3.1. Cancer Detection Studies

Early detection of cancer minimizes the death rate to a great extent. MoS

2-based sensors are highly effective in detecting and treating cancer due to their unique properties, like high surface area, as shown in

Table 1 [

72]. These properties of biosensors help them in adsorbing the molecules of drugs, leading to an improvement in the specificity. Optical biosensors dominate over the other biomedical instruments like enzyme-linked immunosorbent assays (ELISAs), PCR, and electrochemical sensors in detecting such diseases with high accuracy because of properties like its high sensitivity and speed of light. The speed of light property is crucial because it enables instantaneous signal transmission, allowing immediate tracking of biomarker interactions without delays. On the contrary, other instruments, such as ELISA, take hours to produce outputs, and PCR requires cumbersome sample preparation. Light–matter interactions (e.g., plasmonics and photoluminescence shifts) in optical biosensors quantify trace changes in biomarkers at high resolution and can be effectively used to diagnose cancer in its preliminary stage. These sensors are the composition of SnSe allotropes and the heterostructure of MoS

2. One such study based on optical biosensors was conducted by Hossain et al., who investigated a five-layered SPR biosensor using MoS

2, which is capable of identifying various cancerous cells, such as breast cancer and blood cancer [

73]. SPR biosensors are based on the principle of attenuated total reflection (ATR). The sensor has five layers coupling with a prism at the end, which is reliable for wave vector matching (WVM), a crucial step for SPR condition to occur. This MoS

2-based biosensor is typically based on the Kretschmann configuration, which is an optical setup where light passes through a prism to excite surface plasmons at a thin metal film interface. It relies on total internal reflection to generate an evanescent wave that couples with the metal’s electrons at a resonant angle and can easily detect the changes with high sensitivity. Mukundan et al. developed an MoS

2-based biosensor to locate lung cancer cell types, leading to a significant reduction in long waiting times for cancer detection in hospitals [

74]. N-type MoS

2 were grown by the CVD process and a thin film of p-type Cu

2O was grown. The crystal-based structure of the MoS

2 flakes grown was examined using the TEM technique. The MoS

2-grown flakes underwent preliminary processing, shifting the sample onto a Cu

2O thin coating to form the overall p-n junction. Glutathione (GSH) emerged as a crucial biomarker for detecting cancer and various other diseases. A study conducted by Rawat et al. developed an MoS

2-based electrochemical sensor that focused on the highly selective detection of GSH, which was fabricated with the help of standard semiconductor processing techniques. The Glutathione-S-Transferase (GST) was anchored on the surface of MoS

2 and GSH was determined by the electrochemical activity of GSH and CDNB in the presence of GST. The study claimed that the MoS

2-based sensor exhibits excellent stability and repeatability, making it suitable for cancer diagnosis and quantification [

75]. Sri et al. fabricated an MoS

2-based nanosensor to detect Tumor Necrosis Factor (TNF) in cancer patients using the electrophoretic deposition method. The biosensor was fabricated by using the electrophoretic deposition technique on a glass substrate coated with Indium Tin oxide. TNF serves as a critical factor in apoptosis and cancer and it was the first biosensor fabricated to detect TNF in cancer patients [

76]. The study also proved that MoS

2 is a favorable material for the manufacturing of this biosensor due to its 3D structure and high surface area.

An MoS

2-based fluorescence sensor was formed by Cai et al. to find tumors in women’s breasts for the initial diagnosis [

77]. The miR-21 is one of the most important biomarkers for the early-stage diagnosis of breast cancer. The fabricated device tends to have high sensitivity and efficiency, and is less expensive, thus making it favorable for miR-21 location in breast cancer patients. In this study, MoS

2 contacts a DNA probe for fabrication, which is further followed by a DNA-miRNA hybridization process. Another study was provided by Hu et al. using an MoS

2 biosensor based on Chalcogenide MoS

2 Au-Ag nanocomposites having higher sensitivity and satisfactory repeatability and stability [

78]. MoS

2 was successfully synthesized and proved to be a valuable material to improve the detection performance. The peaks of silver and gold established the effective electrodeposition of metals on the MoS

2-modified connector. The components of MoS

2-Au-Ag were studied and analyzed using energy dispersive spectroscopy (EDS). The results of the study claimed that the modified glass carbon electrode has high sensitivity and the framework of the fabricated sensor was investigated by TEM. Peng et al. aimed to develop a highly sensitive but cost-effective approach for the detection of PD-1—a checkpoint regulator related to cancer immune evasion. The sensor was fabricated using MoS

2 nanosheets as the quenching agent and nanofiber paper was used as a substrate for the immunosensor. The fabricated sensor is cost-effective, portable, and exhibits excellent quenching efficiency and excellent selectivity with its practical applicability in clinical applications [

79]. Another study was conducted by Lai et al. using a photoelectrochemical biosensing chip based on MoS

2, aiming to achieve better sensitivity through a straight interdigitated zigzag electrode and growing an MoS

2 layer on a silicon-based substrate using the CVD method [

80]. The experiment is mainly divided into two parts: fabrication (including three sub-parts: electrode fabrication, cell culture, and MoS

2 growth) and measurement, where a p-type substrate of thickness about 200 µm was used. The N-type substrate was used as a base substrate on which MoS

2 was grown. There are two primary procedures for the experiment to occur; generating the electron–hole pairs by the photoelectric effect is the initial step and the second step involves the occurrence of an electrochemical reaction between the electron–hole pairs and samples produced by the photoelectric effect. Research was also conducted to examine the correlation between the number of modified cells and the photocurrent. Qin et al. conducted a study to identify several biomarkers by employing MoS

2 as a tunable electrochemical biosensor. The feature of MoS

2 to stimulate the enzymes for changing the substrate color is used to determine cancer biomarkers. The study also claimed that the process involved is low-cost, simple, and has high sensitivity and faster speed as compared to the other traditional methods used for cancer biomarker detection [

81]. Another study for tumor therapy was conducted by Cao et al., aiming to develop a multifunctional nanoplatform for targeted cancer therapy. The platform developed in the study consisted of upconversion nanoparticles combined with MoS

2 quantum dots. The motive was to develop multifunctional nanoplatforms for improving the precision and efficacy of cancer treatments by minimizing the side effects [

82]. Enzyme-based nanosensors like ZIF@HAgel-GOx leverage metabolic pathways for cancer therapy, but MoS

2 biosensors offer superior capabilities. Unlike enzyme systems that are limited by stability issues and specific metabolic targets, MoS

2 biosensors provide exceptional versatility, enabling ultrasensitive, multimodal detection of diverse cancer biomarkers through electrical, optical, and plasmonic sensing mechanisms.

