Inter-Relationship between Coating Micro/Nanostructure and the Tribological Performance of Zr–C Gradient Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Deposition

2.2. Microstructure, Composition and Morphology

2.3. Mechanical Evaluation

2.4. Tribological Tests

2.5. Fracture Toughness and Adhesion

3. Results and Discussion

3.1. Chemical Composition of Coatings

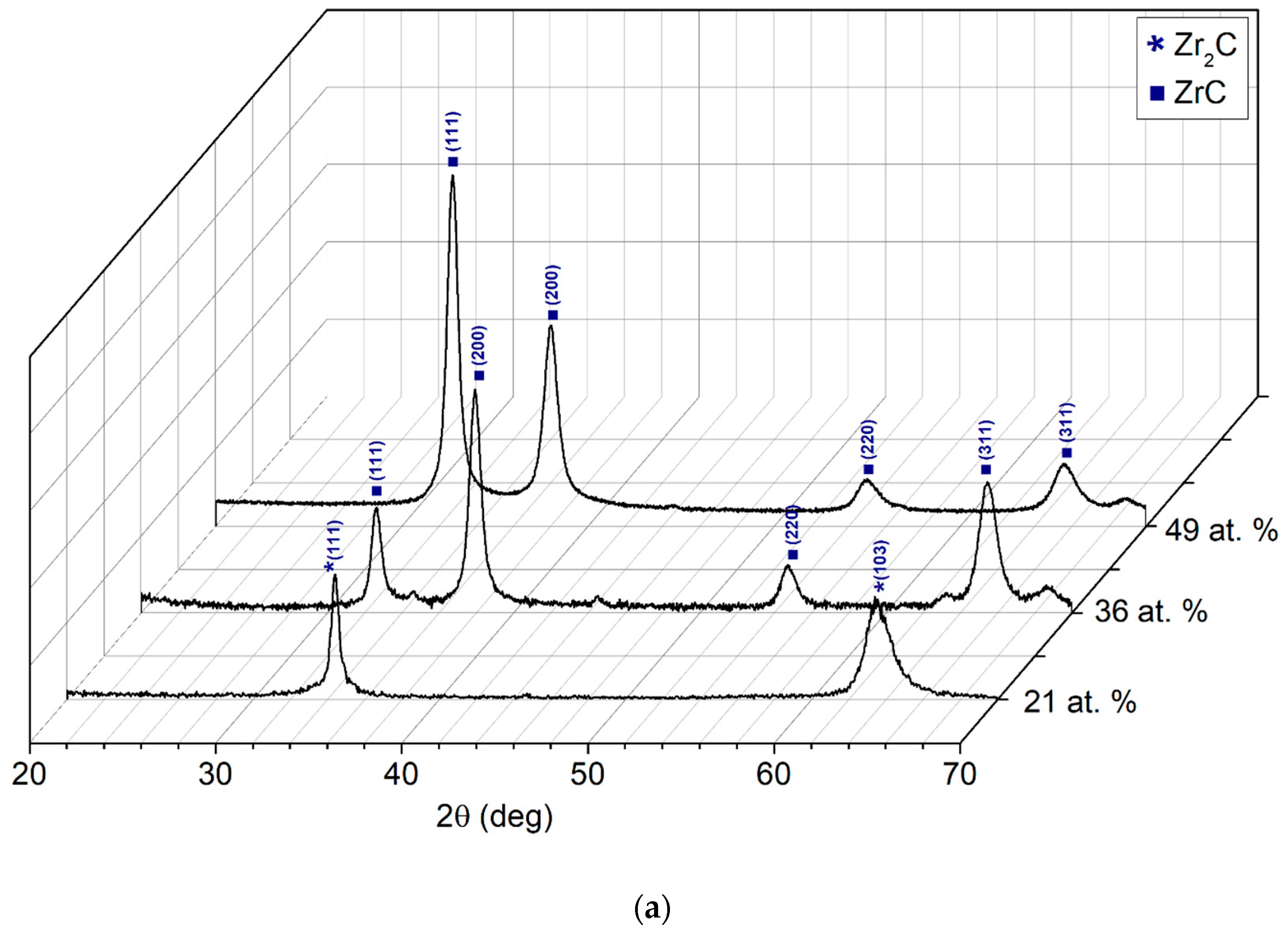

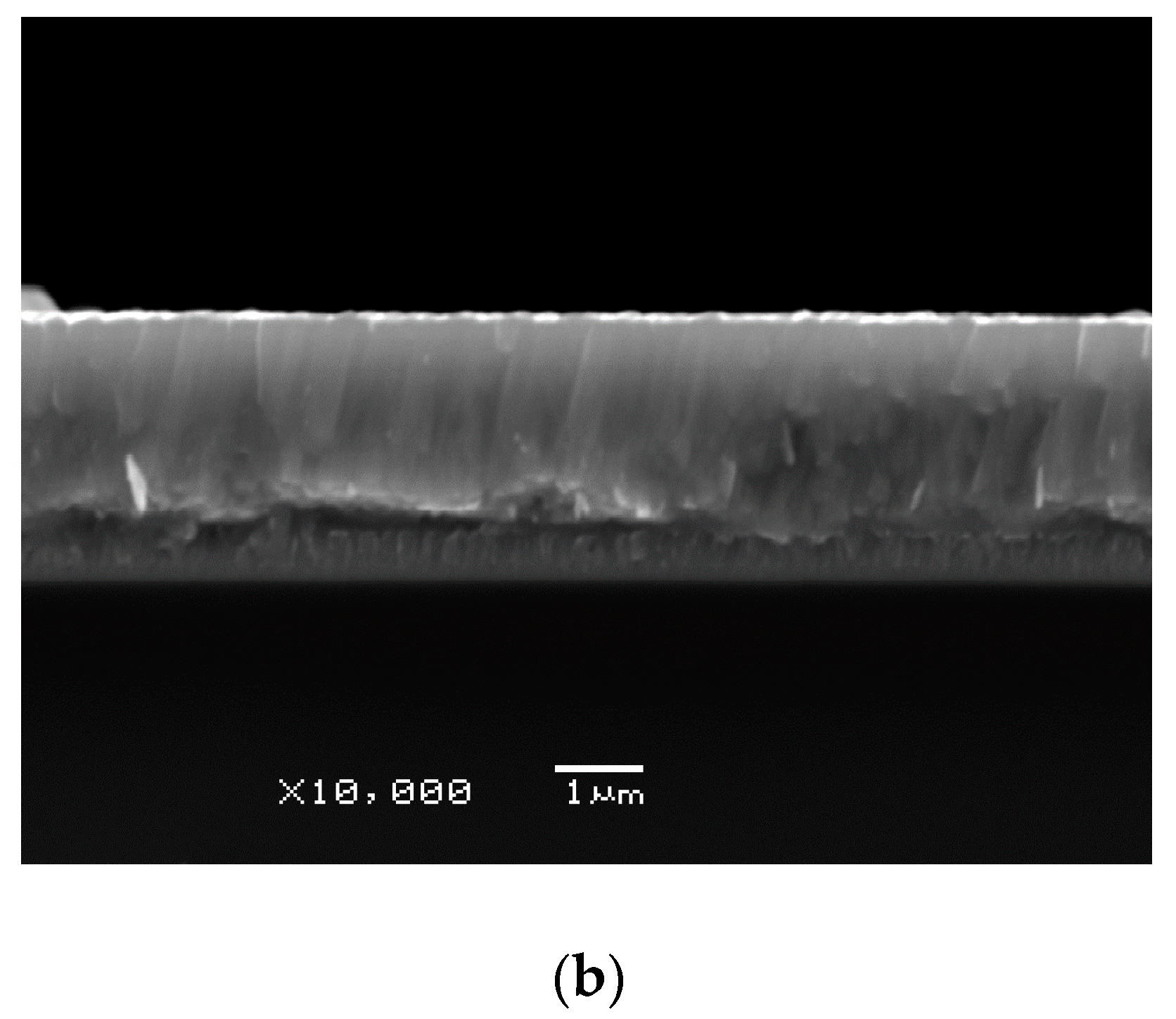

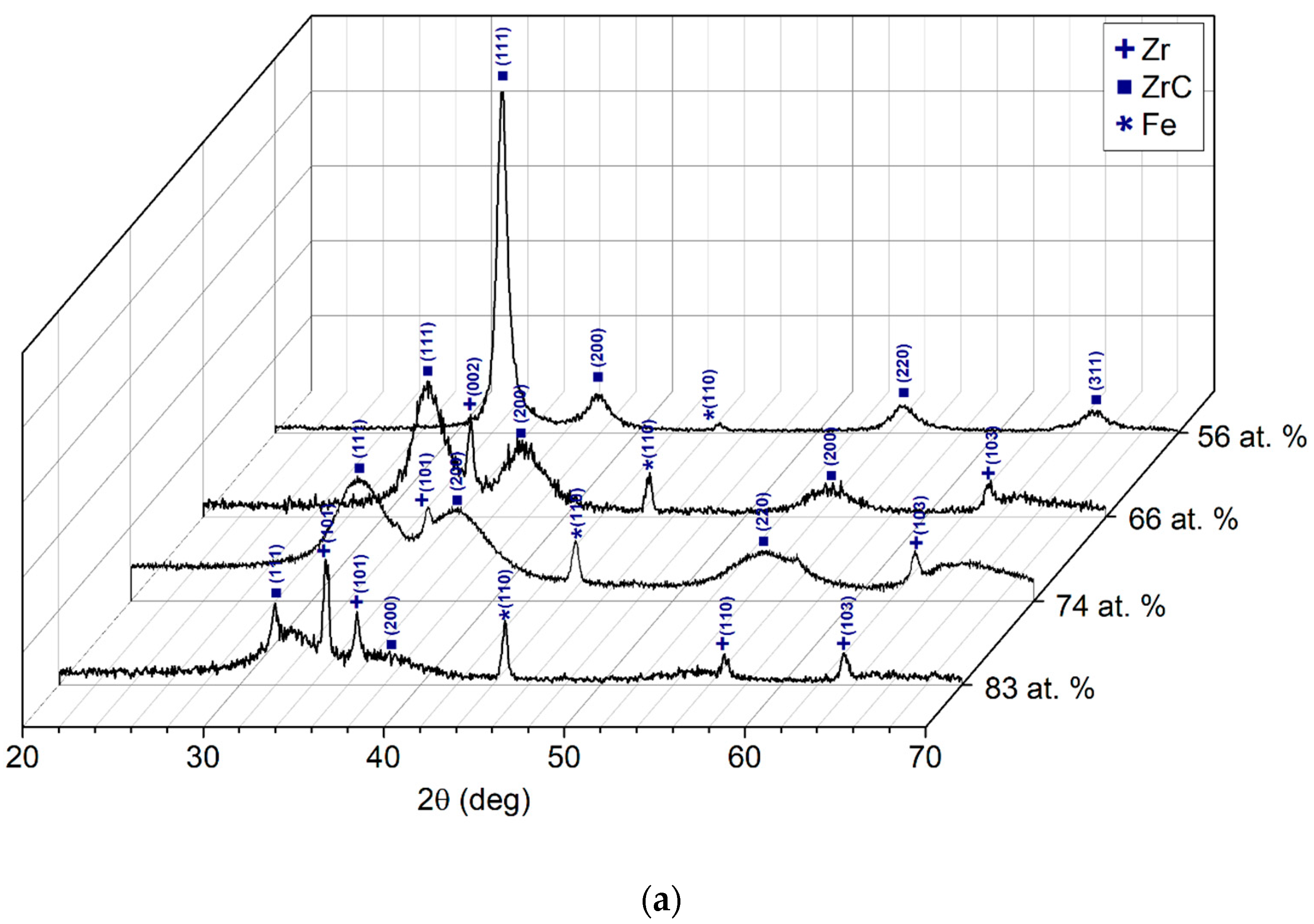

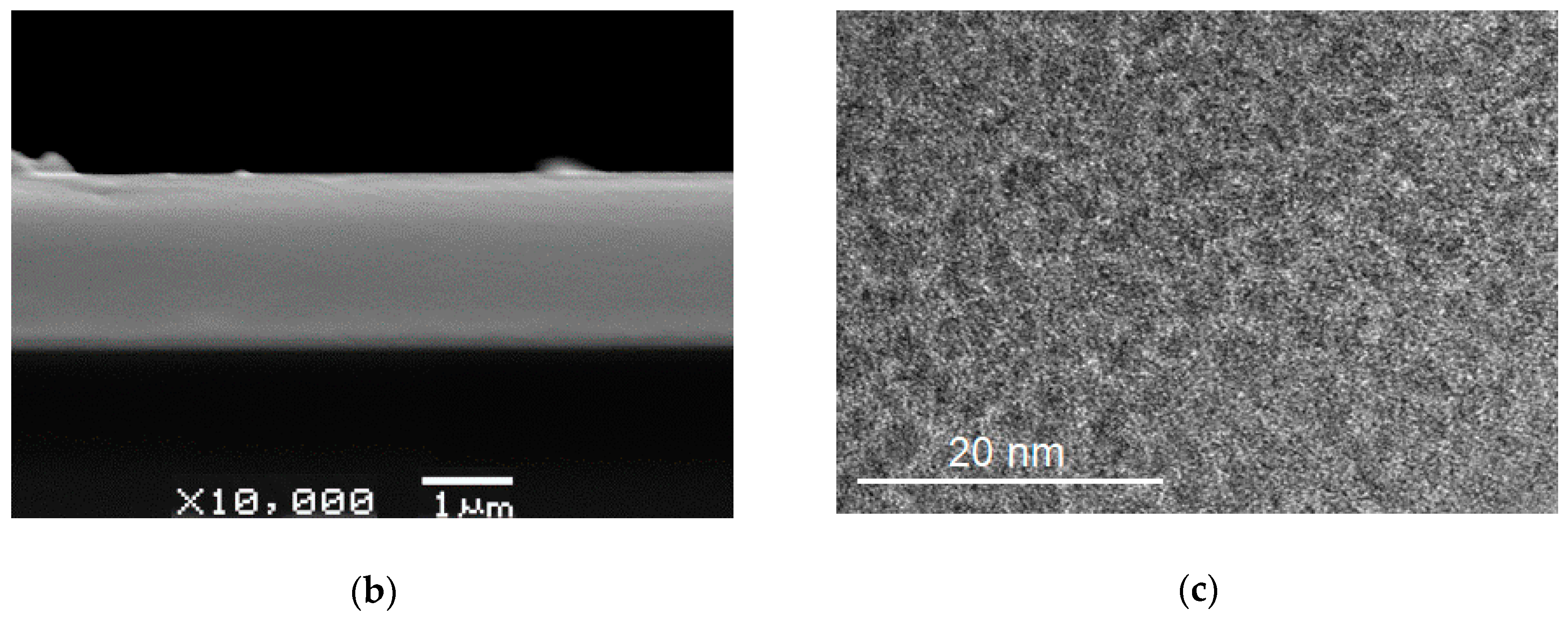

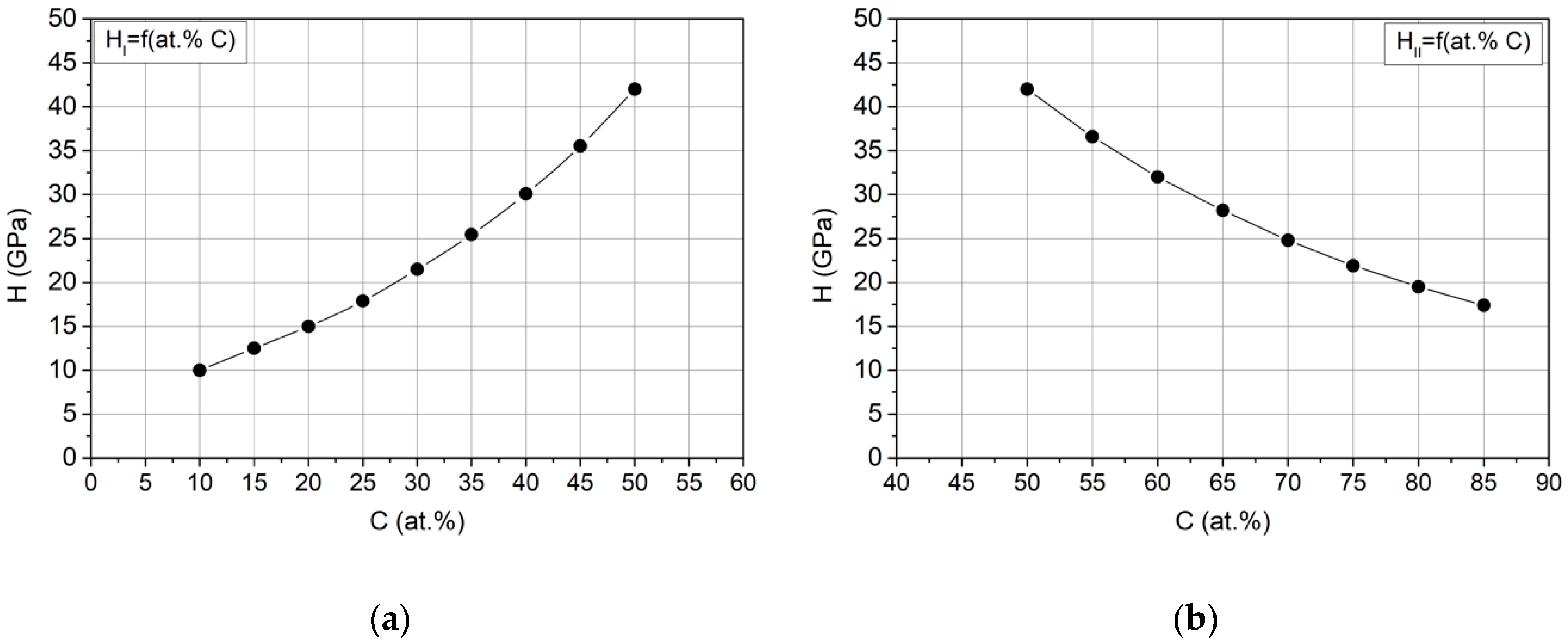

3.2. Characteristics of Zr–C Coatings

3.3. Selection of C Content Profile in FGM Coating

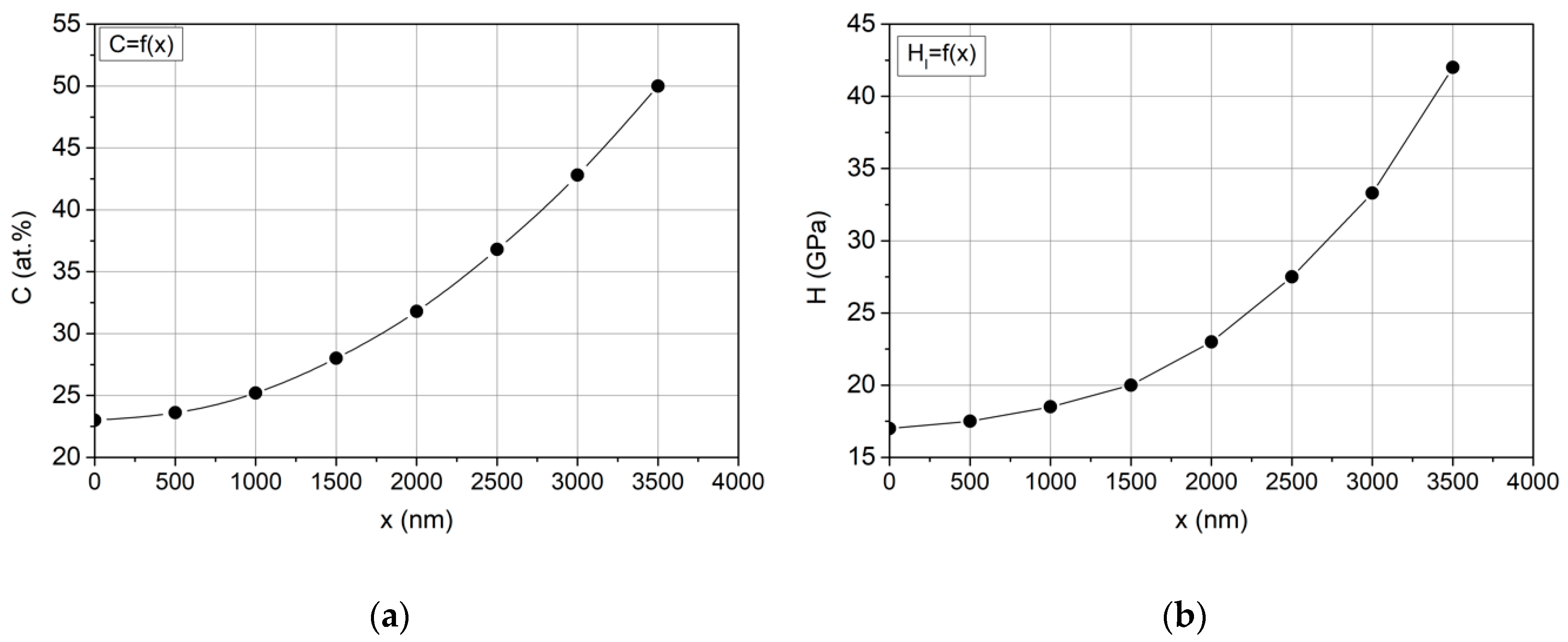

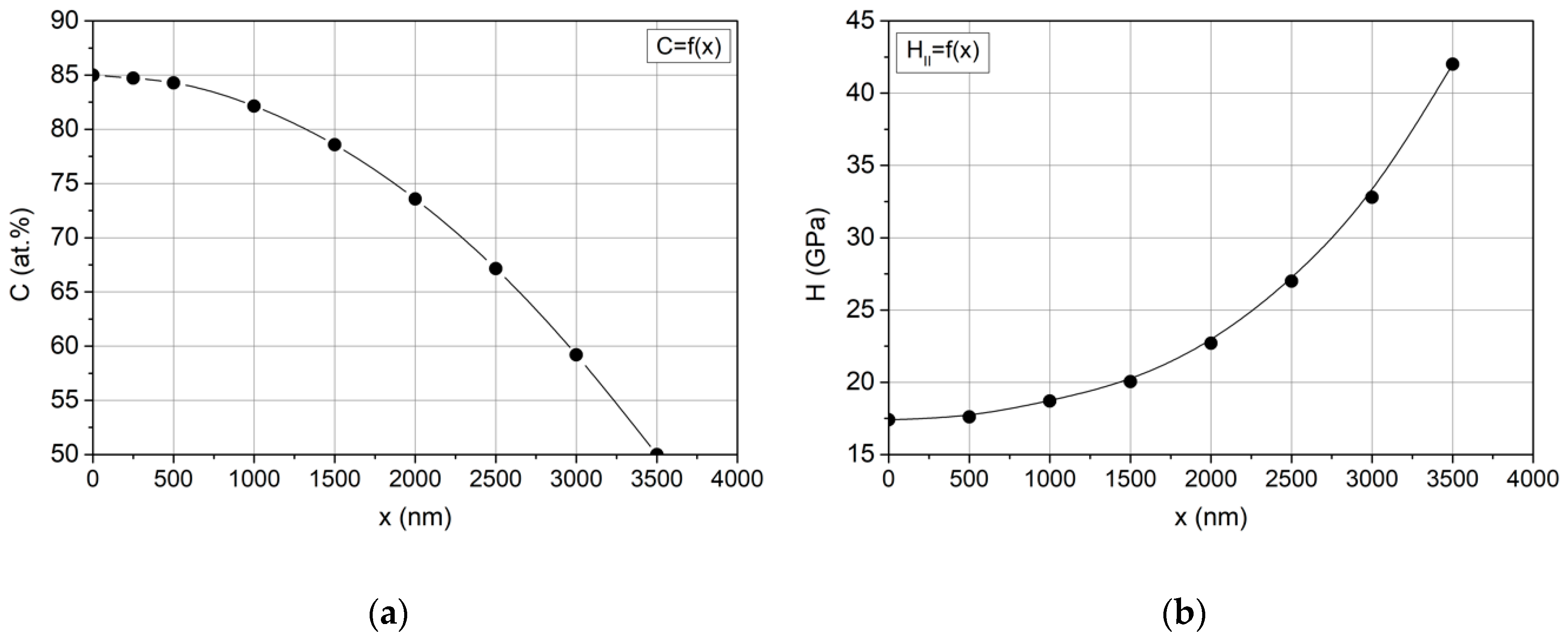

