Study on the Behavior of BOPP Film Treated by Corona Discharge

Abstract

1. Introduction

2. Experimental

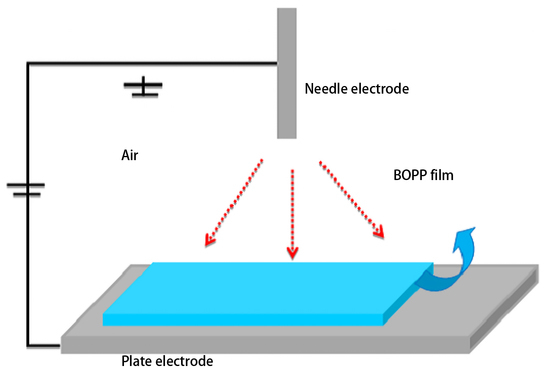

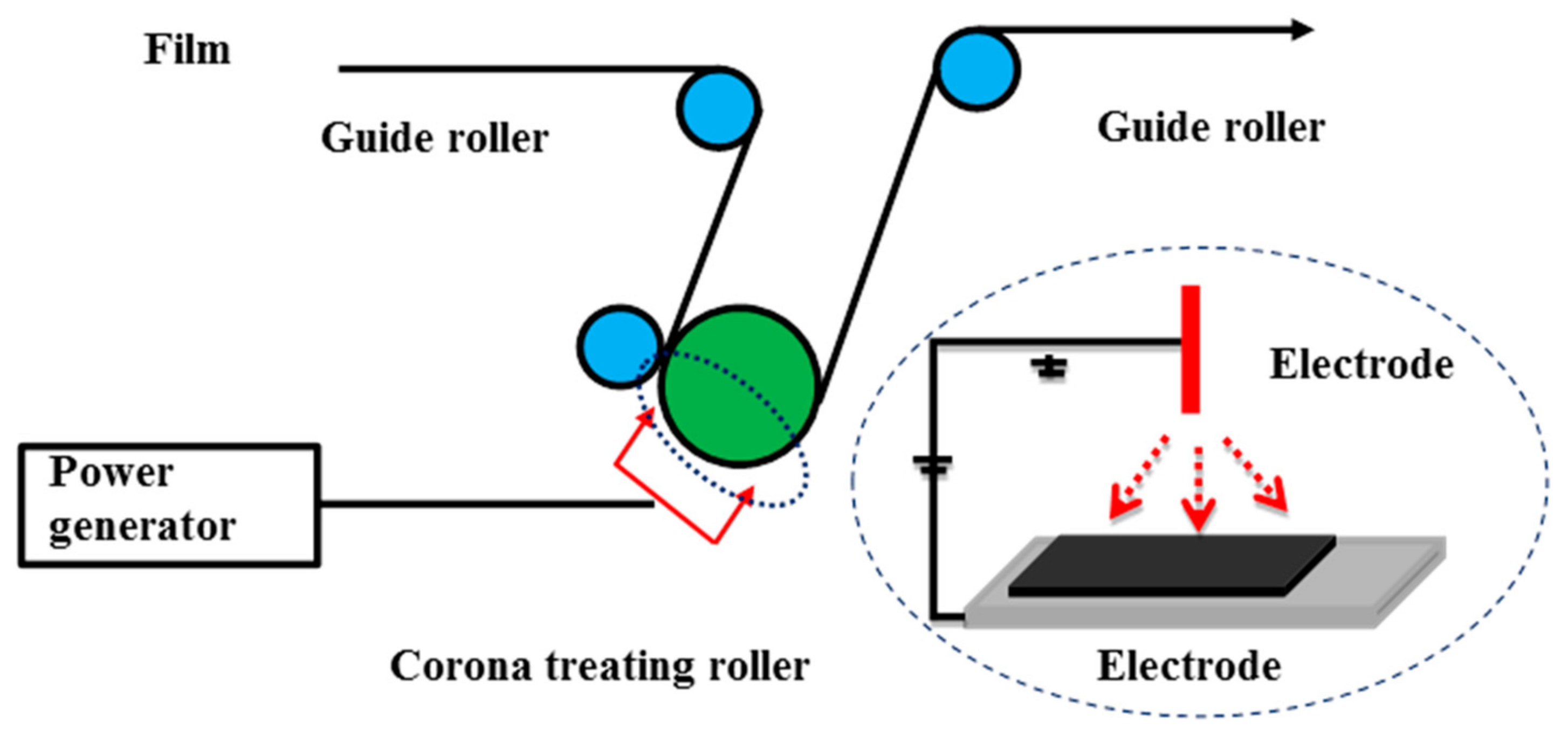

2.1. The Corona Discharge Treatment for BOPP Film

2.2. Characterization

3. Results and Discussion

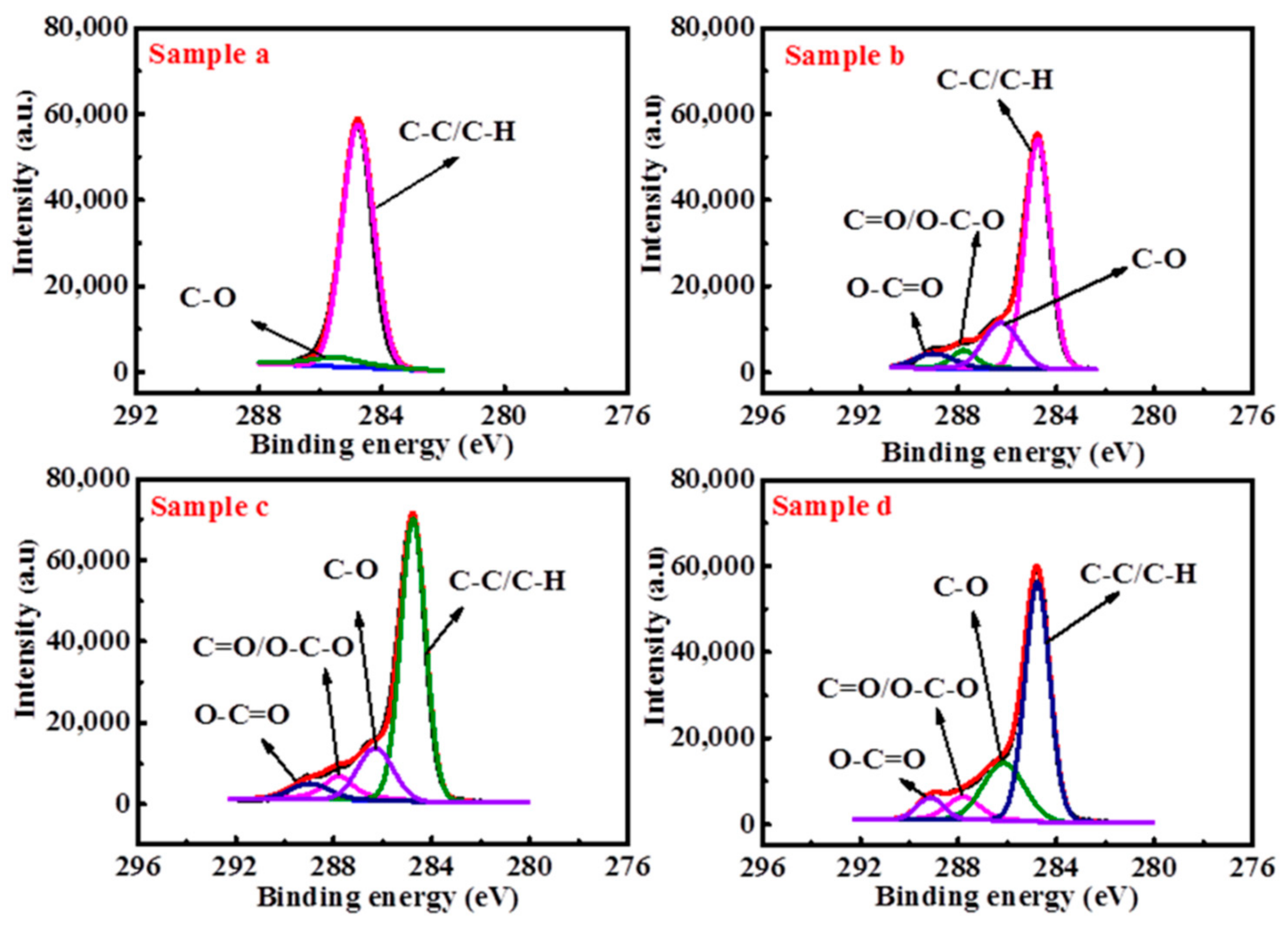

