Effect of the Common Solvents on UV-Modified Photopolymer and EPDM Flexographic Printing Plates and Printed Ink Films

Abstract

1. Introduction

2. Materials and Methods

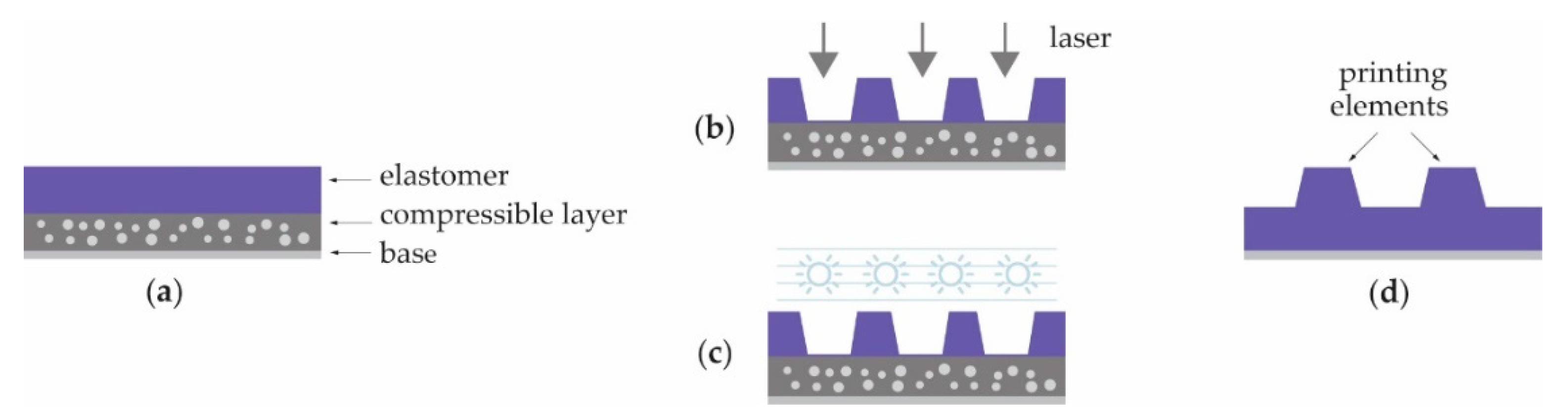

2.1. Production of the Flexographic Printing Plates

2.2. Surface Treatment of Printing Plates and Swelling Experiment