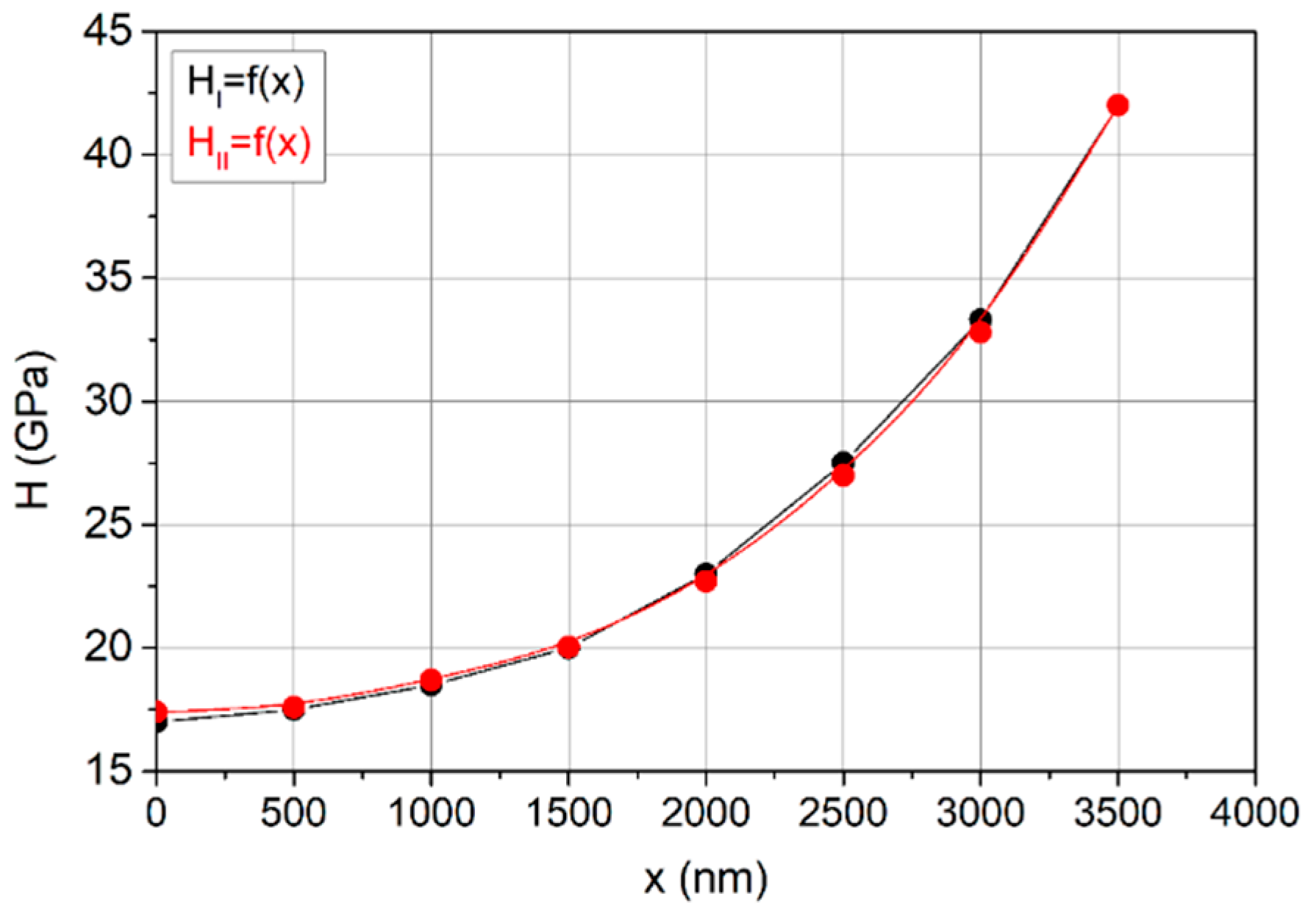

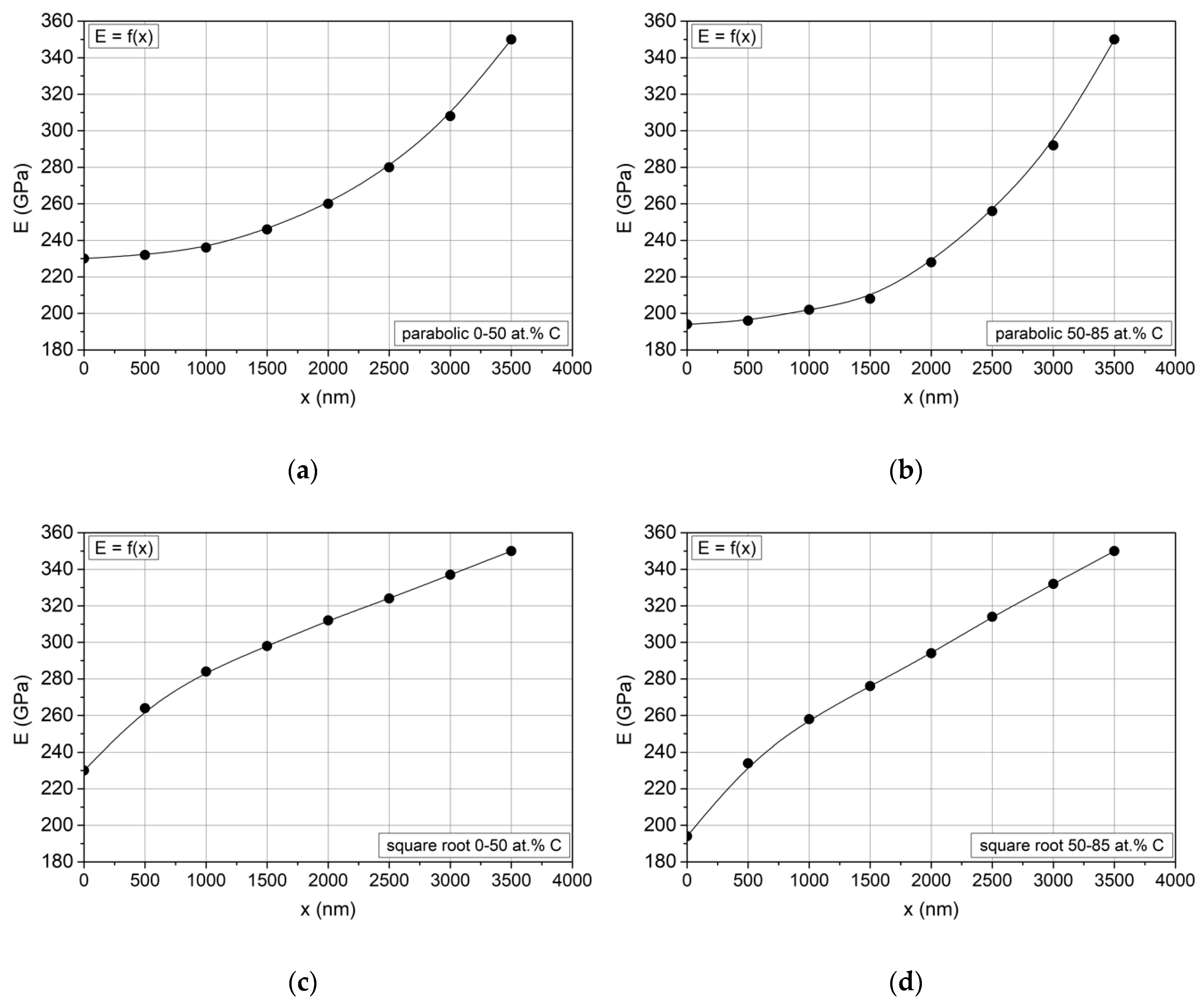

3.3.1. Parabolic Profiles

3.3.2. Square Root Profiles

3.4. Results of Investigations in Relation to Coating Properties

3.4.1. Thickness of Coatings

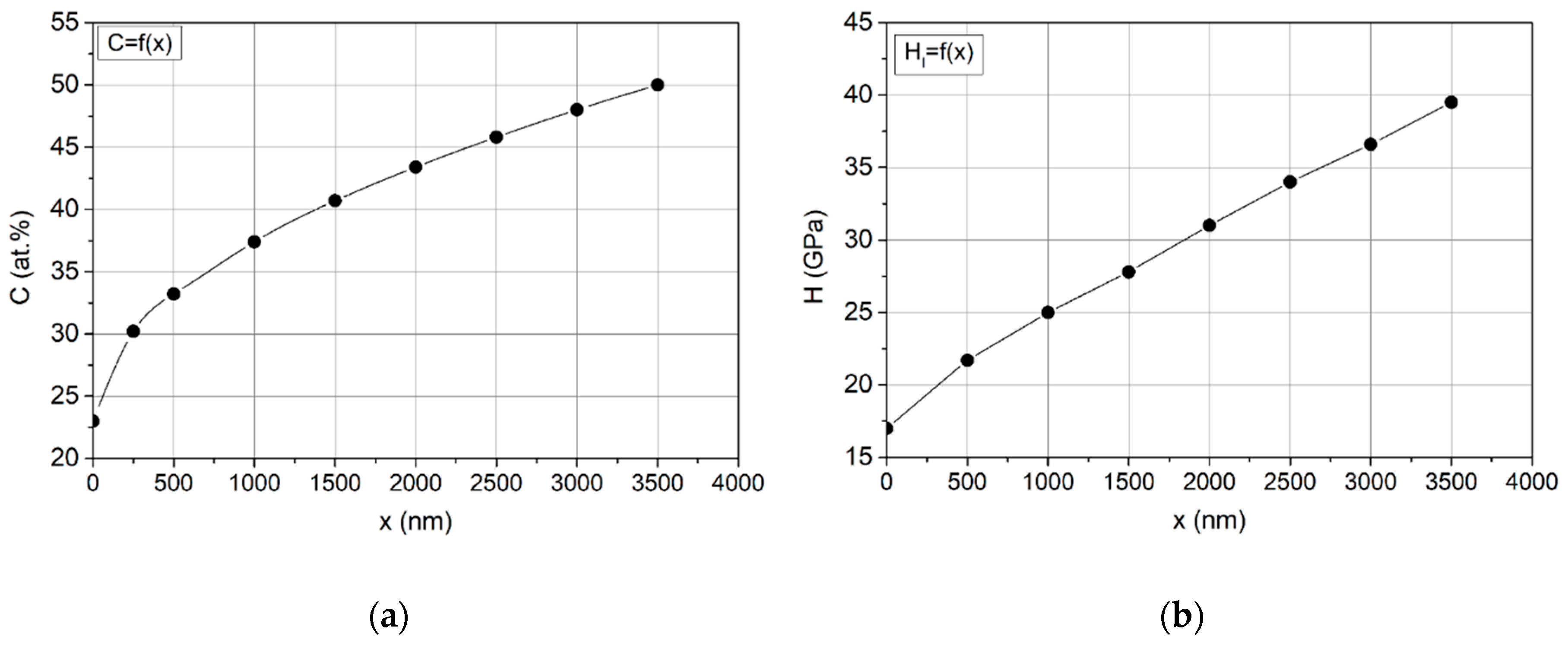

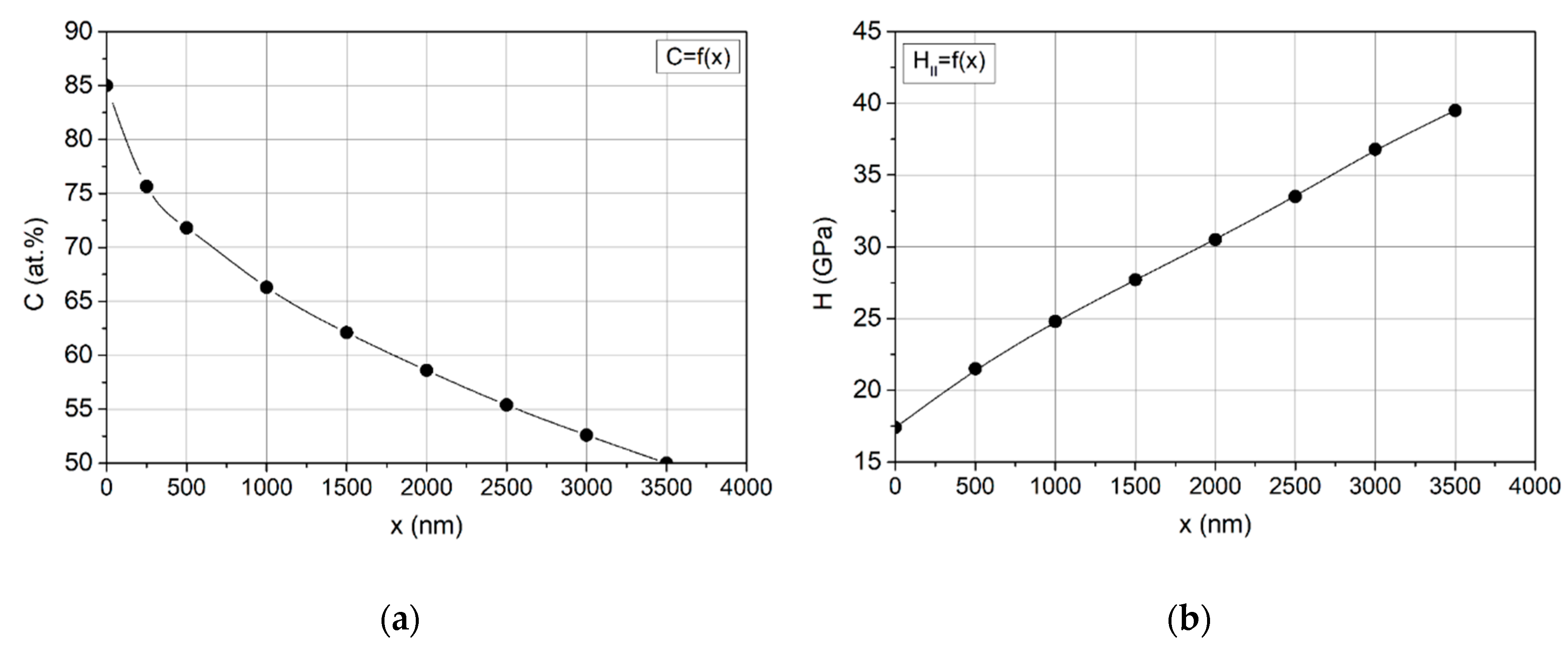

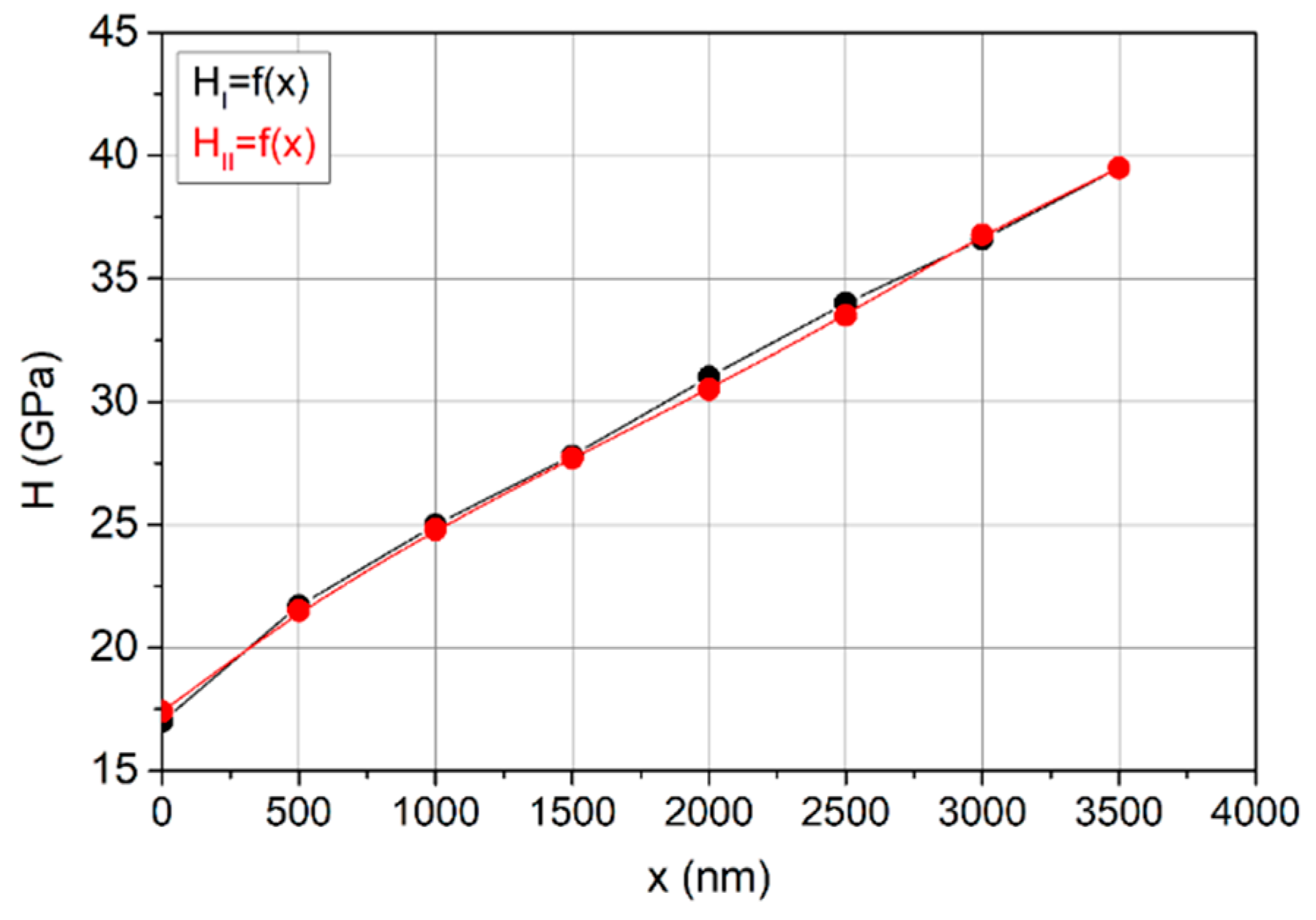

3.4.2. Hardness of Coatings

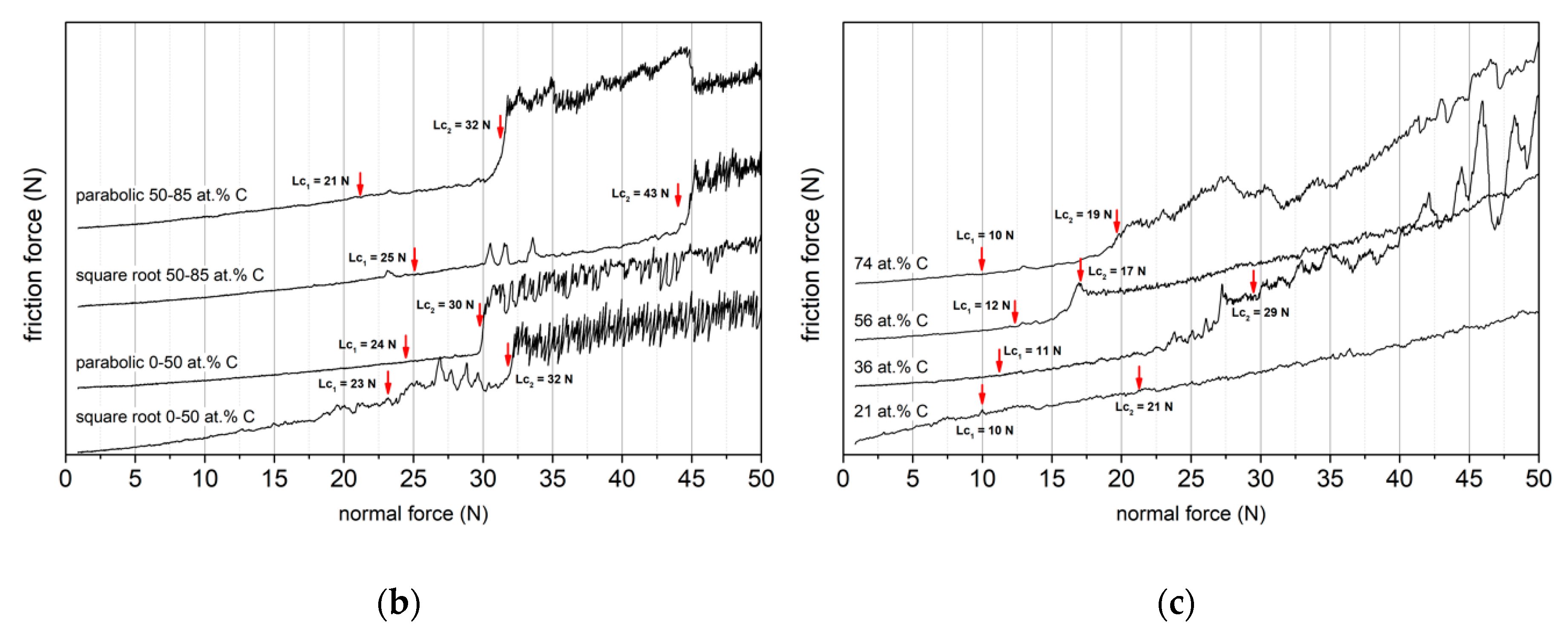

3.4.3. Evaluation of Coating Adhesion Using the Scratch Test

3.4.4. Evaluation of Coatings Using Rockwell C Method

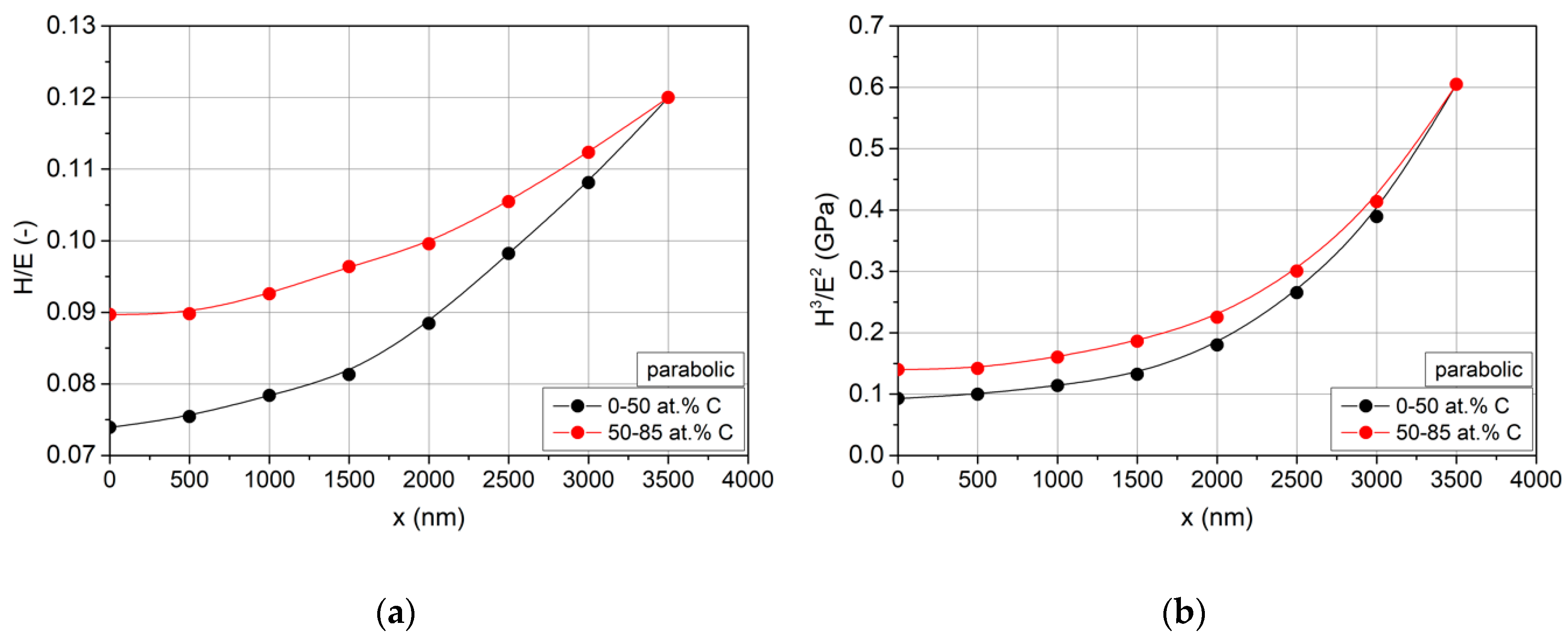

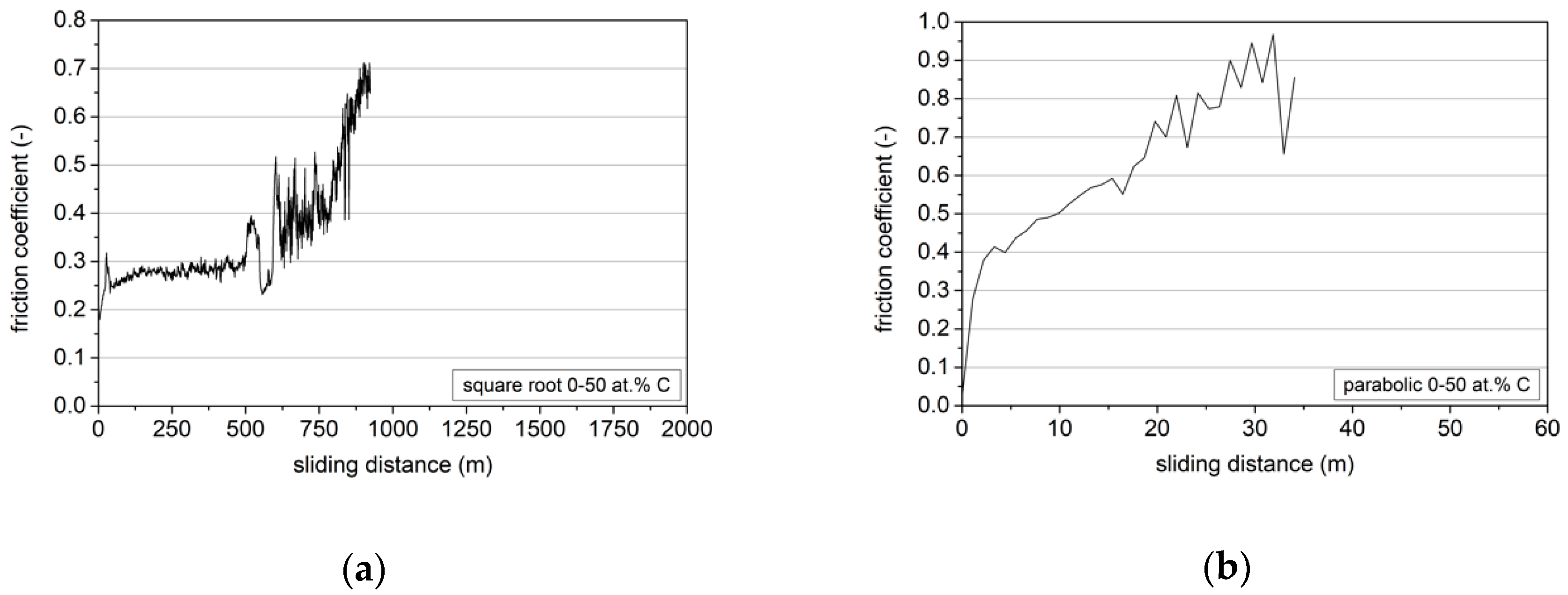

3.4.5. H/E and H3/E2

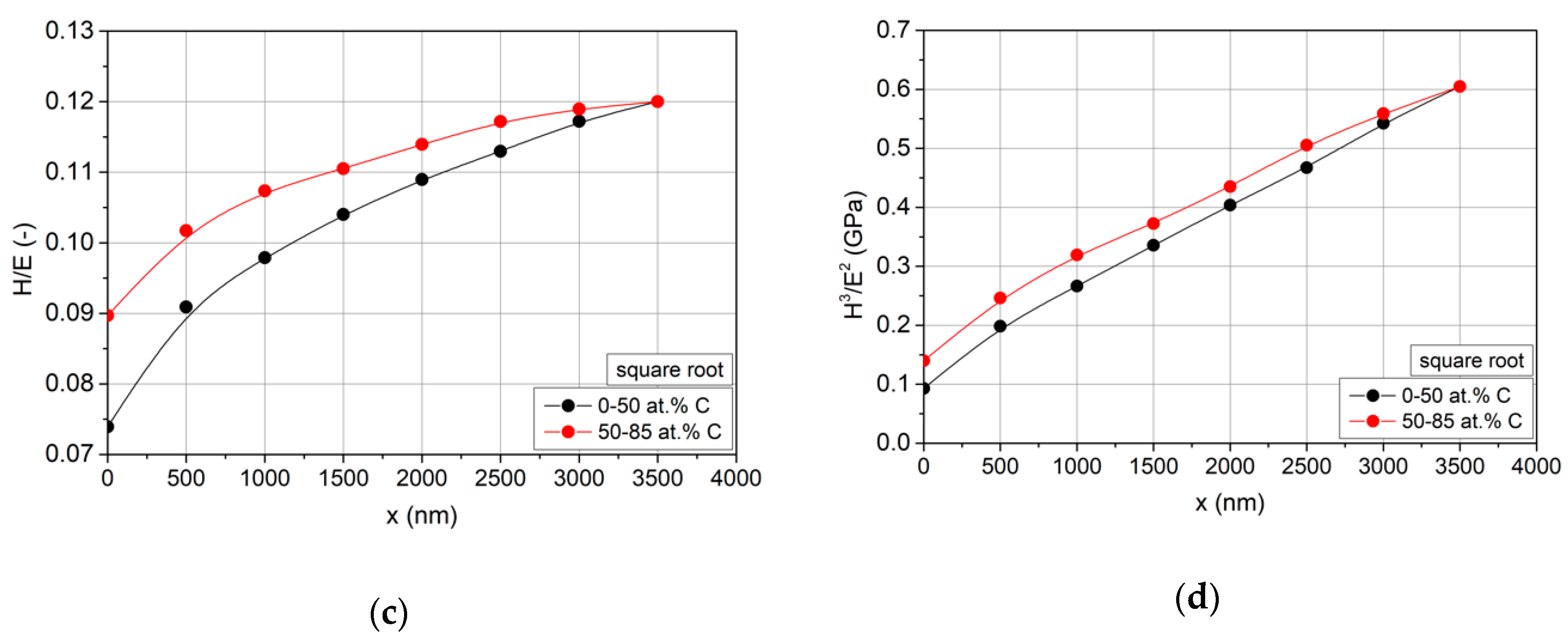

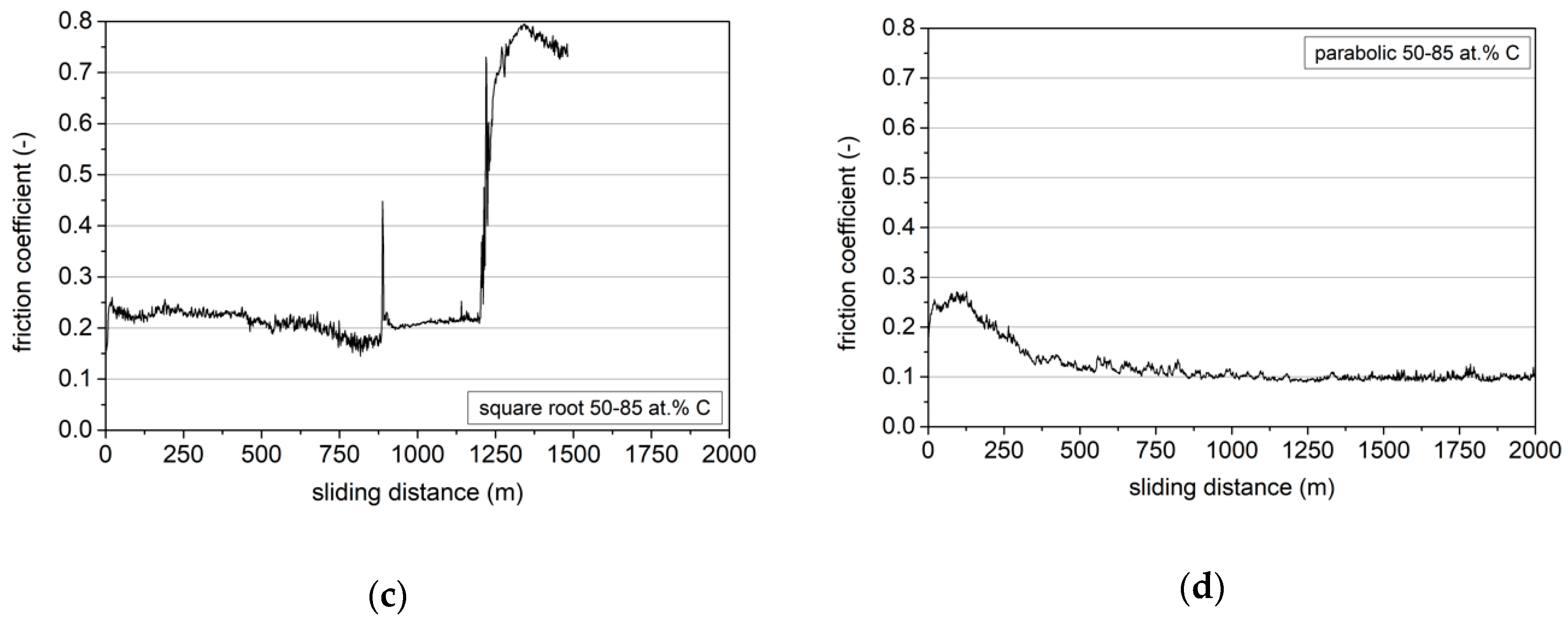

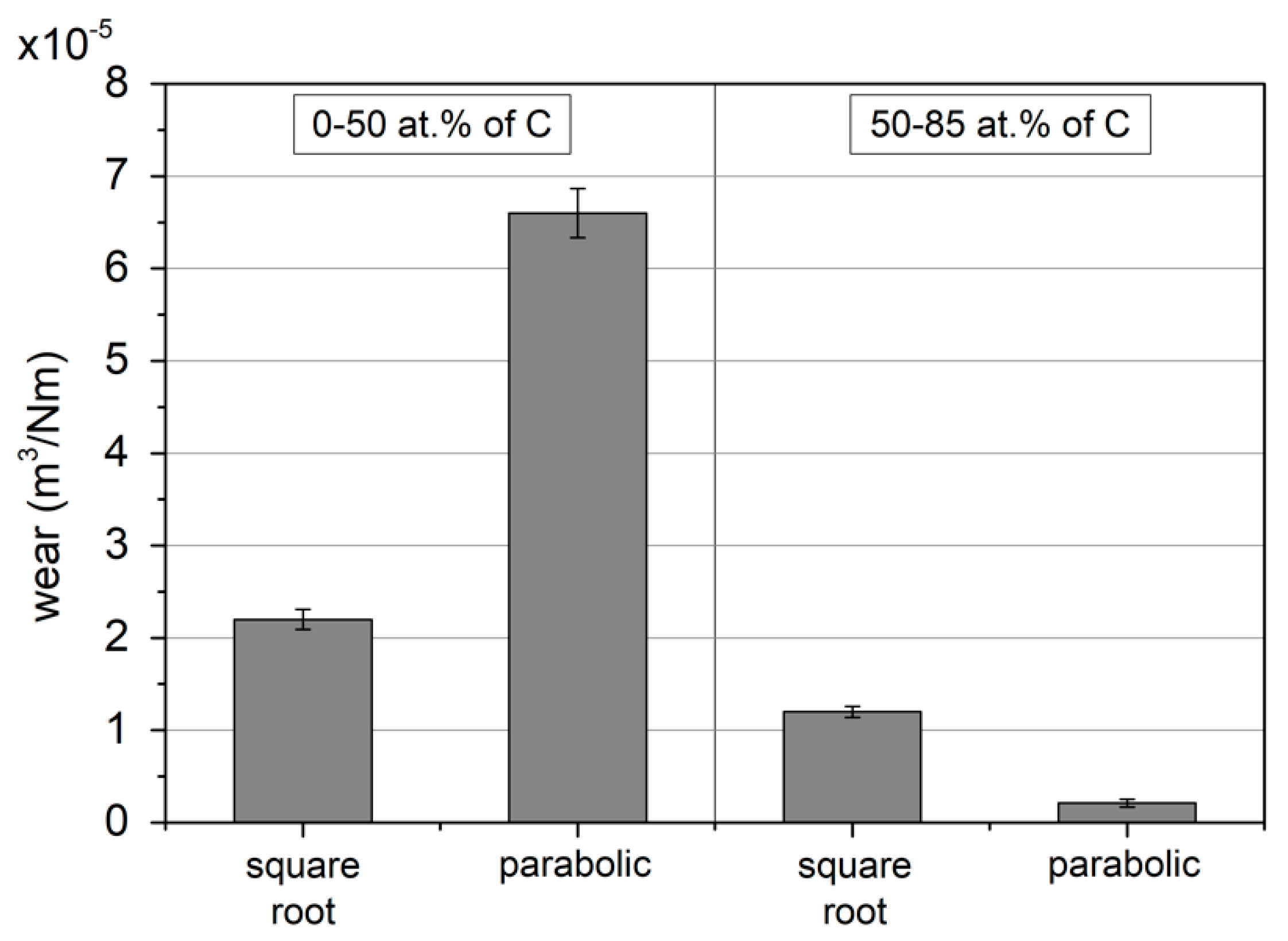

3.4.6. Friction and Wear

