Lab-on-a-Chip Electrochemical Biosensors for Foodborne Pathogen Detection: A Review of Common Standards and Recent Progress

Abstract

1. Introduction

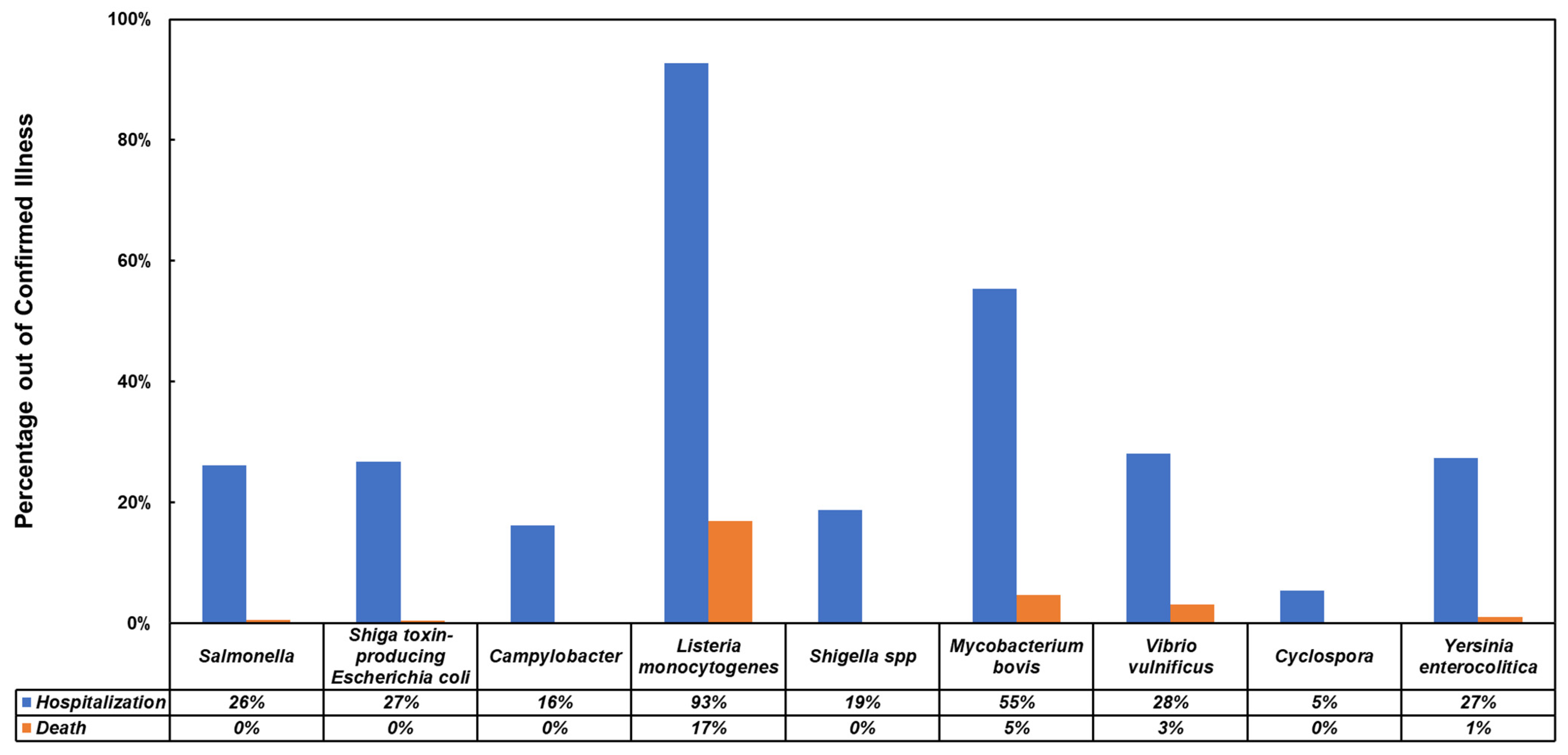

2. Foodborne Pathogen Statistics and Standards

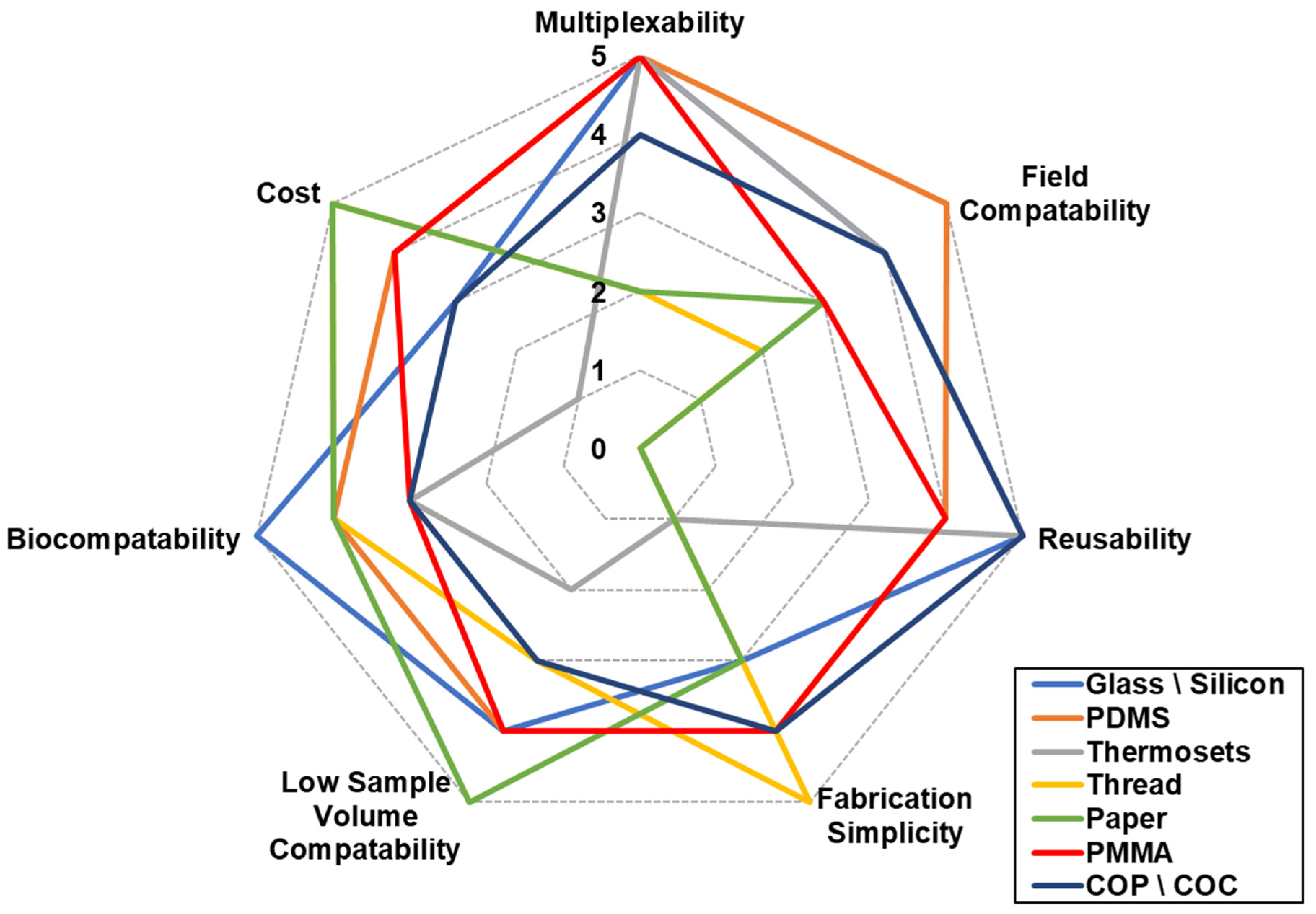

3. Microfluidic Channel Material Choice

3.1. Glass

3.2. Silicon

3.3. PDMS

3.4. PMMA

3.5. COP/COC

3.6. Thermosets

3.7. Paper

3.8. Thread Based

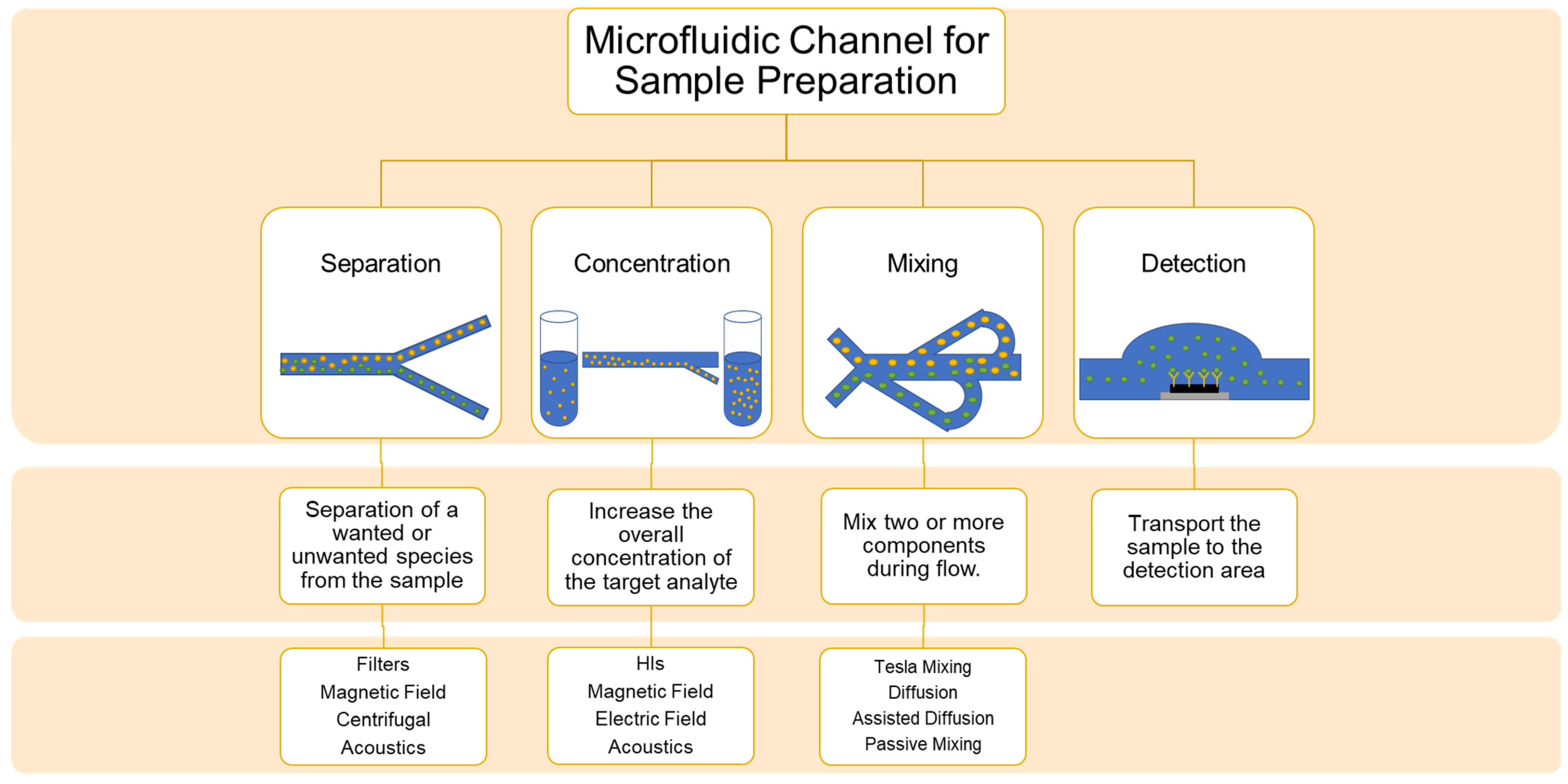

4. Microfluidics for Sample Preparation in Electrochemical Biosensors

4.1. Microfluidic Separation Channel

4.2. Microfluidic Concentration Channel

4.3. Microfluidic Detection Channel

4.4. Microfluidic Mixing Channel

5. Lab-on-a-Chip Electrochemical Biosensors

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FDA. Foodborne Pathogens. Available online: https://www.fda.gov/food/outbreaks-foodborne-illness/foodborne-pathogens (accessed on 10 January 2022).

- Jahan, S. Epidemiology of foodborne illness. In Scientific, Health and Social Aspects of the Food Industry; Valdez, B., Schor, M., Zlatev, R., Eds.; InTech: Rijeka, Croatia, 2012; pp. 321–342. ISBN 978-953-307-916-5. [Google Scholar]

