SiO2-Based Nanostructured Superhydrophobic Film with High Optical Transmittance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of SiO2-Based Nanostructured Superhydrophobic Surface

2.3. Characterization

3. Results and Discussion

4. Conclusions

- (1)

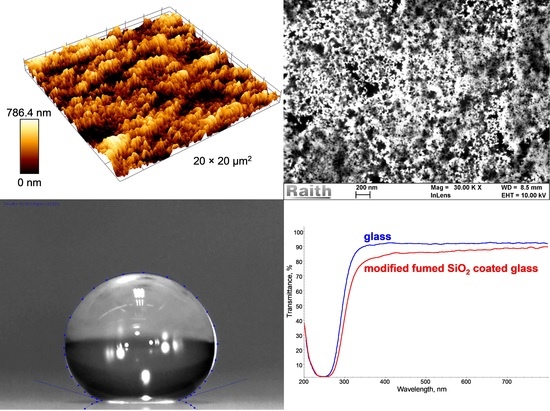

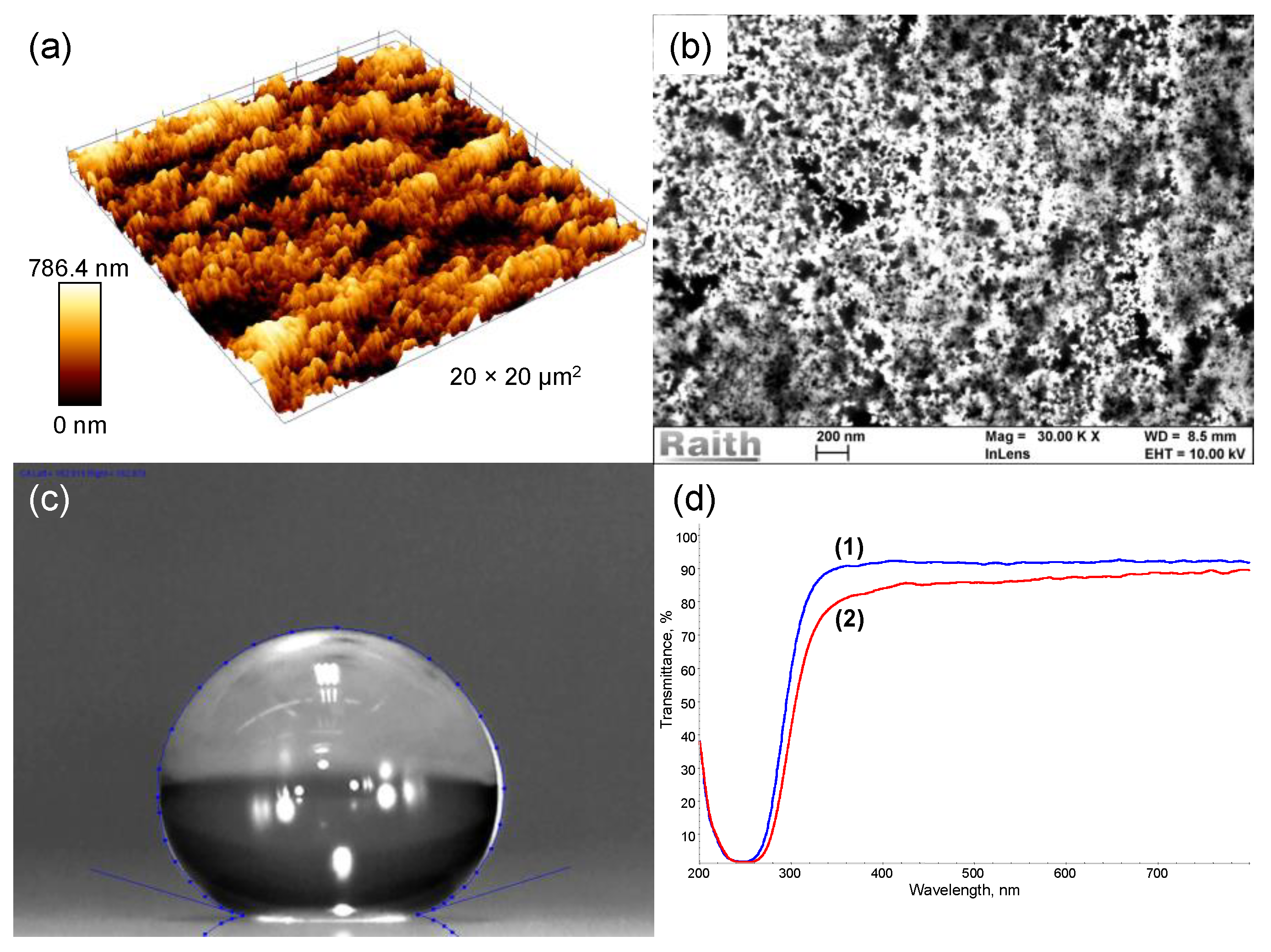

- The film surface exhibited a branched network structure composed of interconnected quasi-spherical nanoparticles (size ~10–35 nm) with submicrometer-scale roughness (Rq = 252.7 nm).

- (2)

- The fabricated film exhibited a composite wetting mode and was found to be effectively superhydrophobic with CA of 163 ± 1° and hysteresis as low as ~2°, which was attributed to the synergistic effect of convenient surface morphology and chemistry.

- (3)

- The superhydrophobic film exhibited an excellent self-cleaning performance.

- (4)

- The SiO2-based nanostructured film exhibited high optical transmittance in the visible spectrum portion. This was possible to achieve due to the submicrometer-scale roughness and branched network structure of the film surface.

- (5)