The integration of MoS2 in biosensing technology constitutes a revolutionary step in early cancer detection, providing an exclusive combination of chemical, electrical, and optical properties that make it immensely appealing for use in biomedical applications. One of the most significant benefits lies in its high surface area-to-volume ratio, which supports high drug-loading rates with better interaction with biomolecules. This aspect ensures that even trace levels of cancer biomarkers can be easily captured and sensed, which is pivotal for early detection. Apart from this, MoS2 also boasts exceptional photoluminescence and plasmonics, which make it an attractive option for optical biosensors that demand high sensitivity and real-time detection features. Its tunable electronic bandgap also enables scientists to design it for different configurations of sensors, i.e., electrochemical, fluorescence, or photoelectrochemical biosensors. While these attributes make MoS2 an exciting material for use in sensors, it is equally important to examine its limitations. One of its major drawbacks is that it is generally difficult to produce reproducible and homogeneous synthesis of MoS2 nanosheets, which was achieved by taking up methodologies such as CVD. The thickness of layers, direction of crystalline structure, or purity differences may lead to deviations in the performance of sensors. Other than that, although MoS2 allows for good biocompatibility, minimal study of long-term toxicity behaviors and biodegradation has been carried out, which causes concern for its safe integration with medical practices. Apart from that, though MoS2 is renowned for multifunctional sensory functionality, the integration of these capabilities in a miniaturized, portable, and affordable system still remains an outstanding problem in design.

3.2. Medical Industry Studies

MoS

2 has various applications in the field of the medical industry and employing MoS

2-based sensors in the medical field instead of traditional methods is rapidly increasing due to its distinct properties like biocompatibility, high sensitivity, and selectivity as shown in

Table 2 [

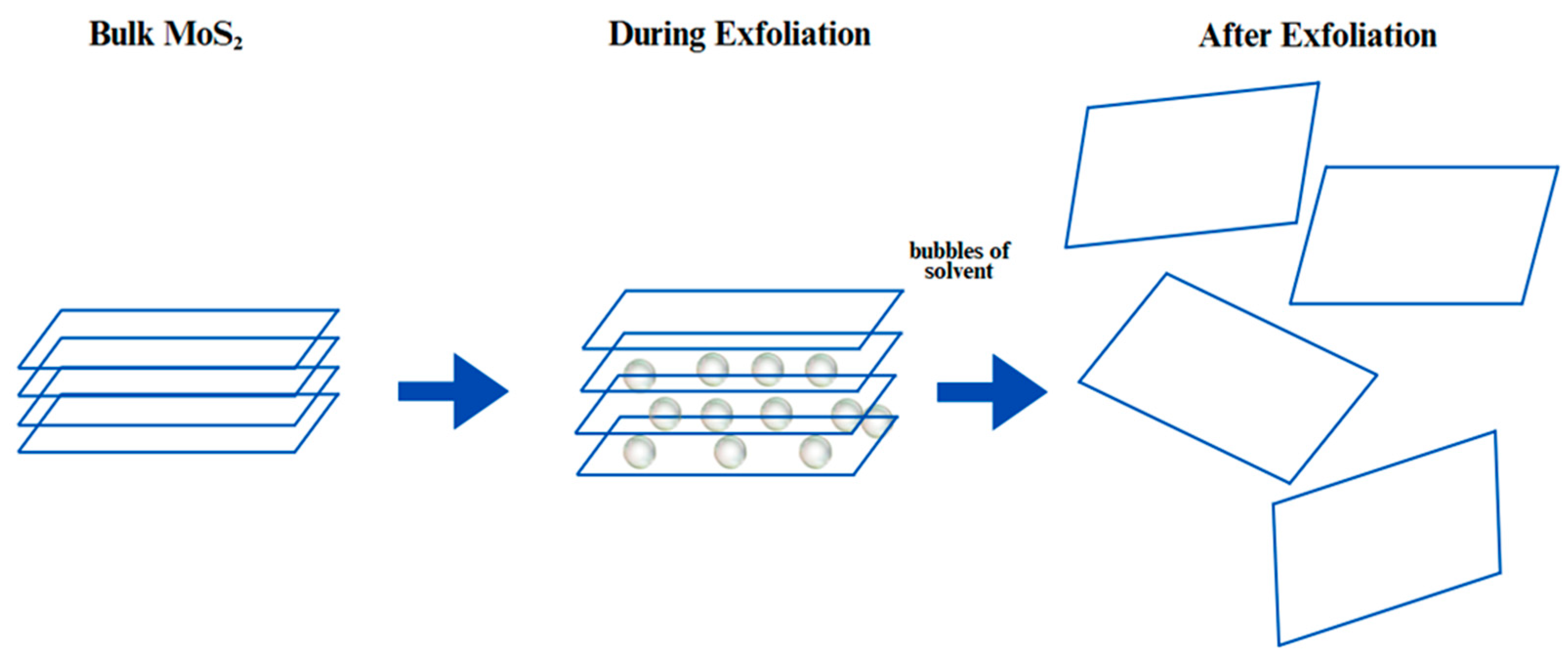

83]. A study by Rehman et al. investigated dual modification of h-MoS

2 nanosheets with electrodeposited nickel nanoparticles (NiNPs) for simultaneous biosensing of uric acid (UA) and dopamine (DA). They highlighted an easy ultrasonic method of synthesis of h-MoS

2 from a bulk of MoS

2 with subsequent electrodeposition of NiNPs over glassy carbon electrode (GCE). The prepared GCE electrochemical sensor showed high sensitivity and selectivity, attributed to synergistic effects between 2D material and metal nanoparticles. Cyclic voltammetry (CV), differential pulse voltammetry (DPV), and electrochemical impedance spectroscopy (EIS) characterization confirmed improved sensing performance. Low detection limits of 7.3 µM and 2.1 µM for UA and DA, respectively, were achieved by the sensor, with impressive anti-interference capability even in the presence of interfering substances like glucose and ascorbic acid. Thus, it serves as a promising small-molecule detection platform for use in clinical diagnosis [

84]. Another study conducted by Campos et al. investigated the MoS

2 nanomaterials exhibiting excellent absorption in the near-infrared window, making them suitable for controlled drug release, which enhances the accumulation of drugs at the tumor site by minimizing the side effects on the healthy tissues [

85]. The preparation of MoS

2-based nanosheets was completed using the LPE method, followed by intercalation with PVP. Further, ultrasonication was performed for about 6 h, ensuring effective penetration and interaction with cells for retaining necessary photothermal properties. Nurrohman et al. claimed that MoS

2-based biosensors are highly effective in photothermal therapy where near-infrared light is converted to heat for inducing localized thermal ablation of cancer cells and tissues. These sensors are also capable of detecting biological molecules and other analytes, making them valuable for medical industries [

