1. Introduction

Researchers working in the nanotechnology field aim to exploit the multitude of functional chemical and physical properties of nanostructures assembled in complex nanodevices [

1,

2,

3]. It is, nowadays, fully established that the chemical and physical properties of nanostructures are significantly different from the corresponding bulk materials due to effects arising from the atomic-scale behavior of matter: surface effects, energy quantization, interference effects, single electron effects, etc. [

1,

2,

3]. The successful development of nanotechnology is dependent on the full exploitation of the “nanofabrication” of shape-, size-, structure-designed nanostructures [

4,

5,

6]. These nanostructures can be, then, integrated into the final functional electronic, optical, magnetic, sensing devices. The problems connected to nanofabrication are the basic ones to be solved in order to reach the full development and exploitation of nanodevices. We can generally define nanofabrication as the collection of processes and methodologies, both physical and chemical, to assemble single atoms or molecules in a controlled manner (top-down approach) in a nanostructure with the desired size, shape, and structure or to “sculpt” (bottom-up approach) massive materials to obtain nanostructures or nanostructured materials with controlled sizes and geometries [

4,

5,

6]. However, to be industrially attractive, these processes and methodologies need to be simple, versatile, and cost-effective, with a high throughput.

In this sense, nowadays, the interaction processes of ions, electrons and photons with matter are, commonly, used both in the “bottom-up” and “top-down” approaches for the fabrication of nanostructures [

4,

5,

6]. These interaction processes lead to energy transfer to the irradiated material so as to induce, for example, the controlled self-assembly of the material atoms and molecules in nanostructures. In particular, in this review, we focus the attention on the use of the laser-matter interaction to structure matter at the nanoscale. In fact, recent developments in the area of fast and ultrafast pulsed lasers (on the range of nano-, pico-, femto-second) have drawn new and fascinating perspectives in the field of nanofabrication: a multitude of nanostructures can be, currently, produced by exploiting the interaction of lasers with thin films deposited on functional substrates allowing a fine control of shape, size, structure on the basis of the process parameters [

7,

8,

9,

10]. The main advantages of the laser-based nanofabrication approach include the ability to manipulate materials with dimensions from the micrometer range to the nanometer one, minimize thermal damage to the substrate and neighboring regions, non-contact nature, non-planar manipulations and the possibility of combining this technique with other fabrication steps such as surface chemical treatments [

7,

8,

9,

10,

11]. Moreover, a great advantage over other techniques is given by the versatility: by simply choosing the laser characteristics (energy density, wavelength, duration of the pulse, number of pulses), a wide “range” of nanostructures can be generated. Finally, by exploring the interference phenomena obtained from the simultaneous use of two or more lasers, complex periodic arrangements of nanostructures can be fabricated [

7,

8,

9,

10,

11].

Among the wide-range class of nanostructures, those of metallic nature are particularly interesting and promising [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22]: in fact, metal nanostructures are the subject of numerous studies for their unique electronic, catalytic, sensing, and optical properties [

12,

13,

14,

15]. The production of nanodevices exploiting the characteristics of metal nanostructures is, now, well-established and, in more recent years, this topic has received a new impetus from the plasmonic research field [

12,

13,

14,

15,

22,

23,

24,

25]. The study of the optical properties of noble metals (especially Au and Ag) represents, to date, a research field of particular interest, as a result of their potential applications in new photonic and sensing devices [

12,

13,

14,

15,

22,

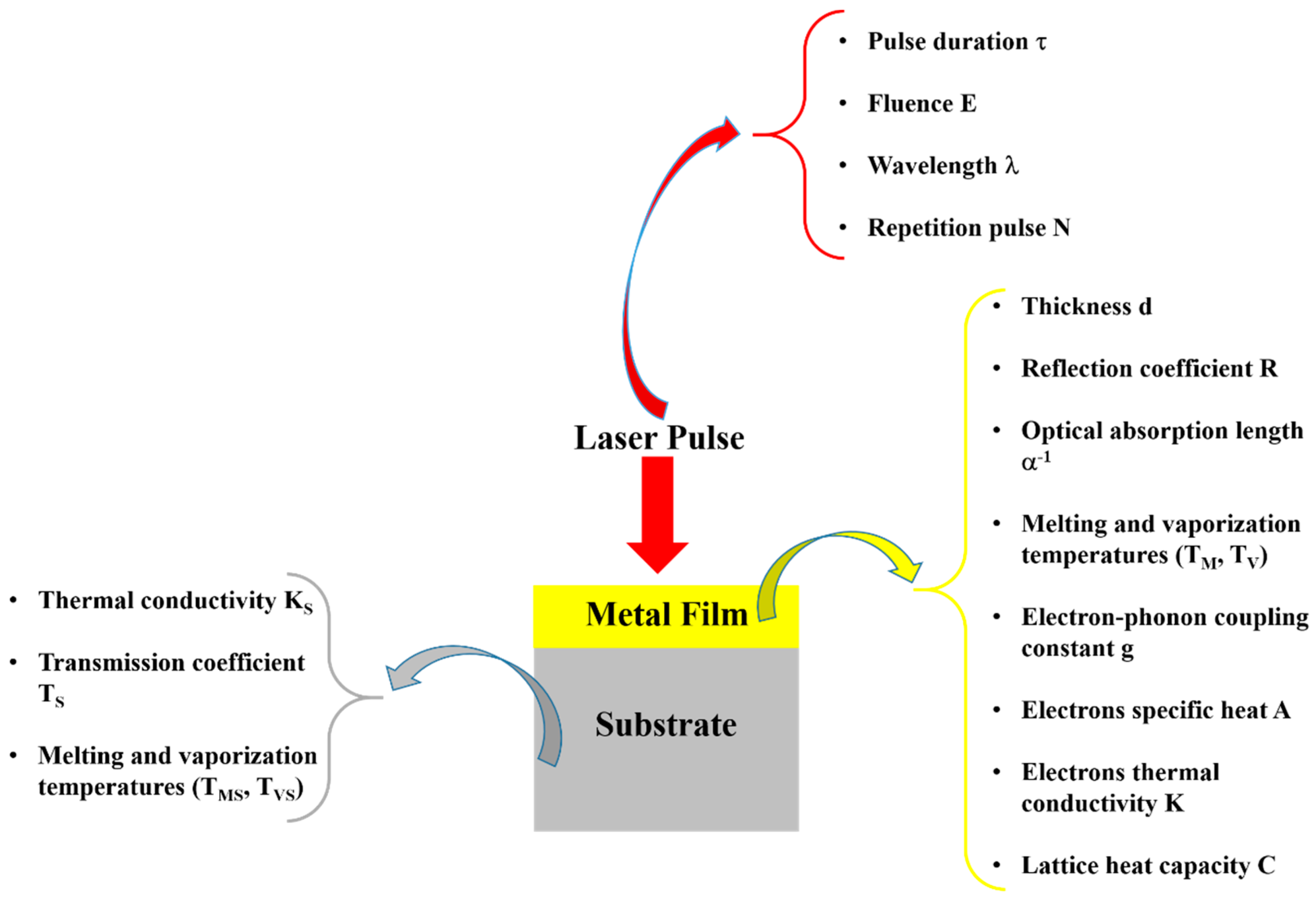

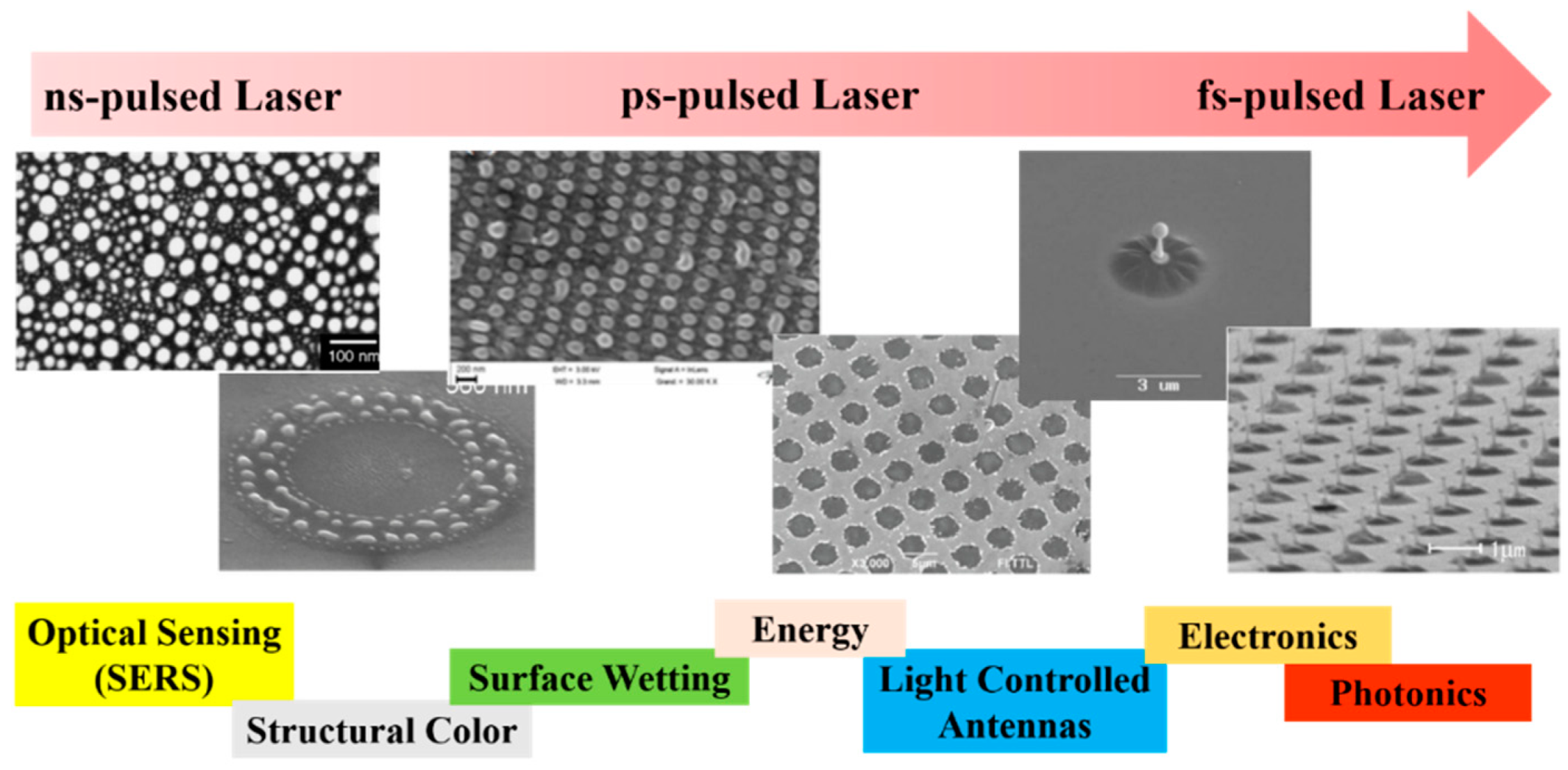

23]. In these applications, the size and shape of the metal nanostructures are crucial in determining the device’s optical response. Complex-morphology metal nanostructures are highly desirable in order to enhance the incident electromagnetic radiation by the so-called hot-spots effect, which is of paramount importance, for example, in Surface-Enhanced Raman Spectroscopy. So, the extraordinary interest in laser-based structuring approaches of thin metal films deposited on substrates arises from the possibility to produce large arrays of tunable surface-supported metal nanostructures. In this case, the size, shape and structure can be widely tunable by the properties of the nano-second, pico-second, and femto-second pulsed lasers used to process the starting metal films by the optical and thermal properties of the metal film and by the optical and thermal properties of the film supporting substrate; see

Figure 1.

Depending on the nature of the properties of the metal film, of the substrate, and of the type laser, metal nanoparticles [

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53], metal microbumps [

54], spatially ordered metal nanostructures such as spikes and ripples (laser-induced periodic surface structures) [

55,

56], metal nanobumps and nanojets [

57,

58,

59,

60,

61,

62,

63,

64,

65,

66,

67] can be produced; the study of which has continued until very recent times [

68,

69,

70,

71,

72,

73,

74,

75,

76,

77,

78,

79,

80,

81,

82,

83].

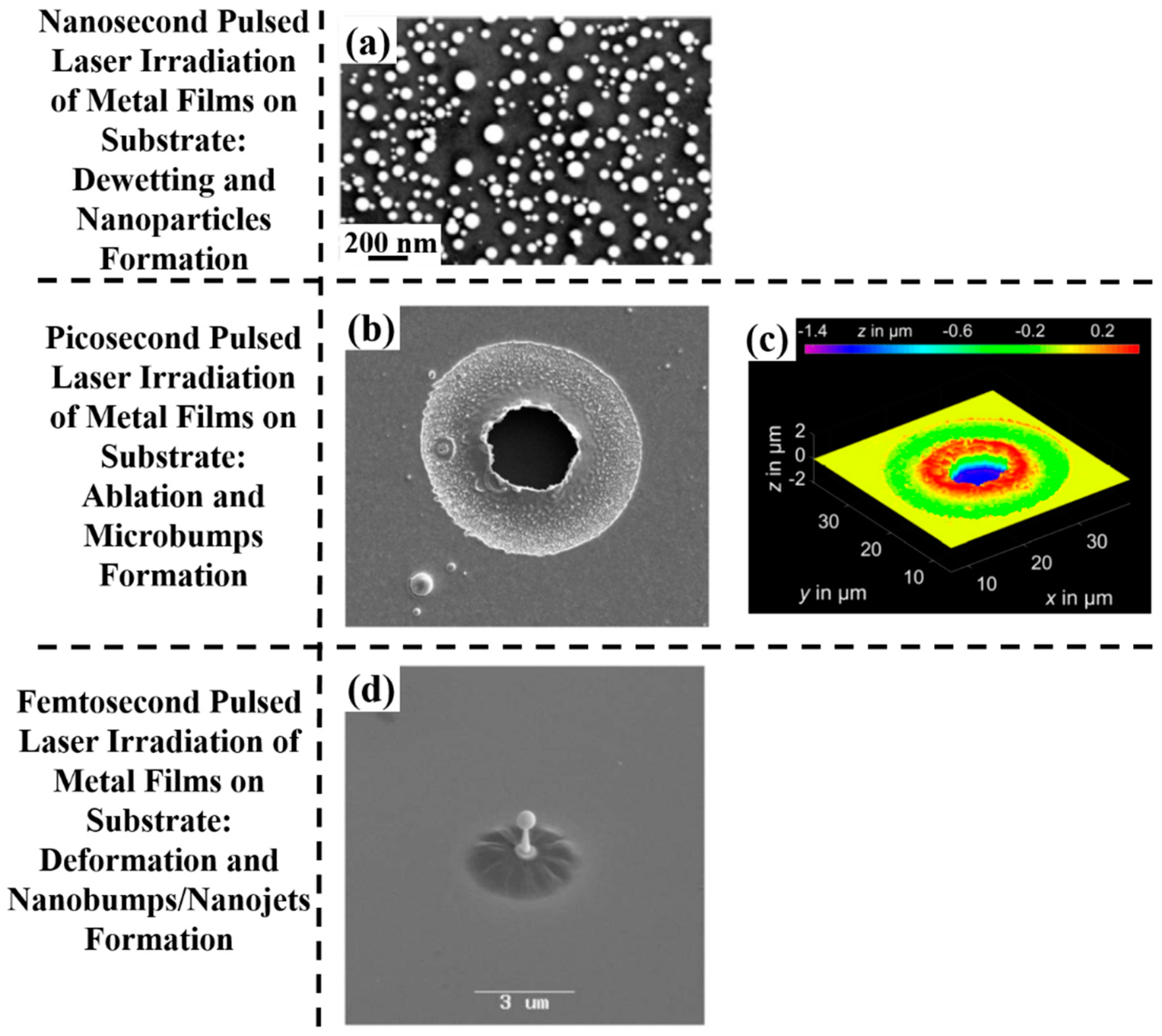

From a general point of view, a first classification on the pulsed laser effect on a metal film can be made on the basis of the pulse duration: typically, in a metal film subjected to irradiation with nanosecond laser pulses, the dominant dynamics is the material melting; irradiation with femtosecond laser pulses causes more complicated dynamics, including film ablation and deformation [

7,

8,

9,

10].

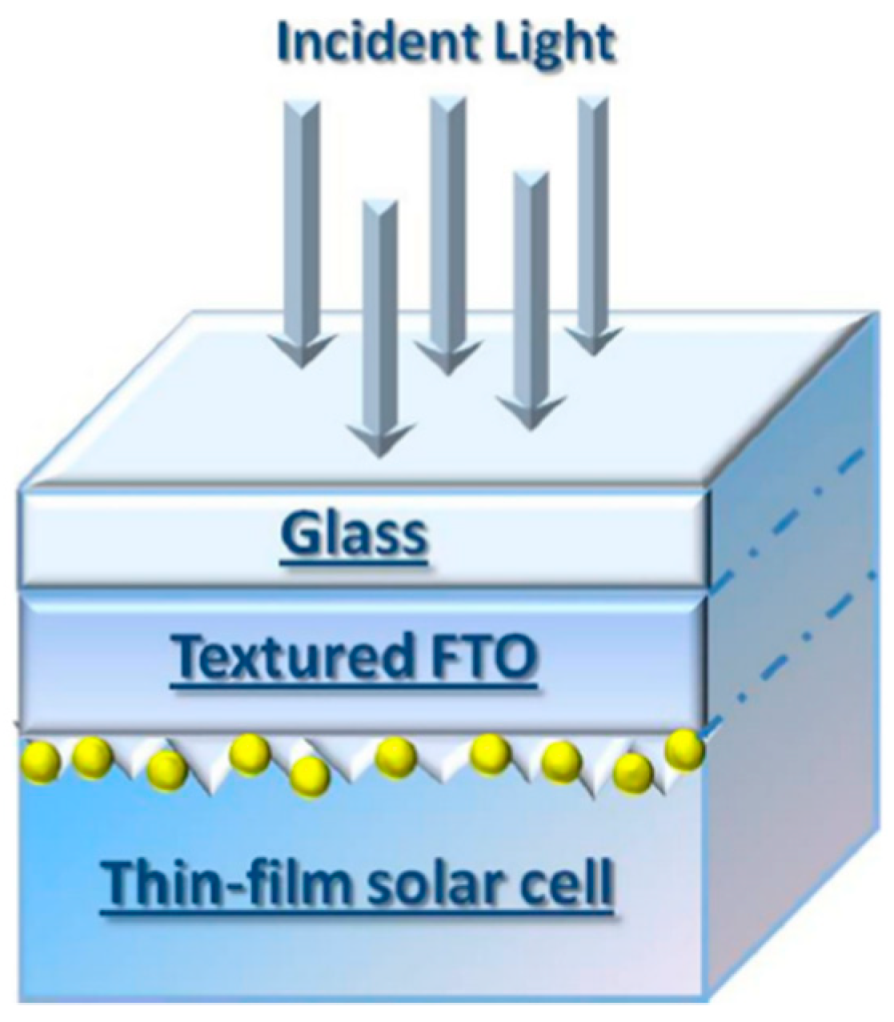

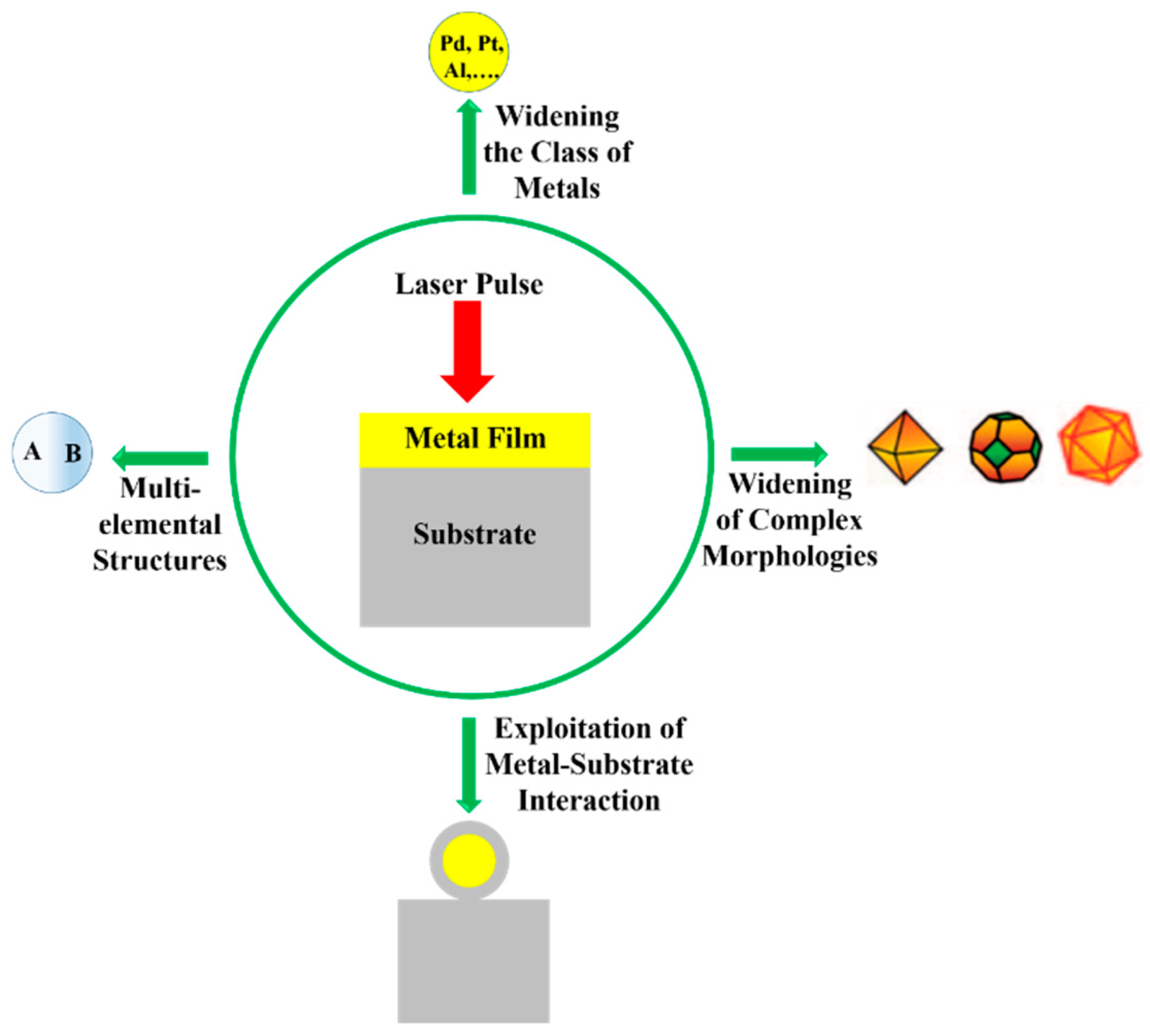

So, for example, arrays of spherical metal nanoparticles on the surface can be easily prepared by exploiting the molten-phase dewetting process of the deposited metal film when irradiated by nanosecond pulsed laser, while complex-morphology metal nanostructures can be obtained by using a pico-second or femto-second pulsed laser, see the schematic examples in

Figure 2. Obviously, the optical, thermal, and elastic properties of the metal film also play a key role in the laser-induced structuring process; and, also, the role of the substrate in the formation of the metal nanostructures is significant due to its effect on the propagation of the laser-generated heat (for example, in the case of an oxide substrate, by having a low thermal conductivity, a relatively small amount of laser-generated heat is dispersed through the substrate. As a result, the heat is almost completely confined within the metal film. A substrate having a higher conductivity allows a more efficient heat dispersion through the substrate itself).

The recent literature has mainly focused on the study of the effects, in terms of nano- and micro-structuration, as a result of irradiation with nano-second, pico-second, femto-second pulsed lasers on metal films (Au, Ag, Ni, Mo, Co, Cr, Fe, Ti, Zn, Al, Pt, Cu) deposited on oxide (SiO

2, Al

2O

3, borosilicate glasses, quartz), semiconductor (Si, GaN), transparent and conductive (ITO, FTO) substrates. In this sense,

Table 1 summarizes the recent literature concerning the type of used laser (nano-second, pico-second, femto-second) on various metal films deposited on specific substrates with the indication of the typology of the obtained nanostructures. This study shows the growing importance of fast and ultrafast pulsed lasers for nanostructuring metal films on surfaces in view of functional applications. Due to the extension, complexity, and importance of this research field, in the present review, we attempt, by starting from the discussion of specific cases, to focus our attention on the basic microscopic mechanisms and processes and on the general physical concepts suitable for the establishment of the properties of the materials. Starting from the discussion of the characteristics of the laser-metals interaction, the review aims to comprehensively schematize the main classes of metal nanostructures which can be fabricated by exploiting the processing of the deposited metal films with fast and ultrafast pulsed lasers.

In each discussed specific example, the main involved thermal, optical, mechanical parameters and processes governing the metal film structuration are elucidated. In this way, the review aims at establishing a general framework connecting the processes parameters to the characteristics (shape, size, etc.) of the produced nanostructures. This could be a step ahead towards the use of the pulsed laser approach for the controlled design and fabrication of metal nanostructures with desired morphological and structural properties in view of their engineering in real devices. In particular, the review is organized as follows:

The first part (

Section 2) is devoted to a synthetic discussion of the phenomena, processes and parameters occurring when metals are irradiated by laser pulses. Starting form general concepts and descriptions, the attention is then focused on the fast and ultrafast pulsed laser interaction with metal films. The roles of the laser pulse duration and the optical, electronic, and thermal properties of the films are particularly highlighted so as to establish general working ranges for the film nanostructuration process.

The second part (

Section 3,

Section 4 and

Section 5) focuses on the illustration and discussion of some seminal literature experimental works on the use of nanosecond (

Section 3), picosecond (

Section 4), femtosecond (

Section 5) pulsed lasers for nanostructuring thin metal films on functional substrates. Starting from the discussions of these examples, the general classes of metal nanostructures which can be produced are highlighted. In addition, in each case, the effect of the film thickness of the film, the optical, thermal and mechanical properties of the supporting substrate, and the optical and thermal properties of the laser energy are discussed. So, as a consequence, the methods to control the obtained nanostructures shape and size are established as a function of the process parameters such as the laser pulse duration and energy, metal film thickness, nature of the substrate. A short part (

Section 6) illustrates some notable technological applications for the laser-produced metal nanostructures. In particular, it outlines the strengths of the laser-based fabrication process on the basis of such applications. Finally, the concluding part (

Section 7) summarizes the main conclusions and discusses the open points, future perspectives and challenges.

