Abstract

Silicon photonic (SiP) sensors offer a promising platform for robust and low-cost decentralized diagnostics due to their high scalability, low limit of detection, and ability to integrate multiple sensors for multiplexed analyte detection. Their CMOS-compatible fabrication enables chip-scale miniaturization, high scalability, and low-cost mass production. Sensitive, specific detection with silicon photonic sensors is afforded through biofunctionalization of the sensor surface; consequently, this functionalization chemistry is inextricably linked to sensor performance. In this review, we first highlight the biofunctionalization needs for SiP biosensors, including sensitivity, specificity, cost, shelf-stability, and replicability and establish a set of performance criteria. We then benchmark biofunctionalization strategies for SiP biosensors against these criteria, organizing the review around three key aspects: bioreceptor selection, immobilization strategies, and patterning techniques. First, we evaluate bioreceptors, including antibodies, aptamers, nucleic acid probes, molecularly imprinted polymers, peptides, glycans, and lectins. We then compare adsorption, bioaffinity, and covalent chemistries for immobilizing bioreceptors on SiP surfaces. Finally, we compare biopatterning techniques for spatially controlling and multiplexing the biofunctionalization of SiP sensors, including microcontact printing, pin- and pipette-based spotting, microfluidic patterning in channels, inkjet printing, and microfluidic probes.

1. Introduction

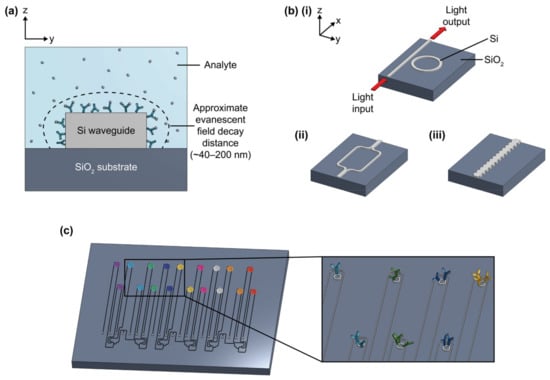

Biosensors, which comprise a transducer and biorecognition element, aim to meet increasing demands for medical diagnostics by permitting rapid testing, guiding personalized care, and reducing healthcare costs in decentralized and low-resource settings [1,2,3]. Silicon photonic (SiP) sensors are one class of optical refractometric sensors with promise as sensitive, rapid, and inexpensive transducers for point-of-care (POC) biosensing [4]. Compared to other types of transducers employed for biosensing, such as electrochemical [5], piezoelectric [6], and mechanical (e.g., microcantilever) [7] sensors, some advantages of SiP sensors are their high sensitivity, wide dynamic range, compatibility with label-free operation, mechanical stability, and insensitivity to electromagnetic interferences [8]. SiP devices can be patterned with wafer-scale semiconductor fabrication techniques, allowing for reproducible, inexpensive, and highly scalable production [1,9,10]. These devices consist of nanoscale patterned silicon or silicon nitride structures that can guide and manipulate light, owing to the high refractive index contrast between the structures themselves and the surrounding media [1,11]. In SiP sensors, near-infrared light is confined in silicon or silicon nitride waveguides [1,12]. A portion of the light’s electric field, known as the evanescent field, extends outside the waveguide and interacts with the surrounding medium to create a refractive index-sensitive region (Figure 1a) [1]. A change in the refractive index within this region due to analyte capture on the waveguide surface, for example, perturbs the evanescent field and changes the effective refractive index, neff, of the guided optical mode [1,4]. This translates to a shift in the optical phase, and in the case of resonant circuit architectures, leads to a resonance wavelength shift that is proportional to the amount of bound analyte, yielding a quantifiable change in the device’s optical spectrum [1,4,12]. This change is typically read out using benchtop-scale optical inputs (e.g., broadband optical source or tunable laser) and outputs (e.g., spectrum analyzer or photodetector) [12,13,14,15,16].

Figure 1.

(a) Illustration of cross-section of silicon photonic (SiP) sensor, showing the SiO2 substrate, Si strip waveguide (height: 220 nm, width: 500 nm), and approximate evanescent field decay distance (~40–200 nm, depending on waveguide geometry and light polarization). (b) Illustration of four different SiP sensing architectures, including (i) microring resonator (MRR), (ii) Mach-Zehnder interferometer (MZI), and (iii) Bragg grating sensor. (c) Visual depiction of a multiplexed SiP MRR sensor chip, showing different rings functionalized with different antibodies (different antibodies are represented by different colors). Antibodies in (a) and (c) are not to scale.

Interferometers, microring resonators (MRR), and Bragg gratings (Figure 1b) are among the SiP biosensing architectures that have been demonstrated for disease biomarker detection at concentrations down to the pg/mL scale [17,18]. Readers are directed elsewhere [1] for a detailed description of the principles of operation of each of these sensing architectures. Porous silicon sensors, which are fabricated with electrochemically etched crystalline silicon, have also been widely used in Bragg reflector and PhC configurations for biosensing since the late 1990s and are compatible with many of the same functionalization approaches [19]. This review, however, will mainly focus on planar SiP sensors, which permit greater optical confinement and guidance. Dozens of these individually addressable planar SiP sensors can be fabricated on a single millimeter-scale chip [10]. This permits multiplexed sensing, which is the simultaneous detection of multiple analytes from a single sample. Some benefits afforded by multiplexed biosensing are (1) the opportunity to diagnose multiple conditions/diseases from the same sample, (2) more selective and reliable diagnosis of a single condition by using multiple biomarkers to inform decision-making [20,21,22], and (3) the opportunity to include controls and reference sensors (e.g., to control for temperature fluctuations) to improve measurement accuracy [23,24,25,26]. In addition to these benefits afforded by multiplexed functionalization with different bioreceptors, multiple sensors on the same chip with identical functionalization offer the benefit of replicate measurements to improve accuracy and replicability (e.g., serving as technical replicates allowing for exclusion of failed measurements and averaging out the effects of sensor-to-sensor variability and some assay issues) [27].

The process of functionalizing the sensor surface with biorecognition elements (also called bioreceptors) that selectively bind target analytes is essential to accurate SiP biosensing. The performance characteristics of the biosensor, such as sensitivity, reproducibility, and stability, are inextricably linked to the biofunctionalization chemistry [28]. Here, we broadly characterize biofunctionalization in terms of bioreceptor selection, bioreceptor immobilization strategy (attachment to the sensor surface), and biopatterning technique. Designing antifouling surface modifications is also often included in biofunctionalization procedures to prevent non-specific binding. However, this topic has been reviewed in detail elsewhere [29] and will not be a major focus of the current review.

Many different biofunctionalization strategies are available and should be carefully chosen and optimized to suit the application and sensor architecture. In general, the selected bioreceptor should have good selectivity toward the target analyte to ensure low cross-reactivity with non-target molecules in the sample, high affinity toward the target to achieve fast, sensitive detection, good stability to retain consistent binding activity over time, and reproducible production to ensure predictable and replicable sensor performance across batches/lots of reagents [30]. The strategy used to immobilize bioreceptors on the sensor must not damage the sensor surface or the bioreceptors, and it should be compatible with any system-level integration required for the sensor chips (e.g., chip-mounted lasers and detectors, photonic wire bonds, etc.). It should also allow for oriented bioreceptor immobilization to optimize target accessibility and binding activity, permit uniform bioreceptor coverage on the sensor surface to ensure predictable and consistent target binding across all active sensing areas, have good stability to prevent bioreceptor detachment, and be reproducible [29,31]. The patterning strategy refers to the method by which bioreceptors are deposited on specific locations of the sensor surface (Figure 1c). This is required for multiplexed sensing and to confine bioreceptors to active sensing areas, thus preventing target depletion from dilute samples during sensing [32,33,34]. The selected patterning technique should not damage the sensor surface or bioreceptors. It should also have sufficient resolution for the selected application, be multiplexable so multiple different bioreceptors can be handled and deposited on a single substrate, produce uniform patterns with good spot-to-spot reproducibility, be compatible with the immobilization protocol (e.g., patterning under conditions that preserve functional groups on the silicon surface), and have low reagent consumption to conserve costly and precious reagents.

In addition to the general biosensor functionalization needs outlined in the previous paragraph, SiP devices have unique needs that distinguish them from other biosensors. Many immobilization techniques (e.g., covalent crosslinking) and bioreceptor types (e.g., antibodies, aptamers, etc.) [35] are shared across an array of sensing technologies including lateral flow assays [36], electrochemical probes [37], piezoelectric sensors [38] and other optical sensors like SPR [39]. While these sensing technology applications can provide valuable insight to inform functionalization strategies for SiP devices, only some of the findings are relevant because they utilize a variety of surfaces including glass, paper, polymers, specialized membranes (nitrocellulose), quartz, nanomaterials, alloys, metals (gold), and ceramics. Here, we focus specifically on immobilization techniques for silicon, silicon nitride, and other like materials.