86]. Most diseases progress due to changes in biomolecules such as proteins, DNA, and uric acid, which require timely detection for effective diagnosis and treatment. This early recognition is possible with the help of MoS

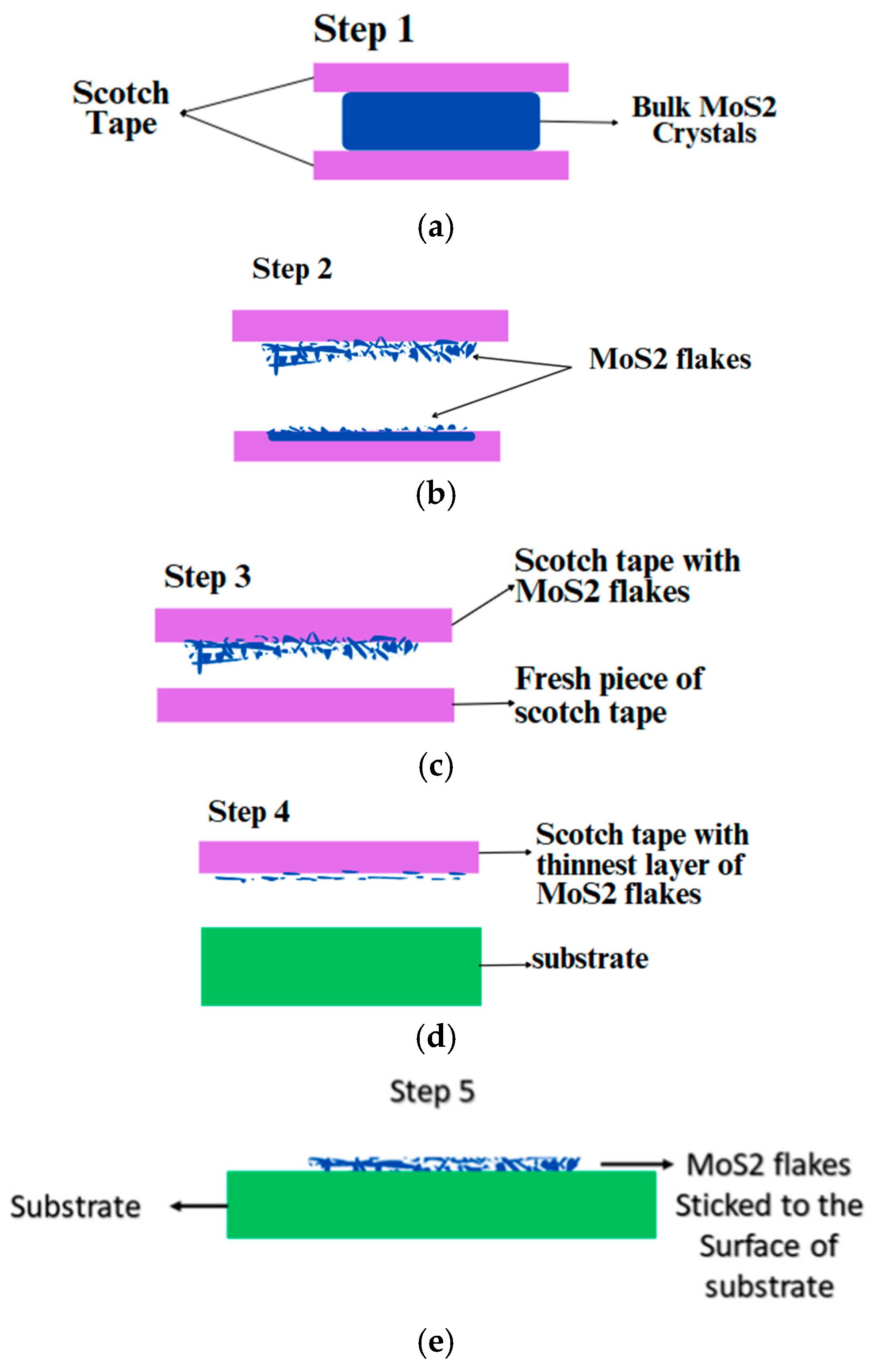

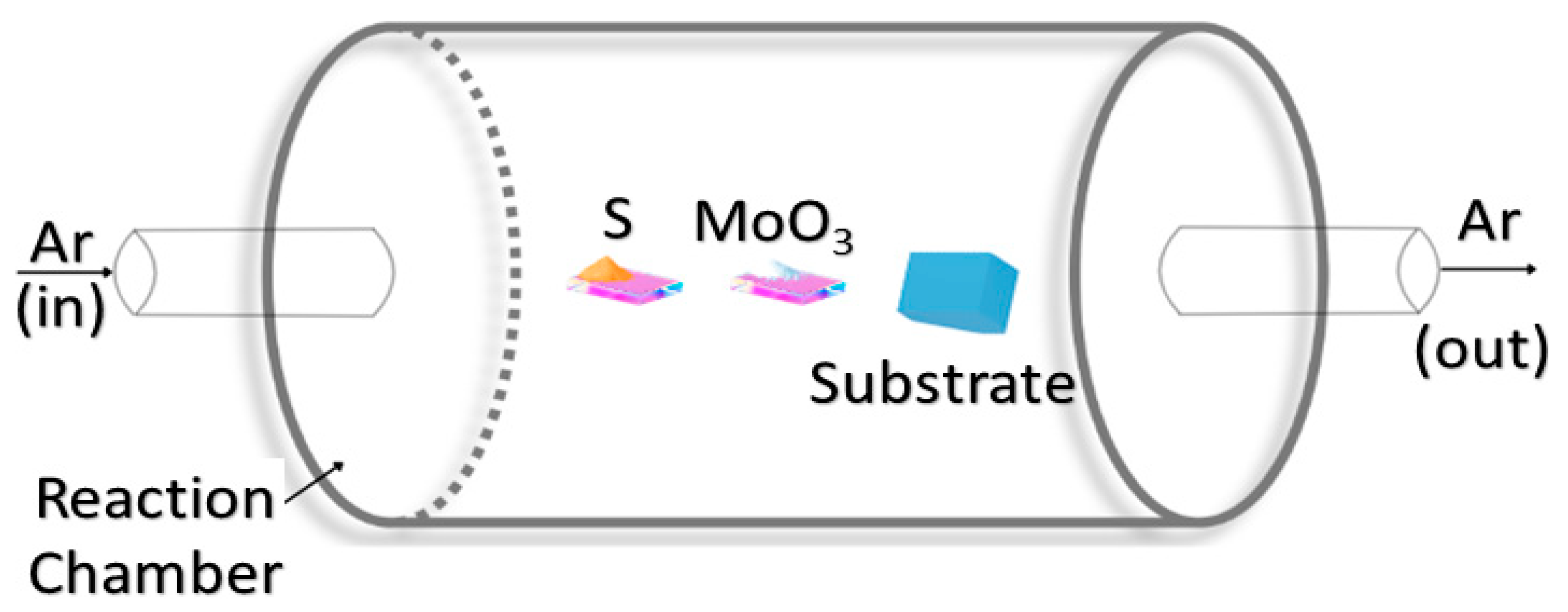

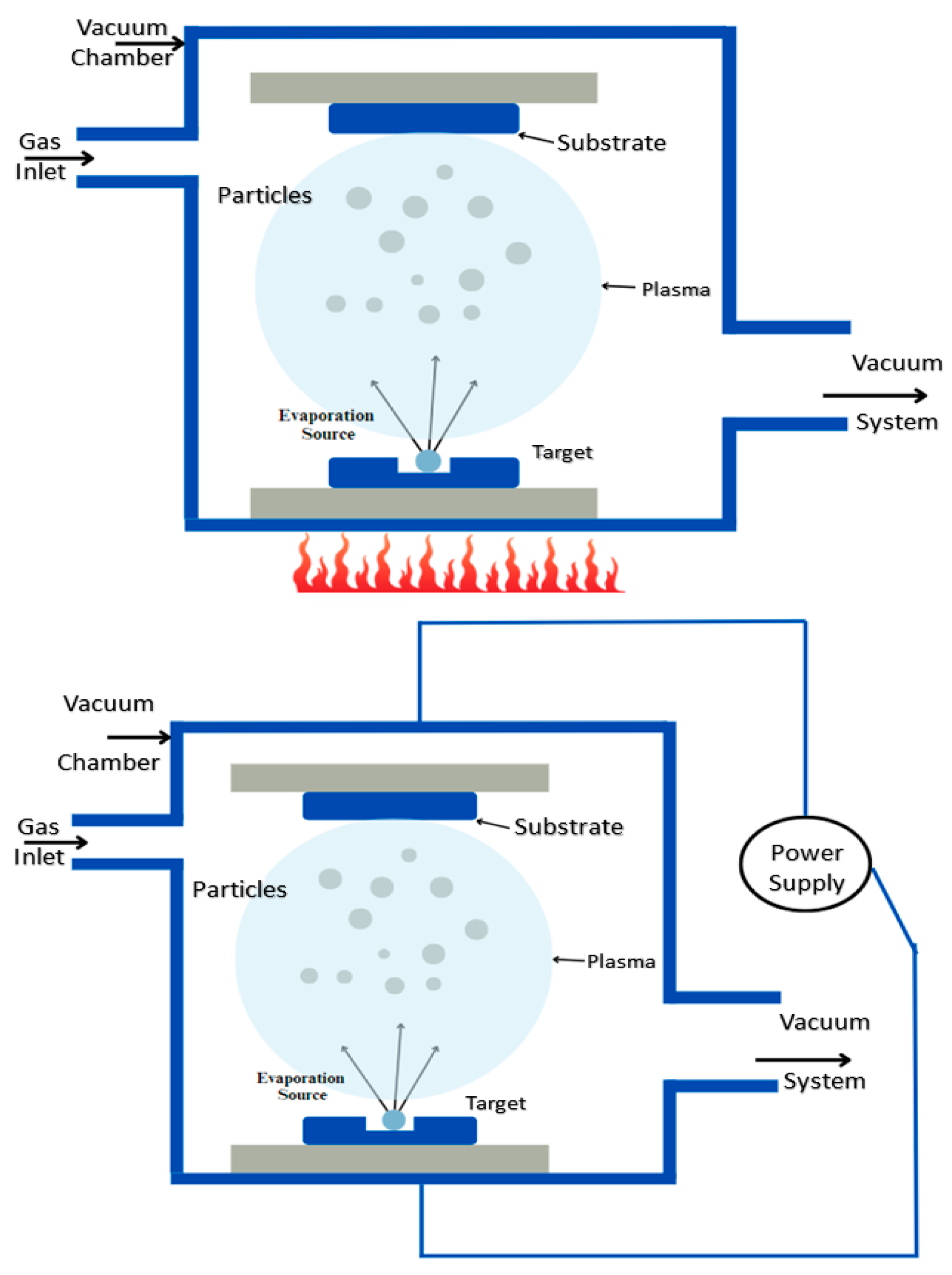

2-based biosensors. Meng et al. discussed the progress that has been made in TMDCs for medical examinations, detection of enzymes, and other biological molecules. In this method, a special CVD method has been applied in the synthesization of two-dimensional TMDCs, where the precursors are passed through a furnace as a gas and react at a very high temperature with the carrier gas to form a substrate layer [

87].

The DNA of the chikungunya virus was detected by Singhal et al. using thin-layered MoS

2 nanosheets based on disposable biosensors. The researchers claimed that the study is the first electrochemical detection approach for detecting chikungunya virus DNA. The proposed biosensor exhibited a maximum range of 100 µm and a minimum range of 0.1 nm towards the chikungunya virus DNA. The sensor was fabricated using screen-print terminals, which are proficient for the probe DNA binding. The fabricated sensor possesses unique properties like high linearity and economic feasibility which make it useful for miniature applications. The comparative study showed that the response of PDNA is nearly equal to that of non-complimentary DNA [

88]. Liu et al. proposed a study to develop a highly sensitive field-effect transistor (FET) using MoS