- CDC. Foodborne Outbreaks. Available online: https://www.cdc.gov/foodsafety/outbreaks/lists/outbreaks-list.html (accessed on 10 December 2022).

- Hoffmann, S.; Batz, M.B.; Morris, J.G. Annual Cost of Illness and Quality-Adjusted Life Year Losses in the United States Due to 14 Foodborne Pathogens†. J. Food Prot. 2012, 75, 1292–1302. [Google Scholar] [CrossRef] [PubMed]

- Hedberg, C.W. Foodborne illness acquired in the United States. Emerg. Infect. Dis. 2011, 17, 1338–1340. [Google Scholar] [CrossRef] [PubMed]

- LeDuc, P.; Agaba, M.; Cheng, C.M.; Gracio, J.; Guzman, A.; Middelberg, A. Beyond disease, how biomedical engineering can improve global health. Sci. Transl. Med. 2014, 6, 266fs48. [Google Scholar] [CrossRef]

- Priyanka, B.; Patil, R.K.; Dwarakanath, S. A review on detection methods used for foodborne pathogens. Indian J. Med. Res. 2016, 144, 327–338. [Google Scholar] [CrossRef]

- Feng, P. Impact of Molecular Biology on the Detection of Foodborne Pathogens. Appl. Biochem. Biotechnol.—Part B Mol. Biotechnol. 1997, 7, 267–278. [Google Scholar] [CrossRef]