2. Laser-Metal Films Interaction: General Considerations

The first and fundamental step in assessing the laser-matter interaction as a nanofabrication tool is understanding the effect of the laser beam on the irradiated material in terms of the laser generated heat in the solid. The laser photons which are absorbed by the irradiated solid give place to an energy source inside the material [

7,

8,

9,

10]. So, the response of the electrons and lattice dynamics in the material to this energy source need to be considered. The interaction of the photons with matter occurs mainly, through electronic excitations. In the range of energies of photons with wavelengths from IR (infrared) to UV (ultraviolet), only the conduction and valence electrons contribute in the excitation processes. Then, for typical laser wavelengths ranging from the near IR to the near UV, the laser energy is absorbed by the electrons through inter- and intra-band energy transitions [

7]. This results in a non-equilibrium electronic distribution. Then, the electrons thermalization occurs through electron-electron and electron-phonon scatterings. In semiconductors and insulators, the laser photons absorption results in electrons transitions from the valence band to the conduction band and the subsequent thermalization process occurs by electron-hole recombination which tends to re-establish the equilibrium condition. Therefore, the thermalization process is dependent on the specific electronic band structure of the material [

7,

8,

9,

10]. However, this recombination process typically occurs in the nanosecond time range scale [

7]. The situation is completely different for laser irradiated metals. In this case, the electrons thermalization process is faster (in the femtosecond time range scale) since it is due to the intraband scattering events since the laser photons are absorbed, mainly, by the free electrons of the metal. A first rough approach to describe the metal heating under laser irradiation can be drawn on the basis of the Drude model [

7]. Within this model, the electron scattering mean time is connected to the free electrons gas conductivity by σ = ne

2τ

D/m, with σ being the conductivity, n being the electron density, m being the electron mass, and τ

D being the electron scattering mean time, typically a few femtoseconds [

7,

8,

9,

10,

11]. More rigorous treatments, however, need to consider the specific characteristics of the non-equilibrium electronic distribution [

7]. In these approaches, for example, the lifetime τ

ee of the excited electrons, due to electron-electron scattering events, is taken into account and connected to the Fermi energy E

F (within a Fermi liquid treatment [

7]) by τ

ee = τ

0(E

F/E-E

F)

2 with E-E

F being the excited electron energy referred to as the Fermi energy and τ

0 being a characteristic time in the order of few femtoseconds. Typical values of the laser wavelength in the UV range establish τ

ee in the 1–10 fs range. Therefore, the thermalization process occurring by electron-electron interaction is very fast and can be detected by only using laser pulses with a duration comparable to τ

ee. For longer laser pulses, the electron-electron thermalization process starts and ends within the pulse duration. On the other hand, a second typology of the thermalization process can occur: electron-lattice (phonon) scattering. The thermal relaxation of electrons in metals through the electron-phonon interaction was studied by Allen [

7,

84]: he developed a model which considers the rate of change of electron and phonon distributions the laser irradiation due to the scattering events, which connects the time evolution of the electronic system temperature T

e to the lattice temperature T

L by the rate equation [

7,

84] ∂T

e/∂t = (T

L − T

e)/τ

ep. In this equation, the term τ

ep represents a characteristic electron-phonon coupling time depending on T

e, on a coupling constant (without physical units) characteristic of the material, and on the material Debye frequency [

7,

84]. Considering reasonable values for T

e (~1000 K), for the coupling constant (~0.5), and for the Debye frequency (~10 meV), then typical values for τ

ep are in the 0.1–1 ps range: the laser generated energy in the electronic system is transferred to the phonon system more rapidly than the characteristic time for the electron-electron energy transfer (since τ

ep ≈ 100–1 000 τ

ee). The consequence is that in metals under pulsed laser irradiations, the thermal dynamic evolutions of the electron and phonon systems occur within very different time scales so that these dynamics can be described separately by two different (but coupled) heat transport equations (jointly named the two-temperatures model) [

7]: C

e(∂T

e/∂t) = ∇(k

e∇T

e) − H(T

e,T

L) − S(t) for the electrons system and C

L(∂T

L/∂t) = H(T

e,T

L) for the phonons system. In these equations, Ce and CL are, respectively, the electronic and lattice specific heats, S(t) is the laser power absorbed by the material per unit volume, H(T

e,T

L) represents the rate of energy transfer from the electronic system to the lattice, and ∇(k

e∇T

e) represents the diffusion term related to the electron energy transfer. A simplified expression for the rate of energy transfer from the electronic system to the lattice is often used [

7,

85]: H(T

e,T

L) = G

ep(T

L − T

e) with G

ep = C

e/τ

ep called the electron-phonon coupling constant. In metals like Cr, Mo, W, and Fe, the electron-phonon relaxation is rapidly giving place to the fast energy transfer from electrons to phonons and, typically, material removal (ablation). In noble metals like Au and Ag, the electron–phonon relaxation is much slower. For example, G

ep ~ 42 × 10

16 W m

−3 K

−1 for Cr and G

ep ~ 2.3 × 10

16 W m

−3 K

−1 for Au [

47,

60,

86]. In noble metals, therefore, due to the slower energy transfer from the electron sub-system, the lattice can melt and the molten phase can exist for a long time. In Au, for example, the laser-generated energy is transferred to the lattice within 15 ps and the equilibrium between electrons and phonons takes place within a time limit of up to 50 ps [

47,

87].

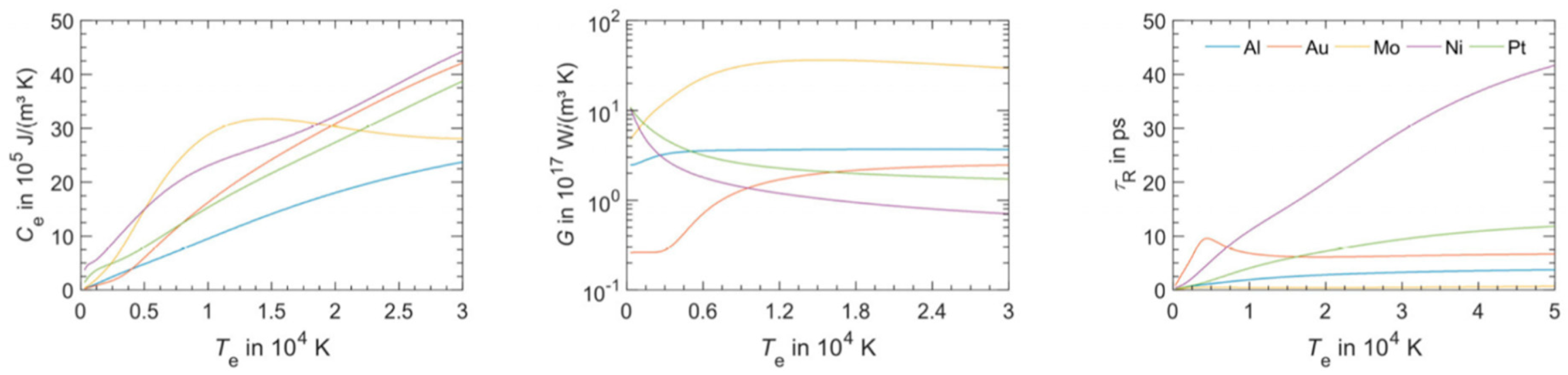

However, in the solution of the two-temperature model equations, the temperature dependence of C

e and G

ep should be considered. As an example,

Figure 3 reports that according to Olbrich et al. [

54], the heat capacity (per material unit volume) of electrons (C

e), the electron-phonon coupling constant (G = G

ep), and the relaxation time to reach a thermal equilibrium between the electron and phonon systems (τ

R) for some selected metals (Al, Au, Mo, Ni, Pt) versus the electronic temperature T

e. On the other hand, considering a laser pulse of duration τ

pulse, the two-temperatures model equations are useful if τ

p is comparable to the lifetime of excited electrons τ

ee and to the electron-phonon coupling time τ

ep (i.e., for the femtosecond or picosecond laser pulse). In fact, instead, if τ

pulse > > τ

ee, τ

ep (as in the case of nanosecond pulsed laser irradiations) then electrons and phonons thermalize within the pulse duration so that T

e = T

L and their dynamics coincide. To illustrate the difference between these situations qualitatively, the case of Cu can be considered [

7] (for which C

e = γT

e with γ = 10

−4 J/cm

3K

2, C

L = 3.4 J/cm

3K, k

e = 4 W/cmK, τ

ep ~ 0.3 ps): considering a laser pulse on Cu with τ

pulse = 50 fs, then the electrons system and the phonons system are completely independent. Under the laser pulse, the electronic temperature suddenly rises and the nit decreases to the original value within a few τ

ep. The lattice temperature, instead, is not influenced by the laser irradiation so that it is constant (to the original value before the laser pulse) during all the evolutions of the electron’s temperature. Considering, now, a laser pulse on Cu with τ

pulse = 5 ps, then the electronic temperature rises and its time-profile is very similar to the time evolution of the laser pulse (typically gaussian) since τ

ee < τ

pulse. In addition, since the laser-generated energy is transferred from the electrons system to the phonons systems within the pulse duration, the lattice temperature T

L increases, reaching a maximum temperature much lower than the maximum temperature reached by the electrons.

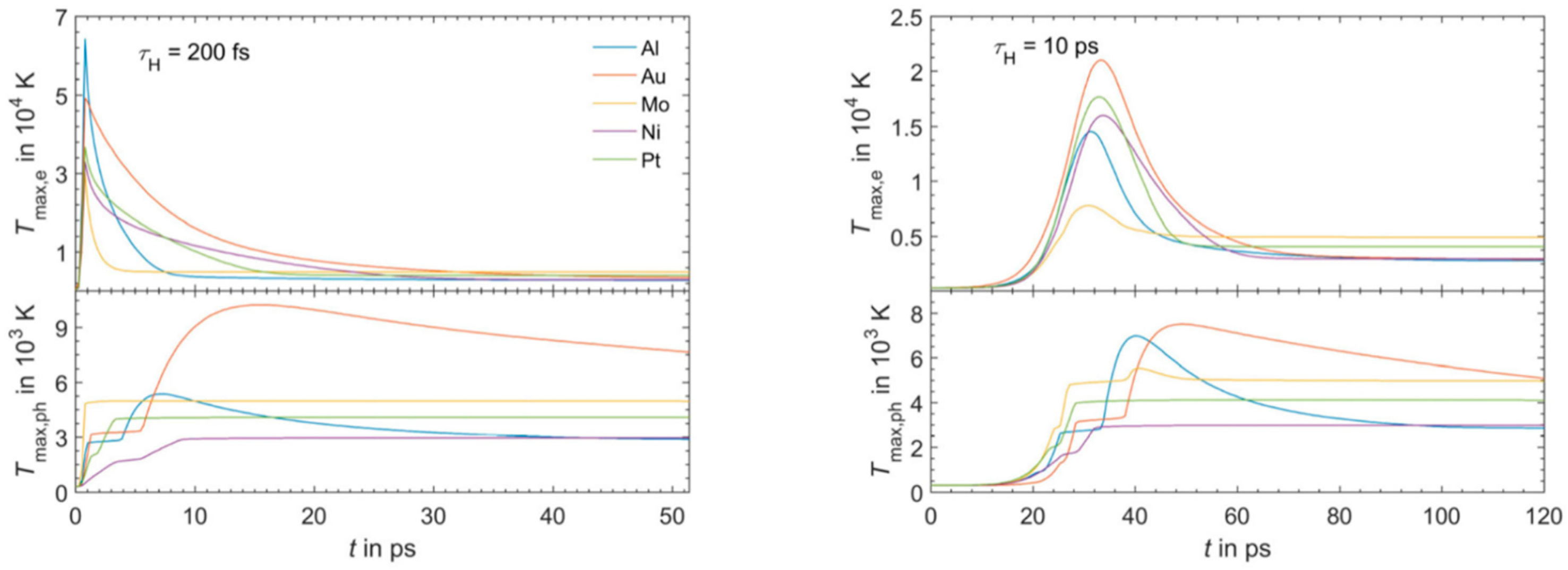

Finally, considering a laser pulse with τ

pulse = 500 ps, then, the electronic and phonons dynamics are practically equal: T

e and T

L show a very similar time-dependent behaviour so that the lattice is heated in the same way as the electronic system and the two systems are in equilibrium condition. Similar considerations can be drawn for other metals; see

Figure 4.

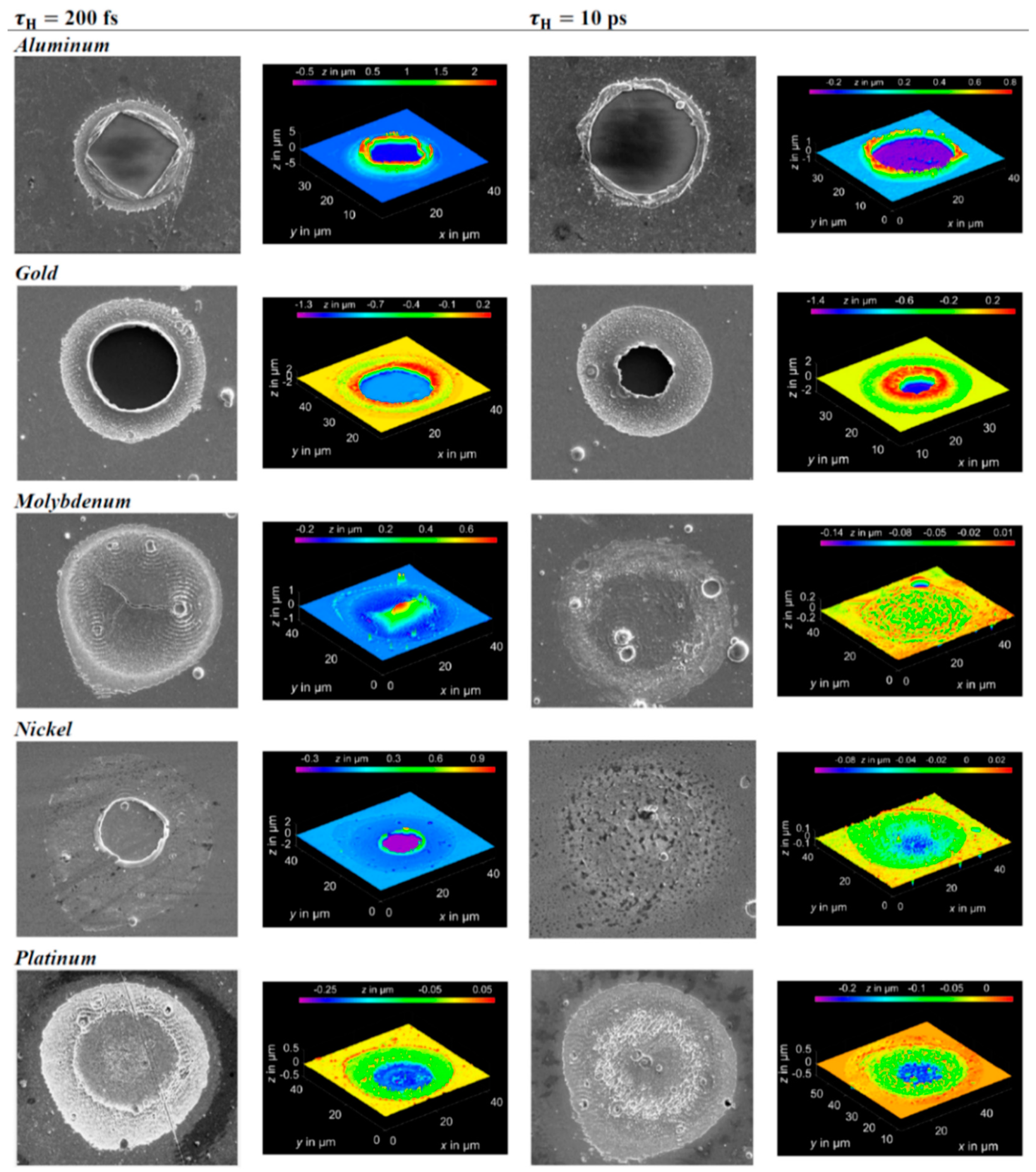

Figure 4 reports the results of calculations performed by Olbrich et al. [

54] for the time evolution of the maximum electronic temperature T

max,e and of the maximum phonons temperature T

max, ph in Al, Au, Mo, Ni, Pt under a pulsed laser irradiation with a pulse duration of τ

H = 200 fs (left) or τ

H = 10 ps (right), laser energy of 1 μJ, laser wavelength of 1028 nm (and considering, for simplicity, zero reflectance for all the metals, only energy diffusion and no vaporization). From these plots, we can observe, for example, that for all the investigated materials, T

max,e is higher for τ

H = 200 fs than for τ

H = 10 ps since the laser-generated energy is completely transferred from the electrons to the phonons during the laser irradiation at τ

H = 10 ps. In addition, we can observe that the highest T

max,e, for τ

H = 200 fs, is reached in Al since it has the lower heat capacity (see

Figure 3). On the other hand, the irradiation for τ

H = 10 ps causes the highest T

max,e in Au since Au possess the higher electron-phonon relaxation time (see

Figure 3). This fact justifies the retarded occurrence for Au (with respect to the other investigated metals) of T

max, ph, after about 50 ps from the laser pulse. Furthermore, for Au, the maximum value for T

max, ph is reached later than the maximum value for T

max,e due to the high value of the electron-phonon relaxation time τ

R.

Now, generally speaking, the specific phenomena taking place (and determining the subsequent material modifications) in a metal when it is irradiated by a laser pulse depend, obviously, on the amount of deposited laser energy and its spatial and temporal distributions [

7,

88]. As previously stated, lasers with a wavelength in the near IR-near UV region interact only with the free electrons of a metal [

7] gaining energy from the electric field and being accelerated. These oscillating electrons also re-emit energy, determining the typical high reflectivity of metals. Furthermore, as stated, the description of the interaction of laser with matter can be simplified if the pulse duration is long compared to the typical scattering times (picoseconds): in this case, the classical Drude theory [

7] can be used for the description. Using this model in particular, the optical properties of the metal can be described by the dielectric index ε = ε

1 + iε

2 with ε

1 = n

2 − κ

2 = 1 − [(ω

p2τ

D2)/1 + ω

2τ

D2] and ε

2 = 2nκ = (ω

p2τ

D)/[ω(1 + ω

p2τ

D2)] being n and κ, respectively, the so-called refractive index and extinction coefficients, ω = 2πc/λ (λ the laser wavelength), τ

D being the mean time between two electronic collisions, and ω

p = √Ne

2/mε

0 (called the plasma frequency) with N the free electron density, e the electron charge, m the electron mass, ε

0 the vacuum dielectric constant. Within this approximation, the metal reflectivity R and the absorption coefficient α are related to n and κ by R = [(n−1)

2 + κ

2]/[(n + 1)

2 + κ

2] and α = 4πκ/λ and, furthermore, the plasma frequency is related to the electrical conductivity σ

el of the metal by σ

el = ω

p2τ

Dε

0. In particular, in the IR spectral range (optical wavelengths), the previous equation can be further simplified due to ω < < 1/τ

D so that R ≈ 1–2 √2ωε

0/σ

el and α≈√2ωσ

el/c

2ε

0 resulting typically in R ≈ 90%–99% and α

−1 ≈ 10 nm for ω < ω

p.

The laser energy absorbed by the metal is then spatially distributed due to heat conduction: in this regard, the thermal properties of the metal and of the supporting substrate play a significant role on the metal modifications. For a laser pulse of duration up to tens of ns, the thermal diffusion length is [

7] z

th = √τ

pulsek

e/C

L < 1 μm, k

e being the metal heat conductivity and C

L being the metal specific heat. In order to describe the heat diffusion in the metal by a simplified one-dimensional heat diffusion equation, the laser spot size must be larger than z

th and, in this case, the simplified equation takes the form [

7] C

L(T)[∂T(z,t)/∂t] = ∂/∂z[k

e(T)(∂T(z,t)/∂z)] + S(z,t) with T(z,t) being the temperature and the depth z and time t; S(z,t) = I

abs(z,t) + ΔU(z,t) is the energy absorbed by the material from the laser (I

abs) summed to the possible material internal heat sinks (ΔU) due to phase transformations. In particular, I

abs can be related to the metal reflectivity R, to the absorption coefficient α, and to the laser irradiance I(t) (laser energy per unit area and unit time) [

7] by I

abs = I(t)α(1 − R)exp(−αz).

It is interesting to illustrate some simple consequences of the material heating and cooling stages [

89], assuming, as a first rough approximation, the temperature-independent values for the material optical and thermal properties and a laser pulse with a rectangular temporal profile of duration τ

p. The heating process involves two characteristic lengths, the absorption length α

−1 and the heat diffusion length l

th = √2Dτ

p, D being the heat diffusivity. In the case of α

−1 < l

th, the heat source is restricted to the material surface and the material temperature increase is [

89] ΔT ≈ [I

0(1-R)/k

e](Dτ

p/2)

1/2 with I

0 = I(t) being the laser irradiance. So, in this case, the energy density required to increase the surface temperature, for example, to the melting temperature, is proportional to the square root of the pulse duration and is independent on the absorption coefficient. The heating and cooling rates are both characterized by τ

p. The heating rate, in particular, is given by (ΔT/τ

p) = [I

0(1 − R)]/[ρC

L(2Dτ

p)

1/2] with ρ being the material density. The heating rate is then inversely proportional to (τ

p)

1/2. On the other hand, in the case α

−1 > l

th, the temperature increase at depth z is [

89] ΔT≈[I

0(1 − R)ατ

pexp(−αz)]/ρC

L which furnishes a heating rate ΔT/τ

p, which is independent of the duration of the laser pulse and which exponentially decreases with the depth in the material.

To complete this brief starting overview, we can consider, in addition, that if during the heating stage the material reaches temperatures higher than the melting temperature, then a significant material evaporation can occur so that an appropriate equation for the evaporation flux should be added in the calculations [

7]. Furthermore, at laser molten metal surfaces, many mechanisms contribute to the material transport phenomena being the most important one connected to the temperature dependence of the material surface tension.

In the next sections, the effects of nanoseconds, picosecond, femtosecond pulsed laser irradiations on thin metal films deposited on substrates will be experimentally presented, highlighting, on the basis of the general considerations exposed in the present section and on the basis of further specific considerations, the microscopic involved processes, the mechanisms and parameters. In this sense, these processes will be analyzed in view of their potential exploitation as nanostructuring tools for metal films towards the controlled fabrication of metal nanostructures on the substrates for various technological applications.

3. Nanostructuration of Thin Metal Films by Nanosecond Pulsed Laser Irradiations

Nanosecond pulsed laser irradiations of thin metal films on substrates is, nowadays, usually used to induce a molten-state dewetting process of the metal films resulting in the formation of nanoscale size metal droplets which can be used, for example, as plasmonic systems in several optical, catalytic, and sensing applications [

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

68,

69,

70,

71,

72]. Several studies focused on the study of the microscopic thermodynamic and kinetic mechanisms involved in the dewetting process so as to reach a strict control on the dewetted nanoparticles, morphology, size, surface density, etc. [

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

68,

69,

70,

71,

72].

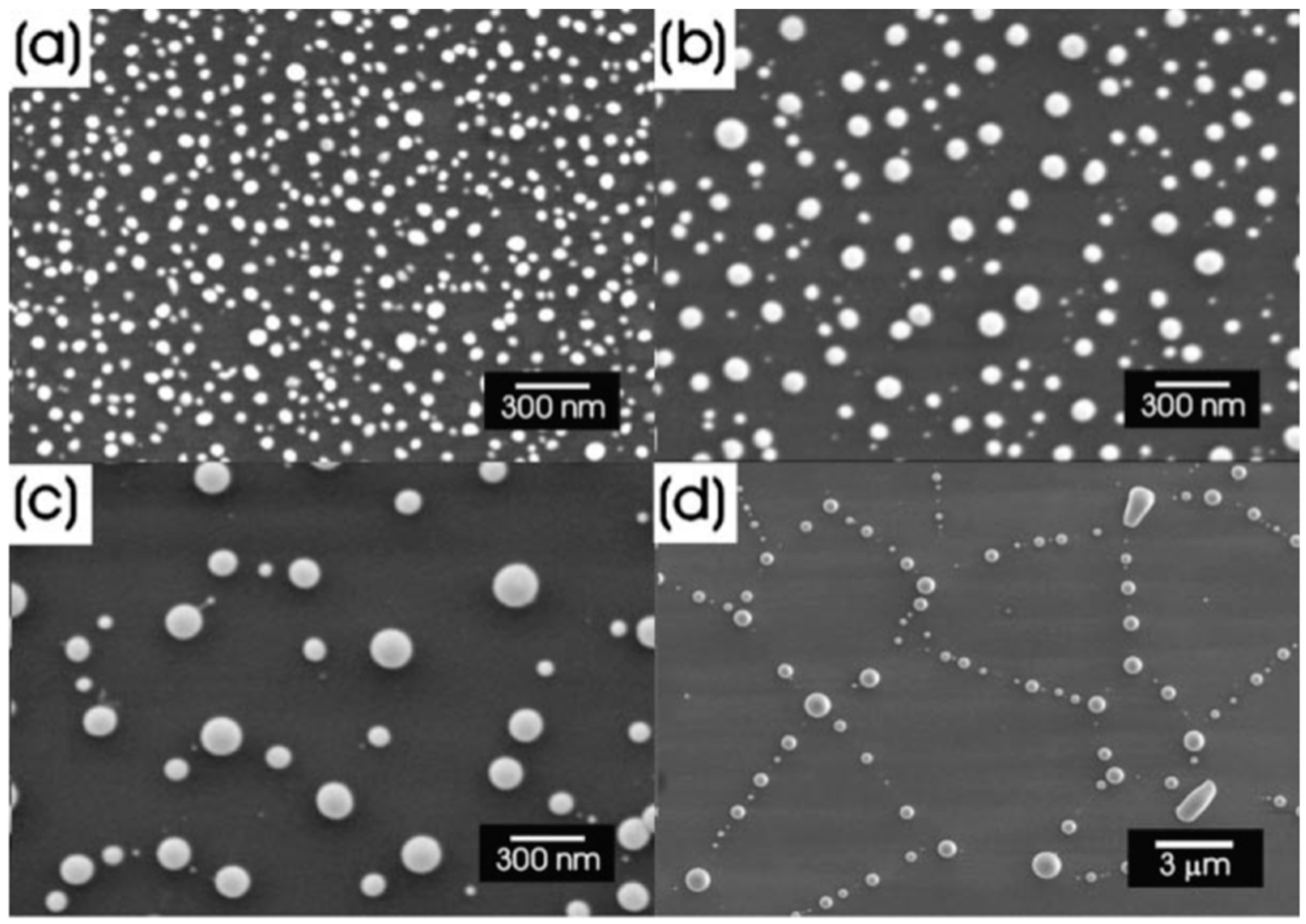

Henley et al. [

26] used nanosecond pulsed laser irradiations for nanostructuring Ni films deposited on SiO

2/Si substrates (a pulse duration of 25 ns, repetition rate of 10 Hz, fluence in the 100–3 00 mJ/cm

2 range, wavelength of 248 nm). In particular, they observed that the irradiation processes result in the formation, from the continuous Ni films, of nanoscale sized hemispherical droplets whose mean diameter is controlled by the starting thickness of the Ni film. For these experiments, the authors used, as supporting substrates for the Ni films, some SiO

2/Si slides with different values of oxide thickness values: 235 and 320 nm of thermal oxide on Si or samples with only the native oxide coating the Si.