Among these other transducer types, SiP sensors likely share the most similarities with SPR sensors, which employ a similar evanescent field-based detection principle. Nevertheless, SiP and SPR sensors exhibit differences in their surface chemistries, evanescent field propagation distances, miniaturizability, and multiplexability, as summarized in Table 1 [4,11,12,40,41,42,43,44,45,46,47,48,49,50,51,52,53]. Due to these differences, SiP devices have unique biofunctionalization needs, providing the main motivation for this review. For example, as SiP surfaces typically consist of 90–220 nm-thick silicon or silicon nitride nanostructures patterned on a silicon dioxide substrate [11,40], while SPR sensors typically have gold surfaces, the efficient thiol self-assembled monolayer-based strategies often used to modify metallic SPR biosensor surfaces are not suitable for SiP devices; instead silane-based chemistries are typically used [31,41]. Another unique consideration is the evanescent field penetration depth. For SiP devices, this is ~40–200 nm, depending on waveguide geometry and polarization (Figure 1a) [4,12]. Consequently, SiP sensors require a very thin biofunctional layer that brings target analytes within ~40–200 nm of the sensor surface. The size of this refractive index-sensitive region must be considered when choosing both the biorecognition element and the immobilization chemistry.

Table 1.

Comparison of SiP and surface plasmon resonance (SPR) sensors, including SPR imaging (SPRi) and localized SPR (LSPR) devices.

Broadly, the more well-established field of SPR sensing offers a few advantages over SiP sensing. For example, SPR permits the use of simple thiol-based self-assembled monolayer functionalization strategies [29,31]. SPR variants (e.g., SPRi and LSPR) are also compatible with excitation via direct illumination and simple colorimetric readout, which are attractive for portable sensing [42,53,54]. Multimodal SPR-SERS (surface-enhanced Raman scattering) sensing is also possible for highly sensitive and reliable analyte detection [55,56,57], while multi-modal sensing strategies based on SiP still require further research and development [58,59]. Nevertheless, large-scale and low-cost production remains a challenge for widespread use of SPR-based sensors outside of the laboratory environment [12,53].

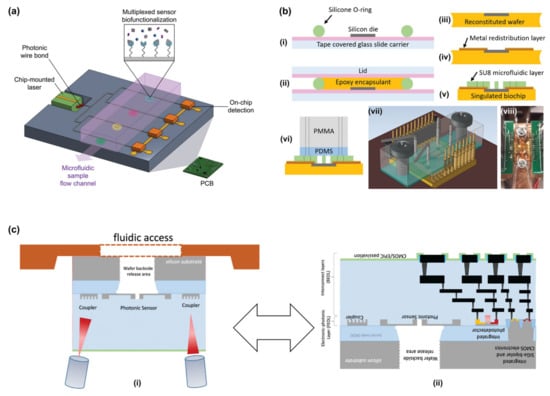

SiP biosensor chips, themselves, are uniquely suited to reliable point-of-care (POC) use owing to their ease of miniaturization, low cost, and ease of multiplexing [1,12]. POC biosensing not only permits accessible diagnosis in decentralized and resource-limited settings, but also facilitates treatment decision-making in situations like stroke and sepsis where rapid confirmation of clinical findings is required and conventional lab-based assays may be too time consuming [20,60]. Further, wearable sensors that can be interfaced with flexible electronics may permit real-time and noninvasive monitoring of physiologically relevant analytes (e.g., in sweat) [61,62]. However, one major challenge associated with the translation of SiP biosensors to POC applications is that SiP devices are typically operated with expensive benchtop-scale fluidics and optical readout systems [13]. Miniaturized system-level integration is possible in principle, though, and work to integrate SiP sensors with microfluidics, CMOS electronics, and on-chip lasers and detectors via photonic wire bonds is underway to produce low-cost and portable complete-system PCB-mounted sensors [13,63,64,65,66]. Another major challenge with this translation is biofunctionalization.

Given the potential of SiP devices for POC biosensing, a major focus of this work is benchmarking SiP biofunctionalization strategies against needs pertaining to their multiplexed use at the POC. Some of these needs include good environmental and temporal stability to ensure predictable performance after transport and storage at ambient conditions, scalability and manufacturability to permit large-scale deployment, low cost to ensure accessibility, compatibility with easy-to-collect biological samples, such as whole blood, urine, and saliva, and biopatterning resolution on the order of 10 µm to complement the sensor miniaturization afforded by SiP technologies [2]. Reusability is another desirable feature for POC devices that could further reduce sensing costs and improve the accessibility of diagnostic tests in remote and low-resource settings [30]. Chip-level integration of SiP sensors introduces additional biofunctionalization needs. Not only must the biofunctionalization workflow be compatible with the SiP chip architecture, but it also must be compatible with attached optical inputs/outputs and electronics. For example, the immobilization chemistry and patterning technique must not damage electrical or photonic wire bonds, chip-mounted lasers, or PCB materials. Additionally, the immobilized bioreceptors need to be stable through any processing and packaging that needs to be done after immobilization.

To date, numerous existing reviews provide an overview of SiP biosensing technologies, focusing largely on the transduction techniques [1,12,14,19,42,67], with limited discussion about surface biofunctionalization. Others have focused on a single class of bioreceptors for biosensing applications (e.g., antibodies [68,69], nucleic acid probes [70,71], and molecularly imprinted polymers [72]), often including discussion about immobilization chemistries specific to that bioreceptor, and others have focused solely on the comparison of multiple bioreceptor classes for biosensing [30,73]. Several reviews have provided detailed discussion about bioreceptor immobilization chemistries for SiP sensors [31,69] and other biosensing technologies [43,74,75,76]. A number of works have explored different patterning techniques for the preparation of microarrays and the multiplexed functionalization of biosensors [32,77,78]. Finally, some reviews have discussed at least two of the three key aspects of biofunctionalization (bioreceptor selection, bioreceptor immobilization strategy, and biopatterning technique) for SiP [29] and other sensor technologies (e.g., SPR [41,79,80] and electrochemical sensors [80,81]). Distinct from these existing works, the current review (1) focuses on the unique functionalization needs and strategies of multiplexed SiP biosensors, (2) discusses all three key aspects of biofunctionalization (bioreceptor selection, immobilization chemistry, and patterning technique) and how they are interrelated, and (3) includes a review of biofunctionalization strategies that have been previously implemented on SiP biosensors. To our knowledge, our review is the first contribution to comprehensively summarize and categorize the biofunctionalization strategies previously demonstrated for SiP biosensors (from 2005 to present) as well as present a critical analysis of the various existing (demonstrated on SiP) and potential (demonstrated on similar sensor types) strategies towards the goal of meeting the performance criteria most relevant to SiP biosensors.

Here, we benchmark biofunctionalization strategies against the needs outlined in Table 2, with specific focus placed on biosensor design for multiplexed POC use [82,83]. First, we critically discuss several bioreceptor classes as biorecognition elements for SiP biosensors. Examples of SiP biosensors employing these bioreceptors are highlighted, including their demonstrated sensing performance and assay format. Strategies for bioreceptor immobilization on SiP platforms are discussed along with their advantages and limitations, with particular focus on gold standard silane-mediated covalent chemistries. Finally, contact and contact-free techniques for patterning bioreceptors on SiP sensors are identified and their performance characteristics are discussed. This review aims to present a balanced discussion of the tradeoffs of a range of biofunctionalization strategies to help guide those designing SiP biosensors in selecting a biofunctionalization approach that meets the unique needs of their intended application.

Table 2.

Biofunctionalization needs for SiP biosensors. Please note that the performance metrics included in this table are general guidelines and designers should tailor these metrics based on their application. Interdependencies between the different columns of this table should also be considered (e.g., more expensive bioreceptors may still be suitable when combined with patterning techniques that permit very low reagent consumption).

2. Bioreceptors

In this section, we introduce several classes of bioreceptors that have been used for SiP sensor functionalization and benchmark them against performance criteria outlined in Table 2. A high-level comparison of these bioreceptors is provided in Table 3. We have included subsections for each bioreceptor class to provide details about the opportunities and tradeoffs associated with each of these bioreceptors. For each bioreceptor class, tables summarizing their key advantages and limitations, and categorizing their use in SiP sensor functionalization approaches demonstrated in the previous literature are provided. Because strategies to improve sensitivity, specificity, stability, and other performance metrics are in many cases dependent on the bioreceptor class, within each subsection we have outlined strategies for these types of improvements as well as provided comparisons with other classes where relevant and available. Where appropriate, comparisons between bioreceptor subtypes are also tabulated according to these performance metrics.

Table 3.

Comparison of different bioreceptor classes based on biofunctionalization needs for SiP biosensors.

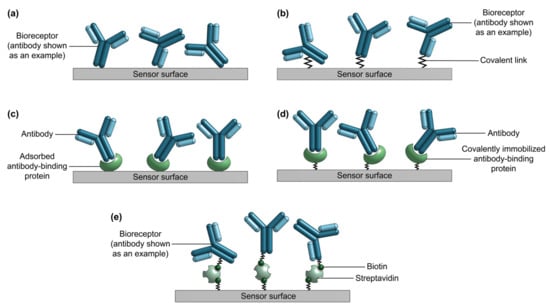

2.1. Antibodies

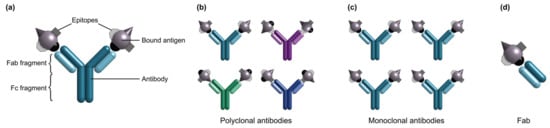

Antibodies (Figure 2) are the most commonly used bioreceptors for diagnostic assays [91,153]. Antibodies are Y-shaped proteins of ~150 kDa in size, which consist of two identical Fab regions (fragment, antigen-binding), and a single Fc region (fragment, crystallizable) [30,33,87]. The Fab regions specifically bind with high affinity to target molecules called antigens via binding sites called epitopes on the antigen surface. Antigens comprise a diverse range of biological molecules including simple sugars, hormones and lipids, complex macromolecules like proteins, nucleic acids, phospholipids and carbohydrates, and even viruses and bacteria [29,33,84]. On the other hand, the Fc region typically interacts with effector molecules and cells in biological systems and may be targeted for antibody immobilization on a solid substrate in biosensing applications [33,87,154]. Millions of antibodies have been validated for tens of thousands of antigen targets, making them a widely-available and flexible bioreceptor option for many different use cases [92,93,94,95]. Antibody production starts by immunizing animals against an antigen to stimulate the production of antigen-specific antibodies by the animals’ B cells [88,155]. Then, the antibodies can be obtained directly from the animal immune-sera. Alternatively, antibody-producing B cells can be immortalized by fusion with hybridoma cells for long-term production.

