A Pragmatic and High-Performance Radiative Cooling Coating with Near-Ideal Selective Emissive Spectrum for Passive Cooling

Abstract

1. Introduction

2. Materials and Methods

2.1. PET Aluminized Film Substrate

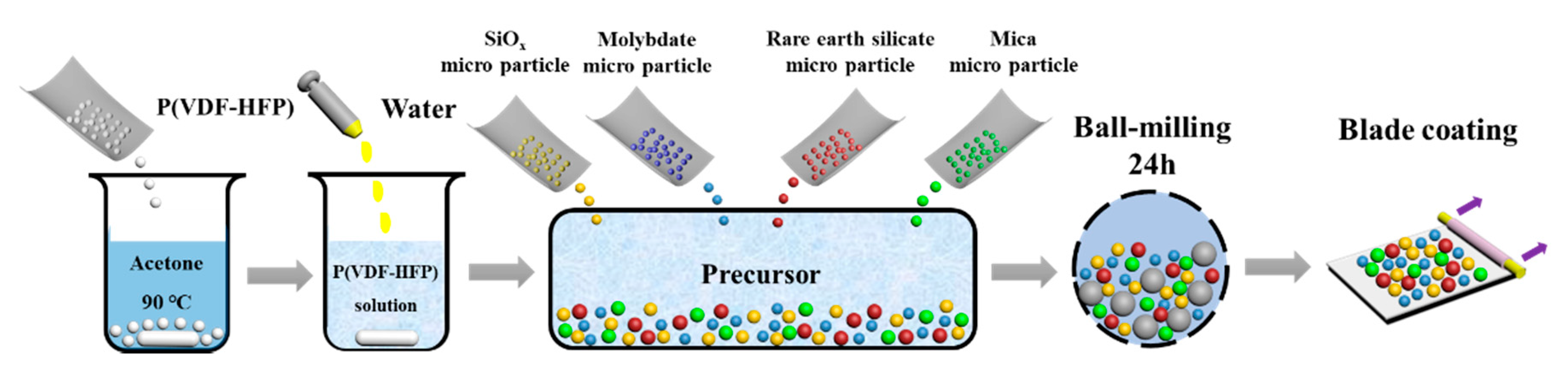

2.2. Preparation of the Radiative Cooling Coating

2.3. Characterization

3. Results and Discussion

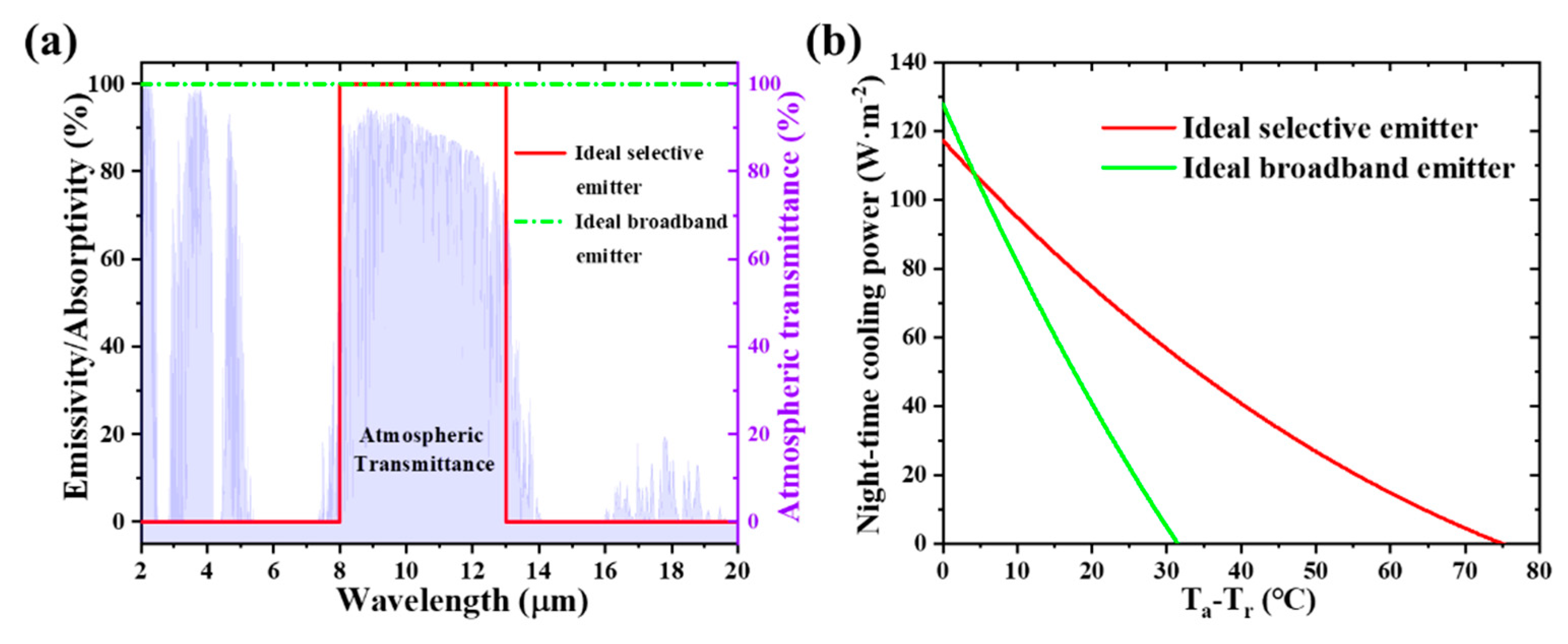

3.1. Theoretical Cooling Performance

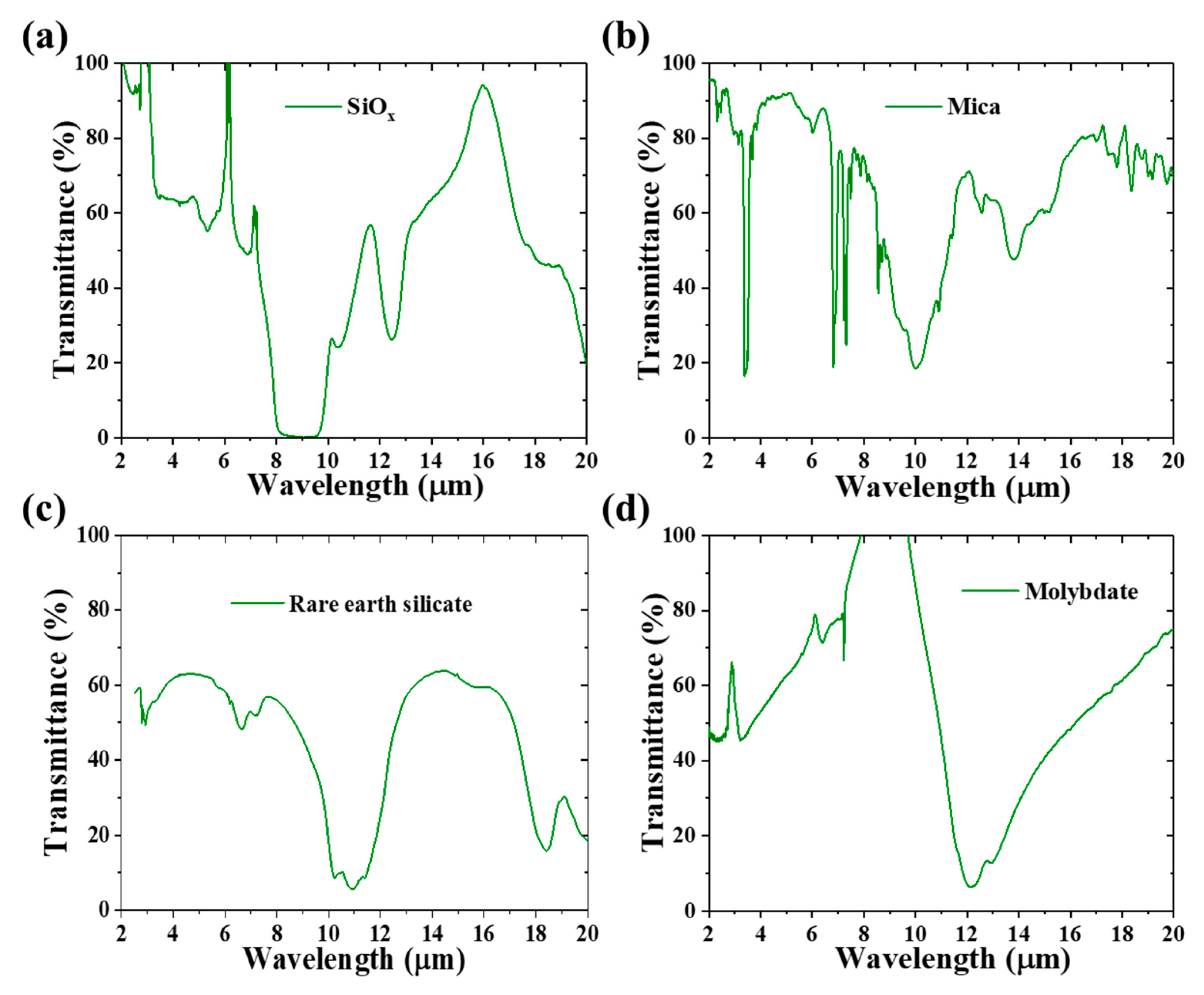

3.2. Optical Characteristics of the Radiative Cooling Coating

3.3. Outdoor Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kelso, J.K. 2011 Buildings Energy Data Book; US Department of Energy: Washington, DC, USA, 2012. [Google Scholar]

- Segar, C. Saudi energy mix: Renewables augment gas. J. Int. Energy Agency 2014, 7, 40–41. [Google Scholar]