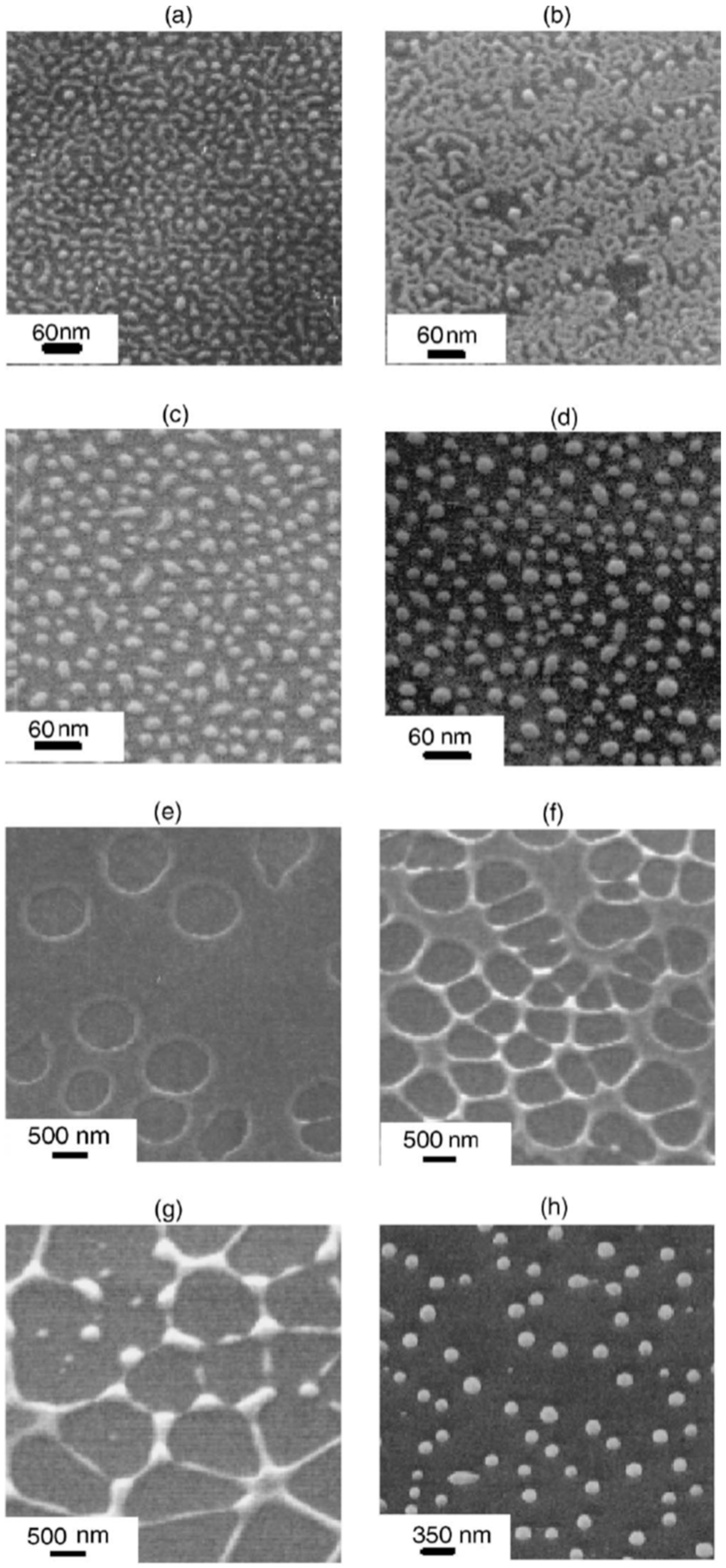

Figure 5 presents the representative Scanning Electron Microscopy (SEM) micrographs of Ni nanoparticles obtained by the laser irradiations of the Ni films with different initial thicknesses, grown on 320 nm-thick SiO

2 on Si substrates. It is clear that after the laser irradiations, the Ni film breaks up into nanoscale-size droplets with circular sections. In this regard, the minimum fluence required to induce the film rupture with the consequent formation of the nanoparticles is a function of the initial film thickness and also a function of the thickness of the oxide layer. At fluences lower than this minimum fluence value, the films were observed to perforate, but the break up into discrete droplets was incomplete. So, in this case, significant ablations of the Ni above 280 mJ/cm

2 took place while, at intermediate fluences, the Ni droplets’ size was unaffected by the laser fluence and by the oxide thickness. Interestingly, the fluence required to form nanoparticles from the films grown on the thinner (235 nm-thick) SiO

2 substrates was higher than for the corresponding Ni film on the 320 nm-thick SiO

2 layers. Furthermore, for Ni films on the Si substrates with only the native oxide layer, no nanostructuring was observed, indicating that the threshold fluence for dewetting was higher than the ablation threshold of the film: this behaviour is, clearly, due to the higher thermal conductivity of Si (150 Wm

−1 K

−1) than that of SiO

2 (1.34 Wm

−1 K

−1). Clearly, the underlying SiO

2 layer, with its low thermal conductivity, better confines the laser generated-heat in the metal film than the Si substrate. The lower thermal conductivity of the substrate allows, then, for the reaching of higher temperatures in the metal films, often higher than the metal films’ melting temperature, resulting in the molten-state dewetting of the films.

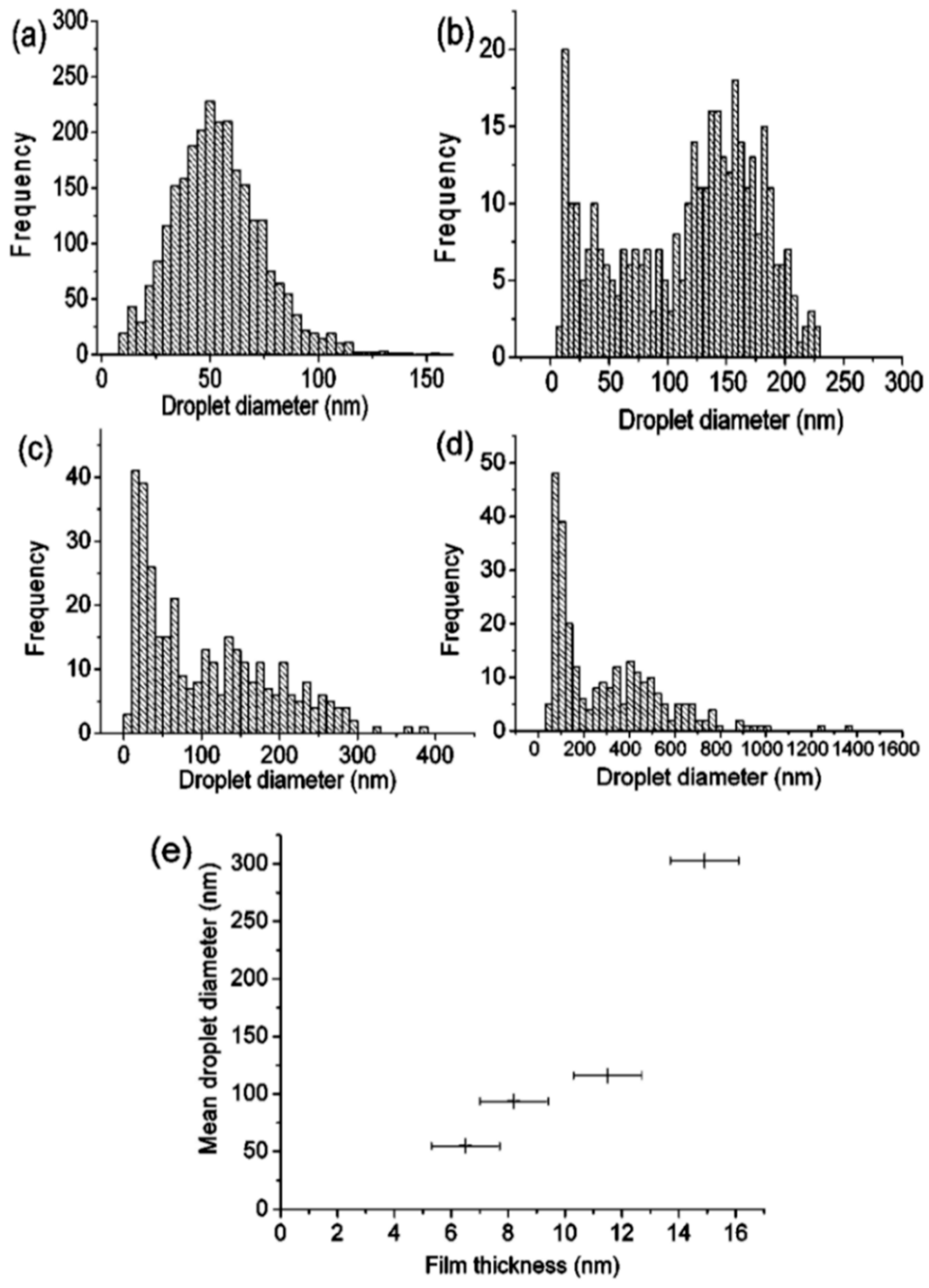

Figure 6a–d presents some representative size distributions of the Ni nanoparticles:

Figure 6a shows a mono-modal distribution,

Figure 6b–d show bi-modal distributions. The reason for this difference is as follows: at fluences lower than the critical one for the complete film dewetting, only partial film perforation and contraction occurs. These arise by molten film retraction and the retraction of the molten film continues away from the center of the formed hole. When the size and density of the holes are high, the holes can coalescence, leaving molten metal filaments. In this stage, the starting continuous film evolved so as to be structured in large particles connected by a web of filaments. At slightly higher fluences, these filaments, which are thermodynamically unstable, can split into smaller droplets. To summarize,

Figure 6e presents the correlation of a mean diameter of the Ni nanoparticles to the initial film thickness showing an increase of the mean nanoparticles’ size, increasing the thickness of the deposited film. Thus, the film thickness can be used to control the size distribution of the Ni nanoparticles. Henley et al. extended their studies to several other metals (Au, Ag, Mo, Ti, Zn) deposited on various substrates (SiO

2, ITO) [

27,

28,

34] in order to determine what materials and laser parameters are required to produce nanoparticles and to draw insights on the structuring mechanisms.

Figure 7 reports SEM images of 20-nm-thick Mo films deposited on 235 nm-thick SiO

2/Si and laser irradiated (248 nm wavelength, 25 ns pulse duration) at (a) a laser fluence slightly below the critical value for complete dewetting (<660 mJ/cm

2) and (b) at a laser fluence slightly above this critical value (>660 mJ/cm

2).

To complete the nanostructuring process of the film in droplets, a much higher fluence than that for Ni films was required since Mo has a much higher melting point (1455 °C for Ni, 2623 °C for Mo). Just below the rupture threshold, the molten films perforate and film retreating process starts with the formation of the characteristic holes and rims at the hole edges (see

Figure 7a). The starting perforations in the molten film occur at thickness inhomogeneities in the film. When the size and density of the perforations is high, holes coalescence occurs so as to give origin to molten metal wires which, being thermodynamically unstable, decay in droplets due to the Rayleigh instability in order to minimize the total surface energy of the system; see

Figure 7b [

27,

34,

45]. In addition,

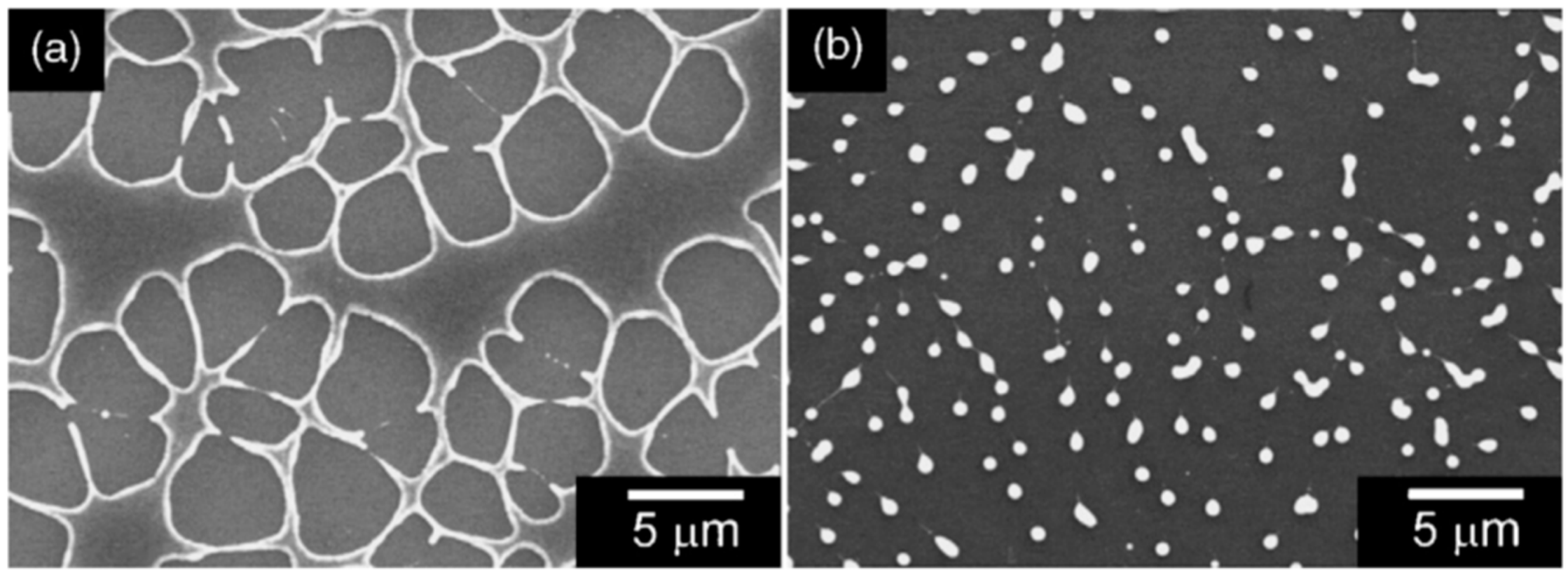

Figure 8 shows a series of SEM images for laser-processed (248 nm wavelength, 25 ns pulse duration) Au and Ag films on 235 nm-thick SiO

2/Si. In particular, the figure presents SEM images of (a) 20 nm-thick Au as-deposited on 230 nm SiO

2/Si, and, then, the 20 nm-thick Au film laser-processed with (b) 125 mJ/cm

2 fluence, (c) 250 mJ/cm

2 fluence, (d) and 430 mJ/cm

2 fluence. In addition, the figure also reports SEM images of (e) 15 nm-thick Ag as-deposited on 230 nm SiO

2/Si and the 15 nm-thick Ag film laser-processed with (b) 150 mJ/cm

2 fluence, (c) 3000 mJ/cm

2 fluence, (d) and 400 mJ/cm

2 fluence. In these cases, the film evolution (perforation and break-up into islands) is similar for Au and Ag and, generally similar to that observed for Ni and Mo. However, for Au and Ag, well-above the threshold (see

Figure 8c,g) smaller particles are observed around the larger ones: they arise from the nanoparticles boiling due to the relative lower boiling temperature for Au and Ag in comparison to Ni and Mo (2700 °C for Au, 2162 °C for Ag, 2913 °C for Ni, 4639 °C for Mo). In same conditions, different results were obtained for the Ti and Zn films on SiO

2 after the laser irradiations [

27,

34]: in these cases, in correspondence of any used laser fluence, no nanoparticles were obtained. This is a strong indication that the interfacial metal-substrate interaction is of paramount importance for the nanoparticles’ production. In this regard,

Figure 9 reports a comparison of the enthalpy of formation of the oxides, ΔH

f, for various metals, including those used by Henley et al. The data for Au, Ag, Ni and Mo (those for which the dewetting process occurs upon laser irradiation) are all in the top half of the table, with ΔH

f < 300 kJ/mol, i.e., they are non-wetting metals. On the contrary, Zn and Ti better wet the substrate since ΔH

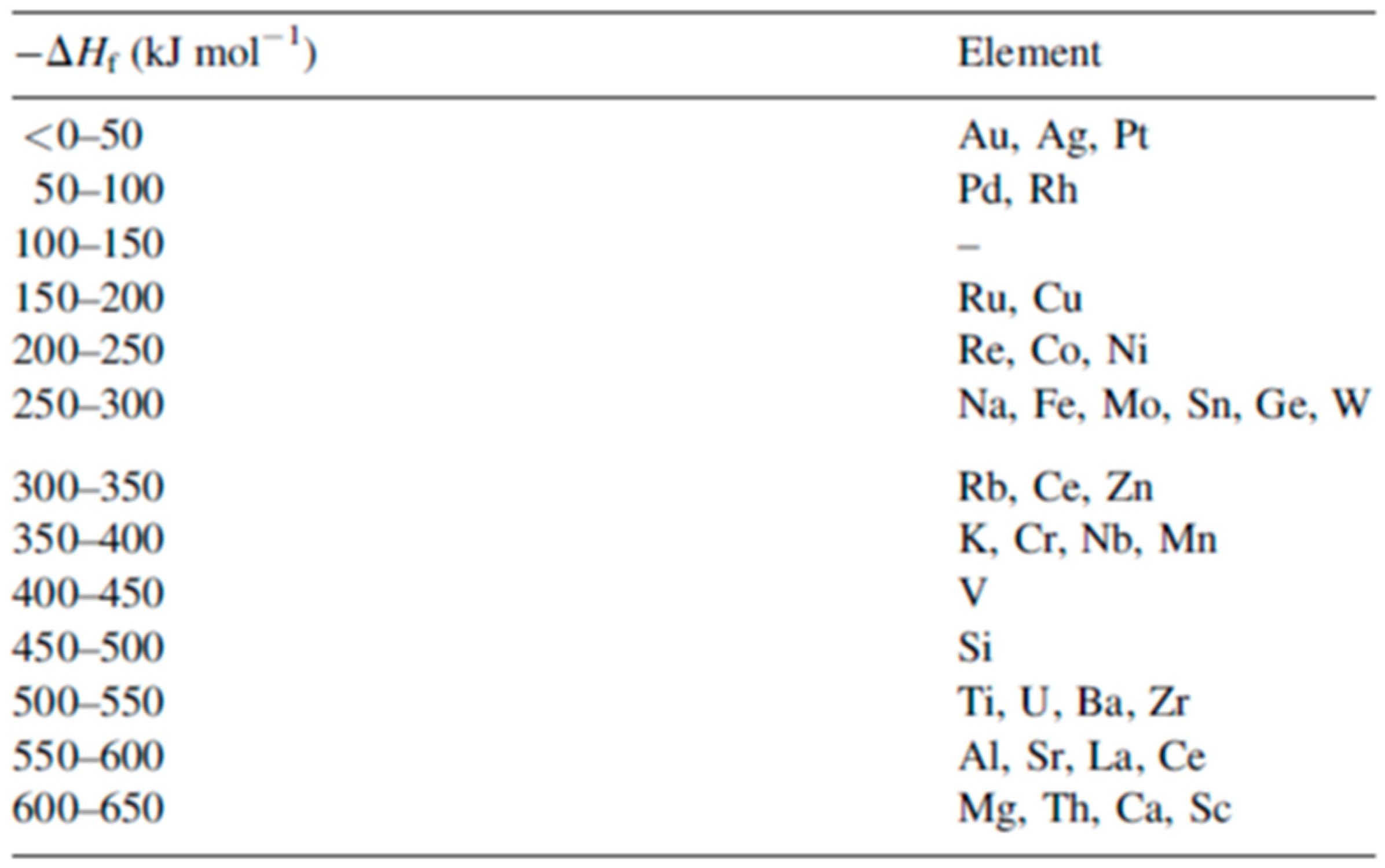

f > 300 kJ/mol. Thus, the non-wetting nature of the metals on the substrate appears as a fundamental condition for the laser-induced dewetting process.

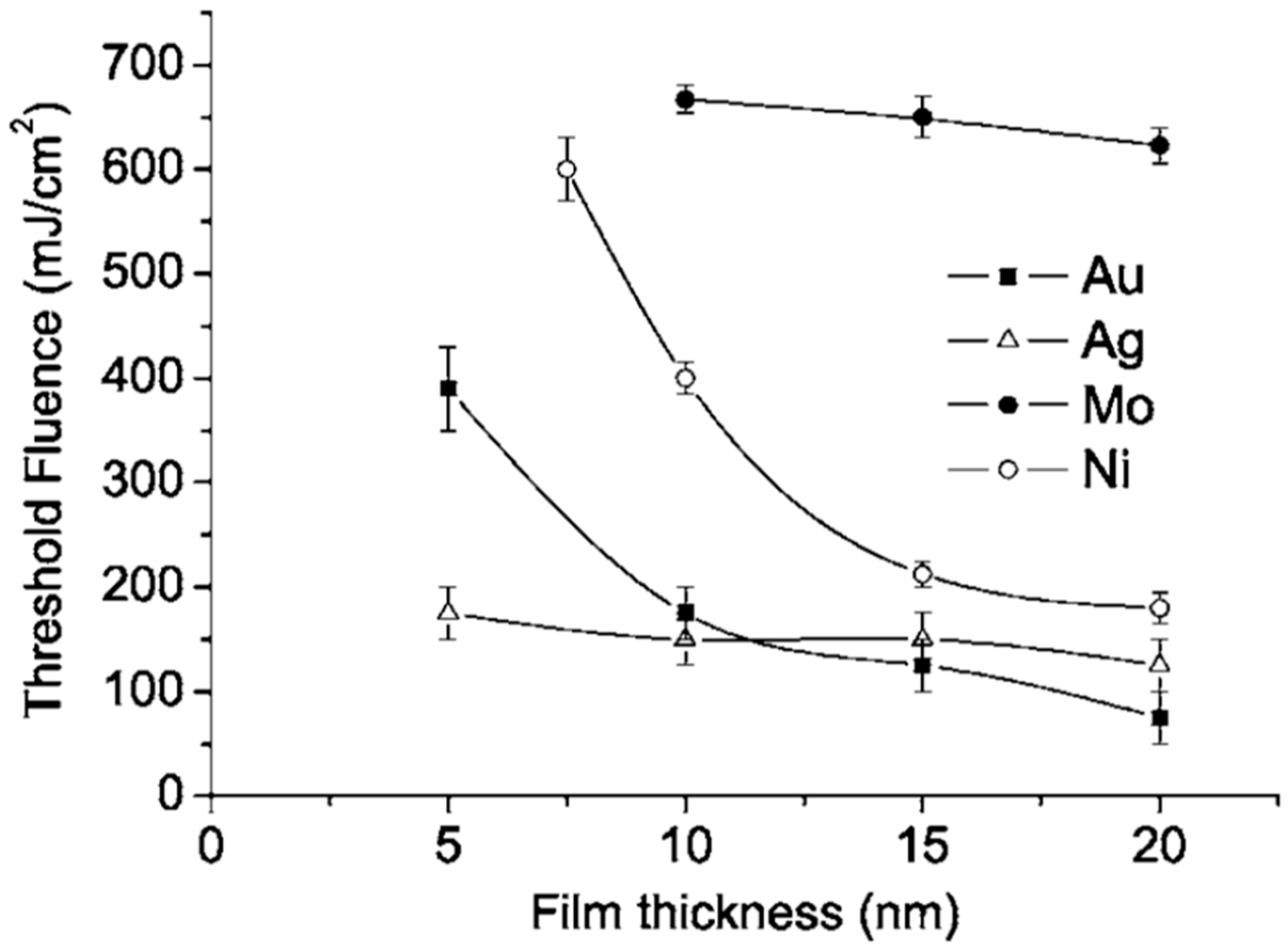

To further investigate the nanostructuring mechanisms, Henley et al. measured the laser fluence threshold for melting Ni, Mo, Au and Ag films versus the film thickness; see

Figure 10 [

27]. It is clear that higher laser fluences were required to dewet thinner Ni films indicating that the heat conduction from the film to the substrate is significant. In addition, as indicated by the SEM images, just below the break-up threshold, the films perforate at thickness inhomogeneities in the film since the fluence required for melting is lower for thicker films. At fluences higher than the threshold for breakup, no change in the Ni droplet size distribution was observed when the film thickness is fixed, while the mean nanoparticles size was found to increase by increasing the initial thickness of the deposited film. As stated, similar results were obtained for Mo, Au and Ag deposited films.