2.3. Measurements of Photopolymer and EPDM Hardness

2.4. Determination of Surface Free Energy

2.5. Scanning Electron Microscopy (SEM Microscopy)

2.6. Printing Process and Measurements of the Properties of the Printed Ink Film

3. Results and Discussion

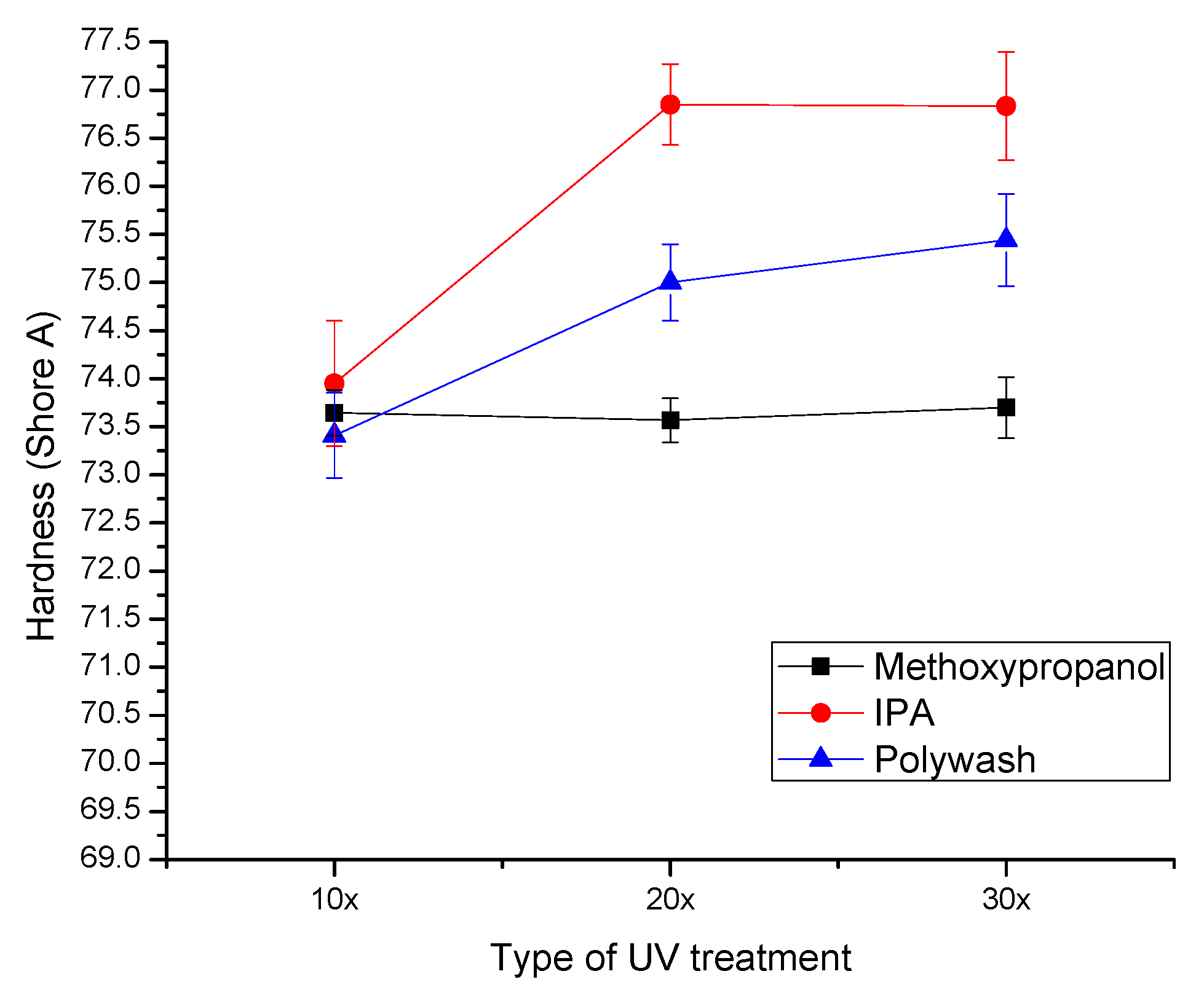

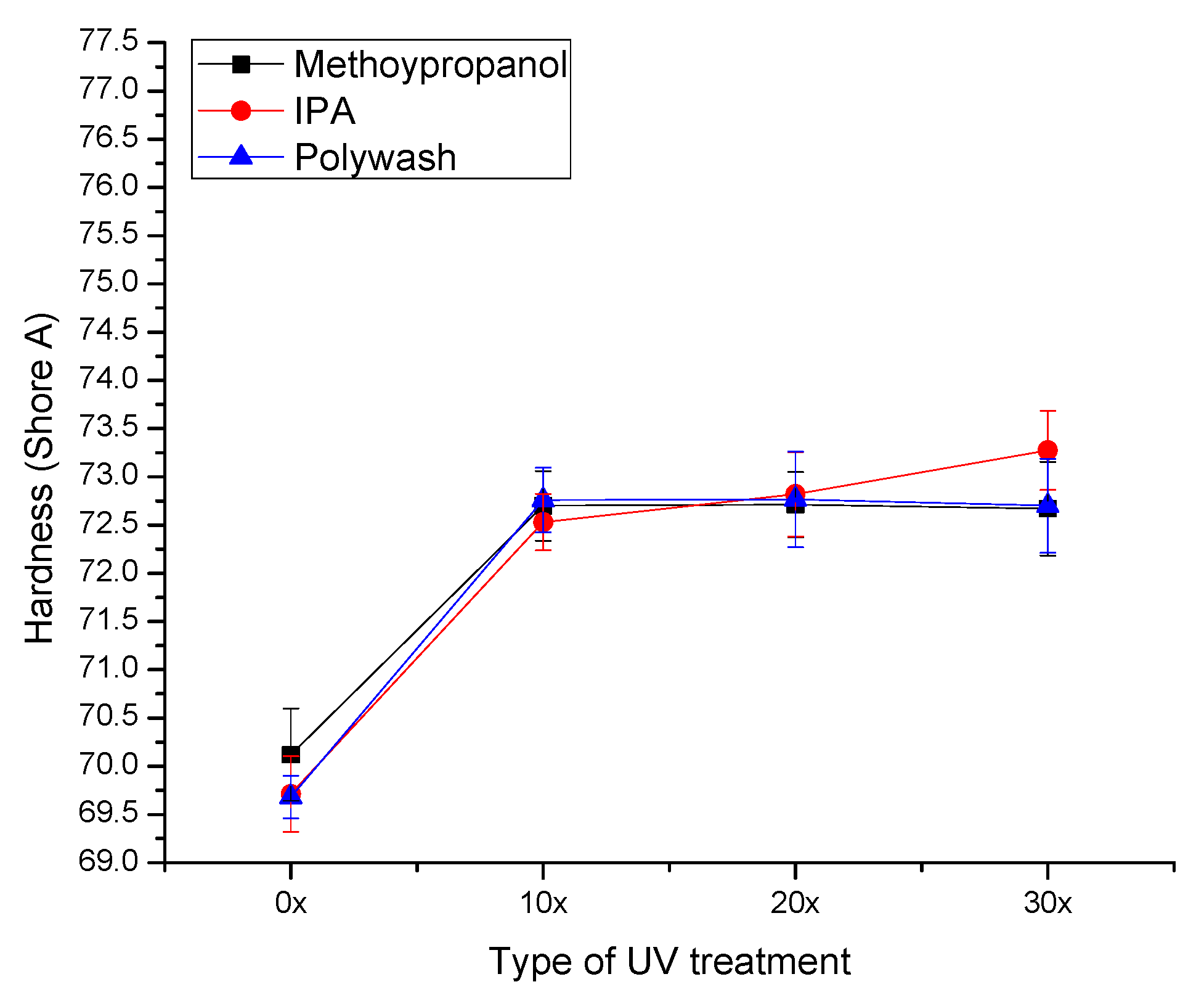

3.1. Hardness of Printing Plates

