Internet of Things (IoT)-Based Environmental Monitoring and Control System for Home-Based Mushroom Cultivation

Abstract

1. Introduction

2. Methods and Materials

2.1. Selection of Mushroom

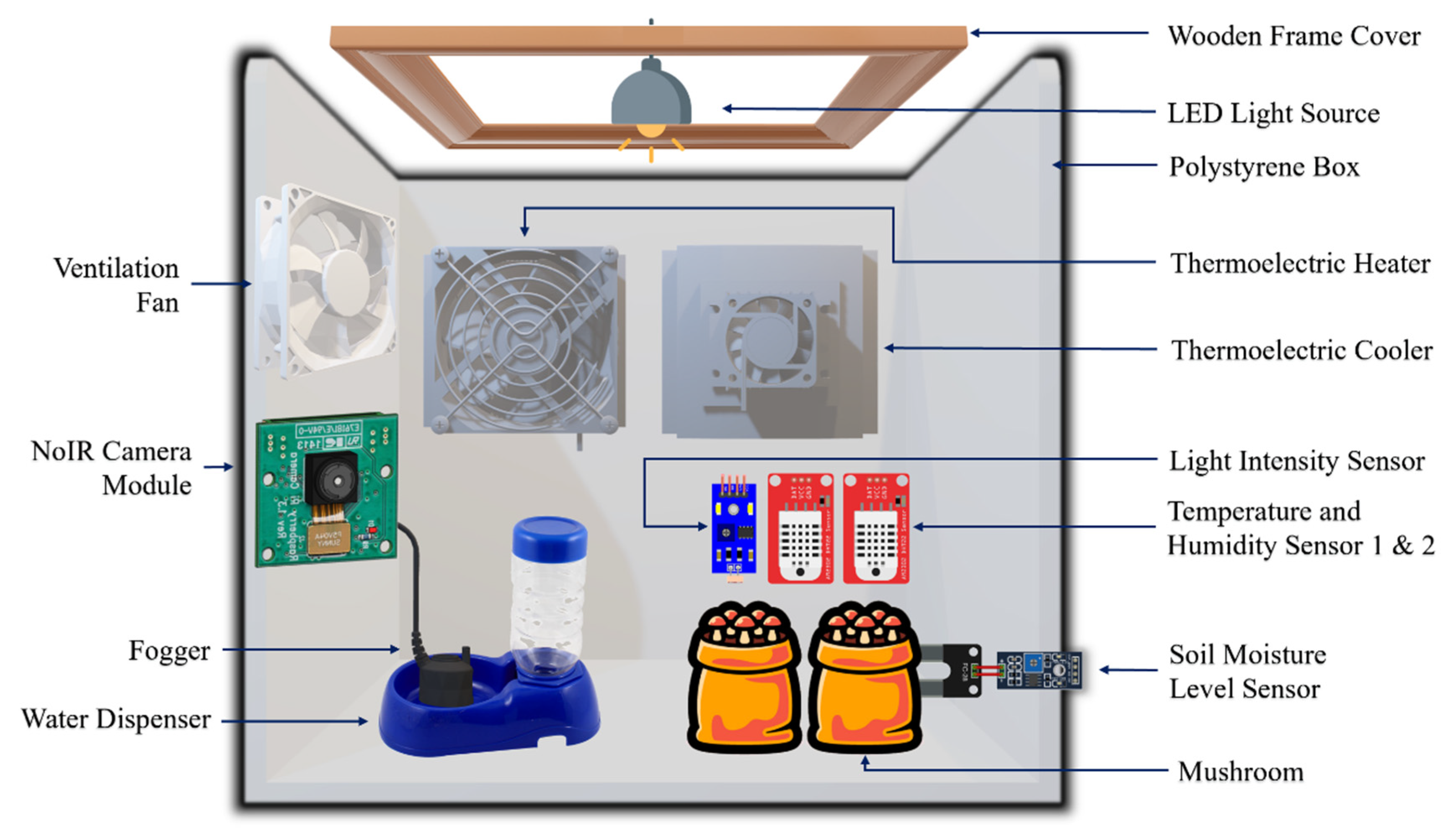

2.2. Design of the Mushroom Cultivation Chamber