2 films for identifying trisomy 21 syndrome DNA. The CVD technique was used to grow the MoS

2 film on the silicon or silicon dioxide substrate. The researchers claimed that the developed biosensor is applicable because of its low cost and high sensitivity, and that it is suitable for large-scale applications in the medical industry. The fabricated sensor could detect DNA even at extremely low concentrations, with detection limits under 100 aM, and provides a high response rate with high sensitivity and high specificity in detecting DNA sequences, making the sensor effective for Down syndrome detection. This approach offers an early, accurate, and cost-effective alternative to the traditional methods used [

89]. Wen et al. fabricated and optimized an MoS

2-based FET biosensor for the detection of Tau protein, which is very crucial for the preliminary detection of Alzheimer’s disease. The detection of Tau protein in blood is challenging with traditional methods and thus requires a novel, sensitive detection method. This study aims to provide four different biofunctionalization methods to enhance the performance of biosensors: No linking molecule (direct adsorption of antibodies on MoS

2 surfaces), PASE-stacking (PASE is used as a linking molecule bound to the surface of MoS

2), APTES-GA covalent bonding (covalent bonds are formed between the surfaces of MoS

2), and Oxygen Plasma Pretreatment (MoS

2 is pretreated with oxygen plasma). The nanofilms of MoS

2 produced by the mechanical exfoliation technique were deposited on the silicon substrate. The performance of the biosensor was dependent on the four different methods of biofunctionalization [

