New Advances in Antenna Design toward Wearable Devices Based on Nanomaterials

Abstract

1. Introduction

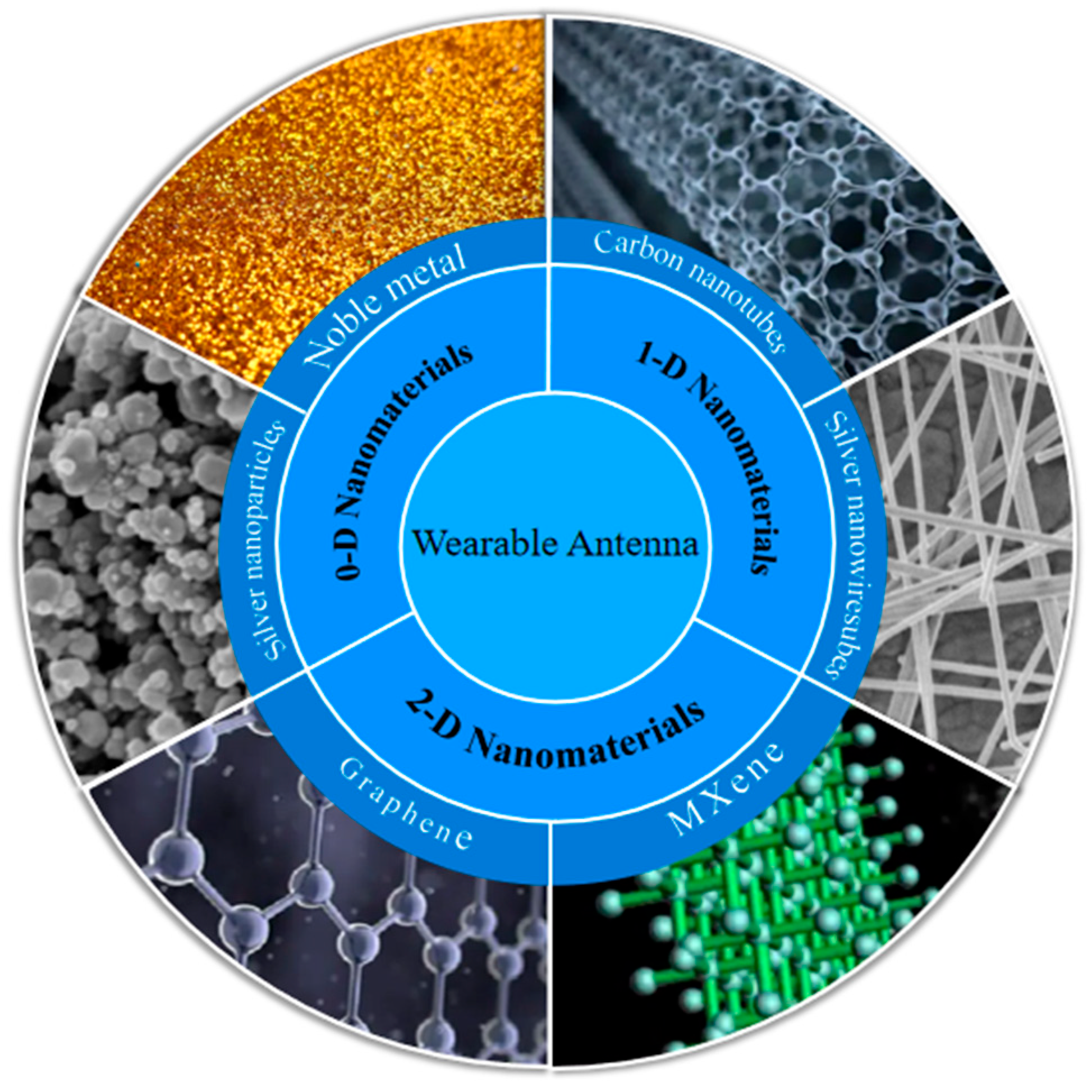

2. Wearable Antenna Parameters

3. Wearable Antenna Materials

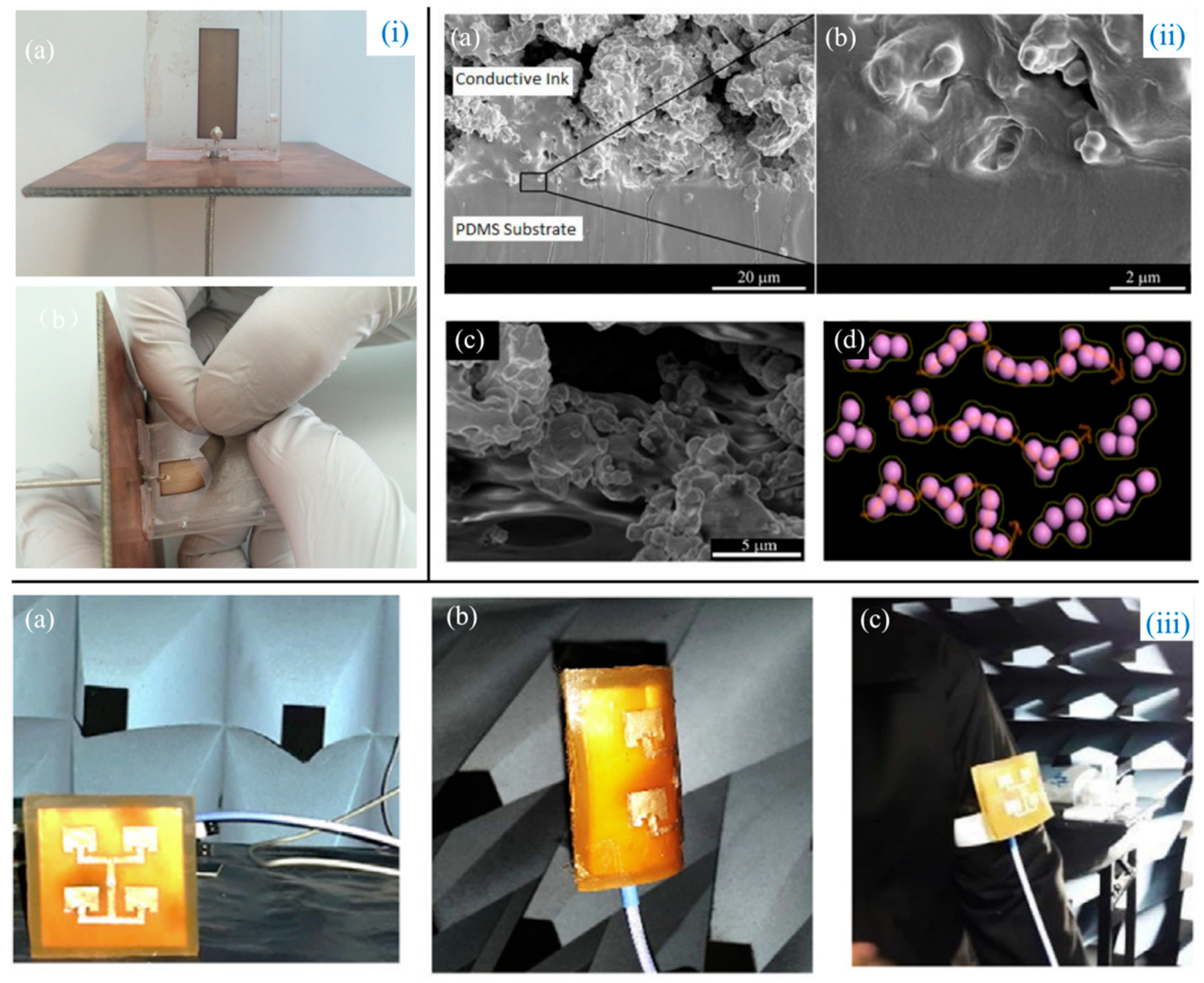

3.1. 0-D Nanomaterial Structure Antenna

| Nanomaterials | Antenna Base | Manufacturing Technology | Antenna Performance | Antenna Parameter | Application | References |