Figure 2.

(a) Illustration of an antibody and bound antigens. Illustrations of different antibody subtypes, including (b) polyclonal antibodies, (c) monoclonal antibodies, and (d) a Fab fragment. Note that polyclonal antibodies are produced as heterogeneous mixtures in which different antibodies may bind to different epitopes of the same antigen. Monoclonal antibodies are produced as homogeneous samples in which all antibodies bind to the same epitope.

There are two major classes of antibodies: polyclonal and monoclonal. Polyclonal antibodies are produced as heterogeneous mixtures from animal serum and individual antibodies in a serum sample may bind to various epitopes on a single antigen [87]. Polyclonal antibodies exhibit significant batch-to-batch variability, partly owing to their animal origin [156]. Antibody quality can vary from animal-to-animal and even throughout an individual animal’s lifetime [156]. Conversely, monoclonal antibodies are produced from immortalized cell lines, are homogeneous in nature, and bind to a single epitope on the target antigen surface [88,156]. Monoclonal antibodies offer excellent specificity and reduced cross-reactivity and variability compared to their polyclonal counterparts; as a result, monoclonal antibodies have been widely used in diagnostic assay applications [86,87,88,90]. More recently, molecular engineering has also been used to generate shorter antibody variants including Fabs, single chain variable fragments, and single domain antibodies that can be produced more easily in vitro and used for applications that solely require epitope binding [29,75,157]. A comparison of polyclonal antibodies, monoclonal antibodies, and Fab fragments as bioreceptors for SiP biosensors is provided in Table 4.

Table 4.

Comparison of antibody subtypes as bioreceptors for SiP biosensors.

Numerous SiP biosensing platforms using antibodies as bioreceptors have been reported in the literature. Conventional ELISAs are typically done in sandwich or competitive assay formats, requiring labeled secondary antibodies or labeled analyte molecules, respectively [160]. SiP platforms, however, permit label-free assays [1]. In the label-free format, binding of a target analyte to surface-bound antibodies is directly monitored, offering the advantages of real-time detection and simple sample preparation [14,161]. Nevertheless, sandwich formats using an unlabeled secondary antibody [18] or labeled antibody combined with subsequent enzymatic amplification [17,162] or protein-based multilayer signal enhancement [163] have been used to achieve more sensitive and specific detection for low-concentration and low-molecular weight analytes. To tether the capture antibodies to the sensor, these antibody-based SiP platforms typically rely on randomly oriented covalent immobilization strategies that target abundant amine or carboxyl groups on the antibody surface [75]. However, other covalent and non-covalent immobilization strategies have also been used [75].

SiP biosensors using antibodies as bioreceptors (Table 5) have been proposed for the biomarker-based diagnosis of cancer [17,18,22,161,163], cardiac disorders [164,165], inflammation [166], and viral infection [167], in addition to the detection of toxins [25,168], viral particles [169,170,171], and bacteria [172]. Such antibody-based SiP platforms have achieved LoDs as low as the pg/mL range using enzymatically or layer-by-layer-enhanced sandwich assay formats [17,163]. Other antibody-based SiP platforms have achieved label-free analyte detection with LoDs in the low-ng/mL range [161,169]. While most of the aforementioned examples employ whole polyclonal or monoclonal antibodies, Chalyan et al. [25] functionalized thiolated silicon oxynitride microring resonators with Fab fragments obtained from protease digestion of polyclonal antibodies for the detection of a carcinogenic mycotoxin, Aflatoxin M1, with a LoD of ~5 nM. The functionalization strategy used in this work targeted sulfhydryl (–SH) groups present on the Fab surface that were liberated from splitting the intact antibody; since these sulfhydryl groups are located opposite to the antigen-binding sites, this strategy ensures highly oriented bioreceptor immobilization, making it an attractive alternative to amine- and carboxyl-targeting strategies [75,173]. Shia and Bailey [168] functionalized silicon microring resonators with recombinantly derived single domain antibodies for the detection of ricin, a lethal protein toxin. The single domain antibodies exhibited improved specificity and lower cross-reactivity compared to a commercial polyclonal anti-ricin antibody.

Table 5.

Demonstrations of SiP biosensors using antibodies or antibody fragments as the biorecognition element and their sensing performance.

Despite their excellent sensitivity and specificity, antibody-based biosensors present notable challenges regarding POC sensing. Namely, antibody discovery is achieved by months-long in vivo screening processes, which are expensive and laborious [89]. Antibody production largely relies on mammalian cell lines, which means that these bioreceptors are costly and require highly trained personnel to produce, precluding their use in highly scalable and low-cost sensors [2,97,98,99,157]. Moreover, among antibody vendors, there is a lack of consistency in the context-specific validation and reporting of antibody specificity and reproducibility for different applications [92,156,178]. The use of animals and cell colonies in antibody production makes these bioreceptors susceptible to sample contamination [89]. This means that choosing successful antibodies for biosensors is often an expensive and time-consuming task involving troubleshooting and returning failed antibodies to suppliers [156,178]. Antibodies are also susceptible to denaturation and require carefully controlled storage conditions, which may be difficult to maintain in POC settings [24,91]. Further, antibody immobilization on a solid substrate is known to reduce antibody binding activity, making the optimization of immobilization strategies using mild chemistries a particular challenge in the design of highly sensitive biosensors [75]. The key advantages and limitations of antibodies as bioreceptors are highlighted in Table 6. Given the limitations of antibodies discussed here, several classes of synthetic affinity reagents have been developed as alternatives to antibodies and have been demonstrated as bioreceptors on SiP platforms [2].

Table 6.

Advantages and limitations of antibodies as bioreceptors.

2.2. Aptamers

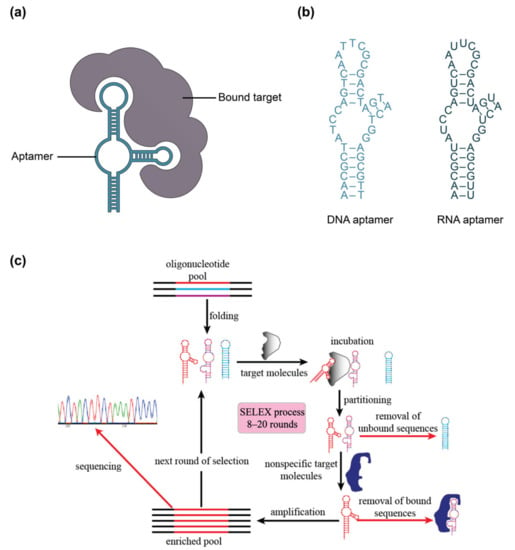

Aptamers, which have been referred to as “synthetic antibodies”, are short, single-stranded DNA or RNA molecules that are systematically selected to bind to a given target molecule (Figure 3) [87,89]. These single-stranded oligonucleotides fold into unique sequence-specific three-dimensional structures that bind to targets with high specificity and affinity via non-covalent effects, including electrostatic interactions, van der Waals, and hydrogen bonding [89,100]. Aptamers are generated using an in vitro process called SELEX (systematic evolution of ligands by exponential enrichment), which allows for the selection of unique target-binding DNA or RNA molecules from a large library (Figure 3c) [100]. The SELEX process begins with a library of around 1015 single-stranded oligonucleotides, each containing a different random sequence of 20–60 nucleotides, flanked by fixed sequences on the 3′ and 5′ ends [89,100]. This library is amplified by the polymerase chain reaction (PCR), then strand-separated to yield ssDNA or transcribed to yield RNA, depending on whether a DNA or RNA aptamer is desired [100,102,179]. These amplified products are then incubated with target molecules and target-bound DNA or RNA are separated from unbound sequences, followed by elution of the bound species. The amplification and target-binding stages of this process are repeated with the enriched pool of target-binding sequences. The process is repeated for a total of 8–20 cycles during which competitive binding causes high-affinity binding sequences to outcompete lower-affinity ones, eventually yielding a pool dominated by sequences with the strongest affinity to the target [100,101,102,179]. An additional negative selection step can also be included in the SELEX process to reduce cross-reactivity of aptamers to structurally similar targets, thus enhancing selectivity [102]. The selected oligonucleotides can subsequently be sequenced and synthesized for analysis and use [100]. The resulting aptamers can achieve comparable, or even better, affinity to their targets when compared to monoclonal antibodies, with typical dissociation constants (KD) in the low nanomolar to picomolar range [85,100,101].

Figure 3.

(a) Illustration of aptamer and bound target. (b) Visual representation of aptamer subtypes: DNA and RNA aptamers. (c) Illustration of SELEX (systematic evolution of ligands by exponential enrichment) process to design aptamers against a target. In (c), different colors in the oligonucleotide pool represent different nucleic acid sequences, while different colors in the sequencing step represent different nucleic acid bases identified by Sanger sequencing or high-throughput sequencing methods. Part (c) is reprinted from Ref. [101] in accordance with the Creative Commons Attribution 4.0 International (CC BY 4.0) license.