90]. A label-free electrochemical biosensor was established by Raj et al., aiming to identify escherichia coli. The hydrothermal technique was used for the synthesization of MoS

2 by combining it with PANI using in situ oxidative polymerization and fabricating the sensor on the glassy carbon electrode [

91]. The sensor was fabricated by combining AuNPs, PANI, and MoS

2 using the green hydrothermal method, followed by situ oxidative polymerization for enhancing the electrical conductivity and surface area, and the chemical reduction method to improve the sensitivity. The fabricated sensor was practically tested by analyzing the urine samples for clinical use and serving public health and food safety. The study claimed that the sensor exhibited unique properties with low detection limits, making it a promising material for early detection of the pathogen in clinical, food, and environmental monitoring. Chen et al. aimed to develop an MoS

2-based microfluid biosensor for the immune detection of Toxoplasma gondii, a zoonotic parasite. The developed biosensor showed excellent properties, proving its potential applications in biomedical fields to detect toxoplasma gondii, and having a good detection range [

92]. The researchers claimed that the novel approach to integrate TCMF with MoS

2 enhanced the biosensing performance of the sensor and the sensor’s specificity was also confirmed against other viruses. García et al. provided a study highlighting different nanomaterials and their potential applications in advanced sensing technologies. The study focused on the development of water purification systems for the removal of pollutants, detection of food contaminants, and monitoring of crop health [

93]. However, while silicon nanowire (SiNW) field-effect transistors are widely used for label-free detection of biomarkers, MoS

2-based biosensors demonstrate superior performance in medical diagnostics. Unlike SiNWs, which suffer from surface oxidation and limited sensitivity in physiological fluids, MoS

2’s atomic thickness and high surface-to-volume ratio enable the detection of biomarkers even in complex biofluids.

MoS2 has become an effective and multifunctional material for medical diagnostics and therapeutics due to its inherent physicochemical properties, particularly because it is biocompatible and atomically layered, with an extremely large surface area. It is an optimum material to interact with biomolecules such as DNA, proteins, enzymes, and small-sized metabolites. One of the greatest properties of MoS2 sensors is that they are extremely sensitive and selective, which allows for ultra-low disease biomarker detection. This is particularly important for early detection, especially in complex diseases like cancer and Alzheimer’s disease, or genetic diseases like trisomy 21. FET and electrochemical sensors based on MoS2 have exhibited steady performance in biomarker detection at sub-attomolar levels, a sensitivity that conventional techniques hardly attain. The tunability of MoS2 also facilitates functionalization with selected targets so that MoS2 can be a highly versatile sensor material. Processes like CVD and exfoliation provide fairly controlled synthesis routes for MoS2 with resulting thin films and nanosheets suitable for integration with devices. Optical properties like significant near-infrared absorption make MoS2 suitable for photothermal cancer therapy and drug delivery with controlled release. Photo-heat conversion capability permits ablation of cancer tissue by concentrating heat without damaging normal cells, eliminating chemotherapy- or radiation-induced side effects. These advantageous properties are compounded by affordability and bendable substrate compatibility, all good qualities that are appropriate for point-of-care and wearability diagnostics. These advantageous properties, however, have some drawbacks. One such drawback is synthesis and functionalization. While high-quality MoS2 can be supplied by CVD, the process is not optimized for economy or for scaling up to large production.

3.3. Food Industry Studies

The development and advancements of MoS

2-based biosensors have led to various emerging applications in food and bioscience as shown in

Table 3. Li et al. provided a study on the importance of biosensors based on two-dimensional materials for food safety. It was noticed that nitrite content was rapidly increasing in crops because of an increase in inorganic fertilizers sprayed in the fields. However, the nitrite content tends to enter the human body along with the food products, which converts the hemoglobin into methemoglobin and hence disrupts the oxygen delivery system in the human body, making it crucial to detect and control the nitrite content effectively. Therefore, two-dimensional-based biosensors play a vital role in food safety and biomolecular detection [

94]. Another study for the detection of synthetic colors in food samples was conducted by Jahani et al., aiming to reduce the side effects of artificial colors in humans. The main goal of this study was to synthesize MoS

2-based biosensors for modifying the electrodes to identify sunset yellow FCF synthetic food dye in food samples, and this MoS

2-based biosensor was successfully implemented to detect FCF in real-life samples [

95]. Nehru et al. proposed an MoS

2-based sensor grown on g-C

3N

4 nanotubes to determine vanillin (VNN) in food samples using the hydrothermal method. Vanillin is an artificial flavoring agent used in perfumes, food products, and beverages, and is beneficial when used in limited quantities. However, the overdose of VN is hazardous and needs to be detected using a cost-effective g-C

3N

4-grown nanotubes approach. The proposed method used for the detection of vanillin in food samples proves to be a very cost-effective and more attractive strategy for food additive detection [

96]. Lin et al. demonstrated an approach for detecting terbutaline sulfate in food samples that were characterized later using techniques like TEM and SEM. The researchers used fresh samples of pork for testing and claimed that the fabricated sensor had excellent electrolytic properties [

97]. Another MoS

2-based user-friendly sensor was developed by Sharma et al. to detect Xanthine (Xn) in fish meat. Keeping fish meat fresh and free from bacteria like Vibrio and Salmonella is a major concern as fish meat has a large market in various industries like pharmaceuticals for multiple medications or fish oil supplements [

98]. Xn is one such bacteria found in rotten fish and the level of Xn increases with an increase in the storage time of fish meat, making it necessary to keep track of Xn in fish meat for diagnosing and monitoring diseases.

Govindasamy et al. proposed an approach where carbon nanotubes are coated with MoS

2 for detecting CAP in food samples like milk [

99]. There are various techniques used for the monitoring of CAP levels in food items but electrochemical methods are low-cost, simple, and portable as compared to other traditional analytical approaches. Another study using carbon nanotubes based on two-dimensional MoS

2 was conducted by Cheng et al. to detect Thiabendazole (TBZ) residues in food samples [

100]. The sensor was fabricated using multiwall carbon nanotubes aligned with layered MoS

2 nanosheets. Zhou et al. demonstrated the use of MoS

2-based electrochemiluminescence (ECL) biosensors for ensuring food safety by detecting contaminants in various samples. There are different types of ECL biosensors available for food sensing applications and all are well known for their high sensitivity, selectivity, and efficiency, especially for examining miniature devices. This approach for sensing the food samples is cost-effective and biocompatible [

101]. Bankole et al. focused on developing biosensor technology mainly in the food and healthcare industry. The study used novel nanomaterials which also improve the sensitivity, selectivity, and stability of the biosensors [

102]. A photoelectrochemical immunosensor based on MoS

2 nanocomposites was developed by Ai et al., aiming to detect N6-methyladenosine, an essential RNA modification. The biosensor was fabricated by assembling an MoS

2 heterojunction, gold nanoparticles, and an m6A antibody. The main aim of this study was to improve the sensitivity and selectivity of the biosensor, hence making it suitable for various environmental and biological applications [

103]. While ELISAs remain the gold standard for detecting food contaminants like allergens and pathogens, MoS

2-based biosensors offer significant advancements for food safety monitoring. Unlike ELISA systems that require lengthy incubation times (typically 2–4 h), complex antibody handling, and specialized lab equipment, MoS

2 biosensors enable rapid on-site detection through their exceptional electrical and optical properties.

