Correlation between Substrate Ion Fluxes and the Properties of Diamond-Like Carbon Films Deposited by Deep Oscillation Magnetron Sputtering in Ar and Ar + Ne Plasmas

Abstract

:1. Introduction

2. Materials and Methods

3. Results

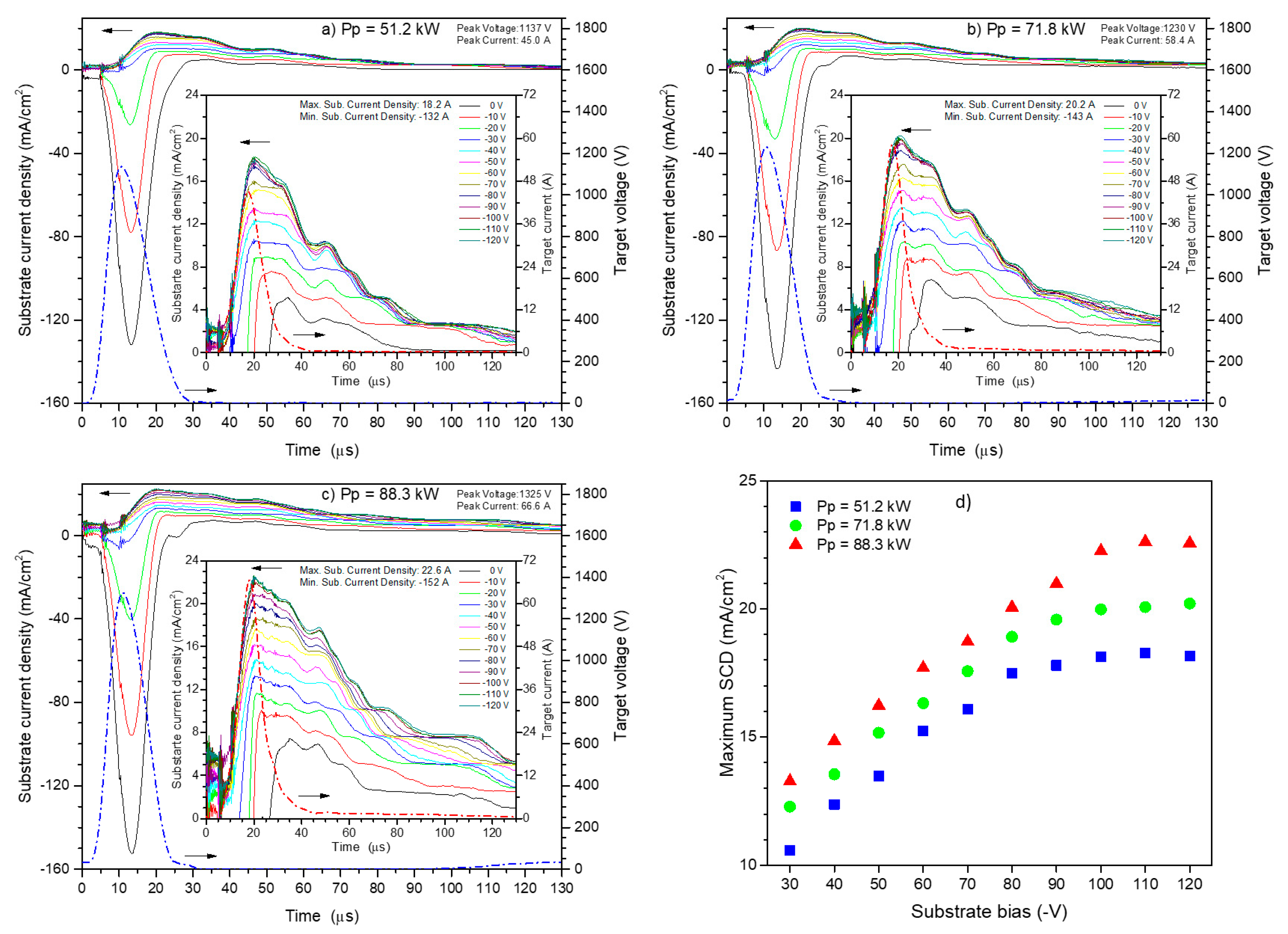

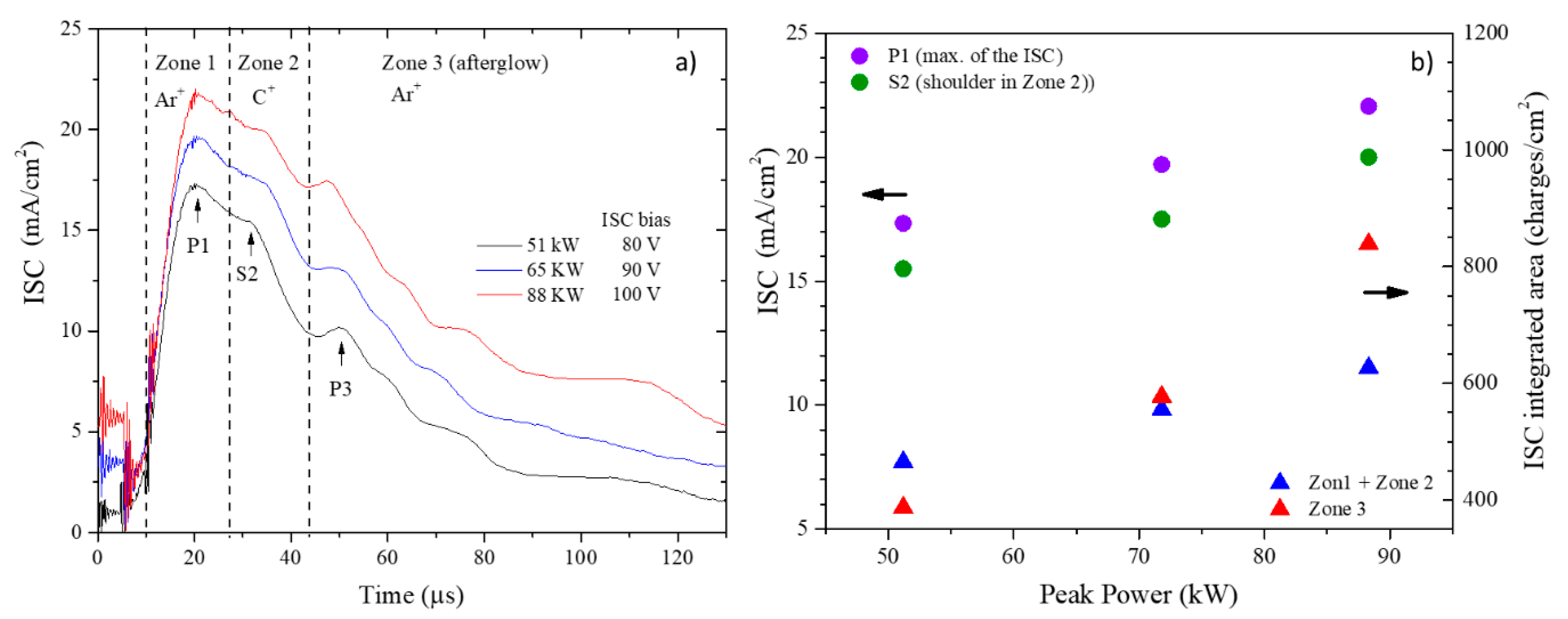

3.1. Evaluation of Substrate Currents in Pure Ar Plasmas

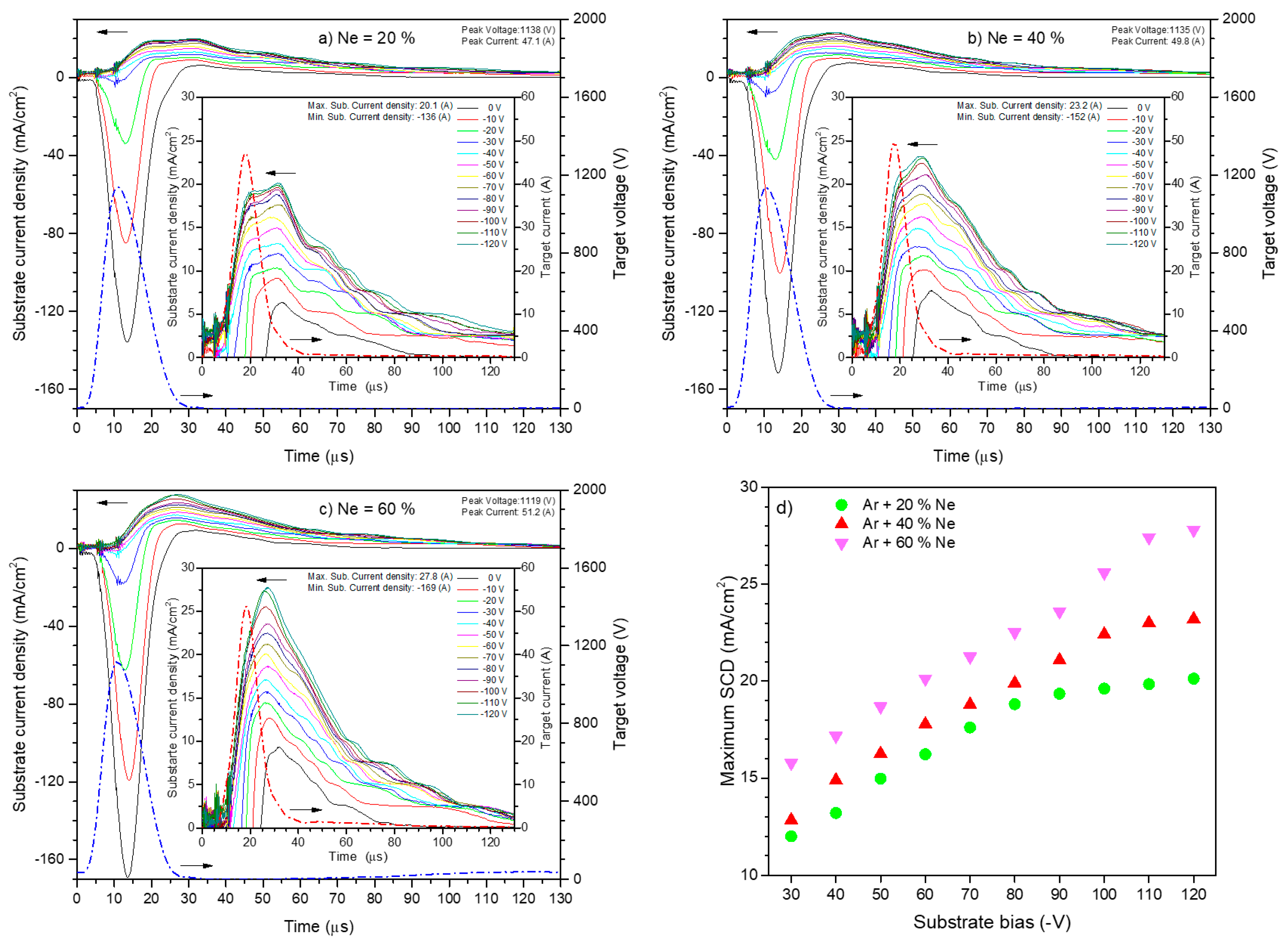

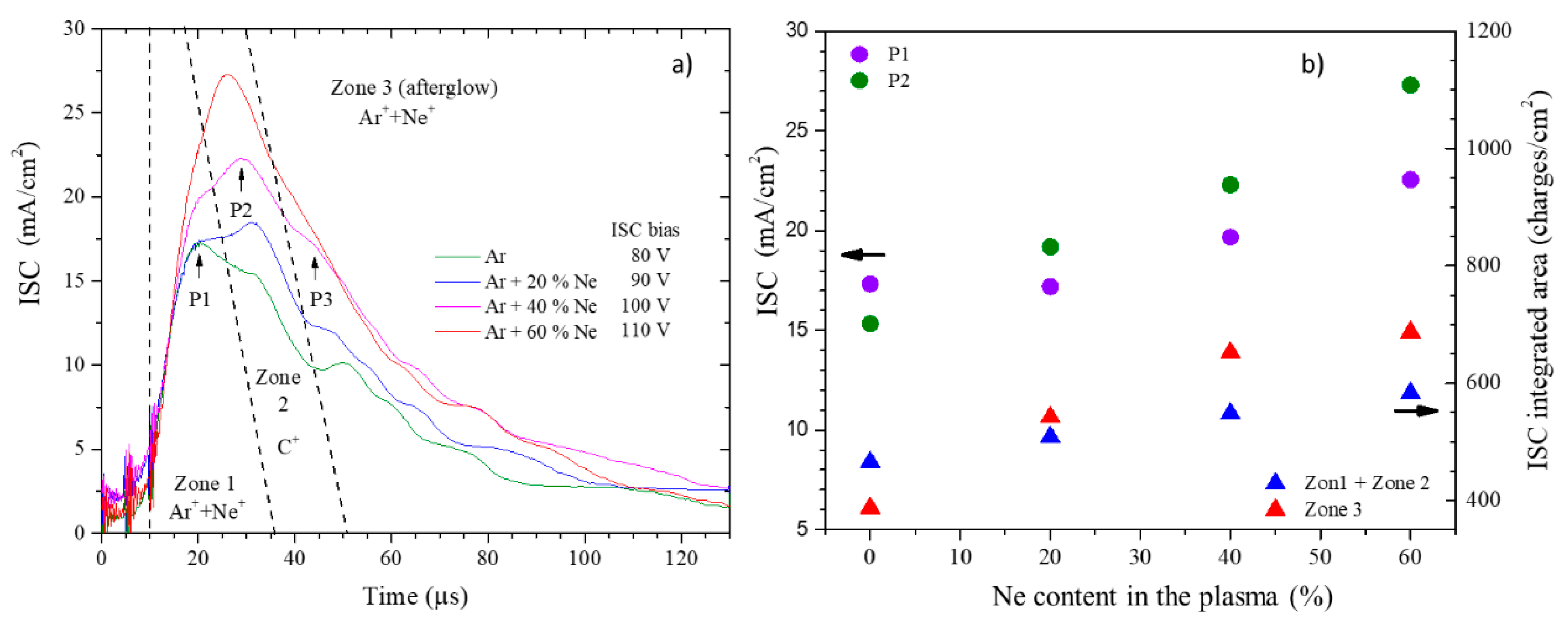

3.2. Ions Saturation Current (ISC) in Ar + Ne Plasmas

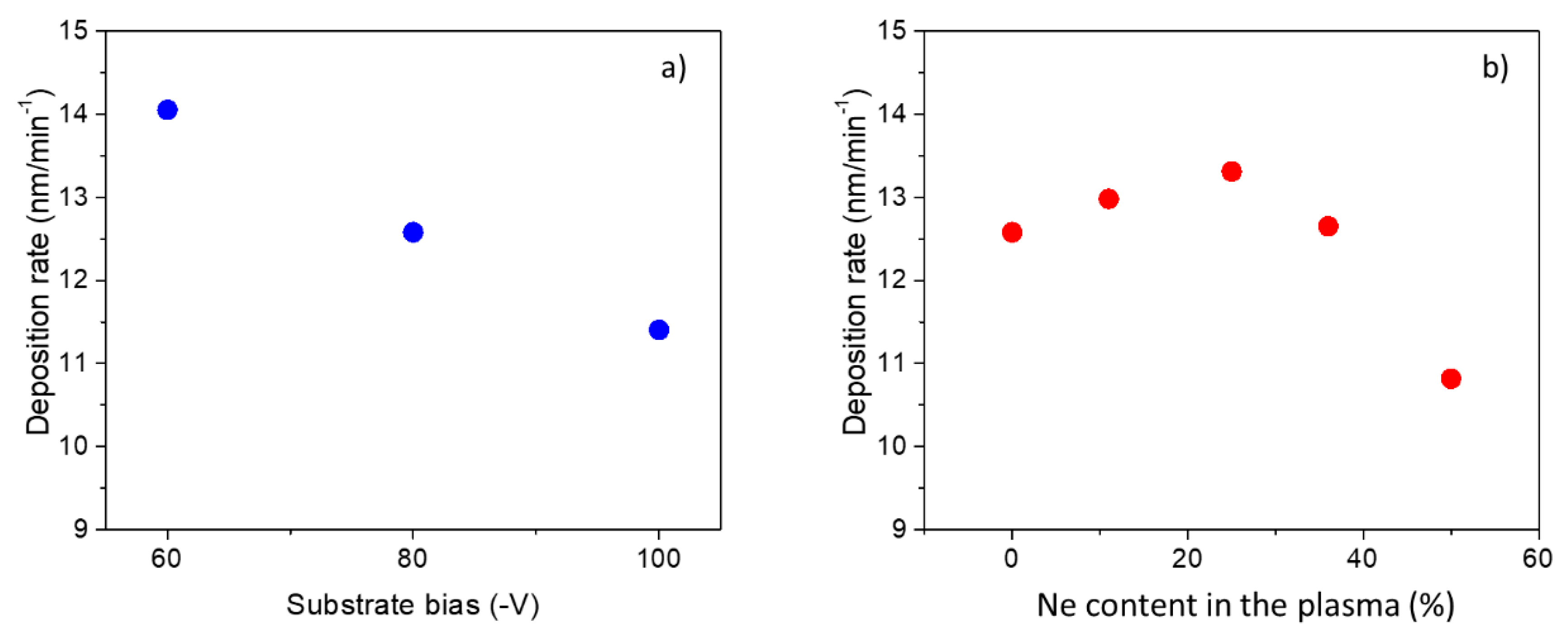

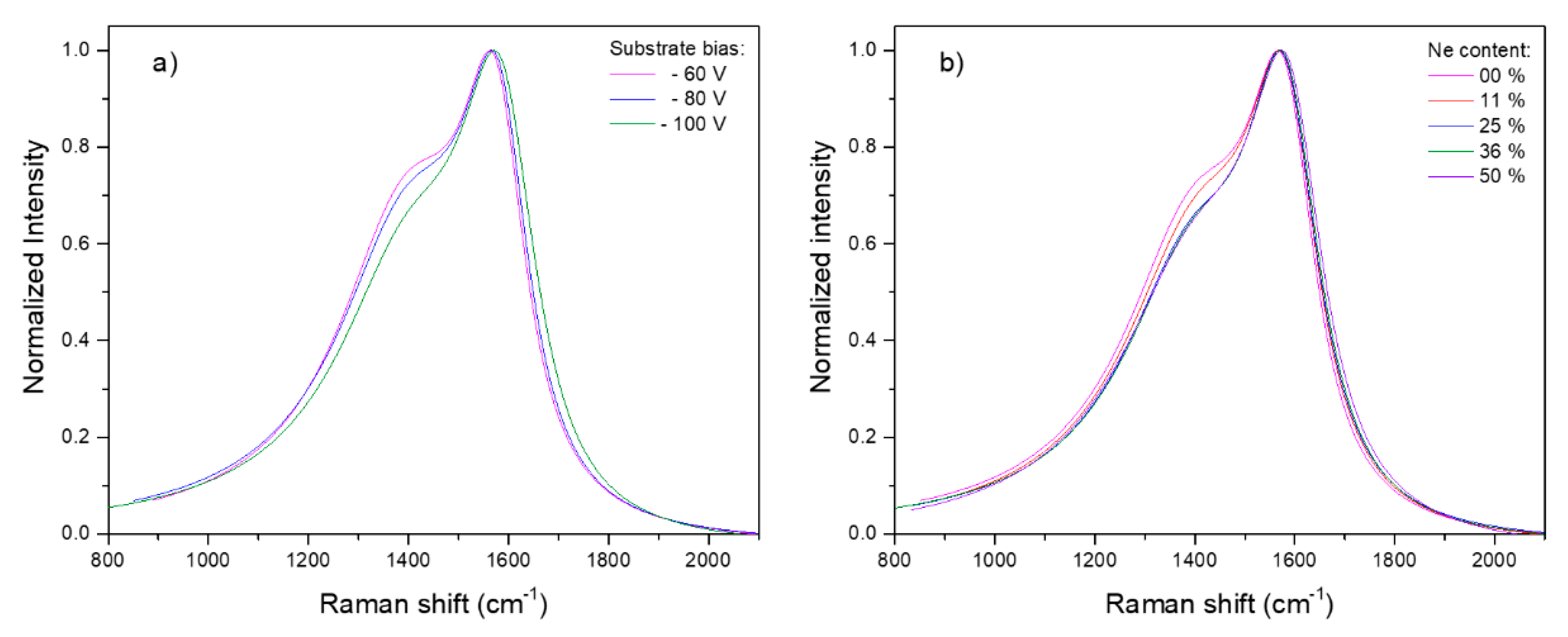

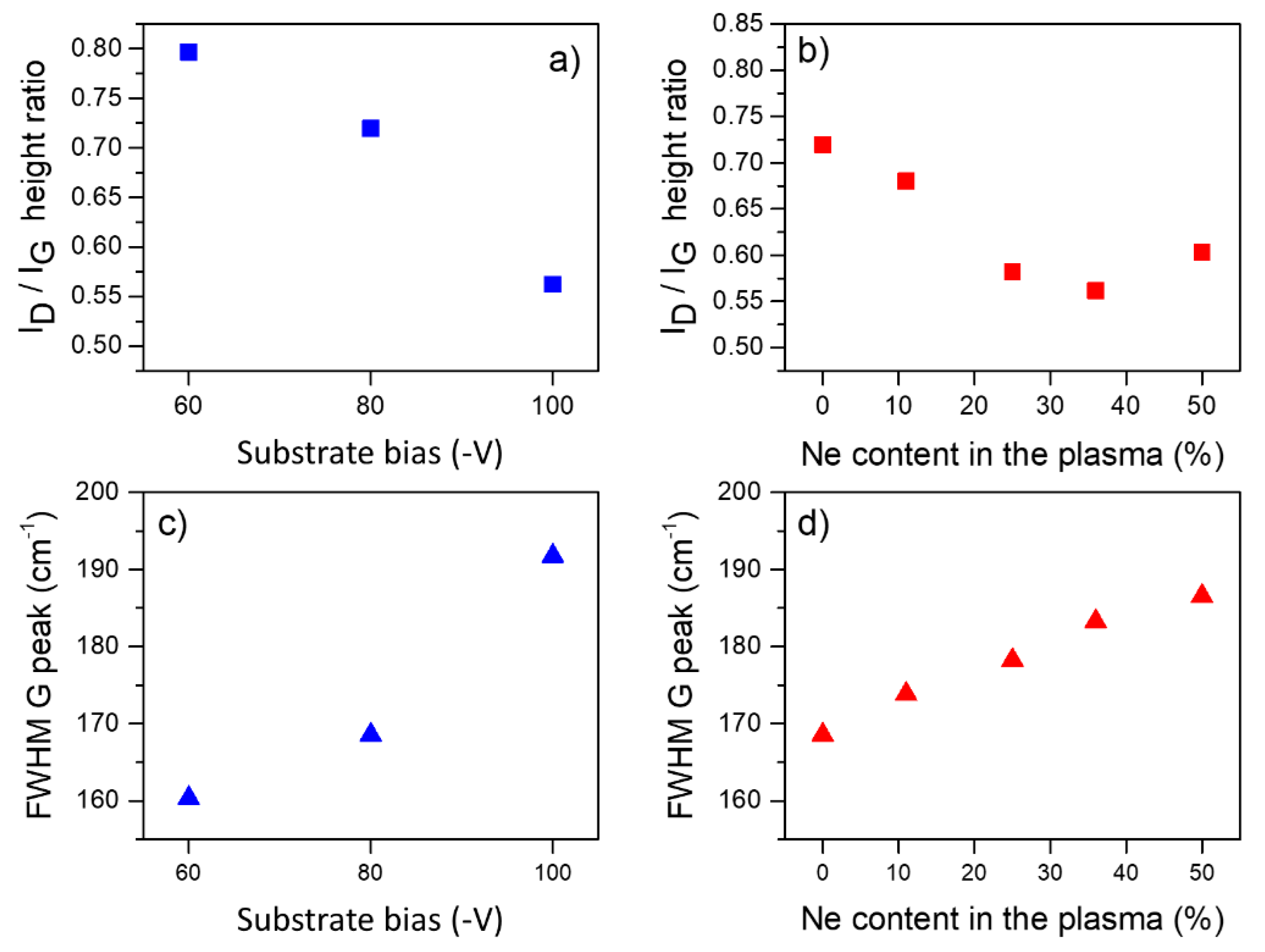