Since their discovery three decades ago, aptamers have been generated against inorganic ions, metabolites, dyes, drugs, amino acids, peptides, proteins, cells, and even tissues [89,100,101,105]. Because the production of antibodies relies on the immune response, antibodies can only be generated for immunogenic and non-toxic targets [89,100]. Conversely, the in vitro SELEX process theoretically allows for the generation of aptamers against any target. Further, given the small size of aptamers (5–30 kDa) compared to antibodies (150–180 kDa), aptamers can be designed against small molecule targets that are inaccessible to antibodies [89]. In evanescent field-based sensing applications, the smaller size of aptamers can allow for greater surface immobilization density and can bring captured analytes closer to the sensor surface, potentially improving sensitivity [113,114]. The selection environment (e.g., buffer type, ionic strength, pH, temperature, etc.) during aptamer generation can also be tailored to the binding conditions required for the intended use case [89,100,180]. This is contrasted to antibodies which are limited to target recognition under physiological conditions.

Other advantages conferred to aptamers by the nature of the SELEX discovery process include fast discovery and low batch-to-batch variability [89]. While antibody discovery requires upward of 6 months, the SELEX process can be completed in a matter of days if high-throughput automated methods are used [89,102]. Additionally, since antibody synthesis relies on animals or cell cultures, batch-to-batch variability can be high; this variability is avoided in aptamer samples because they are generated via chemical synthesis procedures with a low risk of contamination [89]. Aptamers also exhibit better environmental stability, especially thermal stability, and long shelf lives compared to antibodies [89,105]. Namely, aptamers are resistant to high temperatures up to 95 °C and cycles of denaturation and renaturation, while they can also be lyophilized and stored at room temperature [89]. This makes aptamers attractive bioreceptors for point of care devices and opens opportunities for surface regeneration and reusable sensors [96,105]. Finally, aptamer discovery and manufacture are generally lower cost than for antibodies. For example, CamBio offers custom aptamer discovery down to USD 5000 per target [181]. After the aptamer has been selected and sequenced, it can be manufactured at low cost using common oligonucleotide synthesis techniques. For example, Aptagen offers aptamer manufacture at USD 1–4 per milligram for microgram-scale synthesis, US $300 per gram for milligram-scale synthesis, and USD 50 per gram for gram-scale synthesis, while IDT offers DNA oligonucleotide synthesis at CAD 1.40–2.40 per base for 1 µmol quantities for sequences of 5–100 bases in length [89,182]. However, the manufacture of RNA sequences, especially those exceeding 60 bases can be more costly. For example, Bio-Synthesis, Inc. manufactures RNA sequences of 10–30 bases in length for USD 14.50–50 per milligram for 50–1000 mg-scale synthesis, while IDT manufactures RNA sequences of 5–60 bases in length for CAD 24.00 per base at 1 µmol quantities and RNA sequences of 60–120 bases in length for CAD 23.00 per base at 80 nmol quantities [89,106,182]. Table 7 provides a high-level comparison of DNA and RNA aptamers for SiP biosensing.

Table 7.

Comparison of aptamer subtypes as bioreceptors for SiP biosensors.

Table 8 summarizes aptamer-functionalized SiP biosensors that have been demonstrated in the literature. In all of these aptamer-based SiP sensors, label-free sensing formats were used. Park et al. [24] demonstrated IgE and thrombin detection on an aptamer-functionalized silicon microring resonator and demonstrated reproducible surface regenerations for up to 10 cycles after IgE and thrombin binding using a NaOH solution. Byeon and Bailey [174] compared thrombin binding on aptamer-functionalized silicon microring resonators to antibody-functionalized resonators and demonstrated aptamer-functionalized surface regeneration using proteinase K. The authors found that the aptamer had a lower affinity toward thrombin (KD = 8.2 nM) compared to the antibody (KD = 3.3 nM), suggesting a poorer limit of detection for sensing applications relying on steady-state binding. However, the aptamer-functionalized sensors demonstrated faster thrombin-binding kinetics, which could produce a theoretically lower LoD for the aptamer-based sensor in applications that leverage binding kinetics measurements to generate a calibration curve (e.g., by linearly fitting the initial slope of the binding kinetics curve to quantify analyte concentration [161,184]). Christenson et al. [164] presented a comparative study in which aptamer- and antibody-functionalized Photonic Crystal-Total Internal Reflection biosensors were investigated for the detection of cardiac troponin I. The aptamer- and antibody-functionalized sensors achieved detection limits of 0.1 ng/mL and 0.01 ng/mL, respectively. While the aptamer-functionalized sensor demonstrated poorer sensitivity, both sensors achieved clinically relevant limits of detection, and the aptamer sensor was lower cost and did not require refrigeration during storage. Chalyan et al. [25] compared the performance of aptamer- and Fab-functionalized silicon oxynitride microring resonator biosensors for the detection of Aflatoxin M1. A limit of detection of 5 nM was reported for both the aptamer- and Fab-functionalized sensors, though the Fab-functionalized sensor was deemed preferable due to its superior reproducibility. Both Chalyan et al. [25] and Guider et al. [185] reported effective sensor regeneration after Aflatoxin M1 binding using glycine solutions.

Table 8.

Demonstrations of SiP biosensors using DNA aptamers as the biorecognition element and their sensing performance. All demonstrations tabulated here used label-free assay formats.

While aptamers offer notable advantages over antibodies in the context of POC diagnostics, they still face challenges such as degradation in biological fluids, low SELEX success rates, lower availability, and highly variable costs. Firstly, aptamers, especially RNA aptamers, are susceptible to nuclease degradation in biological fluids [100,102]. For example, in human serum, the half-life of an unmodified aptamer is about one minute [180]. This limits the use of unmodified aptamers as bioreceptors in diagnostic devices using blood or serum samples. RNA aptamers are also more susceptible to hydrolysis than DNA aptamers at pH >6 [183]. However, chemical modifications, such as the incorporation of 2′-fluoro or 2′-amino-modified nucleotides, are often introduced to aptamers either at the beginning of SELEX or during chemical synthesis to improve their resistance to nuclease degradation [89,186]. These types of modifications can increase an aptamer’s half-life in biological fluids to multiple days [180], but modifications introduced during and after SELEX can add complexity to the SELEX process or change the folding structure and binding properties of the aptamer, respectively [89]. As such, careful optimization is required to achieve effective nuclease resistance without compromising binding performance.

Next, the success rate of SELEX aptamer generation is lower than in vivo antibody generation, likely due to the lower structural diversity of nucleotides compared to amino acids and the small size of aptamers [101,180]. This increases the time and resources required to optimize aptamers for new targets. However, this <30% SELEX success rate could be improved through the use of specialized SELEX technology variants, personalized protocols, optimized oligonucleotide libraries, and quality control measures [180,187]. The target-binding performance of an aptamer depends on its structural conformation, which can be influenced by pH, ionic strength, and temperature [180]. Therefore, to ensure predictable binding, aptamer selection must be carried out in buffer systems similar to those used in the final application. However, this may also mean that an aptamer that performs well in solutions of a purified target in buffer may not perform as well in complex biological samples. Lastly, aptamers lack the type of extensive commercial infrastructure and investment seen in the antibody market and usually must be custom-synthesized by a handful of companies [89]. A summary of the key advantages and limitations of aptamers as bioreceptors is provided in Table 9.

Table 9.

Advantages and limitations of aptamers as bioreceptors.

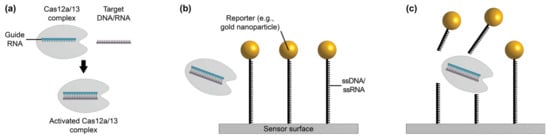

2.3. Nucleic Acid Probes (Hybridization-Based Sensing)

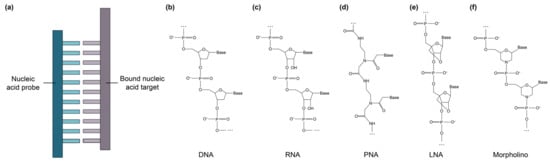

Short, single-stranded nucleic acid probes have been widely used for the detection of nucleic acid targets via hybridization-based SiP sensing (Figure 4) [80,107,188]. Both ssDNA and RNA sequences can be immobilized on a biosensor surface, where they bind complementary nucleic acid target sequences through hydrogen bond formation, yielding DNA-DNA, DNA-RNA, or RNA-RNA duplexes [33,70,189]. Such biosensors are often called genosensors [81]. Compared to aptamers, which can be designed to bind many different types of target molecules, nucleic acid probes can only bind other nucleic acids [30]. Additionally, the function of nucleic acid probes depends primarily on their nucleotide sequence, not on their three dimensional structure: once the target gene sequence is known, the complementary probe can be designed directly [30]. This means that nucleic acid probes can be designed against a new target very quickly compared to antibodies and aptamers. Short nucleic acid probes of 100 nucleotides or less can be synthesized using well-characterized phosphoramidite chemistry [103,104,111,112]. This synthetic method of nucleic acid synthesis is highly reproducible, allows for the incorporation of functional groups like thiols and amines to aid in probe immobilization on solid substrates, and is typically low-cost [81,111,112,190]. Another key advantage of nucleic acid probe-based biosensors is that they can be thermally or chemically regenerated with good reproducibility between sensing cycles [80].

Figure 4.

(a) Illustration of nucleic acid bioreceptor and bound nucleic acid target. Comparisons of the chemical structures of different nucleic acid subtypes, including (b) DNA, (c) RNA, (d) PNA, (e) LNA, and (f) morpholino, shown as line structures informed by Refs. [73,191].

