Hybrid ZrO2/Cr2O3 Epoxy Nanocomposites as Organic Coatings for Steel

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Methods and Techniques

2.2.1. Synthesis of Zirconium Oxide Nanoparticles (ZrO2 NPs)

2.2.2. Synthesis of Chromium Oxide Nanoparticles (Cr2O3NPs)

2.2.3. ZrO2/Cr2O3 Epoxy Nanocomposite Coating Films

2.3. Characterization Study of the Prepared ZrO2 NPs and Cr2O3NPs

2.4. Mechanical and Corrosion Resistances Property of ZrO2/Cr2O3 Coating Films

3. Results and Discussion

3.1. Characterization of the Prepared ZrO2 and Cr2O3 NPs

3.2. Surface Morphology and Thermal Characteristics of ZrO2/Cr2O3 Epoxy Nanocomposite Coating

3.3. Mechanical Properties and Anticorrosion Properties of ZrO2/Cr2O3 Epoxy Nanocomposite Coating on the Steel Substrate

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Atta, M.A.; El-Saeed, M.A.; El-Mahdy, M.G.; Al-Lohedana, A.H. Application of magnetite nano-hybrid epoxy as protective marine coatings for steel. RSC Adv. 2015, 5, 101923–101931. [Google Scholar] [CrossRef]

- Atta, M.A.; El-Saeed, M.A.; Al-Shafey, H.I.; Al-Lohedana, A.N.; Tawfeek, M.A.; Wahbey, M. Effect of inorganic nanomaterials types functionalized with smart nanogel on anti-corrosion and mechanical performances of epoxy coatings. Int. J. Electrochem. Sci. 2017, 12, 1167–1182. [Google Scholar] [CrossRef]

- Mohammad loo, H.E.; Sarabi, A.A.; Asemani, H.R.; Ahmadi, P. A comparative study of eco-friendly hybrid thin films: With and without organic coating application. Prog. Org. Coat. 2018, 125, 432–442. [Google Scholar] [CrossRef]

- Sababi, M.; Terryn, H.A.; Mol, J.M.C. The influence of a Zr-based conversion treatment on interfacial bonding strength and stability of epoxy coated carbon steel. Prog. Org. Coat. 2017, 105, 29–36. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Attar, M.M. An evaluation of the corrosion resistance and adhesion properties of an epoxy-nanocomposite on a hot-dip galvanized steel (HDG) treated by different kinds of conversion coatings. Surf. Coat. Technol. 2011, 205, 4649–4657. [Google Scholar] [CrossRef]

- Asemani, H.R.; Ahmadi, P.; Sarabi, A.A.; Mohammadloo, H.E. Effect of zirconium conversion coating: Adhesion and anti-corrosion properties of epoxy organic coating containing zinc aluminum polyphosphate (ZAPP) pigment on carbon mild steel. Prog. Org. Coat. 2016, 94, 18–27. [Google Scholar] [CrossRef]

- Hosseini, R.M.; Sarabi, A.A.; Mohammadloo, H.E.; Sarayloo, M. The performance improvement of Zr conversion coating through Mn incorporation: With and without organic coating. Surf. Coat. Technol. 2014, 258, 437–446. [Google Scholar] [CrossRef]

- Golru, S.S.; Attar, M.M.; Ramezanzadeh, B. Effects of surface treatment of aluminium alloy 1050 on the adhesion and anticorrosion properties of the epoxy coating. Appl. Surf. Sci. 2015, 345, 360–368. [Google Scholar] [CrossRef]

- Golru, S.S.; Attar, M.M.; Ramezanzadeh, B. Morphological analysis and corrosion performance of zirconium based conversion coating on the aluminum alloy 1050. J. Ind. Eng. Chem. 2015, 24, 233–244. [Google Scholar] [CrossRef]

- Ghanbari, A.; Attar, M.M. Surface free energy characterization and adhesion performance of mild steel treated based on zirconium conversion coating: A comparative study. Surf. Coat. Technol. 2014, 246, 26–33. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Mirabedini, S.M.; Kabiri, K.; Jamali, S. Corrosion performance of epoxy coatings containing silane treated ZrO2 nanoparticles on mild steel in 3.5% NaCl solution. Corros. Sci. 2011, 53, 89–98. [Google Scholar] [CrossRef]

