Plasma Treatment Reduced the Discoloration of an Acrylic Coating on Hot-Oil Modified Wood Exposed to Natural Weathering

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design and Preparation of Wood Samples

2.2. Hot-Oil Modification and Plasma Treatment of Wood Samples

2.3. Contact Angle and Adhesion Measurements

2.4. Scanning Electron Microscopy and Confocal Profilometry

2.5. Exposure of Samples to Natural Weathering and Evaluation of Coating Performance

3. Results

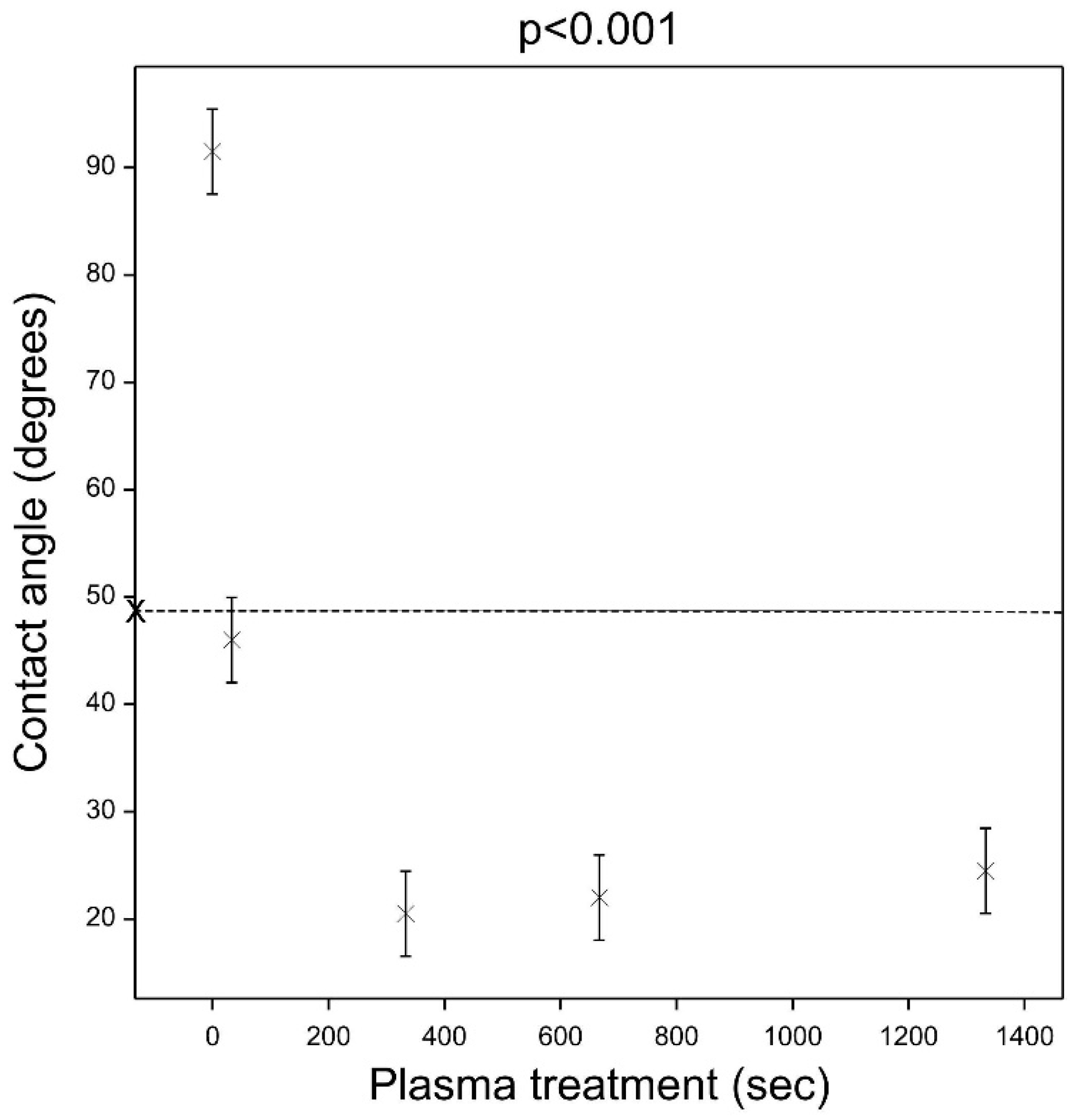

3.1. Contact Angle and Adhesion Measurements

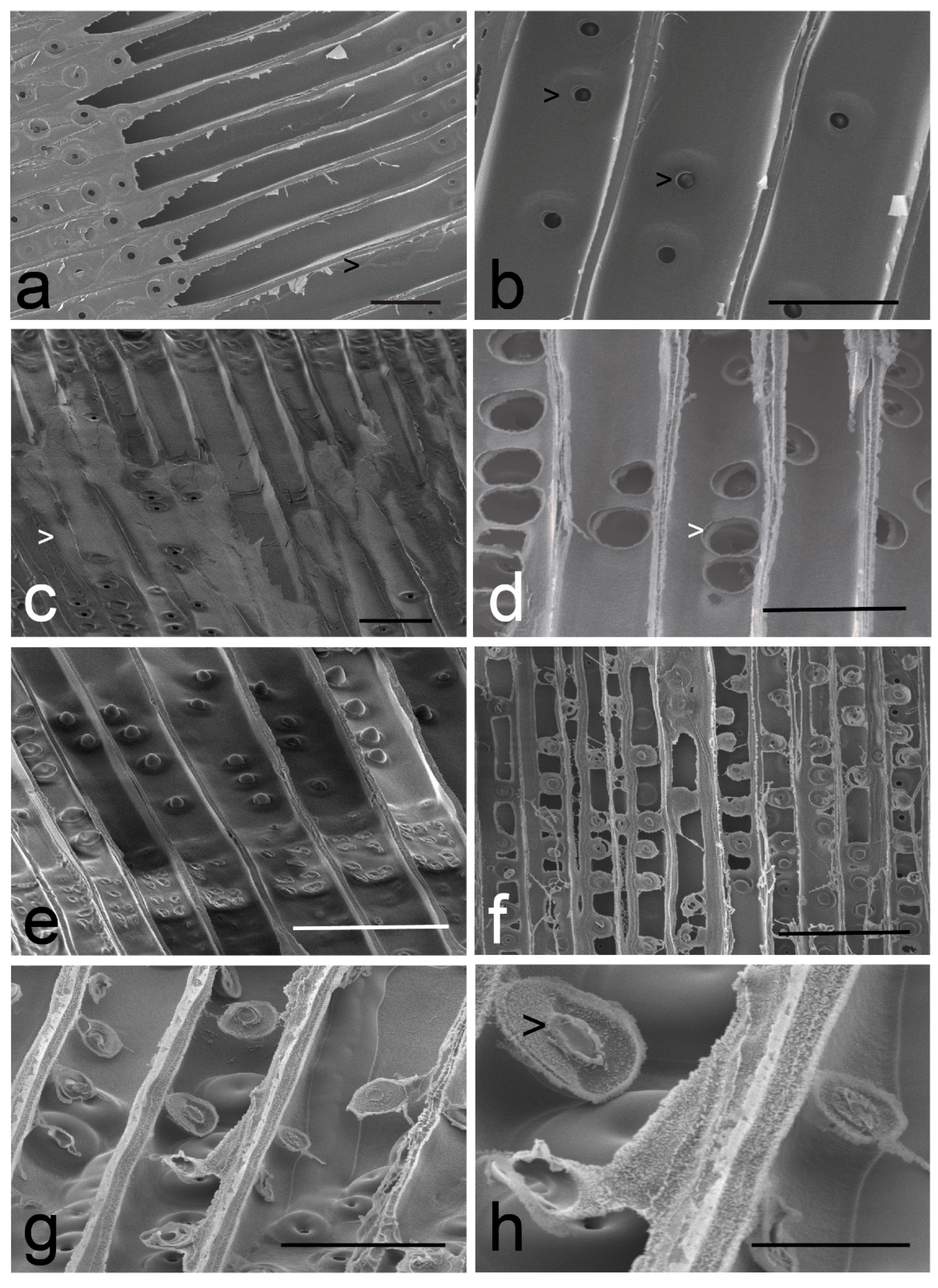

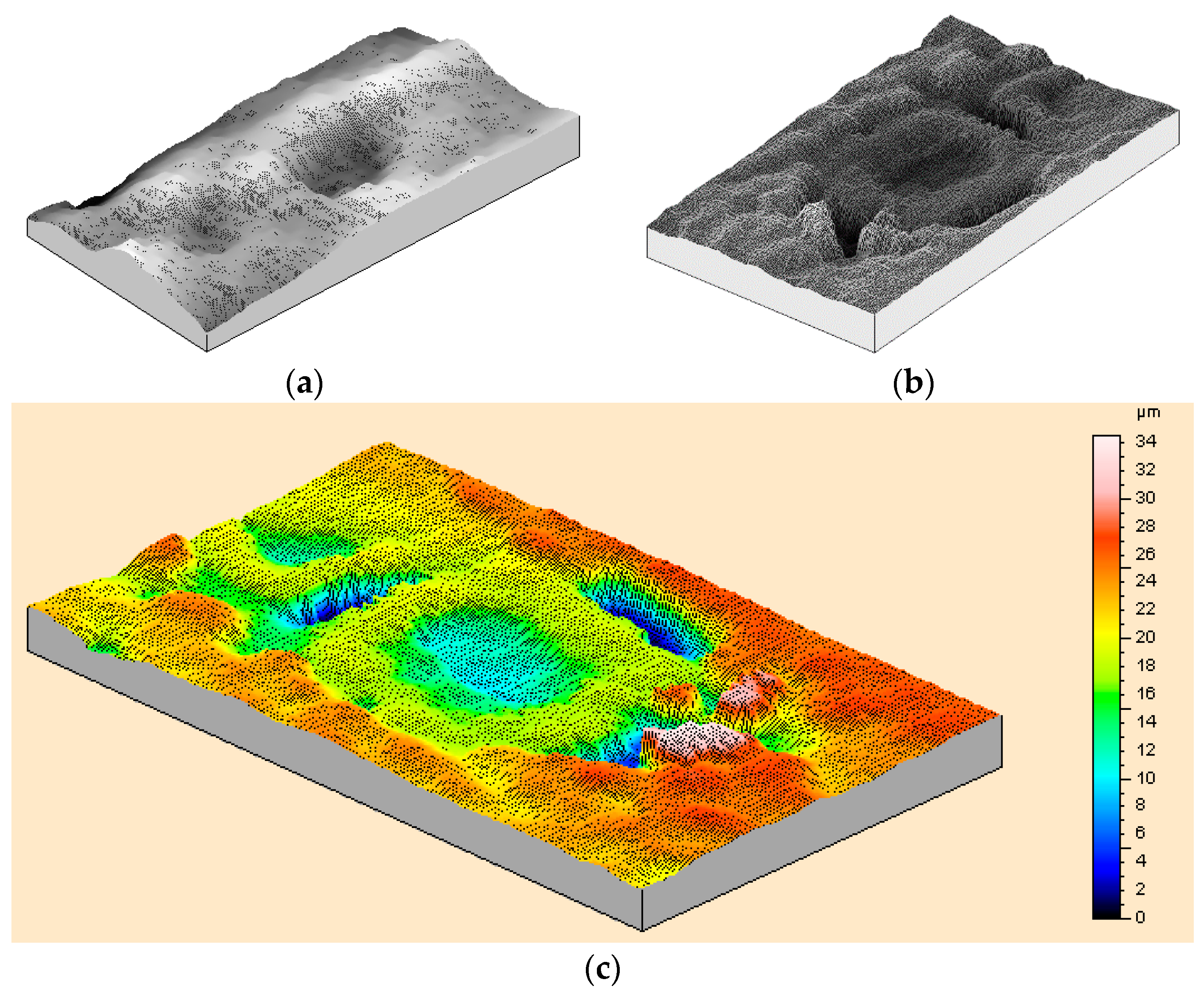