In addition to conventional ssDNA and RNA probes, synthetic nucleic acid analogues with functional chemical modifications to improve binding performance and biostability have recently been explored for biosensing applications. These include peptide nucleic acids (PNAs), locked nucleic acids (LNAs), and morpholinos [23,30,73,81,110,115,116,117,191,192]. PNAs (Figure 4d) are synthetic DNA mimics that can hybridize to complementary DNA and RNA, but have a backbone consisting of N-(2-aminoethyl)-glycine units linked by peptide bonds, rather than the sugar-phosphate backbone usually found in DNA [81]. Unlike natural nucleic acids, PNAs are uncharged, giving them improved hybridization stability [73]. Their hybridization stability is also impacted to a greater extent by single base mismatches than DNA-DNA hybridization, making PNAs more selective than DNA probes and a good choice for detecting single nucleotide polymorphisms [193]. PNAs also exhibit ionic insensitivity and improved pH, thermal, and enzymatic stability [73]. LNAs (Figure 4e) are another class of synthetic DNA mimics in which the ribose is locked in the 3′-endo conformation, resulting in reduced conformational flexibility, improved biostability, and enhanced binding affinity toward the target sequence [30,81,101]. Morpholinos (Figure 4f) are synthetic nucleic acid analogues in which the sugar-phosphate backbone is replaced by alternating morpholine rings, connected by phosphoramidite groups [110]. Morpholinos are uncharged and possess many of the same characteristics as PNAs, but morpholinos exhibit improved solubility, poorer stability at low pH, and improved flexibility of synthesis regarding sequence length, offering the opportunity to bind longer DNA and RNA target sequences, compared to PNAs [108]. Table 10 provides a comparison between these nucleic acid subtypes and benchmarks them against functionalization performance criteria for SiP biosensing.

Table 10.

Comparison of nucleic acid subtypes as bioreceptors for SiP biosensors.

Numerous SiP sensing platforms have been demonstrated in the literature using nucleic acids or nucleic acid analogues as biorecognition elements for the detection of ssDNA and RNA biomarkers with applications in the detection of cancer [23,192,194,195,196,197] and bacteria [198,199] (Table 11). Often, a label-free assay format is used on these sensing platforms. For example, Sepúlveda et al. [200] demonstrated label-free detection of short ssDNA targets down to 300 pM using a silicon nitride Mach-Zehnder interferometer sensor functionalized with ssDNA probes, while Shin et al. [197] demonstrated specific and label-free detection of longer ssDNA targets (>100 nucleotides) on ssDNA-functionalized silicon microring resonators down to 400 fmol, which corresponds to 16 µL of a 25 nM sample. A silicon nitride slot waveguide Mach-Zehnder interferometer functionalized with methylated ssDNA probes was demonstrated by Liu et al. [192] to quantify the methylation density of a DNA-based cancer biomarker at sample concentrations down to 1 fmol/µL or 1 nM. Nucleic acid-functionalized SiP sensors have also been used for microRNA detection, as demonstrated by Qavi and Bailey [194], who used a ssDNA-functionalized silicon MRR sensor for the rapid and label-free quantification of microRNAs. In this work, the authors reported a limit of detection of 150 fmol, which represented the minimum quantity of microRNA that could be reasonably detected in solution with the reported biosensor. Based on the supporting information provided for this work, this detection limit corresponded to a 75 µL analysis volume of 2 nM microRNA. Synthetic nucleic acid analogues have been demonstrated as receptors and targets for SiP sensors. Yousuf et al. [110] recently demonstrated the detection of short ssDNA targets on morpholino-functionalized suspended silicon microrings down to 250 pM, while Hu et al. [201] demonstrated PNA detection using ssDNA-functionalized planar SiP sensors.

Table 11.

Demonstrations of SiP biosensors using nucleic acid probes as the biorecognition element and their sensing performance.

In contrast to these label-free methods, Qavi et al. [109] amplified the detection of microRNA on a ssDNA-functionalized silicon microring resonator sensor using S9.6 anti-DNA:RNA antibodies. The S9.6 antibody selectively binds to DNA-RNA heteroduplexes and was shown here to effectively amplify the signal after microRNA hybridization, achieving a limit of detection of 350 amol, corresponding to 35 µL of a 10 pM microRNA sample. This was a 3-fold improvement compared to label-free microRNA detection on the same sensor. This work also demonstrated preliminary results demonstrating that LNA probes could be used to capture the microRNA targets, followed by successful, albeit slightly less effective, amplification with the S9.6 antibody. Kindt and Bailey [196] improved the limit of detection of a ssDNA-functionalized silicon microring resonator sensor for the detection of mRNA using streptavidin-coated beads. This bead-based amplification improved the sensor’s limit of detection to 512 amol, compared to 32 fmol without bead-based amplification.

To date, most nucleic acid hybridization-based biosensors have been demonstrated for the detection of short target sequences due to the tendency of longer sequences to fold and obtain secondary structures [70,198]. These secondary structures significantly slow down binding kinetics, thus increasing sensing times. This challenge can be mitigated by pre-treating the targets via thermal denaturation, fragmentation, or the use of short nucleic acid chaperones which disrupt the nucleic acid target’s secondary structure [196,198]. In one work [198], the folded structures of long transfer-messenger RNA (tmRNA) targets were modified using one of the three following strategies prior to detection: (1) chemical fragmentation, (2) thermal denaturation, or (3) thermal denaturation in the presence of chaperone probes. Subsequently, the treated tmRNA targets were detected in a label-free format on ssDNA-functionalized silicon microring resonators. Chemical fragmentation was found to be the most effective RNA pre-treatment strategy for increasing the binding kinetics and magnitude of the sensor response. In another work [196], short DNA chaperone molecules were used to disrupt the secondary structure of full length mRNA transcripts prior to detection on ssDNA-functionalized silicon microring resonators. This effectively improved the sensing assay’s binding kinetics.

Indeed, the greatest limitation of nucleic acid-based bioreceptors is their limited applicability: they are only suitable for applications requiring nucleic acid targets [30]. Further, nucleic acid targets usually require significant sample preparation prior to detection [188]. For DNA targets, the sample usually must undergo fragmentation to ensure that the target sequence is accessible to the capture probes, followed by denaturation to yield single-stranded sequences. Depending on the abundance of the target, it may also require amplification through PCR or isothermal strategies prior to detection [188,195,199]. For RNA targets, sample preparation may be simpler, but still typically requires a fragmentation step [188]. Finally, DNA and RNA carry an inherent negative charge, making them susceptible to non-specific binding due to electrostatic interactions with non-target molecules [30]. This also poses challenges regarding nucleic acid probe immobilization. For example, nucleic acid probes are repelled by an unmodified SiP sensor’s negatively charged native oxide surface, which means that the SiP surface must be modified with a cationic film should passive adsorption be used for probe immobilization [204]. When covalent immobilization strategies are used, this negative charge increases steric hindrance between adjacent nucleic acid probes, which affects the maximum density of probes that can be immobilized on the sensor surface and the number of available binding sites for targets, potentially limiting sensor sensitivity [201]. This effect, however, can be reduced by employing in situ synthesis of nucleic acid probes on the SiP surface. Hu et al. [201] demonstrated a greater than 5-fold increase in ssDNA probe surface coverage and a greater than 5-fold increase in detection sensitivity for SiP microring resonators and photonic crystal sensors when functionalized via in situ probe synthesis, compared to the covalent immobilization of full ssDNA sequences. Conversely, if the immobilization strategy is optimized and the density of immobilized nucleic probes on the surface becomes too high, hybridization of targets to the surface-bound probes is hindered by steric crowding and electrostatic repulsion, also limiting sensor sensitivity [71]. As such, careful tuning of the spacing between immobilized probes is required for optimal performance. Some of these limitations can be mitigated by the use of uncharged synthetic DNA analogues including PNAs or morpholinos [30]. For example, in a study investigating DNA- and PNA-functionalized electrochemical sensors for the capture of DNA targets, the PNA-functionalized sensors exhibited stronger target capture and demonstrated optimal sensing performance at higher probe surface density than the DNA-functionalized sensors, likely due to reduced steric and electrostatic effects [205]. This contributed, in part, to a greater sensitivity for the PNA-functionalized sensor, which had a very wide dynamic range from pM to µM and a LoD that was 370 times lower than that achieved when using DNA probes. However, the lack of electrostatic repulsion between uncharged DNA analogues can lead to local clustering on the sensor surface, creating a heterogeneous layer of these uncharged probes, thus hindering the reproducibility of the functionalization strategy [193,206]. A summary of the key advantages and limitations of nucleic acid probes for SiP biosensing is provided in Table 12.

Table 12.

Advantages and limitations of nucleic acid probes as bioreceptors.

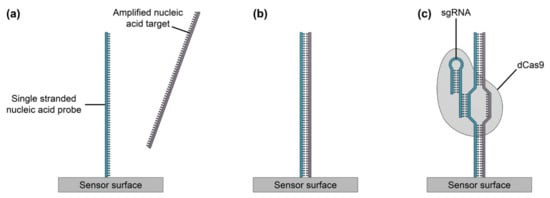

2.4. Molecularly Imprinted Polymers (MIPs)

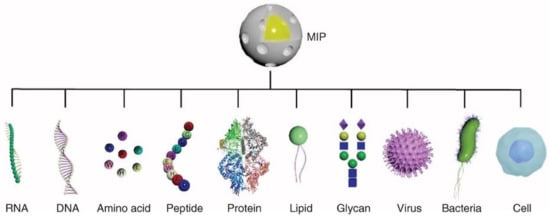

Molecularly Imprinted Polymers (MIPs) are a type of label-free synthetic receptor for binding a broad spectrum of analytes from small molecules and viruses to larger proteins and cell membrane structures (Figure 5) [72]. The first imprinted polymers were developed in the early 1990s and demonstrated the ability to change impedance in response to target binding. Later, more developed MIP films exhibited changes in refractive index upon binding, making them ideal for optical sensors.