|---|---|---|---|---|---|---|

| AgNWs | PET | Inkjet printing | Soft and light | The antenna operates in two frequency bands, 2.02 GHz (−16.02 dB) and 2.3 GHz (−19.33 dB), with a weight of only 0.208 g. | Wearable electronic devices | [41] |

| Flexibility, wearability, and reversible deformability | The reflection coefficient is −23 dB at 2.54 GHz, the −10 dB bandwidth is 530 MHz, and the obtained VSWR is 1.3. | Mobile communication | [43] | |||

| Flexible, frequency reconfigurable | The antenna covers an overall bandwidth of 27.3–40 GHz in the four distinct modes with a measured peak gain of 6.2 dB at 34 GHz. | 5G network | [44] | |||

| Conductive fabric | PDMS | Textile | Extremely bendable and machine washable | The antenna is small in size and more stable. | Wearable electronic devices | [45] |

| PEDOT:PSS | PET | Screen printing | Flexible, metal-free | The antenna shows a low RL of −50 dB and an estimated radiation efficiency of 28% at 2.35 GHz. | Wearable electronic devices | [46] |

| AgNWs | Mitsubishi Photo Paper | Inkjet printing | Soft, environmentally friendly, dual frequency | The antenna, made on a paper substrate with a relative permittivity of 3.6 and a loss tangent of 0.14, experiences a slight shift in resonant frequency when bent. | Wearable electronic devices | [47] |

| PEA | Inkjet printing | Small size, low SAR value | The size of the antenna is 20 × 10 mm2, and it exhibits low SAR effects at 403 MHz and 2.45 GHz, measuring 0.25 W/kg and 0.33 W/kg, respectively. | Wireless biomedical devices | [48] | |

| Polysiloxane–silver composite | PDMS | Inkjet printing | Stretch, roll, or twist | The resonant frequency of the antenna is 2.5 GHz, with an RL much lower than −15 dB. The bandwidth remains consistent with the unstretched condition when stretched at 10% and 20%. | Implantable medical devices | [50] |

| BT | - | Textile technology | High isolation | This flexible antenna can operate simultaneously in both transmit and receive modes, demonstrating robustness to bending. | Wearable device | [51] |

| Fe3O4 | - | Polymer nanocomposite substrate layer technology | Wide bandwidth bottom SAR | The antenna measures 70 × 70 × 4.2 mm³, operates in the 5 GHz to 8.2 GHz frequency range, has a fractional bandwidth (FBW) of 50.34%, achieves a maximum radiation efficiency of 60%, and realizes a gain of 9.8 dB. | Telemedicine | [52] |

| AgNWs | PTFE | Inkjet printing | Low cost and scalability | The antenna achieves a precise human activity recognition accuracy of 91.9%. | Wearable device | [53] |

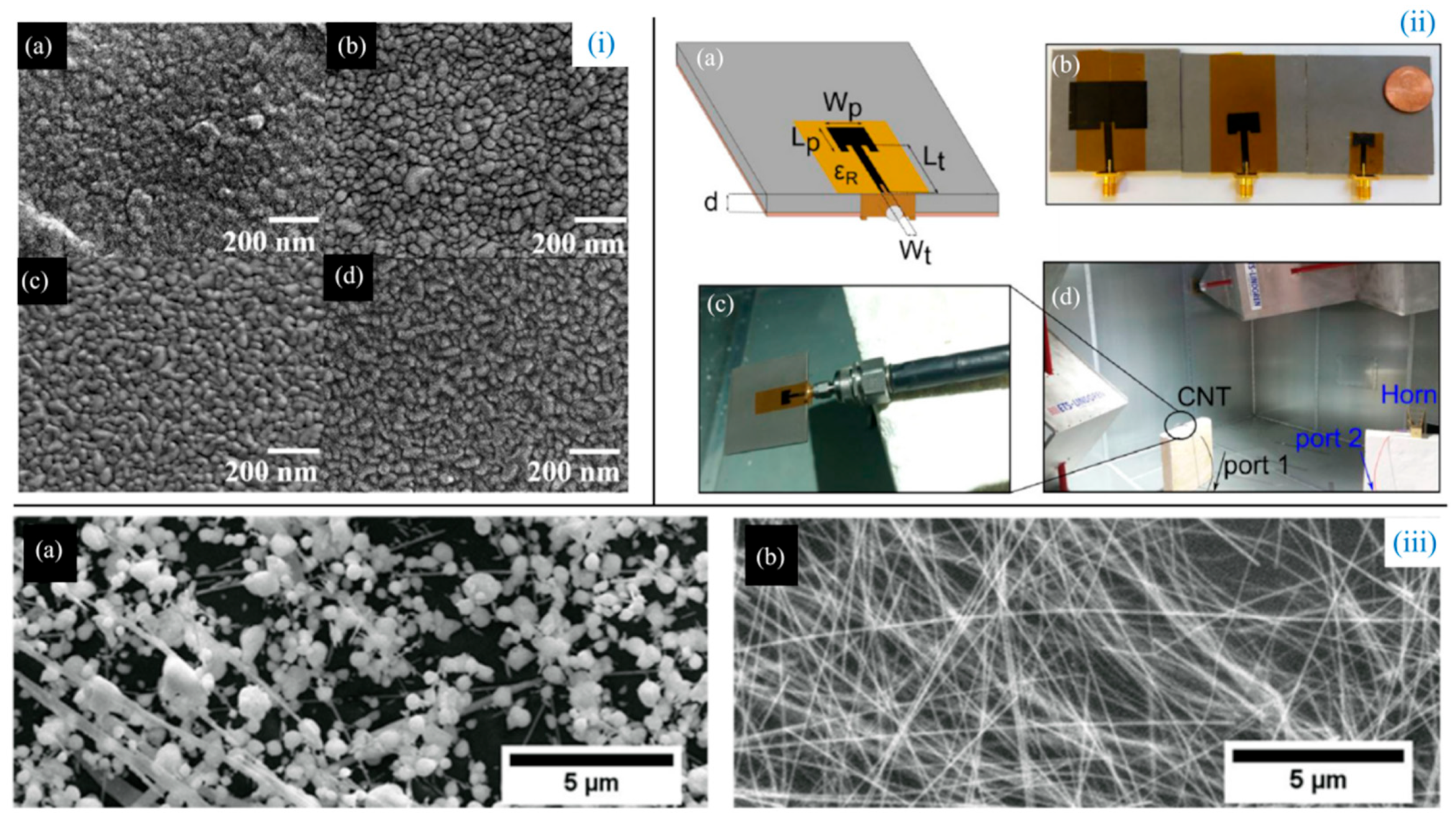

3.2. 1-D Nanomaterial Structure Antenna

3.2.1. Silver Nanowires

3.2.2. Carbon Nanotubes

| Nanomaterials | Antenna Base | Manufacturing Technology | Antenna Performance | Antenna Parameter | Application | References |