2.3. IoT-Based Monitoring System

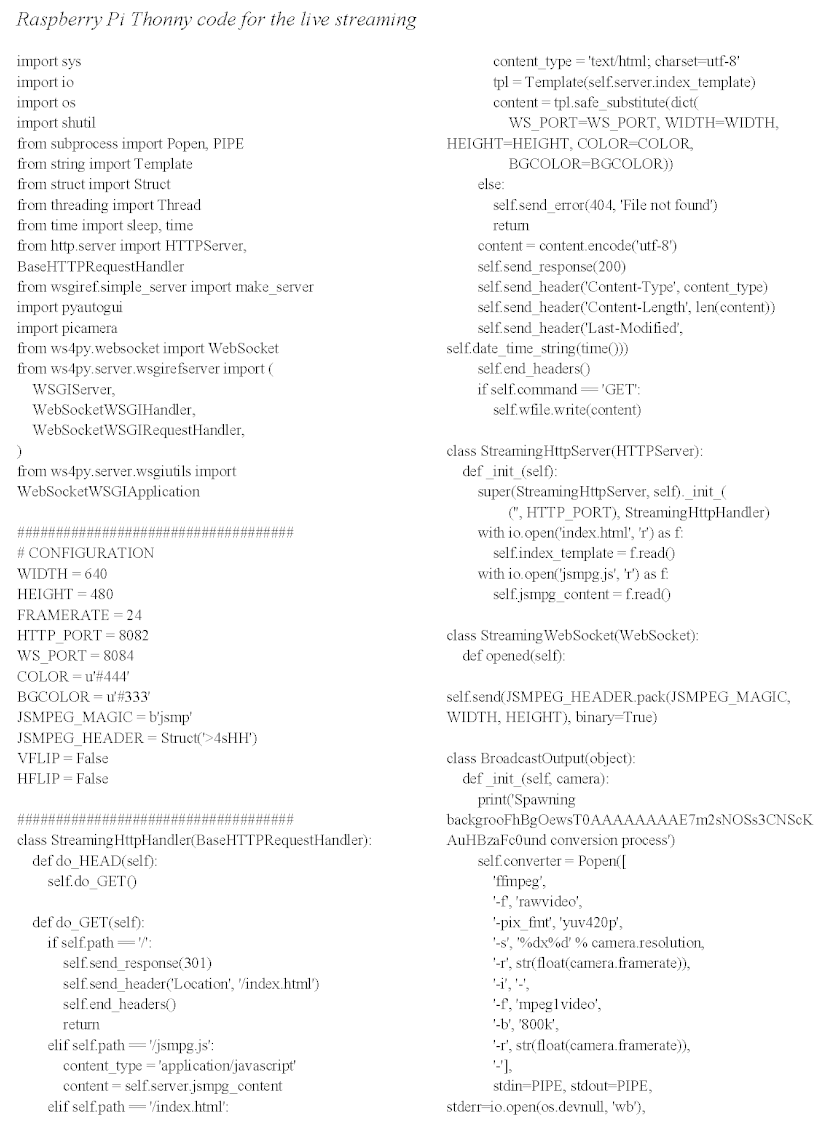

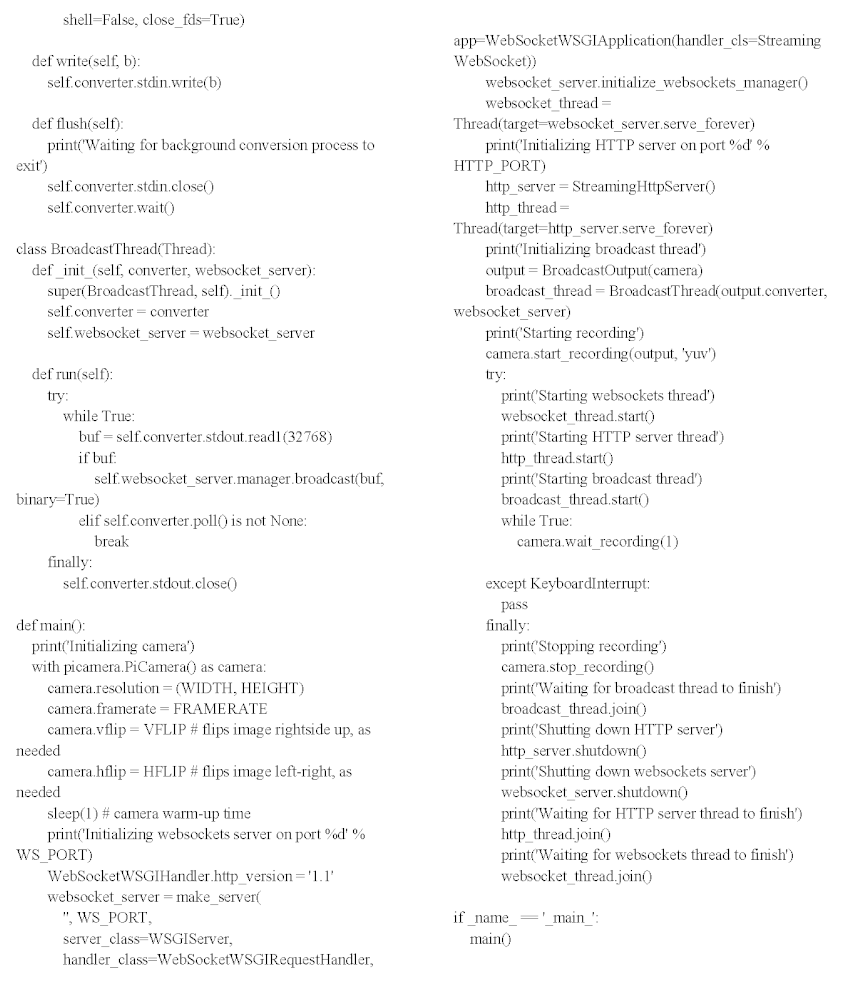

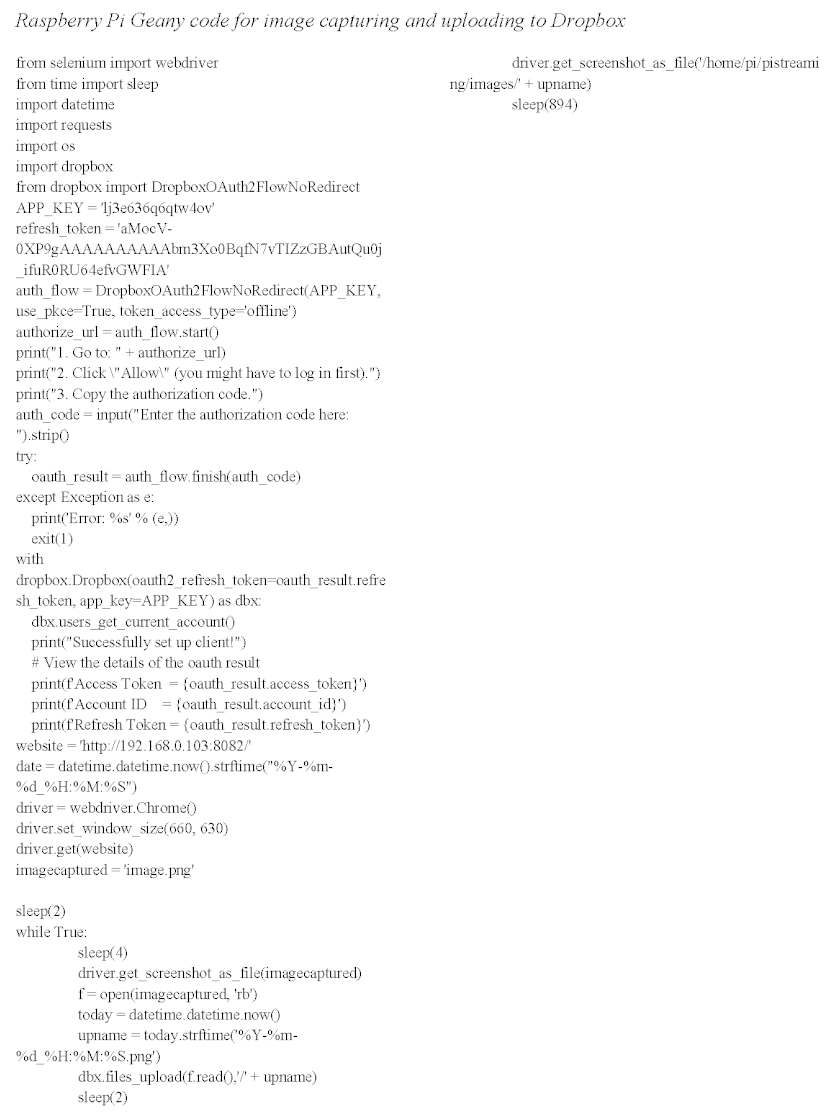

2.3.1. Live Video Monitoring and Image Capturing System

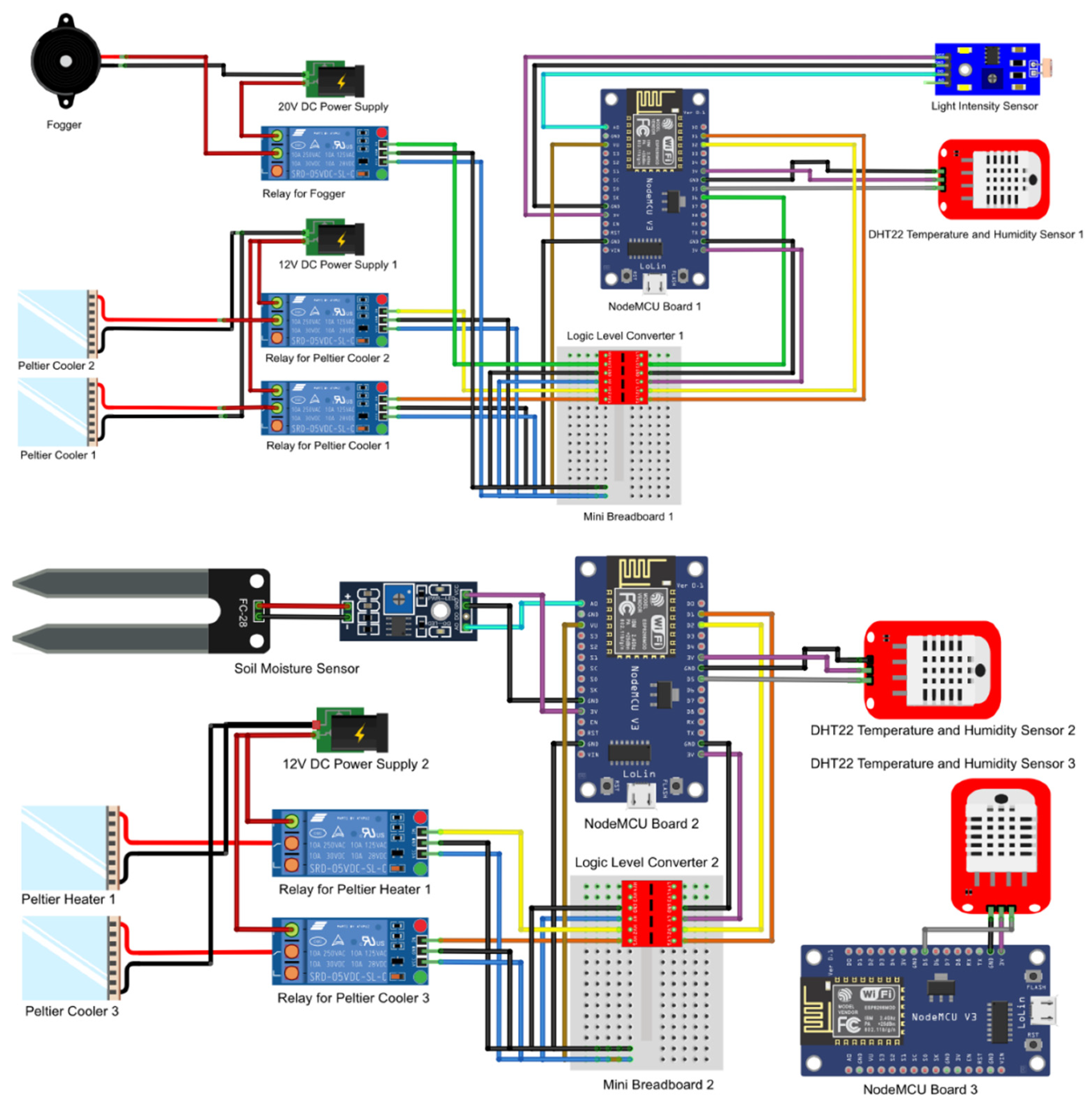

