Electrical Conductivity and Optical Properties of Nanoscale Titanium Films on Sapphire for Localized Plasmon Resonance-Based Sensors

Abstract

1. Introduction

2. Materials and Methods

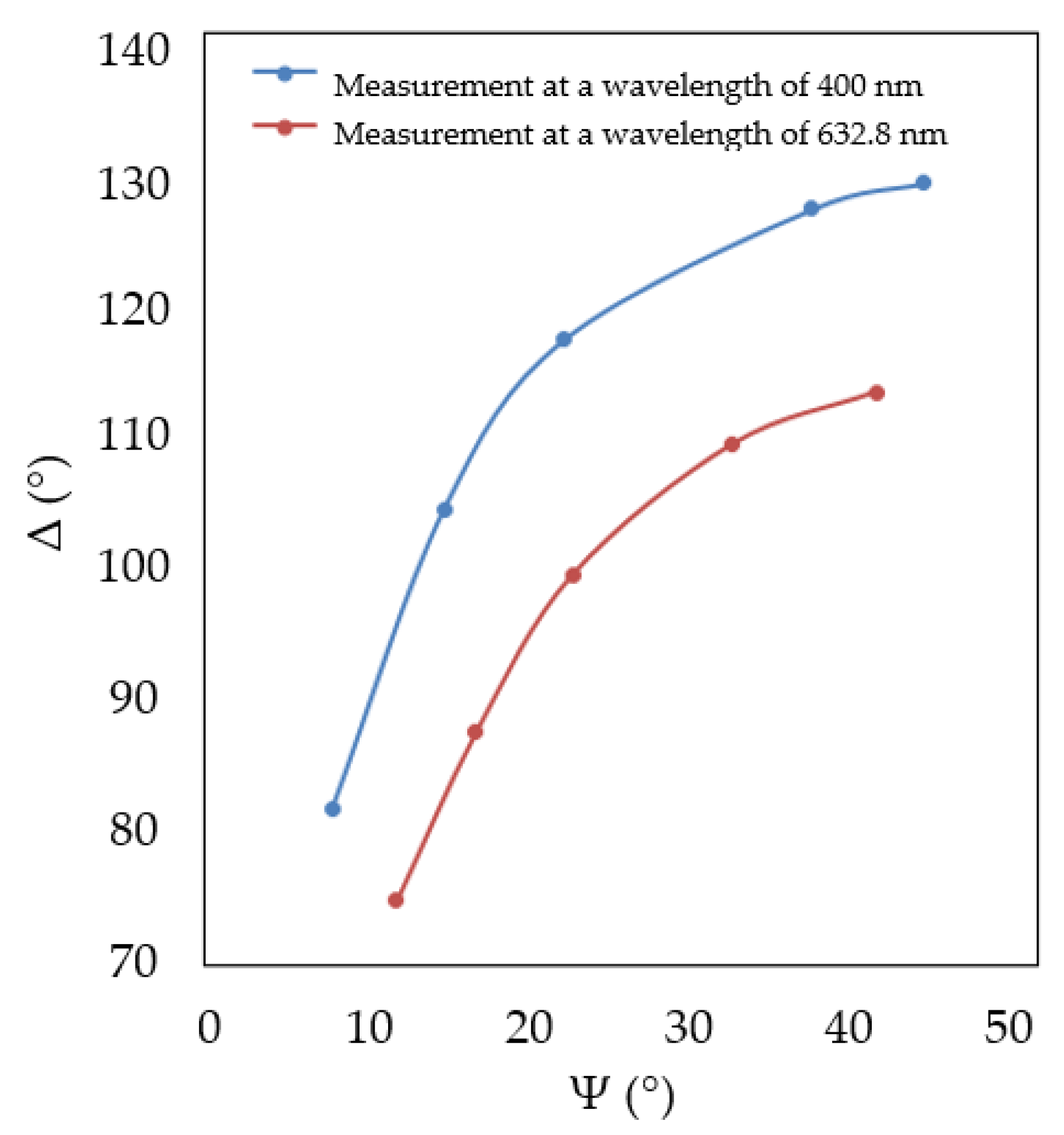

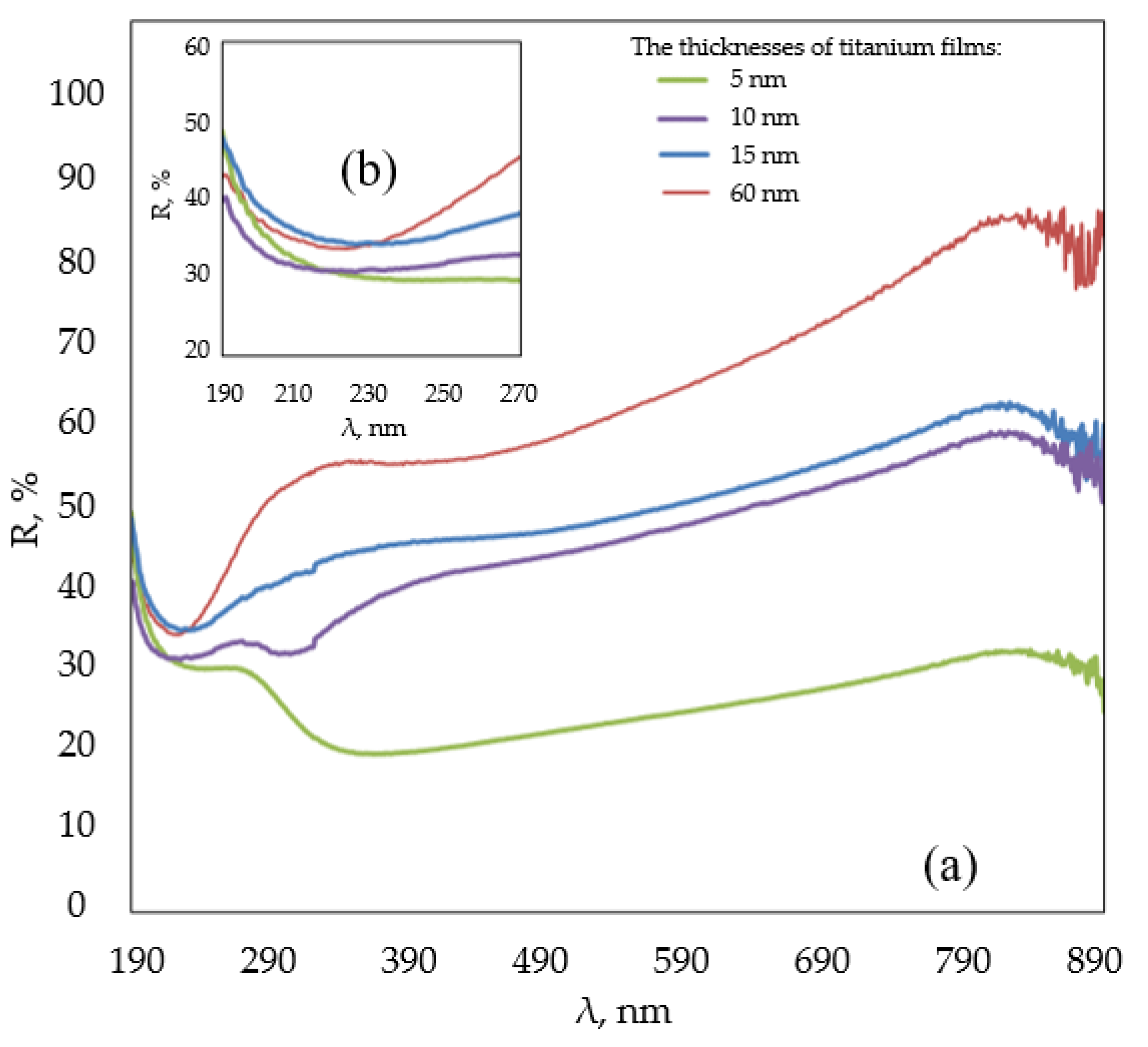

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pompa, P.P.; Martiradonna, L.; Torre, A.D.; Sala, F.D.; Manna, L.; de Vittorio, M.; Calabi, F.; Cingolani, R.; Rinaldi, R. Metal-enhanced fluorescence of colloidal nanocrystals with nanoscale control. Nat. Nanotechnol. 2006, 1, 126–130. [Google Scholar] [CrossRef] [PubMed]

- Nepomnyashchaya, E.; Velichko, E.; Aksenov, E.; Bogomaz, T. Optoelectronic method for analysis of biomolecular interaction dynamics. IOP J. Phys. Conf. Ser. 2014, 541, 1–5. [Google Scholar] [CrossRef]

- Adam, P.M.; Salomon, L.M.; de Fornel, F.; Goudonnet, J.P. Determination of the spatial extension of the surface-plasmon evanescent field of a silver film with a photon scanning tunneling microscope. Phys. Rev. B 1993, 48, 268–283. [Google Scholar] [CrossRef] [PubMed]