|---|---|---|---|---|---|---|

| AgNWs | PDMS | Inkjet printing | Bendable, high radiation efficiency | The antenna can operate in the frequency ranges of 1.2 GHz to 1.5 GHz and 3.2 GHz to 3.8 GHz, with S11 > 10 dB. | Wireless location and 5G | [54] |

| Mold | Low SAR value, stable performance | The antenna achieves S11 < −15 dB, axial ratio less than 3 dB, and a gain of approximately 5.2 dB. | Medical | [55] | ||

| AgNW/PVA | Glass baseboard | Magnetron sputter deposition | Transparent, simple, pollution-free, and small | The AZO/AgNW stacked film has a resistivity of 2.15 × 10−4 Ω·cm and a transmittance of 80.28% in the range of 400 to 800 nm. The transparent antenna constructed with this AZO/AgNW stacked film operates at a frequency of 2.4 GHz. | Glass coating, mobile phone, electronic label | [56] |

| Ag-NW and PEDOT:PSS | - | Inkjet printing | High transparency and high conductivity | This conductive film has excellent adhesion and outstanding mechanical deformation stability, with a resistance change of less than 20% after 10,000 bends. | Flexible optoelectronic devices | [57] |

| AgNWs | - | Inkjet printing | Ultra-wide bandwidth, flexibility, and transparency | This antenna has a bandwidth of up to 26 GHz (18 GHz to 44 GHz), a high radiation efficiency of 55%, a maximum gain of 1.45 dB, and transparency of over 90%. | Windows, solar cells | [58] |

| Spin coating process | Low resistance value, high antenna efficiency | The radiation efficiency of the antenna is 8.9% at 24 GHz and 49.4% at 61 GHz. | Photovoltaics, displays, and touchscreens | [59] | ||

| CNT | PDMS | CPW feed structure excitation | Bandwidth improvement | The antenna bandwidth has increased by 18%. | Body wireless applications | [61] |

| Flexible paper substrate | Inkjet printing | Lightweight, low cost, and conformal properties | The curvature radius of the conformal cylindrical surface and the conductivity of CNTs have a relatively minor impact on the antenna performance in the 2.45 GHz and 5.8 GHz frequency bands. | Wearable electronic devices | [63] | |

| - | Coating | High efficiency and faster data transfer rate | The efficiency of the coated CNT dipole antenna is approximately 59% under perfect matching conditions and around 77% under unmatched impedance conditions with zero loss. | Biomedical engineering | [66] | |

| - | High radiation efficiency | The antenna has a radiation efficiency of 94% in the 10 GHz and 14 GHz frequency bands. | Aerospace | [67] | ||

| Coating | Significantly improved gain and bandwidth | The antenna has a 10 dB impedance bandwidth of 22.2% and a 3 dB axial ratio bandwidth of 9.14%. | Terahertz applications | [68] | ||

| SWNT | PDMS | Direct write Technology | Strong flexibility | The antenna operates at a frequency of 4 GHz. | Implantable medical devices | [69] |

| MWCNT | PU | Dip coating technology | Small in size but less flexible | The monopole antenna has measured gains of −10.0 dB and −5.5 dB in the 2.45 GHz and 5.18 GHz frequency bands, respectively. | Wearable electronic devices | [70] |

| SWNT | - | Textile technology | Strong conductivity and flexibility | The patch antenna has a gain of 6 dB. | Automated aerial vehicle | [71] |

| MXene/SWNT | Latex | Deposition technology | Can shield electromagnetic interference | The S-MXene antenna was highly stretchable (up to 150% uniaxial strain) and demonstrated strain-independent independent reflected power of less than 0.1% as well as remained stable during fatigue tests. | Wearable electronic devices | [72] |

3.3. 2-D Nanomaterial Structure Antenna

| Nanomaterials | Antenna Base | Manufacturing Technology | Antenna Performance | Antenna Parameter | Application | References |

|---|---|---|---|---|---|---|

| Graphene | - | - | Directionality and miniaturization | The resonant frequency of the antenna is 1 terahertz. | Defense, communications | [84] |

| Silicon dioxide | - | Higher gain than copper patch | The antenna achieves a maximum RL of −24.4555 dB with the corresponding VSWR of 1.0413. The maximum gain of 7.1943 dB is achieved with a bandwidth of 522.3 GHz. | Wearable electronic devices | [85] | |

| Polyesteramide | - | Good impedance matching, high bandwidth, and gain | The proposed antenna proved the tunability of the graphene antenna to resonate at different frequencies in the terahertz band, 4.546 THz, 4.636 THz, and 5.347 THz, by varying the chemical potential and relaxation time. | Short-range wireless communication | [86] | |

| Graphene film | Rolling process | High conductivity and good stretchability | The antenna operates at a frequency of 1.63 GHz, with strain sensitivities of 9.8 and 9.36 during bending and stretching, respectively. | Wearables and wireless strain sensing | [87] | |

| GAF | Graphene film | - | Small size and good bending properties | The antenna can work properly within the ultra-wide range from 4.0–8.0 GHz with a maximum measured gain of 4.1 dB. | Wearable device | [88] |

| Good RL and radiation capability | The antenna has dimensions of 50.5 × 48.5 × 2.08 mm³, and it exhibits good RL and radiation capability in the 5G communication band (3.5 GHz) and the ISM band (5.8 GHz). | 5G | [89] | |||

| GAF | - | - | Small size and high sensitivity | The antenna operates in the frequency range of 3.13–4.42 GHz, with dimensions of 50 × 50 mm2. The strain sensitivity during tensile bending and compressive bending is 34.9 and 35.6, respectively. | Wearable electronics and the Internet of Things | [90] |

| HCGAF | PET | Laser engraving | Wireless Body Center Network | The antenna has a 10 dB bandwidth of 2.5 MHz, a resonant frequency of 13.70 MHz, and a quality factor of 9.19. | Identification | [91] |

| Graphene | PDMS | - | Good flexibility, mechanical stability, and lightweight | The antenna has dimensions of 2.57 mm. Within the range of 5.75 to 5.83 GHz, the axial ratio is less than 3 dB, the reflection coefficient is less than −15 dB, and it achieves a gain range of 5.0–6.1 dB. | Human body’s communication system | [92] |