2.3.2. Data Acquisition System

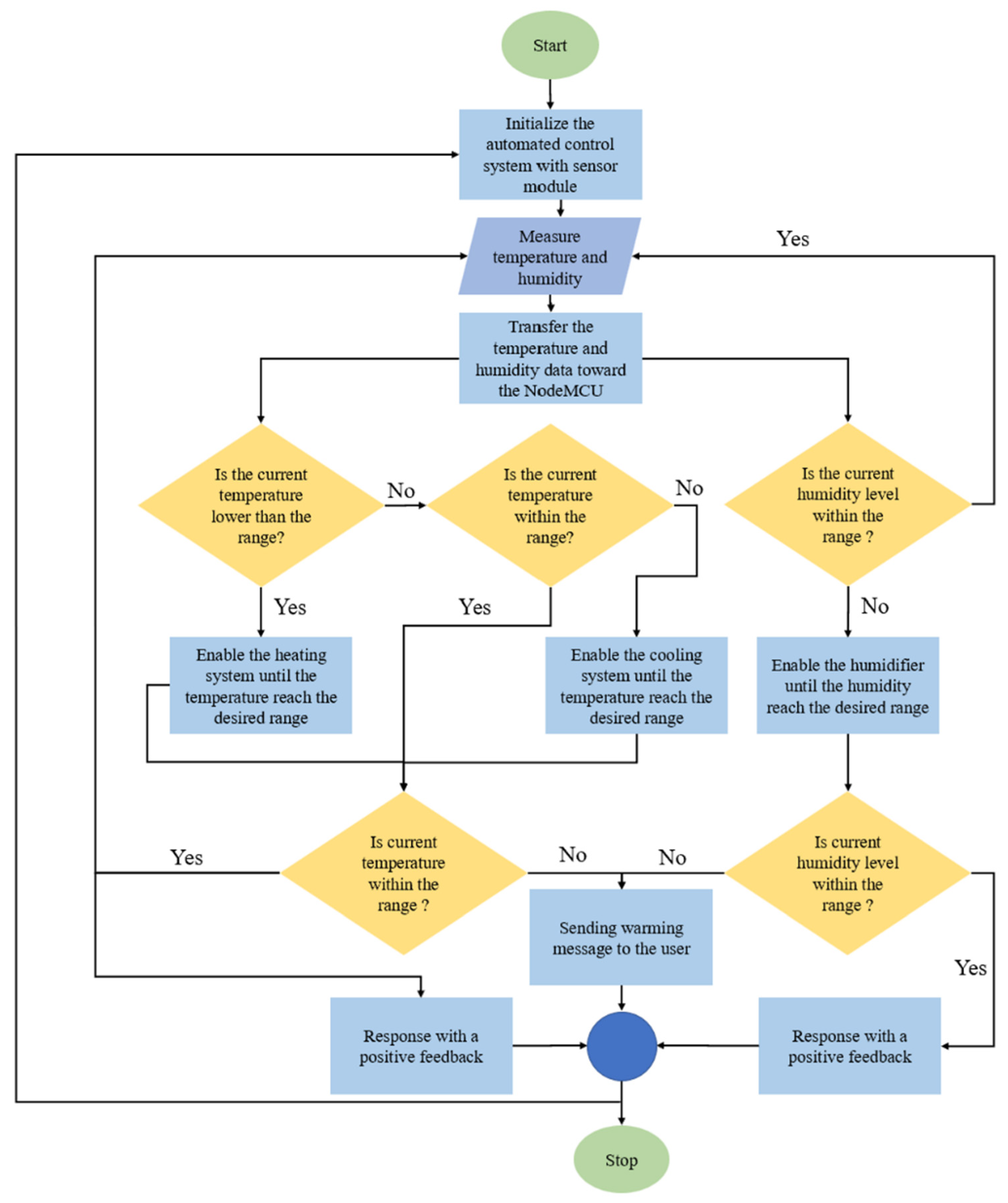

2.4. IoT-Based Environmental Control System

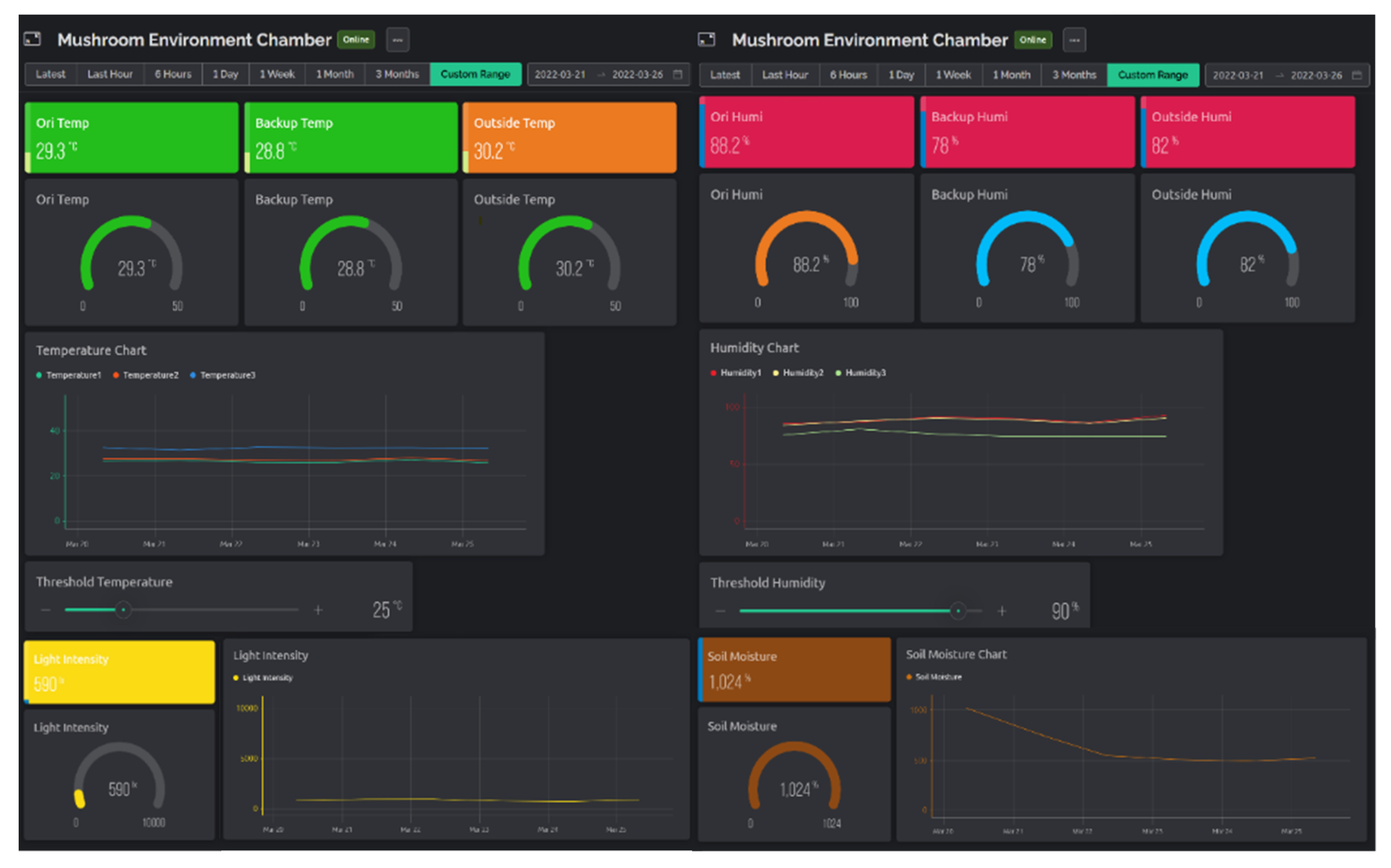

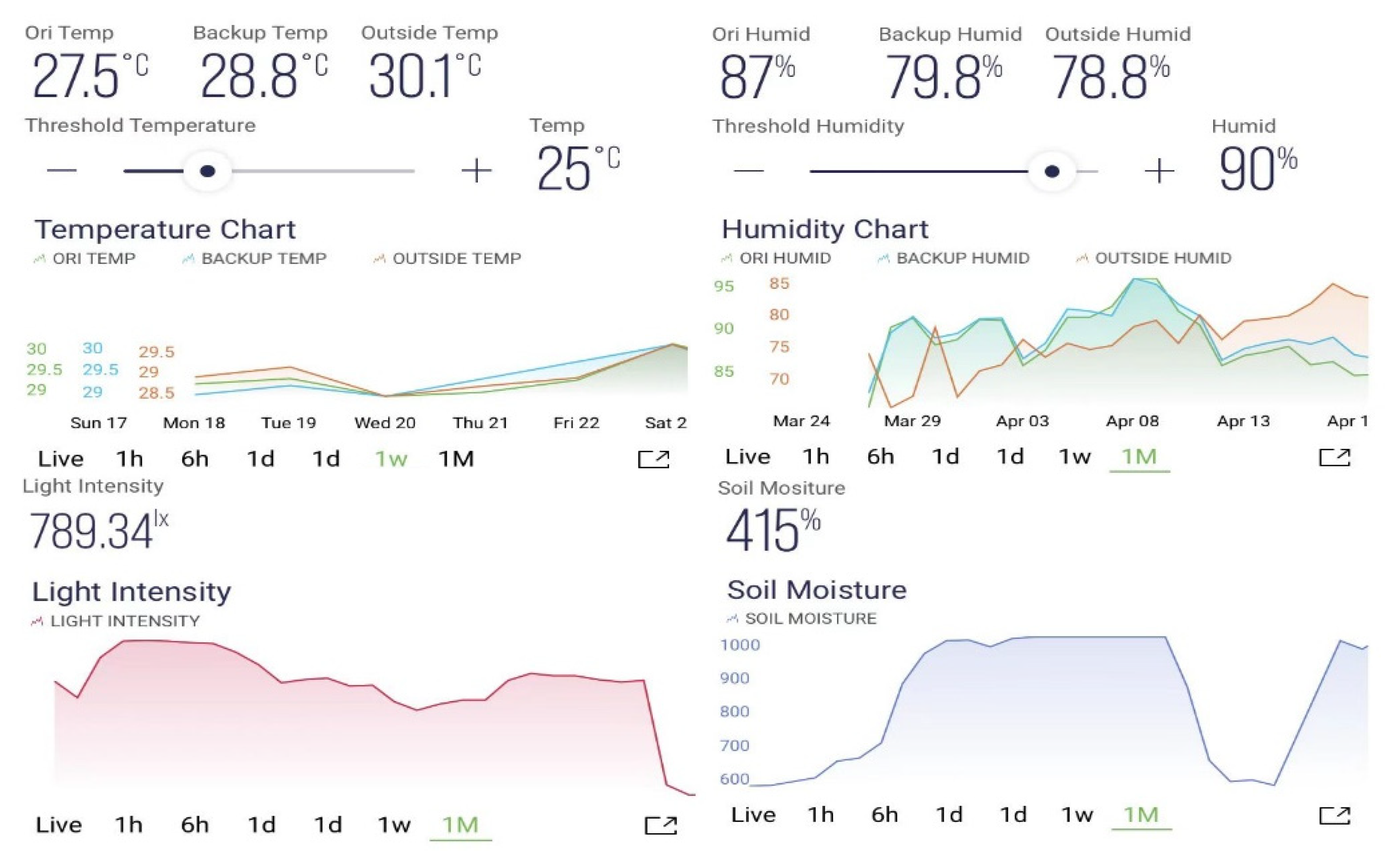

2.5. Web and Mobile Application

2.6. Analysis