MoS2-based biosensors have opened up new doors for food safety assurance, product-quality surveillance, and biomolecular identification in food and bioscience industries. With exceptional surface area, catalysis, and tunable bandgap properties, MoS2 is particularly suitable for electrochemical and optical sensing. One of its main merits is that it can identify toxic additives, synthetic food colors, drug residues, and indicators of spoilage with sensitive detection and high selectivity. For example, Li et al. highlighted the imperative to track nitrite content in food due to its toxic conversion to methemoglobin in humans. MoS2-based sensors provide a fast, efficient solution to this end, providing better response times with minimal operating complexity compared to traditional approaches. Further, scientists like Jahani et al. and Nehru et al. have illustrated MoS2’s capability to identify food coloring such as sunset yellow FCF and flavoring chemicals such as vanillin with affordable probing using inexpensive sensing substrates. These sensors provide significant substitutes for costly spectrophotometric or chromatographic practices that are not only time-consuming but also require complex instrumentation. Further integration of MoS2 with hybrid nanocomposites from material such as carbon nanotubes, g-C3N4, and Au nanoparticles helped improve not only sensor stability but also electrical conductivity, and transduction of the signal. These improvements are visible in works such as those of Govindasamy et al. and Cheng et al., in which MoS2-based nanocomposites identified CAP, thiabendazole in milk products, and other foods. Yet another strong point of MoS2 in food surveillance is that it can be applied to a range of detection modes such as electrochemical, photoelectrochemical, electrochemiluminescence (ECL), etc. Illustrating this with an example from Zhou et al., ECL-based MoS2 sensors possess high sensitivity and reproducibility, which are critical in detecting contaminants in trace quantities. Further, with work by Ai et al. on an MoS2 photoelectrochemical immunosensor for detecting modifications in RNA, we realize that there could be extended use of this material in conducting biomediagnosis and epigenetics-related studies. In comparison to labor-intensive sample preparation, numerous wash steps, and long incubation times involved in enzyme-linked immunosorbent assays (ELISAs), MoS2 biosensors enable label-free, real-time detection with minimal sample preparation. This makes MoS2 a point-of-care and field-deployable food safety system game-changer. In seafood industries, for instance, Sharma et al. demonstrated the ability of MoS2 biosensors to identify spoilage indicators such as Xn in fish meat, which is important for preserving food freshness and avoiding contamination due to bacteria. Such sensors are particularly well-suited for on-site testing due to miniaturization and disposability in supply chains, supermarkets, and restaurants.

3.4. Wearable Health Devices

When it comes to electronic wearable devices, MoS

2 proves to be a fit material because of its atomically thin structure and flexibility, which make it suitable for health monitoring and motion detection technologies as shown in

Table 4. Mondal et al. aimed to develop a highly sensitive MoS

2-based wearable sensor based on honeycomb-like MoS

2 nanotubes to detect human skin moisture. The fabricated sensor proved to be a promising device for rapid and highly efficient response, and hence use for various healthcare and fitness monitoring applications [

104]. Another study on the development of advanced wearable devices was conducted by Shi et al., aiming to develop multifunctional devices for diagnosing oral diseases like dental or healthcare applications. The gas sensor was fabricated by performing the sonication for 21 h for the mixture of the bulk-layered MoS

2 with ethanol and deionized water, which was later filtered and dried in a vacuum oven. The powder of MoS

2 was mixed with sulfuric acid followed by sonication to remove large flakes. Both the mixtures were mixed up using electrostatic adsorption for 1.5 h and the prepared sensor was integrated into the PET substrate. The sensor tends to exhibit exceptional linearity and effective monitoring even during facial and oral movements like swallowing and chewing [

105]. A similar thermoelectric wearable device was fabricated by Guo et al. based on a gold-decorated MoS

2 nanosheet. The main aim of the study was to develop a device that is capable of transforming the heat from the human body to wearable electronic devices. The device was fabricated by chemically exfoliating MoS

2 and forming a layer of gold nanoparticles. MoS

2 was exfoliated using a lithium intercalation process followed by the growth of gold particles. This prepared structure was assembled into thin films and formed into a wristband for testing. The device tends to exhibit strong mechanical stability by maintaining 97% thermoelectric performance, offering a reliable power source for electronic wearable devices [

106]. Rana et al. explored the piezoresistive properties of MoS

2 thin films for the development of a highly sensitive wearable strain sensor to monitor real-time body movements like gestures. The hydrothermal method was used to synthesize MoS

2 and create thin films using liquid-phase exfoliation. It was developed on the flexible polyethylene terephthalate (PET) substrate and tested by changing the current during bending and straightening cycles, which were consistent and showed a balance between sensitivity and durability [

107]. Xu et al. developed a large programmable film of MoS

2 using direct laser writing for monitoring health-related signals. The sensor was fabricated by synthesizing MoS

2 films on silicon or silicon dioxide wafers and shifting them onto a PET substrate with Au-interdigitated electrodes by creating customizable patterns in a programmable manner. The fabricated sensor exhibited excellent piezoresistive behavior, high performance, and excellent stability and was able to monitor various health-related problems. The study demonstrated the use of direct laser writing to produce high-quality MoS

2 films, making way for advancements in healthcare technologies [

108].