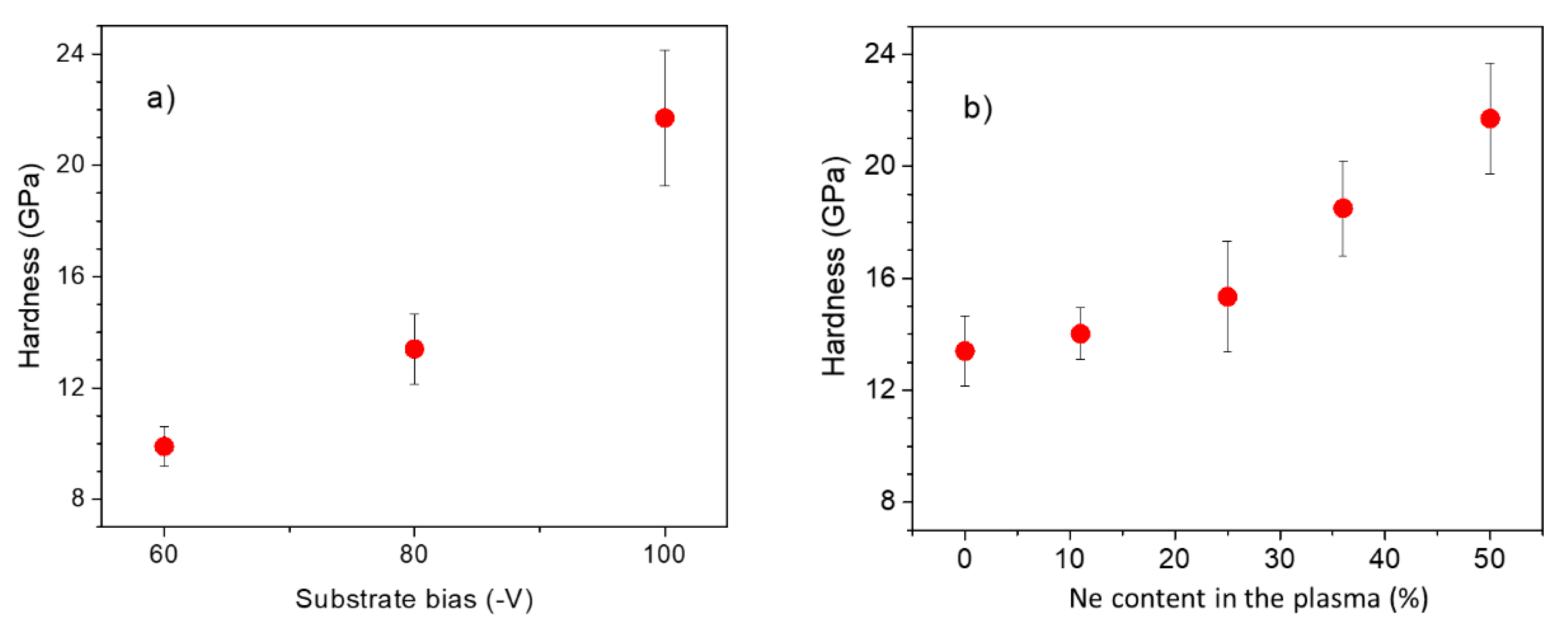

3.3. Properties of the DLC Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| - | Symbol | Description |

| Discharge Pulse Parameters | D | DOMS pulse duration |

| F | pulse frequency | |

| T | oscillation period | |

| ton | oscillation on-time | |

| Vp | oscillation peak voltage | |

| Ip | oscillation peak current | |

| Pp | peak power | |

| Pa | time-averaged power | |

| DCint | charging voltage | |

| t | time | |

| Deposition Techniques | DCMS | direct current magnetron sputtering |

| HiPIMS | high power impulse magnetron sputtering | |

| DOMS | deep oscillation magnetron sputtering | |