2.6.1. Light Intensity Sensor (SN-LIGHT-MOD)

2.6.2. Soil Moisture Sensor (SN MOISTURE-MOD)

2.6.3. Temperature and Humidity Sensor (DHT22)

3. Results and Discussion

3.1. Light Intensity Sensor

3.2. Soil Moisture Sensor

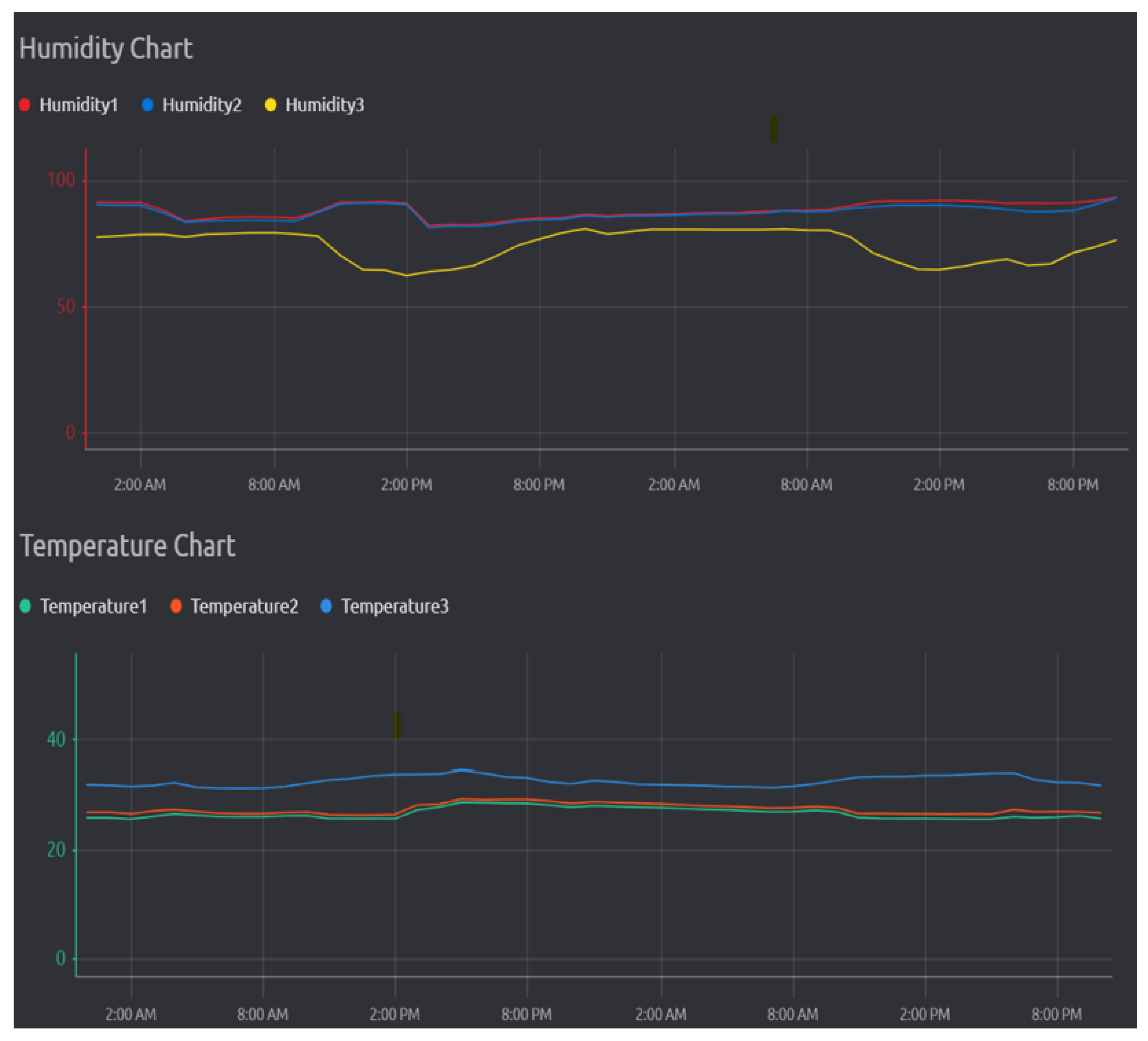