However, the authors also observed that, by cross-sectional SEM images, the contact angle of the dewetted nanoparticles increase by decreasing the wetting nature of the metal on the SiO

2, i.e., by decreasing ΔH

f [

27]: 120° for Au nanoparticles on SiO

2, 118° for Ag nanoparticles on SiO

2, 105° for Ni nanoparticles on SiO

2, and 78° for Mo nanoparticles on SiO

2. For Ti and Zn no breakup into nanoparticles was observed even if we have a lower melting temperature and lower thermal conductivity. Thus, for the break-up of the film, the critical parameter is the metal-substrate interaction, as expressed by the wetting/non-wetting nature related to the ΔH

f value (even if ΔH

f is not the only parameter affecting the wetting/non-wetting behaviour). To analyze the melting of the metal film, Henly et al. [

27] considered that with the pulse duration of a few tens of nanoseconds, the temperature change in the film can be described by the one-dimensional heat conduction equation Cρ(∂T/∂t) = I(z,t)α + [(∂/∂z)(k(∂T/∂z))] with C being the metal heat capacity, ρ being the metal density, T being the temperature at depth z and time t, I being the laser power density, α being the metal absorption coefficient, and k being the metal thermal conductivity. In addition, the total heat Q per unit area deposited in a thin film of thickness d, irradiated by a single laser pulse of duration τ

p supposed, for sake of simplicity, to have a top-hat temporal profile, can be represented by Q = Iτ

p(1 − R)[1 − exp(−αd)] with R (the film reflectivity). Thus, by neglecting the heat conduction, the temperature rise in the thin film is ΔT∝Q/d. Considered that when d → 0 then [(1 − exp(−αd))/d] → α and neglecting heat conduction, then ΔT is significant only when α is large and a thicker film require higher fluences to melt. However, heat conduction cannot be neglected: the rate of heat diffusion from the metal film into the substrate is greater as the film thickness decreases since the temperature gradient across the film increases by decreasing the film thickness. Considering heat conduction, thus, when d < (1/α), a part of the substrate, determined by the thermal diffusion depth of the substrate, is heated. As a consequence, the laser fluence needed for the melting of the film increases with decreasing d. On the other hand, when d > (1/α), then, the heat conduction into the substrate is negligible and the lower fluence is required to melt the film. On the basis of these considerations, according to Henley et al. [

27],

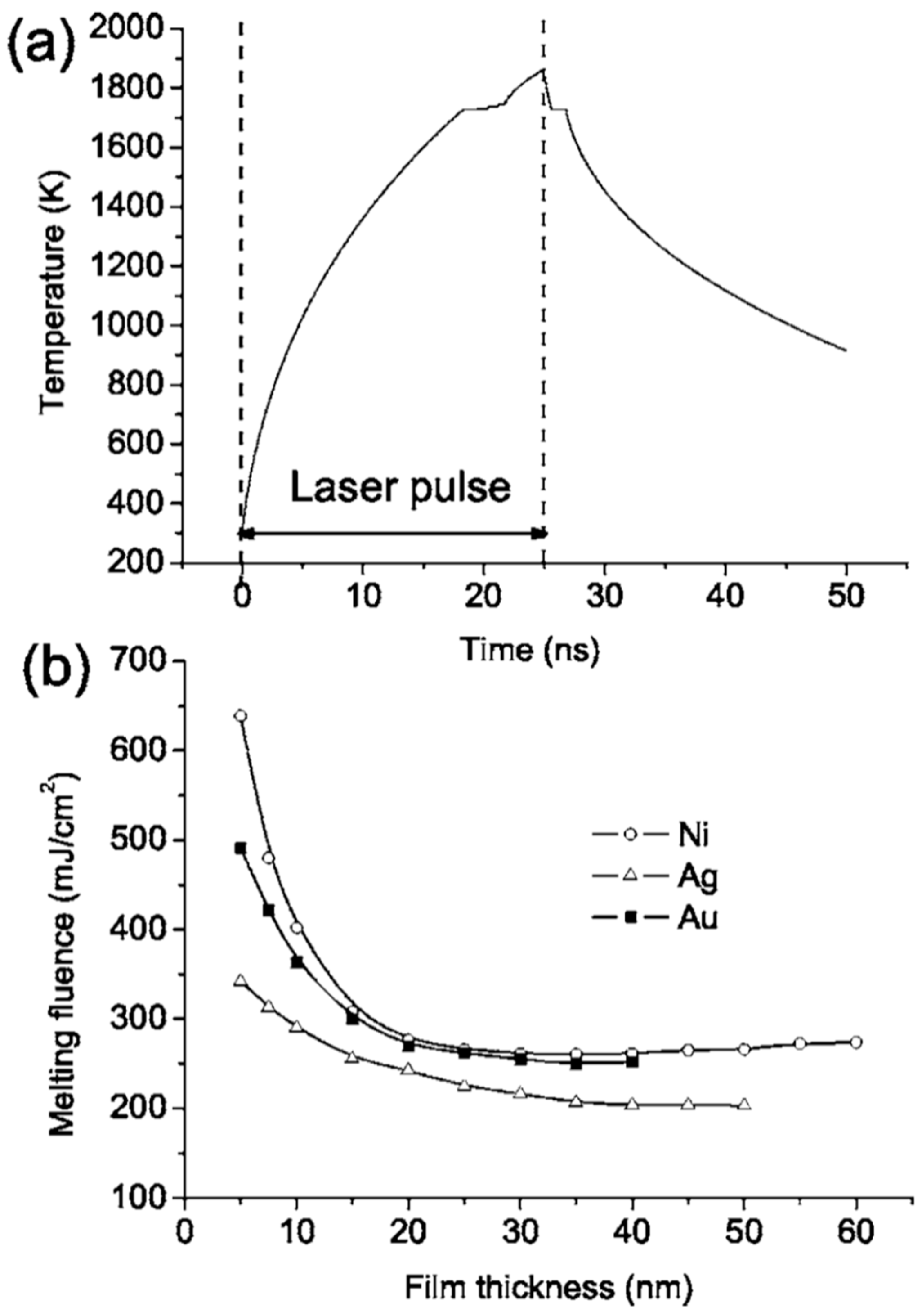

Figure 11a reports a simulation of the temperature time evolution for a 20 nm-thick Ni film on the SiO

2 irradiated by a 25-ns laser pulse with a fluence of 330 mJ/cm

2. According to this calculation, the film temperature rapidly increases during the pulse duration and reaches a level higher than the material melting temperature. At the end of the laser pulse, the film rapidly cools within 100 ns. The simulation shows that rapid cooling through heat conduction into the substrate limits the maximum temperature at a given fluence. The results of this type of simulations also allowed us to calculate the fluence required to melt Ni, Au, and Ag films of different thicknesses—see

Figure 11b [

27]—and these values agree well with the experimental ones (

Figure 10).

As stated, the thermal conductivity of the substrate and the initial film thickness were both critical parameters in determining the threshold fluence for the film melting, dewetting and nanostructuring. Specifically, in this regard, Henley et al. [

27] also simulated the effect of the thermal conductivity of the substrate on the melting fluence.

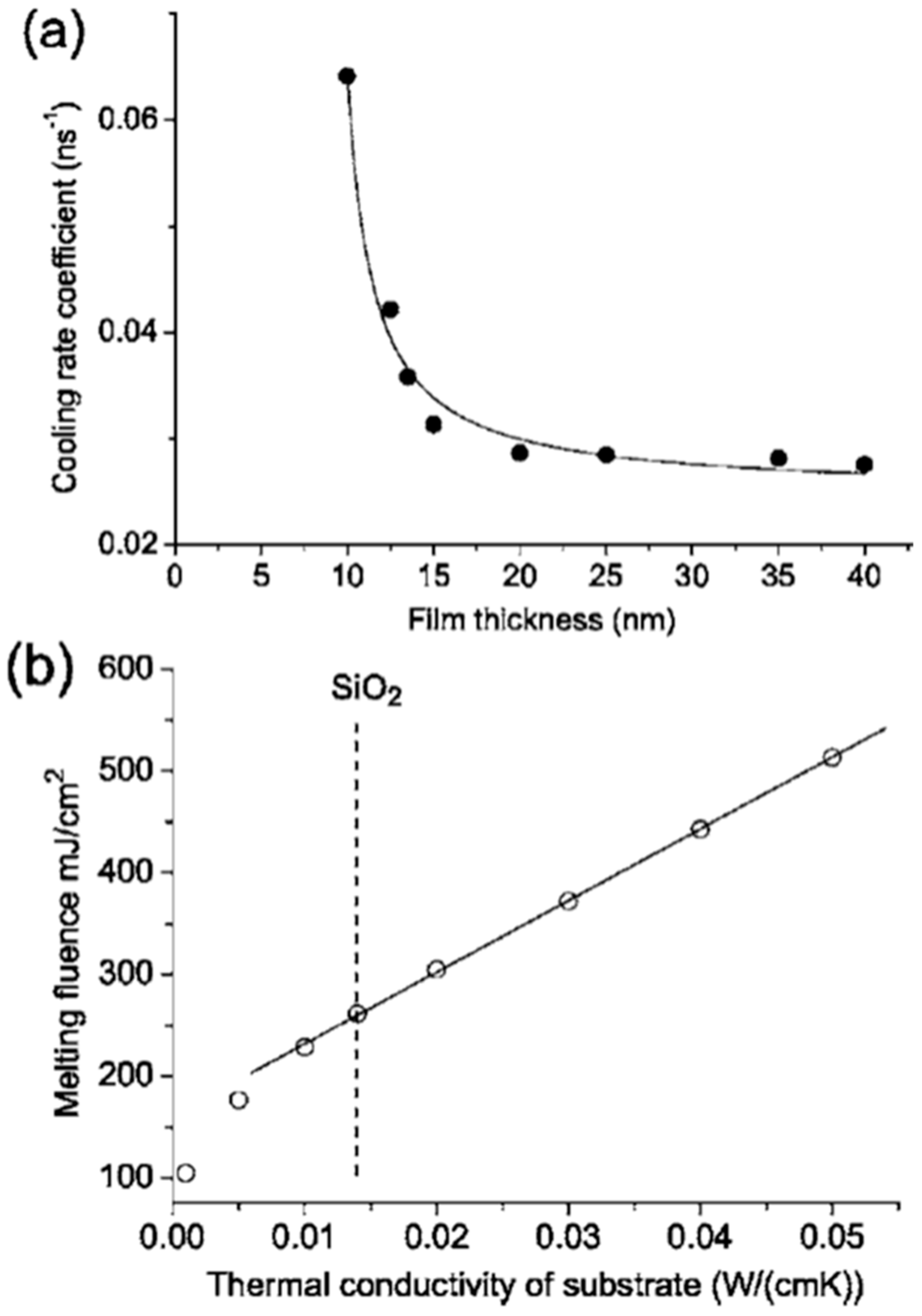

Figure 12a presents the calculated cooling rate coefficient versus the film thickness for the cooling of the Ni layer on SiO

2–, which is initially at the melting temperature; it is interesting to note the increase of the cooling rate by decreasing the film thickness. The effect of the substrate thermal conductivity is calculated in

Figure 12b: the plot shows the calculated melting fluence for a 30-nm-thick Ni film versus the room temperature thermal conductivity of the substrate. The result shows, as expected, a linear increase of the melting fluence by increasing the substrate thermal conductivity.

When the fluence is higher than the threshold for melting, the film dewetting process can occur if the metal film does not wet the substrate. It should be considered, also, that real films present a natural surface roughness which is often quantified by the RMS (Root Mean Square) parameter. Generally, for thick films, the surface roughness is expected to be lower than that for the thinner films. At thickness inhomogeneities in the film, the fluence required for melting will change and for this reason, the film RMS is an important parameter to be considered in the dewetting process since the natural surface roughness results in a local change in the threshold fluence for melting and determining the local hot spots at thicker regions. The melting and dewetting starts from these regions. The dewetting process starts with molten film perforation and the molten film around these perforations draws away from the perforations originating in the holes. According to Favazza et al. [

30,

32,

33,

35,

36], the molten metal retraction velocity can be estimated by v = √2|S|/ρd with ρ being the metal liquid density, d being the film thickness and S = γ

S − γ

F + γ

F/S being the spreading coefficient, γ

S being the substrate surface energy, γ

F being the film surface energy, and γ

F/S being the film-substrate interface energy. When the size and density of the holes is high, then, the retreating molten film between two holes can coalesce into liquid nanowires which are thermodynamically unstable and they decay in nanometer-scale droplets by the Rayleigh instability process. This last stage was, in particular, studied by Ruffino et al. [

45]. In this work, the authors deposited a 5 nm-thick Au film on the SiO

2/Si substrate (with SiO

2 being the native layer on the Si surface) and processed the system by irradiating the Au surface by one laser pulse at a wavelength of 532 nm, a pulse duration of 12 ns and a laser fluence increasing from 0.5 J/cm

2 to 1.5 J/cm

2.

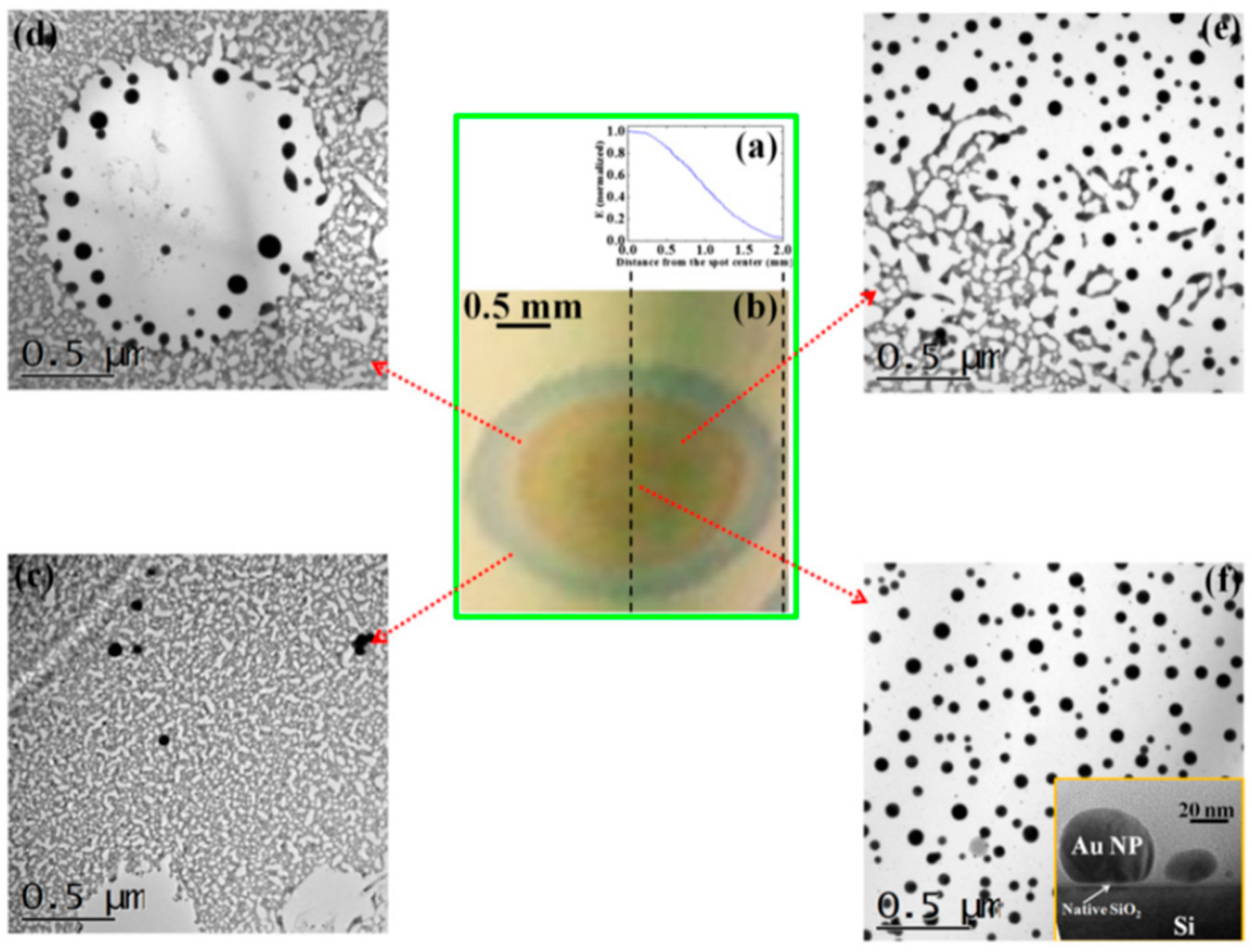

The authors [

45] observed that the laser spatial intensity profile is Gaussian (as reported in

Figure 13a). Due to this gaussian profile, the fixed value for the laser fluence is a circular area of 600 μm in diameter around the center of the laser spot. Outside from this circular region, the laser fluence decreases according to the intensity Gaussian profile till reaching zero at the laser spot edge.

Figure 13b reports an optical photograph of the resulting laser spot on the Au film produced by a laser pulse of fluence, 1 J/cm

2: different colored regions can be identified as characterized by a decreasing laser intensity, increasing the distance from the center (corresponding to the higher value for the laser intensity).

Then,

Figure 13c–f present the Transmission Electron Microscopy (TEM) images acquired in these different regions of the laser spot, i.e., increasing the laser fluence from the spot edge to the center of the spot: (c) >600 μm, (d) between 600 and 300 μm, (e) at about 300 μm, (f) >300 μm. For a low laser fluence (spot edge), the Au film is almost unaltered (

Figure 13c). At enough high laser fluence, the film melts and dewets into nanoparticles (

Figure 13d). The dewetting process can be identified: in this region, the nucleation of holes is evident. The Au liquid retraction velocity was estimated as v ~ 250 m/s. The coalescence process of the holes giving origin to metal filaments can be recognized in

Figure 13e. These thermodynamically unstable filaments split into nanoparticles due to the Rayleigh instability, as can be recognized in

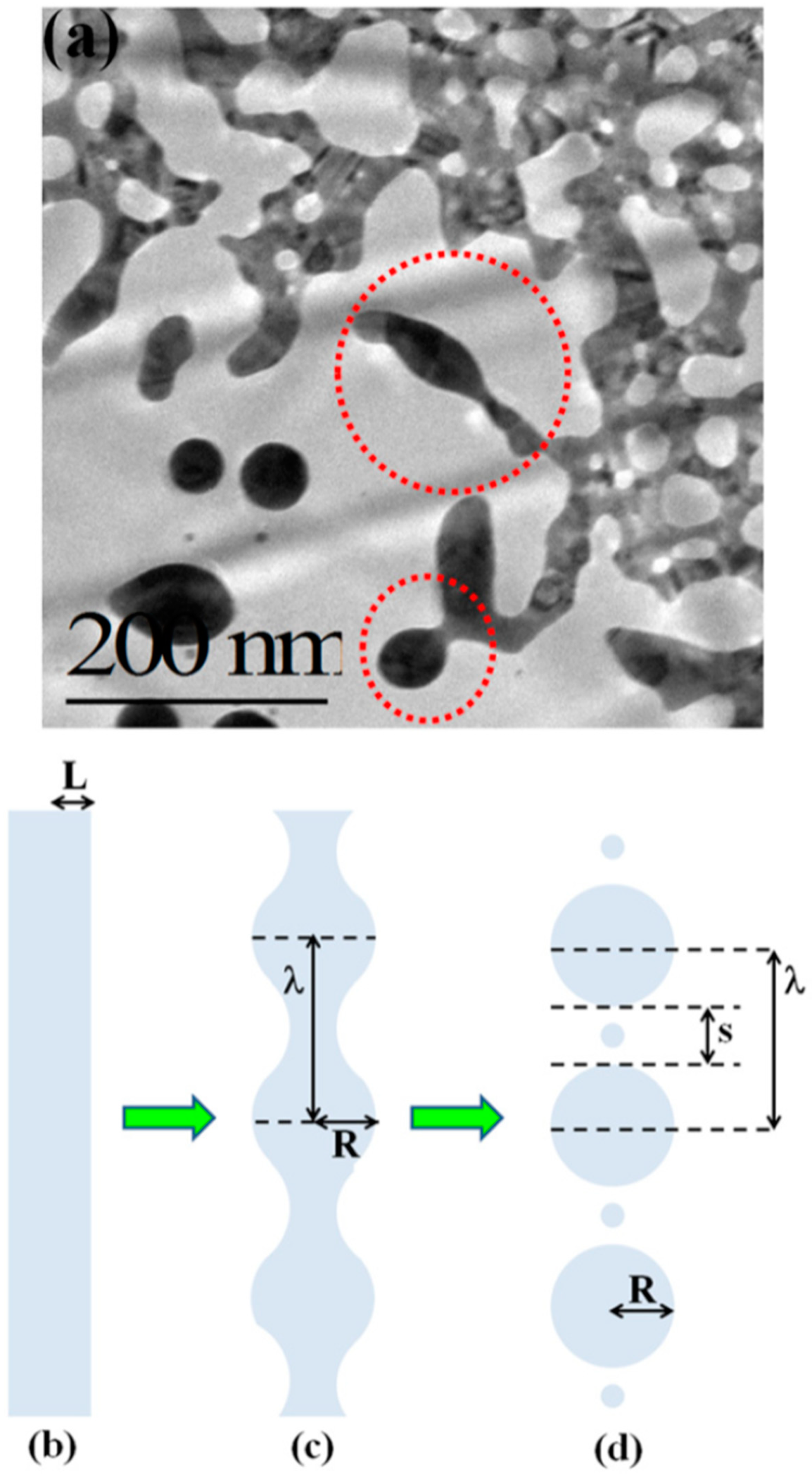

Figure 14a. Regarding the Rayleigh instability process, the problem of capillary instabilities driven by surface energy minimization was studied by Lord Rayleigh [

44,

45,

90], finding that a free non-viscous liquid cylinder is unstable to perturbations with wavelengths λ > 2πL, L being the cylinder radius (

Figure 14b). So, the unstable cylinder spontaneously splits into liquid droplets which, then, after cooling, solidify (

Figure 14c,d).

Figure 14b–d shows a schematic picture of the process. It shows sinusoidal thermal perturbations in a liquid infinite cylinder. Increasing time, the fastest growing wavelength will overcome the slower ones and will determine the size of the resulting droplets. In fact, this wave establishes a positive and negative curvature in the cylinder, producing differences in the cylinder radius along its axis. These differences result in a pressure gradient further promoting the growth of the perturbation. On the other hand, the pressure gradient (pinched regions have higher pressure than the bulging regions) produces a fluid flux causing, finally, the pinched areas to rupture and the transformation of the bulged regions into the spherical particles. The calculations show that the perturbations with a wavelength λ = 9.016L dominate the process. Nichols and Mullins [

44,

45,

91,

92,

93] adapted the original work by Lord Rayleigh to the case of the instability of solid circular cylinders without any contact with other materials [

91].

In this case, the authors found that the wavelength of the dominant perturbations depends on the specific mass-transport mechanism. For surface diffusion, the dominant perturbations are those having λ = 8.89L [

91,

92,

93]. The calculations show, in addition, that the diameter of the split droplet is [

91,

92,

93] D = 3.78L. Thus, for the droplets originating from the cylinder decay, the theory predicts λ/D = 4.7. Ruffino et al. [

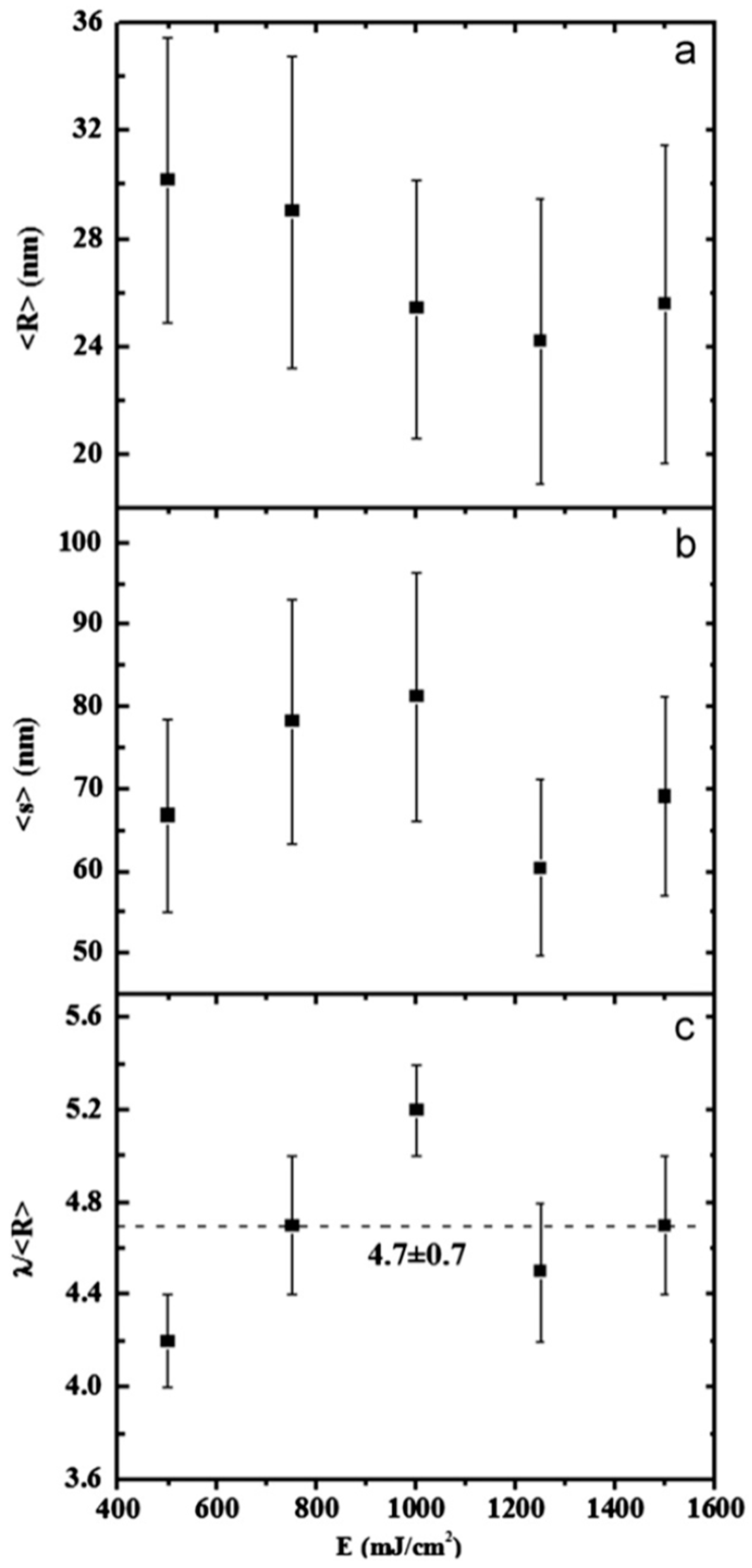

45] interpreted λ as the average center-to-center distance between the dewetted nanoparticles, which was quantified by the TEM images as the average nanoparticles’ diameter < D >. So, they reported the average nanoparticles < D >, the average surface-to-surface nanoparticles distance < s >, and the ratio (λ/< R >) = (< s > + 2 < R >/< R >) versus the laser fluence E (

Figure 15). In particular, the experimental data in

Figure 15c show that (λ/< R >) = 4.7 ± 0.7 independent on the laser fluence in agreement with the predicted value. This is a strong indication for the Rayleigh instability phenomenon as the leading pathway for the dewetting process.