| PLD | pulsed laser deposition | |

| FCA | filtered cathodic arc deposition | |

| Flat Probe | ISC | ion saturation current |

| ERMS | energy resolved mass spectroscopy | |

| SCDs | time-resolved substrate current densities | |

| Te | electron temperature | |

| Raman Spectroscopy | G | graphitic carbon band |

| D | disordered carbon band | |

| ID/IG | ratio of the intensities (height) of D and G bands | |

| FWHMG | full width at half maximum of the G band | |

| BWF | Breit-Wigner-Fano | |

| SEM | scanning electron microscopy | |

| DLC | diamond-like carbon | |

| ta-C | tetragonal amorphous carbon |

References

- Veerasamy, V.; Amaratunga, G.; Milne, W.; Robertson, J.; Fallon, P. Influence of carbon ion energy on properties of highly tetrahedral diamond-like carbon. J. Non-Cryst. Solids 1993, 164, 1111–1114. [Google Scholar] [CrossRef]

- Weissmantel, S.; Reisse, G.; Rost, D. Preparation of superhard amorphous carbon films with low internal stress. Surf. Coat. Technol. 2004, 188, 268–273. [Google Scholar] [CrossRef]

- Logothetidis, S.; Gioti, M.; Patsalas, P.; Charitidis, C. Insights on the deposition mechanism of sputtered amorphous carbon films. Carbon 1999, 37, 765–769. [Google Scholar] [CrossRef]

- Robertson, J. Plasma deposition of diamond-like carbon. Jpn. J. Appl. Phys. 2011, 50, 01AF01. [Google Scholar] [CrossRef]