3.3. Temperature and Humidity Sensor

3.4. Performance of the Environmental Monitoring and Control System

3.5. Performance of the Video and Image Monitoring System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

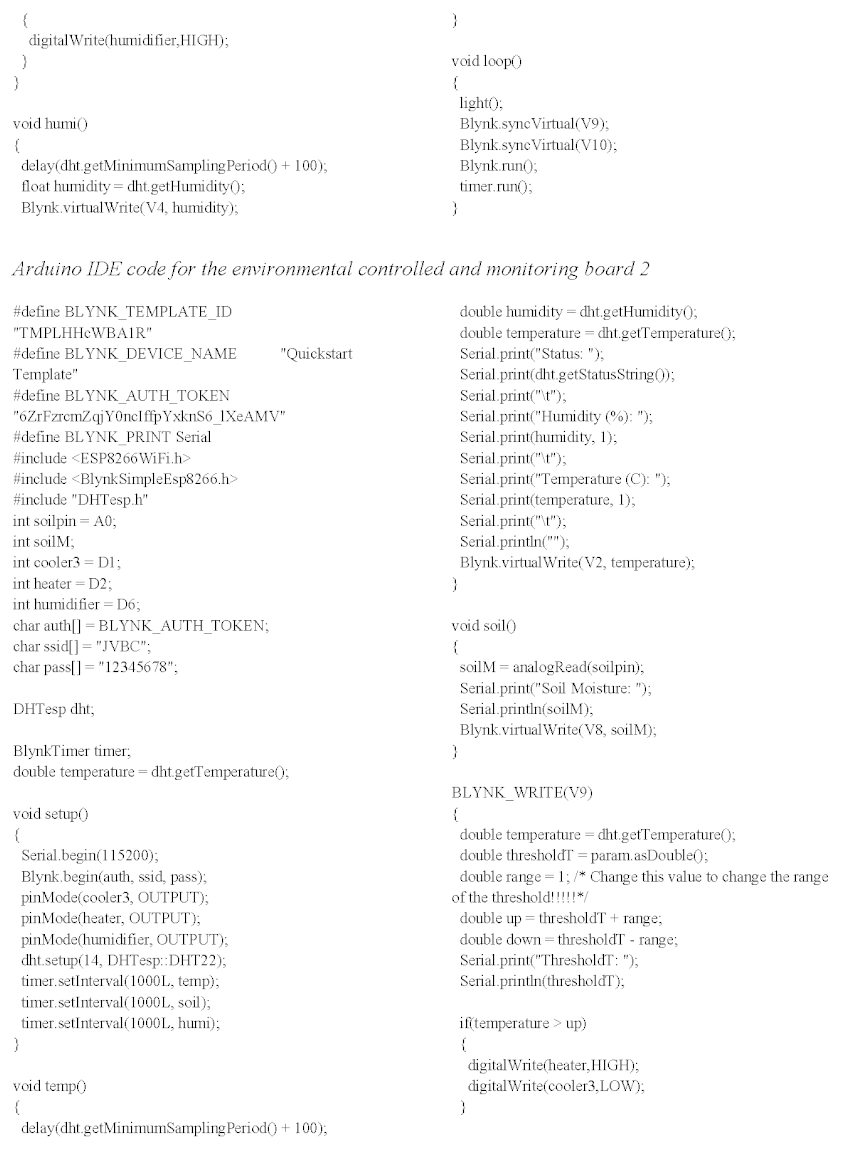

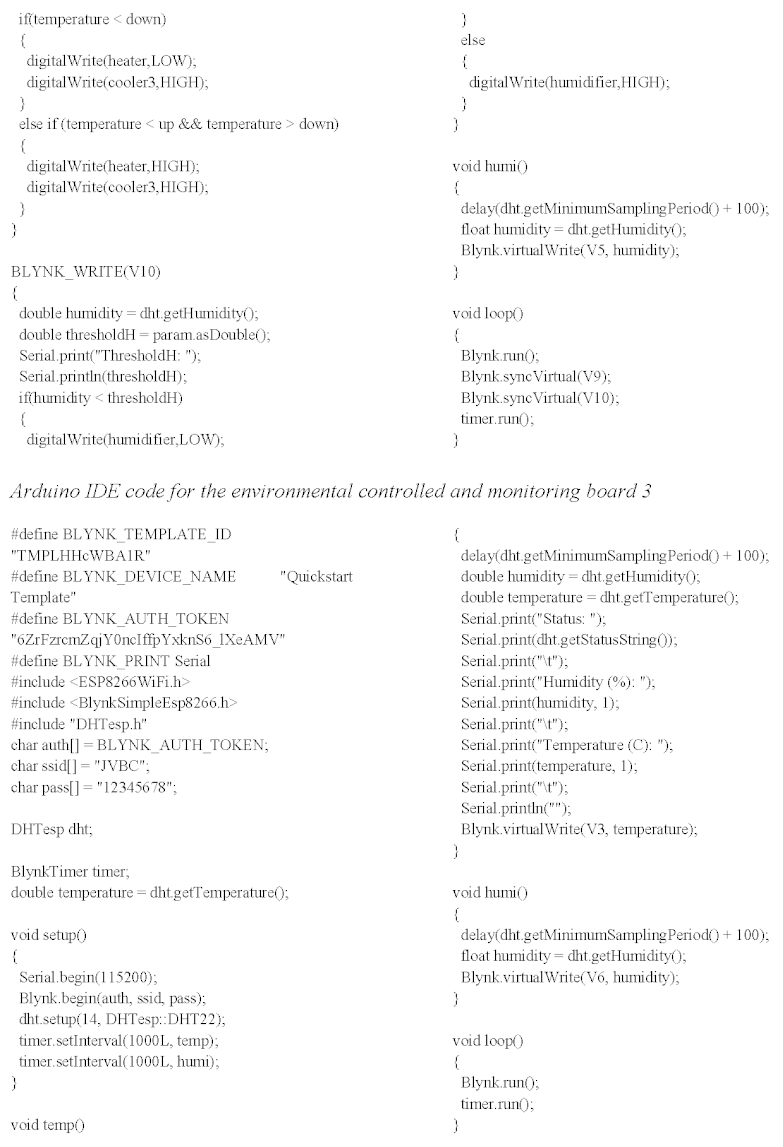

Appendix A

References

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Building a Common Vision for Sustainable Food and Agriculture; Food and Agriculture Organization of the United Nations: Rome, Italy, 2014; ISBN 9789251084717. [Google Scholar]