The laser-induced dewetting process of thin metal films on substrates is largely regarded as an effective method for the spontaneous formation of two-dimensional arrays of nanoparticles by self-organization [

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

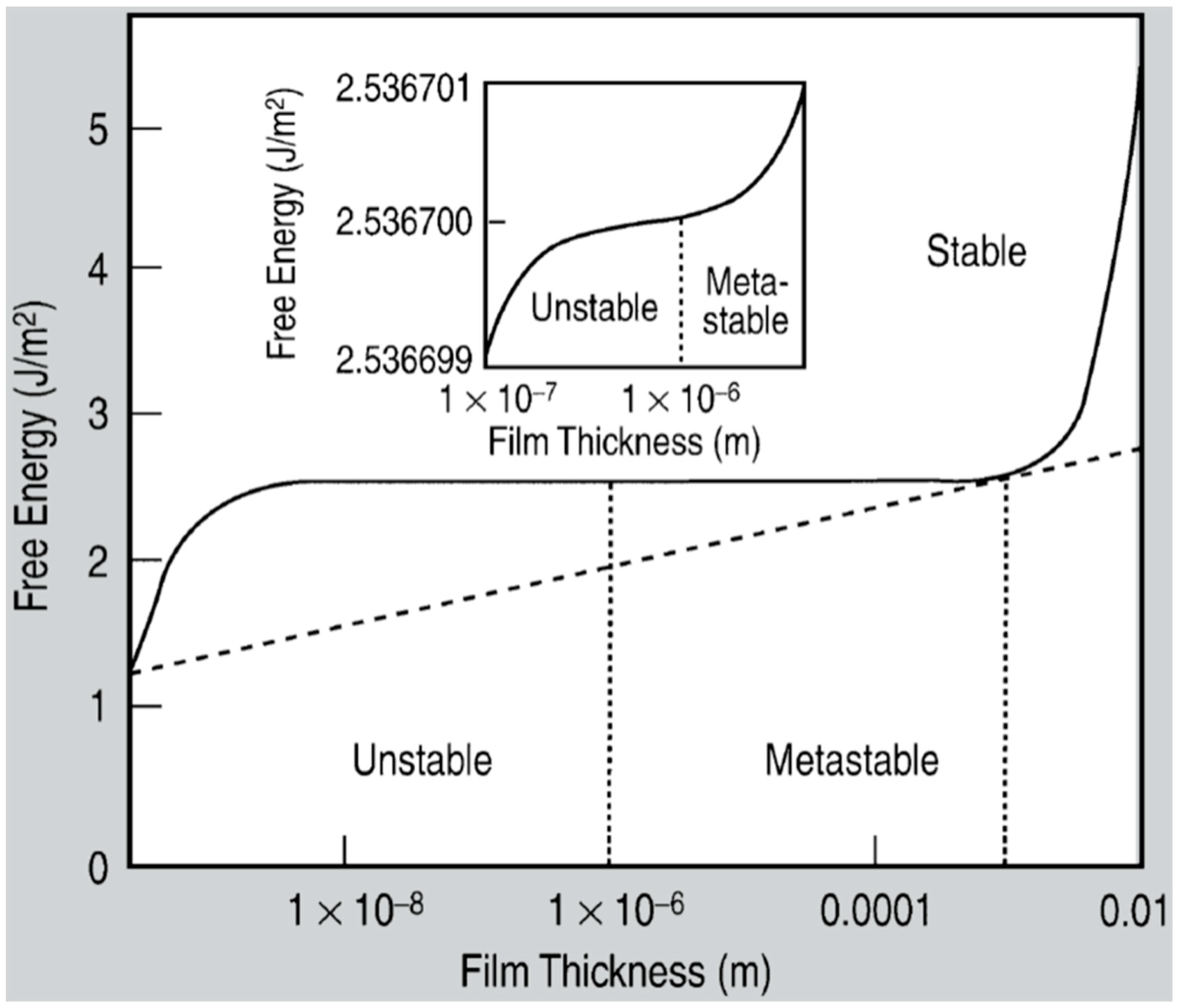

53]. As early stated, the driving force for the spontaneous dewetting of continuous films in droplets is the minimization of the total surface energy of the system which, at constant volume, is lower for a system of spherical droplets on a flat surface than for the continuous film-substrate system [

37]. For film-substrate systems showing this tendency, the plot of the system-free-energy versus the film thickness shows a very similar behaviour to the composition-dependent behavior in two-phases systems characterized by spinodal phase segregation (

Figure 16) [

37]. Thus, such systems are, often, referred to dewet by spinodal dewetting [

37,

78,

79]. The total free energy of a substrate-film system can be expressed as [

37] G(d) = G

surf + G

int + G

vol + G

ext, which is dependent on the thickness d of the film. In this expression, G

surf is the surface energy of the film (in contact with vacuum), i.e., the film surface tension γ

F; G

int represents the film substrate interface energy, i.e., the film-substrate interfacial tension γ

F/S; G

vol is the volume free energy which takes a specific functional form corresponding to the specific system under analysis; G

ext = (1/2)ρgd

2 is the gravitational energy of the film (ρ: the film density), which is, usually, negligible for nanoscale-thick films with respect to the other terms. Regarding, in particular, metal films on inert substrates (as typically on SiO

2) G

vol is, mainly, due to the film intermolecular dispersion forces which are actually the van der Waals interactions between non-polar atoms [

37]. In this case, the theory shows that [

37] G

vol = A/h

2 A being the Hamacker coefficient representing the sign and the magnitude of interaction between the film and the substrate and between the film and vacuum. In the case of metal films on insulating substrates (as SiO

2) in a gaseous or vacuum environment, the resulting free energy is attractive. Furthermore, if the thickness of these films is, typically, in the 1–100 nm range, G

xet is negligible, and, observing

Figure 16, the derivative of the G (d) curve is <0, indicating a thermodynamically unstable regime for the film. In this unstable regime, if material diffusion can occur, the film spontaneously tends to break-up by the first step of the nucleation of holes in the film due to the amplification of the film thickness inhomogeneities. Interestingly, however, in the successive evolution of the dewetting process (leading to the formation of droplets), the characteristic length scales arise since the dewetting dynamics will be dominated by the fastest growing length scale Λ [

37,

94,

95,

96] as seen when the process evolves by the Rayleigh instability mechanism. Theoretical calculations [

37,

96,

97,

98,

99] shows that the characteristic length Λ scales with the film thickness d as Λ∝d

2 which was experimentally verified by several studies confirming a spinodal-like self-organization process for liquid films [

37]. On the other hand, when the film thickness is d > 100 nm (metastable region; see

Figure 16), the dewetting process starts with the formation of holes by homogeneous nucleation in random spatial positions so that the resulting film morphology lacks the characteristic length scales. To study the characteristics of morphology and the pattern of spinodal-like dewetting films, Krishna et al. [

37] deposited Fe films on the SiO

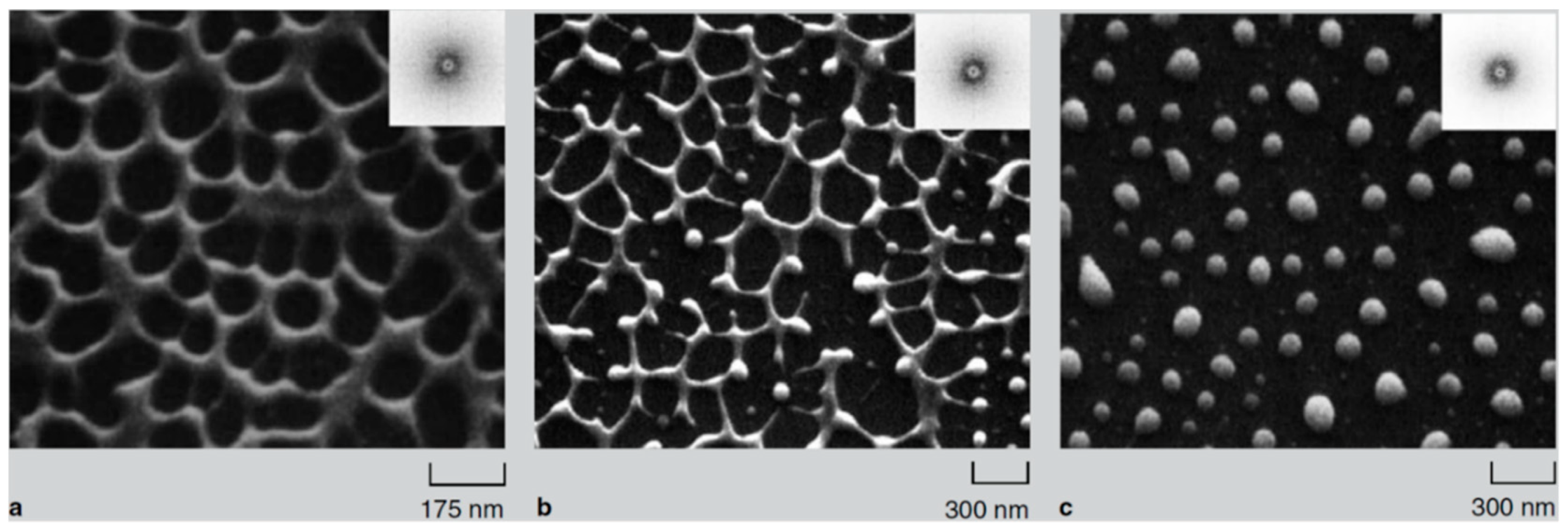

2/Si substrate, increasing the film thickness, however, also maintaining the film thickness below 10 nm. Then, these films were laser processed by laser pulses with a wavelength of 266 nm, a pulse duration of 9 ns, a repletion rate of 50 Hz, with a fluence higher than the threshold for melting and increasing the number of pulses. Some representative resulting morphologies of 3.5 nm-thick Fe film processed by 5 (a), 500 (b), 10000 (c) pulses are reported in

Figure 17. As recognizable by the figure, after 5 pulses, the dewetting morphology is characterized by a cellular web of polygons (

Figure 17a). By increasing the number of pulses, the metal retracted to the edge of the holes, resulting in an array of coalescing polygonal holes (

Figure 17b). Further increasing the number of pulses leads to the formation of nanoparticles preferentially at the junctions of the polygons, as evident in

Figure 17b,c. At every observed stage, a characteristic length scale is present, as evidenced by the annular form of the power spectrum of the spatial correlations in the intensity variation within each pattern (presented as an insert in each image in

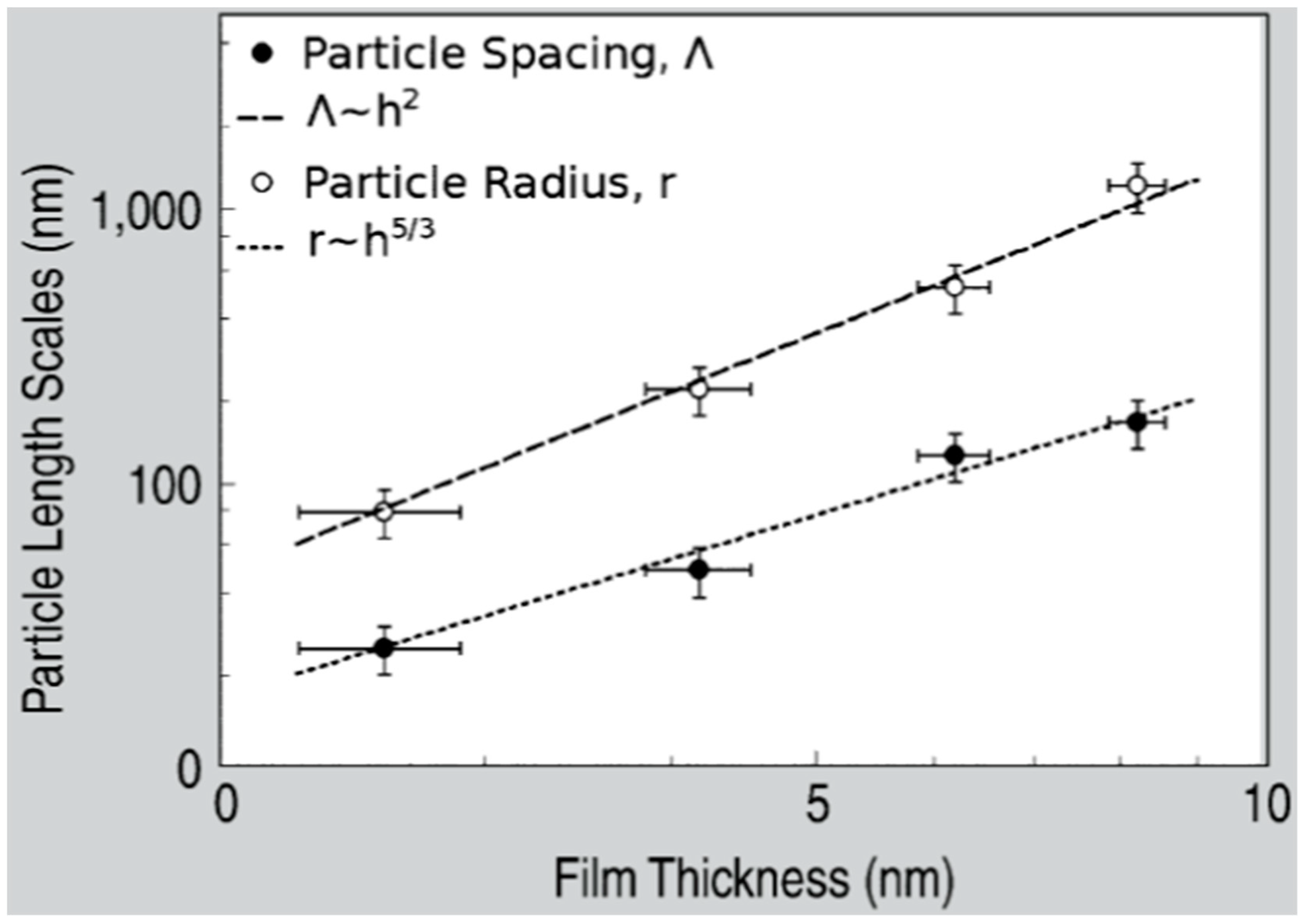

Figure 17). For patterns consisting of polygons, the characteristic length scale represents the mean distance between the centers of the polygons; for the nanoparticles, it represents the interparticle spacing. In this last case, the short-range spatial order indicates the spinodal-like nature of the dewetting process. For spinodal-like dewetting, the theory predicts for the nanoparticles’ radius r and interparticles’ spacing Λ evolutions with the film thickness (d) relations as r∝d

5/3 and Λ

2 [

33,

37,

98,

100,

101]. The authors, then, verified these predictions by plotting (

Figure 18) the experimentally-extracted mean radius r and spacing Λ for the Fe nanoparticles versus the starting thickness of the deposited Fe film, finding excellent accordance. Similar results were found for other metals. Trice et al. [

33] were able to exploit hydrodynamic pattern formation and dewetting, resulting from the pulsed-laser-induced melting of nanoscale-thick Co films to produce two-dimensional spatially ordered metal nanoparticle arrays on SiO

2/Si substrates.

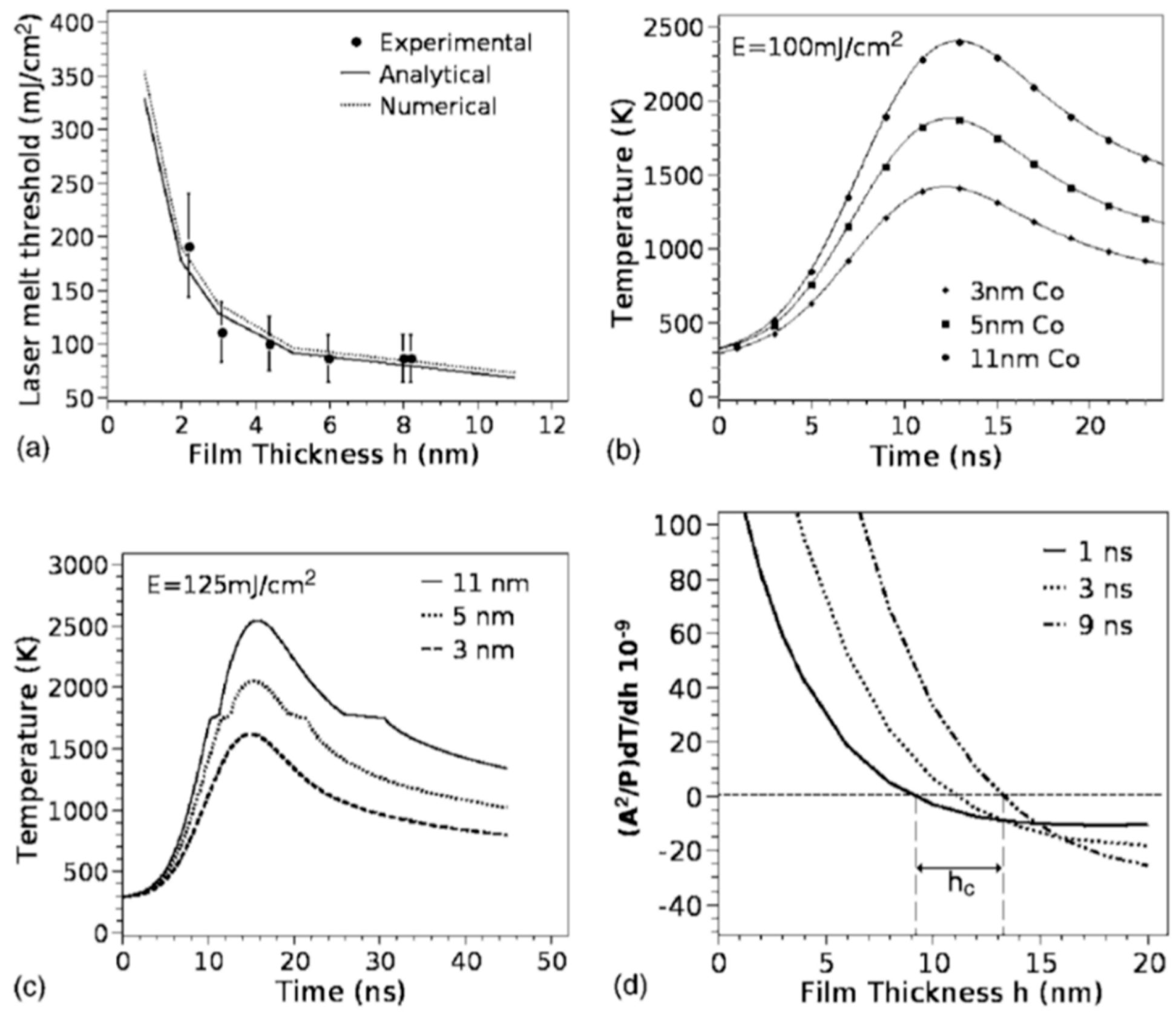

In particular, they investigated the pattern formation for the Co film with a thickness equal or lower than 7 nm, which is lower than the Co absorption length for the used laser pulse (a wavelength of 266 nm, repletion rate of 50 Hz, pulse duration of 9 ns) which was evaluated in about 11 nm.

The pattern formation was investigated as a function of the laser energy density and number of pulses. The pattern formation, as usual, was only observed to occur for a laser energy density higher than a critical value (threshold energy for melting) dependent on the Co film thickness. The authors, in addition, developed a model [

33] which predicts that spontaneous perturbations on the metal film thickness (i.e., natural roughness) would result in intrinsic thermal gradients ∂T/∂h, with h being the film thickness. A critical thickness h

c (≈9 nm) is evaluated by the model so that (∂T/∂h) > 0 for h < h

c and (∂T/∂h) < 0 for h > h

c. Experimentally, the spacing between the dewetted nanoparticles and the particle diameter were found to increase as h

2 and h

5/3, respectively. Overall, the dewetting process is caused by the hydrodynamic instability arising when attractive intermolecular forces (as van der Waals forces) between the atoms forming the film become larger than the film-substrate of interfacial tension which provides the stabilizing effect. Under such conditions, an amplification of the film thickness fluctuations spontaneously occurs, eventually leading to film break-up and the formation of particles with a well-defined spatial order.

According to the theoretical model developed by the authors and their experimental data [

33],

Figure 19 reports (a) the evolution of the laser energy density threshold for melting Co films on SiO

2 versus the film thickness. The plot shows the comparison of experimentally measured values (solid circles) with calculations; (b) the calculated temporal profiles temperature obtained (using temperature independent parameters) for Co films of different thicknesses on SiO

2 under irradiation with 100 mJ/cm

2; (c) the calculated temporal profiles’ temperature obtained for Co films of different thicknesses on SiO

2 (under 125 mJ/cm

2) including the phase change and temperature-dependent parameters in the model; (d) the thermal gradient ∂T/∂h predicted from the thermal model whose magnitude and sign were dependent on the film thickness and time to melt (1, 3, or 9 ns) during the film heating. From the experimental point of view, the authors [

33] conducted a detailed study on the dewetting morphology for various laser energies as a function of the laser number of pulses. They found that for Co films with a thickness in the range of 3–7 nm (

Figure 20 and

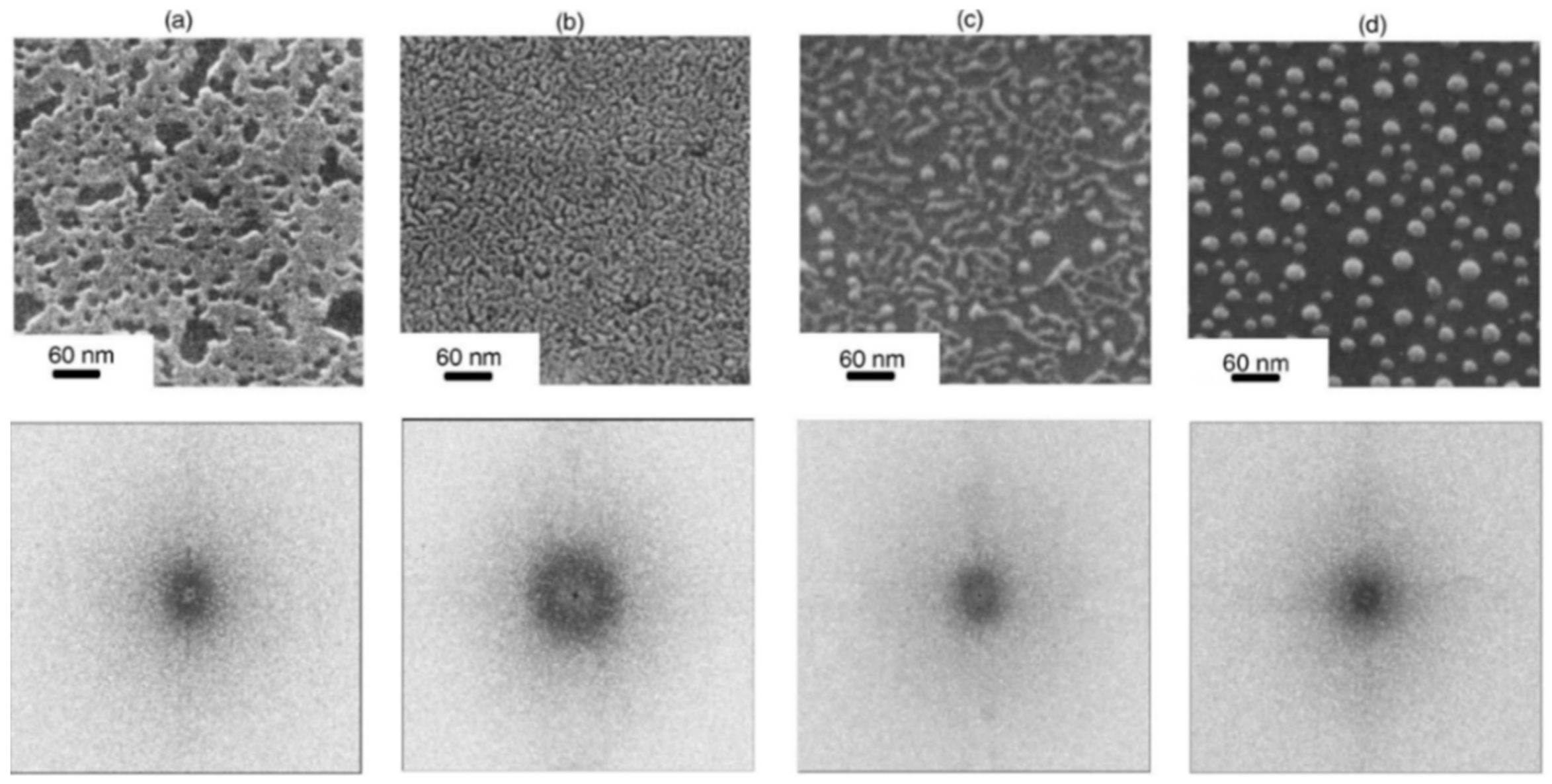

Figure 21), the typical patterns are formed by separated holes at the early stages of irradiation, followed by a cellular network at the later stages, and finally, nanoparticles which continue to remain stable upon further irradiation.

On the other hand, for films with a thickness lower than 3 nm (

Figure 20 and

Figure 21), the morphology appears as discrete holes followed by a bicontinuous structure and followed by a final state characterized, again, by nanoparticles. The general theory of the dewetting process [

33,

102] predicts three main underlaying mechanisms: (1) the homogeneous nucleation and growth in which holes are formed randomly in the location and time on the film surface, therefore, no characteristic length is present in this type of dewetting [

103]; (2) heterogeneous nucleation and growth due to defects, impurities, or more general film heterogeneities and, in this case, the early stages of dewetting could establish a characteristic length scale in the dewetting pattern due to the ordered nucleation sites; (3) thin film hydrodynamic instabilities (as in the case of spinodal dewetting unstable systems and, in this case, the resulting patterns present a well-defined length scale in the holes spacing and size. In this regard,

Figure 20 reports the morphology of a 2 nm-thick Co film as a function of the increasing number of laser pulses at a fluence of 200 mJ/cm

2. Separated holes are visible after a low number of pulses (

Figure 20a) with the pattern evolving to a bicontinuous structure (

Figure 20c,d) and, finally, into nanoparticles (

Figure 20d). A comparison of the density of features in

Figure 20c,d indicates that the nanoparticles originate from wires.

Figure 21a–d shows the pattern morphology after 100 pulses as a function of laser fluence for the 2 nm-thick Co film. The general characteristics of the morphology were similar to those observed as a function of the pulses number, as shown in

Figure 20.

Figure 21e–h presents the morphology of a 4.4 nm-thick Co film as a function of the number of laser pulses at a fluence of 93 mJ/cm

2. Discrete holes are visible after the lowest number of pulses (

Figure 21e), with the pattern evolving to a cellular web (

Figure 21f) as the number of holes increases. Further increasing the number of pulses causes the retraction of the metal towards the edge of the holes so that the pattern evolves to large polygonal structures with evidence for particle formation preferentially at the vertices of the polygons. This is more evident in

Figure 21g. After a high number of pulses, stable (against continued irradiation) nanoparticles were observed (

Figure 21h).

