Improving the Anti-Pilling Performance of Cellulose Fiber Blended Knitted Fabrics with 2,4,6-Trichloropyrimidine Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of TLP Dispersed Emulsions

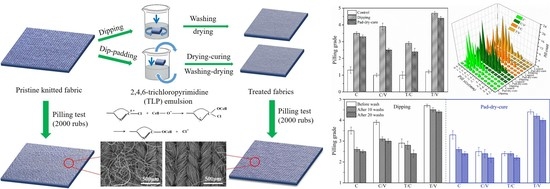

2.3. Preparation of Anti-Pilling Knitted Fabrics

2.4. Characterization and Measurements

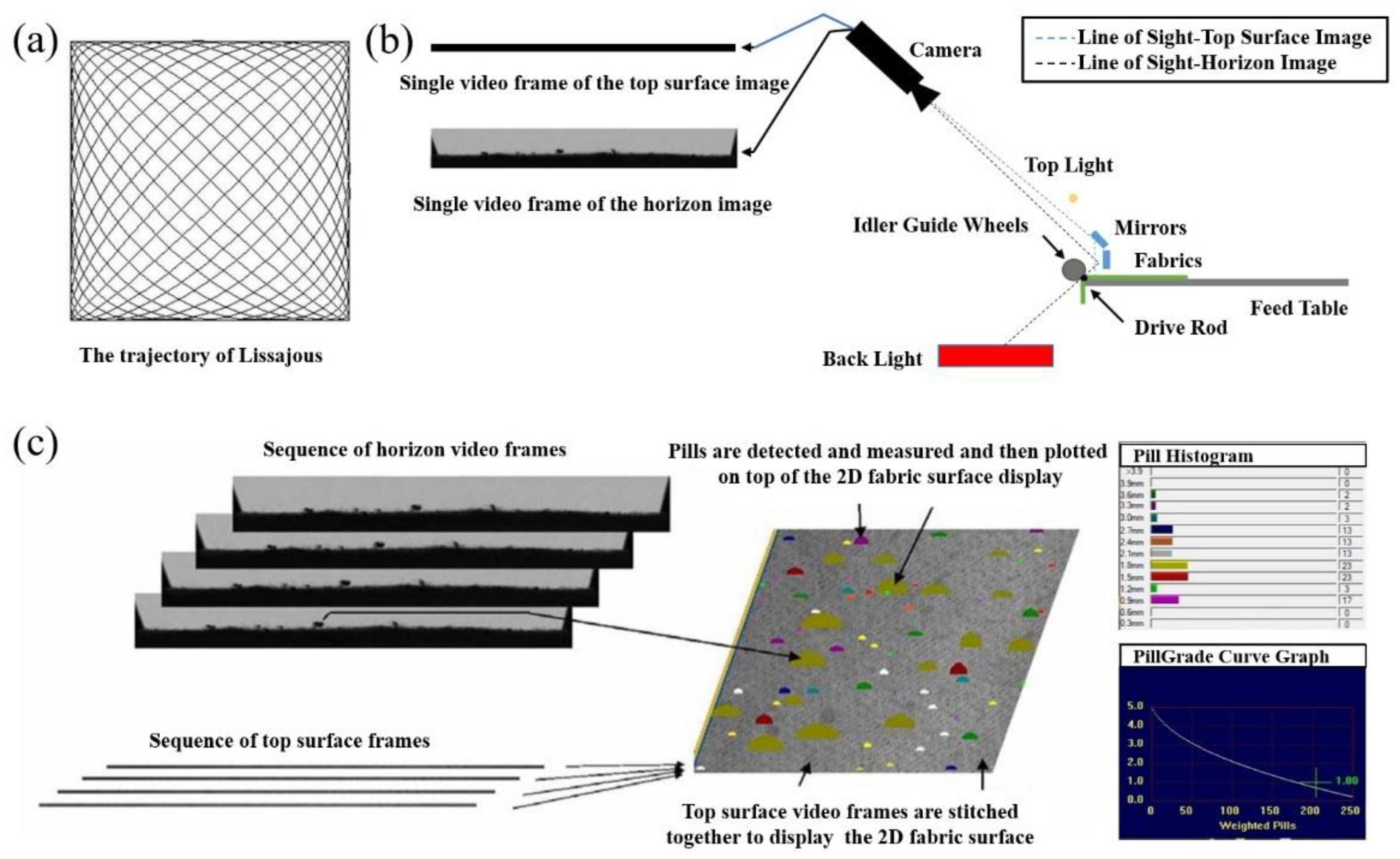

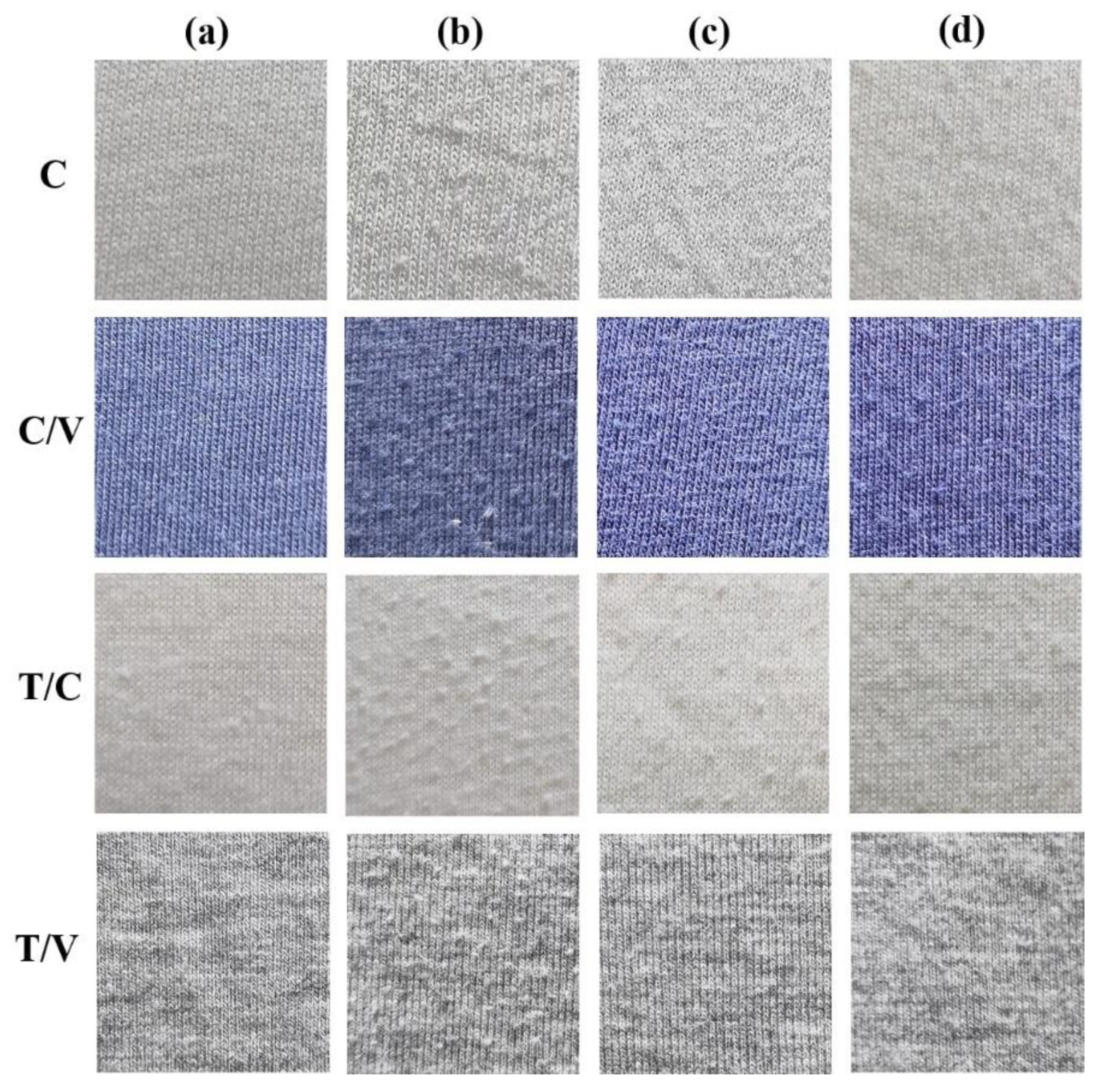

2.4.1. Pilling Characterization

2.4.2. Surface Morphology and Structure Analysis

2.4.3. Thermal Stability and Washing Resistance

2.4.4. Physical and Mechanical Properties

2.4.5. Color Change Performance

3. Results and Discussion

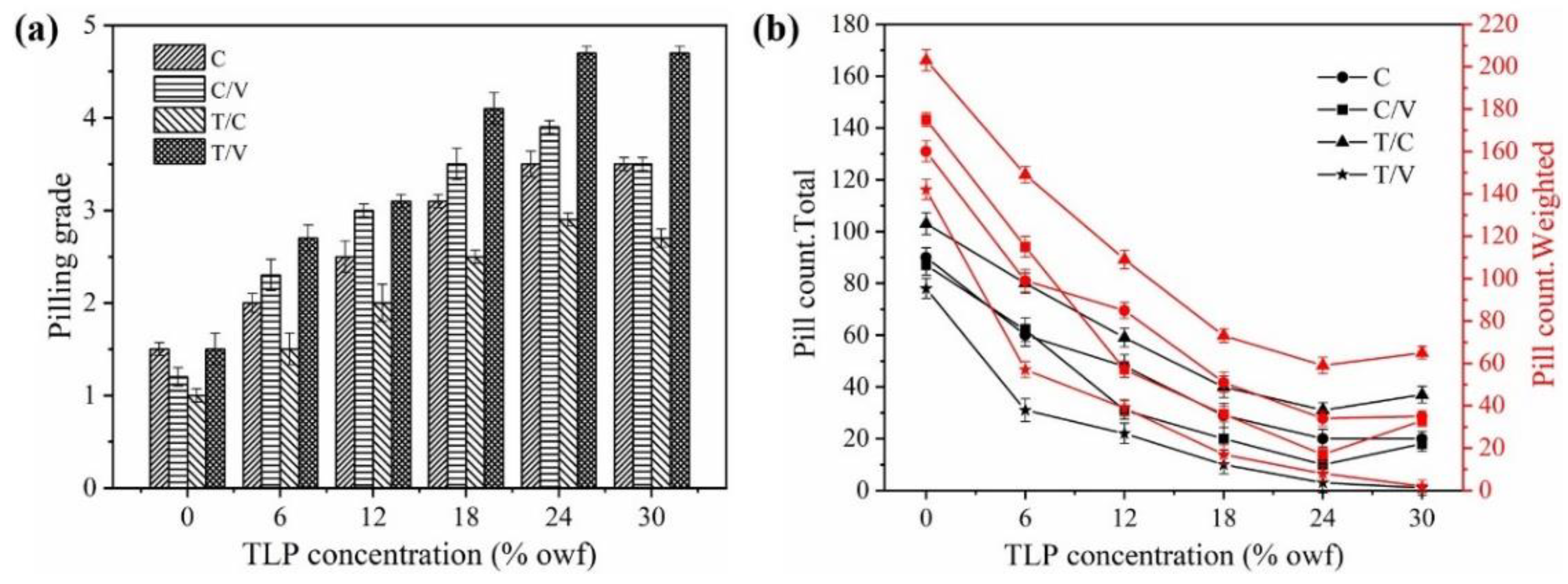

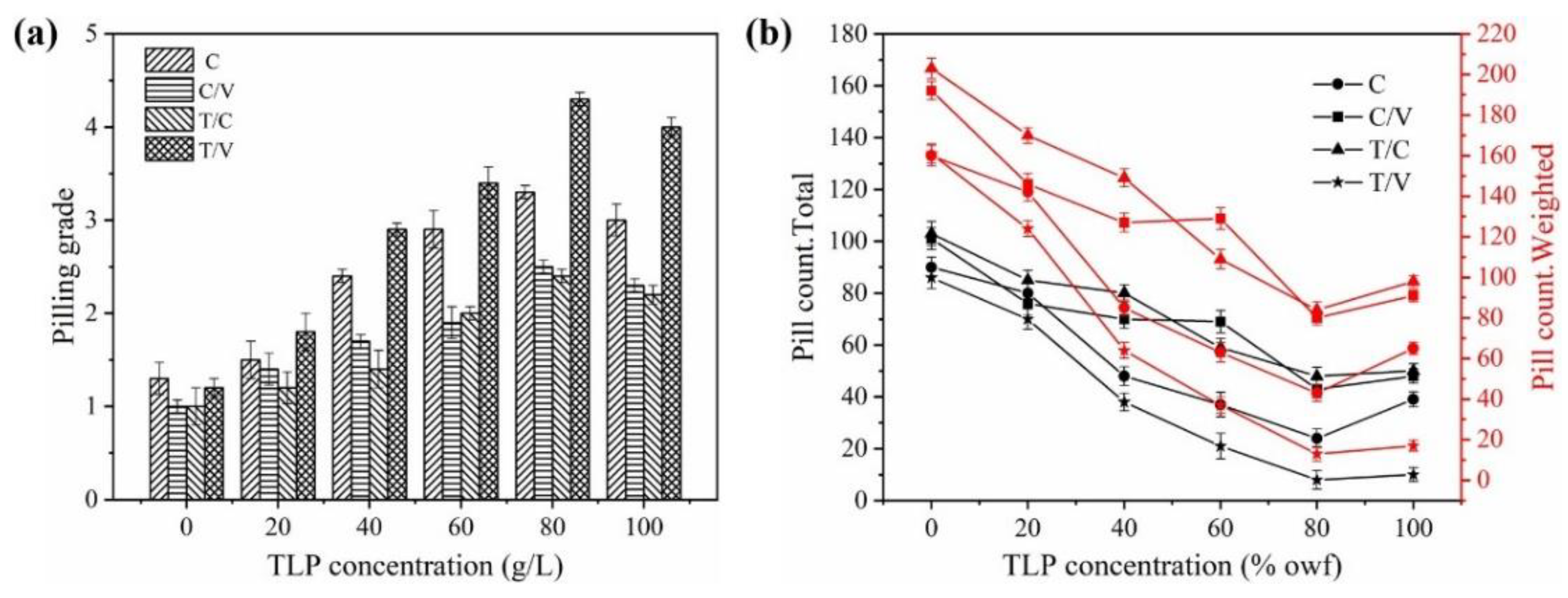

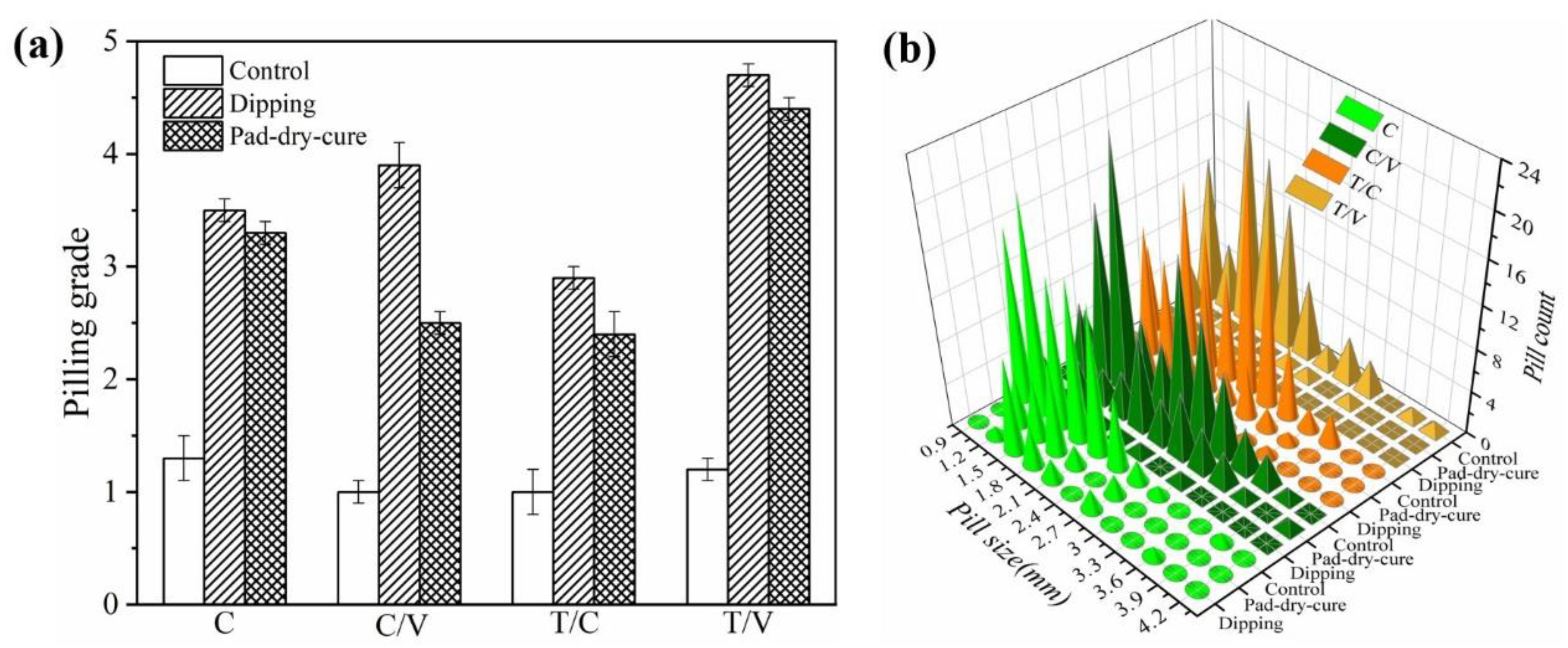