- Mamichev, D.A.; Kuznetsov, I.A.; Maslova, N.E.; Zanaveskin, M.L. Optical sensors based on surface plasmon resonance for high-sensitive biochemical analysis. Mol. Med. 2012, 6, 19–27. (In Russian) [Google Scholar]

- Daghestani, H.N.; Day, B.W. Theory and applications of surface plasmon resonance, resonant mirror, resonant waveguide grating, and dual polarization interferometry biosensors. Sensors 2010, 10, 9630–9646. [Google Scholar] [CrossRef]

- Gandini, C.; Lacquaniti, C.; Monticone, E.; Portesi, C.; Rajteri, M.; Rastello, M.L.; Pasca, E.; Ventura, G. Correlation of critical temperatures and electrical properties in titanium films. Int. J. Mod. Phys. B 2003, 17, 948–952. [Google Scholar] [CrossRef]

- Minz, R.A.; Pal, S.S.; Chopra, A.; Bargujar, S.; Bhatnagar, R.; Sinha, R.K. Magnetron sputtering coated optical fiber probe designs for surface plasmon resonance sensor. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 1–7. [Google Scholar] [CrossRef]

- Rakić, A.D.; Djurišić, A.B.; Elazar, J.M.; Majewski, M.L. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 1998, 37, 5271–5283. [Google Scholar] [CrossRef]

- Igasaki, Y.; Mitsuhashi, H. Crystal structures and electrical properties of titanium films evaporated in high vacuum. Thin Solid Films 1998, 5, 33–42. [Google Scholar] [CrossRef]

- Danilina, T.I.; Troyan, P.E.; Sakharov, Y.V.; Zhidik, Y.S. Ion-plasma methods to obtain nanostructures. Proc. TUSUR Univ. 2017, 20, 40–45. [Google Scholar] [CrossRef]

- Matveev, V.A.; Pleshanov, N.K.; Gerashchenko, O.V.; Bayramukov, V.Y. Complex study of titanium nano-films prepared by magnetron sputtering. J. Surf. Investig. X-ray Synchrotron Neutron Tech. 2014, 8, 991–996. [Google Scholar] [CrossRef]

- Dervaux, J.; Cormier, P.-A.; Moskovkin, P.; Douheret, O.; Konstantinidis, S.; Lazzaroni, R.; Lucas, S.; Snyders, R. Synthesis of nanostructured Ti thin films by combining glancing angle deposition and magnetron sputtering: A joint experimental and modeling study. Thin Solid Films 2017, 636, 644–657. [Google Scholar] [CrossRef]