3.2. Appearance and Microstructure of Hot-Oil and Plasma Treated Wood

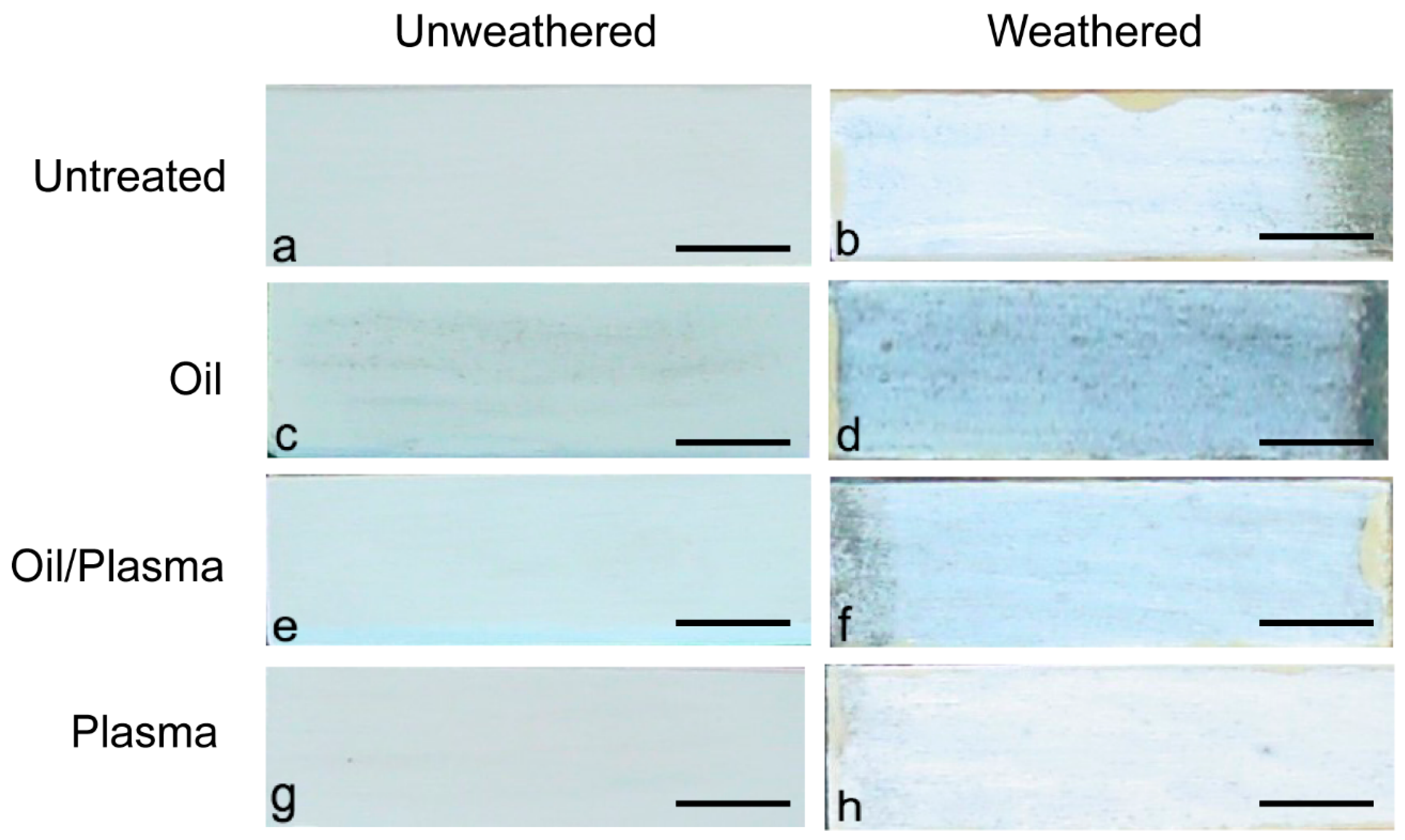

3.3. Performance of an Acrylic Coating on Hot-Oil and Plasma Treated Wood after Natural Weathering

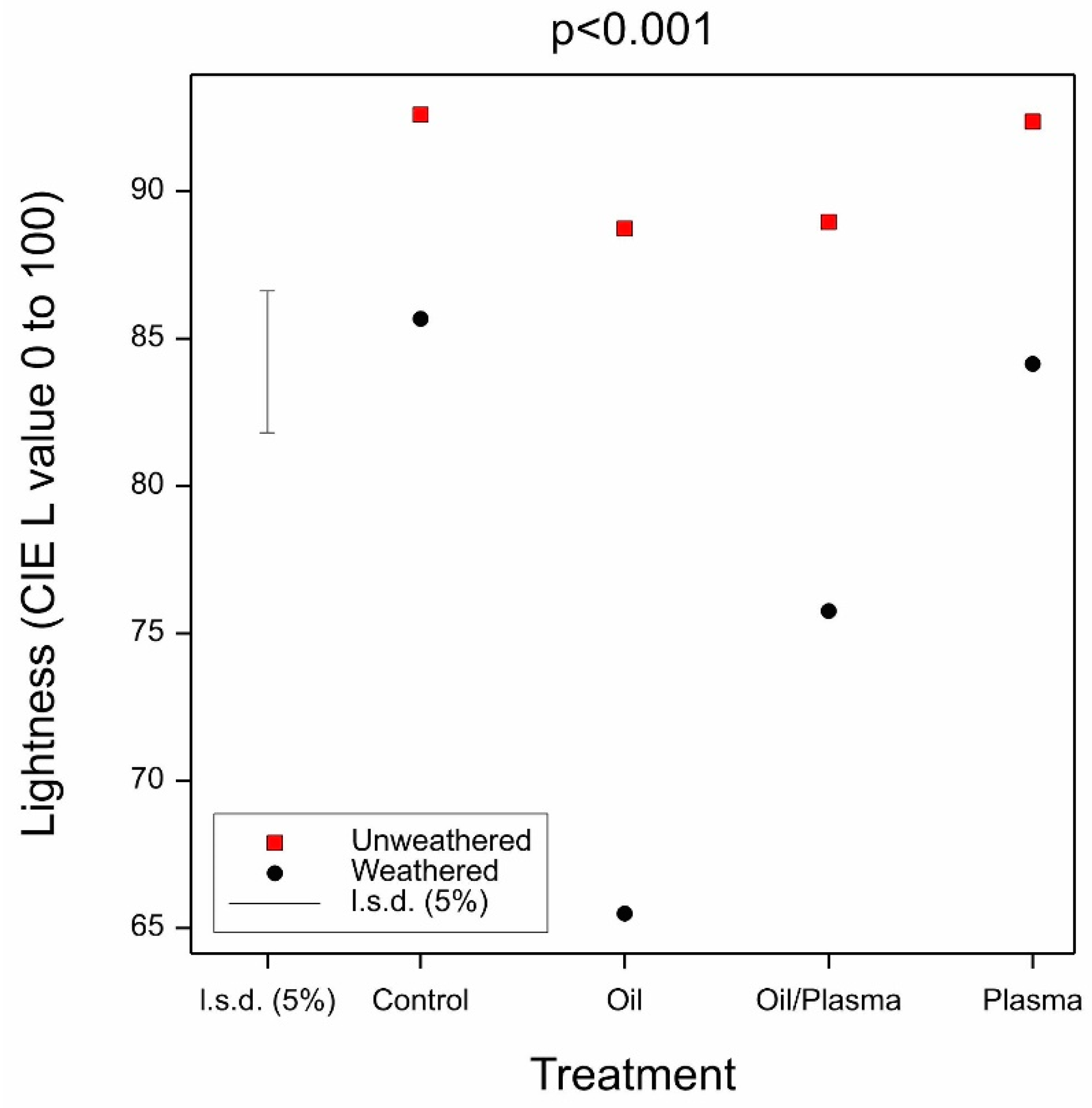

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boenig, H.V. Plasma Science and Technology; Cornell University Press: New York, NY, USA, 1982. [Google Scholar]

- Kaplan, S.L.; Rose, P.W. Plasma surface treatment of plastics to enhance adhesion. Int. J. Adhes. Adhes. 1991, 11, 109–113. [Google Scholar] [CrossRef]

- Suchentrunk, R.; Fuesser, H.J.; Staudigl, G.; Jonke, D.; Meyer, M. Plasma surface engineering—Innovative processes and coating systems for high-quality products. Surf. Coat. Technol. 1999, 112, 351–357. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Zoulalian, A.; Gérardin, P. Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym. Degrad. Stab. 2005, 89, 1–5. [Google Scholar] [CrossRef]

