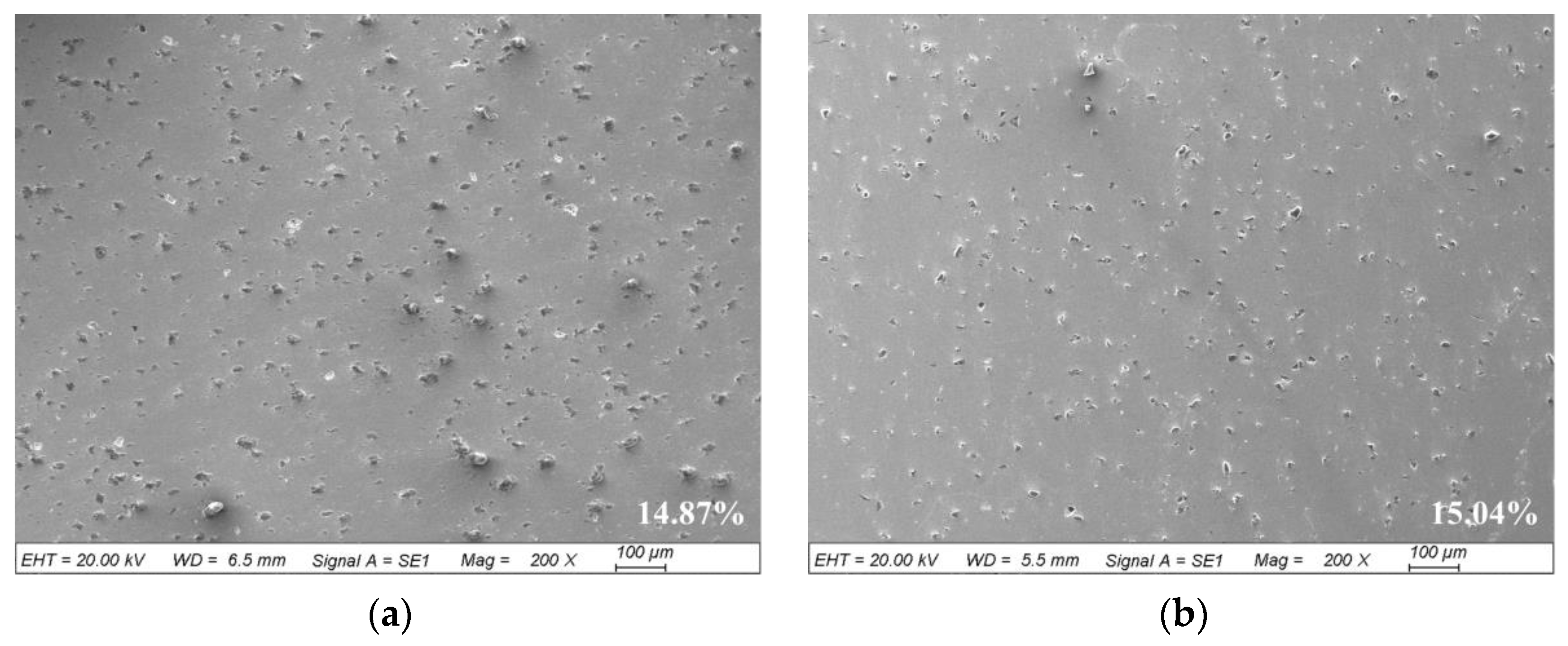

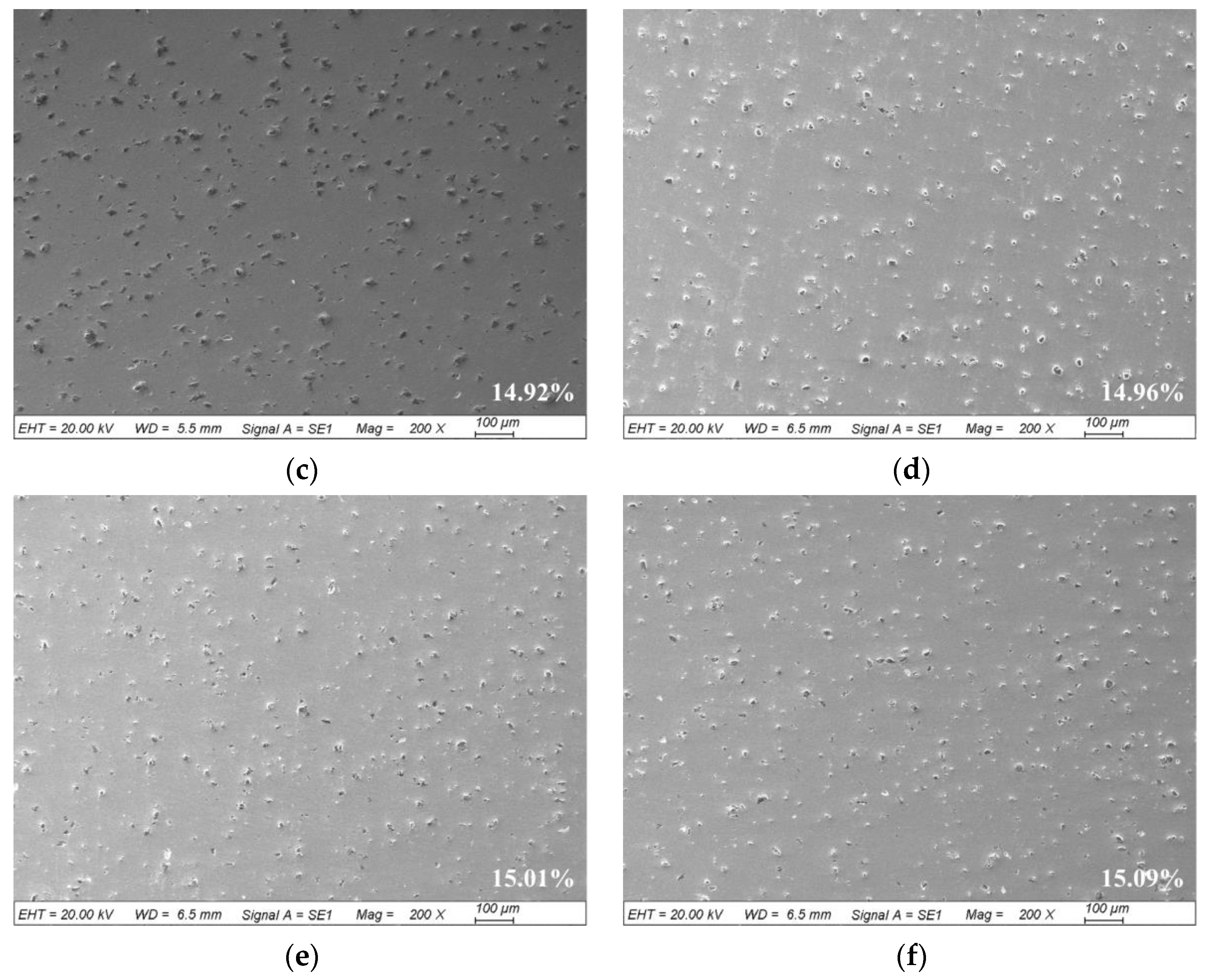

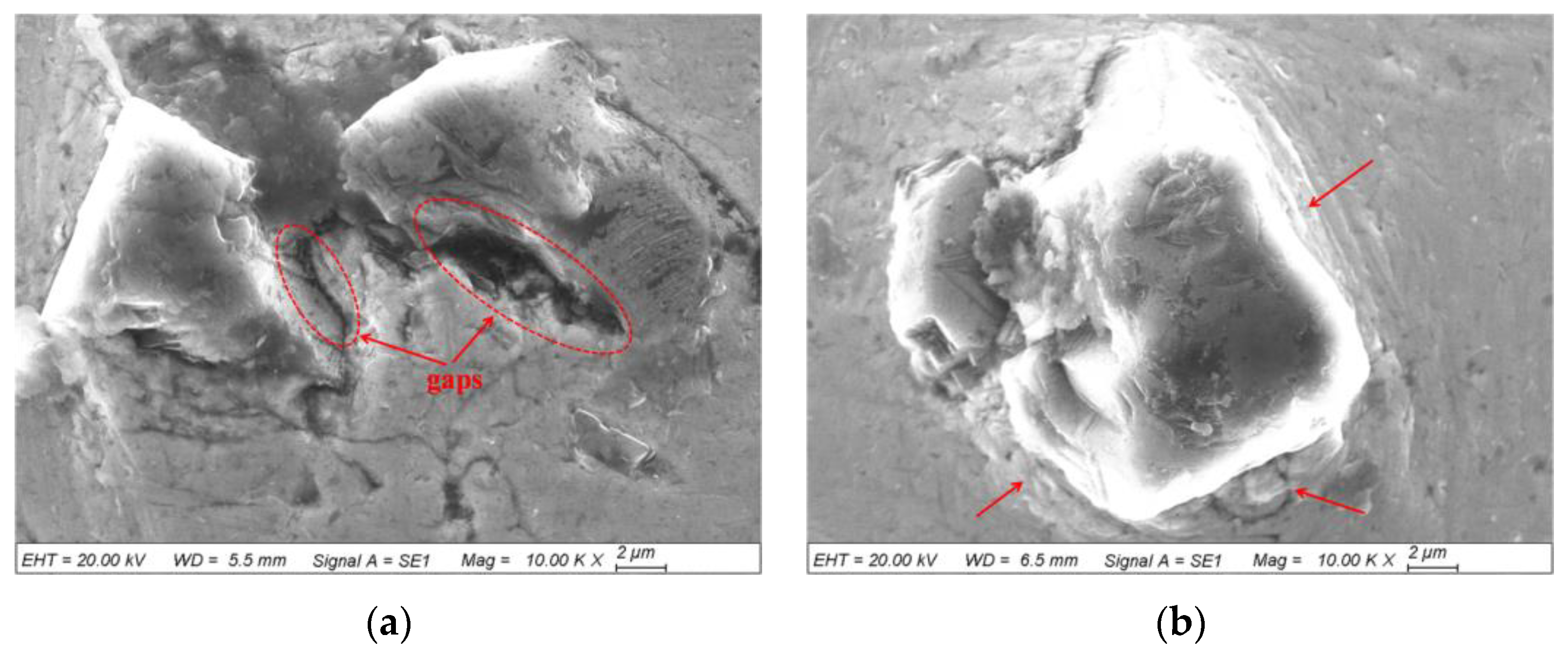

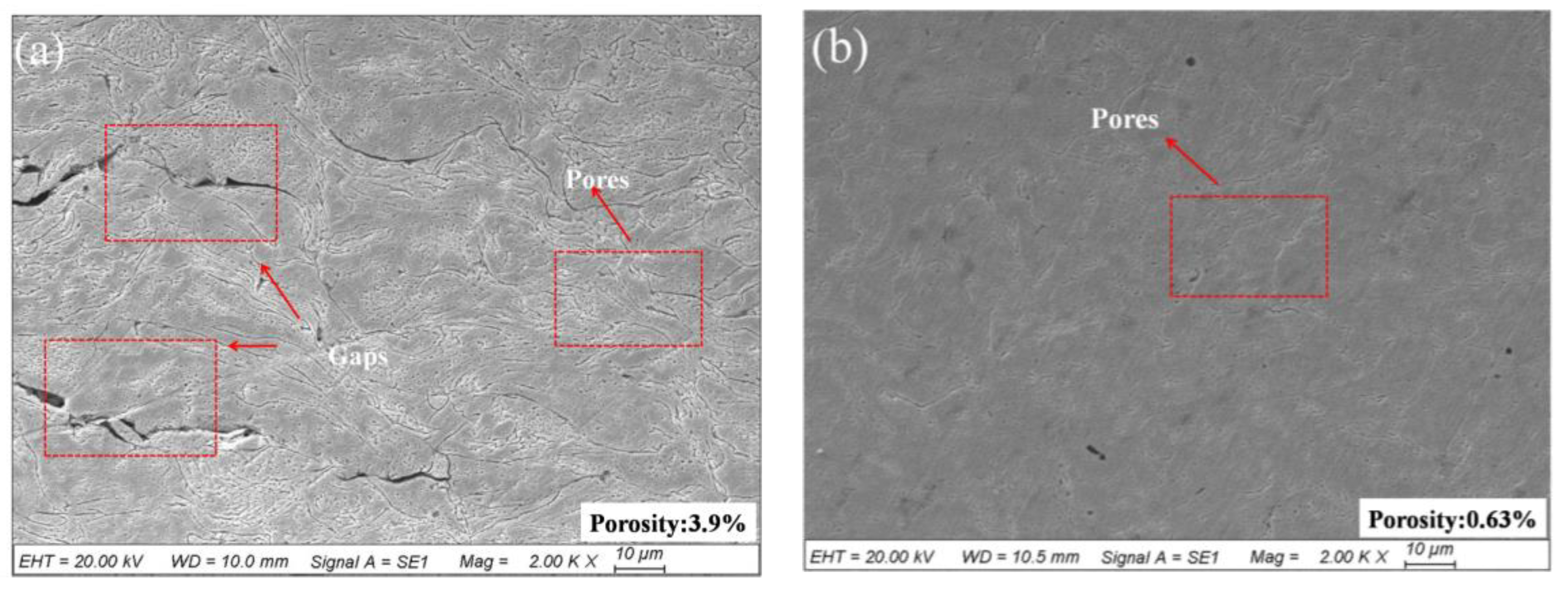