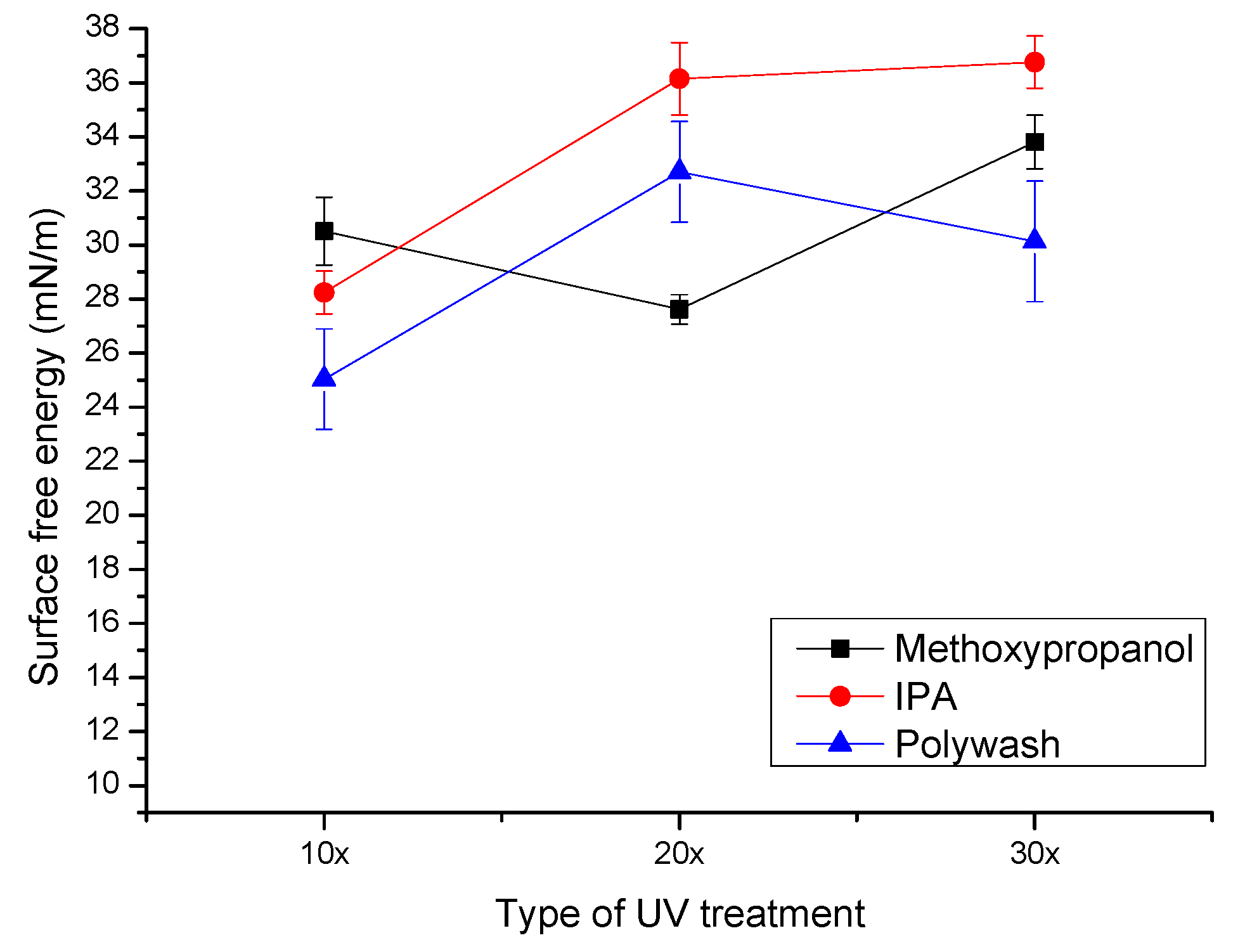

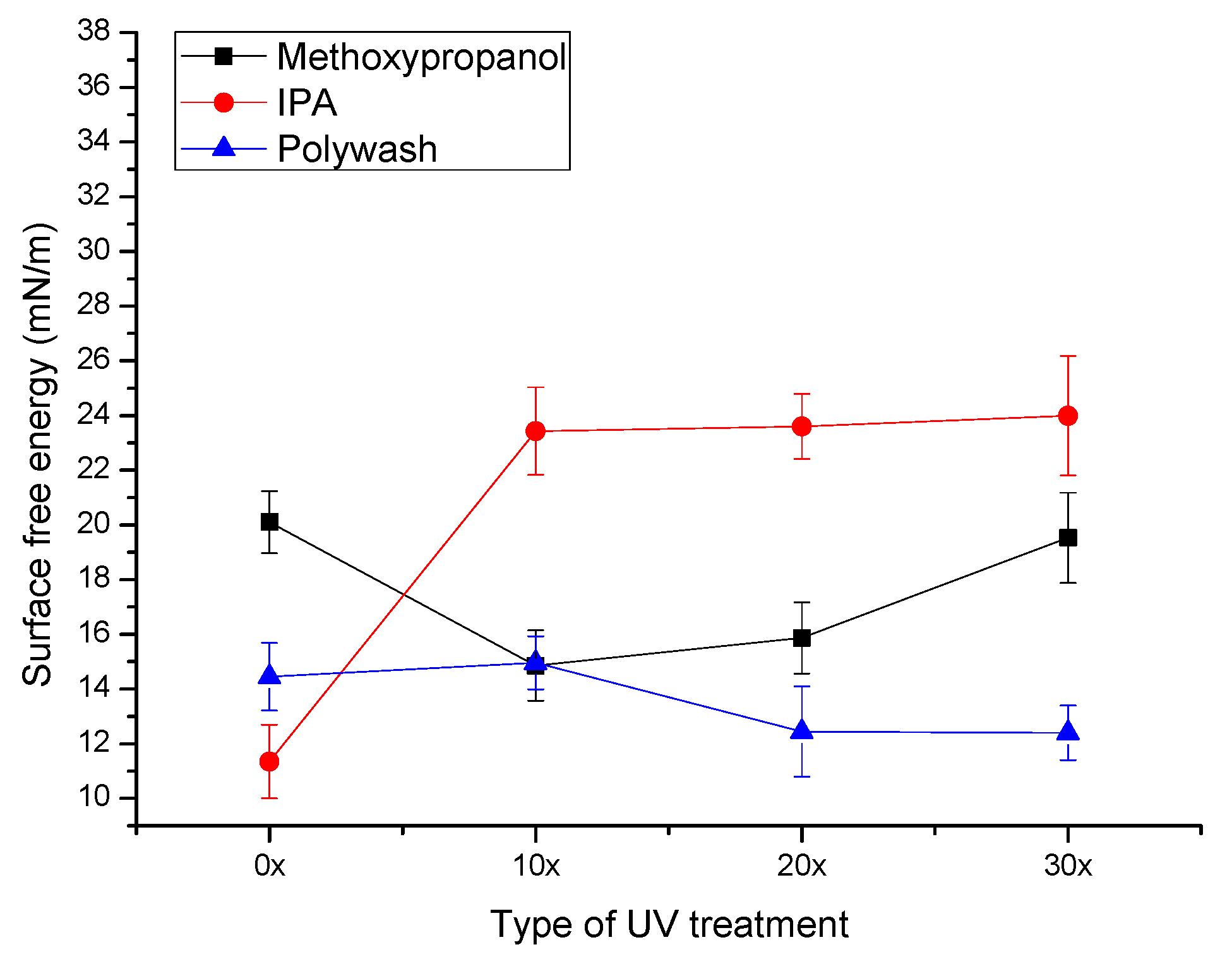

3.2. Surface Free Energy of Printing Plates

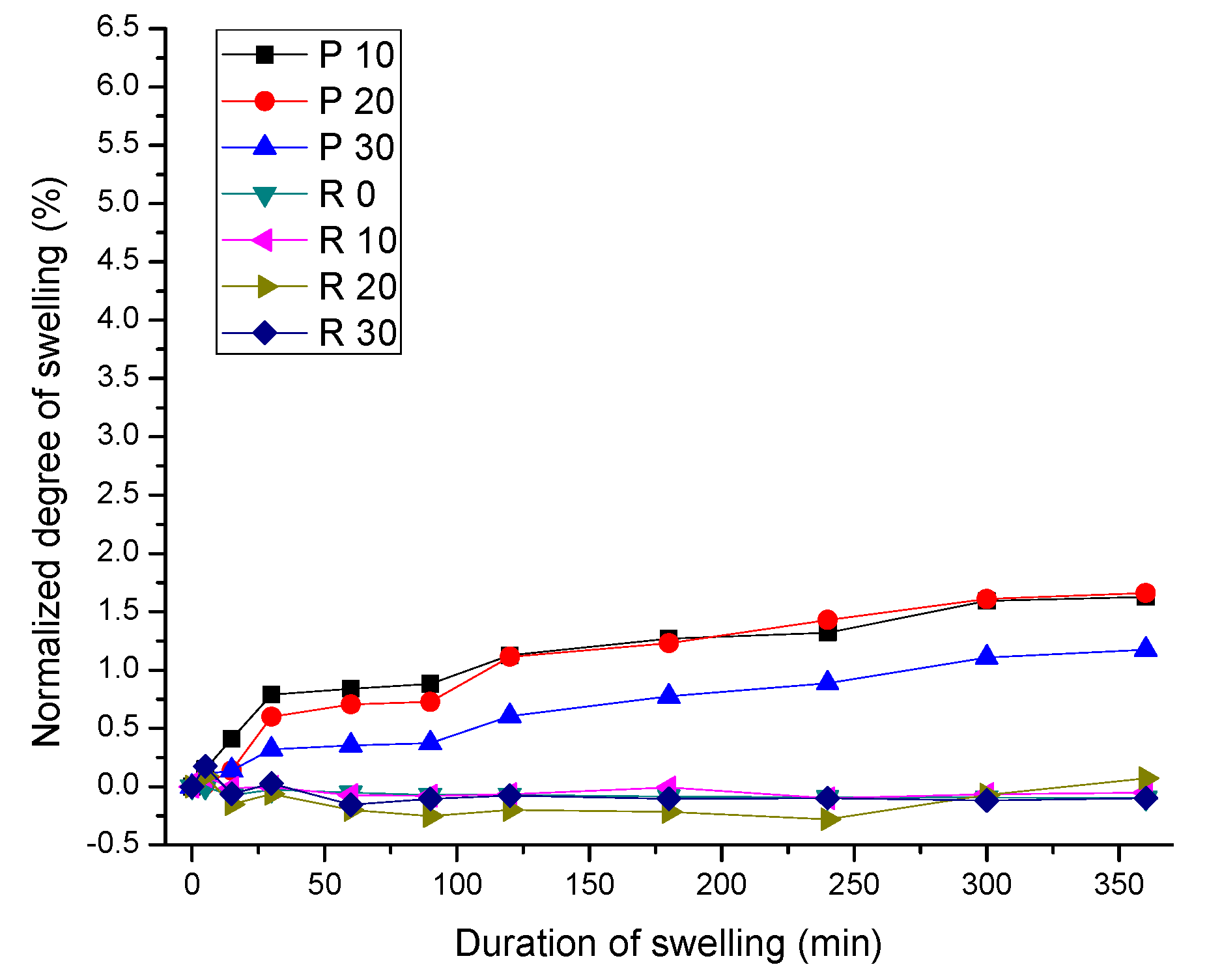

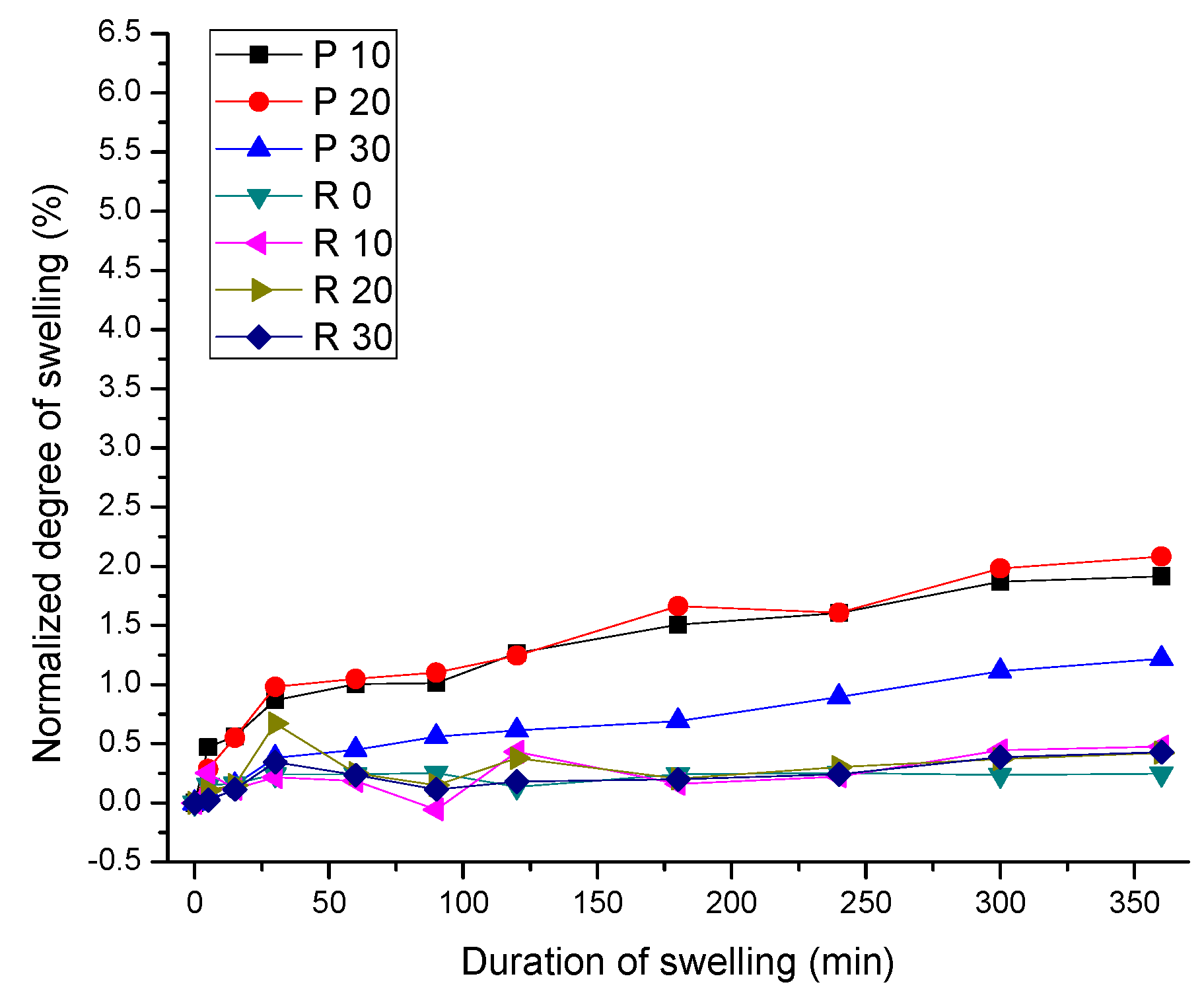

3.3. Swelling of Printing Plates

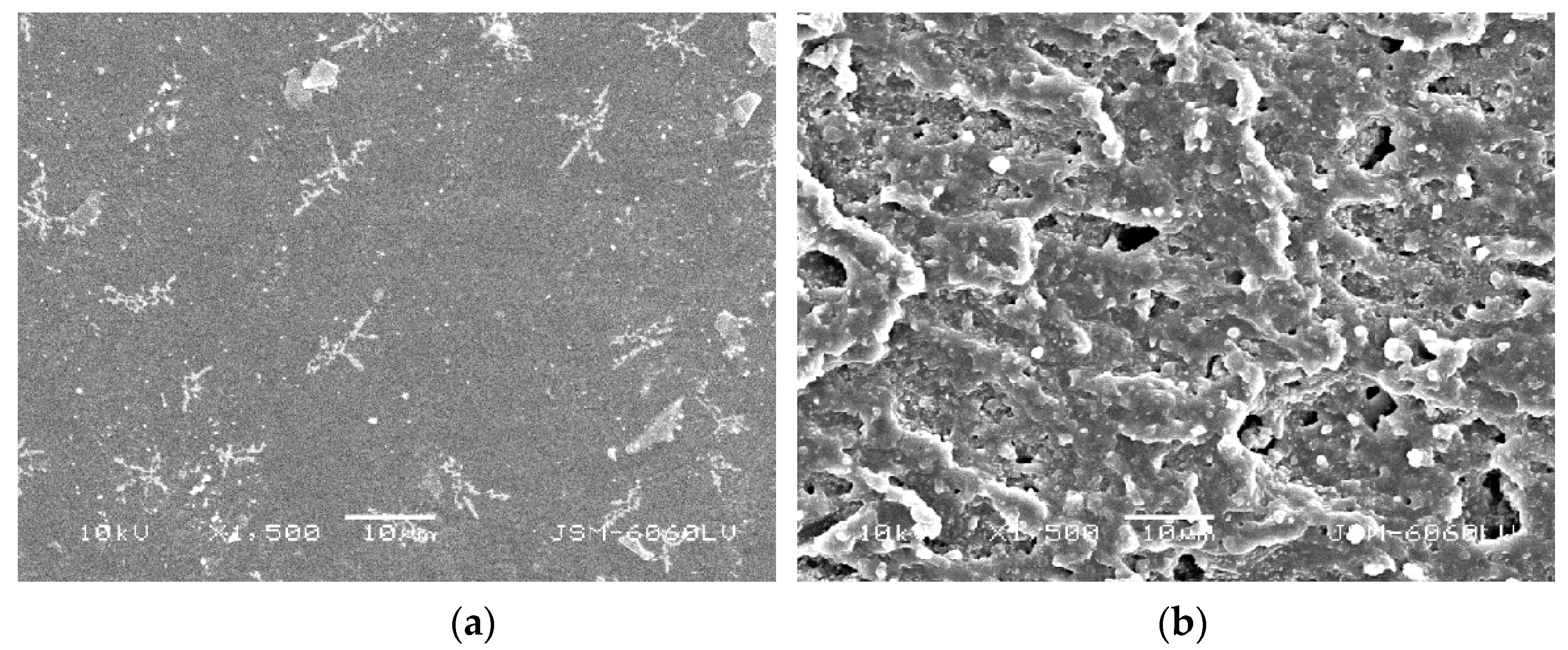

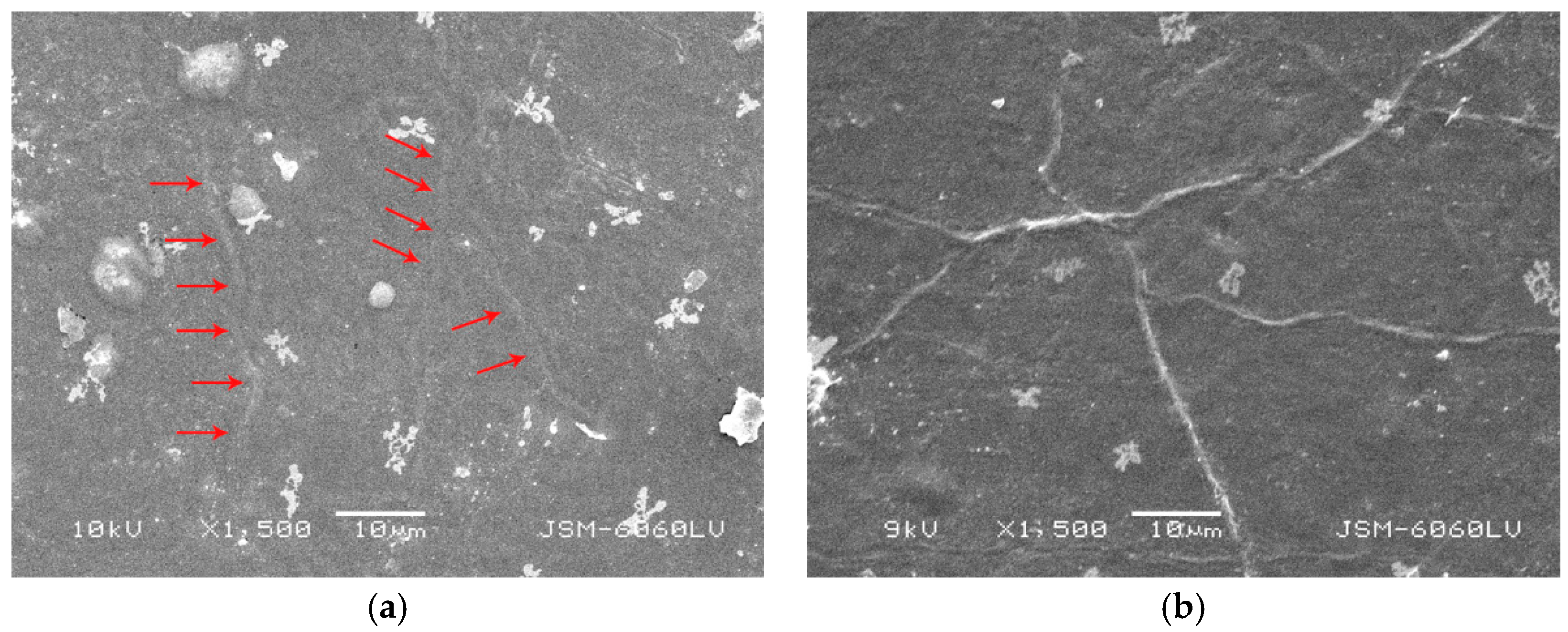

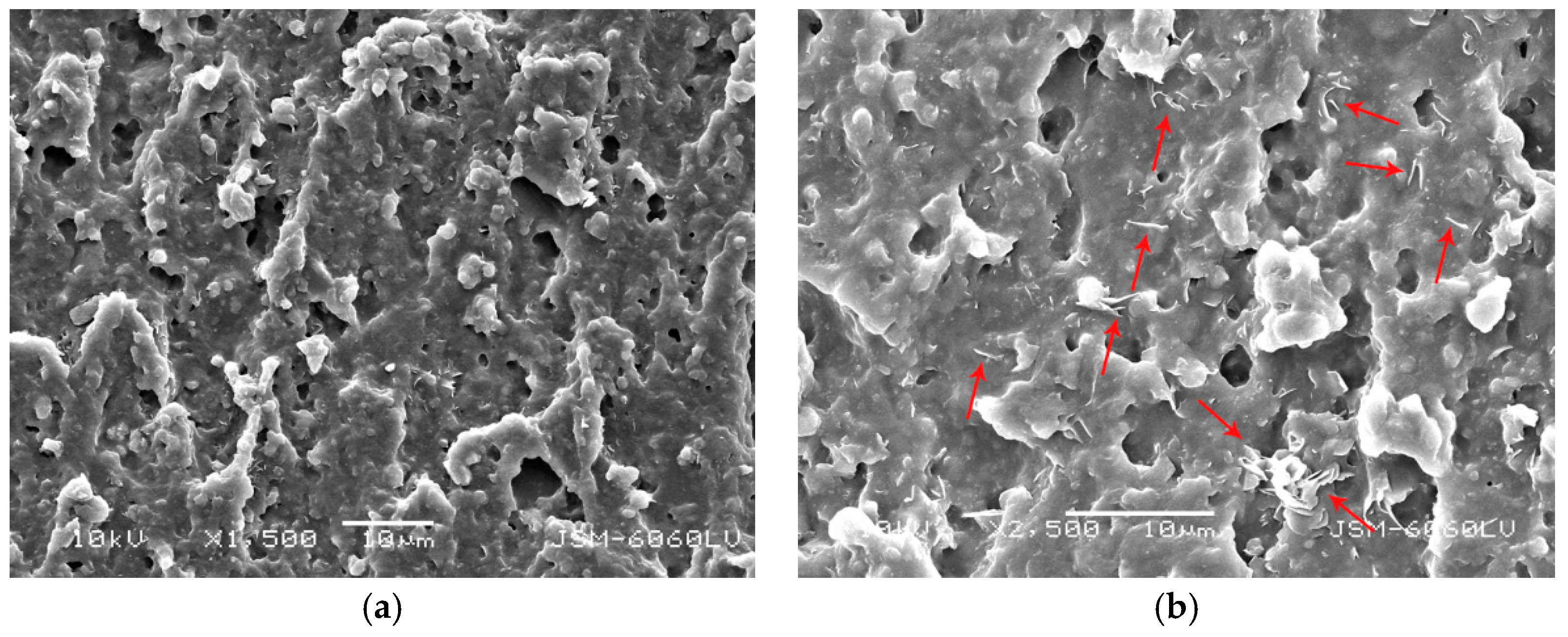