3.1. The Analysis of the Surface Chemical Structure of Corona BOPP Film

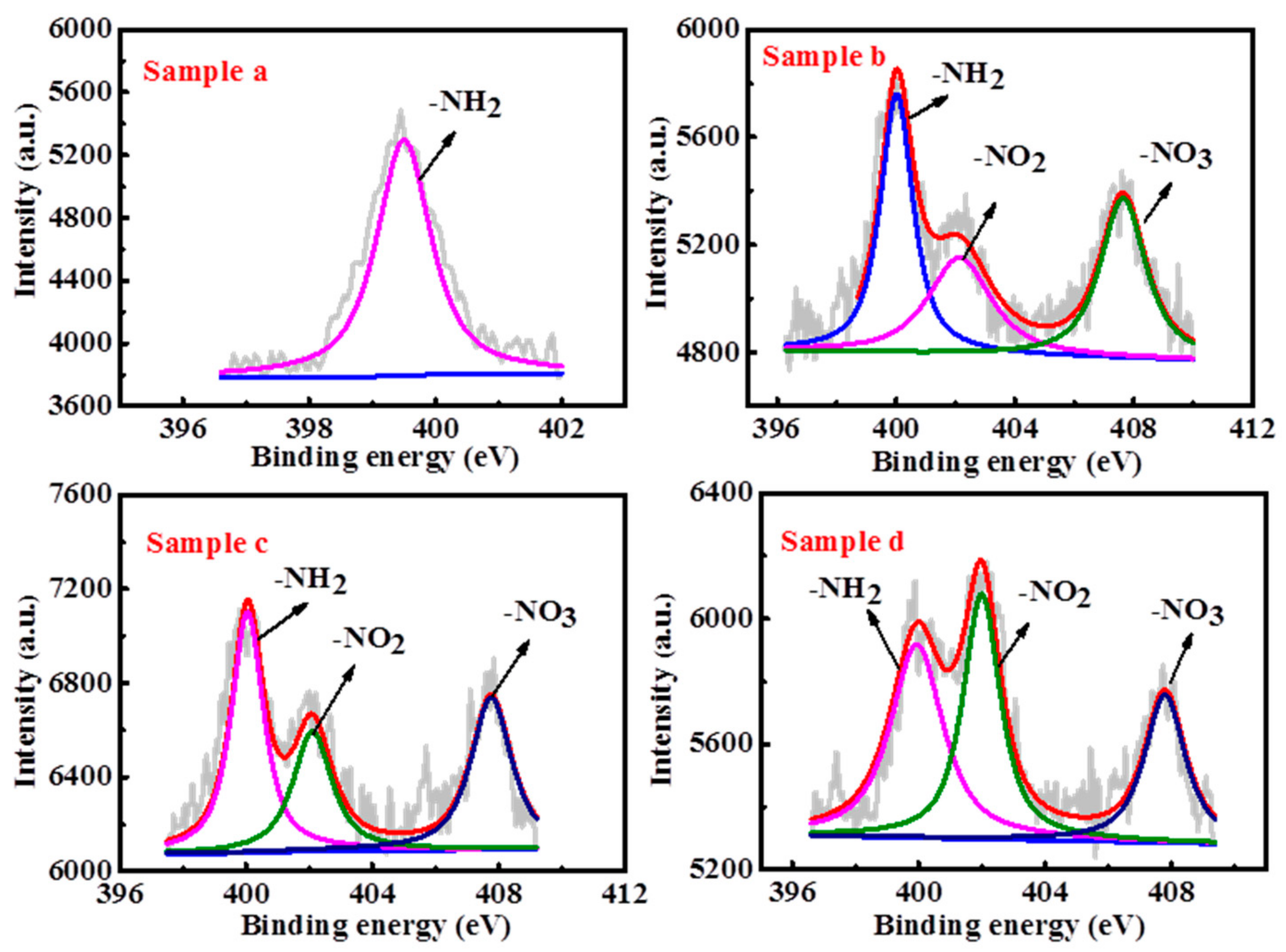

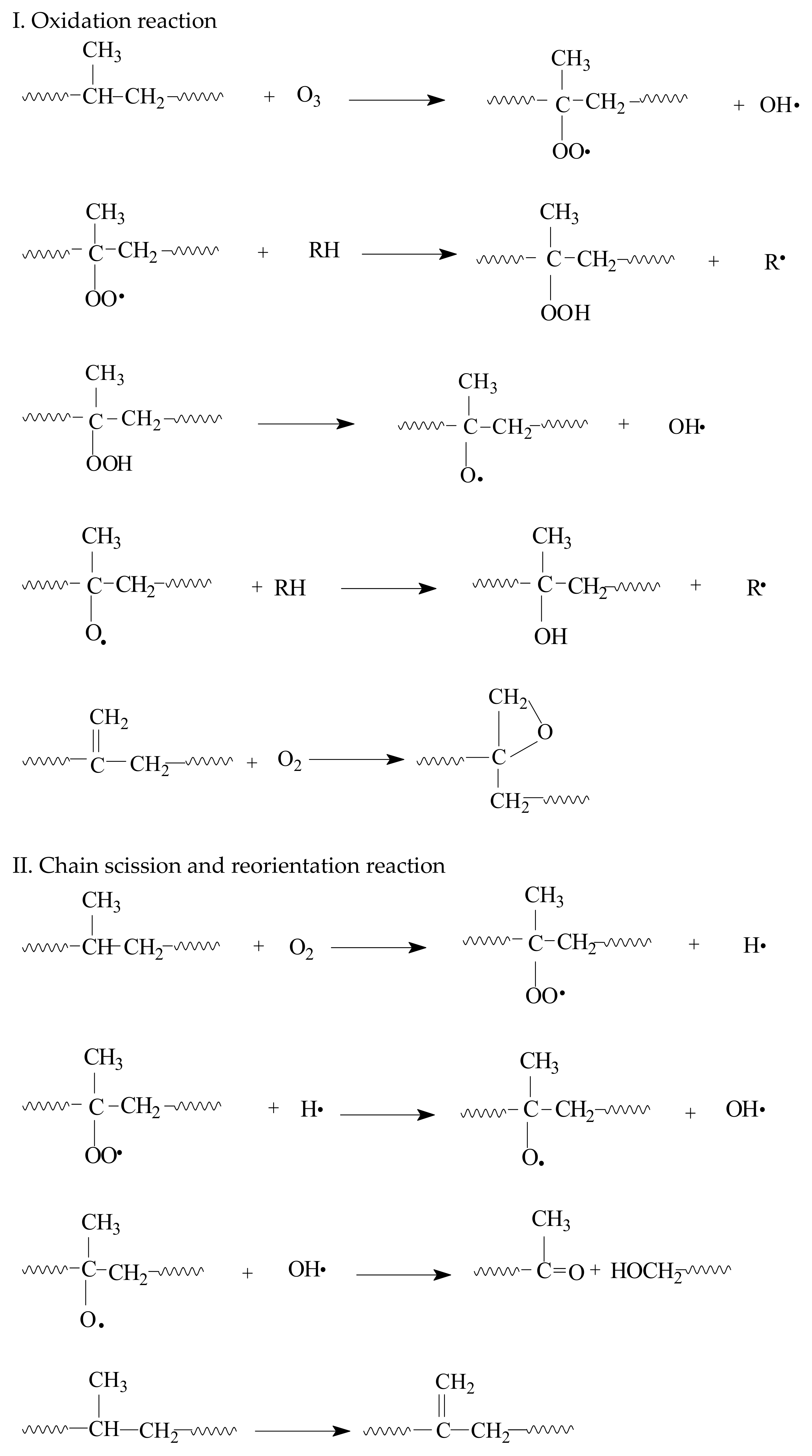

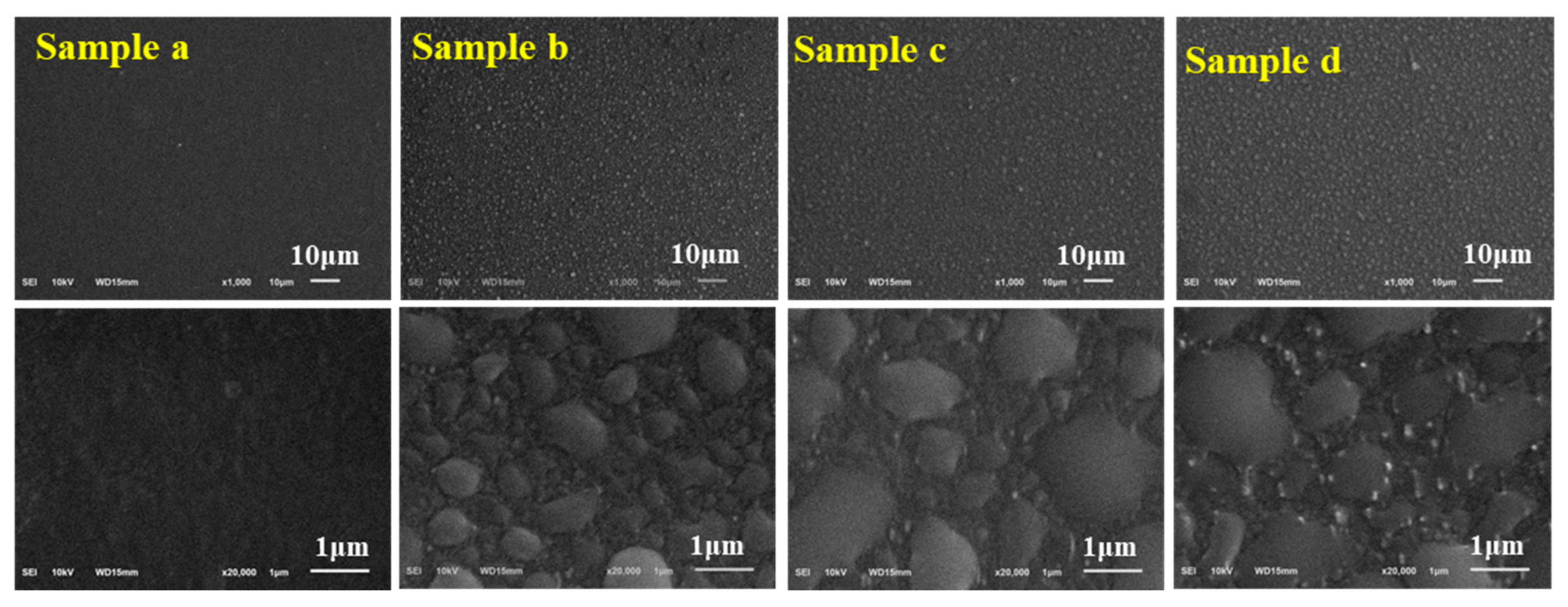

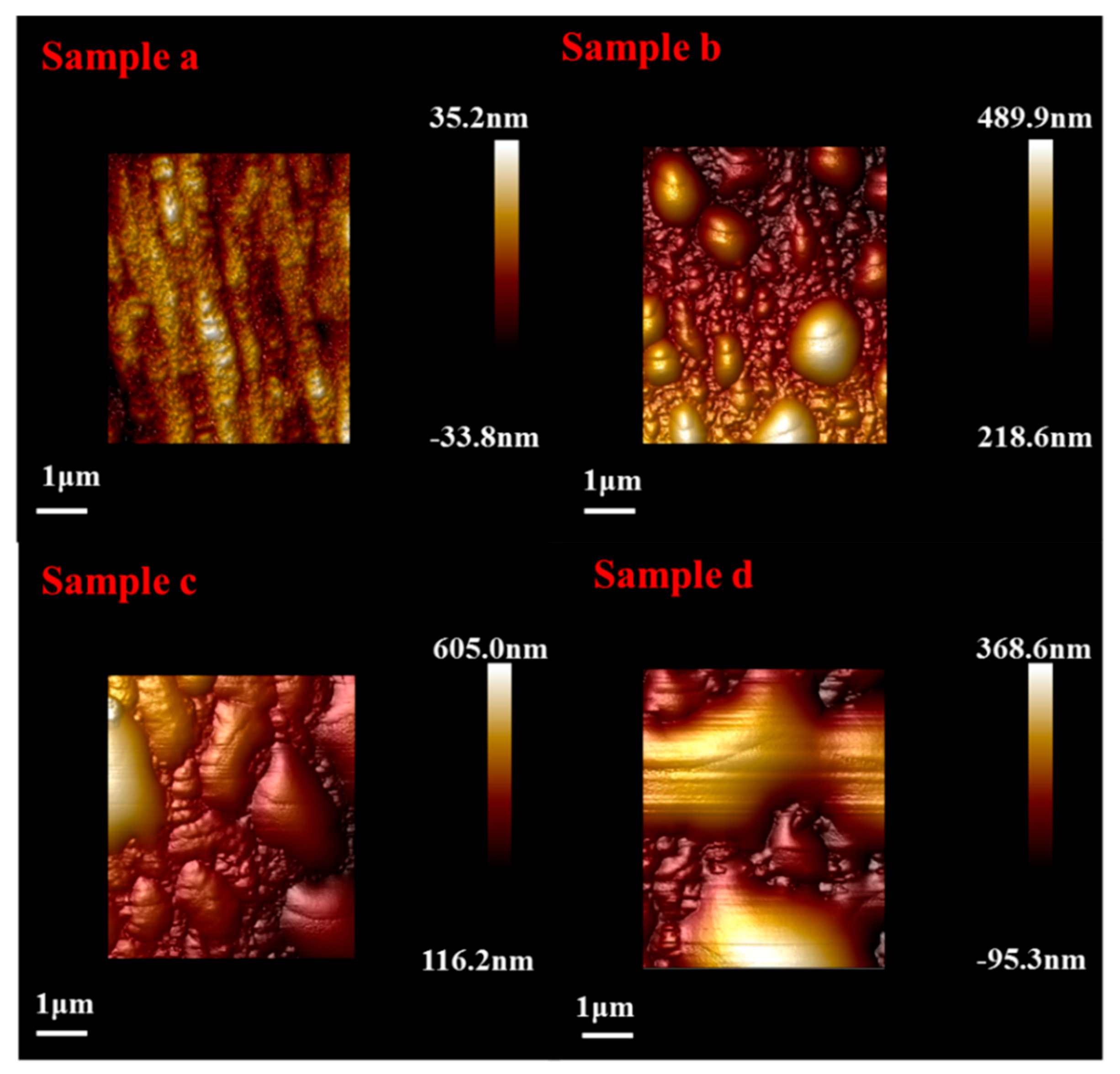

[29]. The absorption peak of 1110–1300 cm−1 belongs to ester group (C–O) [30]. The absorption peak at 1537–1858 cm−1 corresponds to carbonyl absorption peak [30], the absorption peak at 1350 cm−1 belongs to nitrate absorption peak, and the broad absorption peak at 3100–3600 cm−1 comes from the amino group and hydroxyl group absorption peak [31,32]. These new absorption peaks can be attributed to the crack of chemical bonds (e.g., methyl and methylene) on the surface of BOPP film, which are caused by corona discharge treatment and the formation of free radicals. The content of methyl and methylene of sample d in Figure 1C is significantly lower than that in sample a, which can also confirm that methyl and methylene are broken or decomposed. In the presence of nitrogen, oxygen, and ozone in the air, free radicals participate in a series of chemical reactions and polar functional groups containing oxygen are formed, such as aldehydes, ketones, carboxylic acids, carbonyl groups, hydroxyl groups, esters, etc. The detailed ATR-FTIR data is shown in Table 2.