- Wei, H.; Xia, J.; Zhou, W.; Zhou, L.; Hussain, G.; Li, Q.; Ostrikov, K.K. Adhesion and cohesion of epoxy-based industrial composite coatings. Compos. Part B Eng. 2020, 193, 108035. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Mirabedini, S.M.; Esfandeh, M. Corrosion protection of steel by epoxy nanocompositecoatings containing various combinations of clay and nanoparticulate zirconia. Corros. Sci. 2013, 75, 134–141. [Google Scholar] [CrossRef]

- Medina, R.; Haupert, F.; Schlarb, A.K. Improvement of tensile properties and toughness of an epoxy resin by nano zirconium-dioxide reinforcement. J. Mater. Sci. 2008, 43, 3245–3252. [Google Scholar] [CrossRef]

- Guo, Y.; Frankel, G.S. Active corrosion inhibition of AA2024-T3 by trivalent chrome process treatment. J. Corros. 2012, 68, 045002. [Google Scholar] [CrossRef]

- Li, L.; Swain, G.M. Formation and structure of trivalent chromium process coatings on aluminum alloys 6061 and 7075. Corrosion 2013, 69, 1205. [Google Scholar] [CrossRef]

- Qi, J.; Hashimoto, T.; Walton, J.; Zhou, X.; Skeldon, P.; Thompson, G.E. Formation of a trivalent chromium conversion coating on AA 2024-T351 alloy. J. Electrochem. Soc. 2016, 163, C25–C35. [Google Scholar] [CrossRef]

- Li, L.; Desouza, A.L.; Swain, G.M. Effect of deoxidation pretreatment on the corrosion inhibition provided by a trivalent chromium process (TCP) conversion coating on AA2024-T3. J. Electrochem. Soc. 2014, 161, 246–253. [Google Scholar] [CrossRef]

- Li, L.; Swain, G.M. Effects of aging temperature and time on the corrosion protection provided by trivalent chromium process coatings on AA2024-T3. ACS Appl. Mat. Interf. 2013, 5, 7923–7930. [Google Scholar] [CrossRef] [PubMed]

- ASTM D4541-17 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers; ASTM International: West Conshohocken, PA, USA, 2017; Volume 06.02, p. 18. [CrossRef]

- ASTM D522/D522M-17 Standard Test Methods for Mandrel Bend Test of Attached Organic Coatings; ASTM International: West Conshohocken, PA, USA, 2017; Volume 06.01, p. 5. [CrossRef]

- ASTM D2794-93(2019) Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact); ASTM International: West Conshohocken, PA, USA, 2019; Volume 06.01, p. 3. [CrossRef]

- ASTM D3363-20 Standard Test Method for Film Hardness by Pencil Test; ASTM International: West Conshohocken, PA, USA, 2020; Volume 06.01, p. 2. [CrossRef]

- ASTM D4060-19 Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser; ASTM International: West Conshohocken, PA, USA, 2019; Volume 06.01, p. 6. [CrossRef]

- ASTM B117-19 Standard Practice for Operating Salt Spray (Fog) Apparatus; ASTM International: West Conshohocken, PA, USA, 2020; Volume 03.02, p. 11. [CrossRef]

- ASTM D1654-08(2016)e1 Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments; ASTM International: West Conshohocken, PA, USA, 2016; Volume 06.01, p. 4. [CrossRef]

- Davar, F.; Hassankhani, A.; Loghman-Estarki, M.R. Controllable synthesis of metastable tetragonal zirconia nanocrystals using citric acid assisted sol–gel method. Ceram. Inter. 2013, 39, 2933–2941. [Google Scholar] [CrossRef]

- Sigwadi, R.; Dhlamini, M.; Mokrani, T.; Nemavhola, F. Preparation of a high surface area zirconium oxide for fuel cell application. Int. J. Mech. Mater. Eng. 2019, 14, 5. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Yan, Z.F.; Lu, G.Q.; Zhu, Z.H. Synthesis and structure characterization of chromium oxide prepared by solid thermal decomposition reaction. J. Phys. Chem. B 2006, 110, 178–183. [Google Scholar] [CrossRef] [PubMed]

- Palmer, D.A.; Machesky, M.L.; Bénézeth, P.; Wesolowski, D.J.; Anovitz, L.M.; Deshon, J.C. Adsorption of ions on zirconium oxide surfaces from aqueous solutions at high solution temperatures. J. Chem. 2009, 38, 907–924. [Google Scholar] [CrossRef]