- Jarraud, M.; Steiner, A. Summary for Policymakers; Cambridge University Press: Cambridge, UK, 2012; Volume 9781107025, ISBN 9781139177245. [Google Scholar]

- Ariffin, M.A.M.; Ramli, M.I.; Zainol, Z.; Amin, M.N.M.; Ismail, M.; Adnan, R.; Ahmad, N.D.; Husain, N.; Jamil, N. Enhanced Iot-Based Climate Control for Oyster Mushroom Cultivation Using Fuzzy Logic Approach and Nodemcu Microcontroller. Pertanika J. Sci. Technol. 2021, 29, 2863–2885. [Google Scholar] [CrossRef]

- Ferdousi, J.; Riyadh, Z.A.; Hossain, M.I.; Saha, S.R.; Zakaria, M. Mushroom Production Benefits, Status, Challenges and Opportunities in Bangladesh: A Review. Annu. Res. Rev. Biol. 2020, 34, 1–13. [Google Scholar] [CrossRef]

- Mokhena, T.; Mochane, M.; Tshwafo, M.; Linganiso, L.; Thekisoe, O.; Songca, S. We Are IntechOpen, the World’ s Leading Publisher of Open Access Books Built by Scientists, for Scientists TOP 1%; IntechOpen: London, UK, 2016; pp. 225–240. [Google Scholar]

- Xue, Y.; Xie, J.; Xu, X.S.; Yong, L.; Hu, B.; Liang, J.; Li, X.D.; Qing, L. Sen UPLC-QqQ/MS Combined with Similarity Assessment of 17 Nucleic Acid Constituents in 147 Edible Fungi from Sichuan Basin, China. Food Res. Int. 2019, 120, 577–585. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Kalantari, F.; Ting, K.C.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z. Advances in Greenhouse Automation and Controlled Environment Agriculture: A Transition to Plant Factories and Urban Agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- Budzyńska, S.; Siwulski, M.; Budka, A.; Kalač, P.; Niedzielski, P.; Gąsecka, M.; Mleczek, M. Mycoremediation of Flotation Tailings with Agaricus Bisporus. J. Fungi 2022, 8, 883. [Google Scholar] [CrossRef]

- Bellettini, M.B.; Fiorda, F.A.; Maieves, H.A.; Teixeira, G.L.; Ávila, S.; Hornung, P.S.; Júnior, A.M.; Ribani, R.H. Factors Affecting Mushroom Pleurotus spp. Saudi J. Biol. Sci. 2019, 26, 633–646. [Google Scholar] [CrossRef]

- Raman, J.; Jang, K.Y.; Oh, Y.L.; Oh, M.; Im, J.H.; Lakshmanan, H.; Sabaratnam, V. Cultivation and Nutritional Value of Prominent Pleurotus Spp.: An Overview. Mycobiology 2021, 49, 1–14. [Google Scholar] [CrossRef]

- Bellettini, M.B.; Bellettini, S.; Fiorda, F.A.; Pedro, A.C.; Bach, F.; Fabela-Morón, M.F.; Hoffmann-Ribani, R. Diseases and Pests Noxious to Pleurotus Spp. Mushroom Crops. Rev. Argent. Microbiol. 2018, 50, 216–226. [Google Scholar] [CrossRef]

- Nawandar, N.K.; Satpute, V.R. IoT Based Low Cost and Intelligent Module for Smart Irrigation System. Comput. Electron. Agric. 2019, 162, 979–990. [Google Scholar] [CrossRef]

- Yew, G.Y.; Puah, B.K.; Chew, K.W.; Teng, S.Y.; Show, P.L.; Nguyen, T.H.P. Chlorella vulgaris FSP-E cultivation in waste molasses: Photo-to-property estimation by artificial intelligence. Chem. Eng. J. 2020, 402, 126230. [Google Scholar] [CrossRef]

- Kuzlu, M.; Fair, C.; Guler, O. Role of Artificial Intelligence in the Internet of Things (IoT) Cybersecurity. Discov. Internet Things 2021, 1, 1–14. [Google Scholar] [CrossRef]

- Govinda, K.; Saravanaguru, R.A.K. Review on IOT Technologies. Int. J. Appl. Eng. Res. 2016, 11, 2848–2853. [Google Scholar]

- Petrovic, R.; Simic, D.; Drajic, D.; Cica, Z.; Nikolic, D.; Peric, M. Designing laboratory for IoT communication infrastructure environment for remote maritime surveillance in equatorial areas based on the Gulf of Guinea field experiences. Sensors 2020, 20, 1349. [Google Scholar] [CrossRef] [PubMed]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, Investments, and Challenges for Enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Patnaik Patnaikuni, D.R. A Comparative Study of Arduino, Raspberry Pi and ESP8266 as IoT Development Board. Int. J. Adv. Res. Comput. Sci. 2017, 8, 2350–2352. [Google Scholar]

- Zafar, S.; Miraj, G.; Baloch, R.; Murtaza, D.; Arshad, K. Environmental Monitoring System Using IoT and Environmental Monitoring System Using IoT and Cloud Service at Real-Time. Eng. Technol. Appl. Sci. Res. 2018, 8, 3238–3242. [Google Scholar] [CrossRef]

- Rahman, H.; Faruq, M.O.; Abdul, H.; Bin, T.; Rahman, W.; Hossain, M.M.; Hasan, M.; Islam, S.; Moinuddin, M.; Islam, M.T.; et al. IoT Enabled Mushroom Farm Automation with Machine Learning to Classify Toxic Mushrooms in Bangladesh. J. Agric. Food Res. 2022, 7, 100267. [Google Scholar] [CrossRef]

- Satyanarayana, T. Advancing Frontiers in Mycology & Mycotechnology; Springer: Singapore, 2019; ISBN 9789811393488. [Google Scholar]

- Kwon, J.; Kim, S.; Jeon, J.; Kang, Y.; Jang, K. Development of Environmental Control System for High-Quality Shiitake Mushroom (Lentinus Edodes (Berk.) Sing.) Production. J. Biosyst. Eng. 2018, 43, 342–351. [Google Scholar]

- Mahmud, M.S.A.; Buyamin, S.; Mokji, M.M.; Abidin, M.S.Z. Internet of Things Based Smart Environmental Monitoring for Mushroom Cultivation. Indones. J. Electr. Eng. Comput. Sci. 2018, 10, 847–852. [Google Scholar] [CrossRef]

- Subedi, A.; Luitel, A.; Baskota, M.; Acharya, T.D. IoT Based Monitoring System for White Button Mushroom Farming. Multidiscip. Digit. Publ. Inst. Proc. 2020, 42, 46. [Google Scholar] [CrossRef]