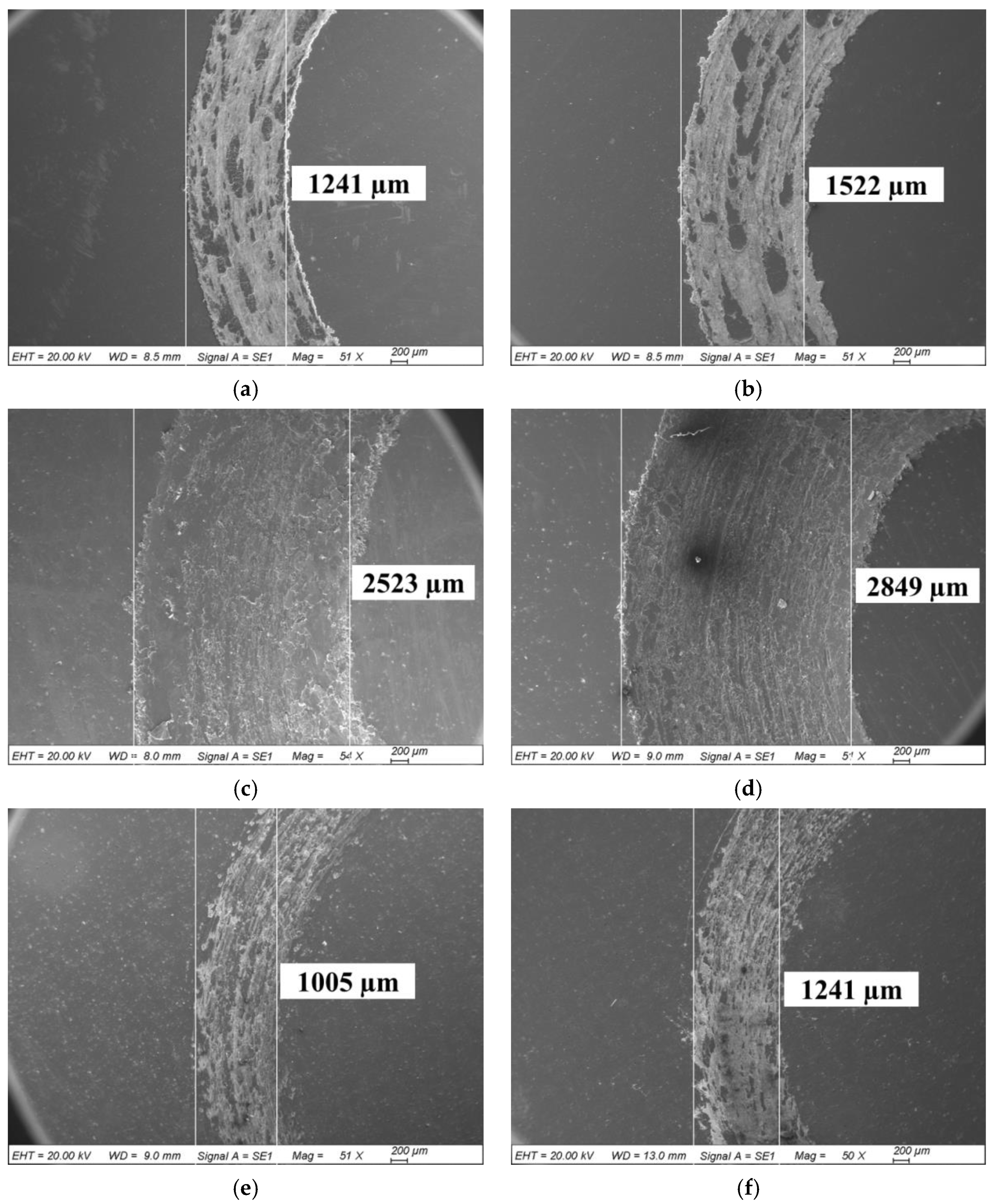

3.2. Coating Microstructure

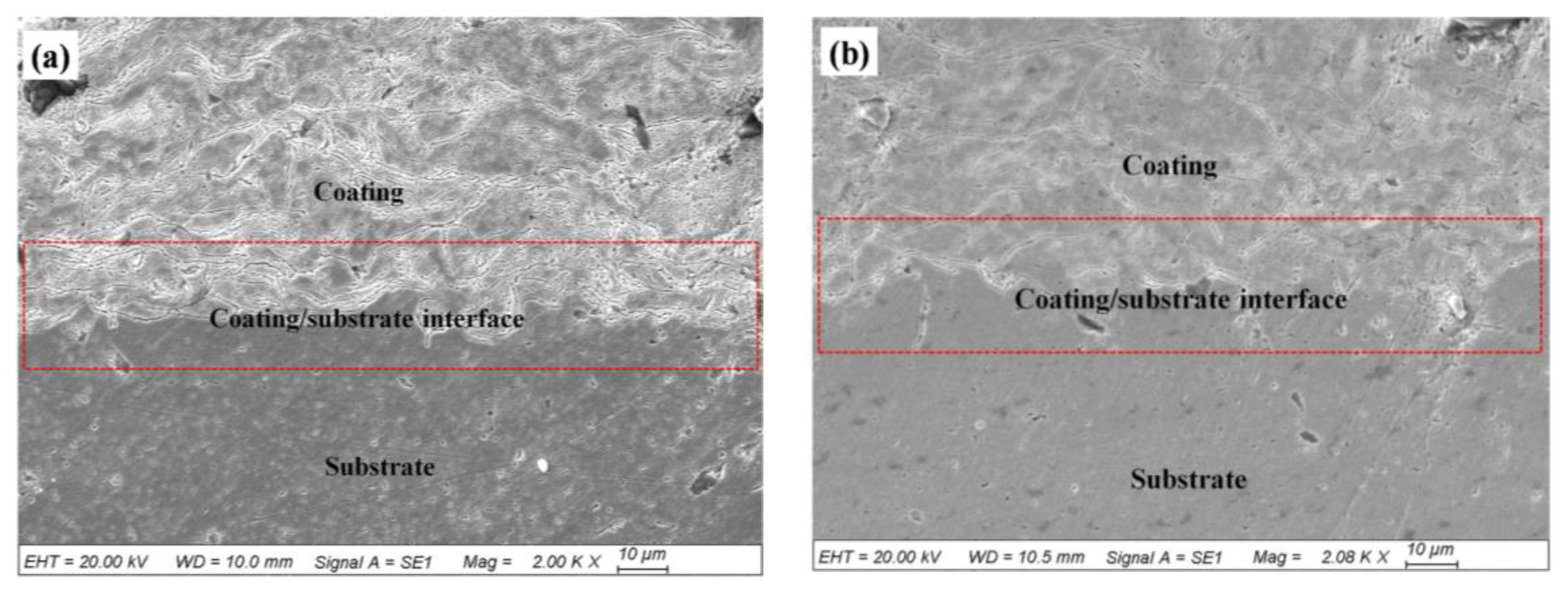

3.3. Cohesive/Adhesive Bonding

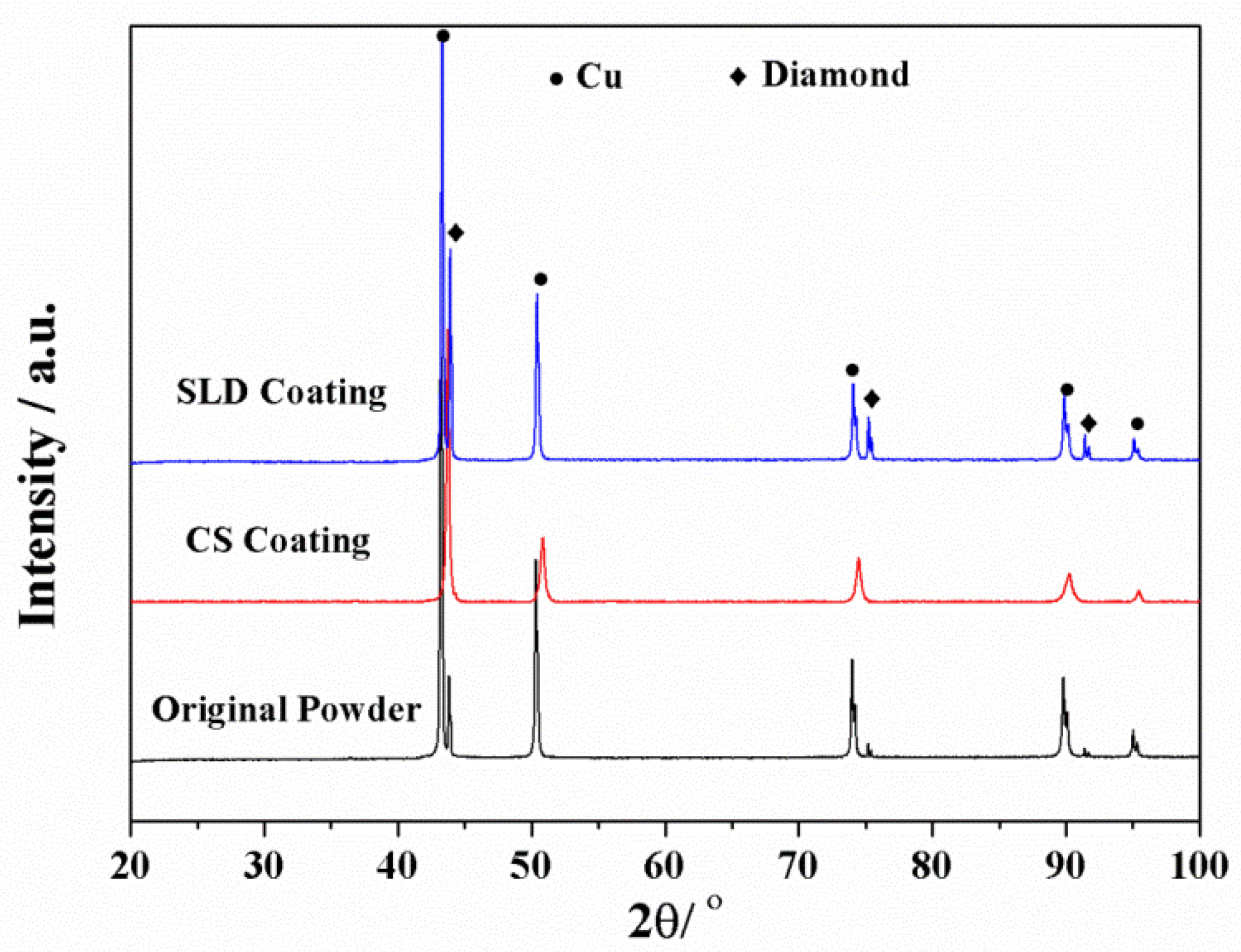