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Jirouš-Rajković, V.; Miklečić, J. Heat-treated wood as a substrate for coatings, weathering of heat-treated wood, and coating performance on heat-treated wood. Adv. Mater. Sci. Eng. 2019, 2019, 8621486. [Google Scholar] [CrossRef]

- Podgorski, L.; Chevet, B.; Onic, L.; Merlin, A. Modification of wood wettability by plasma and corona treatments. Int. J. Adhes. Adhes. 2000, 20, 103–111. [Google Scholar] [CrossRef]

- Wolkenhauer, A.; Avramidis, G.; Militz, H.; Viöl, W. Plasma treatment of heat treated beech wood–investigation on surface free energy. Holzforschung 2008, 62, 472–474. [Google Scholar] [CrossRef]

- Avramidis, G.; Militz, H.; Avar, I.; Viöl, W.; Wolkenhauer, A. Improved absorption characteristics of thermally modified beech veneer produced by plasma treatment. Eur. J. Wood Wood Prod. 2012, 70, 545–549. [Google Scholar] [CrossRef]

- Talviste, R.; Galmiz, O.; Stupavská, M.; Tučeková, Z.; Kaarna, K.; Kováčik, D. Effect of DCSBD plasma treatment on surface properties of thermally modified wood. Surf. Interfaces 2019, 16, 8–14. [Google Scholar] [CrossRef]

- Van Nguyen, T.H.; Nguyen, T.T.; Ji, X.; Guo, M. Enhanced bonding strength of heat-treated wood using a cold atmospheric-pressure nitrogen plasma jet. Eur. J. Wood Wood Prod. 2018, 76, 1697–1705. [Google Scholar] [CrossRef]

- Lee, S.H.; Ashaari, Z.; Lum, W.C.; Halip, J.A.; Ang, A.F.; Tan, L.P.; Chin, K.L.; Tahir, P.M. Thermal treatment of wood using vegetable oils: A review. Constr. Build. Mater. 2018, 181, 408–419. [Google Scholar] [CrossRef]

- Manolache, S.; Jiang, H.; Rowell, R.M.; Denes, F.S. Hydrophobic wood surfaces generated by non-equilibrium, atmospheric pressure (NEAPP) plasma-enhanced coating. Mol. Cryst. Liq. Cryst. 2008, 483, 348–351. [Google Scholar] [CrossRef]

- Petrič, M.; Knehtl, B.; Krause, A.; Militz, H.; Pavlič, M.; Pétrissans, M.; Rapp, A.; Tomažič, M.; Welzbacher, C.; Gérardin, P. Wettability of waterborne coatings on chemically and thermally modified pine wood. J. Coat. Technol. Res. 2007, 4, 203–206. [Google Scholar] [CrossRef]

- Nejad, M.; Shafaghi, R.; Ali, H.; Cooper, P. Coating performance on oil-heat treated wood for flooring. BioResources 2013, 8, 1881–1892. [Google Scholar] [CrossRef]

- Hse, C.Y.; Kuo, M.L. Influence of extractives on wood gluing and finishing-a review. For. Prod. J. 1988, 38, 52–56. [Google Scholar]

- Gobakken, L.R.; Westin, M. Surface mould growth on five modified wood substrates coated with three different coating systems when exposed outdoors. Int. Biodeterior. Biodegrad. 2008, 62, 397–402. [Google Scholar] [CrossRef]

- Harford, C.G. Corrosion Inhibiting Composition for Coating Metal, Coated Metal and Method of Coating. U.S. Patent 2,816,051, 10 December 1957. [Google Scholar]

- Belkind, A.; Zarrabian, S.; Engle, F. Plasma cleaning of metals: Lubricant oil removal. Metal Finish. 1996, 94, 19–22. [Google Scholar] [CrossRef]

- Keller, M.; Ritter, A.; Reimann, P.; Thommen, V.; Fischer, A.; Hegemann, D. Comparative study of plasma-induced and wet-chemical cleaning of synthetic fibers. Surf. Coat. Technol. 2005, 200, 1045–1050. [Google Scholar] [CrossRef]

- Krüger, P.; Knes, R.; Friedrich, J. Surface cleaning by plasma-enhanced desorption of contaminants (PEDC). Surf. Coat. Technol. 1999, 112, 240–244. [Google Scholar] [CrossRef]