Vaghasiya et al. introduced wearable sensors for telehealth by using MoS

2-based nanomaterials for health monitoring and detecting physiological markers like temperature, respiration rate, etc. The paper mainly focused on the development of more efficient, rapid-response sensors that are capable of tracking health data [

109]. The key challenge in the study was to produce 2D materials on a large scale, maintaining the stability, comfort, and privacy of the data collected by the wearable electronic sensors. Five major types of wearable sensors were highlighted in this study, including pressure, strain, temperature, electrochemical, and optoelectronic. They were found to be effective for tracking different health-related parameters effortlessly and wirelessly. The fabricated sensors were sensitive enough for detecting various physiological changes, which made them suitable for personalized healthcare, and it was also concluded that personalized healthcare could be revolutionized by combining wearable devices with advanced AI/ML tools. Another study on the fabrication of wearable devices was conducted by Pang et al. using two-dimensional materials to detect human physiological signals. The use of MoS

2 ensures the conforming of the wearable device with the skin’s surface, allowing non-invasive monitoring of important signs without any discomfort [

110]. Chemical signals are detected from blood fluids like sweat and saliva with the help of MoS

2 in wearable devices. The sensor is combined with a suitable substrate and other two-dimensional materials for improving the functionality and hence enhancing the performance, making it suitable for health monitoring systems. Moreover, it plays an essential role in wearable electronic systems because of its unique properties. Kim et al. developed a highly sensitive and flexible strain-pressure sensor with a cracked paddy-like MoS

2 nanostructure. The researchers observed that the sensor’s performance was improved by increasing the MoS

2 content and adjusting the concentration of MoS

2 nanoflakes. It was successfully tested for monitoring real-time detection of human motions like blinking of an eye, and neck movement. Overall, the study demonstrated the effectiveness of using MoS

2 for high-performance wearable devices [

111]. Another study for the development of a high-performance pressure sensor using an integration of polydimethylsiloxane (PDMS) and 1T-phase MoS

2 was conducted by Yang et al. to monitor human physiological signals like finger movements, speech recognition, and pulse measuring. The sensor was fabricated using a mixture of PDMS and curing agents in a 5:1 to 30:1 ratio along with NaCl salt [

112]. The mixture was later poured and cured into a mold for 4 h at 80 °C. The combination of high electrical conductivity of 1T-MoS

2 and the microstructure of a leaf vein tends to enhance the selectivity of the sensor and pressure response by varying the contact resistance between MoS

2 and PDMS. Yu et al. demonstrated a self-powered MoS

2-based nanogenerator to accelerate the healing of wounds in diabetes. The device tends to exhibit excellent electrical conductivity and efficient photothermal conversion, hence accelerating the process of wound healing in diabetic patients [

113]. Also, while graphene has been widely explored for wearable health monitoring due to its excellent conductivity and flexibility, MoS

2-based biosensors offer distinct advantages for next-generation devices. Unlike graphene, which lacks an inherent bandgap and often requires complex doping to achieve optimal sensing performance, MoS

2’s natural semiconducting properties enable highly sensitive and selective detection of biomarkers at ultra-low concentration, critical for early disease diagnosis.

MoS2 wearable sensors offer extraordinary potential in next-generation healthcare and human monitoring device development. MoS2’s atomically thin nature, mechanical flexibility, tunable bandgap, and semiconducting nature make it an attractive replacement for traditional silicon and even graphene for wearable use. MoS2’s layered structure allows it to be in intimate contact with human skin, forming highly conformal, non-invasive sensing platforms for real-time physiological readings. Mondal et al., for example, described the application of honeycomb-structured MoS2 nanotubes for detecting human skin dampness, which demonstrates the material’s fast response and efficacy in fitness/disease diagnostics. Shi et al. also fabricated a gas sensor on a PET substrate from exfoliated MoS2 with similar detection of oral movements such as chewing and swallowing, which are pivotal in oral disease detection and dental care. These reports demonstrate MoS2’s high sensitivity, mechanical flexibility, and ability to incorporate wearable systems in everyday life without any annoyance or interference. MoS2’s applicability to different sensing mechanisms including piezoresistive, thermoelectric, optical, and electrochemical mechanisms tremendously enhances its scope of application in wearable health monitors. In addition, wearable sensors made from MoS2 nanomaterials have been applied to telemedicine and remote health monitors. Five categories of sensors were classified by Vaghasiya et al., namely pressure, strain, temperature, electrochemical, and optoelectronic, where MoS2’s high sensitivity allowed for detecting infinitesimal physiological changes. This not only allows for health tracking in real time but also for personalization and the addition of AI to health systems. MoS2’s compatibility with biofluids like sweat and saliva, demonstrated by Pang et al., supports their use in biomarker monitoring with non-invasive methods. The compatibility of substrates that mimic skin with the sensor supports wearability over long periods of time along with comfort levels for users. Kim et al. extended this with cracked paddy-like MoS2 nanostructures for motion sensing in real time, e.g., eye blink rates and neck movement—functionality imperative for human–computer interaction and assistive technology. Further, research by Yang et al. with MoS2-PDMS composites exhibited an improved sensitivity to pressures due to leaf vein-like microstructures, pointing to the use of MoS2 with suitable polymers in tactile sensing.

3.5. Other Applications

MoS

2 is widely integrated in the environmental industry for the identification of contaminants like inorganic compounds and poisonous gases in the environment, as shown in

Table 5 and

Figure 6 [

114]. Guo et al. developed a sensor using MoS

2 base along with boronic acid for the sensitive and selective detection of mercury ions in environmental water. The proposed method exhibited excellent optical properties, high quantum yield, strong fluorescence, and highly selective analysis of Hg ions in the contaminated water with a much faster response. This paper also presents an overview of a gas-phase reaction involving methane and a metal catalyst used in CVD. When methane gas splits into carbon (C) and hydrogen gas (H

2) under specific conditions, solid carbon is deposited on a substrate as part of the fabrication process. Particularly in the production of thin films, semiconductors, and nanomaterials, this method is essential to materials science [

115]. Sahatiya et al. proposed a novel approach for wireless monitoring of the environment using a cellulose paper-based MoS

2 sensor with the help of the hydrothermal method. The fabrication of the sensor involves three steps. The initial step is the growth of MoS

2 on the cellulose paper, which was further dipped in a seed solution followed by drying of the paper substrate at 80 °C. The second step includes the growth of Cu

2S by using MoS

2 on cellulose paper as a substrate. The last step is to cut the obtained Cu

2S-MoS

2 cellulose paper into desired pieces followed by a final finishing using silver paste. The fabricated sensor is utilized once and then disposed of and is not further used for other sensing applications. The sensor is capable of measuring the temperature, humidity, human breath, and ethanol adulteration [

116]. Su et al. discussed the recent developments of two-dimensional nanomaterials for developing electrochemical sensors to detect pollutants like bacteria, pesticides, and insecticides [

117]. The recent advancements and electronic properties of MoS

2 such as direct bandgap are discussed in the study. The potential of developing fast, low-cost, and sensitive sensing devices for addressing the need for efficient monitoring tools to control the increase in environmental pollution has been discussed in this study. Singh et al. developed an MoS

2-based nanocomposite biosensor for the selective detection of NH

3. It was noticed that there is a high need for devices that are capable of operating under extreme conditions and the selective detection of NH

3 becomes difficult because the latter is a mixture of various gases and humidity. Thus, there is a need to develop such MoS

2 composite-based NH

3 sensors to operate under such humidified environmental conditions [

118]. The research mainly focused on addressing the problems related to the development of sensors, the successful synthesis of MoS

2, and the electrical and gas sensing properties of the devices made from MoS

2.

