A Method for Evaluating the Impact Wear Behavior of Multilayer TiN/Ti Coating

Abstract

:1. Introduction

2. Materials and Methods

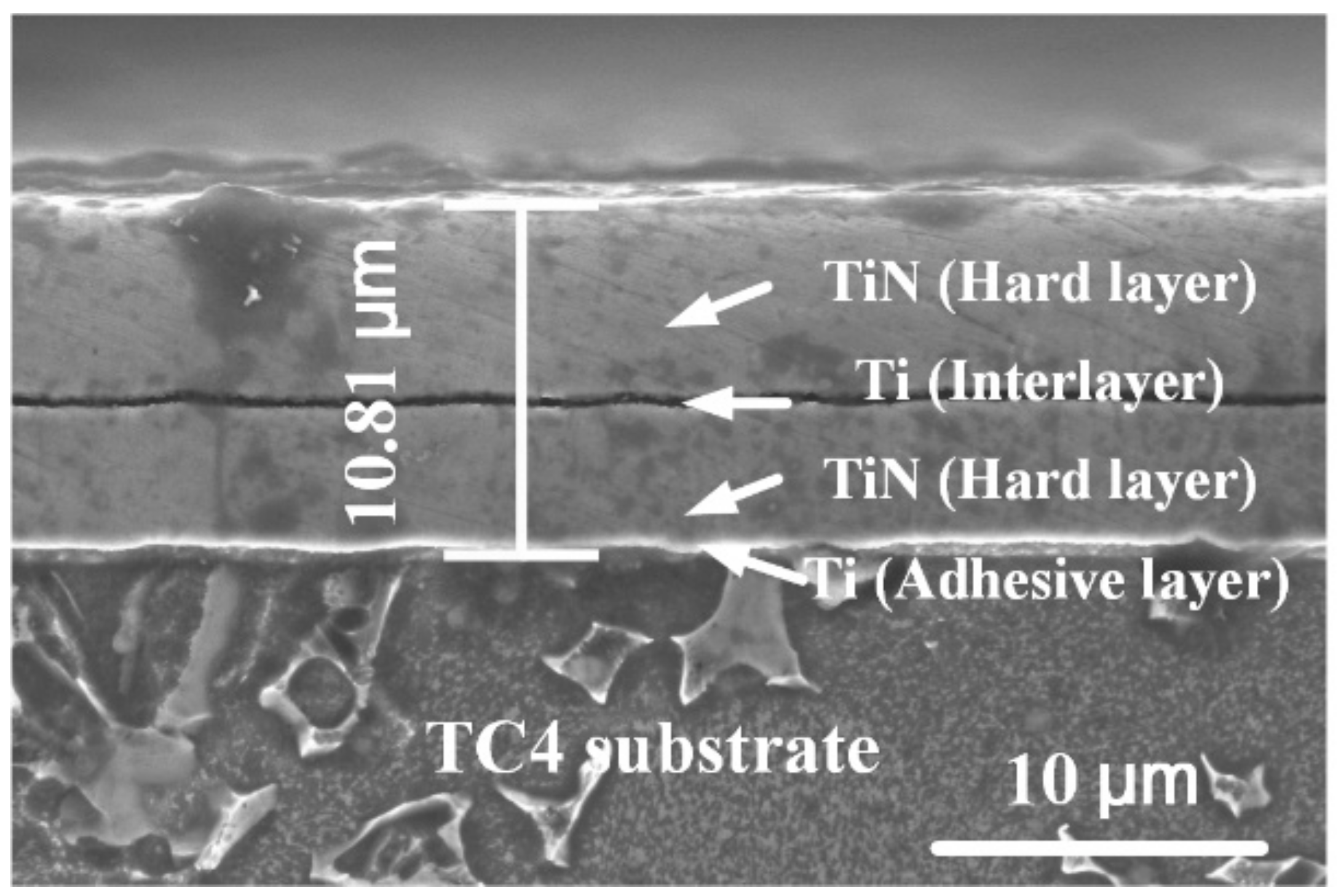

2.1. Coatings Preparation