- Foddai, A.C.G.; Grant, I.R. Methods for detection of viable foodborne pathogens: Current state-of-art and future prospects. Appl. Microbiol. Biotechnol. 2020, 104, 4281–4288. [Google Scholar] [CrossRef] [PubMed]

- Lam, H.M.; Remais, J.; Fung, M.C.; Xu, L.; Sun, S.S.M. Food supply and food safety issues in China. Lancet 2013, 381, 2044–2053. [Google Scholar] [CrossRef] [PubMed]

- Chin, C.D.; Linder, V.; Sia, S.K. Lab-on-a-chip devices for global health: Past studies and future opportunities. Lab Chip 2007, 7, 41–57. [Google Scholar] [CrossRef]

- Castle, L.M.; Schuh, D.A.; Reynolds, E.E.; Furst, A.L. Electrochemical Sensors to Detect Bacterial Foodborne Pathogens. ACS Sensors 2021, 6, 1717–1730. [Google Scholar] [CrossRef] [PubMed]

- Kumar, H.; Kuča, K.; Bhatia, S.K.; Saini, K.; Kaushal, A.; Verma, R.; Bhalla, T.C.; Kumar, D. Applications of nanotechnology in biosensor-based detection of foodborne pathogens. Sensors 2020, 20, 1966. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Nhat Nguyen, U.T.; Hsieh, H.-Y.; Tahara, H.; Chang, Y.-S.; Wang, B.-Y.; Gu, B.-C.; Dai, Y.-H.; Wu, C.-C.; Tsai, I.-J.; et al. Peptide-based electrochemical sensor with nanogold enhancement for detecting rheumatoid arthritis. Talanta 2022, 236, 122886. [Google Scholar] [CrossRef]

- Colburn, A.W.; Levey, K.J.; O’Hare, D.; Macpherson, J.V. Lifting the lid on the potentiostat: A beginner’s guide to understanding electrochemical circuitry and practical operation. Phys. Chem. Chem. Phys. 2021, 23, 8100–8117. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, D.; Cai, G.; Xiong, Y.; Li, Y.; Wang, M.; Huo, H.; Lin, J. Fast and sensitive detection of foodborne pathogen using electrochemical impedance analysis, urease catalysis and micro fl uidics. Biosens. Bioelectron. 2016, 86, 770–776. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Xu, Y.; Sors, T.; Irudayaraj, J.; Ren, W.; Wang, R. Impedimetric detection of bacteria by using a microfluidic chip and silver nanoparticle based signal enhancement. Microchim. Acta 2018, 185, 184. [Google Scholar] [CrossRef]

- Siller, I.G.; Preuss, J.; Urmann, K.; Ho, M.R.; Scheper, T.; Bahnemann, J. 3D-Printed Flow Cells for Aptamer-Based. Sensors 2020, 20, 4421. [Google Scholar] [CrossRef]

- Chiriacò, M.S.; Parlangeli, I.; Sirsi, F.; Poltronieri, P.; Primiceri, E. Impedance sensing platform for detection of the food pathogen listeria monocytogenes. Electronics 2018, 7, 347. [Google Scholar] [CrossRef]

- Liu, J.; Jasim, I.; Shen, Z.; Zhao, L.; Dweik, M.; Zhang, S.; Almasri, M. A microfluidic based biosensor for rapid detection of Salmonella in food products. PLoS ONE 2019, 14, e0216873. [Google Scholar] [CrossRef]

- Dzyadevych, S.V.; Arkhypova, V.N.; Soldatkin, A.P.; El’skaya, A.V.; Martelet, C.; Jaffrezic-Renault, N. Amperometric enzyme biosensors: Past, present and future. Itbm-Rbm 2008, 29, 171–180. [Google Scholar] [CrossRef]

- Lopez-Tellez, J.; Ramirez-Montes, S.; Ferreira, T.A.; Santos, E.M.; Rodriguez, J.A. Application of Voltammetric Sensors for Pathogen Bacteria Detection: A Review. Chemosensors 2022, 10, 424. [Google Scholar] [CrossRef]

- Dutta, P.; Lu, Y.-J.; Hsieh, H.-Y.; Lee, T.-Y.; Lee, Y.-T.; Cheng, C.-M.; Fan, Y.-J. Detection of Candida albicans Using a Manufactured Electrochemical Sensor. Micromachines 2021, 12, 166. [Google Scholar] [CrossRef]

- Fan, Y.-J.; Hsu, Y.-C.; Gu, B.-C.; Wu, C.-C. Voltammetric measurement of Escherichia coli concentration through p-APG hydrolysis by endogenous β-galactosidase. Microchem. J. 2020, 154, 104641. [Google Scholar] [CrossRef]

- Mairhofer, J.; Roppert, K.; Ertl, P. Microfluidic systems for pathogen sensing: A review. Sensors 2009, 9, 4804–4823. [Google Scholar] [CrossRef] [PubMed]

- Fernández-la-Villa, A.; Pozo-Ayuso, D.F.; Castaño-Álvarez, M. Microfluidics and electrochemistry: An emerging tandem for next-generation analytical microsystems. Curr. Opin. Electrochem. 2019, 15, 175–185. [Google Scholar] [CrossRef]

- Sheen, H.-J.; Panigrahi, B.; Kuo, T.-R.; Hsu, W.-C.; Chung, P.-S.; Xie, Q.-Z.; Lin, C.-Y.; Chang, Y.-S.; Lin, C.-T.; Fan, Y.-J. Electrochemical biosensor with electrokinetics-assisted molecular trapping for enhancing C-reactive protein detection. Biosens. Bioelectron. 2022, 210, 114338. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Xing, D.; Li, Y. Micropumps, microvalves, and micromixers within PCR microfluidic chips: Advances and trends. Biotechnol. Adv. 2007, 25, 483–514. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.-Y.; Kim, B. Lab-on-a-Chip Pathogen Sensors for Food Safety. Sensors 2012, 12, 10713–10741. [Google Scholar] [CrossRef]

- Mei, Y.; He, C.; Zeng, W.; Luo, Y.; Liu, C.; Yang, M.; Kuang, Y.; Lin, X.; Huang, Q. Electrochemical Biosensors for Foodborne Pathogens Detection Based on Carbon Nanomaterials: Recent Advances and Challenges. Food Bioprocess Technol. 2022, 15, 498–513. [Google Scholar] [CrossRef]

- Villalonga, A.; Sánchez, A.; Mayol, B.; Reviejo, J.; Villalonga, R. Electrochemical biosensors for food bioprocess monitoring. Curr. Opin. Food Sci. 2022, 43, 18–26. [Google Scholar] [CrossRef]

- Curulli, A. Electrochemical Biosensors in Food Safety: Challenges and Perspectives. Molecules 2021, 26, 2940. [Google Scholar] [CrossRef]

- Schmidt-Speicher, L.M.; Länge, K. Microfluidic integration for electrochemical biosensor applications. Curr. Opin. Electrochem. 2021, 29, 100755. [Google Scholar] [CrossRef]

- Lonchamps, P.-L.; He, Y.; Wang, K.; Lu, X. Detection of pathogens in foods using microfluidic “lab-on-chip”: A mini review. J. Agric. Food Res. 2022, 10, 100430. [Google Scholar] [CrossRef]

- Health Protection Agency. Guidelines for Assessing the Microbiological Safety of Ready-to-Eat Foods Placed on the Market; Health Protection Agency: London, UK, 2009; p. 33. [Google Scholar]

- Faherty, C.S.; Lampel, K.A. Shigella. In Food Microbiology; ASM Press: Washington, DC, USA, 2019; pp. 317–345. [Google Scholar]

- Applied Nutrition Center for Food Safety and of Regulatory Affairs Office CPG Sec 555.320 Listeria Monocytogenes. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/cpg-sec-555320-listeria-monocytogenes#policy (accessed on 15 November 2022).