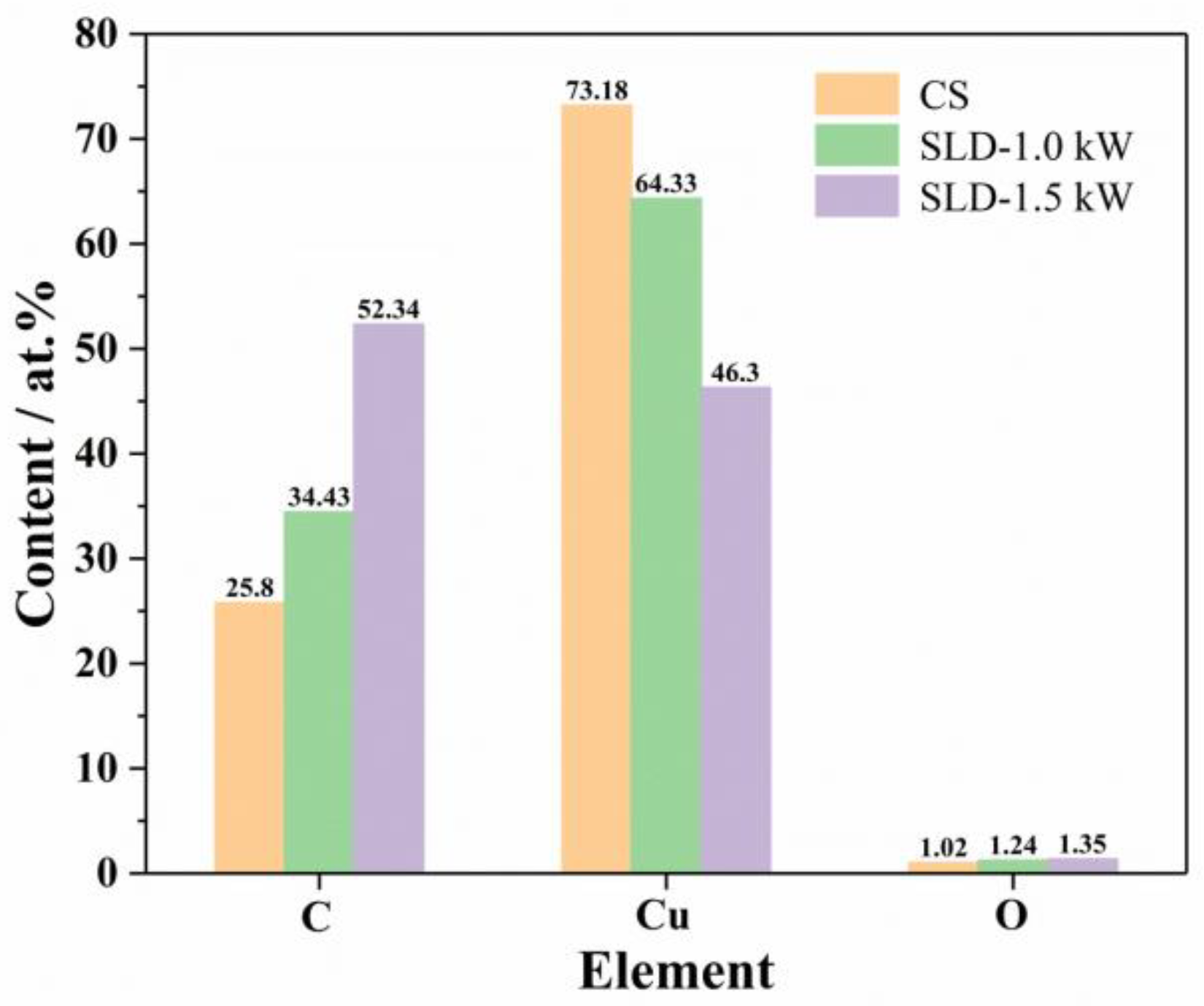

3.4. Phase Composition

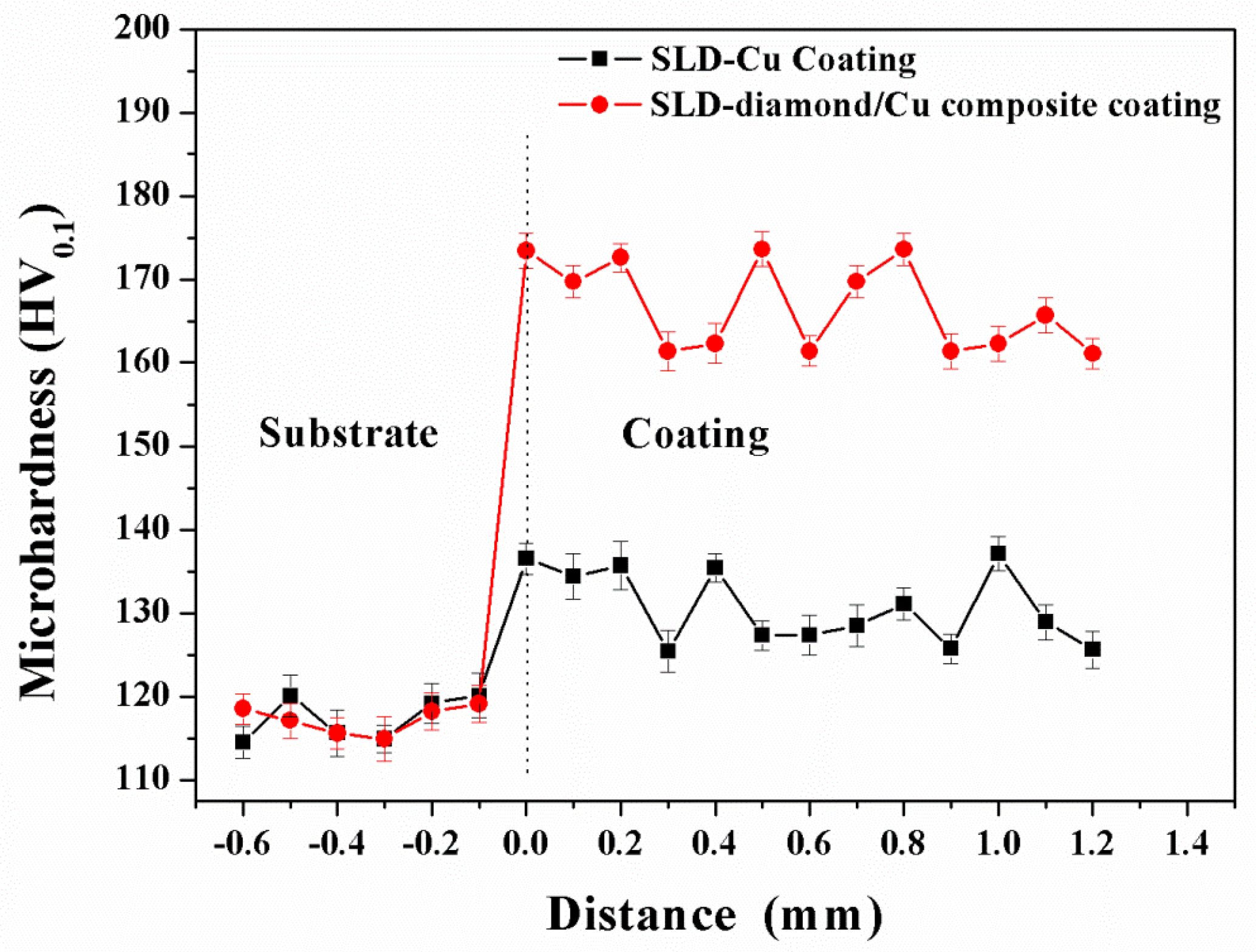

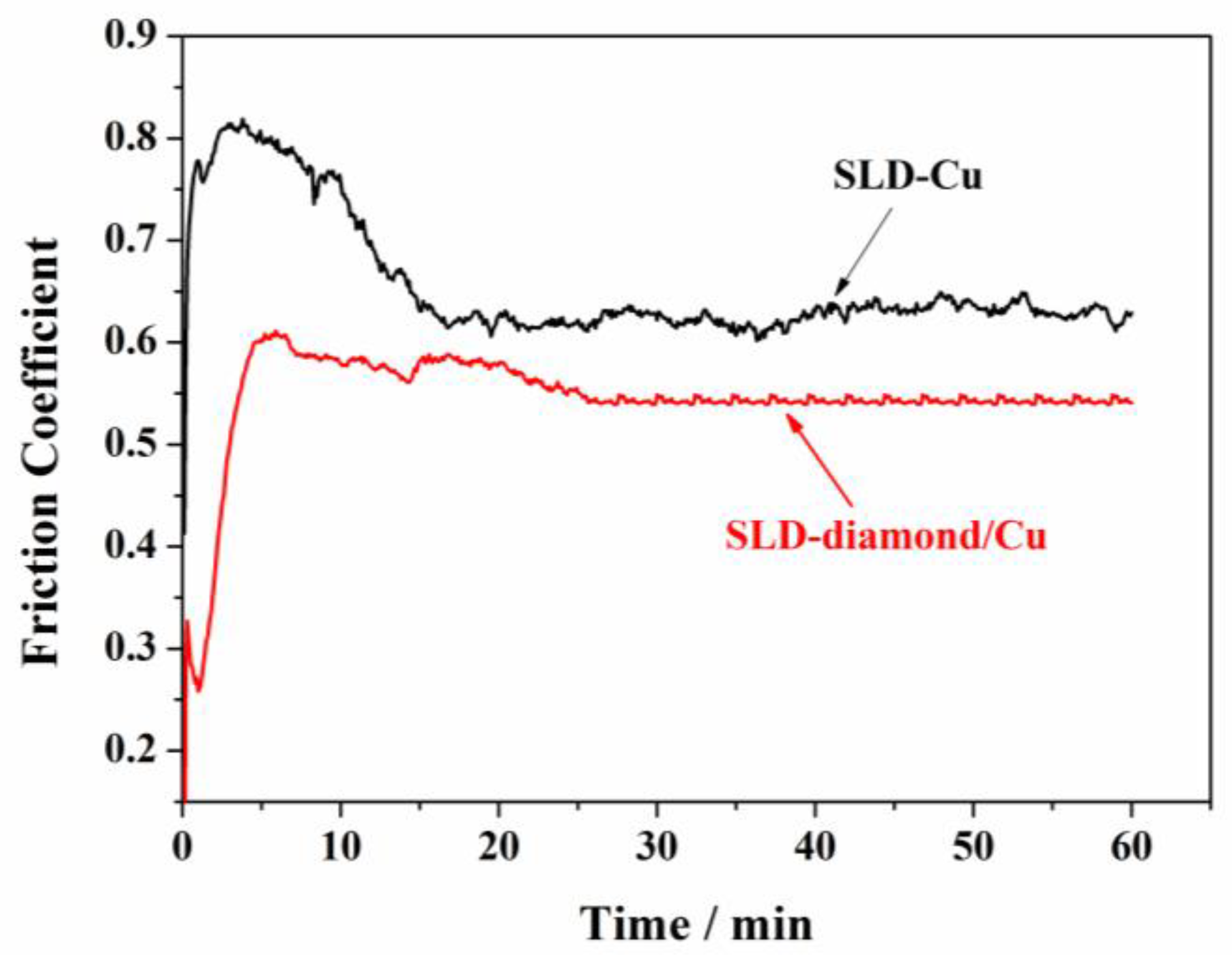

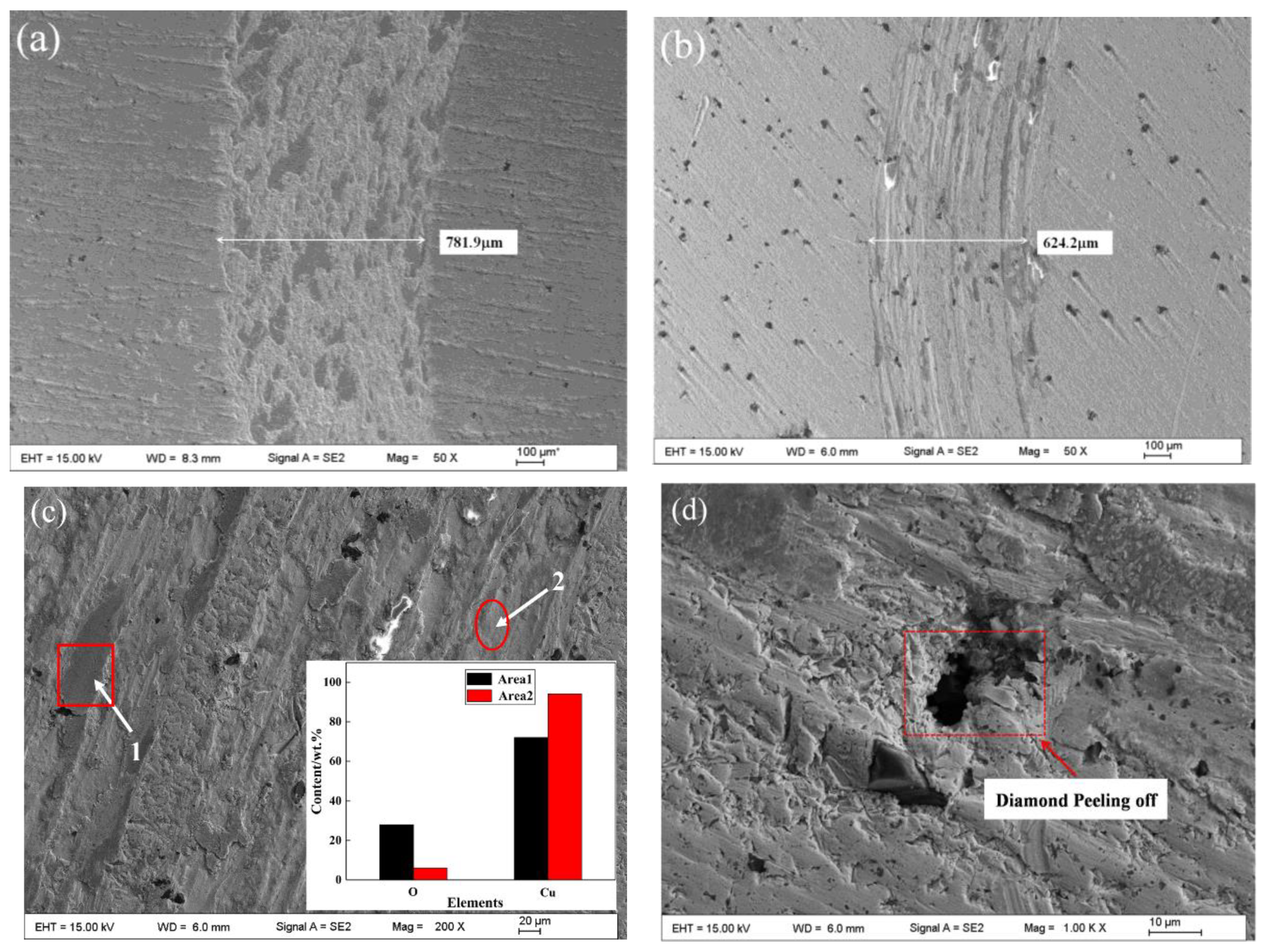

3.5. Micro-Hardness and Tribological Property

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, L.; Wang, W.; Li, B.; Chen, Z.; Jin, Y.; Yao, J. Influence of diamond particle size and content on the microstructure and properties of diamond/Cu composite coating prepared by supersonic laser deposition. Surf. Technol. 2019, 48, 40–46. (In Chinese) [Google Scholar]

- Zhang, X.; Lin, W.; Xu, M.; Cao, S.; Feng, Y.; Zhou, H. Addition of rare earth neodymium to improve interface of diamond/copper composites. Surf. Technol. 2018, 47, 27–32. (In Chinese) [Google Scholar]