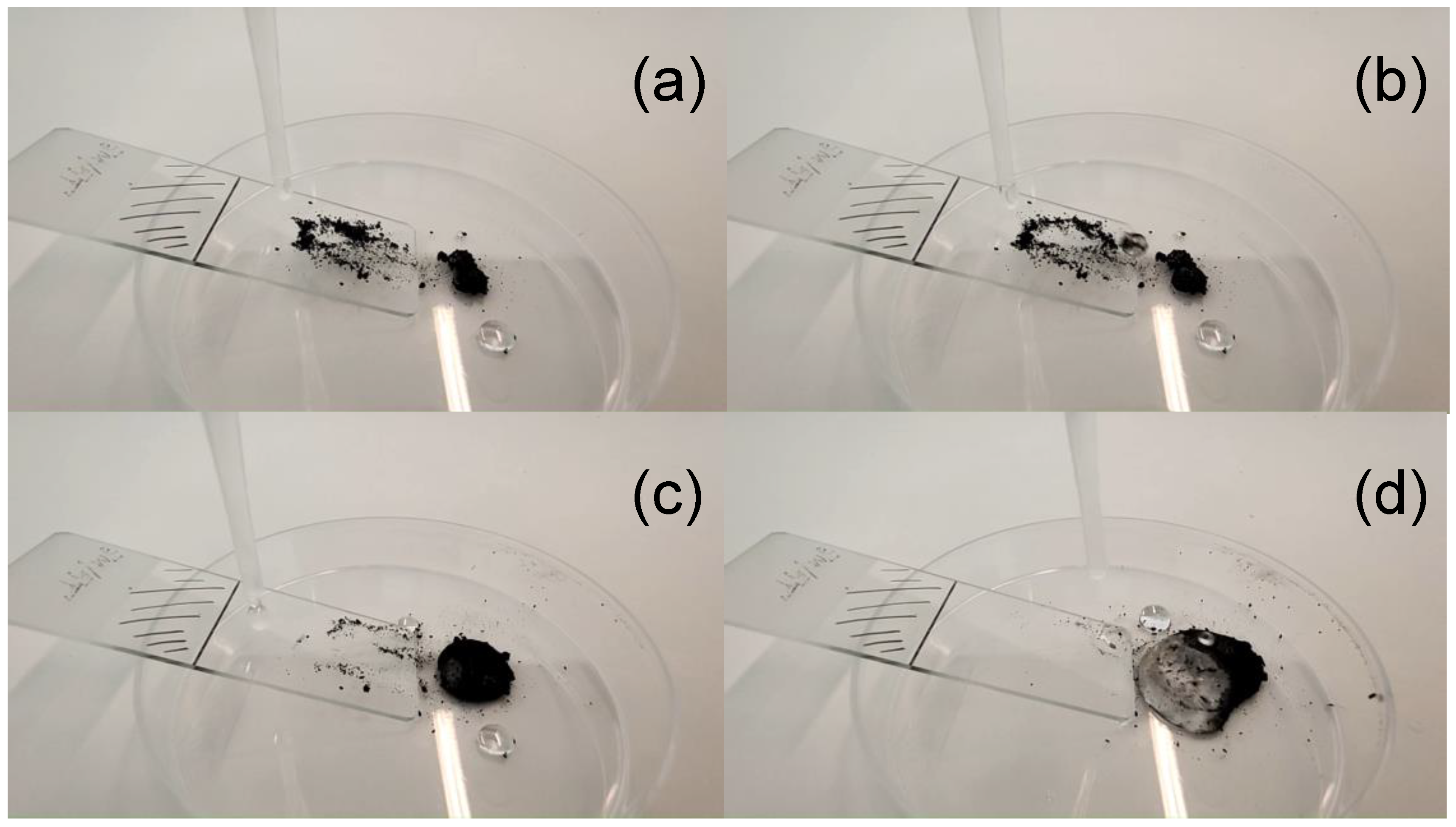

- Raman analysis determined a number of vibrational modes corresponding to hydrophobic methyl groups, thus confirming that fumed SiO2 was successfully modified via silylation derivatization reaction.

- (6)

- The method presented herein is not complicated, allows for obtaining large quantities of modified SiO2 nanoparticle dispersions and can be used in combination with dip-coating, spray-coating, spin-coating, drop-casting and Langmuir-Blodgett deposition.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, W.; Liang, Z.; Dong, B.; Tang, H. Transmittance and self-cleaning polymethylsiloxane coating with superhydrophobic surfaces. Surf. Eng. 2019, 36, 574–582. [Google Scholar] [CrossRef]

- Liang, Z.; Geng, M.; Dong, B.; Zhao, L.; Wang, S. Transparent and robust SiO2/PDMS composite coatings with self-cleaning. Surf. Eng. 2019, 36, 643–650. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.; Xu, P.; Chen, B. Robust and transparent superoleophobic coatings from one-step spraying of SiO2@ fluoroPOS. J. Sol-Gel Sci. Technol. 2020, 93, 79–90. [Google Scholar] [CrossRef]

- Ardekani, S.R.; Aghdam, A.S.R.; Nazari, M.; Bayat, A.; Saievar-Iranizad, E. A new approach for preparation of semi-transparent superhydrophobic coatings by ultrasonic spray hydrolysis of methyltrimethoxysilane. Prog. Org. Coat. 2019, 135, 248–254. [Google Scholar] [CrossRef]