4. Conclusions

- Production of coatings characterized by a gradient of hardness changes according to the square root and parabolic profile, from the substrate/coating phase boundary to the top layer, increases their resistance to cohesion damage characterized by critical force values Lc1.

- The research shows that regardless of the hardness as the key parameter characterizing wear-resistant coatings, other properties (Young’s modulus E, coefficient of friction) and behavior (H/E, H3/E2) also have significant impacts on the performance of Zr–C coatings.

- Among the studied gradient coatings, which differ in the range of changes in carbon content, i.e., 0–50 and 50–85 at.%, lower wear rates and higher values of changes in the H/E and H3/E2 ratios, representing the resistance to elastic and plastic deformation, respectively, characterize coatings with a higher carbon content. These results correspond to the critical forces Lc2, which are also higher for coatings in this carbon content range.

- In the case of coatings with a carbon content in the range of 50–85 at.%, higher values of the critical forces Lc1 and Lc2 are characteristic of a coating with a square root hardness profile compared to coatings with a parabolic hardness change profile.

- The results obtained from direct tests (critical force Lc2, friction coefficient, wear) and based on the application of the mixtures rule form the basis for the design of Zr–C gradient coatings with the desired performance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, W.; Xiong, X.; Huang, B.; Li, G.; Zhang, H.; Chen, Z.; Zheng, X. ZrC