- Das, P.; Paul, S.; Bandyopadhyay, P. HVOF sprayed diamond reinforced nano-structured bronze coatings. J. Alloy. Compd. 2018, 746, 361–369. [Google Scholar] [CrossRef]

- Venkateswarlu, K.; Ray, A.; Gunjan, M.; Mondal, D.; Pathak, L. Tribological wear behavior of diamond reinforced composite coating. Mater. Sci. Eng. A 2006, 418, 357–363. [Google Scholar] [CrossRef]

- Venkateswarlu, K.; Rajinikanth, V.; Naveen, T.; Sinba, D.; Ray, A. Abrasive wear behavior of thermally sprayed diamond reinforced composite coating deposited with both oxy-acetylene and HVOF techniques. Wear 2009, 266, 995–1002. [Google Scholar] [CrossRef]

- Das, P.; Paul, S.; Bandyopadhyay, P. Plasma sprayed diamond reinforced molybdenum coating. J. Alloy. Compd. 2018, 767, 448–455. [Google Scholar] [CrossRef]

- Das, P.; Paul, S.; Bandyopadhyay, P. Preparation of diamond reinforced metal powders as thermal spray feedstock using ball milling. Surf. Coat. Technol. 2016, 286, 165–171. [Google Scholar] [CrossRef]

- Sun, H.; Guo, M.; Meng, F.; Liu, A. Studies on hardfaced overlay of diamond grits reinforced Ni-Based alloy fabricated by laser cladding. Trans. Indian Inst. Met. 2016, 69, 1369–1376. [Google Scholar] [CrossRef]

- Iravani, M.; Khajepour, A.; Corbin, S.; Esmaeili, S. Pre-placed laser cladding of metal matrix diamond composite on mild steel. Surf. Coat. Technol. 2012, 206, 2089–2097. [Google Scholar] [CrossRef]

- Shao, W.; Ivanov, V.; Zhen, L.; Cui, Y.; Wang, Y. A study on graphitization of diamond in Cu–diamond composite materials. Mater. Lett. 2003, 58, 146–149. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef]

- Kwon, H.; Cho, S.; Kawasaki, A. Diamond-Reinforced Metal Matrix Bulk Materials Fabricated by a Low-Pressure Cold-Spray Process. Mater. Trans. 2015, 56, 108–112. [Google Scholar] [CrossRef]

- Li, W.; Zhang, D.; Huang, C.; Yin, S.; Yu, M.; Wang, F.; Liao, H. Modelling of impact behaviour of cold spray particles: Review. Surf. Eng. 2014, 30, 299–308. [Google Scholar] [CrossRef]

- Luo, X.; Li, C.; Shang, F.; Yang, G.; Wang, Y.; Li, C. High velocity impact induced microstructure evolution during deposition of cold spray coatings: A review. Surf. Coat. Technol. 2014, 254, 11–20. [Google Scholar] [CrossRef]

- Yin, S.; Wang, X.; Suo, X.; Liao, H.; Guo, Z.; Li, W.; Coddet, C. Deposition behavior of thermally softened Cu particles in cold spraying. Acta Mater. 2013, 61, 5105–5118. [Google Scholar] [CrossRef]

- Woo, D.; Heer, F.; Brewer, L.; Hooper, J.; Osswald, S. Synthesis of nanodiamond-reinforced aluminum metal matrix composites using cold-spray deposition. Carbon 2015, 86, 15–25. [Google Scholar] [CrossRef]

- Woo, D.; Sneed, B.; Peerally, F.; Heer, F.; Brewer, L.; Hooper, J.; Osswald, S. Synthesis of nanodiamond-reinforced aluminum metal composite powders and coatings using high-energy ball milling and cold spray. Carbon 2013, 63, 404–415. [Google Scholar] [CrossRef]

- Aldwell, B.; Yin, S.; Mcdonnell, K.; Trimble, D.; Hussain, T.; Lupoi, R. A novel method for metal–diamond composite coating deposition with cold spray and formation mechanism. Scr. Mater. 2016, 115, 10–13. [Google Scholar] [CrossRef]

- Yin, S.; Xie, Y.; Cizek, J.; Ekoi, E.; Hussain, T.; Dowling, D.; Lupoi, R. Advanced diamond-reinforced metal matrix composites via cold spray: Properties and deposition mechanism. Compos. Part B 2017, 113, 44–54. [Google Scholar] [CrossRef]

- Li, B.; Yao, J.; Zhang, Q.; Li, Z.; Yang, L. Microstructure and tribological performance of tungsten carbide reinforced stainless steel composite coatings by supersonic laser deposition. Surf. Coat. Technol. 2015, 275, 58–68. [Google Scholar] [CrossRef]

- Bray, M.; Cockburn, A.; O’Neill, W. The Laser-assisted Cold Spray process and deposit characterization. Surf. Coat. Technol. 2009, 203, 2851–2857. [Google Scholar] [CrossRef]

- Lupoi, R.; Sparkes, M.; Cockburn, A.; O’Neill, W. High speed titanium coatings by supersonic laser deposition. Mater. Lett. 2011, 65, 3205–3207. [Google Scholar] [CrossRef]

- Olakanmi, E. Optimization of the quality characteristics of laser-assisted cold-sprayed (LACS) aluminum coatings with Taguchi design of experiments (DOE). Mater. Manuf. Process. 2014, 31, 1490–1499. [Google Scholar] [CrossRef]

- Olakanmi, E.; Doyoyo, M. Laser-assisted cold-sprayed corrosion- and wear-resistant coatings: A review. J. Therm. Spray Technol. 2014, 23, 765–785. [Google Scholar] [CrossRef]

- Li, B.; Yang, L.; Li, Z.; Yao, J.; Zhang, Q.; Chen, Z.; Dong, G.; Wang, L. Beneficial Effects of Synchronous Laser Irradiation on the Characteristics of Cold-Sprayed Cu Coatings. J. Therm. Spray Technol. 2015, 24, 836–847. [Google Scholar] [CrossRef]

- Jones, M.; Cockburn, A.; Lupoi, R.; Sparkes, M.; O’Neill, W. Solid-state manufacturing of tungsten deposits onto molybdenum substrates with supersonic laser deposition. Mater. Lett. 2014, 134, 295–297. [Google Scholar] [CrossRef]

- Luo, F.; Cockburn, A.; Lupoi, R.; Sparkes, M.; O’Neill, W. Performance comparisonof Stellite 6 deposited on steel using supersonic laser deposition and lasercladding. Surf. Coat. Technol. 2012, 212, 119–127. [Google Scholar] [CrossRef]

- Li, B.; Jin, Y.; Yao, J.; Li, Z.; Zhang, Q.; Zhang, X. Influence of laser irradiation on deposition characteristics of cold sprayed Stellite-6 coatings. Opt. Laser Technol. 2018, 100, 27–39. [Google Scholar] [CrossRef]