| - | Chemical vapor deposition | High data rates and efficient communication | The antenna covers a bandwidth from 3–9 GHz. | Health monitoring | [94] | |

| CST | Small size, high directivity, small SAR | The antenna exhibits an RL of −25.05 dB at the resonant frequency of 2.4 GHz and −25.17 dB at the second resonant frequency of 3.94 GHz. | Biotelemetry | [95] | ||

| Fabric base | Deposition method | Not suitable for stretching but bendable | The antenna is cost-effective and environmentally friendly. | Wearable sensor | [97] | |

| Textile technology | Lightweight and mechanical stability | The antenna has a diameter of 55.3 mm, a bandwidth of 109 MHz, a gain of 5.45 dB, an efficiency of 56%, and covers the entire ISM band in a bent state, with a SAR of less than 0.003 W/Kg. | Medical | [98] | ||

| Textile technology | Flexible and easy to integrate | The antenna has a bandwidth of 3.3–3.8 GHz, a peak gain of 3.17 dB at 3.7 GHz, and an efficiency of 64%. | 5G wearables | [99] | ||

| Textile technology | Soft and high transfer efficiency | The antenna has a bandwidth of 2–8 GHz. | Biomedical Science | [100] | ||

| Kapton substrate | Screen printing | Highly conductive antenna with high efficiency | The measured maximum antenna gain is 2.3 dB at 4.8 GHz. | Wearable communication devices | [104] | |

| PEDOT/Graphene | Teflon substrate | - | High flexibility and robustness | The antenna achieves close to 80% efficiency in the bandwidth range of 3.8–6.2 GHz. | Wearable device | [106] |

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Ma, B.; Zhai, R.; Li, R.; Zhang, N.; Zhang, K.; Zhang, S. Experimental approach of contact mechanics for polyethylene materials with human skin under wet condition. J. Adhes. Sci. Technol. 2023, 37, 3222–3235. [Google Scholar] [CrossRef]

- Wang, C.; Liu, C.; Shang, F.; Niu, S.; Ke, L.; Zhang, N.; Ma, B.; Li, R.; Sun, X.; Zhang, S.; et al. Tactile sensing technology in bionic skin: A review. Biosens. Bioelectron. 2023, 220, 114882. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Liu, C.; Sun, X.; Huang, W. Current Development of Materials science and engineering towards epidermal sensors. Prog. Mater. Sci. 2022, 128, 100962. [Google Scholar] [CrossRef]

- Hasni, U.; Topsakal, E. Wearable antennas for on-body motion detection. In Proceedings of the 2020 IEEE USNC-CNC-URSI North American Radio Science Meeting (Joint with AP-S Symposium), Montreal, QC, Canada, 5–10 July 2020; pp. 1–2. [Google Scholar]

- Ashyap, A.Y.; Zainal Abidin, Z.; Dahlan, S.H.; Majid, H.A.; Saleh, G. Metamaterial inspired fabric antenna for wearable applications. Int. J. RF Microw. Comput.-Aided Eng. 2019, 29, e21640. [Google Scholar] [CrossRef]

- Saeidi, T.; Al-Gburi, A.J.A.; Karamzadeh, S. A Miniaturized Full-Ground Dual-Band MIMO Spiral Button Wearable Antenna for 5G and Sub-6 GHz Communications. Sensors 2023, 23, 1997. [Google Scholar] [CrossRef]

- Mahmood, S.N.; Ishak, A.J.; Saeidi, T.; Alsariera, H.; Alani, S.; Ismail, A.; Soh, A.C. Recent advances in wearable antenna technologies: A review. Prog. Electromagn. Res. B 2020, 89, 1–27. [Google Scholar] [CrossRef]

- Li, W.; Zu, H.; Liu, J.; Wu, B. A low-profile ultrawideband Antenna based on flexible graphite films for on-body wearable applications. Materials 2021, 14, 4526. [Google Scholar] [CrossRef]

- Al-Dulaimi, Z.; Elwi, T.A.; Atilla, D.C. Design of a meander line monopole antenna array based hilbert-shaped reject band structure for MIMO applications. IETE J. Res. 2022, 68, 2353–2362. [Google Scholar] [CrossRef]

- Ali, S.M.; Sovuthy, C.; Imran, M.A.; Socheatra, S.; Abbasi, Q.H.; Abidin, Z.Z. Recent advances of wearable antennas in materials, fabrication methods, designs, and their applications: State-of-the-art. Micromachines 2020, 11, 888. [Google Scholar] [CrossRef]

- Yan, S.; Soh, P.J.; Vandenbosch, G.A. Wearable ultrawideband technology—A review of ultrawideband antennas, propagation channels, and applications in wireless body area networks. IEEE Access 2018, 6, 42177–42185. [Google Scholar] [CrossRef]

- El Gharbi, M.; Fernández-García, R.; Ahyoud, S.; Gil, I. A review of flexible wearable antenna sensors: Design, fabrication methods, and applications. Materials 2020, 13, 3781. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Ye, Z.; Ren, Y.; Farhat, M.; Chen, P.-Y. Recent Advances in Nanomaterials Used for Wearable Electronics. Micromachines 2023, 14, 603. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Halder, A.; Tang, Y.; Hou, C.; Wang, H.; Duus, J.Ø.; Chi, Q. Engineering two-dimensional layered nanomaterials for wearable biomedical sensors and power devices. Mater. Chem. Front. 2018, 2, 1944–1986. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, Q.; Ma, S.; Yang, W.; Wang, Q.; Yang, C.; Jin, B.; Liu, C. Current advances and challenges in nanosheet-based wearable power supply devices. Iscience 2021, 24, 103477. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, W.; Zeng, J.; He, Z.; Wang, X.; Zhu, Z.; Hu, R.; Liu, C.; Wang, Q. Wearable non-invasive glucose sensors based on metallic nanomaterials. Mater. Today Bio 2023, 20, 100638. [Google Scholar] [CrossRef]

- Garg, A.; Chalak, H.; Belarbi, M.; Zenkour, A.; Sahoo, R. Estimation of carbon nanotubes and their applications as reinforcing composite materials–an engineering review. Compos. Struct. 2021, 272, 114234. [Google Scholar] [CrossRef]

- Fahad, S.; Yu, H.; Wang, L.; Haroon, M.; Ullah, R.S.; Nazir, A.; Naveed, K.-u.-R.; Elshaarani, T.; Khan, A. Recent progress in the synthesis of silver nanowires and their role as conducting materials. J. Mater. Sci. 2019, 54, 997–1035. [Google Scholar] [CrossRef]

- Asiya, S.; Kyzas, G.Z.; Pal, K.; de Souza, F.G., Jr. Graphene functionalized hybrid nanomaterials for industrial-scale applications: A systematic review. J. Mol. Struct. 2021, 1239, 130518. [Google Scholar]