- Mirabedini, M.S.; Behzadnasab, M.; Kabir, K. Effect of various combinations of zirconia and organoclay nanoparticles on mechanical and thermal properties of an epoxy nanocomposite coating. Compos. Part A 2012, 43, 2095–2106. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A.; Bondioli, F.; Messori, M. Improving epoxy adhesives with zirconia nanoparticles. Compos. Interfaces 2010, 17, 873–892. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.A.; Nguyen, T.H.; Nguyen, T.V.; Thai, H.; Shi, X. Effect of nanoparticles on the thermal and mechanical properties of epoxy coatings. J. Nanosc. Nanotech. 2016, 16, 9874–9881. [Google Scholar] [CrossRef]

- Zhou, K.; Gui, Z.; Hu, Y.; Jiang, S.; Tang, G. The influence of cobalt oxide–graphene hybrids on thermal degradation, fire hazards and mechanical properties of thermoplastic polyurethane composites. Compos. Part A 2016, 88, 10–1811. [Google Scholar] [CrossRef]

- Khan, R.; Azhar, M.R.; Anis, A.; Alam, M.A.; Boumaza, M.; Al-Zahrani, S.M. Facile synthesis of epoxy nanocomposite coatings using inorganic nanoparticles for enhanced thermo-mechanical properties: A comparative study. J. Coat. Technol. Res. 2016, 13, 159–169. [Google Scholar] [CrossRef]

- Bhattacharya, M. Polymer nanocomposites—A comparison between carbon nanotubes, graphene, and clay as nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef]

- Zotti, A.; Zuppolini, S.; Borriello, A.; Zarrelli, M. Thermal and mechanical characterization of an aeronautical graded epoxy resin loaded with hybrid nanoparticles. Nanomaterials 2020, 10, 1388. [Google Scholar] [CrossRef] [PubMed]

- Dwivedi, D.; Lepková, K.; Becker, T. Carbon steel corrosion: A review of key surface properties and characterization methods. RSC Adv. 2017, 7, 4580–4610. [Google Scholar] [CrossRef] [Green Version]

| Coating Design | NPs Weight % (wt.%) | Tg (°C) |

|---|---|---|

| Blank epoxy (E) | 0 | 23.8 ± 0.2 |

| Epoxy/ZrO2/Cr2O3 NPs | 0.5 | 24.6 ± 0.1 |

| 1.0 | 25.9 ± 0.3 | |

| 1.5 | 30.3 ± 0.1 | |

| 2.5 | 35.6 ± 0.2 |

| Coating Design | NPs Weight % (wt.%) | Hardness (Newton) | Adhesion (MPa) | Impact (Joule) | Pending | Weight Loss (mg)/1000 Cycles |