- Yao, J.; Yang, L.; Li, B.; Li, Z. Characteristics and performance of hard Ni60 alloy coating produced with supersonic laser deposition technique. Mater. Des. 2015, 83, 26–35. [Google Scholar] [CrossRef]

- Yao, J.; Li, Z.; Li, B.; Yang, L. Characteristics and bonding behavior of Stellite 6 alloy coating processed with supersonic laser deposition. J. Alloy. Compd. 2016, 661, 526–534. [Google Scholar] [CrossRef]

- Lupoi, R.; Cockburn, A.; Bryan, C.; Sparkes, M.; Luo, F.; O’Neill, W. Hardfacing steel with nanostructured coatings of Stellite-6 by supersonic laser deposition. Light-Sci. Appl. 2012, 1, e10. [Google Scholar] [CrossRef]

- Birt, A.; Champagne, V.; Sisson, R.; Apelian, D. Statistically Guided Development of Laser-Assisted Cold Spray for Microstructural Control of Ti-6Al-4V. Metall. Mater. Trans. A 2017, 48, 1931–1943. [Google Scholar] [CrossRef]

- Yao, J.; Yang, L.; Li, B.; Li, Z. Beneficial effects of laser irradiation on the deposition process of diamond/Ni60 composite coating with cold spray. Appl. Surf. Sci. 2015, 330, 300–308. [Google Scholar] [CrossRef]

- Yang, L.; Li, B.; Yao, J.; Li, Z. Effects of diamond size on the deposition characteristic and tribological behavior of diamond/Ni60 composite coating prepared by supersonic laser deposition. Diam. Relat. Mater. 2015, 58, 139–148. [Google Scholar] [CrossRef]

- Li, B.; Jin, Y.; Yao, J.; Li, Z.; Zhang, Q. Solid-state fabrication of WCp-reinforced Stellite-6 composite coatings with supersonic laser deposition. Surf. Coat. Technol. 2017, 321, 386–396. [Google Scholar] [CrossRef]

- Assadi, H.; Gartner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Assadi, H.; Schmidt, T.; Richter, H.; Kliemann, J.; Binder, K.; Gärtner, F.; Klassen, T.; Kreye, H. On parameter selection in cold spraying. J. Therm. Spray Technol. 2011, 20, 1161–1176. [Google Scholar] [CrossRef]

- Fukumoto, M.; Wada, H.; Tanade, K.; Yamada, M.; Yamaguchi, E.; Niwa, A.; Sugimoto, M.; Izawa, M. Effect of substrate temperature on deposition behavior of Cu particles on substrate surfaces in the cold spray process. J. Therm. Spray Technol. 2007, 16, 643–650. [Google Scholar] [CrossRef]

- Legoux, J.; Irissou, E.; Moreau, C. Effect of substrate temperature on the formation mechanism of cold-sprayed aluminum, zinc and tin coatings. J. Therm. Spray Technol. 2007, 16, 619–626. [Google Scholar] [CrossRef]

- Yin, S.; Wang, X.; Li, W.; Guo, X. Examination on substrate preheating process in cold gas dynamic spraying. J. Therm. Spray Technol. 2011, 20, 852–859. [Google Scholar] [CrossRef]

- Yu, M.; Li, W.; Wang, F.; Suo, X.; Liao, H. Effect of particle and substrate preheating on particle deformation behavior in cold spraying. Surf. Coat. Technol. 2013, 220, 174–178. [Google Scholar] [CrossRef]

- Ko, K.; Choi, J.; Lee, H.; Lee, B. Influence of oxide chemistry of feedstock on cold sprayed Cu coatings. Powder Technol. 2012, 218, 119–123. [Google Scholar] [CrossRef]

- Li, W.; Li, C.; Liao, H. Significant influence of particle surface oxidation on deposition efficiency, interface microstructure and adhesive strength of cold-sprayed Cu coatings. Appl. Surf. Sci. 2010, 256, 4953–4958. [Google Scholar] [CrossRef]

- Maruschak, P.; Panin, S.; Zakiev, I.; Poltaranin, M.; Sotnikov, A. Scale levels of damage to the raceway of a spherical roller bearing. Eng. Fail. Anal. 2016, 59, 69–78. [Google Scholar] [CrossRef]

- Archard, J. Properties of composite materials. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

| Coating | ∆m (g) | t (s) | Rf (g/min) | Rd (g/min) | DE (%) |

|---|---|---|---|---|---|

| CS | 1.164 ± 0.023 | 6 | 40 | 11.64 ± 0.23 | 29.1 ± 0.58 |

| SLD-0.5kW | 1.220 ± 0.019 | 6 | 40 | 12.20 ± 0.19 | 30.5 ± 0.48 |

| SLD-1.0 kW | 2.152 ± 0.032 | 6 | 40 | 21.52 ± 0.32 | 53.8 ± 0.80 |

| SLD-1.5 kW | 2.024 ± 0.021 | 6 | 40 | 20.24 ± 0.21 | 50.6 ± 0.52 |

| SLD-2.0 kW | 1.948 ± 0.018 | 6 | 40 | 19.48 ± 0.18 | 48.7 ± 0.45 |

| SLD-2.5 kW | 1.892 ± 0.016 | 6 | 40 | 18.92 ± 0.16 | 47.3 ± 0.40 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Zhang, G.; Li, B.; Wang, W.; Huang, X.; Chen, Z.; Dong, G.; Zhang, Q.; Yao, J. Study on Microstructure and Tribological Performance of Diamond/Cu Composite Coating via Supersonic Laser Deposition. Coatings 2020, 10, 276. https://doi.org/10.3390/coatings10030276

Wu L, Zhang G, Li B, Wang W, Huang X, Chen Z, Dong G, Zhang Q, Yao J. Study on Microstructure and Tribological Performance of Diamond/Cu Composite Coating via Supersonic Laser Deposition. Coatings. 2020; 10(3):276. https://doi.org/10.3390/coatings10030276

Chicago/Turabian StyleWu, Lijuan, Gang Zhang, Bo Li, Weilin Wang, Xuanjie Huang, Zhijun Chen, Gang Dong, Qunli Zhang, and Jianhua Yao. 2020. "Study on Microstructure and Tribological Performance of Diamond/Cu Composite Coating via Supersonic Laser Deposition" Coatings 10, no. 3: 276. https://doi.org/10.3390/coatings10030276

APA StyleWu, L., Zhang, G., Li, B., Wang, W., Huang, X., Chen, Z., Dong, G., Zhang, Q., & Yao, J. (2020). Study on Microstructure and Tribological Performance of Diamond/Cu Composite Coating via Supersonic Laser Deposition. Coatings, 10(3), 276. https://doi.org/10.3390/coatings10030276