- Applied Nutrition Center for Food Safety and of Regulatory Affairs Office CPG Sec. 527.300 Dairy Products—Microbial Contaminants and Alkaline Phosphatase Activity (CPG 7106.08). Available online: https://www.federalregister.gov/documents/2010/12/23/2010-32232/compliance-policy-guide-sec-527300-dairy-products-microbial-contaminants-and-alkaline-phosphatase (accessed on 15 November 2022).

- Sanitation Program National Shellfish Nssp Guide for the Control of Molluscan Shellfish. Available online: https://www.issc.org/Data/Sites/1/media/2009 nssp guide/2009 nssp guide updated 08-08-2011.pdf (accessed on 15 November 2022).

- Zolti, O.; Suganthan, B.; Maynard, R.; Asadi, H.; Locklin, J.; Ramasamy, R.P. Electrochemical Biosensor for Rapid Detection of Listeria monocytogenes. J. Electrochem. Soc. 2022, 169, 067510. [Google Scholar] [CrossRef]

- United States Department of Agriculture. Introduction to the Microbiology of Food Processing: Small Plant News Guidebook Series; United States Department of Agriculture: Washington DC, USA, 2012; pp. 1–64. [Google Scholar]

- Centers for Disease Control and Prevention. Mycobacterium Bovis (bovine tuberculosis) in Humans; Centers for Disease Control and Prevention: Atlanta, Georgia, 2011; p. 2. [Google Scholar]

- Ohio Department of Health. IDCM Section 3: Vibriosis. In Infectious Disease Control Manual (IDCM); Ohio Department of Health: Columbus, OH, USA, 2019; pp. 1–8. [Google Scholar]

- Ohio Department of Health. IDCM Section 3: Yersiniosis. In Infectious Disease Control Manual (IDCM); Ohio Department of Health: Columbus, OH, USA, 2019; pp. 1–5. [Google Scholar]

- Robilotti, E.; Deresinski, S.; Pinsky, B.A. Norovirus. Clin. Microbiol. Rev. 2015, 28, 134–164. [Google Scholar] [CrossRef] [PubMed]

- Smith, H. V Cyclospora. In Infectious Disease: Foodborne Disease; Simjee, S., Ed.; Humana Press Inc.: Totowa, NJ, USA, 2007; pp. 277–301. ISBN 9781588295187. [Google Scholar]

- Rangel, J.M.; Sparling, P.H.; Crowe, C.; Griffin, P.M.; Swerdlow, D.L. Epidemiology of Escherichia coli O157:H7 outbreaks, United States, 1982–2002. Emerg. Infect. Dis. 2005, 11, 603–609. [Google Scholar] [CrossRef]

- Cartwright, E.J.; Jackson, K.A.; Johnson, S.D.; Graves, L.M.; Silk, B.J.; Mahon, B.E. Listeriosis outbreaks and associated food vehicles, United States, 1998–2008. Emerg. Infect. Dis. 2013, 19, 1–9. [Google Scholar] [CrossRef]

- McCrickard, L.S.; Crim, S.M.; Kim, S.; Bowen, A. Disparities in severe shigellosis among adults—Foodborne diseases active surveillance network, 2002–2014. BMC Public Health 2018, 18, 221. [Google Scholar] [CrossRef]

- Foodborne Diseases Active Surveillance Network. Foodborne Diseases Active Surveillance Network (FoodNet): FoodNet Surveillance Reports for 1996–2020 (Final Reports); U.S. Department of Health and Human Services, CDC: Atlanta, GA, USA, 2021. [Google Scholar]

- Ren, K.; Zhou, J.; Wu, H. Materials for Microfluidic Chip Fabrication. Acc. Chem. Res. 2013, 46, 2396–2406. [Google Scholar] [CrossRef]

- Hou, X.; Zhang, Y.S.; Santiago, G.T.; Alvarez, M.M.; Ribas, J.; Jonas, S.J.; Weiss, P.S.; Andrews, A.M.; Aizenberg, J.; Khademhosseini, A. Interplay between materials and microfluidics. Nat. Rev. Mater. 2017, 2, 17016. [Google Scholar] [CrossRef]

- Nielsen, J.B.; Hanson, R.L.; Almughamsi, H.M.; Pang, C.; Fish, T.R.; Woolley, A.T. Microfluidics: Innovations in Materials and Their Fabrication and Functionalization. Anal. Chem. 2020, 92, 150–168. [Google Scholar] [CrossRef]

- Niculescu, A.-G.; Chircov, C.; Bîrcă, A.C.; Grumezescu, A.M. Fabrication and Applications of Microfluidic Devices: A Review. Int. J. Mol. Sci. 2021, 22, 2011. [Google Scholar] [CrossRef]

- Abdullah, A.; Dastider, S.G.; Jasim, I.; Shen, Z.; Yuksek, N.; Zhang, S.; Dweik, M.; Almasri, M. Microfluidic based impedance biosensor for pathogens detection in food products. Electrophoresis 2019, 40, 508–520. [Google Scholar] [CrossRef] [PubMed]

- Chand, R.; Neethirajan, S. Microfluidic platform integrated with graphene-gold nano-composite aptasensor for one-step detection of norovirus. Biosens. Bioelectron. 2017, 98, 47–53. [Google Scholar] [CrossRef] [PubMed]

- Silva, N.F.D.; Almeida, C.M.R.; Magalhães, J.M.C.S.; Gonçalves, M.P.; Freire, C.; Delerue-Matos, C. Development of a disposable paper-based potentiometric immunosensor for real-time detection of a foodborne pathogen. Biosens. Bioelectron. 2019, 141, 111317. [Google Scholar] [CrossRef]

- Jiang, H.; Sun, Z.; Guo, Q.; Weng, X. Microfluidic thread-based electrochemical aptasensor for rapid detection of Vibrio parahaemolyticus. Biosens. Bioelectron. 2021, 182, 113191. [Google Scholar] [CrossRef] [PubMed]

- Pinti, M.; Kambham, T.; Wang, B.; Prakash, S. Fabrication of Centimeter Long, Ultra-Low Aspect Ratio Nanochannel Networks in Borosilicate Glass Substrates. J. Nanotechnol. Eng. Med. 2013, 4, 020905. [Google Scholar] [CrossRef]

- Pawar, P.; Ballav, R.; Kumar, A. Micromachining of Borosilicate Glass: A State of Art Review. Mater. Today Proc. 2017, 4, 2813–2821. [Google Scholar] [CrossRef]