3.1. Influence of TLP Concentration on Anti-Pilling Performance with Dipping and Pad–Dry–Cure Processes

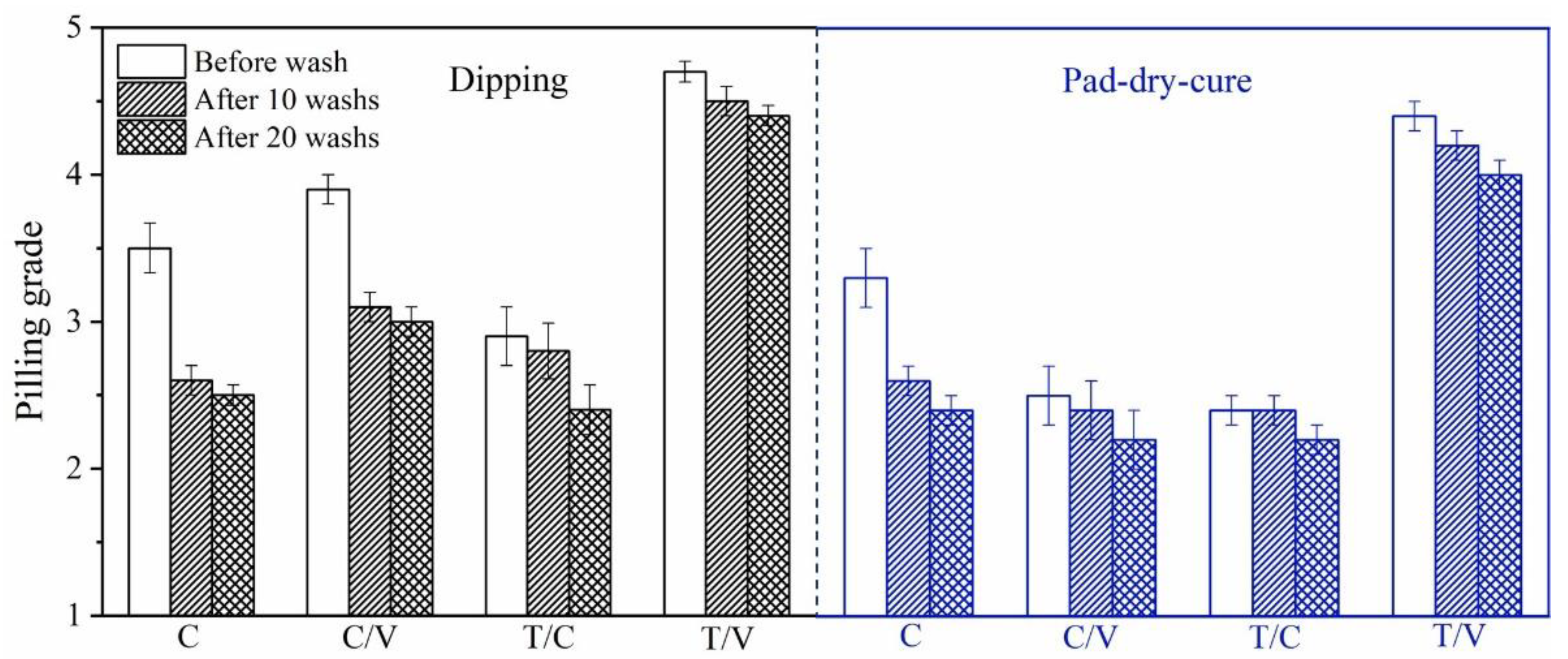

3.2. Anti-Pilling Performance

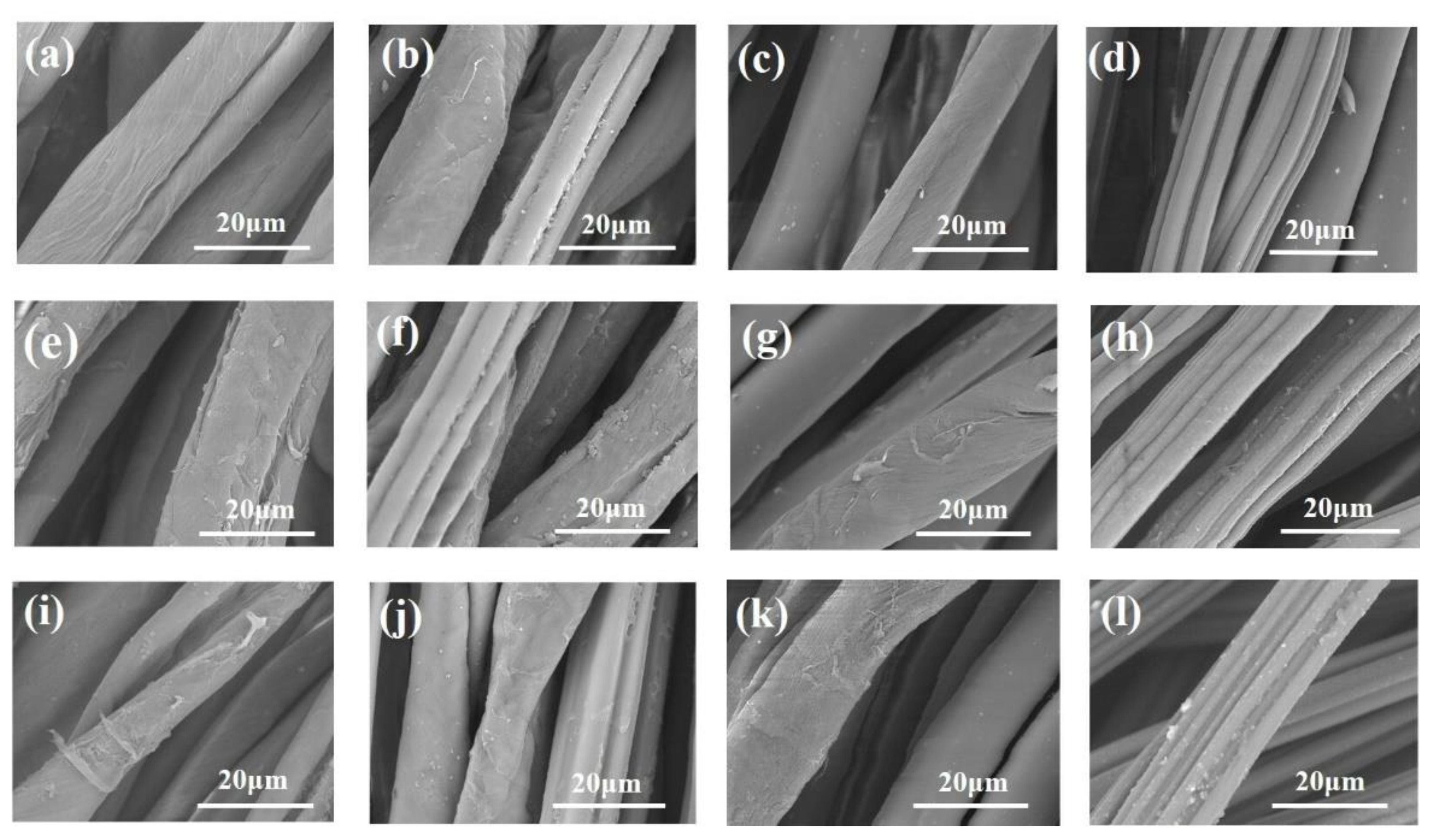

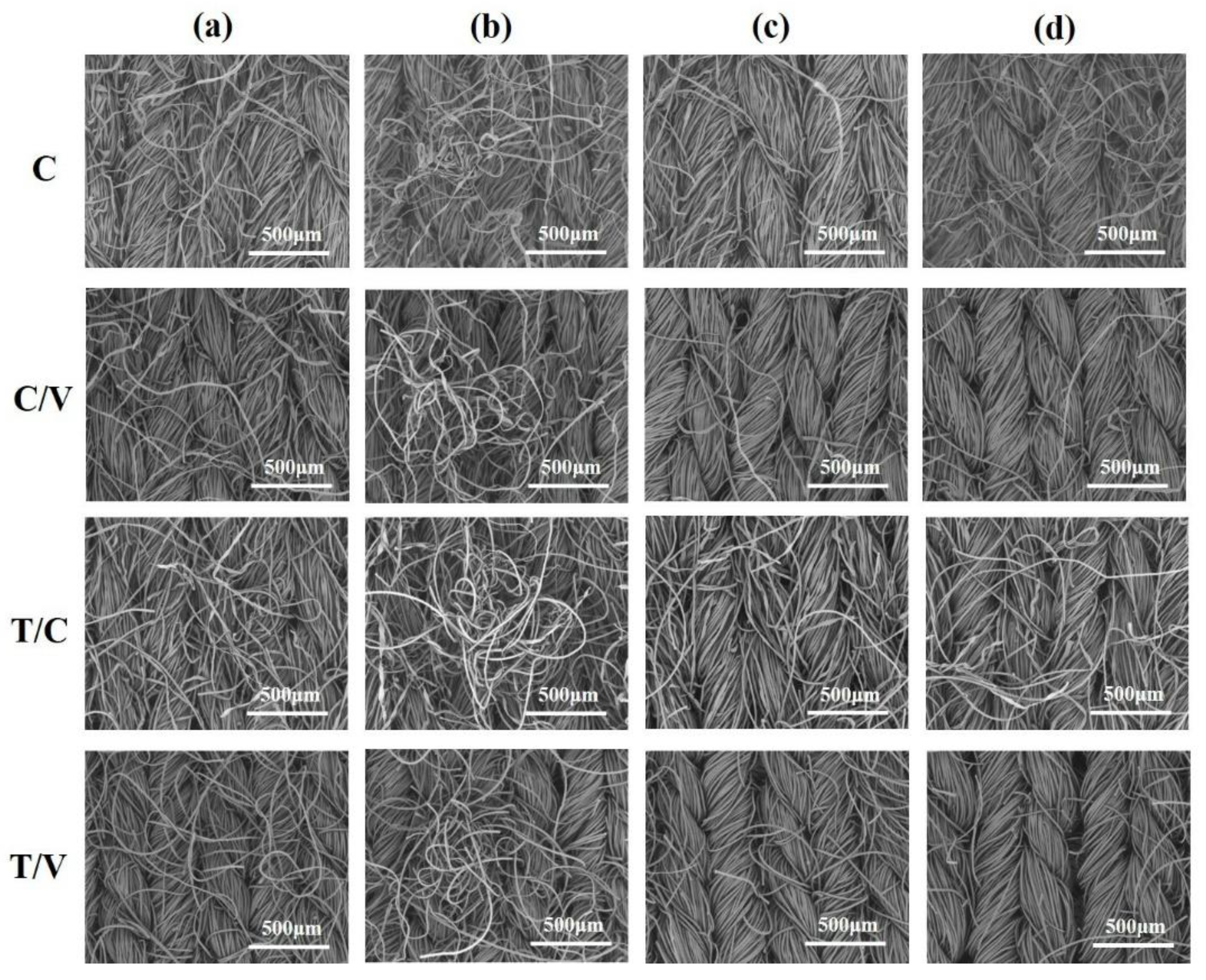

3.3. SEM-EDS Analysis

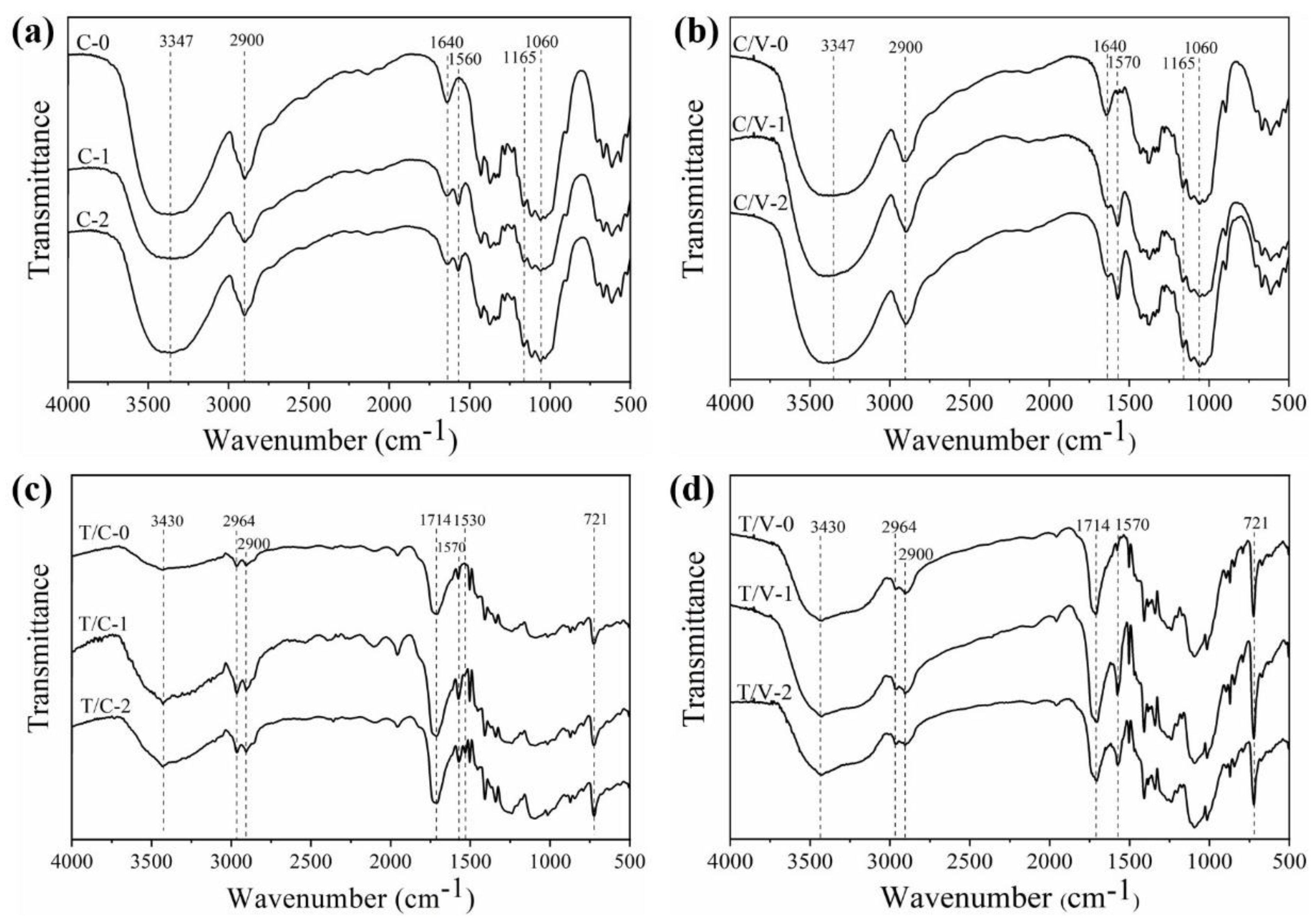

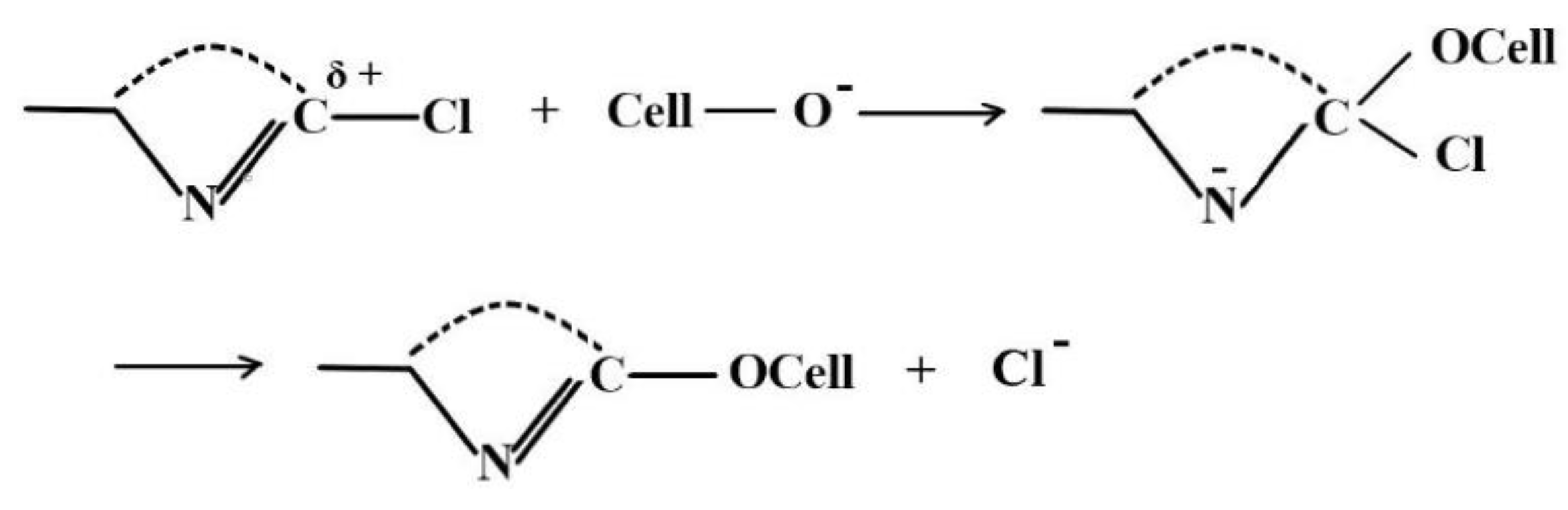

3.4. FT-IR Analysis

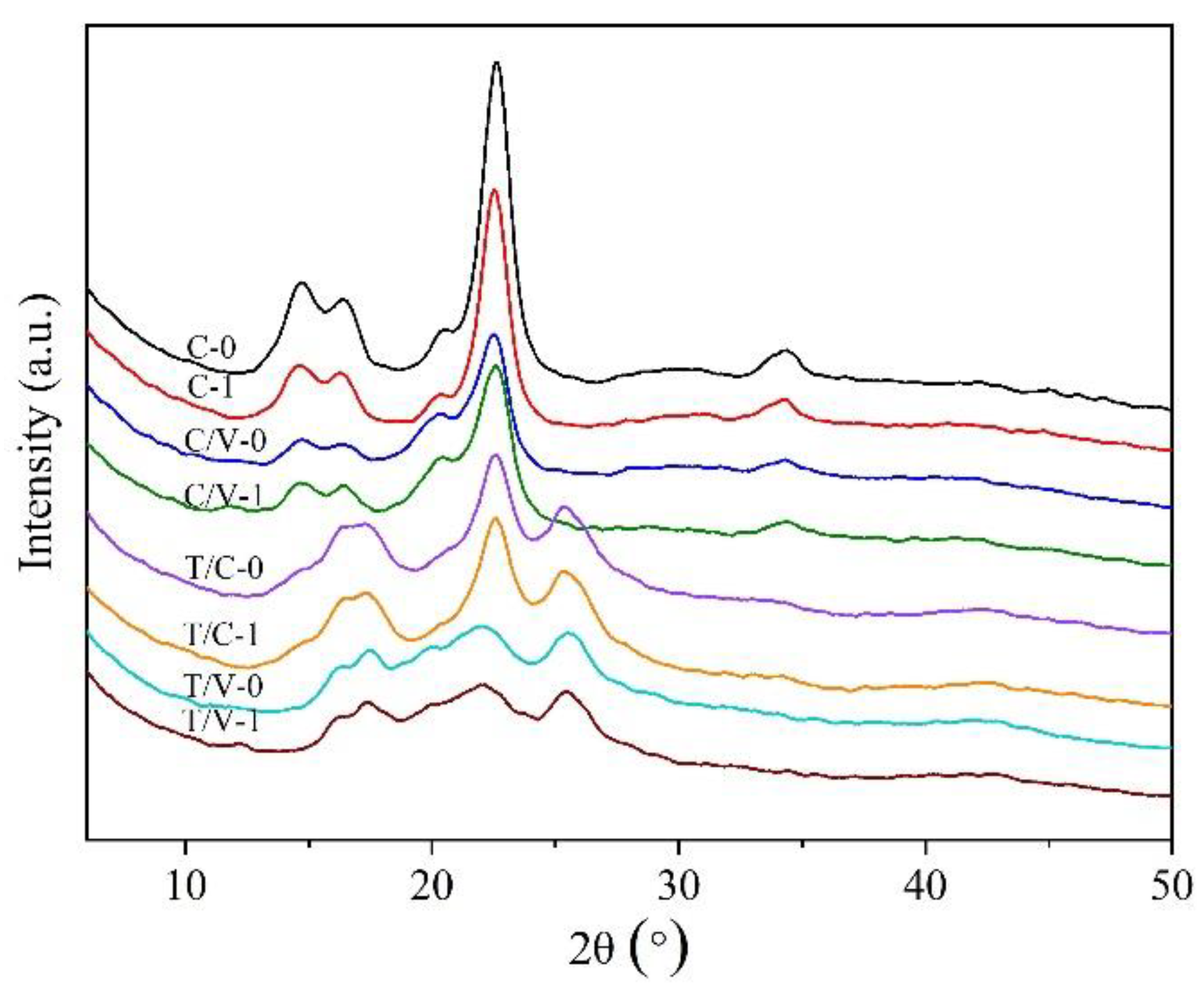

3.5. XRD Analysis

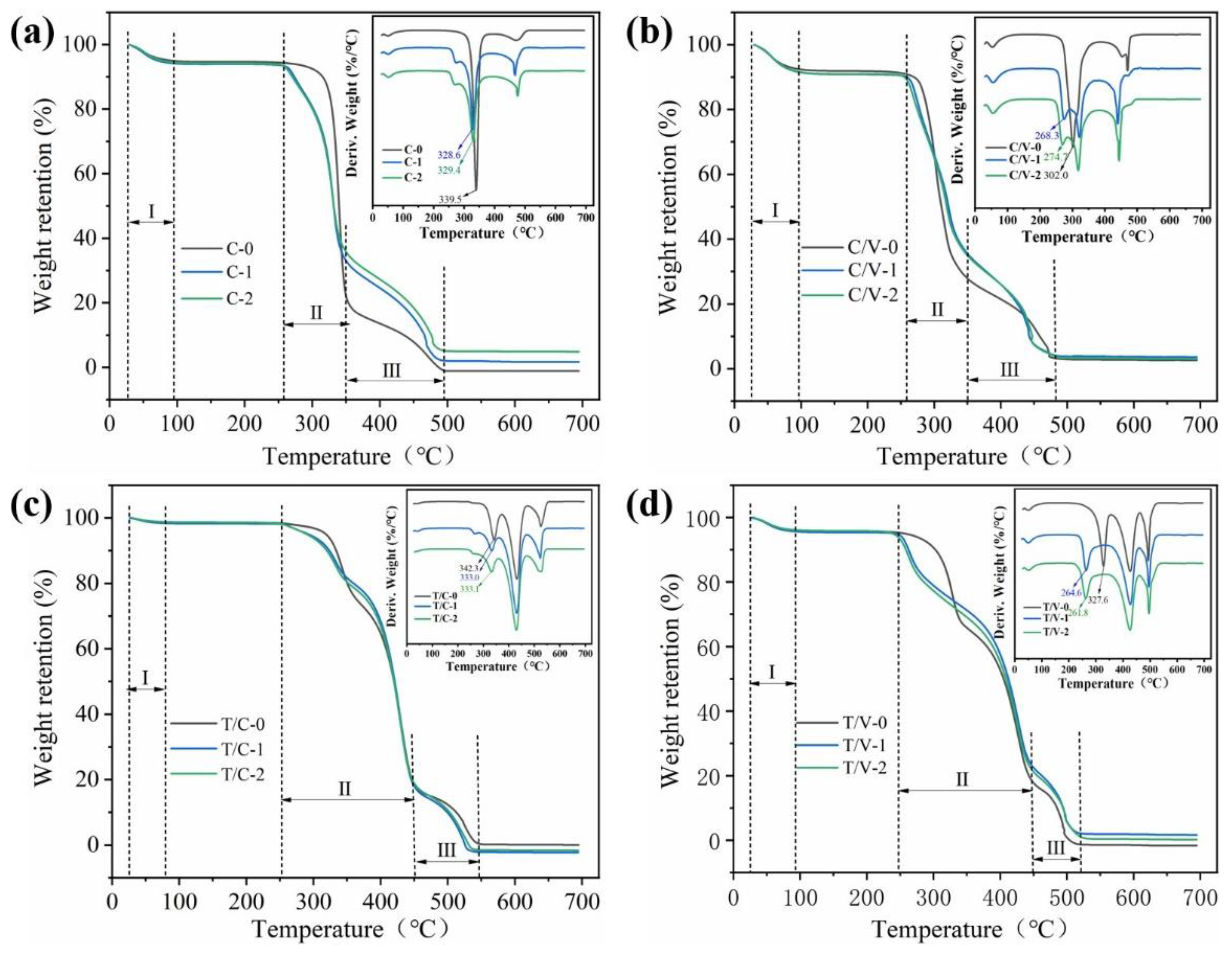

3.6. TG and DTG Analysis

3.7. Physical and Mechanical Properties

3.8. Whiteness, Color Parameters and Colorfastness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wan, A.; Yu, W. Effect of wool fiber modified by ecologically acceptable ozone-assisted treatment on the pilling of knit fabrics. Text Res. J. 2012, 82, 27–36. [Google Scholar] [CrossRef]