Figure 5.

MIPs can be templated with an array of targets including: RNA, DNA, amino acids, peptides, proteins, lipids, glycans, viruses, and bacterial or cell epitopes. Reproduced from Ref. [207] in accordance with the Creative Commons Attribution 4.0 International license (CC BY 4.0).

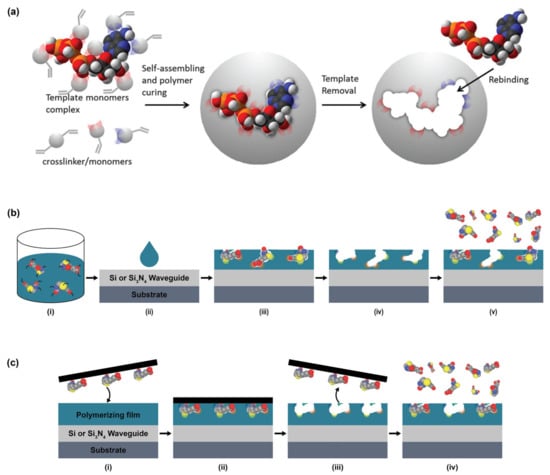

Several strategies for MIP preparation on SiP platforms and representative surfaces have been summarized in Table 13. MIPs are created via template assisted synthesis where an analyte is cured within a polymer making a 3D impression in the form of a binding pocket (Figure 6a) [119,208]. There are two main methods of MIP polymerization or “templating” for optical sensors: solution based (Figure 6b) or surface stamping (Figure 6c) [119,209]. In solution-based MIPs, a target, or template, is solvated in organic solvents with precursors, initiators, and monomers [72]. Smaller molecules are primarily used directly as a template, whereas larger targets (proteins, peptides, etc.) use a smaller binding epitope for imprinting. These formulations are specific to the template and form complexes of reversible covalent or noncovalent interactions with the template’s chemical structure. Next the solution is deposited on a surface and cured by ultraviolet (UV) or thermal polymerization. Solution-based MIPs can be templated onto many shapes such as coatings, thin films, and nanoparticles [210]. This is advantageous since they can conform to many different fiber and waveguide topologies. MIP films can be grown on a variety of photonic sensor designs, dipped on optical fibers, or developed in solution on microspheres [211]. Following MIP synthesis, the template molecules must be extracted, which is often achieved by washing or soaking in solution [211,212,213,214,215] or by plasma-treatment [211], though physically assisted solvent extraction (e.g., microwave- or ultrasound-assisted extraction) and extraction using supercritical or subcritical fluids have also been used [216]. This produces a distribution of exposed binding site geometries due to the template’s random orientation on the polymer surface (Figure 6b). Surface stamping using support molds was the first method of casting [209,217]. Template molecules are crosslinked to a surface mold and pressed onto the polymer surface over the sensor prior to curing. Removal of the mold leaves imprinted binding sites stamped on the surface of the polymer. This method produces more regular pockets in comparison to solution-based MIPs due to the added control over the depth of imprinted binding sites and the opportunity to control template orientation on the surface mold (Figure 6c) [218].

Table 13.

Strategies demonstrated for the preparation of MIPs on SiP sensors and representative surfaces.

Figure 6.

Illustration of MIP templating approaches. (a) MIP templating begins with a template mixed with polymer precursors followed by curing and the template removal. (b,c) Illustration of molecularly imprinted polymer (MIP) showing the random and oriented nature of template orientation on the surface of solution based (b) and stamped (c) MIPs, respectively. In solution-based MIP preparation (b): templates are first solvated in organic solvents with precursors, initiators, and functional monomers (i), followed by deposition on the sensor surface (ii), curing (iii), and template extraction (iv), after which the MIP can be used for target capture (v). Note that the small pieces of color left behind in the binding sites after template extraction, as seen in (iv,v), represent sites where the functional monomers formed non-covalent or covalent bonds with the template. In surface stamping based MIP preparation (c): templates are immobilized on a surface mold (i) and pressed into a polymer film on the sensor surface (i,ii) prior to curing. After curing, the surface mold is removed (iii), leaving imprinted binding sites on the sensor surface, which can be subsequently used for target capture (iv). Part (a) is reproduced with permission from Ref. [210]. Copyright 2016, American Chemical Society.

These methods produce specific binding pockets on the polymer surface that match the three-dimensional molecular structure of the template. Targets primarily bind via hydrogen bonding, electrostatic interactions, and Van der Waals forces. Reversible covalent bonding is less common since it is dependent on the template’s molecular structure, available specialized monomers, and more complex synthesis [220]. Direct adsorption of analytes into the binding pockets produces a change in refractive index or electrochemical (impedance) signal that can be read out by optical and amperometric sensors, respectively.

MIPs are considered an alternative to antibodies since they are highly sensitive, reversible and have both chemical and mechanical stability. They are synthetic making them robust, scalable, low-cost, and shelf-stable [118]. They have been shown to be stable over months in a large temperature range (up to 150 °C) with over 50 adsorption/desorption cycles in organic solvents, acids, and bases [221]. Divinylbenzene MIP bases are twice as robust (up to 100 cycles) in comparison to methacrylate- or acrylamide-based polymers over a larger pH range. Although MIPs are an excellent synthetic method of producing a non-refrigerated product with a long shelf life, there are several limitations to the technology. Currently, synthesis is developed for one target at a time and requires computational studies to downselect polymer precursors and benchtop chemistry to optimize formulation. Computational studies include quantum mechanics/molecular mechanics (QM/MM) calculations (ab initio, molecular dynamics, etc.) between possible precursors and the template molecule [222]. These calculations determine which reagents interact with the chemical structure of the template molecule. Then, MIPs are formulated based on the set and ratios of precursors are empirically tested. The final MIP formulation is selected to maximize sensitivity and specificity, based on these empirical data.

MIPs have limited specificity in complex solutions due to the imprinted nature of the polymers, which include an array of heterogeneous binding pocket orientations [30]. Smaller or like molecules can fill the binding pockets, producing a background signal or affecting the MIP’s affinity toward its target [223]. Formulations thus need to be thoroughly optimized for the template (as described above) and tested against non-imprinted polymers (NIPs) [224]. NIPs are the same composition as the MIPs, only formulated without the template. They are used as a control to determine the sensitivity of the MIPs against nonspecific adsorption. Further studies testing MIPs in real bioanalyte samples are essential to validate their specificity [30]. A summary of the advantages and limitations of MIPs as bioreceptors is provided in Table 14.

Table 14.

Advantages and limitations of MIPs as bioreceptors.

The use of refractive index sensing with MIPs in silicon photonics (Table 15) is limited, although they have been well demonstrated with SPR-based sensors [209]. MIPs can be drop-cast, spray-coated, spin-coated and inkjet printed on the sensor surface. Chen et al. [212] demonstrated thermally polymerized, drop-cast ultrathin film MIPs on a passive SOI microring resonator sensor for testosterone. This method is highly sensitive for sensing ultralow concentrations with a sensitivity of 4.803 nm/(ng·mL). First the template solution is premixed to promote self-assembly between the template and monomers specific to its chemical structure. This produces a pre-polymerized layer surrounding the template in solution that is further complexed with the addition of carboxyl-terminated monomers. This matrix is then drop-cast on the sensor’s surface and thermally treated for 12 h. The combination of the pre-polymerized matrix and dilute solution results in an ultrathin assembled monolayer of MIPs on the surface with a limit of detection of 48.7 pg/mL. Multiple cycles of MIP regeneration (using a 1:1 acetic acid-ethanol rinse) and sensing with a solution of 1 ng/mL testosterone were tested on this platform to assess reproducibility. There was a drift in the sensor response and corresponding decrease in sensitivity as the number of regenerations increased, which the authors attributed to damage to the MIP during testing. Selectivity was also assessed by introducing the small molecule toxin, microcystin-LR, to the sensor, which produced a negligible response.

Table 15.

Demonstrations of SiP biosensors using MIPs as the biorecognition element and their sensing performance.

Photopolymerization can be achieved all at once by direct UV polymerization or in stages by pre-polymerizing in a dilute crosslinking solution followed by the addition of a UV initiator for a final cure. Xie et al. [219] used this process with cascaded microring resonators for sensing progesterone. They used an SU-8 cladding and a slightly larger ring diameter to match the free spectral range of the reference ring to the MIP-coated sensing ring. The MIP is prepared by pre-polymerizing acetic and methacrylic acid with progesterone for 3 h followed by adding UV crosslinkers in a specialized tank for UV curing. This produces a thin self-assembled film on the sensor surface. Their results showed a limit of detection of 83.5 fg/mL which is approximately 3 orders of magnitude lower than enzyme-linked immunosorbent assays (ELISA). The sensor shows good selectivity to progesterone with little to no response with testosterone and the NIP. Eisner et al. [213] used MIP sol-gels to compare airbrush versus electrospray ionization deposition techniques. These sol-gels are formed by hydrolysis and polycondensation of a colloidal liquid into a gel at low temperatures. The colloid includes metal oxides, salts, or alkoxides suspended in solvents. This ceramic-based MIP was designed for the detection of trinitrotoluene (TNT) vapor and was coated on passive silicon racetrack resonators with thicknesses of 500–700 nm to minimize resonant wavelength shift artifacts due to changes in the bulk refractive index surrounding the MIP. The results showed a ~10× increase in response and sensitivity in the electrospray MIP in comparison to airbrushing. The MIP-coated sensors showed a nonspecific response to other nitro-based explosives (2,4-dinitrotoluene (DNT) and 1,3-dinitrobenzene (DNB)); however, the device’s sensitivity was about an order of magnitude greater for TNT than for DNT and DNB.