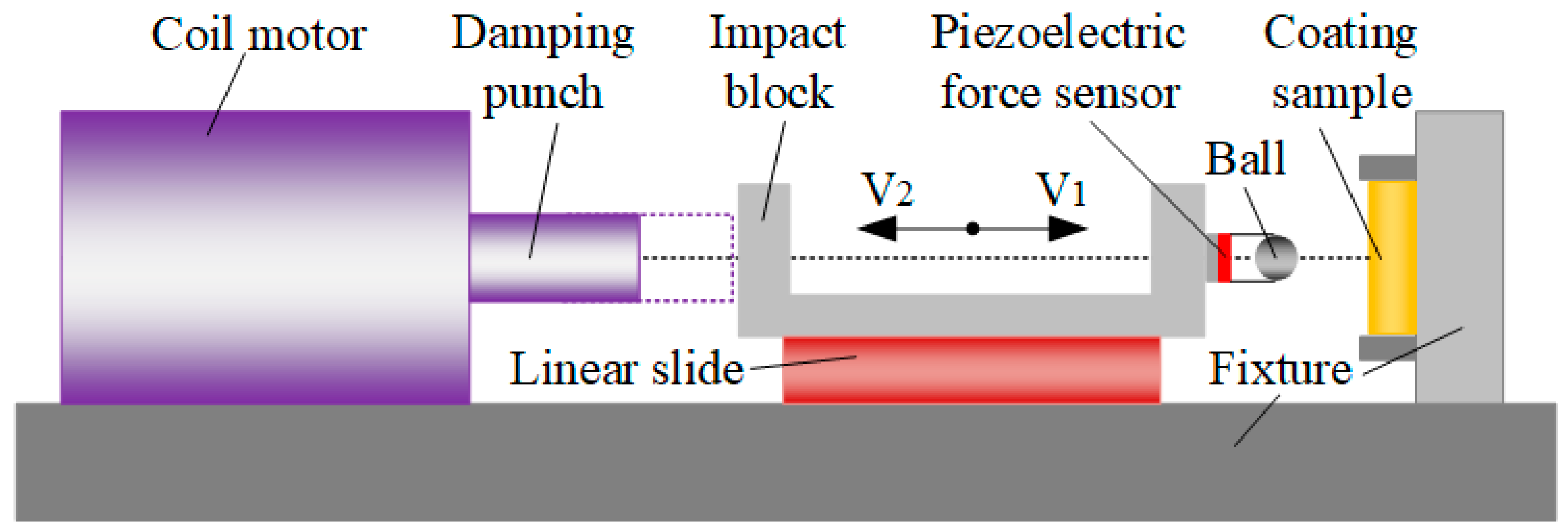

2.2. Impact Wear Experiment

2.3. Numerical Simulation

3. Results and Discussion

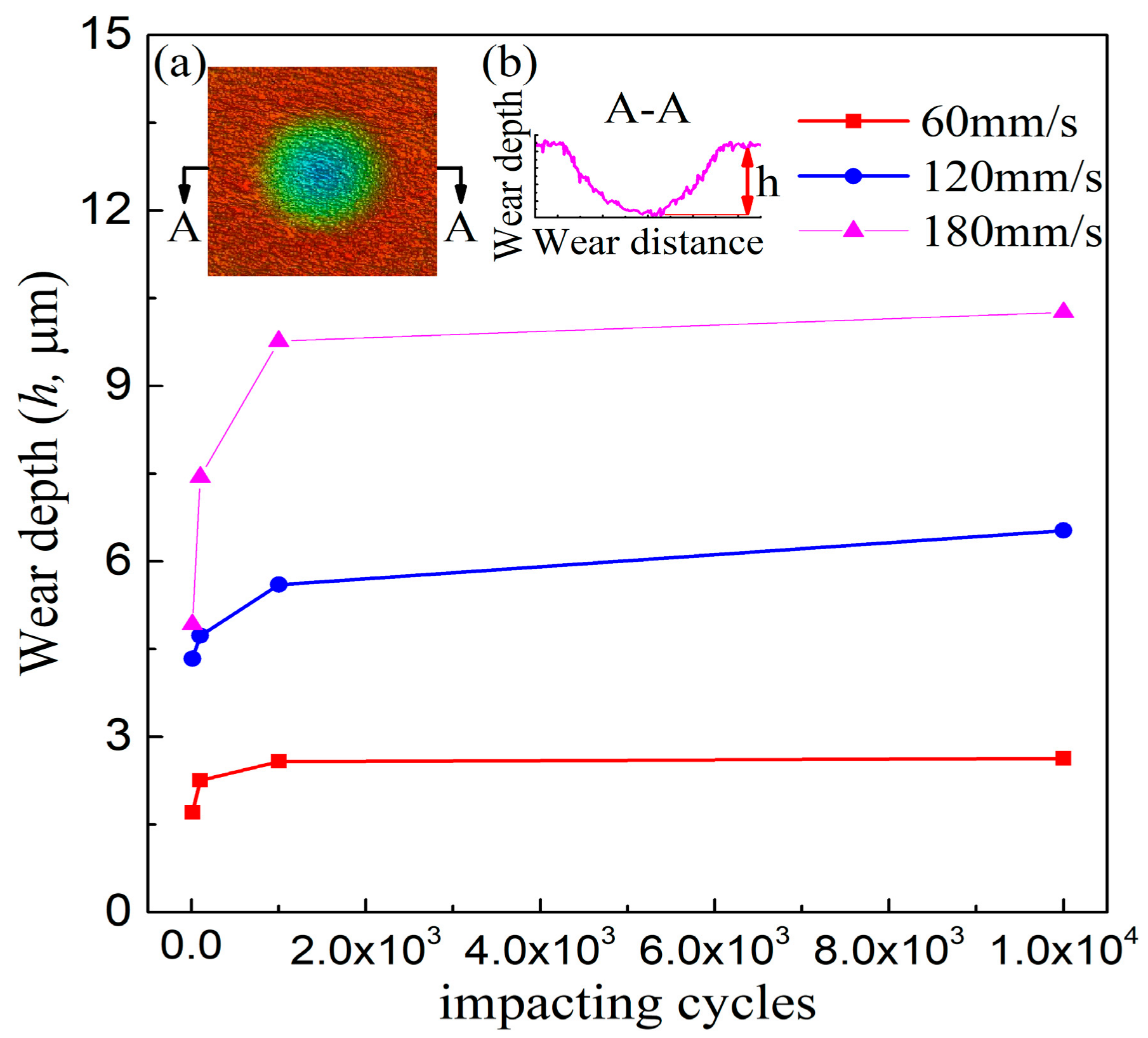

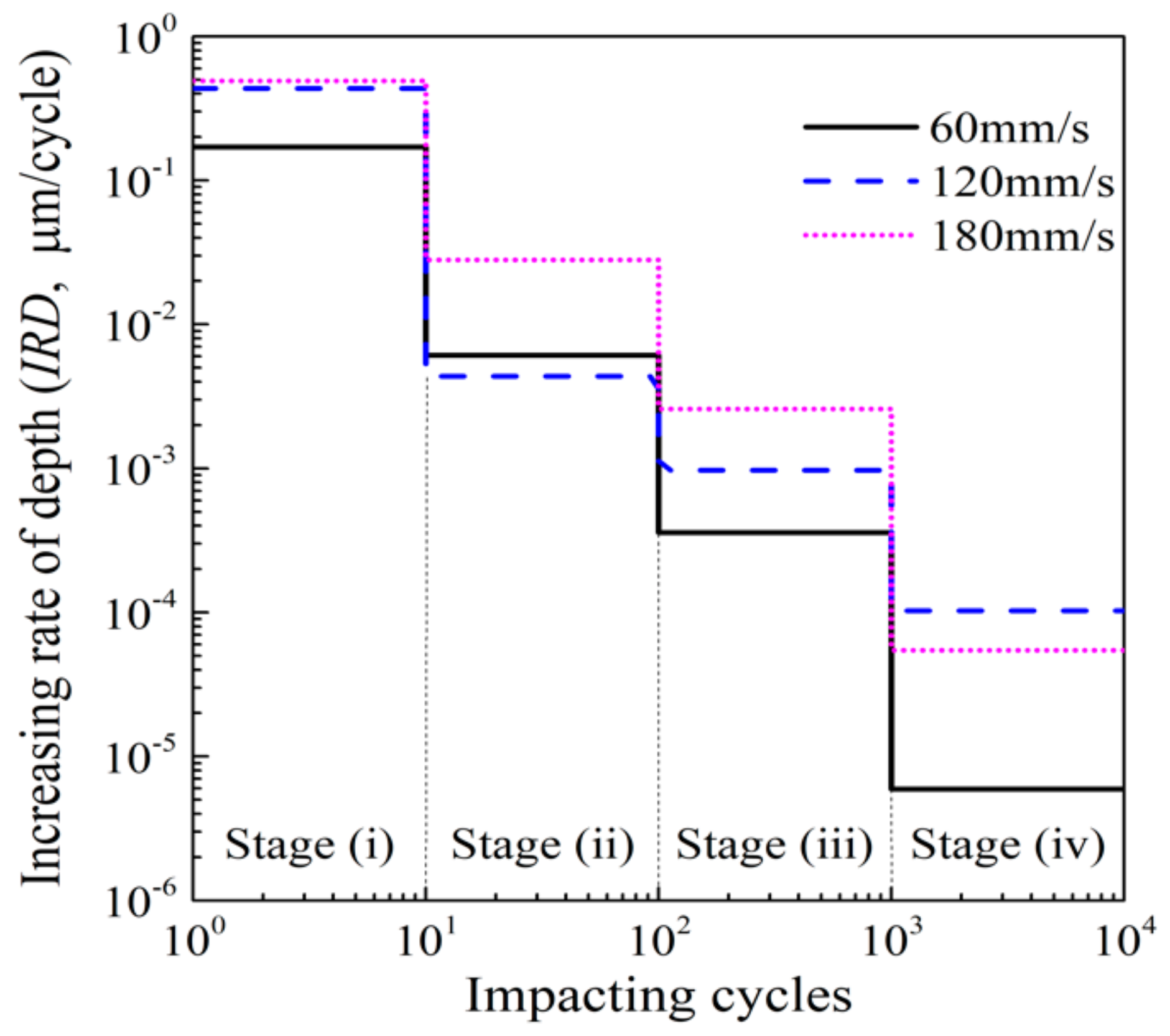