- Panchabikesan, K.; Vellaisamy, K.; Ramalingam, V. Passive cooling potential in buildings under various climatic conditions in India. Renew. Sust. Energ. Rev. 2017, 78, 1236–1252. [Google Scholar] [CrossRef]

- An, C.; Su, J. Improved lumped models for transient combined convective and radiative cooling of multi-layer composite slabs. Appl. Therm. Eng. 2011, 31, 2508–2517. [Google Scholar] [CrossRef]

- Safi, T.S.; Munday, J.N. Improving photovoltaic performance through radiative cooling in both terrestrial and extraterrestrial environments. Opt. Express 2015, 23, A1120–A1128. [Google Scholar] [CrossRef] [PubMed]

- Zou, C.; Ren, G.; Hossain, M.M.; Nirantar, S.; Withayachumnankul, W.; Ahmed, T.; Bhaskaran, M.; Sriram, S.; Gu, M.; Fumeaux, C. Metal-loaded dielectric resonator metasurfaces for radiative cooling. Adv. Opt. Mater. 2017, 5, 1700460. [Google Scholar] [CrossRef]

- Catalanotti, S.; Cuomo, V.; Piro, G.; Ruggi, D.; Silvestrini, V.; Troise, G. Radiative cooling of selective surfaces. Sol. Energy 1975, 17, 83–89. [Google Scholar] [CrossRef]

- Orel, B.; Gunde, M.K.; Krainer, A. Radiative cooling efficiency of white pigmented paints. Sol. Energy 1993, 50, 477–482. [Google Scholar] [CrossRef]

- Mahdavinejad, M.; Javanrudi, K. Assessment of ancient fridges: A sustainable method to storage ice in hot-arid climates. Asian Cult. Hist. 2012, 4, 133–139. [Google Scholar] [CrossRef]

- Gao, M.; Han, X.; Chen, F.; Zhou, W.; Liu, P.; Shan, Y.; Chen, Y.; Li, J.; Zhang, R.; Wang, S.; et al. Approach to fabricating high-performance cooler with near-ideal emissive spectrum for above-ambient air temperature radiative cooling. Sol. Energy Mater. Sol. Cells 2019, 200, 110013. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.K.; Overvig, A.C.; Jia, M.X.; Sun, K.R.; Shi, N.N.; Zhou, H.; Xiao, X.H.; Yu, N.F.; Yang, Y. Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling. Science 2018, 362, 315–318. [Google Scholar] [CrossRef] [PubMed]