- Jung, H.C.; Lu, W.; Wang, S.; Lee, L.J.; Hu, X. Etching of Pyrex glass substrates by inductively coupled plasma reactive ion etching for micro/nanofluidic devices. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2006, 24, 3162. [Google Scholar] [CrossRef]

- Chang, T.-L.; Chen, Z.-C.; Lee, Y.-W.; Li, Y.-H.; Wang, C.-P. Ultrafast laser ablation of soda-lime glass for fabricating microfluidic pillar array channels. Microelectron. Eng. 2016, 158, 95–101. [Google Scholar] [CrossRef]

- Perrone, E.; Cesaria, M.; Zizzari, A.; Bianco, M.; Ferrara, F.; Raia, L.; Guarino, V.; Cuscunà, M.; Mazzeo, M.; Gigli, G.; et al. Potential of CO2-laser processing of quartz for fast prototyping of microfluidic reactors and templates for 3D cell assembly over large scale. Mater. Today Bio 2021, 12, 100163. [Google Scholar] [CrossRef]

- Tang, T.; Yuan, Y.; Yalikun, Y.; Hosokawa, Y.; Li, M.; Tanaka, Y. Glass based micro total analysis systems: Materials, fabrication methods, and applications. Sens. Actuators B Chem. 2021, 339, 129859. [Google Scholar] [CrossRef]

- Aralekallu, S.; Boddula, R.; Singh, V. Development of glass-based microfluidic devices: A review on its fabrication and biologic applications. Mater. Des. 2023, 225, 111517. [Google Scholar] [CrossRef]

- Fan, Y.-J.; Huang, M.-Z.; Hsiao, Y.-C.; Huang, Y.-W.; Deng, C.-Z.; Yeh, C.; Husain, R.A.; Lin, Z.-H. Enhancing the sensitivity of portable biosensors based on self-powered ion concentration polarization and electrical kinetic trapping. Nano Energy 2020, 69, 104407. [Google Scholar] [CrossRef]

- Iliescu, C.; Taylor, H.; Avram, M.; Miao, J.; Franssila, S. A practical guide for the fabrication of microfluidic devices using glass and silicon. Biomicrofluidics 2012, 6, 016505. [Google Scholar] [CrossRef] [PubMed]

- Laser, D.J.; Santiago, J.G. A review of micropumps. J. Micromechanics Microengineering 2004, 14, R35–R64. [Google Scholar] [CrossRef]

- Oh, K.W.; Ahn, C.H. A review of microvalves. J. Micromechanics Microengineering 2006, 16, R13–R39. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Frazer, R.Q.; Byron, R.T.; Osborne, P.B.; West, K.P. PMMA: An Essential Material in Medicine and Dentistry. J. Long. Term. Eff. Med. Implants 2005, 15, 629–639. [Google Scholar] [CrossRef]

- Martynova, L.; Locascio, L.E.; Gaitan, M.; Kramer, G.W.; Christensen, R.G.; MacCrehan, W.A. Fabrication of Plastic Microfluid Channels by Imprinting Methods. Anal. Chem. 1997, 69, 4783–4789. [Google Scholar] [CrossRef]

- Xu, J.; Locascio, L.; Gaitan, M.; Lee, C.S. Room-Temperature Imprinting Method for Plastic Microchannel Fabrication. Anal. Chem. 2000, 72, 1930–1933. [Google Scholar] [CrossRef]

- McCormick, R.M.; Nelson, R.J.; Alonso-Amigo, M.G.; Benvegnu, D.J.; Hooper, H.H. Microchannel Electrophoretic Separations of DNA in Injection-Molded Plastic Substrates. Anal. Chem. 1997, 69, 2626–2630. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Chen, G. Fabrication, modification, and application of poly(methyl methacrylate) microfluidic chips. Electrophoresis 2008, 29, 1801–1814. [Google Scholar] [CrossRef] [PubMed]

- Jena, R.K.; Yue, C.Y.; Lam, Y.C. Micro fabrication of cyclic olefin copolymer (COC) based microfluidic devices. Microsyst. Technol. 2012, 18, 159–166. [Google Scholar] [CrossRef]

- Nunes, P.S.; Ohlsson, P.D.; Ordeig, O.; Kutter, J.P. Cyclic olefin polymers: Emerging materials for lab-on-a-chip applications. Microfluid. Nanofluidics 2010, 9, 145–161. [Google Scholar] [CrossRef]

- Pemg, B.-Y.; Wu, C.-W.; Shen, Y.-K.; Lin, Y. Microfluidic chip fabrication using hot embossing and thermal bonding of COP. Polym. Adv. Technol. 2010, 21, 457–466. [Google Scholar]

- Azouz, A.B.; Murphy, S.; Karazi, S.; Vázquez, M.; Brabazon, D. Fast Fabrication Process of Microfluidic Devices Based on Cyclic Olefin Copolymer. Mater. Manuf. Process. 2014, 29, 93–99. [Google Scholar] [CrossRef]

- Gao, H.; Yan, C.; Wu, W.; Li, J. Application of Microfluidic Chip Technology in Food Safety Sensing. Sensors 2020, 20, 1792. [Google Scholar] [CrossRef]

- Weng, X.; Kang, Y.; Guo, Q.; Peng, B.; Jiang, H. Recent advances in thread-based microfluidics for diagnostic applications. Biosens. Bioelectron. 2019, 132, 171–185. [Google Scholar] [CrossRef]

- Tan, W.; Powles, E.; Zhang, L.; Shen, W. Go with the capillary flow. Simple thread-based microfluidics. Sensors Actuators B Chem. 2021, 334, 129670. [Google Scholar] [CrossRef]

- Berzina, B.; Anand, R.K. Tutorial review: Enrichment and separation of neutral and charged species by ion concentration polarization focusing. Anal. Chim. Acta 2020, 1128, 149–173. [Google Scholar] [CrossRef]

- Singh, C.; Ali, M.A.; Kumar, V.; Ahmad, R.; Sumana, G. Functionalized MoS2 nanosheets assembled microfluidic immunosensor for highly sensitive detection of food pathogen. Sens. Actuators B Chem. 2018, 259, 1090–1098. [Google Scholar] [CrossRef]

- Park, J.; Han, D.H.; Park, J.-K. Towards practical sample preparation in point-of-care testing: User-friendly microfluidic devices. Lab Chip 2020, 20, 1191–1203. [Google Scholar] [CrossRef] [PubMed]

- Ghuman, A. Bacteriophage-Assisted Microfluidic Separation of Pathogens from Food Matrices. Ph.D. Thesis, University of Georgia, Athens, Georgia, 2016. [Google Scholar]

- Zhou, Y.; Ramasamy, R.P. Isolation and separation of Listeria monocytogenes using bacteriophage P100- modi fi ed magnetic particles. Colloids Surf. B Biointerfaces 2019, 175, 421–427. [Google Scholar] [CrossRef] [PubMed]

- Tang, M.; Wang, G.; Kong, S.K.; Ho, H.P. A review of biomedical centrifugal microfluidic platforms. Micromachines 2016, 7, 26. [Google Scholar] [CrossRef]