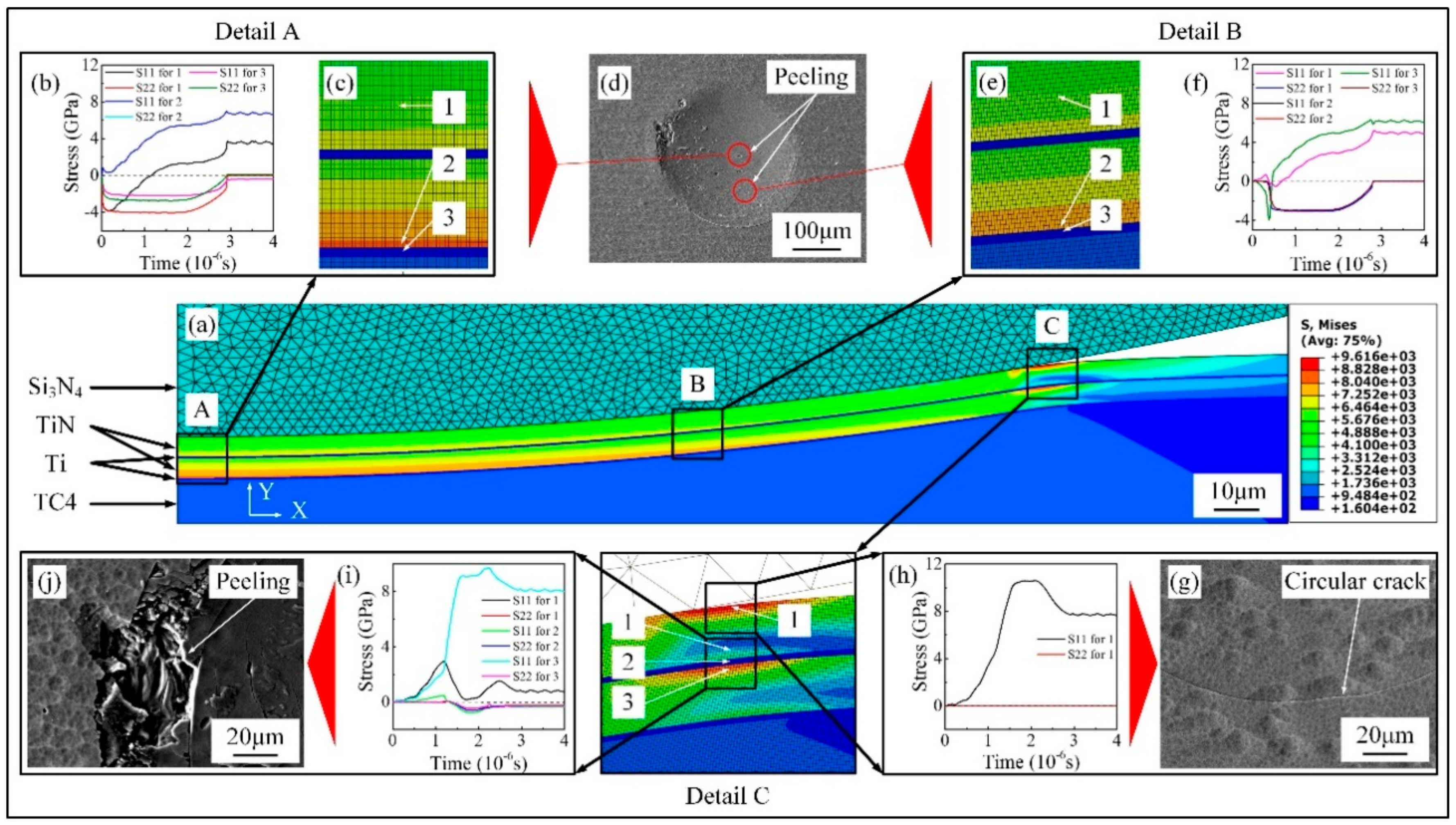

3.1. Dynamic Mechanical Response

3.2. Failure Mechanism

4. Conclusions

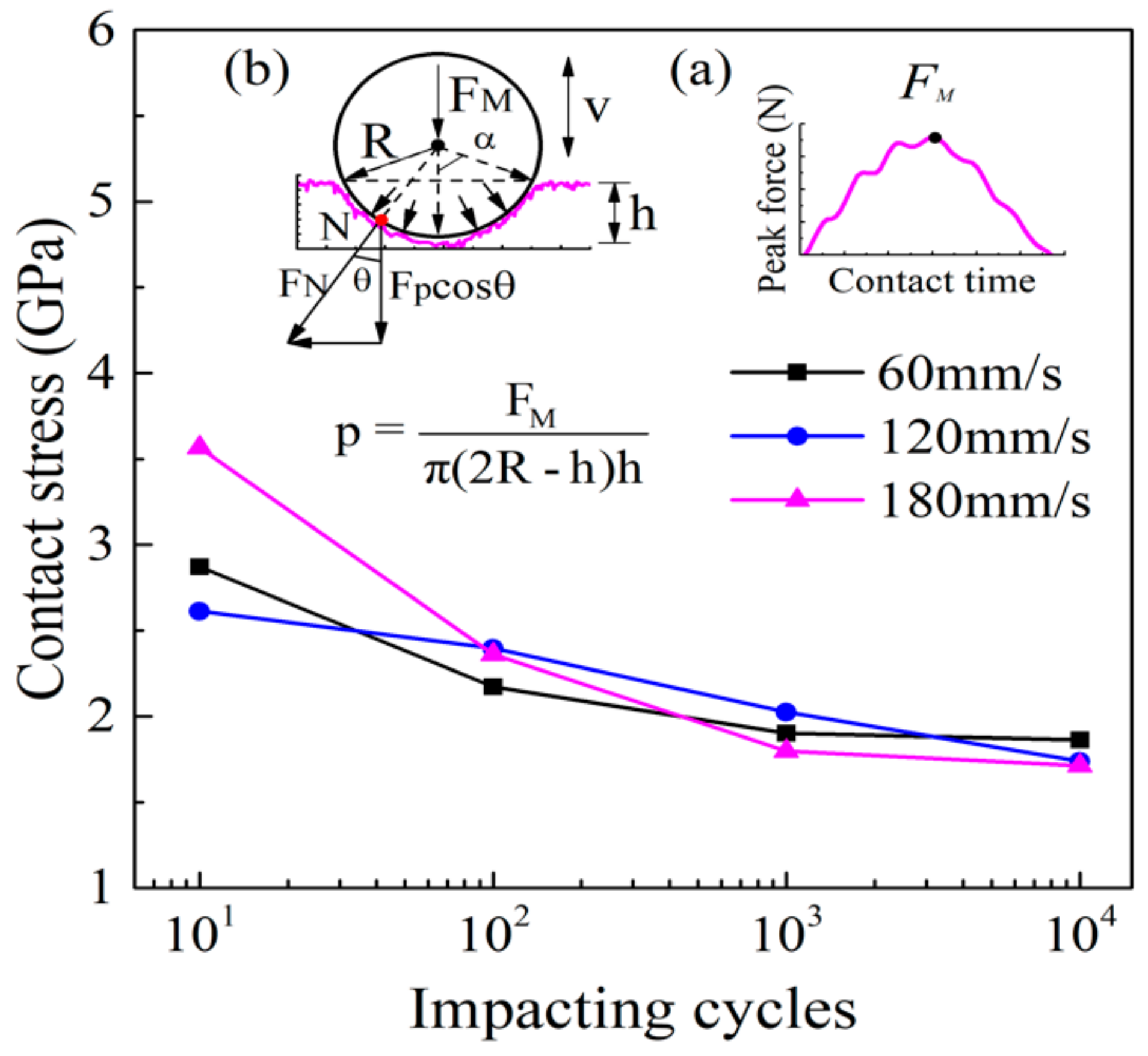

- The wear depth of coatings increases with impact cycles at a gradually decreasing rate. The rate of depth increase is below 10−4 μm/cycle after 103 cycles due to the decreasing contact stress with the increased impact cycles.