- Dalbasi, E.S.; Ozcelik Kayseri, G. A research about the effect of the anti-pilling treatments on different structured cotton knitted fabrics. Tekstil Konfeksiyon 2015, 25, 54–60. [Google Scholar]

- Liu, Y.; Xia, L.; Zhang, Q.; Guo, H.; Wang, A.; Xu, W.; Wang, Y. Structure and properties of carboxymethyl cotton fabric loaded by reduced graphene oxide. Carbohyd. Polym. 2019, 214, 117–123. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Ding, X.M.; Wu, X.Y. A novel method for improving the anti-pilling property of knitted wool fabric with engineered water nanostructures. J. Mater. Res. Technol. 2020, 102, 3649–3658. [Google Scholar] [CrossRef]

- Rong, L.; Liu, H.; Wang, B.; Xu, H.; Zhang, L.; Zhong, Y.; Feng, X.; Sui, X. Durable antibacterial and hydrophobic cotton fabrics utilizing enamine bonds. Carbohyd. Polym. 2019, 211, 173–180. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Chen, D.; Du, Z.; Li, J.; Wang, Y.; Yang, Z. Structure and properties of silk fibroin grafted carboxylic cotton fabric via amide covalent modification. Carbohyd. Polym. 2017, 161, 99–108. [Google Scholar] [CrossRef]

- Wan, A.; Yu, W.; Jiang, G. Pilling properties of wool single jersey made of compact and conventional ring yarns after anti-felting treatment. Text Res. J. 2014, 84, 673–680. [Google Scholar] [CrossRef]

- Karahan, H.A.; Ozdoggan, E.; Demir, A. Effects of atmospheric pressure plasma treatments on some physical properties of wool fibers. Text Res. J. 2009, 79, 1260–1265. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, W. Preparation and characterization of Hot Melt Copolyster (PBTI) ultrafine particles and their effect on the anti-pilling performance of polyester/cotton fabrics. Polymers 2018, 10, 1163. [Google Scholar] [CrossRef] [PubMed]

- Shavandi, A.; Ali, M.A. Graft polymerization onto wool fiber for improved functionality. Prog. Org. Coat. 2019, 130, 182–199. [Google Scholar] [CrossRef]

- Wan, A.; Dai, X.J.; Magniez, K.; Plessis, J.; Yu, W.D.; Wang, X.G. Reducing the pilling propensity of wool knits with a three-step plasma treatment. Text Res. J. 2013, 83, 2051–2059. [Google Scholar] [CrossRef]

- Khandual, A.; Luximon, A.; Pattanayak, A.K. Optimization of acid cellulose enzyme concentration to reduce pilling of bamboo fabric: An objective assessment approach. Fiber Polym. 2011, 12, 816–820. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Brzeziński, S.; Kamińska, I. Multifunctional bioactive and improving the performance durability nano coatings for finishing PET/CO woven fabrics by the sol-gel method. J. Alloys Compd. 2015, 649, 387–393. [Google Scholar] [CrossRef]

- Kim, S.; Park, C.K. Evaluation of fabric pilling using hybrid imaging methods. Fiber Polym. 2006, 7, 57. [Google Scholar] [CrossRef]

- Rombaldoni, F.; Mossotti, R.; Montarsolo, A.; Songia, M.B.; Innocenti, R.; Mazzuchetti, G. Thin film deposition by PECVD using HMDSO-O2-Ar gas mixture on knitted wool fabrics in order to improve pilling resistance. Fiber Polym. 2008, 9, 566–573. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Shen, X. Reducing pilling of knitted woolen fabric based on micro-scale. Int. J. Cloth. Sci. Technol. 2017, 29, 138–147. [Google Scholar]