- Azadmanjiri, J.; Reddy, T.N.; Khezri, B.; Děkanovský, L.; Parameswaran, A.K.; Pal, B.; Ashtiani, S.; Wei, S.; Sofer, Z. Prospective advances in MXene inks: Screen printable sediments for flexible micro-supercapacitor applications. J. Mater. Chem. A. 2022, 10, 4533–4557. [Google Scholar] [CrossRef]

- Prunet, G.; Pawula, F.; Fleury, G.; Cloutet, E.; Robinson, A.J.; Hadziioannou, G.; Pakdel, A. A review on conductive polymers and their hybrids for flexible and wearable thermoelectric applications. Mater. Today Phys. 2021, 18, 100402. [Google Scholar] [CrossRef]

- Nonappa. Precision nanoengineering for functional self-assemblies across length scales. Chem. Commun. 2023, 59, 13800–13819. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Feng, J.; Zhang, H.; Ma, J.; Wu, Z.; Wen, J.; Wang, S.; Tian, Y. Electrohydrodynamic Printing of High-Resolution Self-Reduced Soldered Silver Nanowire Pattern for Wearable Flexible Strain Sensors. Adv. Mater. Technol. 2023, 8, 2300759. [Google Scholar] [CrossRef]

- Liu, X.; Dang, A.; Li, T.; Sun, Y.; Lee, T.-C.; Deng, W.; Wu, S.; Zada, A.; Zhao, T.; Li, H. Plasmonic coupling of Au nanoclusters on a flexible MXene/Graphene oxide fiber for ultrasensitive SERS sensing. ACS Sensors 2023, 8, 1287–1298. [Google Scholar] [CrossRef]

- Almohammed, B.; Ismail, A.; Sali, A. Electro-textile wearable antennas in wireless body area networks: Materials, antenna design, manufacturing techniques, and human body consideration—A review. Text. Res. J. 2021, 91, 646–663. [Google Scholar] [CrossRef]

- Guttula, R.; Nandanavanam, V.R.; Satyanarayana, V. Design and optimization of microstrip patch antenna via improved metaheuristic algorithm. Wirel. Pers. Commun. 2021, 120, 1721–1739. [Google Scholar] [CrossRef]

- Wang, T.; Chen, G.; Zhu, J.; Gong, H.; Zhang, L.; Wu, H. Deep understanding of impedance matching and quarter wavelength theory in electromagnetic wave absorption. J. Colloid. Interface Sci. 2021, 595, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Bird, T.S. Mutual Coupling Between Antennas; Wiley Online Library: New York, NY, USA, 2021. [Google Scholar]

- Li, B.; Sun, Q.; He, J.; Li, Y.; Mao, Q. An improved protection scheme of the ground electrode line based on two frequency components injection. Int. J. Electr. Power Energy Syst. 2021, 129, 106901. [Google Scholar] [CrossRef]

- Sui, X.; Downing, J.R.; Hersam, M.C.; Chen, J. Additive manufacturing and applications of nanomaterial-based sensors. Mater. Today 2021, 48, 135–154. [Google Scholar] [CrossRef]

- Huang, D.; Li, Z.; Zeng, G.; Zhou, C.; Xue, W.; Gong, X.; Yan, X.; Chen, S.; Wang, W.; Cheng, M. Megamerger in photocatalytic field: 2D g-C3N4 nanosheets serve as support of 0D nanomaterials for improving photocatalytic performance. Mater. Today 2019, 240, 153–173. [Google Scholar] [CrossRef]

- Garnett, E.; Mai, L.; Yang, P. Introduction: 1D nanomaterials/nanowires. Chem. Rev. 2019, 119, 8955–8957. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, C.; Zhang, G.; Chen, Y.; Shang, F.; Xia, Q.; Yang, W. Full review: The progress and developing trends of nanosheet-based sensing applications. Coord. Chem. Rev. 2021, 433, 213742. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, S.; Zhao, Y.; Tao, W.; Yu, X.; Zhi, M. Review of layer-by-layer self-assembly technology for fire protection of flexible polyurethane foam. J. Mater. Sci. 2021, 56, 9605–9643. [Google Scholar] [CrossRef]

- Cao, Z.; Wen, Q.; Wang, X.; Yang, Q.; Jiang, F. An Overview of the Miniaturization and Endurance for Wearable Devices. J. Internet Things 2021, 3, 11. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, B.; Chen, W.; Liu, W.; Zhang, S. Current development of wearable sensors based on nanosheets and applications. TrAC Trends Anal. Chem. 2021, 143, 116334. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, T. Recent Progress of Nanostructured Sensing Materials from 0D to 3D: Overview of Structure–Property-Application Relationship for Gas Sensors. Small Methods 2021, 5, 2100515. [Google Scholar] [CrossRef] [PubMed]

- Simegnaw, A.A.; Malengier, B.; Rotich, G.; Tadesse, M.G.; Van Langenhove, L. Review on the Integration of Microelectronics for E-Textile. Materials 2021, 14, 5113. [Google Scholar] [CrossRef] [PubMed]

- Candan, C. Proper Definition and Handling of Dirac Delta Functions [Lecture Notes]. IEEE Signal Process. Mag. 2021, 38, 186–203. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Wongphan, P.; Promhuad, K.; Leelaphiwat, P.; Harnkarnsujarit, N. Morphology and permeability of bio-based poly (butylene adipate-co-terephthalate) (PBAT), poly (butylene succinate) (PBS) and linear low-density polyethylene (LLDPE) blend films control shelf-life of packaged bread. Food Control 2022, 132, 108541. [Google Scholar] [CrossRef]

- Matyas, J.; Slobodian, P.; Munster, L.; Olejnik, R.; Urbánek, P. Microstrip antenna from silver nanoparticles printed on a flexible polymer substrate. Mater. Today Proc. 2017, 4, 5030–5038. [Google Scholar] [CrossRef]

- Deng, Y.; Li, Q.; Zhou, Y.; Qian, J. Fully inkjet printing preparation of a carbon dots multichannel microfluidic paper-based sensor and its application in food additive detection. ACS Appl. Mater. Interfaces 2021, 13, 57084–57091. [Google Scholar] [CrossRef]

- Guo, X.; Hang, Y.; Xie, Z.; Wu, C.; Gao, L.; Liu, C. Flexible and wearable 2.45 GHz CPW-fed antenna using inkjet-printing of silver nanoparticles on pet substrate. Microw. Opt. Technol. Lett. 2017, 59, 204–208. [Google Scholar] [CrossRef]

- Jilani, S.F.; Rahimian, A.; Alfadhl, Y.; Alomainy, A. Low-profile flexible frequency-reconfigurable millimetre-wave antenna for 5G applications. Flex. Print. Electron. 2018, 3, 035003. [Google Scholar] [CrossRef]

- Simorangkir, R.B.; Yang, Y.; Hashmi, R.M.; Björninen, T.; Esselle, K.P.; Ukkonen, L. Polydimethylsiloxane-embedded conductive fabric: Characterization and application for realization of robust passive and active flexible wearable antennas. IEEE Access 2018, 6, 48102–48112. [Google Scholar] [CrossRef]