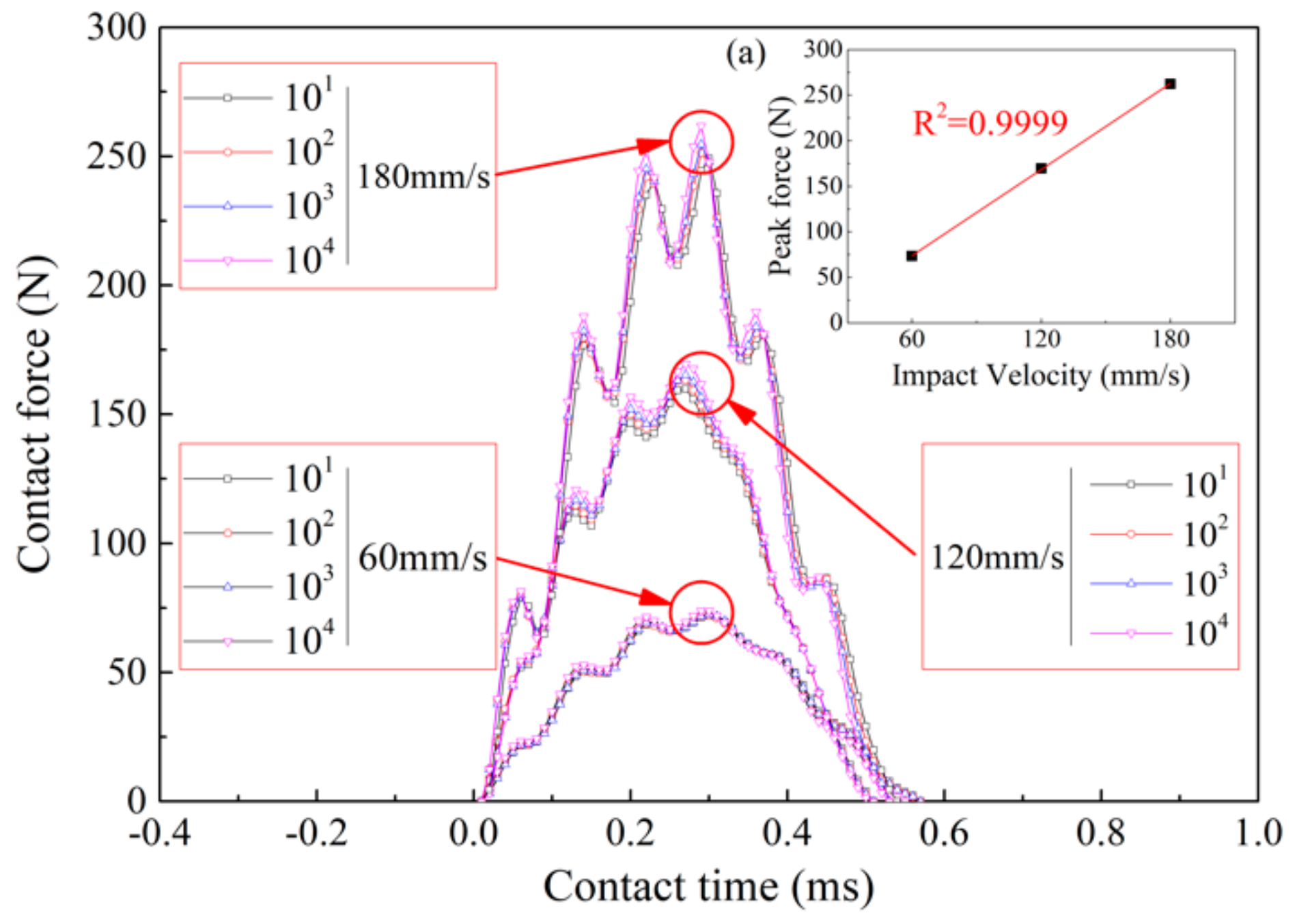

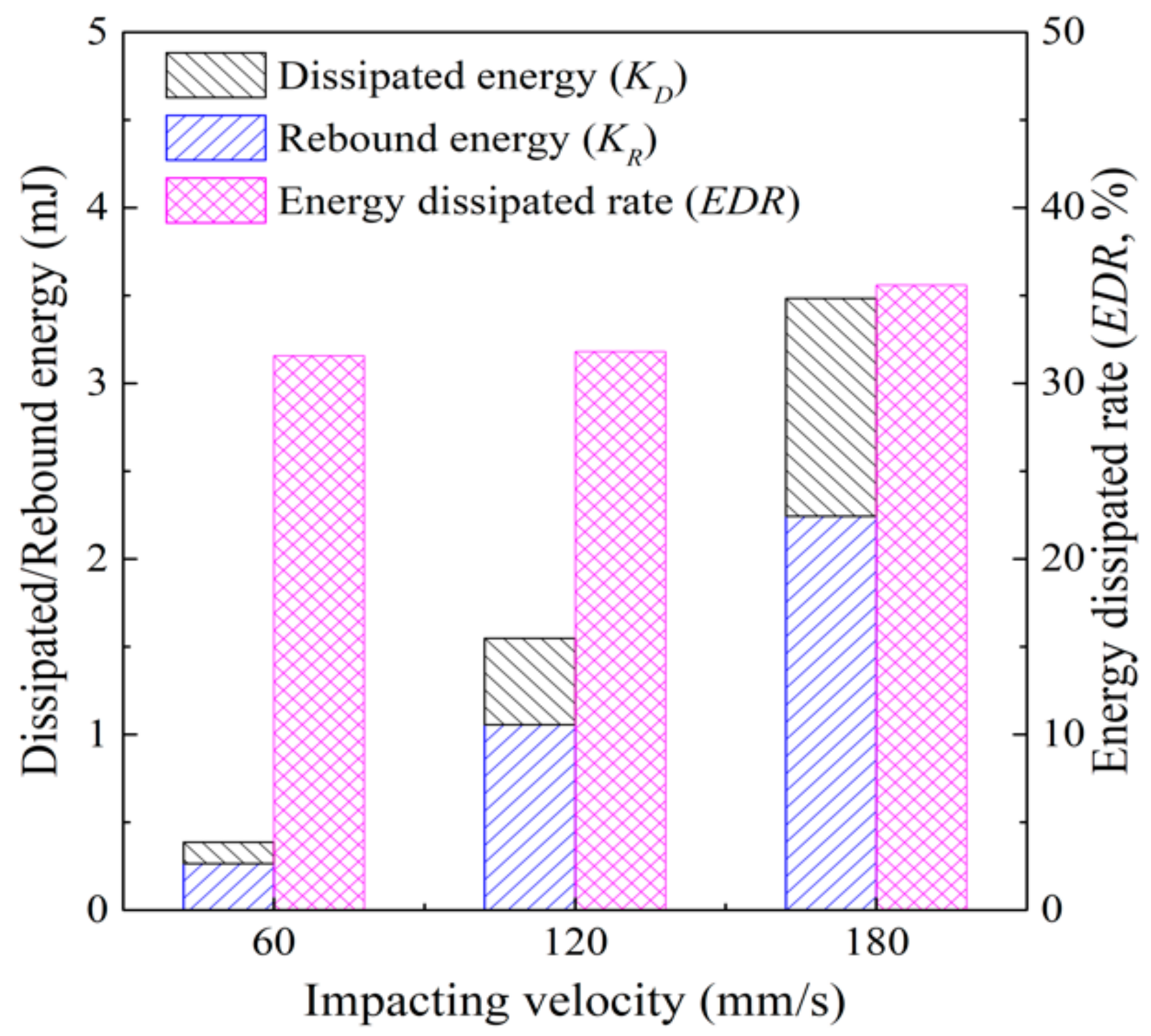

- The contact time keeps almost constant (about 0.55 ms) during a single impact under different impact velocities and cycles. Peak forces also remain unchanged with increasing cycles under the same velocity and increase with impact velocities linearly, reaching a maximum value of 262.26 N at 180 mm/s. The energy dissipated rate (EDR) remains constant with different impact cycles and increases smoothly with impact velocities from 31.58% at 60 mm/s to 35.59% at 180 mm/s.