- Periolatto, M.; Ferrero, F.; Vineis, C.; Rombaldoni, F. Multifunctional finishing of wool fabrics by chitosan UV-grafting: An approach. Carbohyd. Polym. 2013, 98, 624–629. [Google Scholar] [CrossRef]

- Schroeder, M.; Schweitzer, H.B.M.; Guebitz, G.M. Chemical modification of proteases for wool cuticle scale removal. Biocatal. Biotransform. 2004, 22, 299–305. [Google Scholar] [CrossRef]

- Montazer, M.; Mazaheri, F.; Khosravian, S.; Azimi, M.; Bameni Moghadam, M.; Sadeghi, A.H. Application of resins and crosslinking agents on fiber blend fabric to reduce pilling performance, optimized by response surface methodology. J. Vinyl Addit. Technol. 2011, 17, 213–221. [Google Scholar] [CrossRef]

- Milind, M.; Pant, S. Effect of resin finishes on pilling and dimensional stability of knitted fabrics. Man Made Text. India 2014, 42, 9–12. [Google Scholar]

- Xu, W.; Zhou, X. Synthesis and application of silicone modified polyurethane anti-pilling finishing agent. Text. Aux. 2018, 35, 18–21. [Google Scholar]

- Textor, T.; Knittel, D.; Bahners, T.; Schollmeyer, E. Inorganic-organic hybrid polymers for coating textile materials. Curr. Trends Polym. Sci. 2003, 8, 127–133. [Google Scholar]

- Noreen, H.; Zia, M.A.; Ali, S.; Hussain, T. Optimization of bio-polishing of polyester/cotton blended fabrics with cellulases prepared from Aspergillus niger. Indian J. Biot. 2014, 13, 108–113. [Google Scholar]

- Kan, C.W.; Yuen, C.W.M. Effect of low temperature plasma treatment on wool fabric properties. Fiber Polym. 2005, 6, 169–173. [Google Scholar] [CrossRef]

- Mossotti, R.; Lopardo, G.; Innocenti, R. Characterization of plasma-coated wool fabrics. Text. Res. 2009, 79, 853–861. [Google Scholar] [CrossRef]

- Millington, K. Using ultraviolet radiation to reduce pilling of knitted wool and cotton. Text. Res. 1998, 68, 413–421. [Google Scholar] [CrossRef]

- El-Sayed, H.; El-Khatib, E. Modification of wool fabric using ecologically acceptable UV-assisted treatments. J. Chem. Technol. Biot. 2010, 80, 1111–1127. [Google Scholar] [CrossRef]

- Mei, N.; Liu, X.; Dai, J.; Hou, W.; Xu, B. UV-induced grafting of organic–inorganic antibacterial membrane on wool fiber. Prog. Org. Coat. 2012, 74, 622–628. [Google Scholar]

- Sun, F.F.; Ma, N.; Li, Z.M. 2-Amino-4-(2,2,2-trifluoroethoxy) pyrimidine. Acta Cryst. 2006, 62, 3864–3865. [Google Scholar] [CrossRef]

- Zuber, M.; Zia, K.M.; Tabassum, S.; Jamil, T.; Barkaat-ul-Hasin, S.; Khosa, M.K. Preparation of rich handles soft cellulosic fabric using amino silicone based softener, part II: Color fastness properties. Int. J. Biol. Macromol. 2011, 49, 1–6. [Google Scholar] [CrossRef]

- Cheng, X.W.; Tang, R.C.; Guan, J.P.; Zhou, S.Q. An eco-friendly and effective flame retardant coating for cotton fabric based on phytic acid doped silica sol approach. Prog. Org. Coat. 2020, 141, 105539–105547. [Google Scholar] [CrossRef]

- Zahid, M.; Heredia-Guerrero, J.A.; Athanassiou, A.; Bayer, I.S. Robust water repellent treatment for woven cotton fabrics with eco-friendly polymers. Chem. Eng. J. 2017, 319, 321–332. [Google Scholar] [CrossRef]

- Hearle, J.W.S.; Wilkins, A.H. Movement of fibers in assemblies. Text. Inst. 2006, 97, 1–9. [Google Scholar] [CrossRef]

- Garside, P.; Wyeth, P. Identification of cellulosic fibers by FTIR spectroscopy-thread and single fiber analysis by attenuated total reflectance. Stud. Conserv. 2003, 48, 269–275. [Google Scholar] [CrossRef]

- Chung, C.; Lee, M.; Choe, E.K. Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr. Polym. 2004, 58, 417–420. [Google Scholar]

- Bran, J.; Pecastaings, G.; Sèbe, G. A versatile method for the surface tailoring of cellulose nanocrystal building blocks by acylation with functional vinyl esters. Carbohyd. Polym. 2017, 169, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Mihiri Ekanayake, U.G.; Dissanayake, D.M.S.N.; Rathuwadu, N.; Kumarasinghe, R.K.K.G.R.G.; Sanjeewa, K.R.; Mantilaka, M.M.M.G.P.G. Facile fabrication of fiuoro-polymer self-assembled ZnO nanoparticles mediated, durable and robust omniphobic surfaces on polyester fabrics. J. Fluor. Chem. 2020, 235, 109565. [Google Scholar] [CrossRef]

- Xu, Y.H.; Liu, X.; Liu, X.L.; Tan, J.L.; Zhu, H.L. Influence of HNO3/H3PO4-NaNO2 mediated oxidation on the structure and properties of cellulose fibers. Carbohyd. Polym. 2014, 111, 955–963. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.W.; Zhou, M.; Li, Y.; Zhai, S.X.; Jin, K.L.; Fan, Z.Z.; Zhao, H.; Zou, W.R.; Cai, Z.S. Low-salt dyeing of cotton fabric grafted with pH-responsive cationic polymer of polyelectrolyte 2-(N,N-dimethylamino) ethyl methacrylate. Colloids Surf. A 2020, 594, 124573. [Google Scholar] [CrossRef]

- López, F.A.; Mercê, A.L.R.; Alguacil, F.J.; López-Delgado, A. A kinetic study on the thermal behaviour of chitosan. J. Therm. Anal. Calorim. 2008, 91, 633–639. [Google Scholar] [CrossRef]

- Liu, W.; Wang, N.; Han, J.W.; Xu, J.Q.; Li, Z.H.; Qin, W.Q. Thermal degradation behaviors and evolved products analysis of polyester paint and waste enameled wires during pyrolysis. Waste Manag. 2020, 107, 82–90. [Google Scholar] [CrossRef] [PubMed]

- Kan, C.W.; Lam, Y.L. Low stress mechanical properties of plasma-treated cotton fabric subjected to zinc oxide-anti-microbial treatment. Materials 2013, 6, 314–333. [Google Scholar] [CrossRef] [PubMed]

| Knitted Fabrics | Component (%) | Horizontal and Vertical Density (circle/5 cm) | Thickness (mm) | Surface Density (g/m2) |

|---|---|---|---|---|

| Cotton (C, undyed) | 100 | 70 × 85 | 0.65 | 191.3 |

| Cotton/viscose (C/V, dyed) | 60/40 | 80 × 110 | 0.62 | 148.4 |

| Polyester/cotton (T/C, undyed) | 65/35 | 85 × 95 | 0.57 | 182.2 |

| Polyester/viscose (T/V, dyed) | 62/38 | 80 × 140 | 0.71 | 184.3 |

| Sample | Pill Density (cm2/inch2) | Weighted Pill Density (cm2/inch2) | Pill Count | Avg Pill HC Diam (mm/in) | Fuzz Loft | Avg Pilling Grade | ||