ablation protective coating for carbon/carbon composites. Carbon 2009, 47, 3368–3371. [Google Scholar] [CrossRef]

- Kim, J.; Suh, Y.J. Temperature-and pressure-dependent elastic properties, thermal expansion ratios, and minimum thermal conductivities of ZrC, ZrN, and Zr(C0.5N0.5). Ceram. Int. 2017, 43, 12968–12974. [Google Scholar] [CrossRef]

- Yang, J.; Wang, M.; Kang, Y.; Li, D. Influence of bilayer periods on structural and mechanical properties of ZrC/ZrB2 superlattice coatings. Appl. Surf. Sci. 2007, 253, 5302–5305. [Google Scholar] [CrossRef]

- Kumar, D.D.; Kaliaraj, G.S.; Kirubaharan, A.K.; Alagarsamy, K.; Vishwakarma, V.; Baskaran, R. Biocorrosion and biological properties of sputtered ceramic carbide coatings for biomedical applications. Surf. Coat. Technol. 2019, 374, 569–578. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stockel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 149, 273–275. [Google Scholar] [CrossRef]

- Chu, C.L.; Ji, H.L.; Yin, L.H.; Pu, Y.P.; Lin, P.H.; Chu, P.K. Fabrication, properties, and cytocompatibility of ZrC film on electropolished NiTi shape memory alloy. Mater. Sci. Eng. C 2011, 31, 423–427. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Liu, X.L.; Zhang, H.F. Properties of Zr–ZrC–ZrC/DLC gradient films on TiNi alloy by the PIIID technique combined with PECVD. Surf. Coat. Technol. 2008, 202, 3011–3016. [Google Scholar] [CrossRef]

- Ul-Hamid, A. Microstructure, Properties and Applications of Zr-Carbide, Zr-Nitride and Zr-Carbonitride Coatings—A Review. Mater. Adv. 2020, 1, 1012–1037. [Google Scholar] [CrossRef]

- Ming-Hui, D.; Hong-Sen, Z.; Chi, Z.; Xing, J. Characterization of ZrC coatings deposited on biomedical 316L stainless steel by magnetron sputtering method. Surf. Coat. Technol. 2013, 224, 34–41. [Google Scholar] [CrossRef]

- Long, Y.; Javed, A.; Chen, J.; Chen, Z.; Xiong, X. Phase composition, microstructure and mechanical properties of ZrC coatings produced by chemical vapor deposition. Ceram. Int. 2014, 40, 707–713. [Google Scholar] [CrossRef]

- Escudeiro, A.; Figueiredo, N.M.; Polcarb, T.; Cavaleiro, A. Structural and mechanical properties of nanocrystalline Zr co-sputtered a-C(:H) amorphous films. Appl. Surf. Sci. 2015, 325, 64–72. [Google Scholar] [CrossRef]