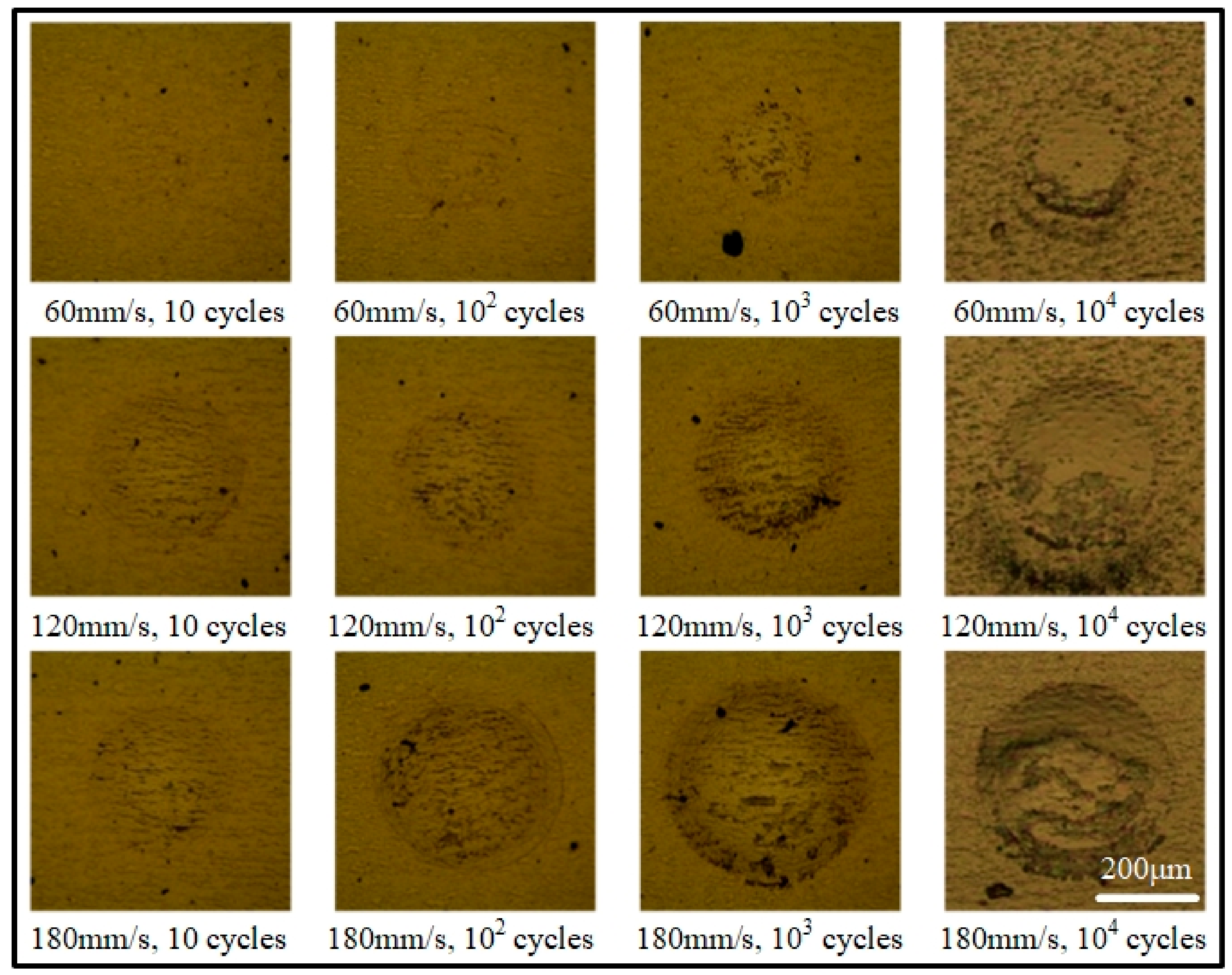

- Two failure mechanisms are found in the impact zones of the coating. These are peeling and circular cracks. Peelings are induced by cycling high stress gradients in hard layers and interfaces between hard layers and interlayer/adhesive layers. Circular cracks are caused by cycling tensile stresses in the form of fatigue at the edge of impacted pits.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Proudhon, H.; Savkova, J.; Basseville, S.; Guipont, V.; Jeandin, M.; Cailletaud, G. Experimental and numerical wear studies of porous Reactive Plasma Sprayed Ti–6Al–4V/TiN composite coating. Wear 2014, 311, 159–166. [Google Scholar] [CrossRef]

- Yang, Q.; Mckellar, R. Nanolayered CrAlTiN and Multilayered CrAlTiN-AlTiN coatings for solid particle erosion protection. Tribol. Int. 2015, 83, 12–20. [Google Scholar] [CrossRef]

- Borawski, B. Multilayer Erosion Resistant Coatings for the Protection of Aerospace Components; Pennsylvania State University: Centre County, PA, USA, 2011. [Google Scholar]

- Zhu, M.; Cai, Z.; Lin, X.Z.; Ren, P.D.; Tan, J.; Zhou, Z. Fretting wear behaviour of ceramic coating prepared by micro-arc oxidation on Al–Si alloy. Wear 2007, 263, 472–480. [Google Scholar] [CrossRef]

- Liu, W.; Chu, Q.; He, R.; Huang, M.; Wu, H.; Jiang, Q.; Chen, J.; Deng, X.; Wu, S. Preparation and properties of TiAlN coatings on silicon nitride ceramic cutting tools. Ceram. Int. 2018, 44, 2209–2215. [Google Scholar] [CrossRef]

- Knotek, O.; Bosserhoff, B.; Schrey, A.; Leyendecker, T.; Lemmer, O.; Esser, S. A new technique for testing the impact load of thin films: The coating impact test. In Metallurgical Coatings and Thin Films 1992; Elsevier: Amsterdam, The Netherlands, 1992; pp. 102–107. [Google Scholar]

- Bantle, R.; Matthews, A. Investigation into the impact wear behaviour of ceramic coatings. Surf. Coat. Technol. 1995, 74–75, 857–868. [Google Scholar] [CrossRef]

- Lawes, S.D.A.; Hainsworth, S.V.; Fitzpatrick, M.E. Impact wear testing of diamond-like carbon films for engine valve-tappet surfaces. Wear 2010, 268, 1303–1308. [Google Scholar] [CrossRef]