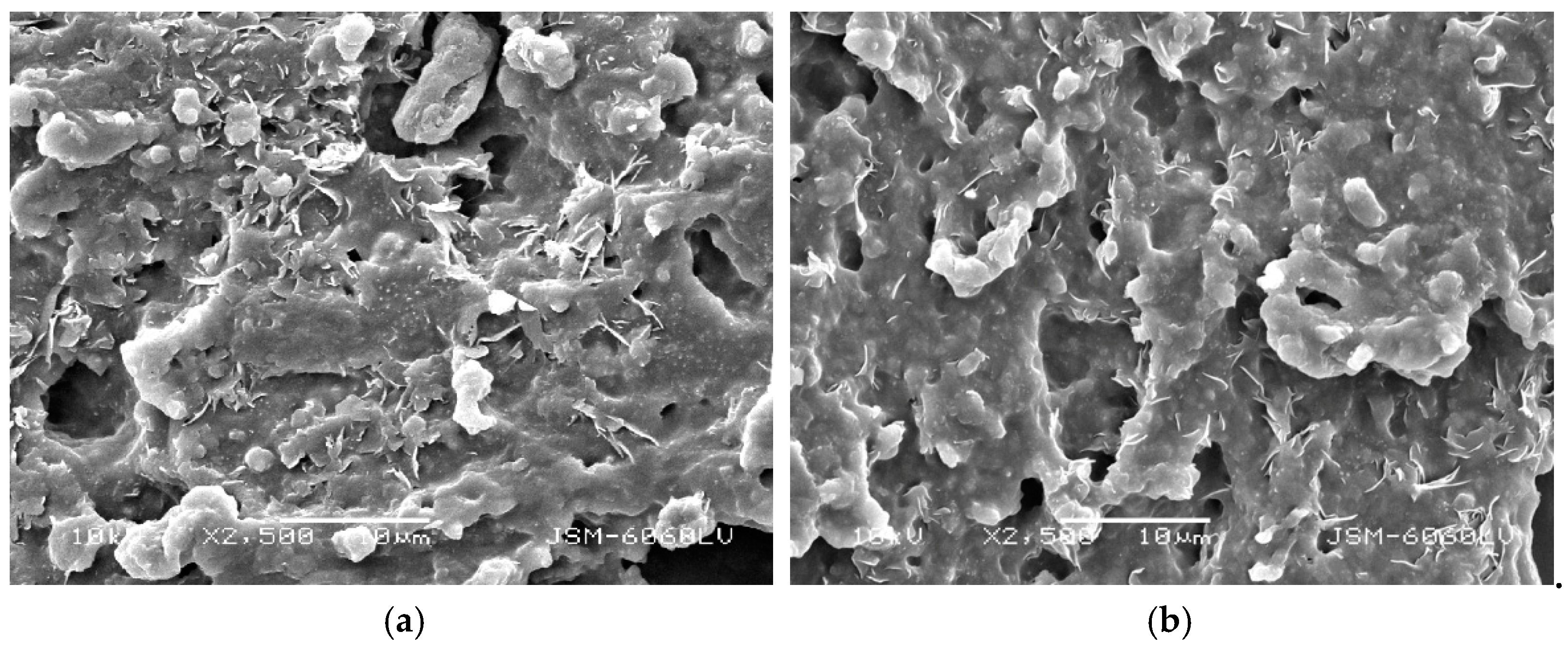

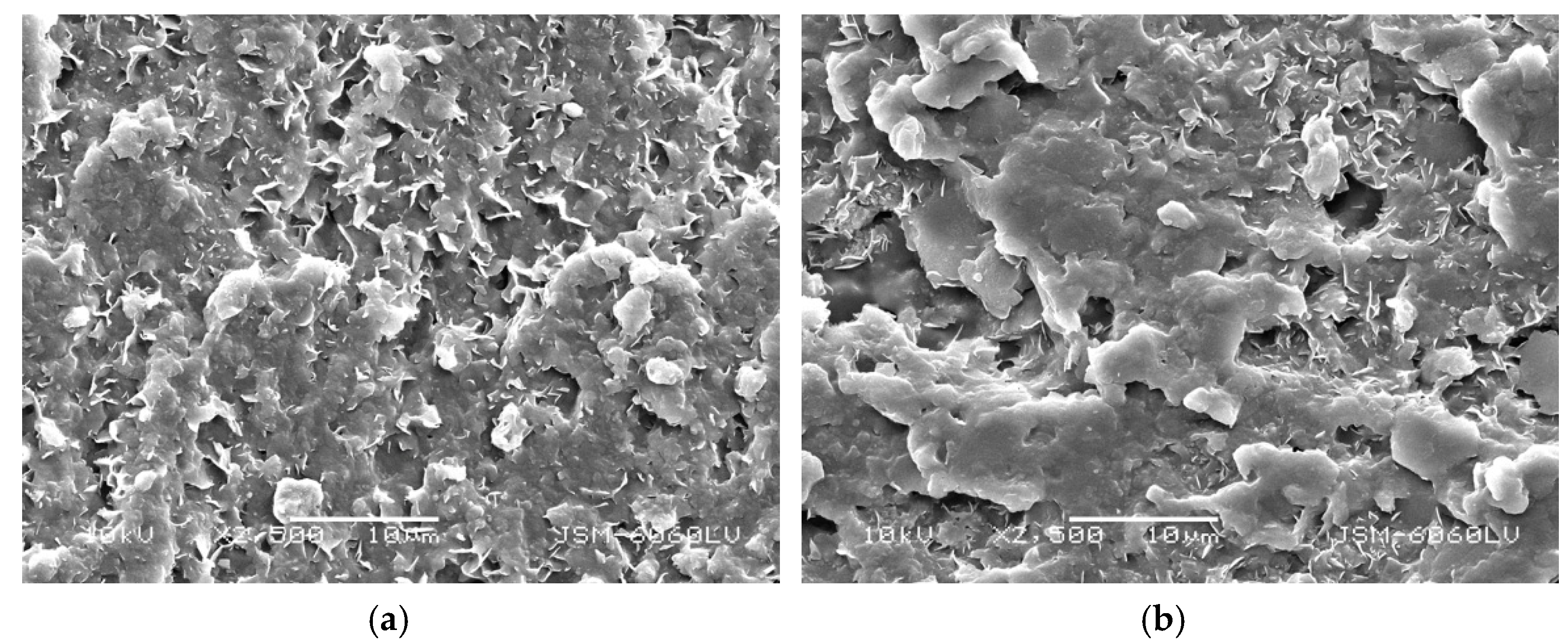

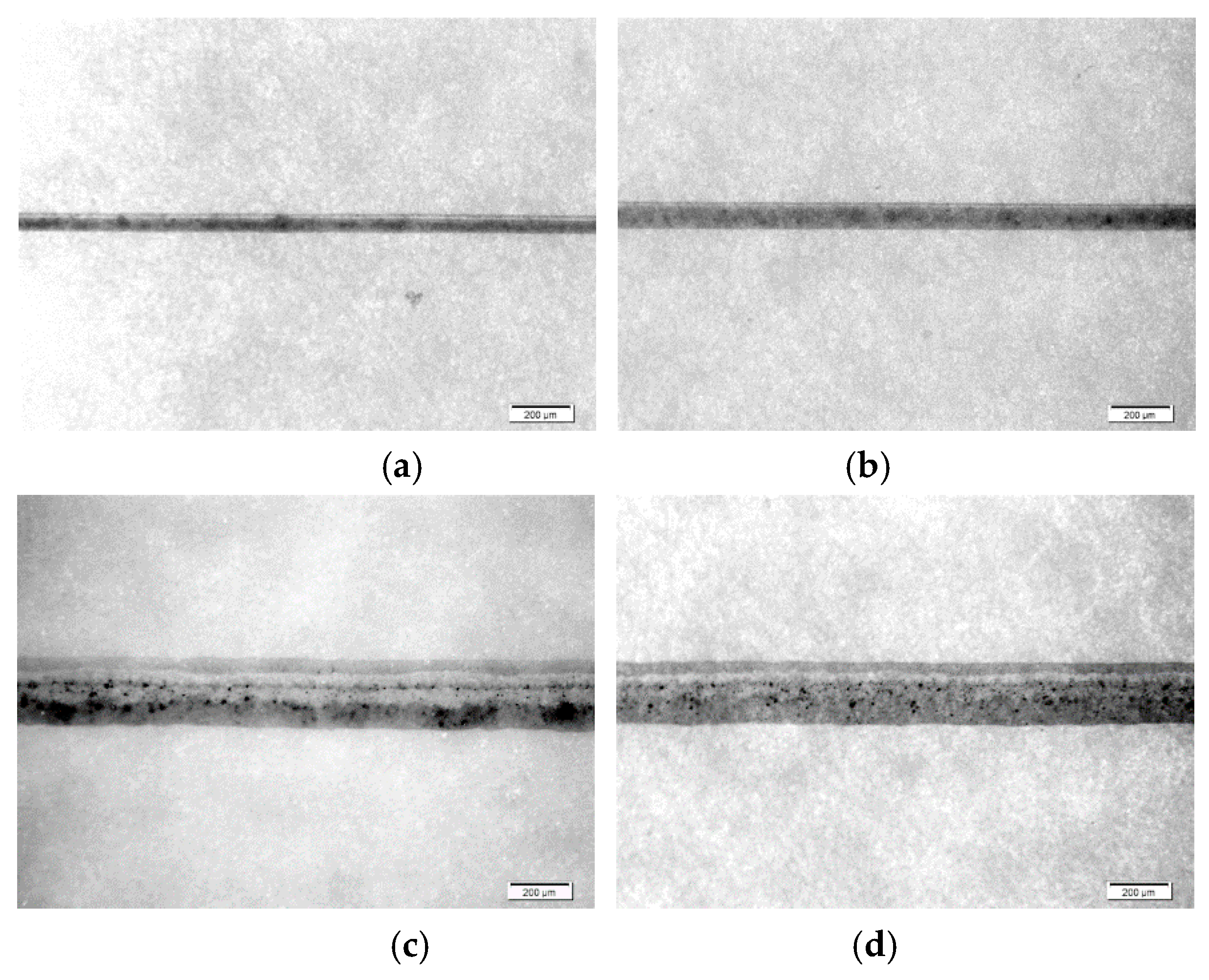

3.4. SEM Images of Printing Plates

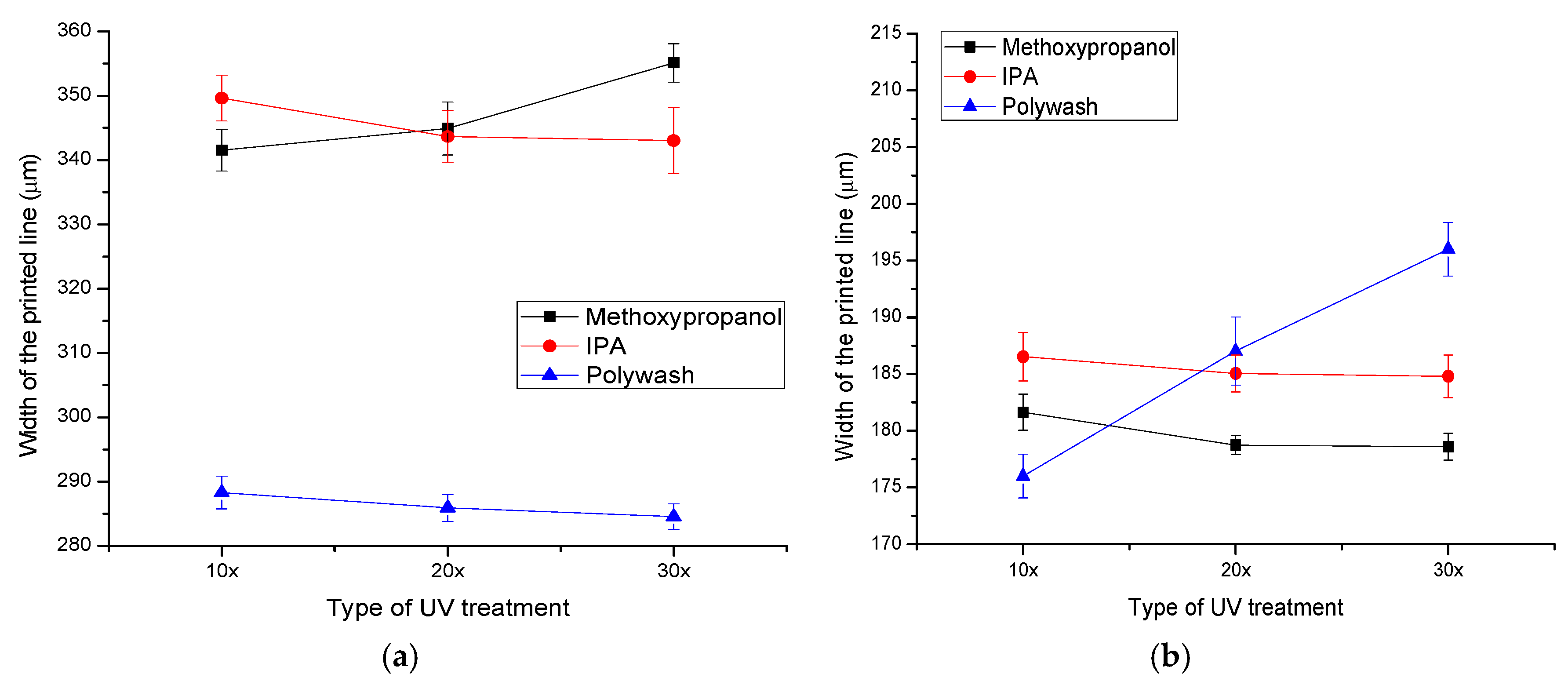

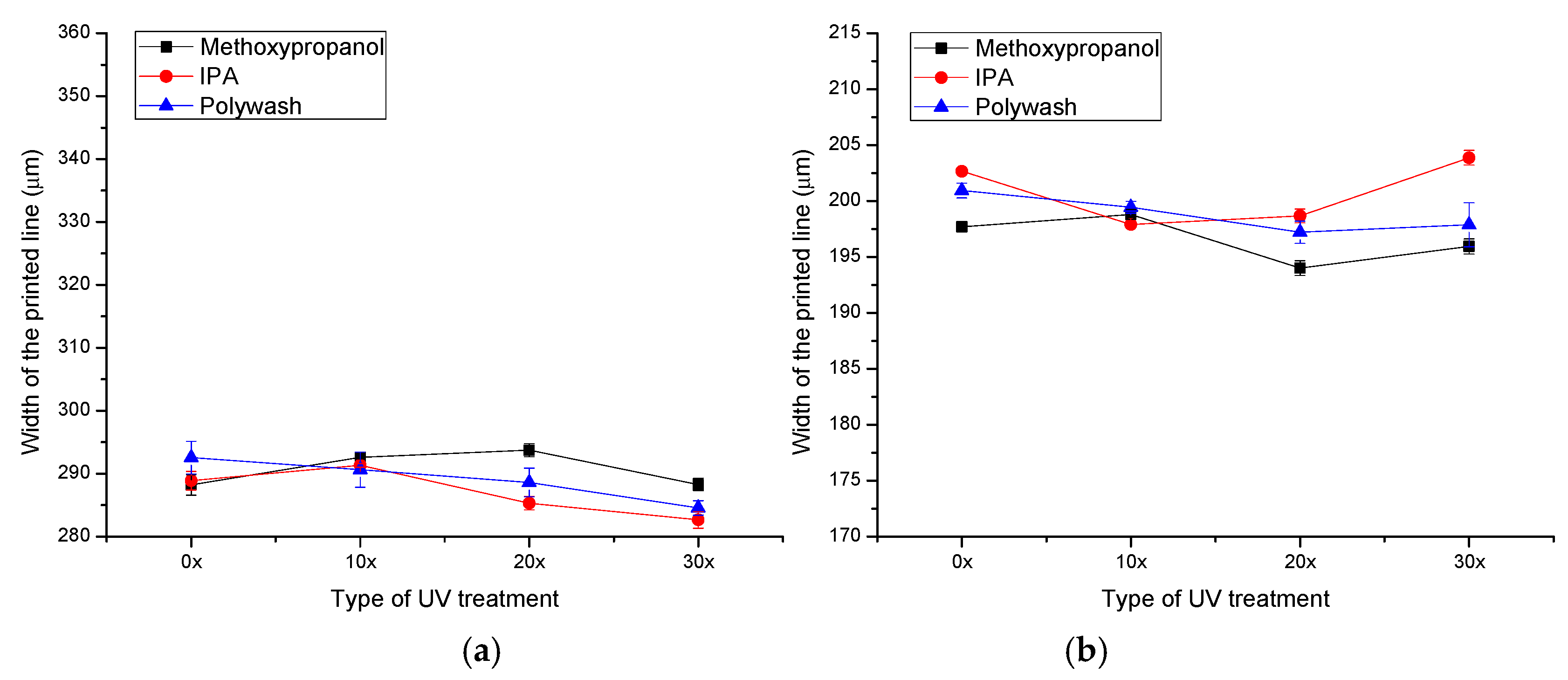

3.5. Width of the Printed Lines

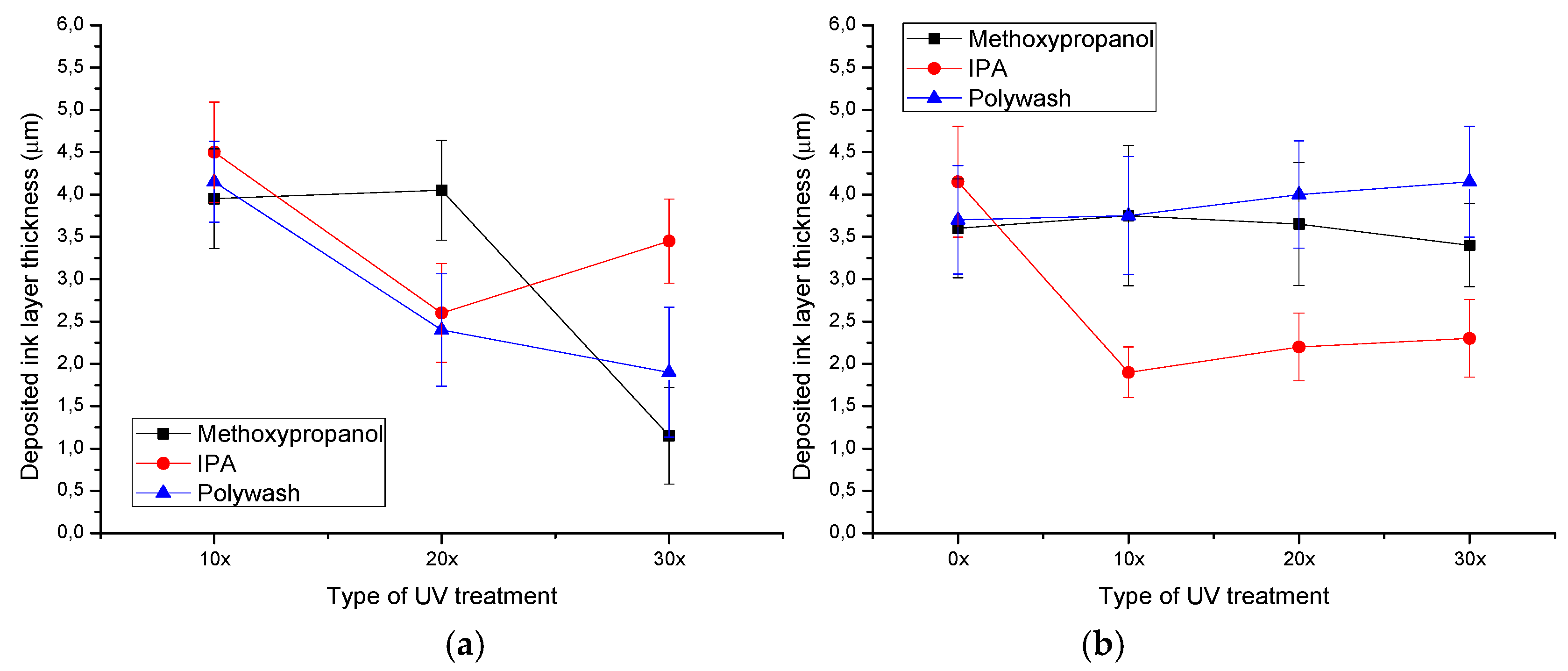

3.6. Thickness of the Printed Ink Film

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Sun, J.; Cui, B.; Chu, F.; Yun, C.; He, M.; Li, L.; Song, Y. Printable nanomaterials for the fabrication of high-performance supercapacitors. Nanomaterials 2018, 8, 528. [Google Scholar] [CrossRef]

- Sun, J.; Yun, C.; Cui, B.; Li, P.; Liu, G.; Wang, X.; Chu, F. A Facile Approach for Fabricating Microstructured Surface Based on Etched Template by Inkjet Printing Technology. Polymers 2018, 10, 1209. [Google Scholar] [CrossRef]

- Bodwell, R.; Scharfenberg, J. Advancing Flexography: The Technical Path Forward. Available online: http://www.intermarketcorp.com/images/business/PosWhitePaper4-11.pdf (accessed on 3 February 2020).