|---|---|---|---|---|---|---|

| Blank epoxy | 0 | 5 ± 0.1 | 3 ± 1.8 | 5 ± 0.2 | Pass | 85 ± 2.2 |

| Epoxy/ZrO2/Cr2O3 NPs | 0.5 | 10 ± 0.3 | 4 ± 0.2 | 7 ± 0.1 | Pass | 65 ± 1.4 |

| 1.0 | 11 ± 0.2 | 6 ± 1.1 | 9 ± 0.3 | Pass | 40 ± 1.1 | |

| 1.5 | 12 ± 0.1 | 9 ± 1.4 | 10 ± 0.1 | Pass | 25 ± 2.1 | |

| 2.5 | 11 ± 0.2 | 7 ± 0.6 | 8 ± 0.2 | Pass | 30 ± 1.8 |

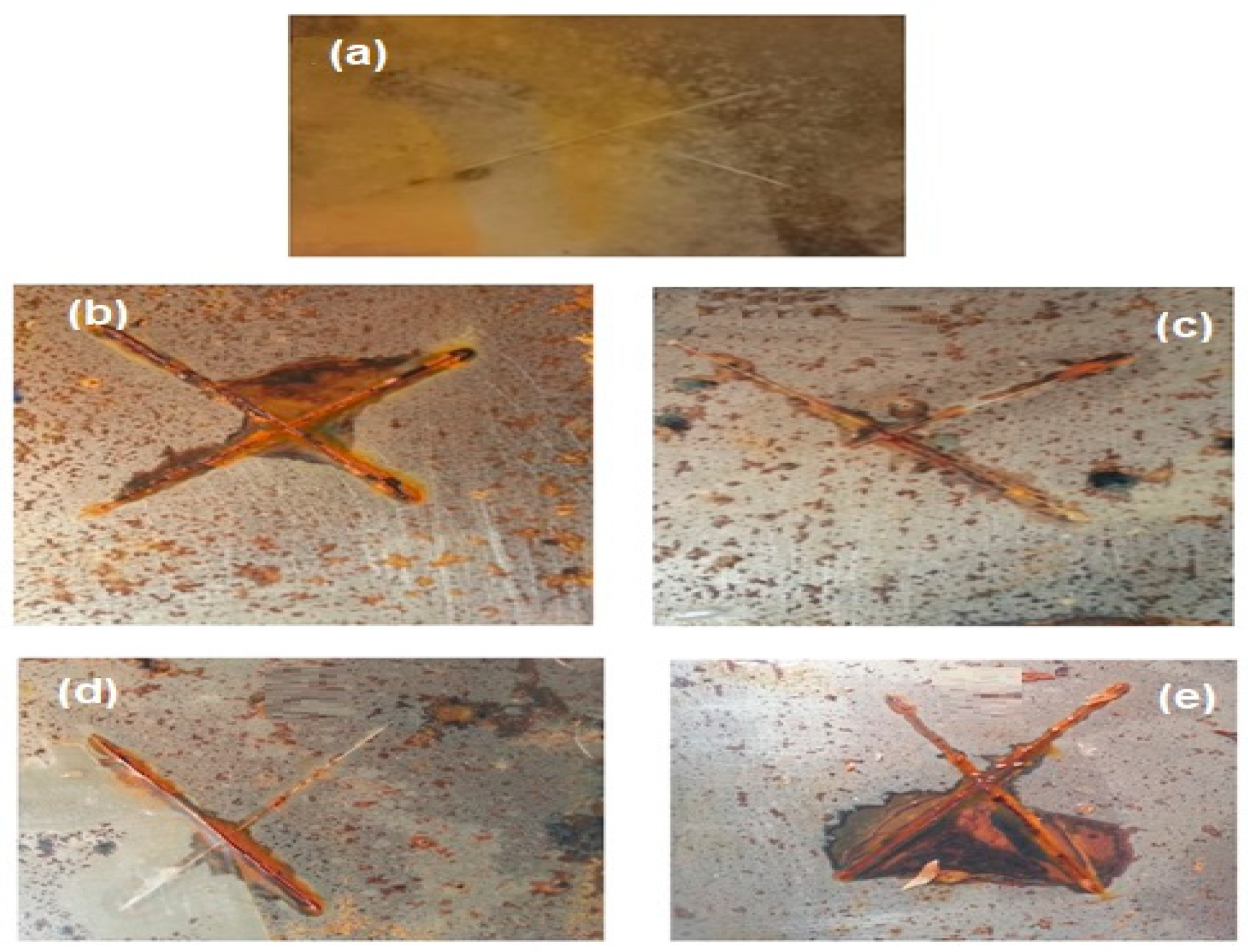

| Coating Design | NPs Weight % (wt.%) | Disbanded Area % | Rating Number (ASTM D-1654) |

|---|---|---|---|

| Blank epoxy | 0 | 19 ± 0.1 | 5 |

| Epoxy/ZrO2/Cr2O3 NPs | 0.5 | 5 ± 0.05 | 7 |

| 1.0 | 2 ± 0.08 | 8 | |

| 1.5 | 1 ± 0.08 | 9 | |

| 2.5 | 2 ± 0.04 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atta, A.M.; Ahmed, M.A.; El-Saeed, A.M.; Abo-Elenien, O.M.; El-Sockary, M.A. Hybrid ZrO2/Cr2O3 Epoxy Nanocomposites as Organic Coatings for Steel. Coatings 2020, 10, 997. https://doi.org/10.3390/coatings10100997

Atta AM, Ahmed MA, El-Saeed AM, Abo-Elenien OM, El-Sockary MA. Hybrid ZrO2/Cr2O3 Epoxy Nanocomposites as Organic Coatings for Steel. Coatings. 2020; 10(10):997. https://doi.org/10.3390/coatings10100997

Chicago/Turabian StyleAtta, Ayman M., Mona A. Ahmed, Ashraf M. El-Saeed, Ossama M. Abo-Elenien, and Maher A. El-Sockary. 2020. "Hybrid ZrO2/Cr2O3 Epoxy Nanocomposites as Organic Coatings for Steel" Coatings 10, no. 10: 997. https://doi.org/10.3390/coatings10100997

APA StyleAtta, A. M., Ahmed, M. A., El-Saeed, A. M., Abo-Elenien, O. M., & El-Sockary, M. A. (2020). Hybrid ZrO2/Cr2O3 Epoxy Nanocomposites as Organic Coatings for Steel. Coatings, 10(10), 997. https://doi.org/10.3390/coatings10100997