- Frihart, C.R.; Wiedenhoeft, A.C.; Jakes, J.E. Wood bonding in the furniture industry and the effect of changing wood supply. In Proceedings of the COST E34 Workshop on Practical Solutions for Furniture and Structural Bonding, Larnaka, Cyprus, 22–23 March 2007; pp. 11–18. [Google Scholar]

- Kurz, W.A.; Dymond, C.C.; Stinson, G.; Rampley, G.J.; Neilson, E.T.; Carroll, A.L.; Ebata, T.; Safranyik, L. Mountain pine beetle and forest carbon feedback to climate change. Nature 2008, 452, 987–990. [Google Scholar] [CrossRef]

- Cai, J.; Cai, L. Effects of thermal modification on mechanical and swelling properties and color change of lumber killed by mountain pine beetle. BioResources 2012, 7, 3488–3499. [Google Scholar]

- Gobakken, L.R.; Høibø, O.A.; Solheim, H. Mould growth on paints with different surface structures when applied on wooden claddings exposed outdoors. Int. Biodeterior. Biodegrad. 2010, 64, 339–345. [Google Scholar] [CrossRef]

- Bardage, S.L. Susceptibility of painted wood to Aureobasidium pullulans: Fungal stain and growth patterns. Holz Roh-u Werkst. 1998, 56, 359–364. [Google Scholar] [CrossRef]

- Jamali, A.; Evans, P.D. Etching of wood surfaces by glow discharge plasma. Wood Sci. Technol. 2011, 45, 169–182. [Google Scholar] [CrossRef]

- Haase, J.G.; Leung, L.H.; Evans, P.D. Plasma pre-treatments to improve the weather resistance of polyurethane coatings on black spruce wood. Coatings 2019, 9, 8. [Google Scholar] [CrossRef]

- Thay, P.D.; Evans, P.D. The adhesion of an acrylic primer to weathered radiata pine surfaces. Wood Fiber Sci. 2007, 30, 198–204. [Google Scholar]

- ASTM D3359-09. Standard Test Methods for Measuring Adhesion by Tape Test; ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Williams, L.J.; Hervé, A. Fisher’s least significant difference (LSD) test. In Encyclopedia of Research Design; Salkind, N., Ed.; SAGE: Thousand Oaks, CA, USA, 2010; p. 6. [Google Scholar]

- Heady, R.D.; Banks, J.G.; Evans, P.D. Wood anatomy of Wollemi pine (Wollemia nobilis, Araucariaceae). IAWA J. 2002, 23, 339–357. [Google Scholar] [CrossRef]

- Thompson, D.W.; Kozak, R.A.; Evans, P.D. Thermal modification of color in red alder veneer. I. Effects of temperature, heating time, and wood type. Wood Fiber Sci. 2007, 37, 653–661. [Google Scholar]

- Kiguchi, M.; Kataoka, Y.; Suzuki, M.; Imamura, Y. Progress towards the service life prediction of coatings for exterior wood by weathering test trials. In Service Life Prediction: Challenging the Status Quo; Martin, J.W., Ryntz, R.A., Dickie, R.A., Eds.; Federation of Societies for Coatings Technology: Bluebell, PA, USA, 2005; pp. 123–134. [Google Scholar]

- Acda, M.N.; Devera, E.E.; Cabangon, R.J.; Ramos, H.J. Effects of plasma modification on adhesion properties of wood. Int. J. Adhes. Adhes. 2012, 32, 70–75. [Google Scholar] [CrossRef]

- De Cademartori, P.H.; de Carvalho, A.R.; Marangoni, P.R.; Berton, M.A.; Blanchet, P.; de Muniz, G.I.; Magalhães, W.L. Adhesion performance and film formation of acrylic emulsion coating on medium density fiberboard treated with Ar plasma. Int. J. Adhes. Adhes. 2016, 70, 322–328. [Google Scholar] [CrossRef]

- Podgorski, L.; Roux, M.L. Wood modification to improve the durability of coatings. Surf. Coat. Int. 1999, 82, 590–596. [Google Scholar] [CrossRef]

- Cho, D.L.; Sjöblom, E. Plasma treatment of wood. J. Appl. Polymer Sci. 1990, 46, 461–472. [Google Scholar] [CrossRef]