- Sivaramakrishnan, M.; Kothandan, R.; Govindarajan, D.K.; Meganathan, Y.; Kandaswamy, K. Active microfluidic systems for cell sorting and separation. Curr. Opin. Biomed. Eng. 2020, 13, 60–68. [Google Scholar] [CrossRef]

- Wang, B.; Park, B. Microfluidic Sampling and Biosensing Systems for Foodborne Escherichia coli and Salmonella. Foodborne Pathog. Dis. 2022, 19, 359–375. [Google Scholar] [CrossRef]

- Ngamsom, B.; Lopez-Martinez, M.J.; Raymond, J.-C.; Broyer, P.; Patel, P.; Pamme, N. On-chip acoustophoretic isolation of microflora including S. typhimurium from raw chicken, beef and blood samples. J. Microbiol. Methods 2016, 123, 79–86. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Li, Z.; Feng, A.; Zhang, J.; Liu, Z.; Li, D. Electrokinetic detection and separation of living algae in a microfluidic chip: Implication for ship’s ballast water analysis. Environ. Sci. Pollut. Res. 2021, 28, 22853–22863. [Google Scholar] [CrossRef]

- Morani, M.; Mai, T.D.; Krupova, Z.; van Niel, G.; Defrenaix, P.; Taverna, M. Recent electrokinetic strategies for isolation, enrichment and separation of extracellular vesicles. TrAC Trends Anal. Chem. 2021, 135, 116179. [Google Scholar] [CrossRef]

- Eun, C.; Koo, B.; Yeong, E.; Yeun, J.; Kim, S.; Shin, Y. Simple and label-free pathogen enrichment via homobifunctional imidoesters using a micro fl uidic (SLIM) system for ultrasensitive pathogen detection in various clinical specimens. Biosens. Bioelectron. 2018, 111, 66–73. [Google Scholar]

- Castillo-león, J.; Svendsen, W.E.; Dimaki, M.; Arima, V.; Akram, M.S.; Miserere, S.; Neuman, C.; Kipling, G.D. Lab-on-a-Chip Devices and Micro-Total Analysis Systems A Practical Guide, 1st ed.; Castillo-león, J., Svendsen, W.E., Eds.; Springer: Cham, Switzerland; Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2015; ISBN 9783319086866. [Google Scholar]

- Shanko, E.-S.; van de Burgt, Y.; Anderson, P.D.; den Toonder, J.M.J. Microfluidic Magnetic Mixing at Low Reynolds Numbers and in Stagnant Fluids. Micromachines 2019, 10, 731. [Google Scholar] [CrossRef]

- Gao, X.; Li, Y. Simultaneous microfluidic pumping and mixing using an array of asymmetric 3D ring electrode pairs in a cylindrical microchannel by the AC electroosmosis effect. Eur. J. Mech.—B/Fluids 2019, 75, 361–371. [Google Scholar] [CrossRef]

- Li, Y.; Cai, S.; Shen, H.; Chen, Y.; Ge, Z.; Yang, W. Recent advances in acoustic microfluidics and its exemplary applications. Biomicrofluidics 2022, 16, 031502. [Google Scholar] [CrossRef] [PubMed]

- Demcenko, A.; Witte, C.; Reboud, J.; Cooper, J.M. Ultrasonic Wave Mixing for Nonlinear Ultrasonics in a Microfluidic Capillary. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; pp. 284–286. [Google Scholar]

- Alexandre, D.L.; Melo, A.M.A.; Furtado, R.F.; Borges, M.F.; Figueiredo, E.A.T.; Biswas, A.; Cheng, H.N.; Alves, C.R. A Rapid and Specific Biosensor for Salmonella Typhimurium Detection in Milk. Food Bioprocess Technol. 2018, 11, 748–756. [Google Scholar] [CrossRef]

- Sheikhzadeh, E.; Chamsaz, M.; Turner, A.P.F.; Jager, E.W.H.; Beni, V. Label-free impedimetric biosensor for Salmonella Typhimurium detection based on poly [pyrrole-co-3-carboxyl-pyrrole] copolymer supported aptamer. Biosens. Bioelectron. 2016, 80, 194–200. [Google Scholar] [CrossRef] [PubMed]

- Bagheryan, Z.; Raoof, J.-B.; Golabi, M.; Turner, A.P.F.; Beni, V. Diazonium-based impedimetric aptasensor for the rapid label-free detection of Salmonella typhimurium in food sample. Biosens. Bioelectron. 2016, 80, 566–573. [Google Scholar] [CrossRef]

- Bhardwaj, J.; Devarakonda, S.; Kumar, S.; Jang, J. Development of a paper-based electrochemical immunosensor using an antibody-single walled carbon nanotubes bio-conjugate modified electrode for label-free detection of foodborne pathogens. Sensors Actuators B Chem. 2017, 253, 115–123. [Google Scholar] [CrossRef]

- Hong, S.A.; Kwon, J.; Kim, D.; Yang, S. A rapid, sensitive and selective electrochemical biosensor with concanavalin A for the preemptive detection of norovirus. Biosens. Bioelectron. 2015, 64, 338–344. [Google Scholar] [CrossRef]

- Wang, N.; Pan, G.; Guan, S.; Rong, S.; Wang, D.; Gao, Z.; Tian, P.; Li, Q. A Broad-Range Disposable Electrochemical Biosensor Based on Screen-Printed Carbon Electrodes for Detection of Human Noroviruses. Front. Bioeng. Biotechnol. 2022, 10, 845660. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.I.; Haswell, S.; Gibson, I. Lab-on-a-chip or Chip-in-a-lab: Challenges of Commercialization Lost in Translation. Procedia Technol. 2015, 20, 54–59. [Google Scholar] [CrossRef]

- Cai, G.; Wang, Y.; Zhang, Y.; Zheng, L.; Lin, J. Magnetorheological elastomer and smartphone enable microfluidic biosensing of foodborne pathogen. Chinese Chem. Lett. 2022, 2022, 108059. [Google Scholar] [CrossRef]

- Qi, W.; Zheng, L.; Hou, Y.; Duan, H.; Wang, L.; Wang, S.; Liu, Y.; Li, Y.; Liao, M.; Lin, J. A finger-actuated microfluidic biosensor for colorimetric detection of foodborne pathogens. Food Chem. 2022, 381, 131801. [Google Scholar] [CrossRef]

- Hassan, S.; Tariq, A.; Noreen, Z.; Donia, A.; Zaidi, S.Z.J.; Bokhari, H.; Zhang, X. Capillary-Driven Flow Microfluidics Combined with Smartphone Detection: An Emerging Tool for Point-of-Care Diagnostics. Diagnostics 2020, 10, 509. [Google Scholar] [CrossRef] [PubMed]

- Lakhera, P.; Chaudhary, V.; Bhardwaj, B.; Kumar, P.; Kumar, S. Development and recent advancement in microfluidics for point of care biosensor applications: A review. Biosens. Bioelectron. X 2022, 11, 100218. [Google Scholar] [CrossRef]