- Cosnahan, T.; Watt, A.A.; Assender, H.E. Flexography Printing for Organic Thin Film Transistors. Mater. Today Proc. 2018, 5, 16051–16057. [Google Scholar] [CrossRef]

- Lorenz, A.; Senne, A.; Rohde, J.; Kroh, S.; Wittenberg, M.; Krüger, K.; Clement, F.; Biro, D. Evaluation of Flexographic Printing Technology for Multi-Busbar Solar Cells. Energy Procedia 2015, 67, 126–134. [Google Scholar] [CrossRef]

- Joyce, M.; Pal, L.; Hicks, R.; Agate, S.; Williams, T.S.; Ray, G.; Fleming, P.D. Custom tailoring of conductive ink/substrate properties for increased thin film deposition of poly(dimethylsiloxane) films. J. Mater. Sci. Mater. Electron. 2018, 29, 10461–10470. [Google Scholar] [CrossRef]

- Alem, S.; Graddage, N.; Lu, J.; Kololuoma, T.; Movileanu, R.; Tao, Y. Flexographic printing of polycarbazole-based inverted solar cells. Org. Electron. 2018, 52, 146–152. [Google Scholar] [CrossRef]

- Rentzhog, M. Water-Based Flexographic Printing on Polymer-Coated Board. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2006. [Google Scholar]

- Izdebska, J.; Sabu, T. Printing on Polymers: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9788578110796. [Google Scholar] [CrossRef]

- Cruz, S.M.F.; Rocha, L.A.; Viana, J.C. Printing Technologies on Flexible Substrates for Printed Electronics. IntechOpen 2018, 1, 47–70. [Google Scholar] [CrossRef]

- Bornemann, N.; Sauer, H.M.; Dörsam, E. Gravure printed ultrathin layers of small-molecule semiconductors on glass. J. Imag. Sci. Technol. 2011, 55, 040201. [Google Scholar] [CrossRef]

- Joshi, A.V.; Dettke, C.; Steingraeber, J. Investigation on electrostatic assist and gravure process parameters on solid mottle reduction for shrink films. J. Coat. Technol. Res. 2016, 13, 375–383. [Google Scholar] [CrossRef]

- Hyun, W.J.; Secor, E.B.; Hersam, M.C.; Frisbie, C.D.; Francis, L.F. High-resolution patterning of graphene by screen printing with a silicon stencil for highly flexible printed electronics. Adv. Mater. 2015, 27, 109–115. [Google Scholar] [CrossRef]

- Andersson, C.; Johnson, J.; Järnström, L. Ultraviolet-induced aging of flexographic printing plates studied by thermal and structural analysis methods. J. Appl. Polym. Sci. 2009, 112, 1636–1646. [Google Scholar] [CrossRef]

- Todd, R.E. Printing Inks: Formulation Principles, Manufacture and Quality Control Testing Procedures; Pira International: London, UK, 1994. [Google Scholar]

- Speirs, H.M. Introduction to Printing and Finishing; British Printing Industries Federation and Pira International: London, UK, 2003; ISBN 10: 1858029066; ISBN 13: 9781858029061. [Google Scholar]

- Cusdin, G. Flexography: Principles & Practices, 5th ed.; Foundation of Flexographic Technical Association: Ronkonkoma, NY, USA, 1999. [Google Scholar]

- Hamblyn, A. Effect of Plate Characteristics on Ink Transfer in Flexographic Printing. Ph.D. Thesis, Swansea University, Swansea, UK, 2015; pp. 2–5. [Google Scholar]

- Thompson, B. Printing Materials: Science and Technology (Pira Printing Guide Series); Pira International: Surrey, UK, 1998. [Google Scholar]

- Rentzhog, M.; Fogden, A. Correlations between properties of water-based flexographic inks and their print uniformity on PE-coated board. Nord. Pulp Pap. Res. J. 2006, 21, 403–410. [Google Scholar] [CrossRef]

- Bohlin, E.; Lestelius, M.; Johansson, C. Flexographic ink-coating interactions - Effects of porous structure variations of coated paperboard. Nord. Pulp Pap. Res. J. 2013, 28, 573–581. [Google Scholar] [CrossRef]

- Peters, A.C.I.; Overbeek, G.; Annable, T. Bimodal particle size distribution polymer/oligomer combinations for printing ink applications. Prog. Org. Coat. 2000, 38, 137–150. [Google Scholar] [CrossRef]

- Tipsotnaiyana, N.; Jarupan, L.; Noppakundilograt, S. Enhancement of flexographic print quality on bleached kraft liner using nano-silica from rice husk. Prog. Org. Coat. 2015, 87, 232–241. [Google Scholar] [CrossRef]

- INTERGRAF (International Confederation for Printing and Allied Industries). Flexography and Packaging Gravure. Available online: https://ec.europa.eu/environment/archives/air/stationary/solvents/activities/pdf/155_en.pdf (accessed on 3 February 2020).

- Mantis, D.; Dfh, D. Solvent Based Printing Inks. Available online: https://ocp.teiath.gr › TGT_UNDER100 › Παρουσιάσεις (accessed on 3 February 2020).

- Jenkins, J. The Effects of Common Solvents on Different Types of Flexographic Printing Plates. Ph.D. Thesis, Rochester Institute of Technology, New York, NY, USA, 1985. [Google Scholar]

- Poljacek, S.M.; Cigula, T.; Tomasegovic, T.; Brajnović, O. Meeting the quality requirements in the flexographic plate making process. Int. Circ. Graph. Educ. Res. 2013, 6, 62–68. [Google Scholar]

- Foundation of Flexographic Technical Association. FIRST, Flexographic Image Reproduction Specifications & Tolerance, 3rd ed.; Foundation of Flexographic Technical Association: New York, NY, USA, 2003. [Google Scholar]

- Johnson, J. Aspects of Flexographic Print Quality and Relationship to Some Printing Parameters; Karlstad University: Karlstad, Sweden, 2008; ISBN 9789170631870. [Google Scholar]

- Galton, D.; Bould, D.; Claypole, T. The effect of surface properties on the printability of flexographic printing plates. Adv. Print. Media Technol. 2010, 37, 277–283. [Google Scholar]

- Poljaček, S.M.; Tomašegović, T.; Cigula, T.; Gojo, M.; Milčić, D. Formation of the printing elements in the photopolymer material used in flexography. Key Eng. Mater. 2014, 611–612, 883–891. [Google Scholar]

- Tomašegović, T.; Poljaček, S.M.; Leskovac, M. UVA and UVC modification of photo polymeric surface and application for flexographic deposition of thin coatings. J. Appl. Polym. Sci. 2016, 133, 43526. [Google Scholar] [CrossRef]

- Tomašegović, T.; Beynon, D.; Claypole, T.; Poljaček, S.M. Tailoring the properties of deposited thin coating and print features in flexography by application of UV-ozone treatment. J. Coat. Technol. Res. 2016, 13, 815–828. [Google Scholar] [CrossRef]

- Flint Group, nyloflex® ACE Digital. Available online: https://www.flintgrp.com/media/1296/nyloflex_ace_en.pdf (accessed on 3 February 2020).

- Knöll, R. Photopolymerizable Flexographic Printing Elements Comprising SIS/SBS Mixtures as Binder for the Production of Flexographic Printing Plates. U.S. Patent 6,531,263, 11 March 2003. [Google Scholar]

- Lee, T.Y.; Guymon, C.A.; Jönsson, E.S.; Hoyle, C.E. The effect of monomer structure on oxygen inhibition of (meth)acrylates photopolymerization. Polymer 2004, 45, 6155–6162. [Google Scholar] [CrossRef]

- Cushner, S.; Fan, R.N.; Leberzammer, E.; Shea, P.T.; Zoeren, C.M. Van Laser Engravable Single-Layer Flexographic Printing Element. U.S. Patent 5,798,202, 25 August 1998. [Google Scholar]

- Burberry, M.S.; Tutt, L.W.; Rowley, L.A. System for Direct Engraving of Flexographic Printing Members. U.S. Patent 8,941,028, 27 January 2015. [Google Scholar]

- The New Conti Laserline Flexographic Printing Plate. Available online: https://www.conti-laserline.com/pages/produkte/know-how/digital/digital_en.html (accessed on 3 February 2020).

- Birkan Laser Engraved Elastomer Printing Plates. Available online: https://www.birkan.de/pdf/en/BIRKAN_Laser-engraved-elastomer-printing-plates_en.pdf (accessed on 3 February 2020).

- Mogg, B.T.; Claypole, T.; Deganello, D.; Phillips, C. Flexographic printing of ultra-thin semiconductor polymer layers. Transl. Mater. Res. 2016. [Google Scholar] [CrossRef]

- Aktiprint L - Technigraf. Available online: http://en.technigraf.de/portfolio/aktiprint-l/ (accessed on 3 February 2020).

- Tomašegović, T. Functional Model of Photopolymer Printing Plate. Ph.D. Thesis, University of Zagreb Faculty of Graphic Arts, Zagreb, Croatia, 2016. [Google Scholar]

- National Center for Biotechnology Information. 1-Methoxy-2-propanol, CID=7900. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/1-Methoxy-2-propanol (accessed on 3 February 2020).

- National Center for Biotechnology Information. PubChem Database. Isopropyl Alcohol, CID=3776. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Isopropyl-alcohol (accessed on 3 February 2020).