- McKenzie, D.; Muller, D.; Pailthorpe, B. Compressive-stress-induced formation of thin-film tetrahedral amorphous carbon. Phys. Rev. Lett. 1991, 67, 773. [Google Scholar] [CrossRef]

- Jacobs, R. 10—Industrial development of carbon-based coatings. In Proceedings of the International Conference on Metallurgical Coatings and Thin Films (ICMCTF), San Diego, CA, USA, 24–28 April 2017. [Google Scholar]

- Chhowalla, M. Thick, well-adhered, highly stressed tetrahedral amorphous carbon. Diam. Relat. Mater. 2001, 10, 1011–1016. [Google Scholar] [CrossRef]

- Tucker, M.; Ganesan, R.; McCulloch, D.; Partridge, J.; Stueber, M.; Ulrich, S.; Bilek, M.; McKenzie, D.; Marks, N. Mixed-mode high-power impulse magnetron sputter deposition of tetrahedral amorphous carbon with pulse-length control of ionization. J. Appl. Phys. 2016, 119, 155303. [Google Scholar] [CrossRef]

- Lattemann, M.; Abendroth, B.; Moafi, A.; McCulloch, D.; McKenzie, D. Controlled glow to arc transition in sputtering for high rate deposition of carbon films. Diam. Relat. Mater. 2011, 20, 68–74. [Google Scholar] [CrossRef]

- Nakao, S.; Yukimura, K.; Nakano, S.; Ogiso, H. DLC coating by HiPIMS: The influence of substrate bias voltage. IEEE Trans. Plasma Sci. 2013, 41, 1819–1829. [Google Scholar] [CrossRef]