- Kumar, S.S.; Sharma, A.; Rao, G.M.; Suwas, S. Investigations on the effect of substrate temperature on the properties of reactively sputtered zirconium carbide thin films. J. Alloy. Compd. 2017, 695, 1020–1028. [Google Scholar] [CrossRef]

- Mydłowska, K.; Czerwińska, E.; Gilewicz, A.; Dobruchowska, E.; Jakubczyk, E.; Szparaga, Ł.; Ceynowa, P.; Ratajski, J. Evolution of Phase Composition and Antibacterial Activity of Zr–C Thin Films. Processes 2020, 8, 260. [Google Scholar] [CrossRef]

- Szparaga, Ł.; Bartosik, P.; Gilewicz, A.; Mydłowska, K.; Ratajski, J. Optimisation of mechanical properties of ZrC multilayer coatings. Thin Solid Films 2020, 704, 138016. [Google Scholar] [CrossRef]

- Gilewicz, A.; Mydłowska, K.; Ratajski, J.; Szparaga, Ł.; Bartosik, P.; Kochmański, P.; Jędrzejewski, R. Structural, mechanical and tribological properties of ZrC thin films deposited by magnetron sputtering. Vacuum 2019, 169, 108909. [Google Scholar] [CrossRef]

- Meng, Q.N.; Wen, M.; Mao, F.; Nedfors, N.; Jansson, U.; Zheng, W.T. Deposition and characterization of reactive magnetron sputtered zirconium carbide films. Surf. Coat. Technol. 2013, 232, 876–883. [Google Scholar] [CrossRef]

- Andersson, M.; Urbonaite, S.; Lewin, E.; Jansson, U. Magnetron sputtering of Zr–Si–C thin films. Thin Solid Films 2012, 520, 6375–6381. [Google Scholar] [CrossRef]

- Markworth, A.J.; Saunders, J.H. A model of structure optimization for a functionally graded material. Mater. Lett. 1995, 22, 103–107. [Google Scholar] [CrossRef]

- Markworth, A.J.; Ramesh, K.S.; Parks, W.P. Modelling studies applied to functionally graded materials. J. Mater. Sci. 1995, 30, 2183–2193. [Google Scholar] [CrossRef]

- Nemat-Alla, M. Reduction of thermal stresses by developing two-dimensional functionally graded materials. Int. J. Solids. Struct. 2003, 40, 7339–7356. [Google Scholar] [CrossRef]

- Wang, C.; Pureza, J.M.; Yang, Y.; Chung, Y.W. Investigation of hardness and fracture toughness properties of Fe/VC multilayer coatings with coherent interfaces. Surf. Coat. Technol. 2016, 288, 179–184. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-ray Diffraction, 2nd ed.; Addison-Wesley Publishing Company Inc.: Reading, MA, USA, 1978; ISBN 0-201-01174-3. [Google Scholar]

- Dahan, I.; Admon, U.; Frage, N.; Sariel, J.; Dariel, M.P.; Moore, J.J. The development of a functionally graded TiC–Ti multilayer hard coating. Surf. Coat. Technol. 2001, 137, 111–115. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Holmberg, K.; Fancey, K.S.; Pace, A.R.; Matthews, A.; Matthes, B.; Broszeit, E. Coating evaluation methods: A round robin study. Tribol. Ser. 1990, 17, 453–463. [Google Scholar] [CrossRef]

- Rutherford, K.L.; Hutchings, I.M. A micro-abrasive wear test, with particular application to coated systems. Surf. Coat. Technol. 1996, 79, 231–239. [Google Scholar] [CrossRef]

- PN-EN ISO 26423:2016-05. Ceramika Wysokiej Jakości (Ceramika Zaawansowana, Techniczna Ceramika Zaawansowana)—Wyznaczanie Grubości Powłoki Metodą Wyszlifowywania Krateru; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Bull, S.J.; Rickerby, D.S. The inter-relationship between coating microstructure and the tribological performance of PVD coatings. Tribol. Ser. 1990, 17, 337–349. [Google Scholar] [CrossRef]

- Patscheider, J.; Zehnder, T.; Diserens, M. Structure–performance relations in nanocomposite coatings. Surf. Coat. Technol. 2001, 146, 201–208. [Google Scholar] [CrossRef]

- Bull, S.J.; Rickerby, D.S. Compositional, microstructural and morphological effects on the mechanical and tribological properties of chromium nitrogen films. Surf. Coat. Technol. 1990, 43, 732–744. [Google Scholar] [CrossRef]

- Rickerby, D.S.; Bull, S.J. Engineering with surface coatings: The role of coating microstructure. Surf. Coat. Technol. 1989, 39–40, 315–328. [Google Scholar] [CrossRef]

- Ou, Y.X.; Lin, J.; Che, H.L.; Moore, J.J.; Sproul, W.D.; Lei, M.K. Mechanical and tribological properties of CrN/TiN superlattice coatings deposited by a combination of arc-free deep oscillation magnetron sputtering with pulsed dc magnetron sputtering. Thin Solid Films 2015, 594, 147–155. [Google Scholar] [CrossRef]

- Sui, X.; Liu, J.; Zhang, S.; Yang, J.; Hao, J. Microstructure, mechanical and tribological characterization of CrN/DLC/Cr-DLC multilayer coating with improved adhesive wear resistance. Appl. Surf. Sci. 2018, 439, 24–32. [Google Scholar] [CrossRef]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J. Mater. Process. Technol. 2003, 143, 481–485. [Google Scholar] [CrossRef]

- Broitman, E.; Hultman, L. Adhesion improvement of carbon-based coatings through a high ionization deposition technique. J. Phys. Conf. Ser. 2012, 370, 012009. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, X.B.; Zhao, Z.W.; Gao, J.B.; Zhou, Y.W.; Gao, P.; Guo, Y.Y.; Lv, Z. Evaluation of the adhesion and failure mechanism of the hard CrN coatings on different substrates. Surf. Coat. Technol. 2019, 364, 135–143. [Google Scholar] [CrossRef]

- Chen, X.; Du, Y.; Chung, Y.W. Commentary on using H/E and H3/E2 as proxies for fracture toughness of hard coatings. Thin Solid Films 2019, 688, 137265. [Google Scholar] [CrossRef]

- Blažek, J.; Musil, J.; Stupka, P.; Čerstvý, R.; Houška, J. Properties of nanocrystalline Al–Cu–O films reactively sputtered by DC pulse dual magnetron. Appl. Surf. Sci. 2011, 258, 1762–1767. [Google Scholar] [CrossRef]

- Musil, J.; Jílek, R.; Meissner, M.; Tölg, T.; Čerstvý, R. Two-phase single layer Al-O-N nanocomposite films with enhanced resistance to cracking. Surf. Coat. Technol. 2012, 206, 4230–4234. [Google Scholar] [CrossRef]

- Musil, J.; Sklenka, J.; Čerstvý, R.; Suzuki, T.; Mori, T.; Takahashi, M. The effect of addition of Al in ZrO2 thin film on its resistance to cracking. Surf. Coat. Technol. 2012, 207, 355–360. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Leylan, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behavior. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Masanta, M.; Shariff, S.M.; Choudhury, A.R. Evaluation of modulus of elasticity, nano-hardness and fracture toughness of TiB2–TiC–Al2O3 composite coating developed by SHS and laser cladding. Mater. Sci. Eng. A Struct. 2011, 528, 5327–5335. [Google Scholar] [CrossRef]

| C2H2 Volumetric Flow Rate, sccm | C, at.% | Zr, at.% | O, H and Others, at.% |

|---|---|---|---|

| 0 | ~0.0 | 91.8 | 8.2 |

| 1.5 | 20.7 | 71.6 | 7.7 |

| 2.0 | 35.9 | 58.4 | 5.7 |

| 2.5 | 50.8 | 44.9 | 4.3 |

| 3.5 | 52.9 | 43.7 | 3.4 |

| 4.5 | 63.3 | 33.0 | 3.7 |

| 6.5 | 79.0 | 18.9 | 2.1 |

| Gradient Type | Coating Thickness, μm |

|---|---|

| square root, 0–50 at.% of C | 3.6 |

| square root, 50–85 at.% of C | 3.2 |

| parabolic, 0–50 at.% of C | 3.8 |

| parabolic, 50–85 at.% of C | 3.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ratajski, J.; Gilewicz, A.; Mydłowska, K.; Szparaga, Ł. Inter-Relationship between Coating Micro/Nanostructure and the Tribological Performance of Zr–C Gradient Coatings. Coatings 2020, 10, 1121. https://doi.org/10.3390/coatings10111121

Ratajski J, Gilewicz A, Mydłowska K, Szparaga Ł. Inter-Relationship between Coating Micro/Nanostructure and the Tribological Performance of Zr–C Gradient Coatings. Coatings. 2020; 10(11):1121. https://doi.org/10.3390/coatings10111121

Chicago/Turabian StyleRatajski, Jerzy, Adam Gilewicz, Katarzyna Mydłowska, and Łukasz Szparaga. 2020. "Inter-Relationship between Coating Micro/Nanostructure and the Tribological Performance of Zr–C Gradient Coatings" Coatings 10, no. 11: 1121. https://doi.org/10.3390/coatings10111121

APA StyleRatajski, J., Gilewicz, A., Mydłowska, K., & Szparaga, Ł. (2020). Inter-Relationship between Coating Micro/Nanostructure and the Tribological Performance of Zr–C Gradient Coatings. Coatings, 10(11), 1121. https://doi.org/10.3390/coatings10111121