- Joe, C.; Lee, B.H.; Kim, S.H.; Ko, Y.; Gu, M.B. Aptamer duo-based portable electrochemical biosensors for early diagnosis of periodontal disease. Biosens. Bioelectron. 2022, 199, 113884. [Google Scholar] [CrossRef] [PubMed]

- Cruz, A.F.D.; Norena, N.; Kaushik, A.; Bhansali, S. A low-cost miniaturized potentiostat for point-of-care diagnosis. Biosens. Bioelectron. 2014, 62, 249–254. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Hao, L.; Qi, W.; Huo, X.; Xue, L.; Liu, Y.; Zhang, Q.; Lin, J. A sensitive Salmonella biosensor using platinum nanoparticle loaded manganese dioxide nanoflowers and thin-film pressure detector. Sensors Actuators B Chem. 2020, 321, 128616. [Google Scholar] [CrossRef]

- Zhang, F.; Luo, L.; Gong, H.; Chen, C.; Cai, C. A magnetic molecularly imprinted optical chemical sensor for specific recognition of trace quantities of virus. RSC Adv. 2018, 8, 32262–32268. [Google Scholar] [CrossRef]

- Yang, S.; Ouyang, H.; Su, X.; Gao, H.; Kong, W.; Wang, M.; Shu, Q.; Fu, Z. Dual-recognition detection of Staphylococcus aureus using vancomycin-functionalized magnetic beads as concentration carriers. Biosens. Bioelectron. 2016, 78, 174–180. [Google Scholar] [CrossRef]

- Cheng, C.; Peng, Y.; Bai, J.; Zhang, X.; Liu, Y.; Fan, X.; Ning, B.; Gao, Z. Rapid detection of Listeria monocytogenes in milk by self-assembled electrochemical immunosensor. Sens. Actuators B Chem. 2014, 190, 900–906. [Google Scholar] [CrossRef]

- Radhakrishnan, R.; Jahne, M.; Rogers, S.; Suni, I.I. Detection of Listeria Monocytogenes by Electrochemical Impedance Spectroscopy. Electroanalysis 2013, 25, 2231–2237. [Google Scholar] [CrossRef]

- Chen, Q.; Lin, J.; Gan, C.; Wang, Y.; Wang, D.; Xiong, Y.; Lai, W.; Li, Y.; Wang, M. A sensitive impedance biosensor based on immunomagnetic separation and urease catalysis for rapid detection of Listeria monocytogenes using an immobilization-free interdigitated array microelectrode. Biosens. Bioelectron. 2015, 74, 504–511. [Google Scholar] [CrossRef]

- Wang, D.; Chen, Q.; Huo, H.; Bai, S.; Cai, G.; Lai, W.; Lin, J. Efficient separation and quantitative detection of Listeria monocytogenes based on screen-printed interdigitated electrode, urease and magnetic nanoparticles. Food Control. 2017, 73, 555–561. [Google Scholar] [CrossRef]

- Che, Y.; Li, Y.; Slavik, M. Detection of Campylobacter jejuni in poultry samples using an enzyme-linked immunoassay coupled with an enzyme electrode. Biosens. Bioelectron. 2001, 16, 791–797. [Google Scholar] [CrossRef] [PubMed]

- Viswanathan, S.; Rani, C.; Ho, J.A. Electrochemical immunosensor for multiplexed detection of food-borne pathogens using nanocrystal bioconjugates and MWCNT screen-printed electrode. Talanta 2012, 94, 315–319. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Wang, R.; Li, Y. Rapid detection of Escherichia coli O157:H7 and Salmonella Typhimurium in foods using an electrochemical immunosensor based on screen-printed interdigitated microelectrode and immunomagnetic separation. Talanta 2016, 148, 200–208. [Google Scholar] [CrossRef]

- Zelada-Guillén, G.A.; Sebastián-Avila, J.L.; Blondeau, P.; Riu, J.; Rius, F.X. Label-free detection of Staphylococcus aureus in skin using real-time potentiometric biosensors based on carbon nanotubes and aptamers. Biosens. Bioelectron. 2012, 31, 226–232. [Google Scholar] [CrossRef] [PubMed]

- Altintas, Z.; Akgun, M.; Kokturk, G.; Uludag, Y. A fully automated microfluidic-based electrochemical sensor for real-time bacteria detection. Biosens. Bioelectron. 2018, 100, 541–548. [Google Scholar] [CrossRef]

- Puiu, M.; Bala, C. Microfluidics-integrated biosensing platforms as emergency tools for on-site field detection of foodborne pathogens. TrAC Trends Anal. Chem. 2020, 125, 115831. [Google Scholar] [CrossRef]

- Carrell, C.; Kava, A.; Nguyen, M.; Menger, R.; Munshi, Z.; Call, Z.; Nussbaum, M.; Henry, C. Beyond the lateral flow assay: A review of paper-based microfluidics. Microelectron. Eng. 2019, 206, 45–54. [Google Scholar] [CrossRef]

| Foodborne Pathogen | Food Products [35,41,42] | USDA Minimum Infective Dose (MID) Levels [Cells] [36,41,43,44,45,46] | British Standard [CFU/g] [35,36] | FDA Standard [CFU/g] [37,38,39] | Meaning [35,36,37,38,39] |

|---|---|---|---|---|---|

| Campylobacter spp. | Poultry, beef, dairy products, and untreated drinking water. | xa400–500 | >0.04 | Any detectable presence c | Potential health hazard and unfit for human consumption |

| <0.04 | No detectable presence c | Fit for human consumption | |||

| Shiga toxin-producing Escherichia coli | Under cooked beef, dairy products made with unpasteurized milk or post pasteurization contaminated milk, vegetables, and untreated drinking water. | 10–100 | >100 | Any detectable presence c | Not fit for human consumption |

| 20–100 | No detectable presence c | Farther testing is needed mostly still fit for human consumption | |||

| <20 | Fit for human consumption | ||||

| Salmonella typhimurium | Eggs, poultry, pork, beef, dairy products, seeds, herbs, vegetables, chocolate. | 15–20 | >0.04 | Any detectable presence c | Potential health hazard and unfit for human consumption |

| <0.04 | No detectable presence c | Fit for human consumption | |||

| Listeria monocytogenes | Poultry, pork, beef, dairy products, bread, fish | Unknown. May vary with the strain and susceptibility of the individual. | >100 | >100 d | Not fit for human consumption |

| 10–100 | Not fit for vulnerable groups consumption (e.g., hospital food) | ||||

| <10 | <100 d | Fit for human consumption | |||

| Shigella spp. | Foods that are consumed raw, fruits, vegetables, recreational water, water contaminated with stool. | a 10 | a S. sonnei < 500 CFU | NA | Potentially injurious to health and/ or unfit for human consumption |

| a S. dysenteriae <200 CFU | |||||

| a S. flexneri < 140 CFU | |||||

| a Virulent strain < 10 CFU | |||||

| Mycobacterium bovis | Contaminated, unpasteurized dairy products, cattle, bison, elk, and deer. Can be acquired through air or wounds of contaminated animal. | b 1 CFU | NA | NA | Potentially injurious to health and/ or unfit for human consumption |