[29]. The absorption peak of 1110–1300 cm−1 belongs to ester group (C–O) [30]. The absorption peak at 1537–1858 cm−1 corresponds to carbonyl absorption peak [30], the absorption peak at 1350 cm−1 belongs to nitrate absorption peak, and the broad absorption peak at 3100–3600 cm−1 comes from the amino group and hydroxyl group absorption peak [31,32]. These new absorption peaks can be attributed to the crack of chemical bonds (e.g., methyl and methylene) on the surface of BOPP film, which are caused by corona discharge treatment and the formation of free radicals. The content of methyl and methylene of sample d in Figure 1C is significantly lower than that in sample a, which can also confirm that methyl and methylene are broken or decomposed. In the presence of nitrogen, oxygen, and ozone in the air, free radicals participate in a series of chemical reactions and polar functional groups containing oxygen are formed, such as aldehydes, ketones, carboxylic acids, carbonyl groups, hydroxyl groups, esters, etc. The detailed ATR-FTIR data is shown in Table 2.3.2. The Analysis of Surface Morphology and Topology of Corona BOPP Film

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhou, T.Y.; Tsui, G.C.P.; Liang, J.Z.; Zou, S.Y.; Tang, C.Y.; Mišković-Stanković, V. Thermal properties and thermal stability of PP/MWCNT composites. Compos. Part B Eng. 2016, 90, 107–114. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, X. Isotactic polypropylene toughened with poly(acrylonitrile–butadiene–styrene): Compatibilizing role of maleic anhydride grafted polypropylene. Polym. Eng. Sci. 2019, 59, E317–E326. [Google Scholar] [CrossRef]

- Ota, Y.; Ito, S.; Kobayashi, M.; Kitade, S.; Sakata, K.; Tayano, T.; Nozaki, K. Crystalline isotactic polar polypropylene from the palladium-catalyzed copolymerization of propylene and polar monomers. Angew. Chem. Int. Ed. 2016, 55, 7505–7509. [Google Scholar] [CrossRef] [PubMed]

- Green, C.D.; Vaughan, A.S.; Stevens, G.C.; Pye, A.; Sutton, S.J.; Geussens, T.; Fairhurst, M.J. Thermoplastic cable insulation comprising a blend of isotactic polypropylene and a propylene-ethylene copolymer. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 639–648. [Google Scholar] [CrossRef]

- Xu, J.; Howard, M.J.; Mittal, V.; Bates, F.S. Block copolymer micelle toughened isotactic polypropylene. Macromolecules 2017, 50, 6421–6432. [Google Scholar] [CrossRef]

- Zhang, Z.-C.; Deng, L.; Lei, J.; Li, Z.-M. Isotactic polypropylene reinforced atactic polypropylene by formation of shish-kebab superstructure. Polymer 2015, 78, 120–133. [Google Scholar] [CrossRef]

- Yang, C.; Zhe, X.; Zhang, M.; Wang, M.; Wu, G. Radiation effects on the foaming of atactic polypropylene with supercritical carbon dioxide. Radiat. Phys. Chem. 2017, 131, 35–40. [Google Scholar] [CrossRef]

- He, M.; Wang, Q.; Zhao, W.; Zhao, C. A substrate-independent ultrathin hydrogel film as an antifouling and antibacterial layer for a microfiltration membrane anchored via a layer-by-layer thiol–ene click reaction. J. Mater. Chem. B 2018, 6, 3904–3913. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Bai, Y.; Cheng, B.; Liu, W. Adhesion properties of atactic polypropylene/acrylate blend copolymer and its adhesion mechanism for untreated polypropylene materials. Int. J. Adhes. Adhes. 2018, 80, 7–15. [Google Scholar] [CrossRef]

- Tsou, C.-H.; Yao, W.-H.; Hung, W.-S.; Suen, M.-C.; De Guzman, M.; Chen, J.; Tsou, C.-Y.; Wang, R.Y.; Chen, J.-C.; Wu, C.-S. Innovative plasma process of grafting methyl diallyl ammonium salt onto polypropylene to impart antibacterial and hydrophilic surface properties. Ind. Eng. Chem. Res. 2018, 57, 2537–2545. [Google Scholar] [CrossRef]

- Ščetar, M.; Kurek, M.; Režek Jambrak, A.; Debeaufort, F.; Galić, K. Influence of high power ultrasound on physical–chemical properties of polypropylene films aimed for food packaging: Barrier and contact angle features. Polym. Int. 2017, 66, 1572–1578. [Google Scholar] [CrossRef]