- Li, Z.; Sinha, S.K.; Treich, G.M.; Wang, Y.; Yang, Q.; Deshmukh, A.A.; Sotzing, G.A.; Cao, Y. All-organic flexible fabric antenna for wearable electronics. J. Mater. Chem. C 2020, 8, 5662–5667. [Google Scholar] [CrossRef]

- Baytöre, C.; Zoral, E.Y.; Göçen, C.; Palandöken, M.; Kaya, A. Coplanar flexible antenna design using conductive silver nano ink on paper substrate for wearable antenna applications. In Proceedings of the 2018 28th International Conference Radioelektronika (RADIOELEKTRONIKA), Prague, Czech Republic, 19–20 April 2018; pp. 1–6. [Google Scholar]

- Al-Adhami, A.; Ercelebi, E. A Flexible Metamaterial Based Printed Antenna for Wearable Biomedical Applications. Sensors 2021, 21, 7960. [Google Scholar] [CrossRef] [PubMed]

- Susmel, L. Notches, nominal stresses, fatigue strength reduction factors and constant/variable amplitude multiaxial fatigue loading. Int. J. Fatigue 2022, 162, 106941. [Google Scholar] [CrossRef]

- Ramli, M.R.; Ibrahim, S.; Ahmad, Z.; Abidin, I.S.Z.; Ain, M.F. Stretchable conductive ink based on polysiloxane–Silver composite and its application as a frequency reconfigurable patch antenna for wearable electronics. ACS Appl. Mater. Interfaces 2019, 11, 28033–28042. [Google Scholar] [CrossRef]

- Zhou, Y.; Soltani, S.; Li, B.M.; Wu, Y.; Kim, I.; Soewardiman, H.; Werner, D.H.; Jur, J.S. Direct-write spray coating of a full-duplex antenna for e-textile applications. Micromachines 2020, 11, 1056. [Google Scholar] [CrossRef]

- Alqadami, A.S.; Jamlos, M.F.; Jamlos, M.A. Efficacy of a wideband flexible antenna on a multilayer polymeric nanocomposites Fe3O4-PDMS substrate for wearable applications. Curr. Appl. Phys. 2019, 19, 1259–1265. [Google Scholar] [CrossRef]

- Su, W.; Zhu, J.; Liao, H.; Tentzeris, M.M. Wearable antennas for cross-body communication and human activity recognition. IEEE Access 2020, 8, 58575–58584. [Google Scholar] [CrossRef]

- Qiu, H.; Liu, H.; Jia, X.; Liu, X.; Li, Y.; Jiang, T.; Xiong, B.; Yang, Y.; Ren, T.-l. Ink-injected dual-band antennas based on graphene flakes, carbon nanotubes and silver nanowires. RSC Adv. 2018, 8, 37534–37539. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.H.; Cui, Z.; Yue, T.; Zhu, Y.; Werner, D.H. Compact, highly efficient, and fully flexible circularly polarized antenna enabled by silver nanowires for wireless body-area networks. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 920–932. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-T.; Ho, Y.-R.; Huang, D.-Z.; Huang, J.-J.J.S.; Technology, C. AZO/silver nanowire stacked films deposited by RF magnetron sputtering for transparent antenna. Surf. Coat. Technol. 2019, 360, 95–102. [Google Scholar] [CrossRef]

- Nair, N.M.; Pakkathillam, J.K.; Kumar, K.; Arunachalam, K.; Ray, D.; Swaminathan, P. Printable silver nanowire and PEDOT: PSS nanocomposite ink for flexible transparent conducting applications. ACS Appl. Electron. Mater. 2020, 2, 1000–1010. [Google Scholar] [CrossRef]

- Li, W.; Meredov, A.; Shamim, A. Silver nanowire based flexible, transparent, wideband antenna for 5G band application. In Proceedings of the 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Atlanta, GA, USA, 7–12 July 2019; pp. 275–276. [Google Scholar]

- Dao, Q.; Tchuigoua, R.; Geck, B.; Manteuffel, D.; von Witzendorff, P.; Overmeyer, L. Optically transparent patch antennas based on silver nanowires for mm-wave applications. In Proceedings of the 2017 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, San Diego, CA, USA, 9–14 July 2017; pp. 2189–2190. [Google Scholar]

- Arun, H. Advancements in the use of carbon nanotubes for antenna realization. AEU-Int. J. Electron. Commun. 2021, 136, 153753. [Google Scholar] [CrossRef]

- Mansor, M.; Rahim, S.; Hashim, U. A CPW-fed 2.45 GHz wearable antenna using conductive nanomaterials for on-body applications. In Proceedings of the 2014 IEEE Region 10 Symposium, Kuala Lumpur, Malaysia, 14–16 April 2014; pp. 240–243. [Google Scholar]

- Behera, S.K.; Karmakar, N.C. Chipless RFID printing technologies: A state of the art. IEEE Microw. Mag. 2021, 22, 64–81. [Google Scholar] [CrossRef]

- Cheng, G.; Wu, Y.-M.; Li, B. CNT-based conformal antenna design suitable for inkjet printing. In Proceedings of the 2017 International Applied Computational Electromagnetics Society Symposium (ACES), Suzhou, China, 1–4 August 2017; pp. 1–2. [Google Scholar]

- Wang, Y.; Zhang, X.; Zhang, X.; Zhou, T.; Cui, Z.; Zhang, K. A novel terahertz metasurface based on a single-walled carbon nanotube film for sensing application. J. Mater. Chem. A 2022, 10, 1780–1787. [Google Scholar] [CrossRef]

- Alsulami, Q.A.; Rajeh, A. Synthesis of the SWCNTs/TiO2 nanostructure and its effect study on the thermal, optical, and conductivity properties of the CMC/PEO blend. Results Phys. 2021, 28, 104675. [Google Scholar] [CrossRef]

- Hajjyahya, M.; Ishtaiwi, M.; Sayyed, J.; Saddouq, A. Design of Carbon Nanotube Antenna in Nanoscale Range. Open J. Antennas Propag. 2021, 9, 57–64. [Google Scholar] [CrossRef]

- Amram Bengio, E.; Senic, D.; Taylor, L.W.; Headrick, R.J.; King, M.; Chen, P.; Little, C.A.; Ladbury, J.; Long, C.J.; Holloway, C.L. Carbon nanotube thin film patch antennas for wireless communications. Appl. Phys. Lett. 2019, 114, 203102. [Google Scholar] [CrossRef]

- Chowdhury, M.S.U.; Rahman, M.A.; Hossain, M.A.; Mobashsher, A.T. A transparent conductive material based circularly polarized nano-antenna for THz applications. In Proceedings of the 2020 IEEE Region 10 Symposium (TENSYMP), Dhaka, Bangladesh, 5–7 June 2020; pp. 754–757. [Google Scholar]

- Aissa, B.; Haddad, E.; Jamroz, W.; Nedil, M. Design and fabrication of fluidic patch antenna based liquid metal alloy (EGaIn) and single wall carbon nanotubes nanocomposites. In Proceedings of the 2013 IEEE Antennas and Propagation Society International Symposium (APSURSI), Orlando, FL, USA, 7–13 July 2013; pp. 1856–1857. [Google Scholar]