- Tombesi, A.; Li, S.; Sathasivam, S.; Page, K.; Heale, F.L.; Pettinari, C.; Carmalt, C.J.; Parkin, I.P. Aerosol-assisted chemical vapour deposition of transparent superhydrophobic film by using mixed functional alkoxysilanes. Sci. Rep. 2019, 9, 7549. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, G.; Tian, J.; Yu, Z.; Deng, Q.; Yu, M. Facile fabrication of fluorine-free, transparent and self-cleaning superhydrophobic coatings based on biopolymer castor oil. Mater. Lett. 2018, 230, 84–87. [Google Scholar] [CrossRef]

- Siri, R.; Thongrom, S.; van Dommelen, P.; Muensit, N.; Daengngam, C. Demonstrating spray deposition of self-regulated nanorough layers for stable transparent superhydrophobic film coatings. Thin Solid Films 2019, 686, 137429. [Google Scholar] [CrossRef]

- Su, Q.; Wen, F.; Huang, Y.; Wang, B. Abrasion resistant semitransparent self-cleaning coatings based on porous silica microspheres and polydimethylsiloxane. Ceram. Int. 2019, 45, 401–408. [Google Scholar] [CrossRef]

- Chen, C.; Weng, D.; Chen, S.; Mahmood, A.; Wang, J. Development of Durable, Fluorine-free, and Transparent Superhydrophobic Surfaces for Oil/Water Separation. ACS Omega 2019, 4, 6947–6954. [Google Scholar] [CrossRef] [PubMed]

- Smith, B.W.; Suzuki, K. Microlithography: Science and Technology; CRC Press: Boca Raton, FL, USA, 2018; p. 662. [Google Scholar]

- Stalder, A.F.; Kulik, G.; Sage, D.; Barbieri, L.; Hoffmann, P. A snake-based approach to accurate determination of both contact points and contact angles. Colloids Surf. A Physicochem. Eng. Asp. 2006, 286, 92–103. [Google Scholar] [CrossRef] [Green Version]