- Smirnov, S.V.; Chistoedova, L.A.; Litvinova, V.A. Frame and properties of pellicles of tantalum obtained by a magnetron sputtering. Proc. TUSUR Univ. 2005, 4, 80–83. (In Russian) [Google Scholar]

- Lyahov, I.G.; Bulah, K.V.; Il’in, A.S. The investigation of the microstructure of titanium thin films for cryogenic detectors with various modes of magnetron sputtering. J. Radio Electron. 2012, 9, 1–13. (In Russian) [Google Scholar]

- Grosse, P. Freie Elektronen in Festkörpern; Springer: Berlin/Heidelberg, Germany, 1979; p. 296. [Google Scholar] [CrossRef]

- Kralkina, E.A.; Nekliudova, P.A.; Nikonov, A.M.; Vavilin, K.V.; Zadiriev, I.I. Properties of titanium coatings deposited in a magnetron discharge with ion assistance using an inductive RF discharge in a magnetic field. Appl. Phys. 2019, 4, 41–46. (In Russian) [Google Scholar]

- Bogolyubova, S.; Polyakova, E.; Rezvyi, R. Ellipsometric methods for control of parameters of materials and radioelectronics structures. Radio Ind. 2016, 26, 59–62. [Google Scholar] [CrossRef][Green Version]

- Abelès, F. Optical properties of metallic films. Phys. Thin Films 1971, 6, 151–204. [Google Scholar] [CrossRef]

- Chang-Hasnain, J.C.; Harbison, J.B.; Hasnain, G.; Von Lehmen, A.C.; Florez, L.T.; Stoffel, N.G. Dynamic, polarization, and transverse mode characteristics of vertical cavity surface emitting lasers. IEEE J. Quantum Electron. 1991, 27, 1402–1409. [Google Scholar] [CrossRef]

- Ordal, M.A.; Long, L.L.; Bell, R.J.; Bell, S.E.; Bell, R.R.; Alexander, R.W.; Ward, C.A. Optical properties of the metals Al, Co, Cu, Au, Fe, Pb, Ni, Pd, Pt, Ag, Ti, and W in the infrared and far infrared. Appl. Opt. 1983, 22, 1099–1119. [Google Scholar] [CrossRef]

- Mie, G. Contributions to the optics of turbid media, particularly of colloidal metal solutions. Ann. Phys. 1908, 25, 377–445. [Google Scholar] [CrossRef]

- Ni, E.; Jiang, X. Microwave measurement of the permittivity for high dielectric constant materials using an extra-cavity evanescent waveguide. Rev. Sci. Instrum. 2002, 73, 3997–4002. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korotkova, K.; Bainov, D.; Smirnov, S.; Yunusov, I.; Zhidik, Y. Electrical Conductivity and Optical Properties of Nanoscale Titanium Films on Sapphire for Localized Plasmon Resonance-Based Sensors. Coatings 2020, 10, 1165. https://doi.org/10.3390/coatings10121165

Korotkova K, Bainov D, Smirnov S, Yunusov I, Zhidik Y. Electrical Conductivity and Optical Properties of Nanoscale Titanium Films on Sapphire for Localized Plasmon Resonance-Based Sensors. Coatings. 2020; 10(12):1165. https://doi.org/10.3390/coatings10121165

Chicago/Turabian StyleKorotkova, Klavdiya, Dashi Bainov, Serafim Smirnov, Igor Yunusov, and Yury Zhidik. 2020. "Electrical Conductivity and Optical Properties of Nanoscale Titanium Films on Sapphire for Localized Plasmon Resonance-Based Sensors" Coatings 10, no. 12: 1165. https://doi.org/10.3390/coatings10121165

APA StyleKorotkova, K., Bainov, D., Smirnov, S., Yunusov, I., & Zhidik, Y. (2020). Electrical Conductivity and Optical Properties of Nanoscale Titanium Films on Sapphire for Localized Plasmon Resonance-Based Sensors. Coatings, 10(12), 1165. https://doi.org/10.3390/coatings10121165