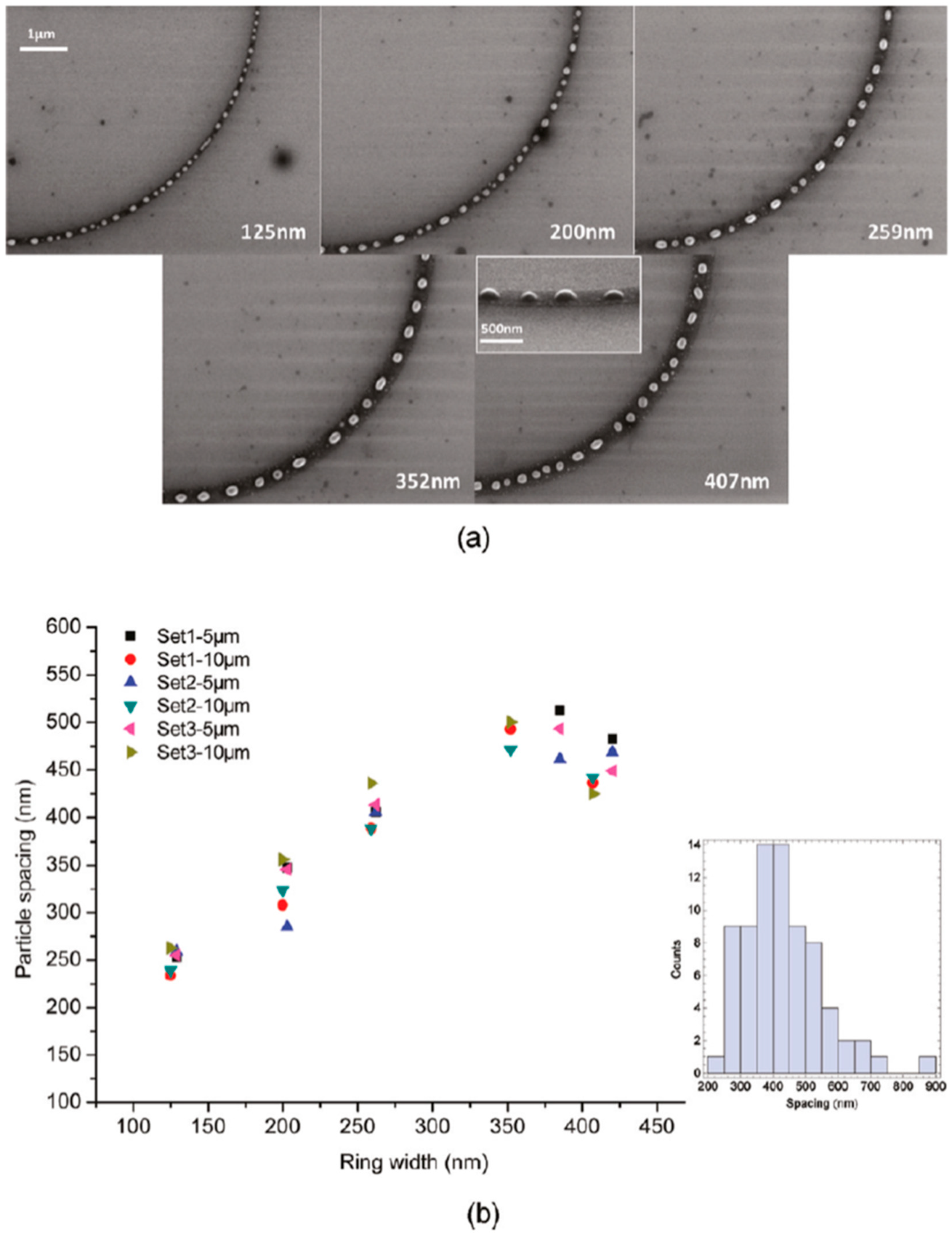

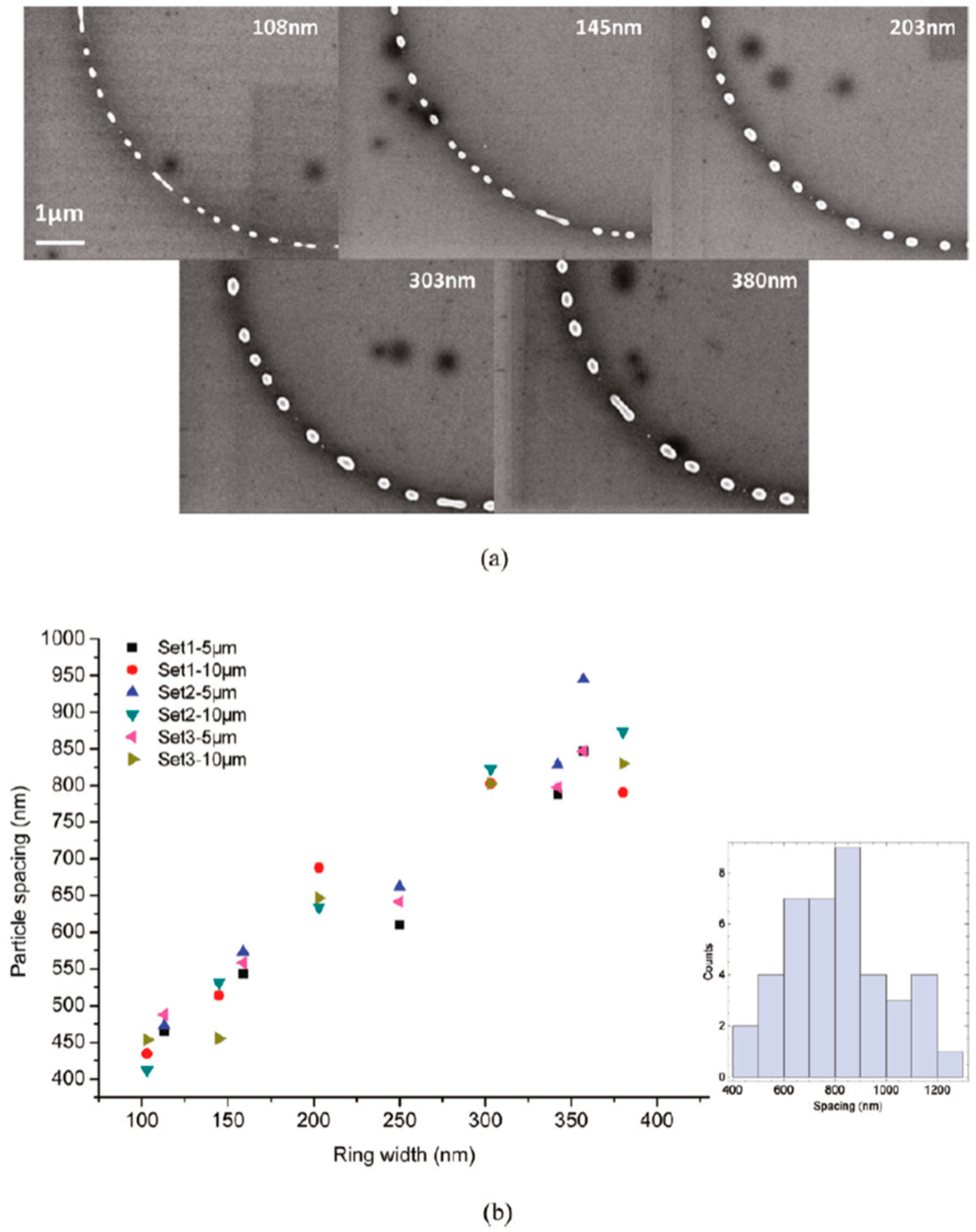

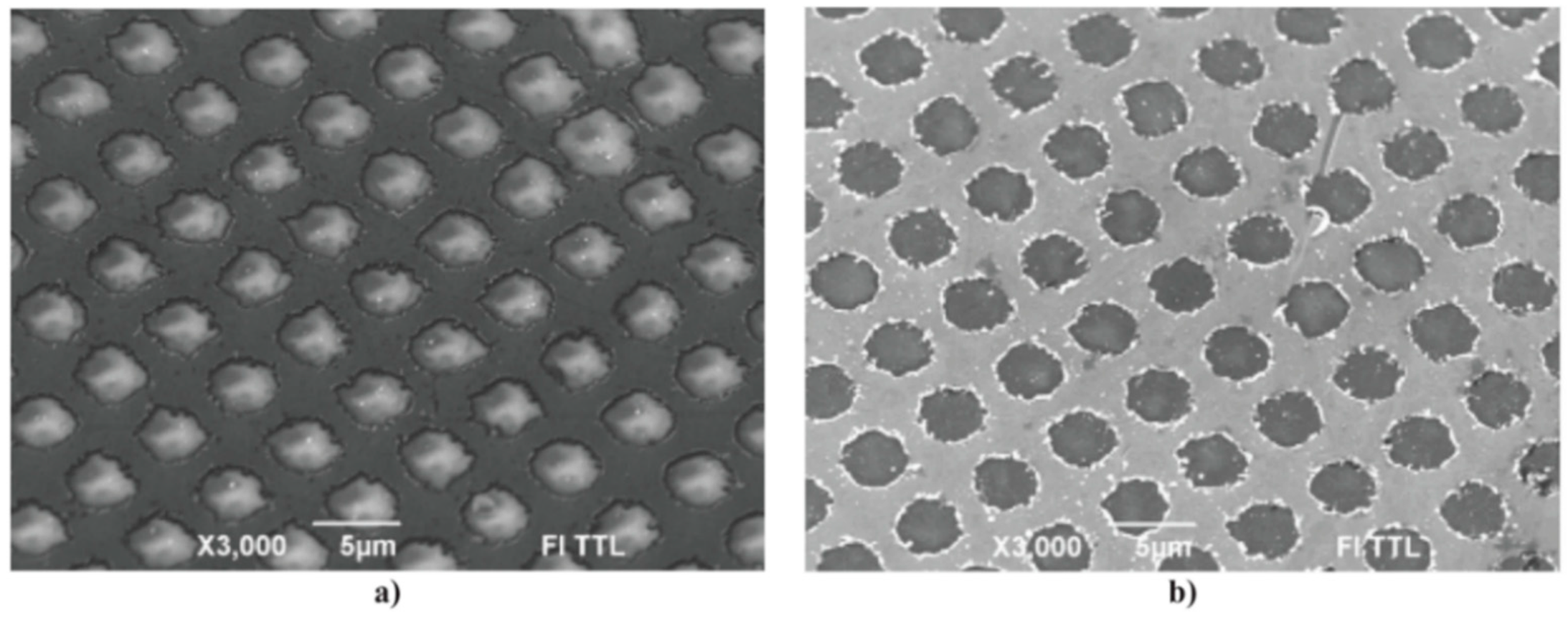

Wu et al. [

42] exploited the laser-induced dewetting approach for the nanostructuration of patterned metal films on substrates, i.e., to produce, on the surface, two-dimensional arrays of metal nanoparticles with specific spatial arrangements. In particular, they produced, on 100 nm-thick SiO

2 deposited on Si, nanoscale-thick Cu rings by the electron beam lithography approach. Cu rings with two thicknesses (7.8 and 15 nm), two radii (5 and 10 μm), and variable ring widths (ranging from 103 to 420 nm) were patterned. These continuous Cu rings were melted by laser irradiations using five pulses, a laser wavelength of 248 nm, a pulse duration of 18 ns, and a laser fluence of 160 mJ/cm

2 (higher than the threshold for melting).

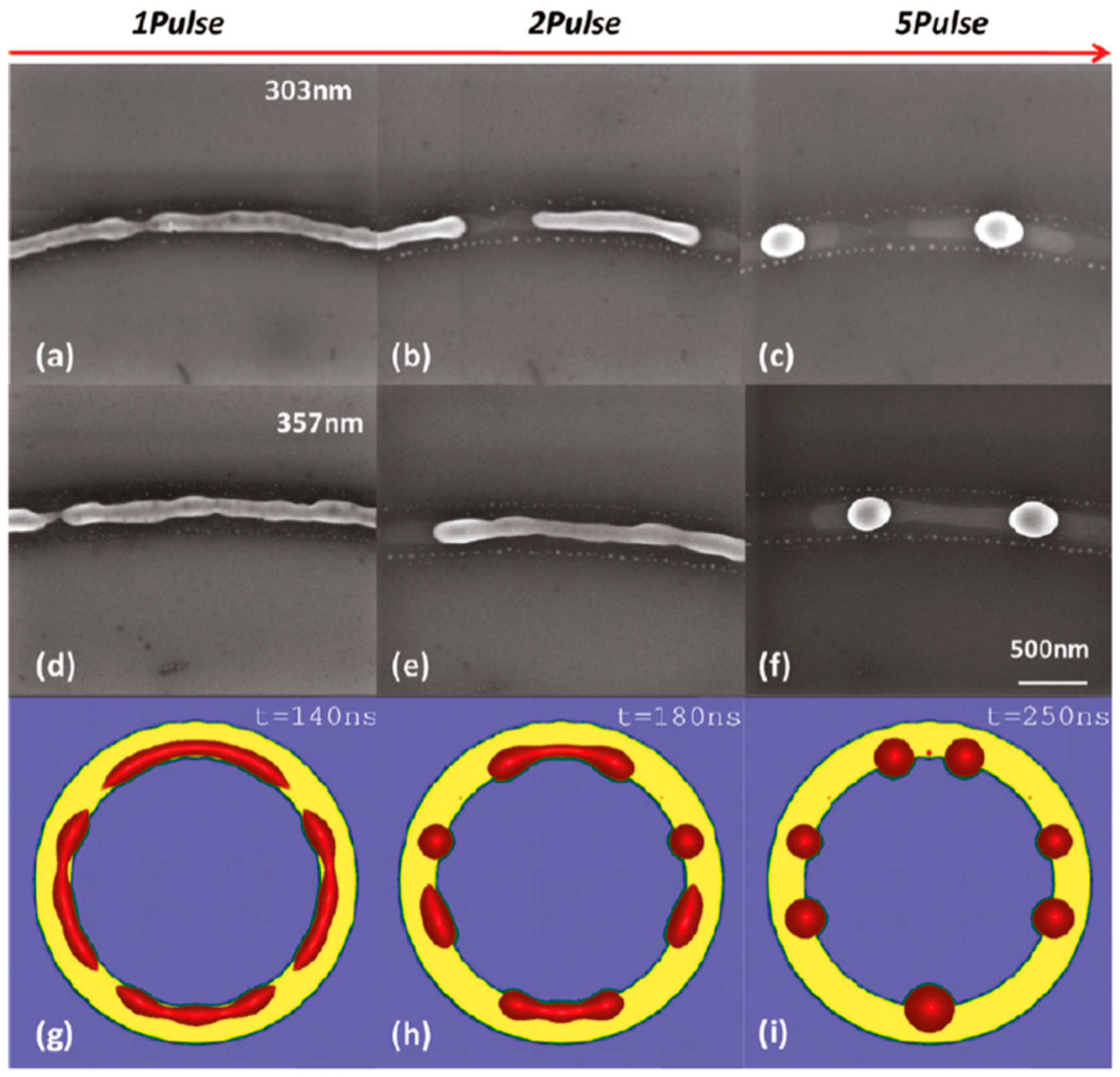

Figure 22 and

Figure 23 show the formation of ordered rings of Cu nanoparticles whose spacings (and sizes) increase smoothly and monotonically by increasing the ring width. Such an increase of the average spacing with the ring width should be determined by a ring evolution dominated by the Rayleigh instability (i.e., the contraction of the ring followed by a breakup in droplets) [

104]. However, the authors, crossing experimental and theoretical investigations, found some confirmations and some discrepancies for the Rayleigh instability as the leading driving phenomenon. In fact, the authors developed models to evaluate the typical time scales for different processes (thin film instability, Rayleigh instability) and the influence of these time scales on ring dewetting was analyzed for different initial thicknesses of the ring with the results summarized in the following:

- a)

7.8 nm-thick ring: for the width of the ring lower than or equal to 350 nm, the mean spacing between the formed Cu nanoparticles increases by increasing the ring width (see

Figure 22) and basically follows the length scale as expected from the Rayleigh instability mechanism. However, for a ring width larger than 350 nm, the data in

Figure 22 suggest a saturation regime followed by the particles spacing decreasing the bu, further increasing the ring width. However, the theoretical calculations show that for the 100 nm wide ring, the time for the molten ring to reach the equilibrium shape is ~2 ns, which is less than the thin film instability time calculated in 6.5 ns. So, the dynamics of the molten ring formation is faster than the thin film instability and the subsequent molten ring is expected to decay according to the Rayleigh instability. For rings with a width of 300 and 500 nm, the calculated time scale for thin-film instability is shorter than the calculated retraction time. However, the difference is not very large and, therefore, the Rayleigh instability can be considered the dominant mechanism determining the distance between the Cu droplets. To further extend the conclusions for the 7.8 nm-thick rings, the authors [

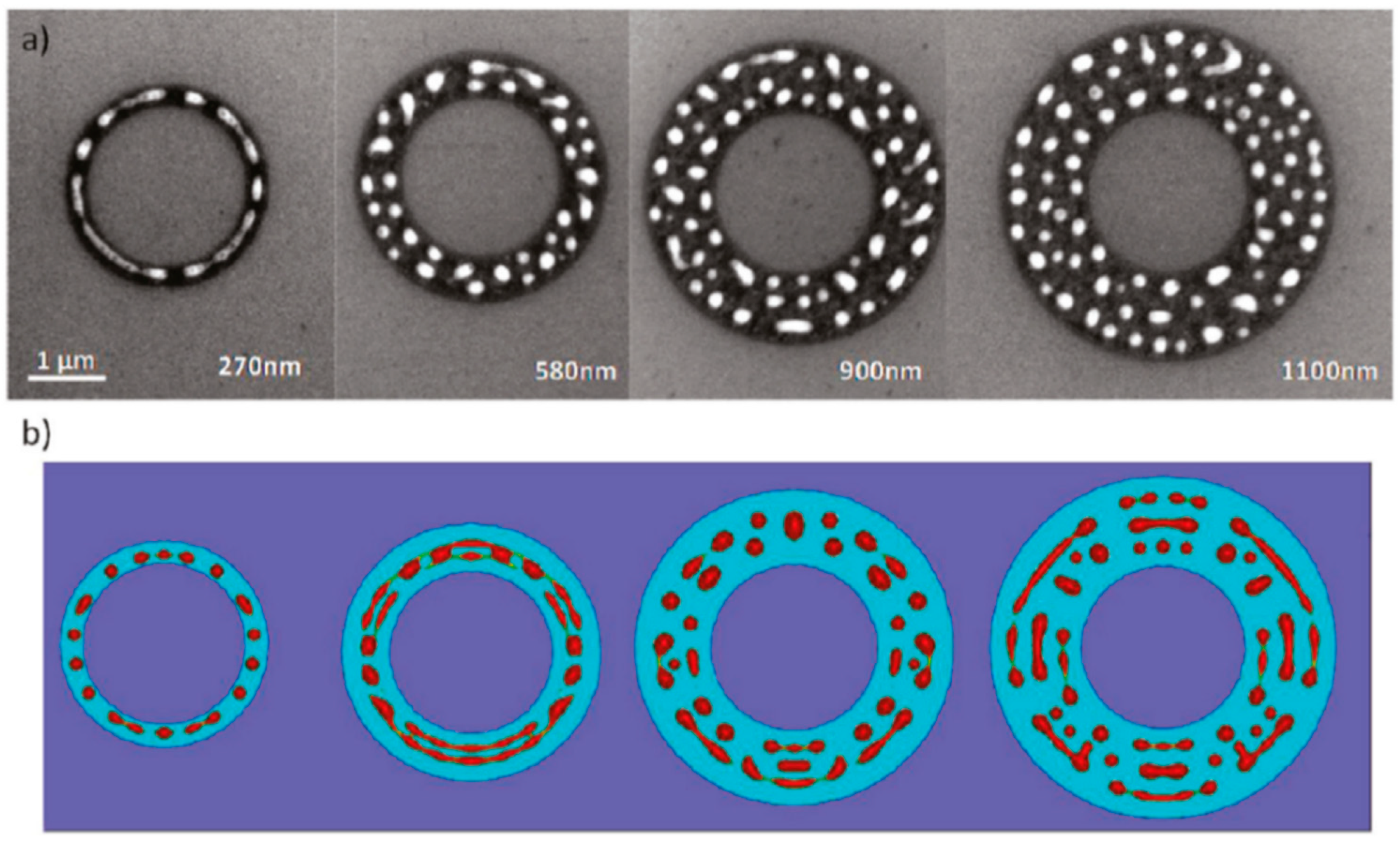

42] also fabricated rings with a width ranging from 270 nm to 1100 nm and a radius of 1 μm (see

Figure 24). In this case, the authors observed a transition from a single rivulet to several concentric rings of nanoparticles, as recognizable both from the experimental SEM images and the two-dimensional (2D) simulations in

Figure 24. In particular, the 2D numerical simulations shown in

Figure 24b indicate that the original ring evolves into two rings which subsequently decay in droplets following the Rayleigh mechanism.

- b)

15 nm-thick rings: in this case, the rings are predicted by the author’s model to decay due to the Rayleigh instability and this prediction is in general agreement with the experimental trend observed in

Figure 25. However, the experimental average spacing for the obtained nanoparticles is larger than the expected one considering only the Rayleigh mechanism.

Figure 25, in particular, reports a comparison of the experimental observations and 2D numerical calculations to draw further information on the involved phenomena. In the experimental part (

Figure 25a–f), the instability evolution can be observed to increase the number of laser pulses by increasing the ring width (303 and 357 nm). In the simulation row (

Figure 25g–i), the results of the 2D simulations carried out for the ring width of 350 nm and radius of 1 μm radius are reported. The distance between the drops in the experiments (see

Figure 25c–f) appears large compared to the wavelength of the fastest growing perturbations which can be seen in

Figure 25a,d.

This is due to the fact that the starting ring initially breaks into sections at a few locations (four in the example shown in

Figure 25h), leading to rivulets longer than the wavelength of the perturbation growing at the highest rate. These rivulets, if long enough, consequently decay into droplets. However, if the rivulets are not sufficiently long (about twice the maximum wavelength of the growing perturbations’ maximum), they may decay just into a single particle.

Overall, for both the thin and thick rings, the distance between the particles is larger than the one predicted by the Rayleigh mechanism. This difference between the experimental results and the prediction of the Rayleigh model is particularly significant for thicker rings and this difference is imputated by the authors to nonlinear effects combined with the fast-circumferential transport.

These results by Wu et al. [

42], then, throw new light on the previous results by Henley et al. [

27] and Trice and al. [

33]: even if hydrodynamic film instabilities are the main reason for the film dewetting, the results of Wu et al. [

42] show, also, the necessity, in particular conditions (thicker rings) to invoke additional (nonlinear) mechanisms affecting the metal films’ dewetting process.