- Genzer, J.; Efimenko, K. Creating long-lived superhydrophobic polymer surfaces through mechanically assembled monolayers. Science 2000, 290, 2130–2133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Genzer, J.; Efimenko, K. Recent developments in superhydrophobic surfaces and their relevance to marine fouling: A review. Biofouling 2006, 22, 339–360. [Google Scholar] [CrossRef] [PubMed]

- Parvate, S.; Dixit, P.; Chattopadhyay, S. Superhydrophobic Surfaces: Insights from Theory and Experiment. J. Phys. Chem. B 2020, 124, 1323–1360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Crick, C.R.; Parkin, I.P. Water droplet bouncing—A definition for superhydrophobic surfaces. Chem. Commun. 2011, 47, 12059–12061. [Google Scholar] [CrossRef]

- Kacem, I.B.; Gautron, L.; Coillot, D.; Neuville, D.R. Structure and properties of lead silicate glasses and melts. Chem. Geol. 2017, 461, 104–114. [Google Scholar] [CrossRef] [Green Version]

- Nekvindova, P.; Svecova, B.; Stanek, S.; Vytykacova, S.; Mackova, A.; Malinsky, P.; Machovic, V.; Spirkova, J. The Raman spectroscopy use for monitoring of changes in the glass structure of the thin layers caused by ion implantation. Ceram. Silikáty 2015, 59, 187–193. [Google Scholar]

- Deschamps, T.; Martinet, C.; Bruneel, J.; Champagnon, B. Soda-lime silicate glass under hydrostatic pressure and indentation: A micro-Raman study. J. Phys. Condens. Matter 2011, 23, 035402. [Google Scholar] [CrossRef]

- Volovšek, V.; Furić, K.; Bistričić, L.; Leskovac, M. Micro Raman Spectroscopy of Silica Nanoparticles Treated with Aminopropylsilanetriol; Macromolecular symposia, Wiley Online Library: Weinheim, Germany, 2008; pp. 178–182. [Google Scholar]

- Schneider, B.; Štokr, J.; Schmidt, P.; Mihailov, M.; Dirlikov, S.; Peeva, N. Stretching and deformation vibrations of CH2, C (CH3) and O (CH3) groups of poly (methyl methacrylate). Polymer 1979, 20, 705–712. [Google Scholar] [CrossRef]

- Song, Y.; Huang, Y.; Havenga, E.A.; Butler, I.S. Vibrational spectra of crystalline tetrakis (trimethylsilyl) silane (IV), Si [Si (CH3) 3] 4, at high pressures. Vib. Spectrosc. 2001, 27, 127–134. [Google Scholar] [CrossRef]

- Efimov, A.M.; Pogareva, V.G. IR absorption spectra of vitreous silica and silicate glasses: The nature of bands in the 1300 to 5000 cm−1 region. Chem. Geol. 2006, 229, 198–217. [Google Scholar] [CrossRef]

- Deng, X.; Mammen, L.; Butt, H.-J.; Vollmer, D. Candle soot as a template for a transparent robust superamphiphobic coating. Science 2012, 335, 67–70. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazauskas, A.; Jucius, D.; Puodžiukynas, L.; Guobienė, A.; Grigaliūnas, V. SiO2-Based Nanostructured Superhydrophobic Film with High Optical Transmittance. Coatings 2020, 10, 934. https://doi.org/10.3390/coatings10100934

Lazauskas A, Jucius D, Puodžiukynas L, Guobienė A, Grigaliūnas V. SiO2-Based Nanostructured Superhydrophobic Film with High Optical Transmittance. Coatings. 2020; 10(10):934. https://doi.org/10.3390/coatings10100934

Chicago/Turabian StyleLazauskas, Algirdas, Dalius Jucius, Linas Puodžiukynas, Asta Guobienė, and Viktoras Grigaliūnas. 2020. "SiO2-Based Nanostructured Superhydrophobic Film with High Optical Transmittance" Coatings 10, no. 10: 934. https://doi.org/10.3390/coatings10100934

APA StyleLazauskas, A., Jucius, D., Puodžiukynas, L., Guobienė, A., & Grigaliūnas, V. (2020). SiO2-Based Nanostructured Superhydrophobic Film with High Optical Transmittance. Coatings, 10(10), 934. https://doi.org/10.3390/coatings10100934