- Olejník, R.; Goňa, S.; Slobodian, P.; Matyáš, J.; Moučka, R.; Daňová, R. Polyurethane-carbon nanotubes composite dual band antenna for wearable applications. Polymers 2020, 12, 2759. [Google Scholar] [CrossRef] [PubMed]

- Bayram, Y.; Zhou, Y.; Shim, B.S.; Xu, S.; Zhu, J.; Kotov, N.A.; Volakis, J.L. E-textile conductors and polymer composites for conformal lightweight antennas. IEEE Trans. Antennas Propag. 2010, 58, 2732–2736. [Google Scholar] [CrossRef]

- Li, Y.; Tian, X.; Gao, S.P.; Jing, L.; Li, K.; Yang, H.; Fu, F.; Lee, J.Y.; Guo, Y.X.; Ho, J.S. Reversible crumpling of 2D titanium carbide (MXene) nanocoatings for stretchable electromagnetic shielding and wearable wireless communication. Adv. Funct. Mater. 2020, 30, 1907451. [Google Scholar] [CrossRef]

- Tanaka, H.; Ohno, Y.; Tadokoro, Y. Adaptive control of angular sensitivity for VHF-band nano-antenna using CNT mechanical resonator. IEEE Trans. Mol. Biol. Multi-Scale Commun. 2016, 3, 24–32. [Google Scholar] [CrossRef]

- Mohammed, K.I.; Zaidan, A.A.; Zaidan, B.B.; Albahri, O.S.; Alsalem, M.A.; Albahri, A.S.; Hashim, M. Real-time remote-health monitoring systems: A review on patients prioritisation for multiple-chronic diseases, taxonomy analysis, concerns and solution procedure. J. Med. Syst. 2019, 43, 223. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Bao, J.; Tian, Y.; Wang, Z.; Li, N. Design of High Gain Wearable Antenna Based on Wireless Body Area Network Communications. J. Phys. Conf. Ser. 2021, 1971, 012018. [Google Scholar] [CrossRef]

- Kamel, S.; Khattab, T.A. Recent advances in cellulose supported metal nanoparticles as green and sustainable catalysis for organic synthesis. Cellulose 2021, 28, 4545–4574. [Google Scholar] [CrossRef]

- Zavanelli, N.; Yeo, W.-H. Advances in screen printing of conductive nanomaterials for stretchable electronics. ACS Omega 2021, 6, 9344–9351. [Google Scholar] [CrossRef]

- Kumar, A.; Shaikh, M.O.; Chuang, C.-H. Silver nanowire synthesis and strategies for fabricating transparent conducting electrodes. Nanomaterials 2021, 11, 693. [Google Scholar] [CrossRef]

- Ashok Kumar, S.S.; Bashir, S.; Ramesh, K.; Ramesh, S. A review on graphene and its derivatives as the forerunner of the two-dimensional material family for the future. J. Mater. Sci. 2022, 57, 12236–12278. [Google Scholar] [CrossRef]

- Tallentire, J. The new “Gold Rush”: Graphene’s research renaissance. In Graphene; Jenny Stanford Publishing: Singapore, 2022; pp. 135–162. [Google Scholar]

- Mohanty, A.; Acharya, O.P.; Appasani, B.; Sooksood, K.; Mohapatra, S.K. A THz Metamaterial Absorber with Multiple Polarization: Insensitive, Sensitive, and Tunable. ECTI Trans. Electr. Eng. Electron. Commun. 2021, 19, 165–173. [Google Scholar] [CrossRef]

- Han, Y.-L.; Turns, J.; Cook, K.E.; Mason, G.S.; Shuman, T.R. Students’ Experience of an Integrated Electrical Engineering and Data Acquisition Course in an Undergraduate Mechanical Engineering Curriculum. IEEE Trans. Educ. 2022, 65, 331–343. [Google Scholar] [CrossRef]

- Goyal, T.; Majumder, M.K.; Kaushik, B.K. Modeling and fabrication aspects of Cu-and carbon nanotube-based through-silicon vias. IETE J. Res. 2021, 67, 377–393. [Google Scholar] [CrossRef]

- Dash, S.; Patnaik, A. Material selection for TH z antennas. Microw. Opt. Technol. Lett. 2018, 60, 1183–1187. [Google Scholar] [CrossRef]

- Atser, A.; Mom, J.; Igwue, G. The Comparative Analysis of Graphene Nano-based and Copper Nano-based Patched Antenna using HFSS. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Nsukka, Nigeria, 11–13 November 2020; p. 012020. [Google Scholar]

- Abohmra, A.; Jilani, F.; Abbas, H.; Imran, M.A.; Abbasi, Q.H. Terahertz antenna based on graphene for wearable applications. In Proceedings of the 2019 IEEE MTT-S International Wireless Symposium (IWS), Guangzhou, China, 19–22 May 2019; pp. 1–3. [Google Scholar]

- Tang, D.; Wang, Q.; Wang, Z.; Liu, Q.; Zhang, B.; He, D.; Wu, Z.; Mu, S. Highly sensitive wearable sensor based on a flexible multi-layer graphene film antenna. Sci. Bull. 2018, 63, 574–579. [Google Scholar] [CrossRef] [PubMed]

- Fang, R.; Song, R.; Zhao, X.; Wang, Z.; Qian, W.; He, D. Compact and low-profile UWB antenna based on graphene-assembled films for wearable applications. Sensors 2020, 20, 2552. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Song, R.; Jiang, S.; Hu, Z.; He, D. Low profile and miniaturized dual-band antenna based on graphene assembled film for wearable applications. Int. J. RF Microw. Comput.-Aided Eng. 2022, 32, e23050. [Google Scholar] [CrossRef]

- Zhang, J.; Song, R.; Zhao, X.; Fang, R.; Zhang, B.; Qian, W.; Zhang, J.; Liu, C.; He, D. Flexible graphene-assembled film-based antenna for wireless wearable sensor with miniaturized size and high sensitivity. ACS omega. 2020, 5, 12937–12943. [Google Scholar] [CrossRef]

- Li, S.; Song, R.; Zhang, B.; Huang, B.; Zhao, X.; He, D. Wearable near-field communication bracelet based on highly conductive graphene-assembled films. Int. J. RF Microw. Comput.-Aided Eng. 2021, 31, e22479. [Google Scholar] [CrossRef]

- Zu, H.-R.; Wu, B.; Zhang, Y.-H.; Zhao, Y.-T.; Song, R.-G.; He, D.-P. Circularly polarized wearable antenna with low profile and low specific absorption rate using highly conductive graphene film. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 2354–2358. [Google Scholar] [CrossRef]

- Ergoktas, M.S.; Bakan, G.; Steiner, P.; Bartlam, C.; Malevich, Y.; Ozden-Yenigun, E.; He, G.; Karim, N.; Cataldi, P.; Bissett, M.A. Graphene-enabled adaptive infrared textiles. Nano Lett. 2020, 20, 5346–5352. [Google Scholar] [CrossRef] [PubMed]