Hydrogel-based MIP thin films are less successful since they expand and contract based on water content and salinity, producing unwanted effects. Reddy et al. [225] sensed hemoglobin on silicon oxynitride waveguides for dual polarization interferometry. The gels initially increased in thickness and mass upon injection of a control solution, but the response was transient suggesting adsorption and desorption of the control on the hydrogel surface. In contrast, the target, hemoglobin, produced a continuous signal and remained selective in solutions containing <1% pooled bovine serum.

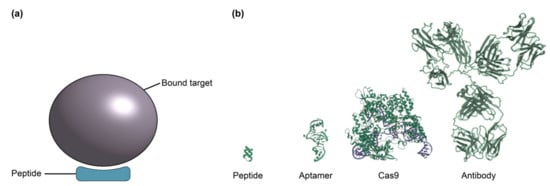

2.5. Peptides and Protein-Catalyzed Capture Agents

Synthetic and native peptides are an attractive method of capture for chemical and biological targets in SiP due to their small size in comparison to antibodies, aptamers, and other larger components (Figure 7) [226,227,228]. Peptides are differentiated from proteins by their size (2–70 amino acids) and flexible structure. There are two main types of peptides for attachment: native and synthetic [120]. Native peptides are small binding epitopes or ligands found in nature that selectively bind to a specific site on the target of interest. They are primarily recombinant and produced by cloning the peptide in an organism. The peptide sequence is inserted into a plasmid, expressed in bacteria, insect or mammalian cells and purified for processing [229].

Figure 7.

(a) Illustration of peptide bound target. (b) Comparison of peptide, aptamer, Cas9 enzyme and antibody relative sizes, informed by protein data bank crystal structures 2AU4, 4OO8 and 1IGY [226,227,228]. Peptides are smaller than aptamers, antibodies, and many other bioreceptor classes discussed here, offering potential improvement in SiP biosensor sensitivity by bringing the binding interaction into a region of the evanescent field with higher field intensity.

Synthetic peptides are chemically synthesized using solid phase peptide synthesis (SPPS) or solution-based synthesis (SPS) [230]. Synthetic peptides are made using D-amino acids instead of the more naturally occurring L-amino acids seen in native peptides. D- and L-amino acids are enantiomers, or the same amino acid sequence with a mirror image structure. This change in configuration makes D-amino acids less susceptible to enzyme degradation without changing their biological function. SPS was the first synthesis method, developed in 1901, where a chain of amino acids is grown one residue at a time in solution [231]. SPPS followed in 1963 and uses a solid support for anchoring the peptide chain that enables washing steps between the addition of successive amino acids. Both methods start from a primary amino acid using selective protecting groups (FMOC, BOC) where successive amino acids are added in a step-by-step fashion to form a chain [232]. Generally, SPPS is the most common method since it is a well-established commercially available process and contributed to the Nobel Prize in Chemistry in 1984 [231]. Its use of a support and wash cycles results in a higher production of correctly formed peptides, removes reaction byproducts, as well as decreases the tendency of aggregation and incomplete reactions. However, SPS is still used since the lack of a support enables more challenging structures (cyclic), nonstandard components, and a larger array of coupling conditions (acidic, oxidative) [233].

Protein-catalyzed capture (PCC) agents are specialized, short (20 amino acid), synthetic peptides optimized to capture a target of interest [234]. They are considered “synthetic antibodies” due to their comparable high specificity and affinity for a target without the temperature sensitivity or stability issues common in enzymes, aptamers, and antibodies [235]. PCCs are highly selective since they are computationally designed based on the binding sites of proteins and other targets. Screening of chemical peptide libraries, such as one-bead one-compound (OBOC), identifies peptide components with high specificity and selectivity to the target of interest [236,237]. Due to this design, their affinity can be tailored to the specific dynamic range needed for sensing. Agnew et al. [234] evaluated the epitope binding sites and affinity of PCCs to those of monoclonal antibodies of the same target using principal component analysis. Their analysis covered 14 different protein targets as well as considered their physicochemical properties and molecular binding interactions. The results showed that PCCs are able to match and surpass antibody affinities with the majority of the binding driven by electrostatic interactions and hydrogen bonding.

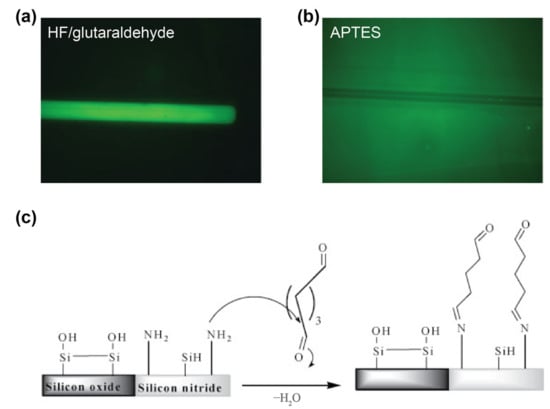

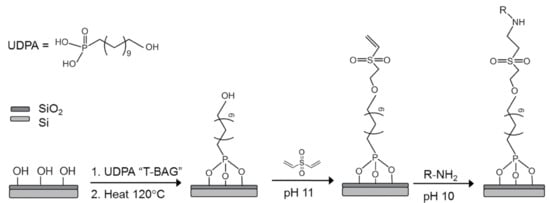

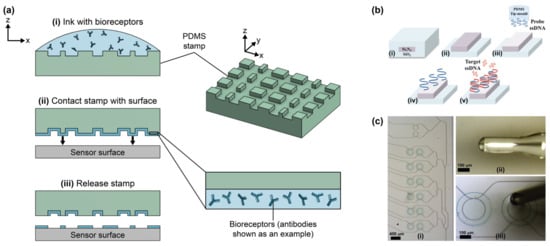

In the literature, peptides and PCCs have been demonstrated as bioreceptors against antibodies [238], cancer cells [239], viral proteins [91], and streptavidin [240] on SiP platforms (Table 16). Angelopoulou et al. compared recombinant SARS-CoV-2 spike protein peptide on silicon nitride MZI sensors to conventional ELISA assays [238]. Silicon nitride MZI sensors were crosslinked via glutaraldehyde to the spike peptide against SARS-CoV-2 in a manner that selectively attached the peptides to only the silicon nitride waveguides and not the surrounding silicon dioxide. The reference was blocked with bovine serum albumin as a control for non-specific binding. The label-free peptide MZI showed a 80 ng/mL limit of detection and correlated with the ELISA results of 37 diluted serum samples. The addition of an antibody as a label improved the limit of detection to 20 ng/mL.

Table 16.

Demonstrations of SiP biosensors using peptides as the biorecognition element and their sensing performance. All tabulated demonstrations used a label-free assay format.

Martucci et al. [239] used idiotype peptides to determine the surface capture efficiency of tumor cells on silicon surfaces. Idiotype peptides are ligands from the binding site of receptors on the surface of immune cells that bind to antigens on the surface of lymphoma cells. They are specific to a subset of B-cells and can specifically identify lymphoma cells. The authors functionalized the surface of porous silicon microcavities by submerging in a 5% amino-terminated silane solution, crosslinking with a double N-succinimidyl terminated linker to crosslink to a primary amine on the peptide. The authors moved away from crosslinking antibodies to silicon surfaces since antibodies are known to have problems assembling monolayers in the same orientation due to their large size and multiple crosslinking sites [241,242]. Their results showed that the idiotype peptide covered 85% of the sensor’s surface with a uniform, oriented layer and had a detection efficiency of 8.5 × 10−3 cells/µm2.

PCCs are starting to become a more well-known method for biological sensing using silicon photonics due to their good stability and long shelf life. They are temperature stable, showing little to no change in affinity after heating to 90 °C, and resistance against protease degradation [91,243]. Layouni et al. [91] showed a PCC specific to Chikungunya virus E2 protein on porous silicon microcavities and with positive detection in response to 1 µM E2 viral protein. In addition, their results showed no statistical significance in sensor response between previously heated (90 °C, 1 h) and unheated PCCs. This stability was further confirmed by PCCs for vascular endothelial growth factor maintaining 81% of their affinity after 1 h using standard ELISA assays. Another work with porous silicon microcavities for PCC sensing of streptavidin showed detection of 5 µM streptavidin using PCCs immobilized via click chemistry crosslinking [240]. A summary of the advantages and limitations of peptides and PCCs as bioreceptors is provided in Table 17.

Table 17.

Advantages and limitations of peptides and PCCs as bioreceptors.