- Siracusa, V.; Ingrao, C. Correlation amongst gas barrier behaviour, temperature and thickness in BOPP films for food packaging usage: A lab-scale testing experience. Polym. Test. 2017, 59, 277–289. [Google Scholar] [CrossRef]

- Leelaphiwat, P.; Auras, R.A.; Burgess, G.J.; Harte, J.B.; Chonhenchob, V. Preliminary quantification of the permeability, solubility and diffusion coefficients of major aroma compounds present in herbs through various plastic packaging materials. J. Sci. Food Agric. 2018, 98, 1545–1553. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.X.; Yu, J.S.; Hu, W.; Chen, G.L. Partial hydrophilic modification of biaxially oriented polypropylene film by an atmospheric pressure plasma jet with the allylamine monomer. Appl. Surf. Sci. 2016, 387, 957–964. [Google Scholar] [CrossRef]

- Hu, W.; Bai, Y.; Zhang, C.; Li, N.; Cheng, B. Coating based on the modified chlorinated polypropylene emulsion for promoting printability of biaxially oriented polypropylene film. J. Adhes. Sci. Technol. 2018, 32, 50–67. [Google Scholar] [CrossRef]

- Chen, W.X.; Yu, J.S.; Chen, G.L.; Qiu, X.P.; Hu, W.; Bai, H.Y.; Shao, J.Z. Development of a novel protocol for the permanent hydrophilic modification of a BOPP film for high quality printing with water-based ink. RSC Adv. 2015, 5, 87963–87970. [Google Scholar] [CrossRef]

- Kalapat, N.; Amornsakchai, T.; Srikhirin, T. Surface modification of biaxially oriented polypropylene (BOPP) film using acrylic acid-corona treatment: Part II. Long term aging surface properties. Surf. Coat. Technol. 2013, 234, 67–75. [Google Scholar] [CrossRef]

- Dai, L.; Xu, D. Polyethylene surface enhancement by corona and chemical co-treatment. Tetrahedron Lett. 2019, 60, 1005–1010. [Google Scholar] [CrossRef]

- Kalapat, N.; Amornsakchai, T. Surface modification of biaxially oriented polypropylene (BOPP) film using acrylic acid-corona treatment: Part I. Properties and characterization of treated films. Surf. Coat. Technol. 2012, 207, 594–601. [Google Scholar] [CrossRef]

- Rocca-Smith, J.R.; Karbowiak, T.; Marcuzzo, E.; Sensidoni, A.; Piasente, F.; Champion, D.; Heinz, O.; Vitry, P.; Bourillot, E.; Lesniewska, E.; et al. Impact of corona treatment on PLA film properties. Polym. Degrad. Stab. 2016, 132, 109–116. [Google Scholar] [CrossRef]

- Popelka, A.; Novák, I.; Al-Maadeed, M.A.S.A.; Ouederni, M.; Krupa, I. Effect of corona treatment on adhesion enhancement of LLDPE. Surf. Coat. Technol. 2018, 335, 118–125. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, D.; Wadsworth, L.C. Corona treatment of polyolefin films—A review. Adv. Polym. Technol. 1999, 18, 171–180. [Google Scholar]

- Vishnuvarthanan, M.; Rajeswari, N. Effect of mechanical, barrier and adhesion properties on oxygen plasma surface modified PP. Innov. Food Sci. Emerg. Technol. 2015, 30, 119–126. [Google Scholar] [CrossRef]

- Mercado-Cabrera, A.; Jaramillo-Sierra, B.; López-Callejas, R.; Valencia-Alvarado, R.; de la Piedad-Beneitez, A.; Peña-Eguiluz, R.; Barocio-Delgado, S.; Muñoz-Castro, A.; Rodríguez-Méndez, B. Surface modification of polypropylene fiber for hydrophilicity enhancement aided by DBD plasma. Prog. Org. Coat. 2013, 76, 1858–1862. [Google Scholar] [CrossRef]

- Navaneetha Pandiyaraj, K.; Ram Kumar, M.C.; Arun Kumar, A.; Padmanabhan, P.V.A.; Deshmukh, R.R.; Bah, M.; Ismat Shah, S.; Su, P.-G.; Halleluyah, M.; Halim, A.S. Tailoring the surface properties of polypropylene films through cold atmospheric pressure plasma (CAPP) assisted polymerization and immobilization of biomolecules for enhancement of anti-coagulation activity. Appl. Surf. Sci. 2016, 370, 545–556. [Google Scholar] [CrossRef]

- Pandiyaraj, K.N.; Selvarajan, V.; Deshmukh, R.R.; Gao, C. Modification of surface properties of polypropylene (PP) film using DC glow discharge air plasma. Appl. Surf. Sci. 2009, 255, 3965–3971. [Google Scholar] [CrossRef]