Chen et al. focused on developing two-dimensional TMDCs-based biosensors for environmental applications. The water quality was analyzed using a TMDC biosensor which mainly focused on detecting ions and non-ionic molecules and hence offering real-time monitoring, which is very useful for environmental analysis. However, the performance depends on the intrinsic properties. Their study highlighted the unique physical and chemical properties of TMDC [

119]. It was also observed that 2D TMDCs are costly, have poor uniformity, and face major challenges with large-scale production in TMDC device fabrication. Another study for colorimetric determination of Hg ions with high sensitivity and high selectivity in environmental water was introduced by Ma et al. with the help of MoS

2-based composites. The MoS

2 nanosheets were synthesized and the resulting MoS

2 nanocomposites were characterized using techniques like SEM and TEM to confirm the chemical composition. Researchers found that this method for colorimetric detection proves to be an effective and practical method for detecting the trace amounts of mercury ions in environmental water samples [

120]. Bolukbasi et al. presented a precise and selective approach for electrochemical sensors based on MoS

2 nanocomposites for paraoxon detection in tap water samples, which is a toxic organophosphorus pesticide, using the hydrothermal method. The sensor used molecular imprinting technology, leading to a highly sensitive and selective approach with a detection limit of

M. It was also recorded that the MoS

2-based nanocomposites can be further utilized to determine the environmental pollutants, which also improves the voltammetric to determine the complex samples [

121]. Another study was conducted by Wang et al., enhancing an MoS

2-based electrochemical biosensor to detect bisphenol A in environmental water. The sensor was fabricated using Au nanoparticles, MoS

2 nanoflowers, and ionic graphene for the formation of a nanocomposite. The fabricated sensor was later characterized using techniques like TEM, SEM, and X-ray diffraction, which also confirmed that the sensor tends to have a large surface area and good dispersion. The cost-effective sensor was able to hold potential for a wide range of applications in pollutant detection because of its excellent performance characteristics [

122]. Amalraj et al. developed a biosensor using CuO@PDA-MoS

2 nanospheres combined with an ssDNA probe for the detection of mercury ions and chloramphenicol (CAP) in water. For the detection process, the mercury ions played an essential role in cleaving the PS-RNA linkage in ssDNA, which releases the fluorophore, whereas the CAP interacts with the leftover ssDNA to form a complex which is released from CuO@PDA-MoS

2. The fabricated sensors tend to high selectivity when used for real water samples, and a wide linear detection range, making it fit for environmental samples [

123]. Sphere-like MoS

2 nanosheets were used by Nehru et al., accurately monitoring the toxic pollutants like nitrobenzene in the samples of environmental water. The sensor was fabricated using the hydrothermal method by imposing MoS

2 nanosheets on reduced graphene oxide and further characterizing using techniques like TEM, XPS (X-ray photoelectron spectroscopy), and FTIR (Fourier-transform infrared spectroscopy) [

124]. It was also tested in real water samples from tap water that showed effective detection of NB with satisfactory recovery rates. Also, MoS

2 biosensors demonstrate superior performance compared to conventional carbon nanotube (CNT)-based sensors for environmental monitoring applications. While CNT sensors have been extensively used for detecting pollutants like heavy metals and toxic gases, MoS

2 offers enhanced selectivity through its tunable electronic properties and surface chemistry, enabling more accurate discrimination between similar contaminants. The atomically thin structure of MoS

2 provides exceptional sensitivity, capable of detecting trace-level pollutants at concentrations below what CNT-based systems can reliably measure. Furthermore, MoS

2 exhibits better environmental stability, particularly in aqueous conditions where CNTs are prone to oxidative degradation, making MoS

2 particularly advantageous for long-term water quality monitoring applications.

The integration of MoS2 in environmental sensors is a significant leap forward in creating efficient, sensitive, miniaturized sensing platforms to identify contaminants. MoS2’s large surface area to volume, adjustable bandgap, and efficient adsorption properties make it particularly suitable to react well with a range of environmental contaminants such as heavy metals (for instance, mercury), toxic gases such as ammonia, and organic contaminants such as bisphenol A and paraxo-n. Hydrothermal, CVD, and aqueous-based LPE methods for synthesizing MoS2 nanomaterials have been found to be efficient to produce sensors that are capable of detecting trace amounts of contaminants in complex environmental matrices such as drinking water and environmental wastewater. Colorimetric and electrochemical biosensors based on MoS2 nanocomposite matrices have been found to demonstrate high sensitivity and specificity for detecting contaminants like Hg2+ ions and nitrobenzene, contributing immensely to environmental health, environmental security, and regulation. Further, the better aqueous system environmental stability of MoS2 over a material like carbon nanotubes (CNTs), with their avidity for water that predisposes them to oxidative breakdown, presents an unheralded advantage. The ability of MoS2 biosensors to detect, in real time, label-free and selective conditions under humid or hostile environmental conditions makes them extremely promising candidates for water purification, air pollution management, and agricultural farm management. Further, MoS2’s ability to be functionalized on paper-based, lossy substrates or microfluidic substrates adds an additional layer of economical and ecological relevance, which renders them compatible with field-based deployment. Nonetheless, their integration in environmental sensing is not without limitations. The reproducibility and upscalability of fabrication pose a major limitation. While hydrothermal and LPE fabrication methods are economical and low-tech, these methods tend to induce layer thickness, surface defects, and morphological inconsistencies that are detrimental to uniformity of performance. Conversely, technical-intensive methods like CVD, while efficient to produce high-quality, uniform-quality films, are still costly and technically demanding to use in large-scale environmental sensing systems. Another significant concern is MoS2-based sensors’ selectivity in complex environmental matrices. Under optimal laboratory conditions, their good sensitivity may be undermined by interference from structurally similar impurities in real-world environments or changes in environmental sample pH and ionic strength. Further, non-uniformity in synthesis, functionalization, and characterization protocols across studies renders comparison of performance levels complex and discourages commercial use. Long-term stability, especially under continuous use with exposure to changing contaminants, is also a concern. MoS2, being somewhat more stable than most other nanomaterials, still tends to oxidize or degrade over long timescales, especially under exposure to UV radiation or oxidizing molecules. Another shortcoming is its requirement for a complicated functionalization process that allows high selectivity. Such process steps, such as the addition of molecular imprinting or use of targeted binding probes, have a tendency to increase fabrication complexity and costs. Some MoS2 composites also contain environmentally unwanted chemicals or rare elements, raising questions about sustainability and ecotoxicity.