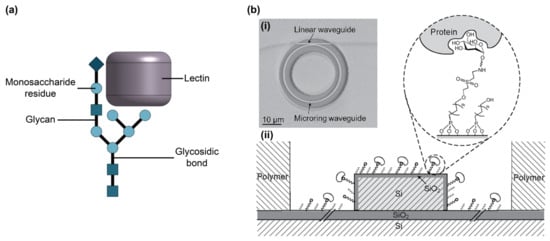

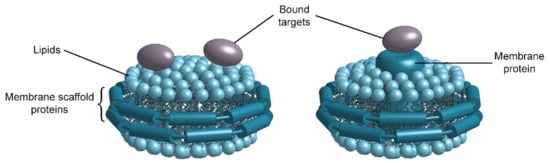

2.6. Glycans and Lectins

Both glycans and lectins have been employed as biosensor recognition elements on SiP devices (Figure 8). Glycans are carbohydrates which are covalently conjugated to proteins (glycoproteins) and lipids (glycolipids) [122,244]. In biological systems, glycoconjugates are typically found on cell surfaces, in the extracellular matrix, or in cellular secretions, and participate in intermolecular and cell–cell recognition events. Glycans consist of monosaccharides linked together in linear or branched structures by glycosidic bonds [244]. The diversity of their constituent monosaccharide residues and the position and configuration of their glycosidic bonds give glycans significant structural variability [128,244]. Lectins are non-immune proteins that recognize and bind glycoconjugates and non-conjugated glycans via carbohydrate recognition domains (CRD) [121,122,134]. Specific lectin-glycan binding is affinity-based and facilitated by hydrogen bonding, metal coordination, van der Waals and hydrophobic interactions [121]. The CRDs of lectins may target monosaccharide residues or they may show poor affinity toward monosaccharides and, instead, preferentially bind oligosaccharides based on their glycosidic linkages [121,122,244]. The affinity of individual CRD-glycan interactions are weak, with dissociation constants in the micromolar to millimolar range [121,122]. Multivalent binding between lectins and glycans, however, allows for higher-avidity interactions, with dissociation constants that are multiple orders of magnitude lower [122,123]. Namely, some lectins possess multiple CRDs that bind to multiple monosaccharide residues on a polysaccharide or to multiple proximal carbohydrates immobilized on a densely-coated solid substrate [121,122,123]; moreover, lectins can recognize homogeneous carbohydrate-coated surfaces or mixed glycan patches. Conversely, in the case of lectins with only one CRD, higher-avidity binding may be achieved by the clustering of many lectin molecules [122]. While many lectins have been identified and their glycan-binding characteristics have been characterized, these only encompass a small fraction of the diverse set of glycans that are found in nature [123]. Compared to proteins and nucleic acids, the functional study of glycans lags far behind [129].

Figure 8.

(a) Illustration of a glycan and bound lectin. (b) (i) SEM image of a microring resonator and (ii) cross-section of microring resonator waveguide using glycans as bioreceptors. The glycans are immobilized using an organophosphonate linking strategy and used for lectin (protein) capture. Part (b) is adapted with permission from Ref. [126]. Copyright 2012 American Chemical Society.

Glycans can be immobilized easily on biosensor surfaces in an oriented manner; for example, the terminal amine group of a glycan derivative can be targeted for site-directed covalent amine coupling to a surface [244]. In comparison, lectins possess more complex structures, making oriented immobilization more challenging.

Homogeneous glycan samples for biosensing applications cannot be synthesized easily in large quantities using biological systems, making chemical and chemoenzymatic synthesis the preferred routes of production for structurally defined glycans and glycoconjugates [127,245]. Multi-milligram quantities of polysaccharides up to 50 mers in length can be rapidly and reproducibly synthesized and optionally conjugated to nonglycan entities, like proteins, to yield glycoconjugates [127,128]. Nevertheless, chemical glycan synthesis is in its infancy and is inherently more challenging than oligonucleotide and oligopeptide synthesis because glycans are often highly branched and their biosynthesis is not template-driven [129]. Chemical glycan synthesis requires the modification of one monosaccharide hydroxyl group at a time in the presence of many others and the careful control of glycosidic linkage positions [127]. Currently, the synthesis of complex and highly branched glycan structures remains a major challenge [129].

Lectins may be purified from various organisms, though yields, especially for animal-derived lectins, are often too low for practical use [130]. Consequently, recombinant techniques are usually required for the production of lectins in multi-gram quantities [130]. Notably, anti-carbohydrate antibodies can be generated for glycan capture, but, due to the poor immunogenicity of carbohydrates, these antibodies typically have poor affinities toward their targets and limited versatility, making lectins preferable for carbohydrate detection [121]. In comparison to antibodies, the cost of lectin production is also lower. However, similarly to antibodies, the commercial synthesis of lectins is cell-based, and samples may vary in purity, properties, availability, and activity within and between vendors [121]. An overall comparison of glycans and lectins as bioreceptors for SiP biosensors is detailed in Table 18.

Table 18.

Comparison of glycans and lectins as bioreceptors for SiP biosensors.

Glycan-coupled SiP biosensors can be used for lectin capture and have applications in toxin [132] and virus [126] detection. For example, Ghasemi et al. [132] covalently immobilized GM1 ganglioside glycans on the surface of a TM mode silicon nitride microring resonator sensor for label-free detection of Cholera Toxin subunit B. The authors reported an absolute limit of detection of 400 ag, which corresponds to a surface coverage of 8 pg/mm2. Shang et al. [126] used an organophosphonate strategy to tether glycans and glycoproteins to silicon microring resonators for label-free detection of various lectins and norovirus-like particles. The authors reported a limit of detection of 250 ng/mL for the norovirus-like particles. The functionalized sensors also demonstrated excellent stability, retaining strong binding performance after one month of storage at ambient conditions and after multiple cycles of surface regenerations with high-salt and high- and low-pH solutions. Indeed, the good chemical stability of glycans, even at ambient and dry conditions for prolonged periods of time, is an attractive characteristic of glycan-conjugated biosensors [124,125]. Other publications have demonstrated glycan- and glycoconjugate-functionalized SiP sensors for the label-free detection of common lectins, with limits of detection down to the ng/mL range [133,246].

Given that various diseases, such as cancer, autoimmune diseases, infections, and chronic inflammatory diseases are associated with glycan aberrations, glycans are valuable disease biomarkers [121,129]. Lectin-coupled biosensors have, therefore, been proposed for glycan biomarker-based disease diagnosis [121,129]. While lectin-coupled SiP sensors have seldom been reported in the literature, Yaghoubi et al. [131] reported a lectin-coupled porous silicon sensor using reflectometric interference Fourier transform spectroscopy for label-free detection of bacteria. The authors functionalized sensors with three different lectins, concanavalin A (Con A), wheat germ agglutinin (WGA), and ulex europaeus agglutinin (UEA), and found that the Con A- and WGA-coupled sensors demonstrated the greatest binding affinities for E. coli and S. aureus, respectively and demonstrated limits of detection of approximately 103 cells/mL. Table 19 provides a summary of SiP biosensors demonstrated in the literature that use glycans or lectins as bioreceptors.

Table 19.

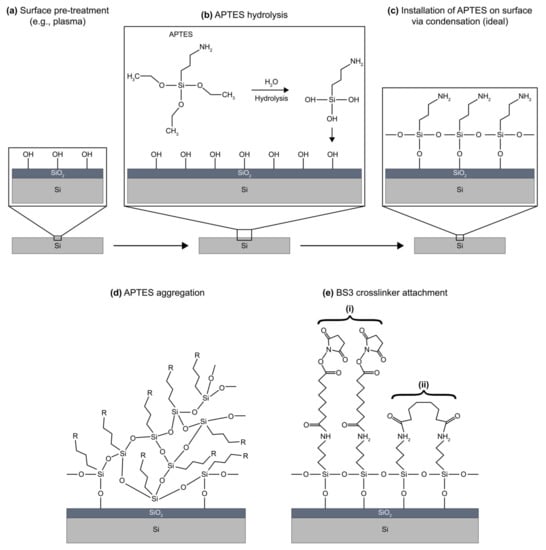

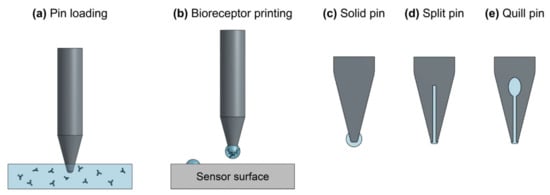

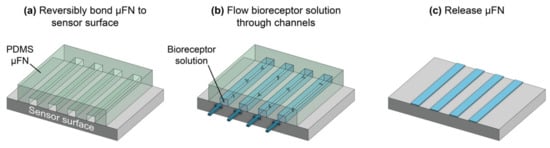

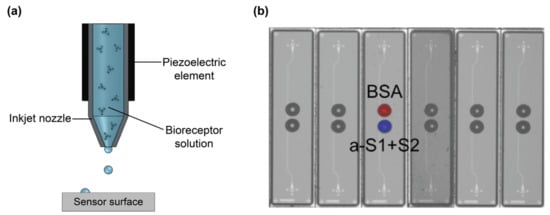

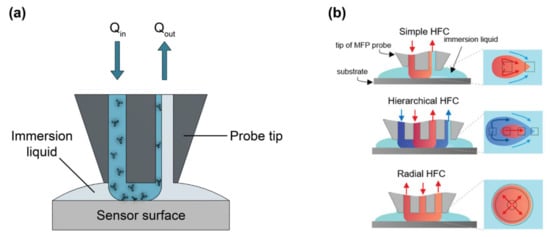

Demonstrations of SiP biosensors using glycans or lectins as the biorecognition element and their sensing performance. All tabulated demonstrations used label-free assay formats.