- Hansen, C.M. Hansen Solubility Parameters: A User’s Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Liu, J.; Zheng, X.J.; Tang, K.Y. Study on the gravimetric measurement of the swelling behaviors of polymer films. Rev. Adv. Mater. Sci. 2013, 33, 452–458. [Google Scholar]

- ISO 7619-1:2010 Rubber, Vulcanized or Thermoplastic—Determination of Indentation Hardness—Part 1: Durometer Method (Shore Hardness). Available online: https://www.iso.org/obp/ui/#iso:std:iso:48:-4:ed-1:v1:en (accessed on 3 February 2020).

- OCA Product Series. Available online: https://www.dataphysics-instruments.com/Downloads/OCA_EN.pdf?v=1.4 (accessed on 3 February 2020).

- Van Oss, C.J.; Giese, R.F.; Li, Z.; Murphy, K.; Norris, J.; Chaudhury, M.K.; Good, R.J. Contact Angle, Wettability and Adhesion; Mittal, K.L., Ed.; VSP: Utrecht, The Netherlands, 1993; pp. 269–284. [Google Scholar]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- IGT Testing Systems Pte Ltd. IGT Printability Tester F1. Available online: http://www.igt.com.sg/products/details/igt-printability-tester-f1-f1-basic-f1-uv-f1-corrugated-f1-100 (accessed on 3 February 2020).

- User Manual. Coating Thickness Gauge. SaluTron© D4/D5. Available online: https://www.salutron.de/fileadmin/redakteure/dokumente/Instruction-manual-SaluTron-D4-5.pdf (accessed on 3 February 2020).

- Poljaček, S.M.; Tomašegović, T.; Gojo, M. Influence of UV exposure of the surface and mechanical properties of flexographic printing plate. In Proceedings of the GRID 2012 Symposium, Novi Sad, Serbia, 15–16 November 2012; pp. 135–140. [Google Scholar]

- Abu-Abdeen, M.; Elamer, I. Mechanical and swelling properties of thermoplastic elastomer blends. Mater. Des. 2010, 31, 808–815. [Google Scholar] [CrossRef]

- Haseeb, A.S.M.A.; Jun, T.S.; Fazal, M.A.; Masjuki, H.H. Degradation of physical properties of different elastomers upon exposure to palm biodiesel. Energy 2011, 36, 1814–1819. [Google Scholar] [CrossRef]

- Poljaček, S.M.; Tomašegović, T.; Leskovac, M.; Jakovljević, S. Neural network-based UV adjustment of the photopolymer surface for modification of coating properties printed in flexography. J. Coat. Technol. Res. 2019, 17, 271–284. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Shen, J. Effect of UV-irradiation on poly(vinyl chloride) modified by methyl methacrylate-butadiene-styrene copolymer. Polym. Degrad. Stab. 2005, 87, 527–533. [Google Scholar] [CrossRef]

- Simseker, O. Investigation of different solvents in flexographic printing ink’s effects to print quality on coated and uncoated paper. Asian J. Chem. 2011, 23, 2903–2906. [Google Scholar]

- Tomašegović, T.; Mahović Poljaček, S.; Leskovac, M. Customization of flexographic printing plates related to uvc-induced changes in the crosslinking degree. Acta Graph. J. Print. Sci. Graph. Commun. 2016, 27, 31–42. [Google Scholar]

- Apaya, R.P.; Bondí, M.; Price, S.L. The orientation of N-O=C and N-N hydrogen bonds in biological systems: How good is a point charge as a model for a hydrogen bonding atom? J. Comput. Aided. Mol. Des. 1997, 11, 479–490. [Google Scholar] [CrossRef] [PubMed]

- Satpati, A.K.; Bard, A.J. Preparation and characterization of carbon powder paste ultramicroelectrodes as tips for scanning electrochemical microscopy applications. Anal. Chem. 2012, 84, 9498–9504. [Google Scholar] [CrossRef] [PubMed]

- Vasconcelos, G.; Chagas, D.C.; Campos, D.C.; Dias, A.N. Covering with carbon black and thermal treatment by a CO2 laser surfaces of AISI 4340 steel. Mater. Sci. Forum 2012. [Google Scholar] [CrossRef]

- Li, Z.H.; Zhang, J.; Chen, S.J. Effects of carbon blacks with various structures on vulcanization and reinforcement of filled ethylene-propylene-diene rubber. Exp. Polym. Lett. 2008, 2, 695–704. [Google Scholar] [CrossRef]

- Deflorian, F.; Fedrizzi, L.; Rossi, S. Electrochemical Impedance Spectroscopy and Fourier Transform Infrared Spectroscopy of Natural and Accelerated Weathering of Organic Coatings. Corrosion 1998. [Google Scholar] [CrossRef]

| δd (J/cm3)1/2 | δp (J/cm3)1/2 | δh (J/cm3)1/2 | |

|---|---|---|---|

| Methoxypropanol | 15.6 | 7.2 | 13.6 |

| 2-propanol (IPA) | 15.8 | 6.1 | 16.4 |

| Polywash: | - | - | - |

| 4-hydroxy-4-methylpentan-2-one | 7.7 | 4.0 | 5.3 |

| Butyl cellosolve | 16.0 | 7.6 | 12.3 |

| Photopolymer Printing Plate | |||||||

|---|---|---|---|---|---|---|---|

| Solvent | UV Treatment | Hardness (Shore A) | SFE (mN/m) | Max. Normalized Degree of Swelling (%) | Line Width (mm) | Printed Ink Film Thickness (µm) | |

| 0.2 Positive | 0.2 Negative | ||||||

| Methoxy-propanol | 10× | 73.64 | 30.51 | 5.24 | 341.53 | 181.63 | 3.95 |

| 20× | 73.56 | 27.62 | 5.72 | 344.90 | 178.73 | 4.05 | |

| 30× | 73.70 | 33.81 | 4.95 | 355.10 | 178.60 | 1.15 | |

| 2-propanol (IPA) | 10× | 73.95 | 28.24 | 1.63 | 349.63 | 186.53 | 4.50 |

| 20× | 76.85 | 36.15 | 1.66 | 343.60 | 185.07 | 2.60 | |

| 30× | 76.83 | 36.76 | 1.17 | 343.03 | 184.80 | 3.45 | |

| Polywash | 10× | 73.41 | 25.03 | 1.92 | 288.37 | 176.00 | 4.15 |

| 20× | 75.00 | 32.70 | 2.08 | 285.97 | 187.03 | 2.40 | |

| 30× | 75.44 | 30.13 | 1.22 | 284.57 | 196.00 | 1.90 | |

| EPDM Printing Plate | |||||||

|---|---|---|---|---|---|---|---|

| Solvent | UV Treatment | Hardness (Shore A) | SFE (mN/m) | Max. Normalized Degree of Swelling (%) | Line Width (mm) | Printed Ink Film Thickness (µm) | |

| 0.2 Positive | 0.2 Negative | ||||||

| Methoxy-propanol | 0× | 70.12 | 20.10 | 0.24 | 288.23 | 197.7 | 3.60 |

| 10× | 72.70 | 14.86 | 0.25 | 292.60 | 198.8 | 3.75 | |

| 20× | 72.71 | 15.87 | 0.34 | 293.73 | 194.00 | 3.65 | |

| 30× | 72.67 | 19.53 | 0.23 | 288.27 | 195.93 | 3.40 | |

| 2-propanol (IPA) | 0× | 69.71 | 11.35 | −0.10 | 288.90 | 202.67 | 4.15 |

| 10× | 72.53 | 23.43 | −0.05 | 291.32 | 197.90 | 1.90 | |

| 20× | 72.82 | 23.60 | −0.07 | 285.30 | 198.67 | 2.20 | |

| 30× | 73.28 | 23.99 | −0.09 | 282.67 | 203.87 | 2.30 | |

| Polywash | 0× | 69.68 | 14.45 | 0.24 | 292.57 | 200.93 | 3.70 |

| 10× | 72.76 | 14.96 | 0.47 | 290.63 | 199.43 | 3.75 | |

| 20× | 72.77 | 12.44 | 0.42 | 288.60 | 197.20 | 4.00 | |

| 30× | 72.70 | 12.40 | 0.43 | 284.57 | 197.87 | 4.15 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomašegović, T.; Mahović Poljaček, S.; Strižić Jakovljević, M.; Urbas, R. Effect of the Common Solvents on UV-Modified Photopolymer and EPDM Flexographic Printing Plates and Printed Ink Films. Coatings 2020, 10, 136. https://doi.org/10.3390/coatings10020136

Tomašegović T, Mahović Poljaček S, Strižić Jakovljević M, Urbas R. Effect of the Common Solvents on UV-Modified Photopolymer and EPDM Flexographic Printing Plates and Printed Ink Films. Coatings. 2020; 10(2):136. https://doi.org/10.3390/coatings10020136

Chicago/Turabian StyleTomašegović, Tamara, Sanja Mahović Poljaček, Maja Strižić Jakovljević, and Raša Urbas. 2020. "Effect of the Common Solvents on UV-Modified Photopolymer and EPDM Flexographic Printing Plates and Printed Ink Films" Coatings 10, no. 2: 136. https://doi.org/10.3390/coatings10020136

APA StyleTomašegović, T., Mahović Poljaček, S., Strižić Jakovljević, M., & Urbas, R. (2020). Effect of the Common Solvents on UV-Modified Photopolymer and EPDM Flexographic Printing Plates and Printed Ink Films. Coatings, 10(2), 136. https://doi.org/10.3390/coatings10020136