- Abdollah, M.F.B.; Yamaguchi, Y.; Akao, T.; Inayoshi, N.; Miyamoto, N.; Tokoroyama, T.; Umehara, N. Deformation–wear transition map of DLC coating under cyclic impact loading. Wear 2012, 274–275, 435–441. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, T.; Nie, X. Wear failure behaviour of titanium-based oxide coatings on a titanium alloy under impact and sliding forces. J. Alloy. Compd. 2013, 578, 336–344. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Charalampous, P.; Skordaris, G.; Dimofte, F.; Ene, N.M.; Ehinger, R.; Gardner, S.; Modrzejewski, B.S.; Fetty, J.R. Fatigue and adhesion characterization of DLC coatings on steel substrates by perpendicular and inclined impact tests. Surf. Coat. Technol. 2015, 275, 207–213. [Google Scholar] [CrossRef]

- Xu, W.; He, G.; Cai, Z.; Liao, B.; Cao, X.; He, W. Damage analysis of TiN/Ti coatings under cycling impact with hard particles. China Surf. Eng. 2017, 30, 28–35. (In Chinese) [Google Scholar]

- Lin, Y.; Cai, Z.; Chen, Z.; Qian, H.; Tang, L.; Xie, Y.; Zhu, M. Influence of diameter–thickness ratio on alloy Zr-4 tube under low-energy impact fretting wear. Mater. Today Commun. 2016, 8, 79–90. [Google Scholar] [CrossRef] [Green Version]

- Hassani, S.; Klemberg-Sapieha, J.E.; Bielawski, M.; Beres, W.; Martinu, L.; Balazinski, M. Design of hard coating architecture for the optimization of erosion resistance. Wear 2008, 265, 879–887. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Z.; He, W.; Liao, B.; He, G.; Cao, X.; Li, Y. Damage evolution and mechanism of TiN/Ti multilayer coatings in sand erosion condition. Surf. Coat. Technol. 2018, 353, 210–220. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Z. An investigation of impact wear and wear mechanism of TC4 alloy. Lubr. Eng. 2009, 34, 1–4. (In Chinese) [Google Scholar]

- Cai, Z.; Guan, H.; Chen, Z.; Qian, H.; Tang, L.; Zhou, Z.-R.; Zhu, M.-H. Impact fretting wear behavior of 304 stainless steel thin-walled tubes under low-velocity. Tribol. Int. 2017, 105, 219–228. [Google Scholar] [CrossRef]

- Uetz, H.; Föhl, J. Wear as an energy transformation process. Wear 1978, 49, 253–264. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Maliaris, G.; Makrimallakis, S. Strain rate effect on the fatigue failure of thin PVD coatings: An investigation by a novel impact tester with adjustable repetitive force. Int. J. Fatigue 2012, 44, 89–97. [Google Scholar] [CrossRef]

| Parameters | Injection Voltage (kV) | Injection Dose (cm−2) | Arc Current (A) | Bias Voltage (V) | Duty Cycle (%) | Beam (mA) | N2 Flux (sccm) | Working Pressure (Pa) |

|---|---|---|---|---|---|---|---|---|

| 1st Ti+ injection | 8 | 3 × 1016 | / | / | / | / | / | 3 × 10−3 |

| 2nd Ti+ injection | 12 | 3 × 1016 | / | / | / | / | / | 3 × 10−3 |

| Ti layer | / | / | 100 | −200 | 90 | 550 | 0 | 3 × 10−3 |

| TiN layer | / | / | 100 | −200 | 90 | 600 | 22 | 8 × 10−3 |

| Impact Velocity (mm/s) | Kinetic Energy (mJ) | Impact Cycle | |||

|---|---|---|---|---|---|

| 60 ± 0.364 | 0.39 ± 0.005 | 101 | 102 | 103 | 104 |

| 120 ± 0.991 | 1.55 ± 0.026 | 101 | 102 | 103 | 104 |

| 180 ± 1.164 | 3.48 ± 0.046 | 101 | 102 | 103 | 104 |

| Material | Ti6Al4V | Ti | TiN | Si3N4 |

|---|---|---|---|---|

| Density (kg/m3) | 4428 | 5000 | 5220 | 3200 |

| Elastic modulus (GPa) | 110 | 100 | 400 | - |

| Poisson’s ratio | 0.31 | 0.27 | 0.25 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.; Xu, W.; He, W. A Method for Evaluating the Impact Wear Behavior of Multilayer TiN/Ti Coating. Coatings 2020, 10, 132. https://doi.org/10.3390/coatings10020132

Cao X, Xu W, He W. A Method for Evaluating the Impact Wear Behavior of Multilayer TiN/Ti Coating. Coatings. 2020; 10(2):132. https://doi.org/10.3390/coatings10020132

Chicago/Turabian StyleCao, Xin, Weisheng Xu, and Weifeng He. 2020. "A Method for Evaluating the Impact Wear Behavior of Multilayer TiN/Ti Coating" Coatings 10, no. 2: 132. https://doi.org/10.3390/coatings10020132

APA StyleCao, X., Xu, W., & He, W. (2020). A Method for Evaluating the Impact Wear Behavior of Multilayer TiN/Ti Coating. Coatings, 10(2), 132. https://doi.org/10.3390/coatings10020132