- Wagner, O.; Baumstark, R. How to control dirt pick-up of exterior coatings. Macromol. Symp. 2002, 187, 447–458. [Google Scholar] [CrossRef]

- De Meijer, M.; Creemers, J.; Cobben, W. Relationships between the performance of low-VOC wood coatings and the dimensional changes of the wooden substrate. Surf. Coat. Int. Part B Coat. Trans. 2001, 84, 77–85. [Google Scholar] [CrossRef]

- Bjurman, J. Algal growth resistance of paints for coating of wood: A laboratory study. In Proceedings of the International Research Group on Wood Protection Meeting, Whistler, BC, Canada, 25–30 May 1997. [Google Scholar]

- Baileys, R.T.; Webb, D.A. 1958 Cooperative creosote project-XII: An analysis of creosotes from posts after 26 years in test. In Proceedings of the Eighty-Third Annual Meeting of the American Wood-Preservers’ Association, Toronto, ON, Canada, 10–13 May 1987; pp. 163–171. [Google Scholar]

- Bulle, C.S.; Samson, R.; Deschênes, L. Transport of chlorinated dioxins and furans in soil columns: Modeling pentachlorophenol pole-treating oil influence. Chemosphere 2011, 83, 117–123. [Google Scholar] [CrossRef] [PubMed]

- Burnes, T.A.; Blanchette, R.A.; Farrell, R.L. Bacterial biodegradation of extractives and patterns of bordered pit membrane attack in pine wood. Appl. Environ. Microbiol. 2000, 66, 5201–5205. [Google Scholar] [CrossRef] [PubMed]

- Coulibaly, M.L.; Perrier, C.; Marugan, M.; Beroual, A. Aging behavior of cellulosic materials in presence of mineral oil and ester liquids under various conditions. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1971–1976. [Google Scholar] [CrossRef]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. BioResources 2008, 4, 370–404. [Google Scholar]

| Plasma Treatment Time, Seconds | Wettability | Dry and Wet Adhesion Tests | ||

|---|---|---|---|---|

| Sample Size, mm3 | Replication | Sample Size, mm3 | Replication * | |

| 0 | 3 × 15 × 38 | 5 | 3 × 15 × 19 | 5 + 5 |

| 33 | 3 × 15 × 38 | 5 | 3 × 15 × 19 | 5 + 5 |

| 333 | 3 × 15 × 38 | 5 | 3 × 15 × 19 | 5 + 5 |

| 667 | 3 × 15 × 38 | 5 | 3 × 15 × 19 | 5 + 5 |

| 1333 | 3 × 15 × 38 | 5 | 3 × 15 × 19 | 5 + 5 |

| Treatment | Sample Size, mm3 | Replication Unweathered and Weathered Samples * | |

|---|---|---|---|

| Water Absorption Test | Colour Test | ||

| Untreated | 3 × 17 × 55 | 8 + 8 | 8 + 8 |

| Hot oil | 3 × 17 × 55 | 8 + 8 | 8 + 8 |

| Hot oil/plasma | 3 × 17 × 55 | 8 + 8 | 8 + 8 |

| Plasma | 3 × 17 × 55 | 8 + 8 | 8 + 8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamali, A.; Evans, P.D. Plasma Treatment Reduced the Discoloration of an Acrylic Coating on Hot-Oil Modified Wood Exposed to Natural Weathering. Coatings 2020, 10, 248. https://doi.org/10.3390/coatings10030248

Jamali A, Evans PD. Plasma Treatment Reduced the Discoloration of an Acrylic Coating on Hot-Oil Modified Wood Exposed to Natural Weathering. Coatings. 2020; 10(3):248. https://doi.org/10.3390/coatings10030248

Chicago/Turabian StyleJamali, Arash, and Philip D. Evans. 2020. "Plasma Treatment Reduced the Discoloration of an Acrylic Coating on Hot-Oil Modified Wood Exposed to Natural Weathering" Coatings 10, no. 3: 248. https://doi.org/10.3390/coatings10030248

APA StyleJamali, A., & Evans, P. D. (2020). Plasma Treatment Reduced the Discoloration of an Acrylic Coating on Hot-Oil Modified Wood Exposed to Natural Weathering. Coatings, 10(3), 248. https://doi.org/10.3390/coatings10030248