- Setiawati, D.A.; Utomo, S.G.; Murad; Putra, G.M.D. Design of Temperature and Humidity Control System on Oyster Mushroom Plant House Based on Internet of Things (IoT). IOP Conf. Ser. Earth Environ. Sci. 2021, 712, 012002. [Google Scholar] [CrossRef]

- Geng, X.; Zhang, Q.; Wei, Q.; Zhang, T.; Cai, Y.; Liang, Y.; Sun, X. A Mobile Greenhouse Environment Monitoring System Based on the Internet of Things. IEEE Access 2019, 7, 135832–135844. [Google Scholar] [CrossRef]

- Ejigu, N.; Sitotaw, B.; Girmay, S.; Assaye, H. Evaluation of Oyster Mushroom (Pleurotus ostreatus) Production Using Water Hyacinth (Eichhornia Crassipes) Biomass Supplemented with Agricultural Wastes. Int. J. Food Sci. 2022, 2022, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Fasehah, S.N.; Shah, A. Effect of Using Various Substrates on Cultivation of Pleurotus Sajor-Caju. J. Eng. Sci. Technol. 2017, 12, 1104–1110. [Google Scholar]

- Abdurrahman; Umam, R.; Irzaman; Palupi, E.K.; Saregar, A.; Syazali, M.; Junaidi, R.; Wahyudianto, B.; Adi, L.C. Optimization and Interpretation of Heat Distribution in Sterilization Room Using Convection Pipe. Indones. J. Sci. Technol. 2019, 4, 204–219. [Google Scholar] [CrossRef]

- Hoa, H.T.; Wang, C.L. The Effects of Temperature and Nutritional Conditions on Mycelium Growth of Two Oyster Mushrooms (Pleurotus ostreatus and Pleurotus Cystidiosus). Mycobiology 2015, 43, 14–23. [Google Scholar] [CrossRef]

- Zawadzka, A.; Janczewska, A.; Kobus-Cisowska, J.; Dziedziński, M.; Siwulski, M.; Czarniecka-Skubina, E.; Stuper-Szablewska, K. The Effect of Light Conditions on the Content of Selected Active Ingredients in Anatomical Parts of the Oyster Mushroom (Pleurotus ostreatus L.). PLoS ONE 2022, 17, e0262279. [Google Scholar] [CrossRef]

- Han, P.; Mei, H.; Liu, D.; Zeng, N.; Tang, X.; Wang, Y.; Pan, Y. Calibrations of low-cost air pollution monitoring sensors for CO, NO2, O3, and SO2. Sensors 2021, 21, 256. [Google Scholar] [CrossRef]

- Jierula, A.; Wang, S.; Oh, T.M.; Wang, P. Study on accuracy metrics for evaluating the predictions of damage locations in deep piles using artificial neural networks with acoustic emission data. Appl. Sci. 2021, 11, 2314. [Google Scholar] [CrossRef]

| Light Intensity from Light Intensity Measuring Instrument BF05 (lux) | Light Intensity from the Light Sensor SN-LIGHT-MOD (lux) | Absolute Error (lux) | Absolute Percentage Error (%) |

|---|---|---|---|

| 100 | 87 | 13 | 13.00 |

| 200 | 213 | 13 | 6.50 |

| 300 | 281 | 19 | 6.33 |

| 400 | 416 | 16 | 4.00 |

| 500 | 447 | 53 | 10.60 |

| 1000 | 935 | 65 | 6.50 |

| Soil Moisture Level from MLX2 Soil Meter (%) | Soil Moisture Level from Soil Moisture Level Sensor (%) | Absolute Error (%) | Absolute Percentage Error (%) |

|---|---|---|---|

| 22.3 | 21.8 | 0.5 | 2.24 |

| 23.9 | 23.5 | 0.4 | 1.67 |

| 24.6 | 23.8 | 0.8 | 3.25 |

| 10.9 | 9.7 | 1.2 | 11.01 |

| 27.4 | 28.1 | 0.7 | 2.55 |

| 19.2 | 19.6 | 0.4 | 2.08 |

| 13.5 | 14.4 | 0.9 | 6.67 |

| Temperature from the Thermo Hygrometer (°C) | Temperature from the DHT22 Sensor (°C) | Absolute Error (°C) | Absolute Percentage Error (%) |

| 26.6 | 26.4 | 0.2 | 0.75 |

| 27.1 | 26.6 | 0.5 | 1.85 |

| 26.1 | 25.9 | 0.2 | 0.77 |

| 26.3 | 25.7 | 0.6 | 2.28 |

| 27.5 | 27.7 | 0.2 | 0.73 |

| 30.2 | 29.9 | 0.3 | 0.99 |

| 25.8 | 26.1 | 0.3 | 1.16 |

| Humidity from the Thermo Hygrometer (%RH) | Humidity from the DHT22 Sensor (%RH) | Absolute Error (%RH) | Absolute Percentage Error (%) |

| 86.1 | 85.63 | 0.47 | 0.55 |

| 87.1 | 88.4 | 1.3 | 1.49 |

| 78.1 | 80.1 | 2 | 2.56 |

| 67.2 | 65.6 | 1.6 | 2.38 |

| 70.9 | 73.1 | 2.2 | 3.10 |

| 88.6 | 91.6 | 3 | 3.39 |

| 90.1 | 91.65 | 1.55 | 1.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chong, J.L.; Chew, K.W.; Peter, A.P.; Ting, H.Y.; Show, P.L. Internet of Things (IoT)-Based Environmental Monitoring and Control System for Home-Based Mushroom Cultivation. Biosensors 2023, 13, 98. https://doi.org/10.3390/bios13010098

Chong JL, Chew KW, Peter AP, Ting HY, Show PL. Internet of Things (IoT)-Based Environmental Monitoring and Control System for Home-Based Mushroom Cultivation. Biosensors. 2023; 13(1):98. https://doi.org/10.3390/bios13010098

Chicago/Turabian StyleChong, Jiu Li, Kit Wayne Chew, Angela Paul Peter, Huong Yong Ting, and Pau Loke Show. 2023. "Internet of Things (IoT)-Based Environmental Monitoring and Control System for Home-Based Mushroom Cultivation" Biosensors 13, no. 1: 98. https://doi.org/10.3390/bios13010098

APA StyleChong, J. L., Chew, K. W., Peter, A. P., Ting, H. Y., & Show, P. L. (2023). Internet of Things (IoT)-Based Environmental Monitoring and Control System for Home-Based Mushroom Cultivation. Biosensors, 13(1), 98. https://doi.org/10.3390/bios13010098