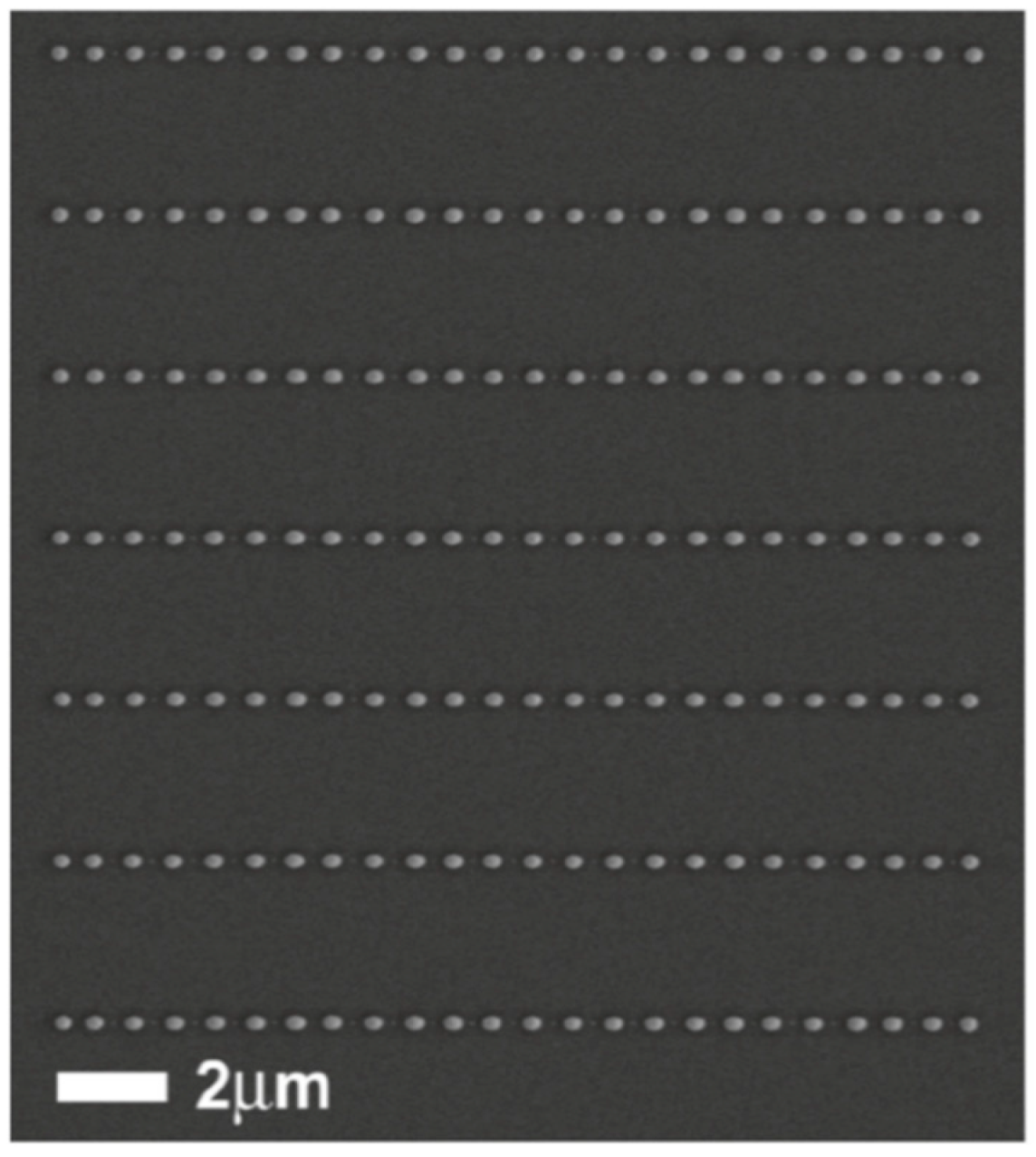

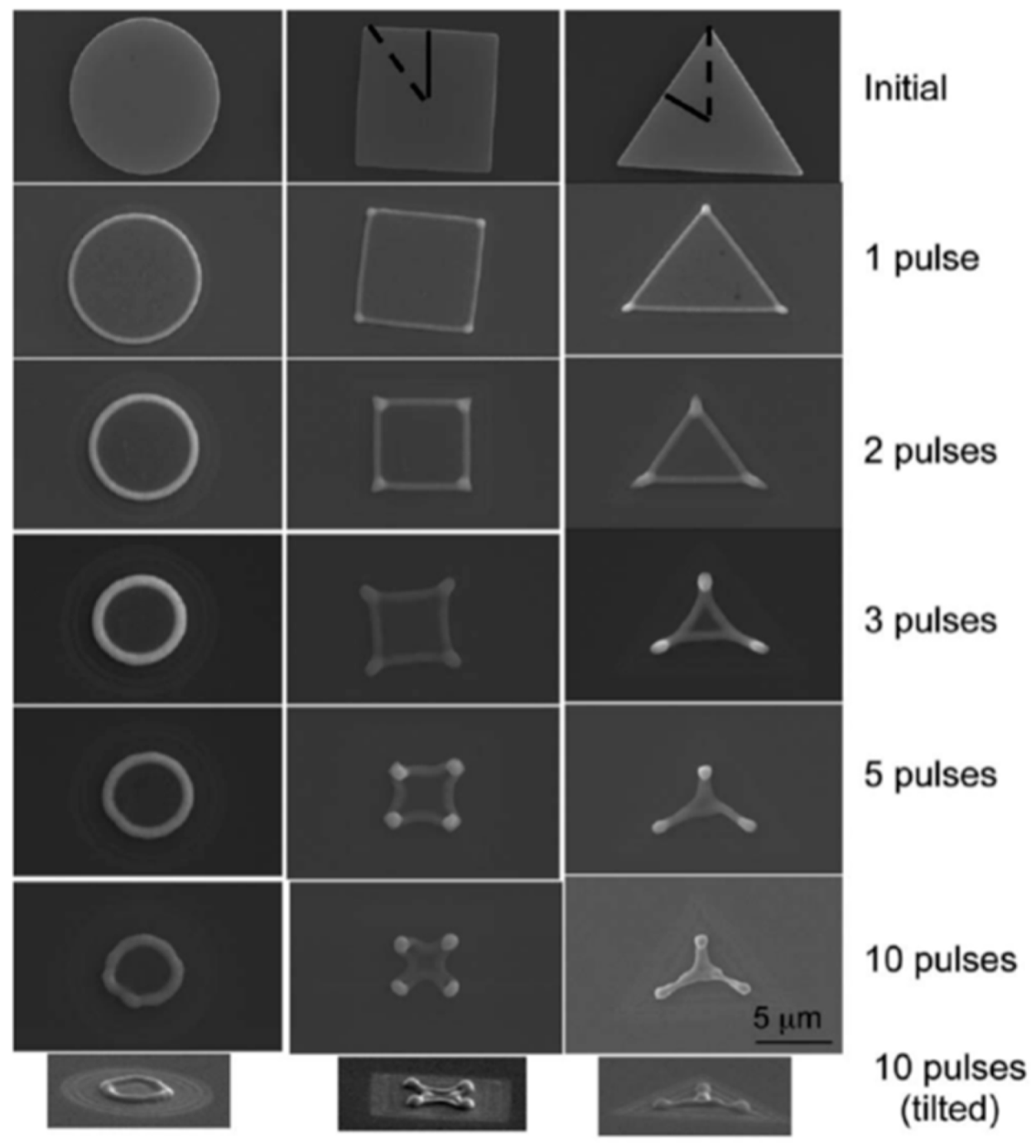

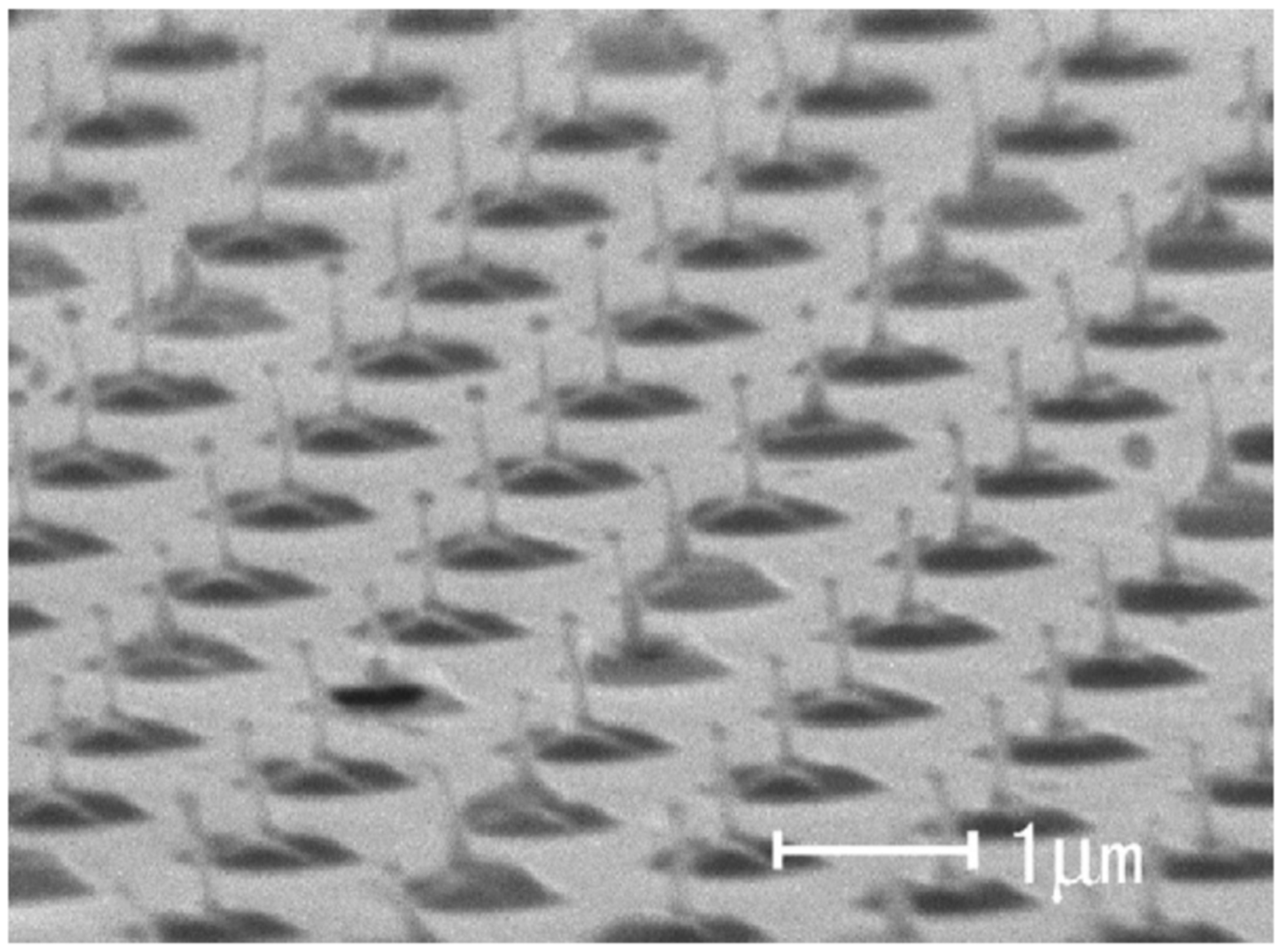

From an experimental point of view, similar approaches to that proposes by Wu et al. were widely used to produce arrays of metal nanoparticles on surfaces with desired spatial configurations as lines of Ni nanoparticles (see

Figure 26) obtained by Fowlkes et al. [

43] or micro- and nano-patterned complex-morphology Ni structures (see

Figure 27) by exploiting the laser-induced dewetting process of patterned films at various intermediate stages as obtained by Rack et al. [

105].

4. Nanostructuration of Thin Metal Films by Picosecond Pulsed Laser Irradiations

Picosecond-pulsed laser irradiation of metals allows the spatial confined removal (ablation) of the material with high accuracy due to the reduced heat affected region compared to nanosecond-pulsed laser irradiation and this peculiarity can be exploited to produce micro- and nano-sized features on metal targets or deposited metal films.

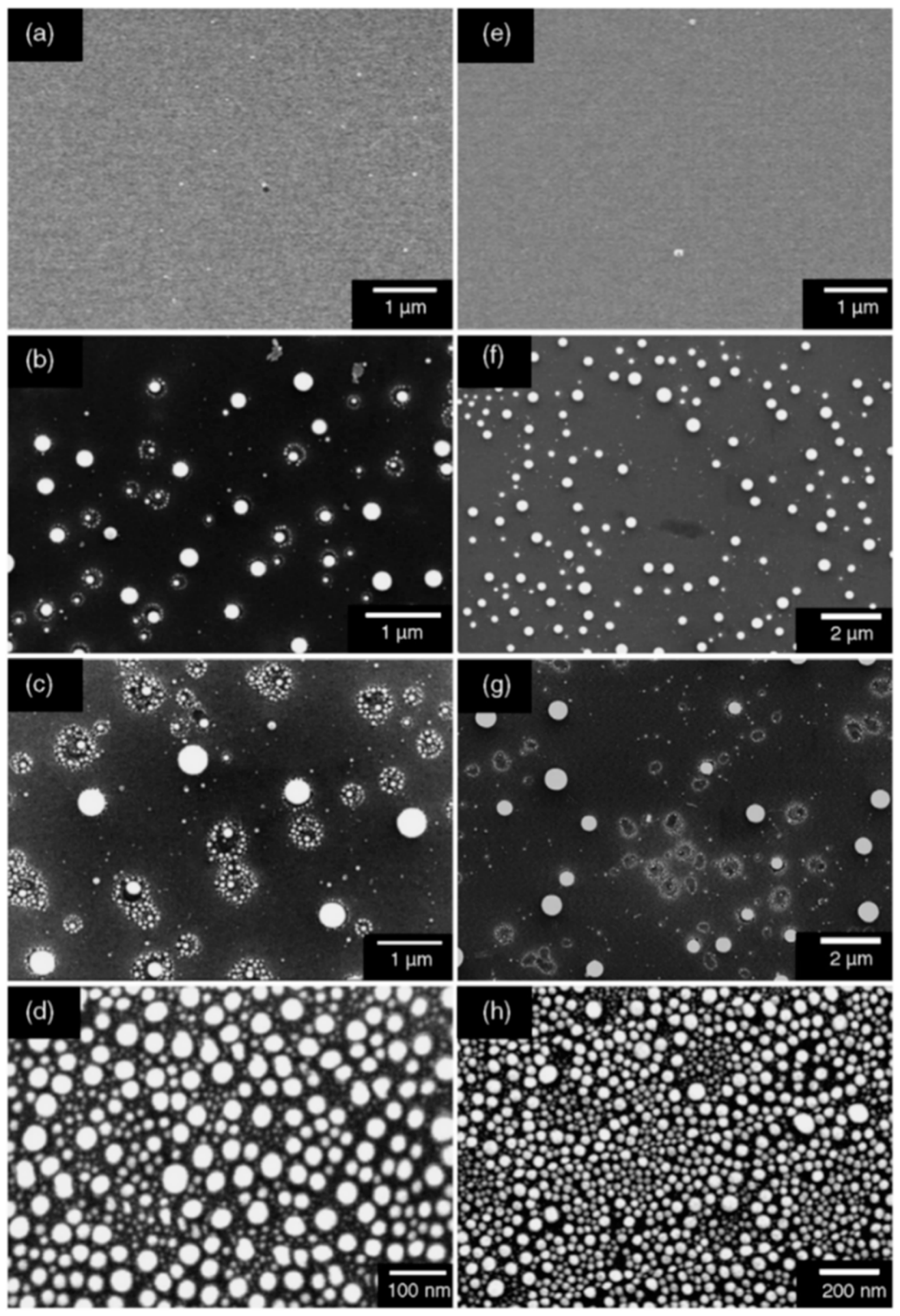

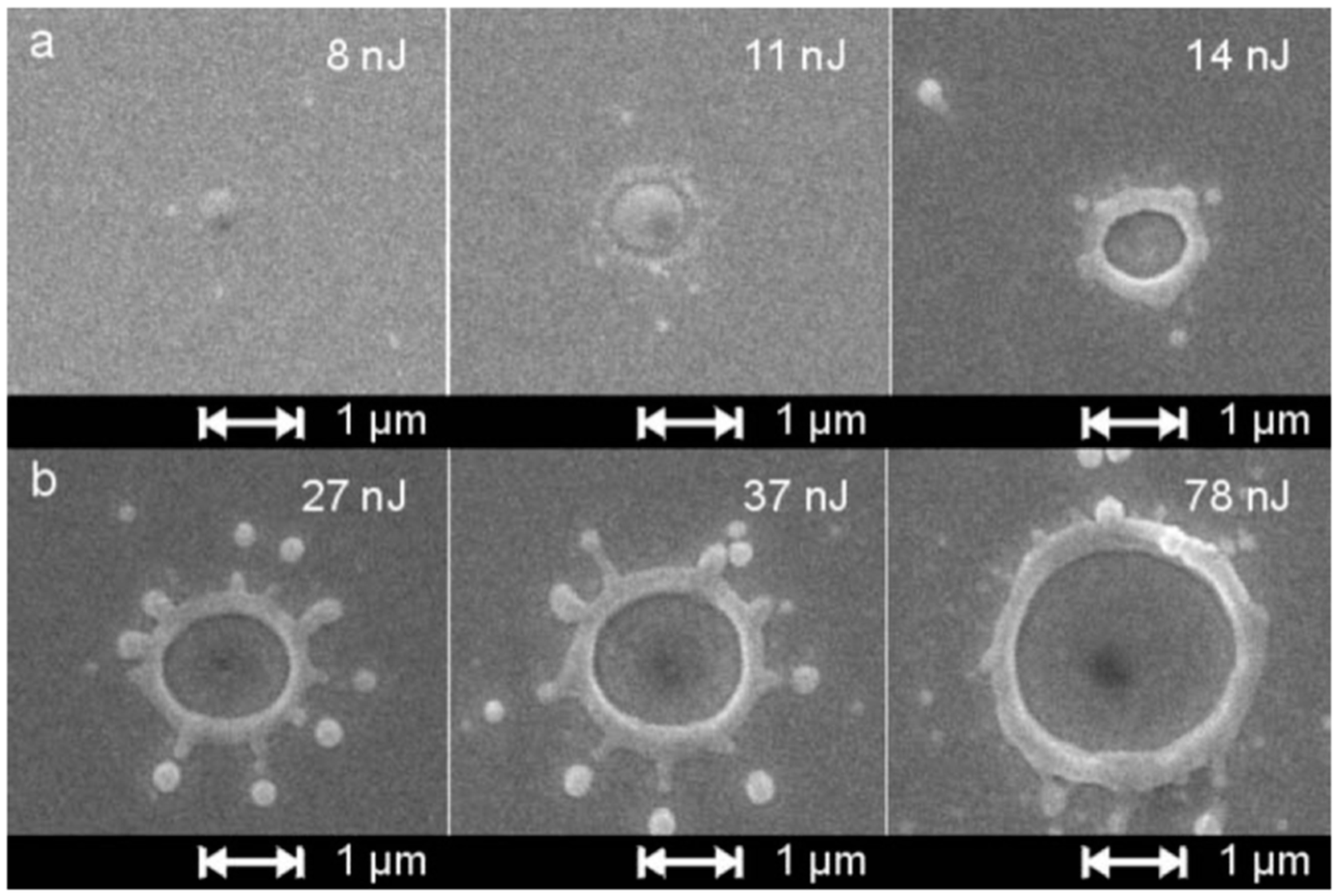

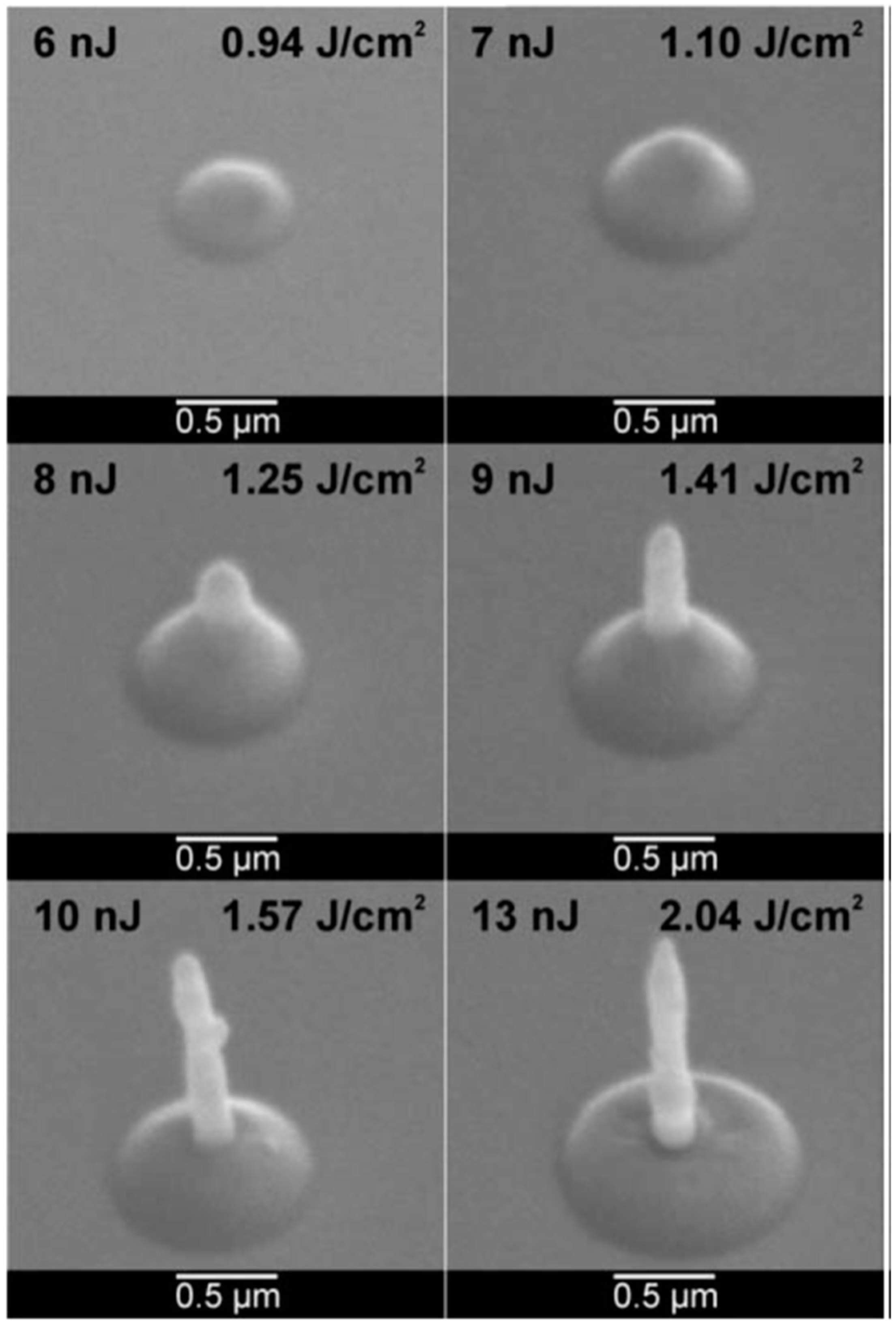

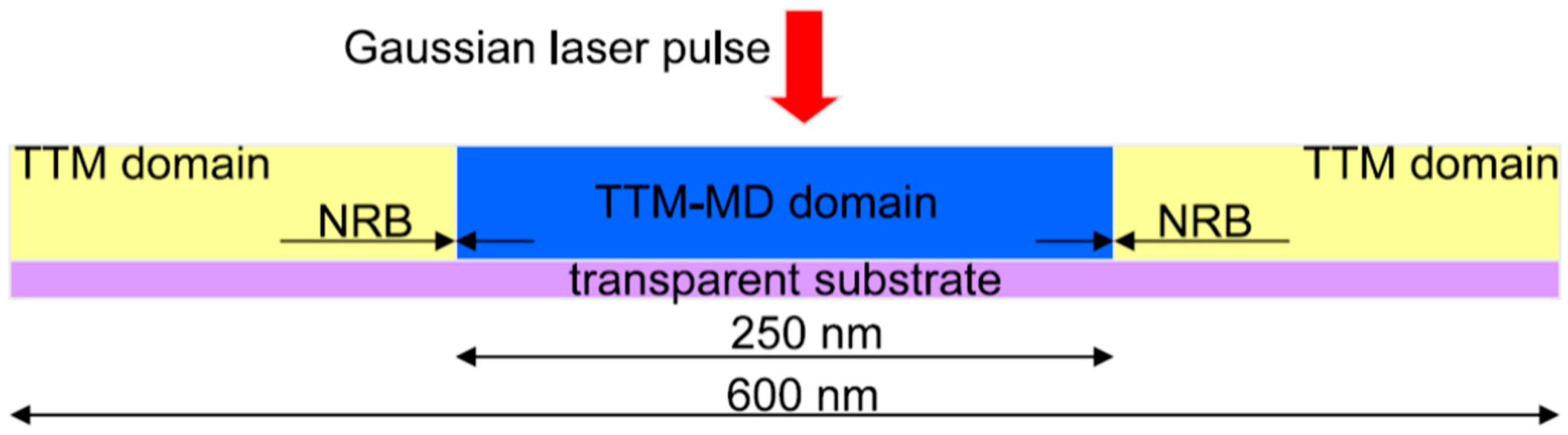

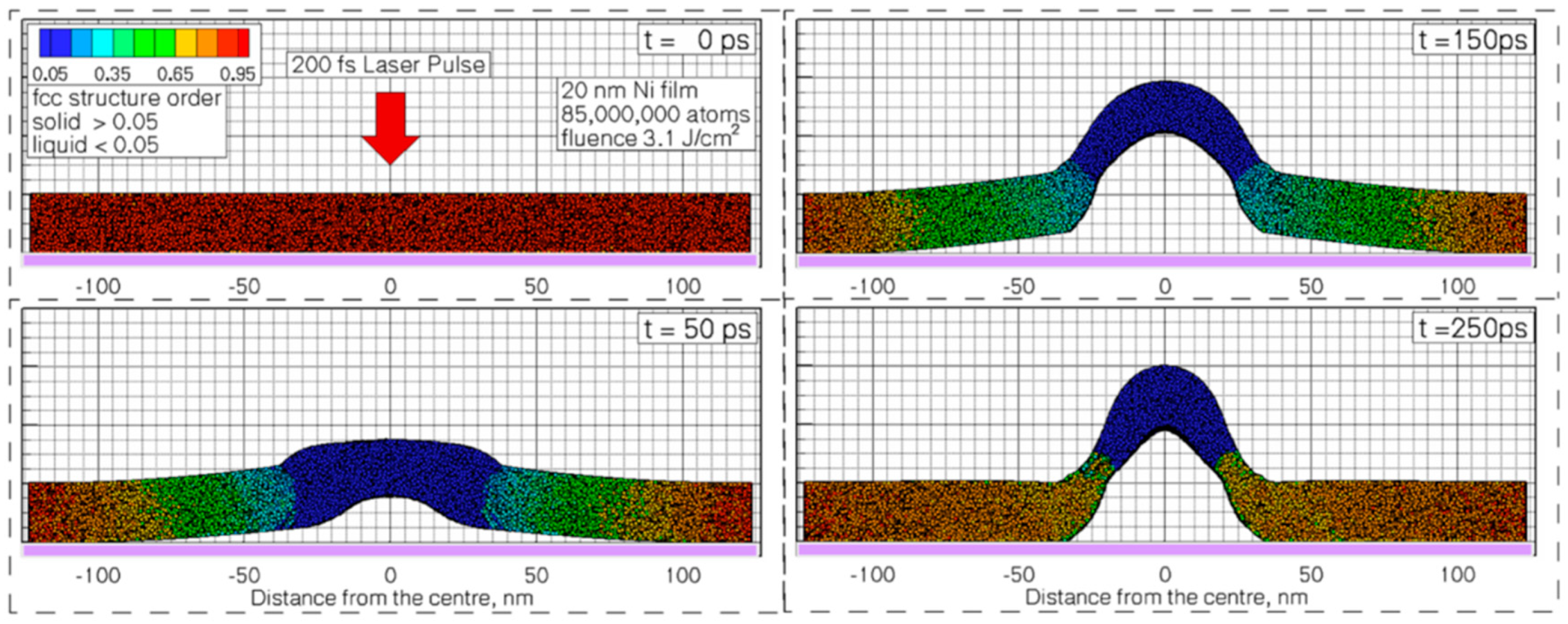

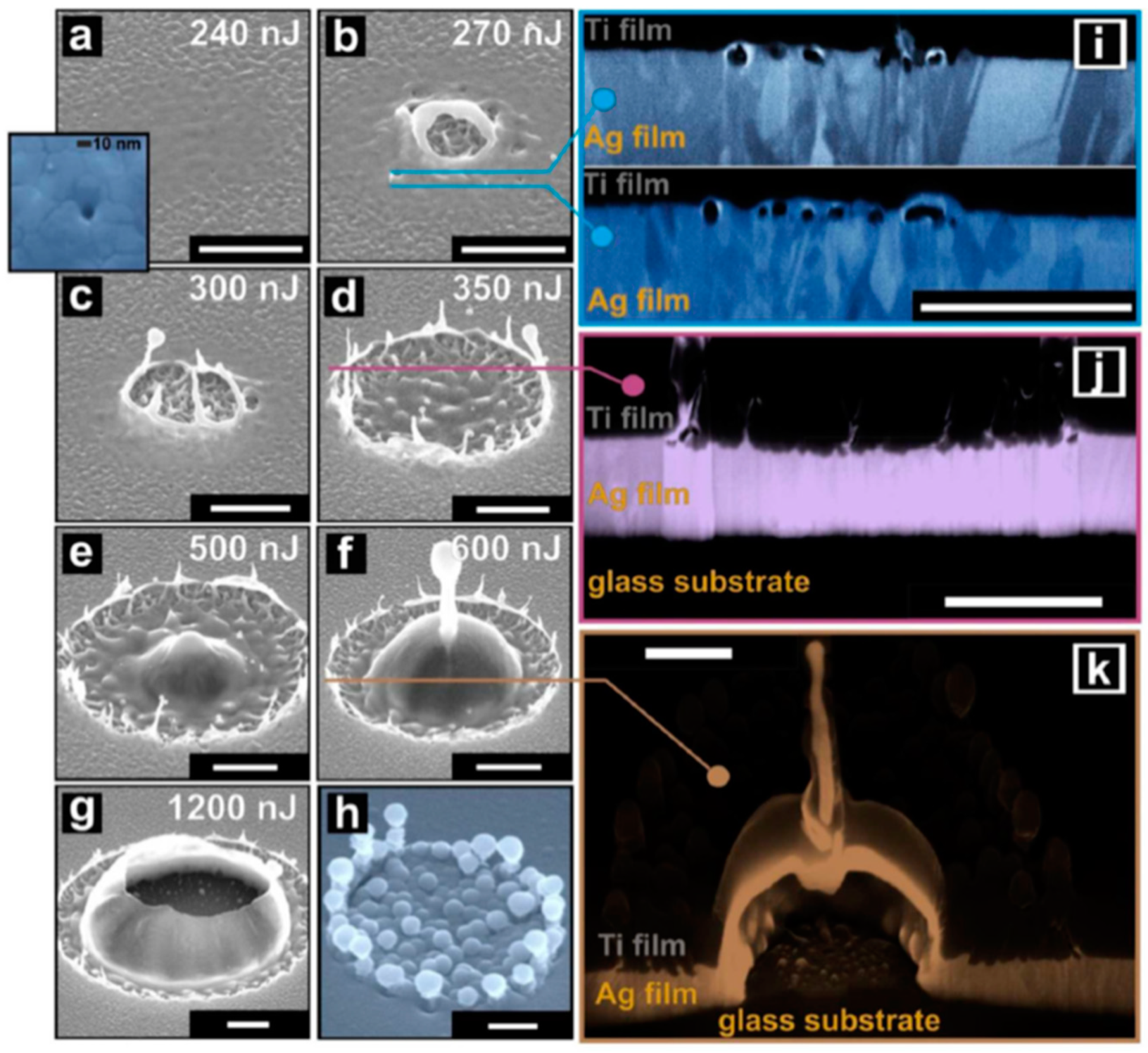

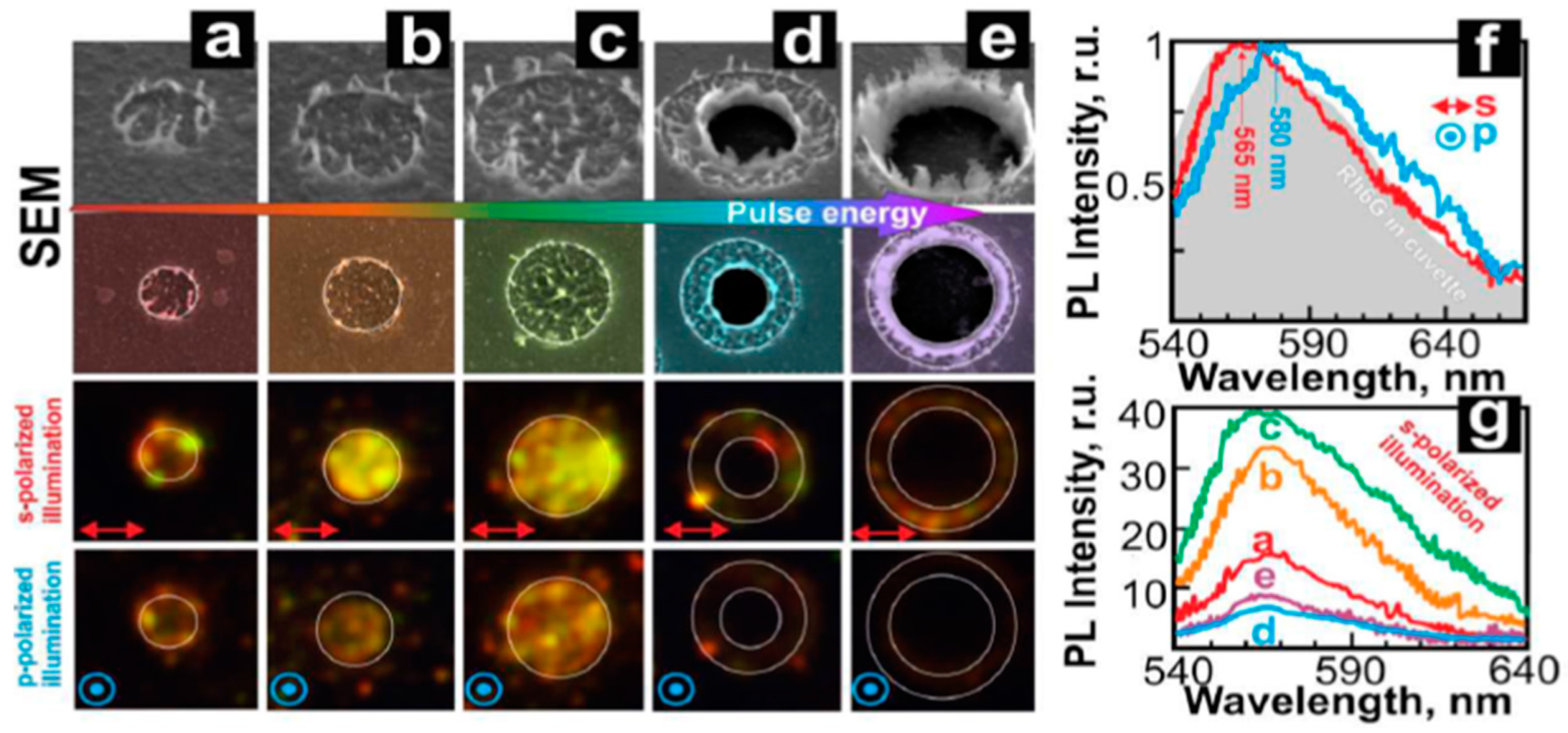

As an example, Olbrich et al. [

54] studied the ablation process of Au, Pt, Al, Ni, Mo films (deposited on glass with a thickness in the 300–2000 nm range) as induced by a single laser pulse with a wavelength of 1028 nm and pulse duration variable in the 200 fs–15 ps range. As we generally discussed in