- Sakthisabarimoorthi, A.; Dhas, S.; Jose, M. Fabrication and nonlinear optical investigations of SiO2@Ag core-shell nanoparticles. Mater. Sci. Semicond. Process 2017, 71, 69–75. [Google Scholar] [CrossRef]

- Mrinmoy, G.; Mrinmoy, S. Effects of in-situ generated coinage nanometals on crystallization and microstructure of fluorophlogopite mica containing glass-ceramics. J. Mater. Sci. Technol. 2015, 31, 110–119. [Google Scholar]

- Wenyan, Z.; Chunhua, L.; Yaru, N. Crystal structure and optical spectra of Er:NaLaxYb9−x(SiO4)6O2 (x = 0, 3, 5, 7, 9) crystals prepared through a hydrothermal routine. Adv. Mater. Res. 2009, 79, 1711–1714. [Google Scholar]

- Vidya, S.; Solomon, S.; Thomas, J.K. Synthesis, sintering and optical properties of CaMoO4: A promising scheelite LTCC and photoluminescent material. Phys. Status Solidi A Appl. Mat. 2012, 209, 1067–1074. [Google Scholar] [CrossRef]

- Hossain, M.M.; Gu, M. Radiative cooling: Principles, Progress, and Potentials. Adv. Sci. 2016, 3, 1500360. [Google Scholar] [CrossRef] [PubMed]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef] [PubMed]

- Bao, H.; Yan, C.; Wang, B.X.; Fang, X.; Zhao, C.Y.; Ruan, X.L. Double-layer nanoparticle-based coatings for efficient terrestrial radiative cooling. Sol. Energy Mater. Sol. Cells 2017, 168, 78–84. [Google Scholar] [CrossRef]

- Wang, W.M.; Fernandez, N.; Katipamula, S.; Alvine, K. Performance assessment of a photonic radiative cooling system for office buildings. Renew. Energy 2018, 118, 265–277. [Google Scholar] [CrossRef]

- Guha, B.; Otey, C.; Poitras, C.B.; Fan, S.H.; Lipson, M. Near-field radiative cooling of nanostructures. Nano Lett. 2012, 12, 4546–4550. [Google Scholar] [CrossRef] [PubMed]

- Bretzlaff, R.S.; Wool, R.P. Frequency shifting and asymmetry in infrared bands of stressed polymers. Macromolecules 1983, 16, 1907–1917. [Google Scholar] [CrossRef]

- Arkema. New Fluoropolymer Latex Technology for Cool Materials Solutions Across an Expanded Color Space. Available online: http://coolcolors.lbl.gov/assets/docs/PAC-2008-03-06/Arkema-slides.pdf (accessed on 13 January 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Li, W.; Tao, S.; Fang, Z.; Lu, C.; Xu, Z. A Pragmatic and High-Performance Radiative Cooling Coating with Near-Ideal Selective Emissive Spectrum for Passive Cooling. Coatings 2020, 10, 144. https://doi.org/10.3390/coatings10020144

Chen M, Li W, Tao S, Fang Z, Lu C, Xu Z. A Pragmatic and High-Performance Radiative Cooling Coating with Near-Ideal Selective Emissive Spectrum for Passive Cooling. Coatings. 2020; 10(2):144. https://doi.org/10.3390/coatings10020144

Chicago/Turabian StyleChen, Mingxue, Wenqing Li, Shuang Tao, Zhenggang Fang, Chunhua Lu, and Zhongzi Xu. 2020. "A Pragmatic and High-Performance Radiative Cooling Coating with Near-Ideal Selective Emissive Spectrum for Passive Cooling" Coatings 10, no. 2: 144. https://doi.org/10.3390/coatings10020144

APA StyleChen, M., Li, W., Tao, S., Fang, Z., Lu, C., & Xu, Z. (2020). A Pragmatic and High-Performance Radiative Cooling Coating with Near-Ideal Selective Emissive Spectrum for Passive Cooling. Coatings, 10(2), 144. https://doi.org/10.3390/coatings10020144