|---|---|---|---|---|---|---|---|---|

| Total | Weighted | |||||||

| C-0 | 3.6/23.1 | 6.4/41.0 | 90 | 160 | 1.12 | 0.044 | 2.75 | 1.3 |

| C-1 | 0.8/5.1 | 1.4/8.7 | 20 | 34 | 1.07 | 0.042 | 1.44 | 3.5 |

| C-2 | 1.0/6.1 | 1.7/11.0 | 24 | 43 | 1.09 | 0.043 | 1.56 | 3.3 |

| C/V-0 | 4.0/25.9 | 7.6/49.2 | 101 | 192 | 1.42 | 0.056 | 2.08 | 1.0 |

| C/V-1 | 0.5/3.1 | 0.8/5.4 | 12 | 21 | 1.07 | 0.042 | 1.26 | 3.9 |

| C/V-2 | 1.8/11.5 | 3.1/20.0 | 45 | 78 | 1.1 | 0.043 | 1.71 | 2.5 |

| T/C-0 | 4.1/26.4 | 8.1/52.0 | 103 | 203 | 1.49 | 0.059 | 2.97 | 1.0 |

| T/C-1 | 1.2/7.9 | 2.3/15.1 | 31 | 59 | 1.28 | 0.051 | 2.20 | 2.9 |

| T/C-2 | 1.9/12.0 | 3.4/22.0 | 47 | 86 | 1.30 | 0.051 | 2.19 | 2.4 |

| T/V-0 | 3.4/22.0 | 6.4/41.2 | 86 | 161 | 1.24 | 0.049 | 1.72 | 1.2 |

| T/V-1 | 0.1/0.5 | 0.2/1.0 | 2 | 4 | 1.02 | 0.040 | 1.27 | 4.7 |

| T/V-2 | 0.3/2.0 | 0.5/3.3 | 8 | 13 | 1.15 | 0.045 | 1.44 | 4.4 |

| Sample | Bursting Strength (N) | Permeability (mm/s) | Antistatic Property | |

|---|---|---|---|---|

| Static Half Period (s) | Electrostatic Voltage (kV) | |||

| C-0 | 550.53 | 572.02 | 1.25 | +1.03 |

| C-1 | 472.92 | 513.23 | 0.13 | +0.55 |

| C-2 | 447.36 | 530.45 | 0.09 | +0.46 |

| C/V-0 | 503.55 | 1182.41 | 0.88 | +0.90 |

| C/V-1 | 447.47 | 912.92 | 0.04 | +0.46 |

| C/V-2 | 430.39 | 972.13 | 0.11 | +0.50 |

| T/C-0 | 885.04 | 1247.61 | 3.10 | +1.00 |

| T/C-1 | 865.15 | 1127.80 | 0.23 | +0.66 |

| T/C-2 | 857.22 | 1166.22 | 0.68 | +0.82 |

| T/V-0 | 403.35 | 1299.23 | 1.87 | +1.08 |

| T/V-1 | 379.15 | 1260.21 | 0.34 | +0.84 |

| T/V-2 | 351.55 | 1286.00 | 0.16 | +0.67 |

| Sample | B (gf cm2/cm) | 2HB (gf cm/cm) | MIU | SMD (μm) | ||||

|---|---|---|---|---|---|---|---|---|

| Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | |

| C-0 | 0.0358 | 0.0338 | 0.0315 | 0.0435 | 0.187 | 0.206 | 2.013 | 5.387 |

| C-1 | 0.0398 | 0.0381 | 0.0329 | 0.0443 | 0.215 | 0.221 | 2.282 | 4.987 |

| C-2 | 0.0432 | 0.0419 | 0.0478 | 0.0589 | 0.204 | 0.219 | 2.318 | 5.126 |

| C/V-0 | 0.0103 | 0.0097 | 0.0109 | 0.0115 | 0.172 | 0.205 | 2.745 | 3.860 |

| C/V-1 | 0.0173 | 0.0264 | 0.0142 | 0.0359 | 0.194 | 0.222 | 2.505 | 3.486 |

| C/V-2 | 0.0137 | 0.0257 | 0.0138 | 0.0325 | 0.188 | 0.232 | 2.125 | 3.880 |

| T/C-0 | 0.0143 | 0.0099 | 0.0122 | 0.0174 | 0.184 | 0.200 | 2.233 | 4.973 |

| T/C-1 | 0.0189 | 0.0119 | 0.0288 | 0.0302 | 0.219 | 0.226 | 2.013 | 4.643 |

| T/C-2 | 0.0136 | 0.0137 | 0.0115 | 0.0149 | 0.211 | 0.243 | 2.282 | 4.418 |

| T/V-0 | 0.0076 | 0.0094 | 0.0115 | 0.0151 | 0.282 | 0.280 | 2.350 | 4.530 |

| T/V-1 | 0.0113 | 0.0099 | 0.0165 | 0.0196 | 0.314 | 0.290 | 2.160 | 4.109 |

| T/V-2 | 0.0102 | 0.0097 | 0.0132 | 0.0120 | 0.290 | 0.299 | 2.373 | 3.528 |

| Sample | Whiteness (%) | Color Parameter | Rubbing Fastness | Washing Fastness | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L | a | b | C | H | Dry | Wet | Staining | Fastness | ||

| C-0 | 80.53 | 95.44 | −0.24 | 1.80 | 1.82 | 97.70 | - | - | - | - |

| C-1 | 80.57 | 95.76 | −0.34 | 1.96 | 2.00 | 99.90 | - | - | - | - |

| C-2 | 68.11 | 94.30 | 0.13 | 4.01 | 4.02 | 91.80 | - | - | - | - |

| C/V-0 | - | 20.95 | 1.57 | −11.16 | 11.27 | 277.99 | 4 | 3–4 | 4–5 | 4 |

| C/V-1 | - | 21.46 | 1.17 | −11.15 | 11.21 | 275.99 | 4 | 3 | 4–5 | 4 |

| C/V-2 | - | 20.67 | 1.69 | −11.09 | 11.22 | 278.64 | 4 | 3 | 4–5 | 4 |

| T/C-0 | 78.82 | 95.52 | −0.53 | 2.22 | 2.28 | 103.42 | - | - | - | - |

| T/C-1 | 79.25 | 95.56 | −0.56 | 2.15 | 2.21 | 104.47 | - | - | - | - |

| T/C-2 | 68.30 | 94.80 | −0.53 | 4.14 | 4.17 | 97.35 | - | - | - | - |

| T/V-0 | - | 55.66 | −0.18 | −1.05 | 1.06 | 260.39 | 4–5 | 4 | 4–5 | 4 |

| T/V-1 | - | 55.39 | −0.12 | −1.36 | 1.36 | 265.07 | 4–5 | 4 | 4–5 | 4 |

| T/V-2 | - | 55.81 | −0.14 | −0.82 | 0.84 | 260.28 | 4–5 | 4 | 4–5 | 4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Xing, T.; Chen, G. Improving the Anti-Pilling Performance of Cellulose Fiber Blended Knitted Fabrics with 2,4,6-Trichloropyrimidine Treatment. Coatings 2020, 10, 969. https://doi.org/10.3390/coatings10100969

Dong X, Xing T, Chen G. Improving the Anti-Pilling Performance of Cellulose Fiber Blended Knitted Fabrics with 2,4,6-Trichloropyrimidine Treatment. Coatings. 2020; 10(10):969. https://doi.org/10.3390/coatings10100969

Chicago/Turabian StyleDong, Xue, Tieling Xing, and Guoqiang Chen. 2020. "Improving the Anti-Pilling Performance of Cellulose Fiber Blended Knitted Fabrics with 2,4,6-Trichloropyrimidine Treatment" Coatings 10, no. 10: 969. https://doi.org/10.3390/coatings10100969

APA StyleDong, X., Xing, T., & Chen, G. (2020). Improving the Anti-Pilling Performance of Cellulose Fiber Blended Knitted Fabrics with 2,4,6-Trichloropyrimidine Treatment. Coatings, 10(10), 969. https://doi.org/10.3390/coatings10100969