- Santiago, J.; Fernández-Martínez, I.; Kozák, T.; Capek, J.; Wennberg, A.; Molina-Aldareguia, J.; Bellido-González, V.; González-Arrabal, R.; Monclús, M. The influence of positive pulses on HiPIMS deposition of hard DLC coatings. Surf. Coat. Technol. 2019, 358, 43–49. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Oliveira, J.; Cavaleiro, A. Effect of peak target power on the properties of Cr thin films sputtered by HiPIMS in deep oscillation magnetron sputtering (DOMS) mode. Surf. Coat. Technol. 2014, 258, 249–256. [Google Scholar] [CrossRef]

- Ferreira, F.; Sousa, C.; Cavaleiro, A.; Anders, A.; Oliveira, J. Phase tailoring of tantalum thin films deposited in deep oscillation magnetron sputtering mode. Surf. Coat. Technol. 2017, 314, 97–104. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Moore, J.J.; Sproul, W.D.; Mishra, B.; Wu, Z. Modulated pulse power sputtered chromium coatings. Thin Solid Films 2009, 518, 1566–1570. [Google Scholar] [CrossRef]

- Samuelsson, M.; Lundin, D.; Jensen, J.; Raadu, M.A.; Gudmundsson, J.T.; Helmersson, U. On the film density using high power impulse magnetron sputtering. Surf. Coat. Technol. 2010, 205, 591–596. [Google Scholar] [CrossRef] [Green Version]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Films 2006, 513, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Sarakinos, K.; Braun, A.; Zilkens, C.; Mráz, S.; Schneider, J.; Zoubos, H.; Patsalas, P. Exploring the potential of high power impulse magnetron sputtering for growth of diamond-like carbon films. Surf. Coat. Technol. 2012, 206, 2706–2710. [Google Scholar] [CrossRef] [Green Version]

- DeKoven, B.; Ward, P.; Weiss, R.E.; Christie, D.J.; Scholl, R.A.; Sproul, W.D.; Tomasel, F.; Anders, A. Carbon thin film deposition using high power pulsed magnetron sputtering. In Proceedings of the 46th Annual Technical Conference Proceedings of the Society of Vacuum Coaters, San Francisco, CA, USA, 3 May 2003. [Google Scholar]

- Aijaz, A.; Sarakinos, K.; Lundin, D.; Brenning, N.; Helmersson, U. A strategy for increased carbon ionization in magnetron sputtering discharges. Diam. Relat. Mater. 2012, 23, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Engels, M. Synthesis of aC coatings by HPPMS using Ar, Ne and He as process gases. Surf. Coat. Technol. 2016, 308, 80–89. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.; Engels, M. Advanced deposition of hard aC: Me coatings by HPPMS using Ne as process gas. Surf. Coat. Technol. 2017, 332, 242–252. [Google Scholar] [CrossRef]

- Aijaz, A.; Ferreira, F.; Oliveira, J.; Kubart, T. Mechanical properties of hydrogen free diamond-like carbon thin films deposited by high power impulse magnetron sputtering with Ne. Coatings 2018, 8, 385. [Google Scholar] [CrossRef] [Green Version]

- Palmucci, M.; Britun, N.; Konstantinidis, S.; Snyders, R. Rarefaction windows in a high-power impulse magnetron sputtering plasma. J. Appl. Phys. 2013, 114, 113302. [Google Scholar] [CrossRef]

- Villamayor, M.M.S.; Keraudy, J.; Shimizu, T.; Viloan, R.P.B.; Boyd, R.; Lundin, D.; Greene, J.E.; Petrov, I.; Helmersson, U. Low temperature (T s/T m< 0.1) epitaxial growth of HfN/MgO (001) via reactive HiPIMS with metal-ion synchronized substrate bias. J. Vac. Sci. Technol. A Vac. Surf. Film. 2018, 36, 061511. [Google Scholar] [CrossRef] [Green Version]

- Greczynski, G.; Lu, J.; Jensen, J.; Petrov, I.; Greene, J.E.; Bolz, S.; Kölker, W.; Schiffers, C.; Lemmer, O.; Hultman, L. Metal versus rare-gas ion irradiation during Ti1−xAlxN film growth by hybrid high power pulsed magnetron/dc magnetron co-sputtering using synchronized pulsed substrate bias. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 061504. [Google Scholar] [CrossRef] [Green Version]

- Cemin, F.; Abadias, G.; Minea, T.; Lundin, D. Tuning high power impulse magnetron sputtering discharge and substrate bias conditions to reduce the intrinsic stress of TiN thin films. Thin Solid Films 2019, 688, 137335. [Google Scholar] [CrossRef]

- Aijaz, A.; Kubart, T. Ion induced stress relaxation in dense sputter-deposited DLC thin films. Appl. Phys. Lett. 2017, 111, 051902. [Google Scholar] [CrossRef]

- Ferreira, F.; Aijaz, A.; Kubart, T.; Cavaleiro, A.; Oliveira, J. Hard and dense diamond like carbon coatings deposited by deep oscillations magnetron sputtering. Surf. Coat. Technol. 2018, 336, 92–98. [Google Scholar] [CrossRef]