| Vibrio vulnificus | Raw or undercooked oysters and other seafood | 106 (102 in predisposed persons) | NA | >30 [MPN/g] e | Not fit for human consumption |

| Yersinia enterocolitica | Raw or undercooked pork | 109 | NA | Any detectable presence c | Not fit for human consumption |

| Norovirus | Contaminated food, drinks, surfaces, or people | 10–100 viral particles | NA | NA | Potentially injurious to health and/ or unfit for human consumption |

| Rotavirus | Stool particles in food and drinks due to bad hygiene. | 10–100 viral particles | NA | NA | Potentially injurious to health and/ or unfit for human consumption |

| Cyclospora | Water, fresh produce, food or water contaminated with stool. | Unknown, predicted to be as low as 200 oocysts. | NA | NA | Potentially injurious to health and/ or unfit for human consumption |

| Goal | Methodology | Foodborne Pathogen | Flow Rate [µL/min] | Sample Volume [µL] | Concentration Range | Channel Material | Detection Technique | Ref. |

|---|---|---|---|---|---|---|---|---|

| Separation | Gradient magnetic field. | Listeria monocytogenes | 1000 | 3500 | 102–105 [CFU/mL] | PDMS | Impedimetric phase shift analysis | [16] |

| SiO2 microbeads separation. | Norovirus | NA | NA | 100 [pM]–3.5 [nM] | PDMS | Differential pulse voltammetry | [56] | |

| Concentration | Dielectrophoresis | Escherichia coli O157:H7 | 2 [µL/min]—sample flow4 [µL/min]—wash flow4 [µL/min]—Ag enhancement | 20 [µL]—sample8 [µL]—wash8 [µL]—Ag enhancement | 103–105 [CFU/mL] | PDMS | Impedimetric | [17] |

| Positive dielectrophoresis | Escherichia coli O157:H7Salmonella typhimurium | 1–2 [µL/min] | 1000 | 10–120 [Cells/mL]—Salmonella typhimurium13–1000 [Cells/mL]—Escherichia coli O157:H7 | Glass | Impedimetric | [55] | |

| Detection | Transporting the solutions to the sensor | Escherichia coli Crooks Strain | 180 | 100 | 105–108 [Cells/mL] | Polyacrylate | Impedimetric | [18] |

| Transporting the solutions to the sensor | Listeria monocytogenes | Sample was dripped into specifically made wells on the microfluidic chip. | 80 | 102–103 [CFU/mL] | PDMS | Impedimetric | [19] | |

| Transporting the solutions to the sensor | Salmonella (B and D) | 2 | NA | 290–1000 [Cells/mL] | PDMS | Impedimetric | [20] | |

| Polymer coated paper modified with PAMAM(NH2)64-Ab | Salmonella typhimurium | NA | 5000 | 101–108 [Cells/mL] | Paper | Potentiometric | [57] | |

| Cotton thread carried the sample to an aptamer with functionalized MoS2 nanosheets | Vibrio parahaemolyticus | NA | 101–106 [CFU/mL] | Cotton thread | CV and DPV | [58] | ||

| Mixing | Tesla mixing structure | Escherichia coli O157:H7 | 2 | 20 | 103–105 [CFU/mL] | PDMS | Impedimetric | [17] |

| Magnetic stirring | Listeria monocytogenes | 2000 | 205 | 102–105[CFU/mL] | PDMS | Impedimetric Phase shift analysis | [16] |

| Food Borne Pathogen | Detection Technique | Bio-Recognition Event | Sample Type | Analysis Time | Detection Range/Detection Limit | References |

|---|---|---|---|---|---|---|

| Listeria monocytogenes | Amperometric | Antigen-antibody | Milk | NR | 102 to 106 [CFU/mL] | [116] |

| Impedimetric | Antigen-antibody | Filtered tomato extract | NR | 4 [CFU/mL] | [117] | |

| Impedimetric | Magnetic nanoparticles-antibody-urease | Spiked lettuce | NR | 3 × 102 [cells] | [118] | |

| Impedimetric | Modified magnetic nanoparticles—antibody-urease | Spiked lettuce | 1 h | 1.6 x 102 [CFU/mL] | [16] | |

| Impedimetric | Micro-electrodes functionalized with antibodies—miniaturized, portable EIS biochip | Milk | NR | 55 [CFU/mL] | [19] | |

| Impedimetric | Immunomagnetic nanoparticles-urease -screen-printed electrode | Spiked lettuce | <3 h | 1.6 x 103 [CFU/mL] | [119] | |

| Campylobacter jejuni | Amperometric | Antibody, phosphatase | Turkey carcass wash | 2.5 h | 102–107 [CFU/mL]LOD = 2 × 104 [CFU/mL] | [120] |

| Amperometric | Antibody | Milk | <1.5 h | 1 × 103–5 × 105 [CFU/ mL]LOD = 4 × 102 [CFU/mL] | [121] | |

| E. coli O157:H7 | Impedimetric | Antibody | Ground beef | NR | 2.05 × 103 [CFU/gr] | [122] |

| Salmonella typhimurium | Amperometric | Antibody | Milk | 125 min | 10 [CFU/mL] | [100] |

| Impedimetric | Aptamer | Apple juice | 45 min | NR | [101] | |

| Impedimetric | Aptamer—Diazonium base | Apple juice | 30 min | NR | [102] | |

| Impedimetric | Interdigitated electrode array coated with Salmonella antibody | Ready to eat turkey | 1 h | 300 cells/mL | [20] | |

| Staphylococcus aureus | Impedimetric | Antibody | Spiked milk | ~30 min | 13 [CFU/mL] | [103] |

| Potentiometric | Aptamers | Pig skin | NR | 2.4 × 103–2.0 × 104 [CFU/mL] | [123] | |

| Norovirus | Cyclic voltammetry | Selective capture agent concanavalin A | Lettuce extract | 60 copies/mL | [104] | |

| Immuno-based electrochemical biosensor | Monoclonal antibody | Clinical fecal sample | 1 h | 104 copies/mL | [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zolti, O.; Suganthan, B.; Ramasamy, R.P. Lab-on-a-Chip Electrochemical Biosensors for Foodborne Pathogen Detection: A Review of Common Standards and Recent Progress. Biosensors 2023, 13, 215. https://doi.org/10.3390/bios13020215

Zolti O, Suganthan B, Ramasamy RP. Lab-on-a-Chip Electrochemical Biosensors for Foodborne Pathogen Detection: A Review of Common Standards and Recent Progress. Biosensors. 2023; 13(2):215. https://doi.org/10.3390/bios13020215

Chicago/Turabian StyleZolti, Or, Baviththira Suganthan, and Ramaraja P. Ramasamy. 2023. "Lab-on-a-Chip Electrochemical Biosensors for Foodborne Pathogen Detection: A Review of Common Standards and Recent Progress" Biosensors 13, no. 2: 215. https://doi.org/10.3390/bios13020215

APA StyleZolti, O., Suganthan, B., & Ramasamy, R. P. (2023). Lab-on-a-Chip Electrochemical Biosensors for Foodborne Pathogen Detection: A Review of Common Standards and Recent Progress. Biosensors, 13(2), 215. https://doi.org/10.3390/bios13020215