- Ibanez-Labiano, I.; Ergoktas, M.S.; Kocabas, C.; Toomey, A.; Alomainy, A.; Ozden-Yenigun, E. Graphene-based soft wearable antennas. Appl. Mater. Today 2020, 20, 100727. [Google Scholar] [CrossRef]

- Bala, R.; Singh, R.; Marwaha, A.; Marwaha, S. Wearable graphene based curved patch antenna for medical telemetry applications. Appl. Comput. Electromagn. Soc. J. (ACES) 2016, 31, 543–550. [Google Scholar]

- Ali, U.; Basir, A.; Zada, M.; Ullah, S.; Kamal, B.; Yoo, H. Performance Improvement of a Dual-Band Textile Antenna for On-Body Through Artificial Magnetic Conductor. IEEE Access 2023, 11, 72316–72331. [Google Scholar] [CrossRef]

- Akbari, M.; Virkki, J.; Sydänheimo, L.; Ukkonen, L. Toward graphene-based passive UHF RFID textile tags: A reliability study. IEEE Trans. Device Mater. Reliab. 2016, 16, 429–431. [Google Scholar] [CrossRef]

- Kapetanakis, T.N.; Nikolopoulos, C.D.; Petridis, K.; Vardiambasis, I.O. Wearable textile antenna with a graphene sheet or conductive fabric patch for the 2.45 GHz band. Electronics 2021, 10, 2571. [Google Scholar] [CrossRef]

- Német, A.; Alkaraki, S.; Abassi, Q.H.; Jilani, S.F. A Biodegradable Textile-based Graphene Antenna for 5G Wearable Applications. In Proceedings of the 2021 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (APS/URSI), Singapore, 4–10 December 2021; pp. 1583–1584. [Google Scholar]

- Labiano, I.I.; Jilani, S.F.; Ergoktas, M.S.; Kocabas, C.; Ozden-Yenigun, E.; Alomainy, A. Graphene-based Textile Ultra Wideband Antennas for Integrated and Wearable Applications. In Proceedings of the 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Atlanta, GA, USA, 7–12 July 2019; pp. 1089–1090. [Google Scholar]

- Huang, X.; Leng, T.; Zhang, X.; Chen, J.C.; Chang, K.H.; Geim, A.K.; Novoselov, K.S.; Hu, Z. Binder-free highly conductive graphene laminate for low cost printed radio frequency applications. Applied Physics Letters. 2015, 106, 203105. [Google Scholar] [CrossRef]

- Leng, T.; Huang, X.; Chang, K.; Chen, J.; Abdalla, M.A.; Hu, Z. Graphene nanoflakes printed flexible meandered-line dipole antenna on paper substrate for low-cost RFID and sensing applications. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1565–1568. [Google Scholar] [CrossRef]

- Huang, X.; Leng, T.; Zhu, M.; Zhang, X.; Chen, J.; Chang, K.; Aqeeli, M.; Geim, A.K.; Novoselov, K.S.; Hu, Z. Highly flexible and conductive printed graphene for wireless wearable communications applications. Sci. Rep. 2015, 5, 18298. [Google Scholar] [CrossRef]

- Lamminen, A.; Arapov, K.; de With, G.; Haque, S.; Sandberg, H.G.; Friedrich, H.; Ermolov, V. Graphene-flakes printed wideband elliptical dipole antenna for low-cost wireless communications applications. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1883–1886. [Google Scholar] [CrossRef]

- Hu, G.; Kang, J.; Ng, L.W.; Zhu, X.; Howe, R.C.; Jones, C.G.; Hersam, M.C.; Hasan, T. Functional inks and printing of two-dimensional materials. Chem. Soc. Rev. 2018, 47, 3265–3300. [Google Scholar] [CrossRef]

- Tung, T.T.; Chen, S.J.; Fumeaux, C.; Kim, T.; Losic, D. N-doped reduced graphene oxide-PEDOT nanocomposites for implementation of a flexible wideband antenna for wearable wireless communication applications. Nanotechnology 2021, 32, 245711. [Google Scholar] [CrossRef] [PubMed]

- Salman, A.R.; Ismail, M.M.; Abd Razak, J.; Ab Rashid, S.R. Design of UTeM logo-shape wearable antenna for communication application by graphene silver nanocomposites. TELKOMNIKA 2022, 20, 647–655. [Google Scholar] [CrossRef]

- Song, R.; Mao, B.; Wang, Z.; Hui, Y.; Zhang, N.; Fang, R.; Zhang, J.; Wu, Y.; Ge, Q.; Novoselov, K.S. Comparison of copper and graphene-assembled films in 5G wireless communication and THz electromagnetic-interference shielding. Proc. Natl. Acad. Sci. USA 2023, 120, e2209807120. [Google Scholar] [CrossRef] [PubMed]

- Morales-Centla, N.; Torrealba-Melendez, R.; Tamariz-Flores, E.I.; López-López, M.; Arriaga-Arriaga, C.A.; Munoz-Pacheco, J.M.; Gonzalez-Diaz, V.R. Dual-Band CPW Graphene Antenna for Smart Cities and IoT Applications. Sensors 2022, 22, 5634. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, J.; Wang, C.; Feng, L.; Song, Z.; Zhao, W.; Wang, Q.; Liu, C. The application of wearable glucose sensors in point-of-care testing. Front. Bioeng. Biotechnol. 2021, 9, 774210. [Google Scholar] [CrossRef] [PubMed]

- Khodabandehlo, A.; Noori, A.; Rahmanifar, M.S.; El-Kady, M.F.; Kaner, R.B.; Mousavi, M.F. Laser-Scribed Graphene–Polyaniline Microsupercapacitor for Internet-of-Things Applications. Adv. Funct. Mater. 2022, 32, 2204555. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Zhang, N.; Liu, C.; Ma, B.; Zhang, K.; Li, R.; Wang, Q.; Zhang, S. New Advances in Antenna Design toward Wearable Devices Based on Nanomaterials. Biosensors 2024, 14, 35. https://doi.org/10.3390/bios14010035

Wang C, Zhang N, Liu C, Ma B, Zhang K, Li R, Wang Q, Zhang S. New Advances in Antenna Design toward Wearable Devices Based on Nanomaterials. Biosensors. 2024; 14(1):35. https://doi.org/10.3390/bios14010035

Chicago/Turabian StyleWang, Chunge, Ning Zhang, Chen Liu, Bangbang Ma, Keke Zhang, Rongzhi Li, Qianqian Wang, and Sheng Zhang. 2024. "New Advances in Antenna Design toward Wearable Devices Based on Nanomaterials" Biosensors 14, no. 1: 35. https://doi.org/10.3390/bios14010035

APA StyleWang, C., Zhang, N., Liu, C., Ma, B., Zhang, K., Li, R., Wang, Q., & Zhang, S. (2024). New Advances in Antenna Design toward Wearable Devices Based on Nanomaterials. Biosensors, 14(1), 35. https://doi.org/10.3390/bios14010035