- Vitelaru, C.; Aijaz, A.; Parau, A.C.; Kiss, A.E.; Sobetkii, A.; Kubart, T. Discharge runaway in high power impulse magnetron sputtering of carbon: The effect of gas pressure, composition and target peak voltage. J. Phys. D Appl. Phys. 2018, 51, 165201. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM–The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2010, 268, 1818–1823. [Google Scholar] [CrossRef] [Green Version]

- Britun, N.; Minea, T.; Konstantinidis, S.; Snyders, R. Plasma diagnostics for understanding the plasma–surface interaction in HiPIMS discharges: A review. J. Phys. D Appl. Phys. 2014, 47, 224001. [Google Scholar] [CrossRef] [Green Version]

- Greczynski, G.; Zhirkov, I.; Petrov, I.; Greene, J.E.; Rosen, J. Time evolution of ion fluxes incident at the substrate plane during reactive high-power impulse magnetron sputtering of groups IVb and VIb transition metals in Ar/N2. J. Vac. Sci. Technol. A Vac. Surf. Films 2018, 36, 020602. [Google Scholar] [CrossRef] [Green Version]

- Greczynski, G.; Hultman, L. Time and energy resolved ion mass spectroscopy studies of the ion flux during high power pulsed magnetron sputtering of Cr in Ar and Ar/N2 atmospheres. Vacuum 2010, 84, 1159–1170. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, S.; Czigány, Z.; Greczynski, G.; Jensen, J.; Hultman, L. Ion mass spectrometry investigations of the discharge during reactive high power pulsed and direct current magnetron sputtering of carbon in Ar and Ar/N2. J. Appl. Phys. 2012, 112, 013305. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, S.; Czigány, Z.; Greczynski, G.; Jensen, J.; Hultman, L. Influence of inert gases on the reactive high power pulsed magnetron sputtering process of carbon-nitride thin films. J. Vac. Sci. Technol. A Vac. Surf. Films 2013, 31, 011503. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, A.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef] [Green Version]

| Pressure (Pa) | Vbias (V) | Vp (V) | Ip (A) | PP (kW) | F (Hz) |

|---|---|---|---|---|---|

| 0.8 | −60 | 1398 | 65 | 91 | 251 |

| −80 | 1401 | 65 | 91 | 250 | |

| −100 | 1400 | 66 | 92 | 253 |

| Pressure (Pa) | Vb (V) | Ne (%) | Vp (V) | Ip (A) | PP (kW) | Fi (Hz) |

|---|---|---|---|---|---|---|

| 0.8 | −80 | 11 | 1396 | 70 | 98 | 253 |

| −80 | 25 | 1398 | 72 | 101 | 254 | |

| −80 | 36 | 1395 | 78 | 109 | 252 | |

| −80 | 50 | 1395 | 80 | 112 | 250 |

| - | Ne (%) | Vp (V) | Ip (A) | Pp (kW) |

|---|---|---|---|---|

| Peak power study | 0 | 1137 | 45 | 51.2 |

| 0 | 1230 | 58.4 | 71.8 | |

| 0 | 1325 | 66.6 | 88.3 | |

| Ne content study | 20% | 1138 | 47.1 | 53.6 |

| 40% | 1135 | 49.8 | 56.6 | |

| 60% | 1119 | 51.2 | 57.2 |

| Ion Energy (eV) | Ar+ Ions | Ne+ Ions | ||

|---|---|---|---|---|

| Sputtering Yield | C Atoms av. Energy (eV) | Sputtering Yield | C Atoms av. Energy (eV) | |

| 300 | 0.06 | 7.2 | 0.10 | 10.8 |

| 600 | 0.15 | 10.4 | 0.19 | 14.7 |

| 900 | 0.23 | 12.6 | 0.25 | 17.3 |

| 1200 | 0.29 | 14.3 | 0.30 | 19.4 |

| 1500 | 0.34 | 15.7 | 0.33 | 21.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, J.; Ferreira, F.; Serra, R.; Kubart, T.; Vitelaru, C.; Cavaleiro, A. Correlation between Substrate Ion Fluxes and the Properties of Diamond-Like Carbon Films Deposited by Deep Oscillation Magnetron Sputtering in Ar and Ar + Ne Plasmas. Coatings 2020, 10, 914. https://doi.org/10.3390/coatings10100914

Oliveira J, Ferreira F, Serra R, Kubart T, Vitelaru C, Cavaleiro A. Correlation between Substrate Ion Fluxes and the Properties of Diamond-Like Carbon Films Deposited by Deep Oscillation Magnetron Sputtering in Ar and Ar + Ne Plasmas. Coatings. 2020; 10(10):914. https://doi.org/10.3390/coatings10100914

Chicago/Turabian StyleOliveira, João, Fábio Ferreira, Ricardo Serra, Tomas Kubart, Catalin Vitelaru, and Albano Cavaleiro. 2020. "Correlation between Substrate Ion Fluxes and the Properties of Diamond-Like Carbon Films Deposited by Deep Oscillation Magnetron Sputtering in Ar and Ar + Ne Plasmas" Coatings 10, no. 10: 914. https://doi.org/10.3390/coatings10100914

APA StyleOliveira, J., Ferreira, F., Serra, R., Kubart, T., Vitelaru, C., & Cavaleiro, A. (2020). Correlation between Substrate Ion Fluxes and the Properties of Diamond-Like Carbon Films Deposited by Deep Oscillation Magnetron Sputtering in Ar and Ar + Ne Plasmas. Coatings, 10(10), 914. https://doi.org/10.3390/coatings10100914