- Navaneetha Pandiyaraj, K.; Deshmukh, R.R.; Arunkumar, A.; Ramkumar, M.C.; Ruzybayev, I.; Ismat Shah, S.; Su, P.-G.; Periayah, M.H.; Halim, A.S. Evaluation of mechanism of non-thermal plasma effect on the surface of polypropylene films for enhancement of adhesive and hemo compatible properties. Appl. Surf. Sci. 2015, 347, 336–346. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Q.; Wadsworth, L.C. Mechanism of corona treatment on polyolefin films. Polym. Eng. Sci. 1998, 38, 965–970. [Google Scholar] [CrossRef]

- Ding, L.; Shao, L.; Bai, Y. Deciphering the mechanism of corona discharge treatment of BOPET film. RSC Adv. 2014, 4, 21782–21787. [Google Scholar] [CrossRef]

- Sellin, N.; de Campos, J.S.C. Surface composition analysis of PP films treated by corona discharge. Mater. Res. 2003, 6, 163–166. [Google Scholar] [CrossRef]

- Barbaro, G.; Galdi, M.R.; Di Maio, L.; Incarnato, L. Effect of BOPET film surface treatments on adhesion performance of biodegradable coatings for packaging applications. Eur. Polym. J. 2015, 68, 80–89. [Google Scholar] [CrossRef]

- Louzi, V.C.; de Campos, J.S.C. Corona treatment applied to synthetic polymeric monofilaments (PP, PET, and PA-6). Surf. Interfaces 2019, 14, 98–107. [Google Scholar] [CrossRef]

- O’Hare, L.-A.; Leadley, S.; Parbhoo, B. Surface physicochemistry of corona-discharge-treated polypropylene film. Surf. Interface Anal. 2002, 33, 335–342. [Google Scholar] [CrossRef]

- Navaneetha Pandiyaraj, K.; Selvarajan, V.; Deshmukh, R.R.; Gao, C. Adhesive properties of polypropylene (PP) and polyethylene terephthalate (PET) film surfaces treated by DC glow discharge plasma. Vacuum 2008, 83, 332–339. [Google Scholar] [CrossRef]

- González, L.T.; Longoria-Rodríguez, F.E.; Sánchez-Domínguez, M.; Leyva-Porras, C.; Acuña-Askar, K.; Kharissov, B.I.; Arizpe-Zapata, A.; Alfaro-Barbosa, J.M. Seasonal variation and chemical composition of particulate matter: A study by XPS, ICP-AES and sequential microanalysis using Raman with SEM/EDS. J. Environ. Sci. 2018, 74, 32–49. [Google Scholar] [CrossRef]

| Sample | Corona Treatment Power (kW) | Corona Cycles |

|---|---|---|

| A | – | – |

| B | 2.0 | 3 |

| C | 3.0 | 3 |

| D | 3.0 | 7 |

| Title | Wavenumber, cm−1 | The Corresponding Group |

|---|---|---|

| pristine BOPP film | 2950, 2872 | –CH3 |

| 2920, 2840 | –CH2– | |

| 2719 |  | |

| Corona BOPP film | 3100–3600 | –NH2, –OH |

| 1350 | R–NO2 | |

| 900~1000 |  | |

| 1630 | –C=C– | |

| 1537–1858 |  , COOH, , COOH, , CHO , CHO | |

| 1110–1300 | C–O– |

| Sample | Element Composition (at.%) | Ratio | |||

|---|---|---|---|---|---|

| C | O | N | O/C | N/C | |

| A | 91.57 | 5.90 | 2.52 | 6.40% | 2.7% |

| B | 77.44 | 20.8 | 1.41 | 26.9% | 1.8% |

| C | 76.33 | 21.96 | 1.71 | 28.8% | 2.2% |

| D | 75.84 | 22.59 | 1.57 | 29.8% | 2.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, L.; Zhang, X.; Wang, Y. Study on the Behavior of BOPP Film Treated by Corona Discharge. Coatings 2020, 10, 1195. https://doi.org/10.3390/coatings10121195

Ding L, Zhang X, Wang Y. Study on the Behavior of BOPP Film Treated by Corona Discharge. Coatings. 2020; 10(12):1195. https://doi.org/10.3390/coatings10121195

Chicago/Turabian StyleDing, Liping, Xiaoyong Zhang, and Yanqing Wang. 2020. "Study on the Behavior of BOPP Film Treated by Corona Discharge" Coatings 10, no. 12: 1195. https://doi.org/10.3390/coatings10121195

APA StyleDing, L., Zhang, X., & Wang, Y. (2020). Study on the Behavior of BOPP Film Treated by Corona Discharge. Coatings, 10(12), 1195. https://doi.org/10.3390/coatings10121195