Section 2, as a laser pulse incides on a metal surface, the laser light can be partially reflected and transmitted throughout the surface. The laser intensity decreases within the metal due to absorption of the laser-generated energy by the electrons of the metal and resulting in an excited non-equilibrium state. The hot electrons diffuse within the material and the electron-electron scattering events provide a transfer energy pathway. After the electron relaxation time, the standard Fermi distribution describes the energy distribution for the electrons and the temperature evolution of the electrons and phonons system can be described by the two-temperatures model. In the theoretical and experimental studies by Olbrich et al. [

54], the metals Au, Pt, Al, Ni and Mo were chosen since they present very different thermophysical properties, especially their electron-phonon relaxation time; see

Figure 3. From a theoretical point of view, the calculations performed by Olbrich et al. [

54] (see

Figure 4), considering a pulse laser irradiation with a pulse duration of τ

H = 200 fs (

Figure 4 left) or τ

H = 10 ps (

Figure 4 right) and a laser energy of 1 μJ and a laser wavelength of 1028 nm, show that for Au, Pt, Al, Ni, and Mo, T

max,e (the maximum electronic temperature) is higher for τ

H = 200 fs than for τ

H = 10 ps. In addition, the highest T

max,e, for τ

H = 200 fs, is reached in Al. On the other hand, the irradiation for τ

H = 10 ps causes the highest T

max,e in Au and, in any case for Au, the maximum value for T

max, ph (the maximum phonons’ temperature) is reached later than the maximum value of T

max,e. These calculations were supported and compared to the experimental results. In particular, the authors [

54] irradiated Au, Pt, Al, Ni, and Mo thin films by a single laser pulse, changing the laser energy for two fixed pulse durations (200 fs and 10 ps) and studied the resulting film morphology modifications. Some results are summarized in

Figure 28 which reports on the images showing the morphological effects of the irradiations on all the investigated metals, fixing a laser energy of 53 μJ and for the two different pulse durations. For each pulse duration, the left images report reflection-mode optical microscopy images and the right images report the corresponding confocal microscopy images. In particular, the authors observed in the cases of Au and Al, that the whole film is ablated and the metal structures remaining on the surface and originating from the ablation process are higher at the edges of the modified ones, indicating a delamination of the film around these regions. A possible explanation for the formation of these structures is presented by the authors [

54] in the spallation process of a microbump [

106,

107]. The morphology evidenced by the confocal microscopy images acquired for Pt, Ni, Mo processed by the 200-fs laser pulse appears due to a non-circular intensity distribution of the laser radiation and on the outer edge. In these cases, the ablation depth of this morphology is measured in about 10–20 nm.

The results in

Figure 28 evidence, also, a dependency of the morphology of the produced features on the pulse duration (which is confirmed also by the dependence, for each metal, of the laser ablation threshold on the pulse duration which, generally, decreases by increasing the pulse duration apart for Au [

54]). Interestingly, the authors observed that the calculated laser energy thresholds for metal melting are lower than that experimentally derived. This difference was ascribed to the fact that small surface layers of molten metal are delaminated from the thin film due to the induced shockwave resulting from the ultrafast expansion of the material under the picosecond laser pulse [

108].

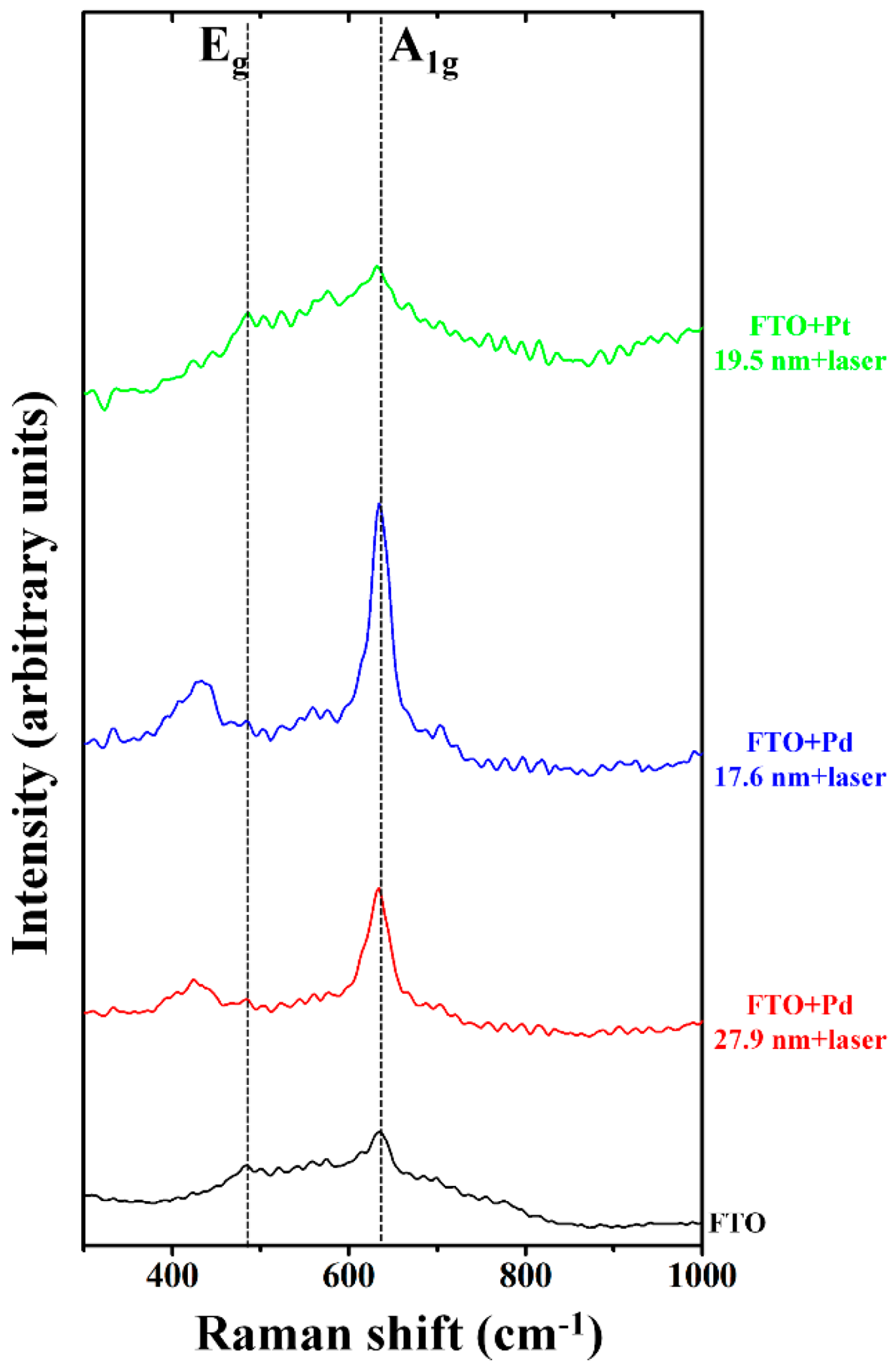

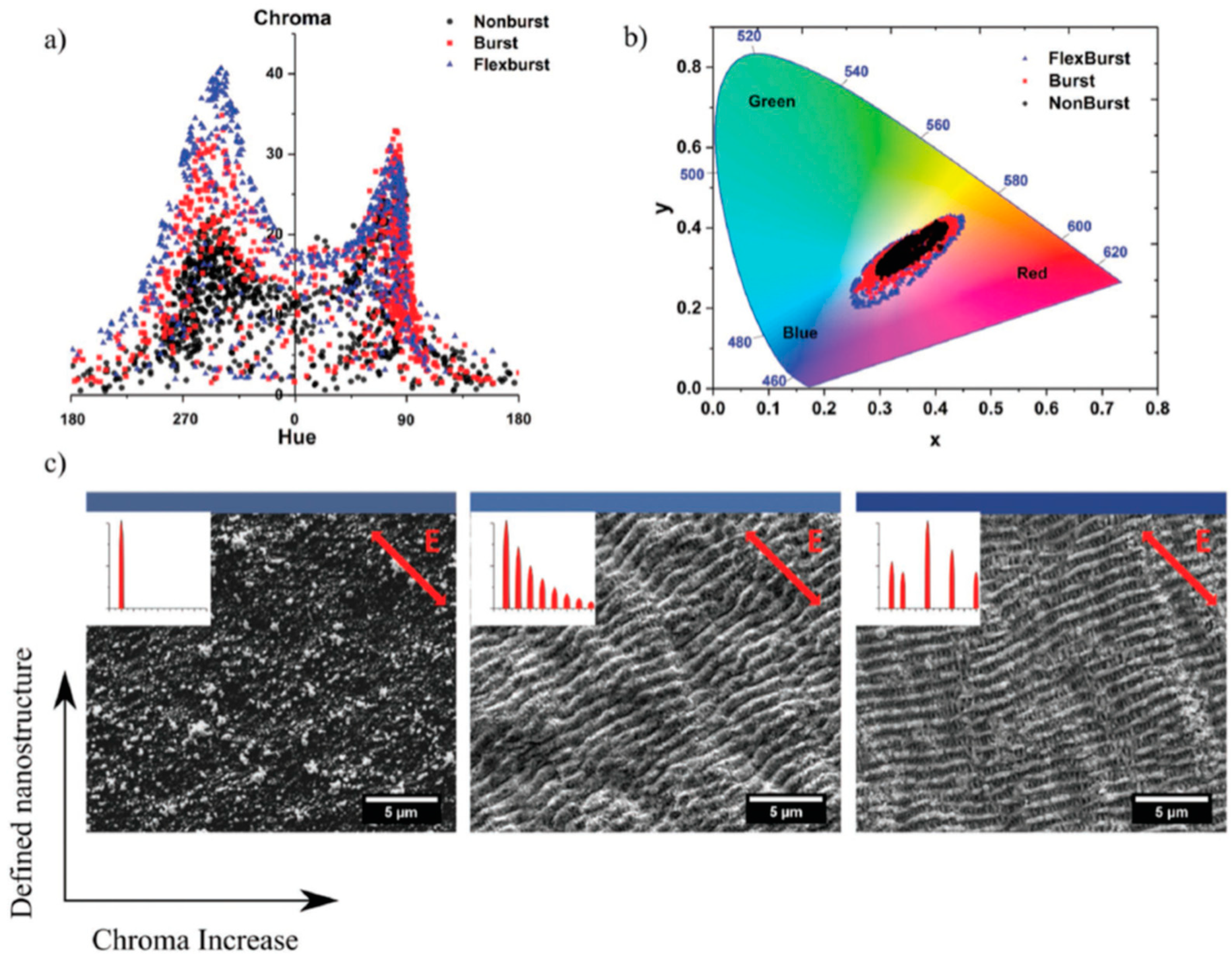

An important aspect related to the material irradiation by picosecond-pulsed laser relies in the formation of periodic surface structures. In this sense, for example, the characteristics of picosecond-pulsed laser-induced surface structure on metals (Cu) were studied by Maragkaki et al. [

109] referring, in this case, to a Cu bulk target instead of a thin film. However, the obtained results are interesting in view of the interpretation of results for deposited metal thin films.

In particular, the authors [

109] studied the mechanisms of the laser-induced periodic surface structures’ formation on the Cu surface (chosen due to its higher electrical and thermal conductivity, higher melting temperature, lower rates of diffusivity, and higher strengths than other standard metals). They focused the studies on the change of the average period for the laser-induced periodic surface structures as a function of the wavelength of the incident laser radiation using a 7 ps-pulsed laser. Interestingly, they compared the experimental results with the predictions obtained supposing that the surface-scattered laser waves are the main driving force for the laser-induced periodic surface structures’ formation, finding, however, a considerable disagreement. On the basis of this finding, they suggest, instead, that hydrodynamic mechanisms can be regarded as the main mechanism for the periodic surface structure formation and the compatible with the experimentally-observed pattern periodicity [

109]. According to Maragkaki et al. [

109], the main theories describing the laser-induced periodic surface structures’ formation are (1) the theory ascribing the laser-induced periodic surface structures’ formation to the interference of the incident laser with the surface scattered wave [

110,

111]; (2) the self-organization processes on the surface [

112,

113,

114,

115,

116]. In particular, for metallic surfaces, surface scattered radiation waves are described by surface plasmon polaritons [

117] evolving in localized plasmons as the surface roughness increases [

118]. In this view, surface roughness act as a coupling means for the incident laser wave with the surface (an effect described by the surface-scattered wave model [

110]). However, several experimental evidences [

113,

114] suggest that, in many situations, the plasmonic-based mechanism cannot solely describe the origin of laser-induced periodic surface structures’ formation without considering additional physical processes. For example, Raman measurements showed that the laser-induced periodic surface structures’ formation takes place in the molten phase [

114], indicating the occurrence of the hydrodynamic process in the pattern generation. For multi-pulse irradiation regimes, it was argued that the plasmonic stage, which governs the laser-induced periodic surface structures’ orientation, does not necessarily determine the periodicity of the final pattern due to the contribution of thermocapillary effects [

119]. The hydrodynamic processes can be more and more important in the formation of the periodic surface structures at high laser fluence for which the metal melting and ablation depths are larger [

120,

121]. From an experimental point of view, Maragkaki et al. [

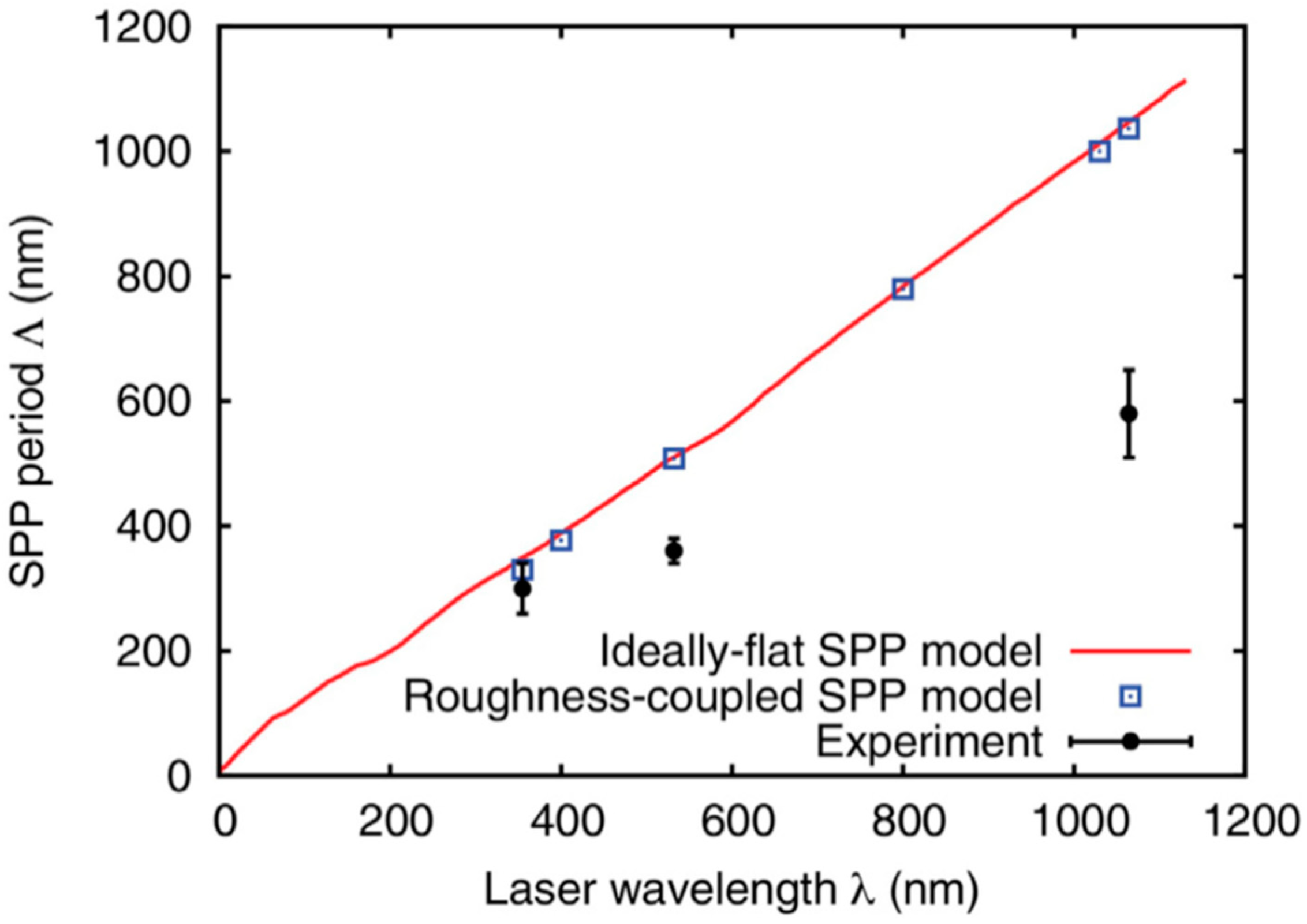

109] produced the laser-induced periodic surface structures on a Cu (bulk target) polished surface at three different wavelengths (355, 532, 1064 nm) of a laser pulse with a duration of 7 ns. The formation and evolution of the surface structures were studied by a scanning electron microscopy analysis. As examples,

Figure 29 and

Figure 30 report the SEM images of the laser-induced periodic surface structures produced by a single laser pulse at different wavelengths (355 nm in

Figure 29 and 1064 nm in

Figure 30). From these images, the authors evaluated the experimental period Λ for the produced surface structures; the black dots in

Figure 31.

According to Maragkaki et al., in the framework of the plasmonic model, the spatial period on the flat metallic surfaces is dependent on the laser wavelength λ by Λ = λ/[Re(√ε/1 + ε)] with ε being the wavelength-dependent dielectric constant of the metal [

109].

Figure 31 reports the prediction of this equation by the full red line. The calculations based on a more advanced model, which considers the shape and filling factors to describe randomly rough surfaces, lead to the blue squares in

Figure 31 (assuming reasonable values for the shape and filling factors).

Figure 31 clearly shows the disagreement between the experimental data and the predictions of the models based on the surface plasmon polaritons, i.e., the surface plasmon polaritons cannot be the only reason for the formation of the laser-induced periodic surface structures. Maragkaki et al. [

109], then, suggested a possible explanation for the laser-induced periodic surface structures’ formation based on a three-steps model involving hydrodynamic effects: (a) in the first step, the interference of the incident laser radiation with the surface scattered waves leads to a periodically modulated electron temperature in the metal; (b) in the second step, the evolution of the amplitude modulation in the electron temperature evolves occurs and, due to the electron-phonon thermalization, leads to an amplitude modulation in the lattice temperature [

122]; (c) in the third step, the molten metal hydrodynamic processes act as a means to relocate materials along the surface, resulting in the laser-induced periodic surface structures’ pattern [

112,

113,

114]. In particular, in this proposed model, metal redistribution induced by hydrodynamic instability should be dependent on many factors, including molten layer depth, melt viscosity and surface tension. These factors can provide the reasons for the deviation of the laser-induced periodic surface structures period from the initial interference pattern dictated on the surface by the interference of the incident and scattered laser waves.

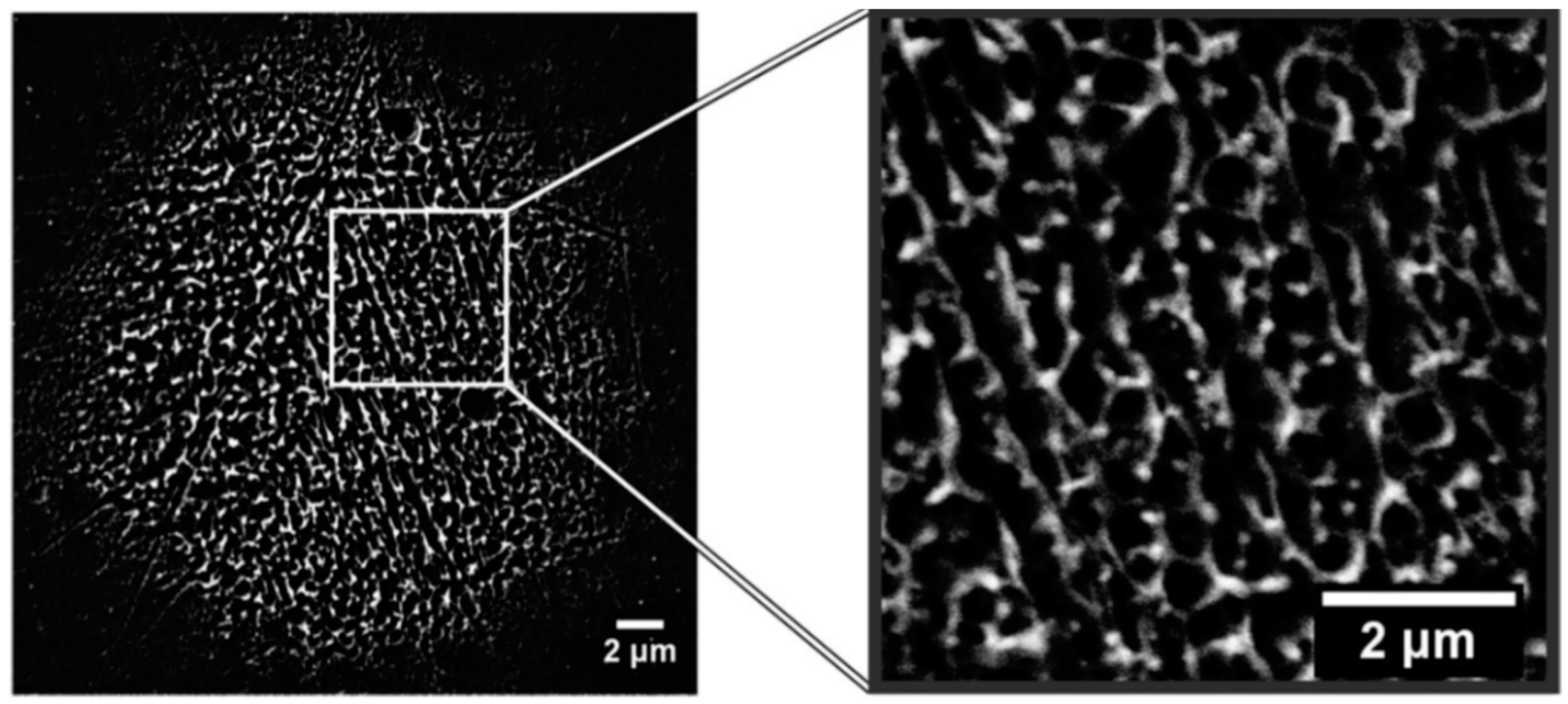

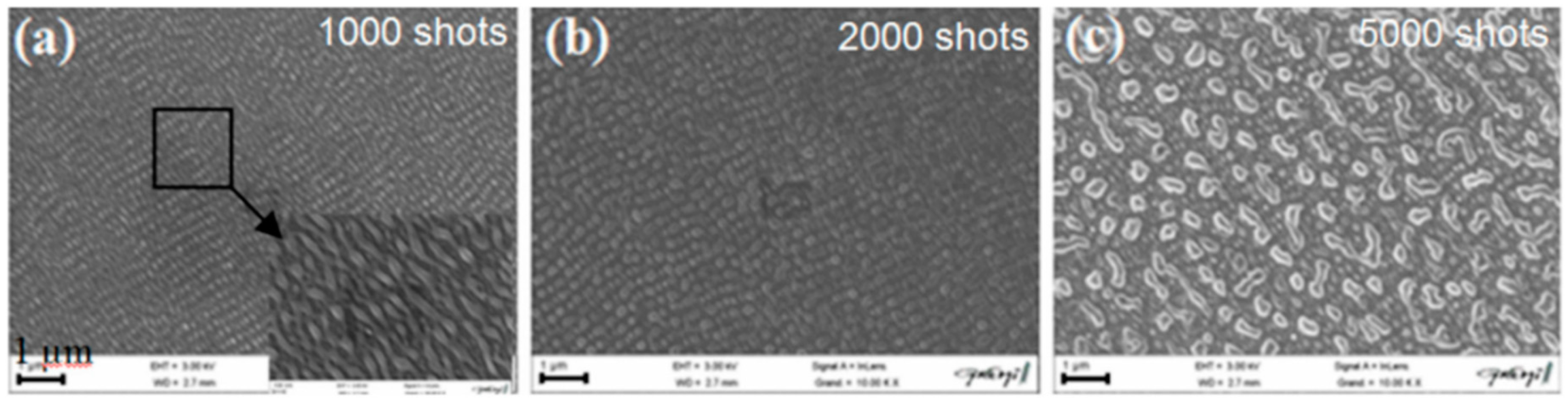

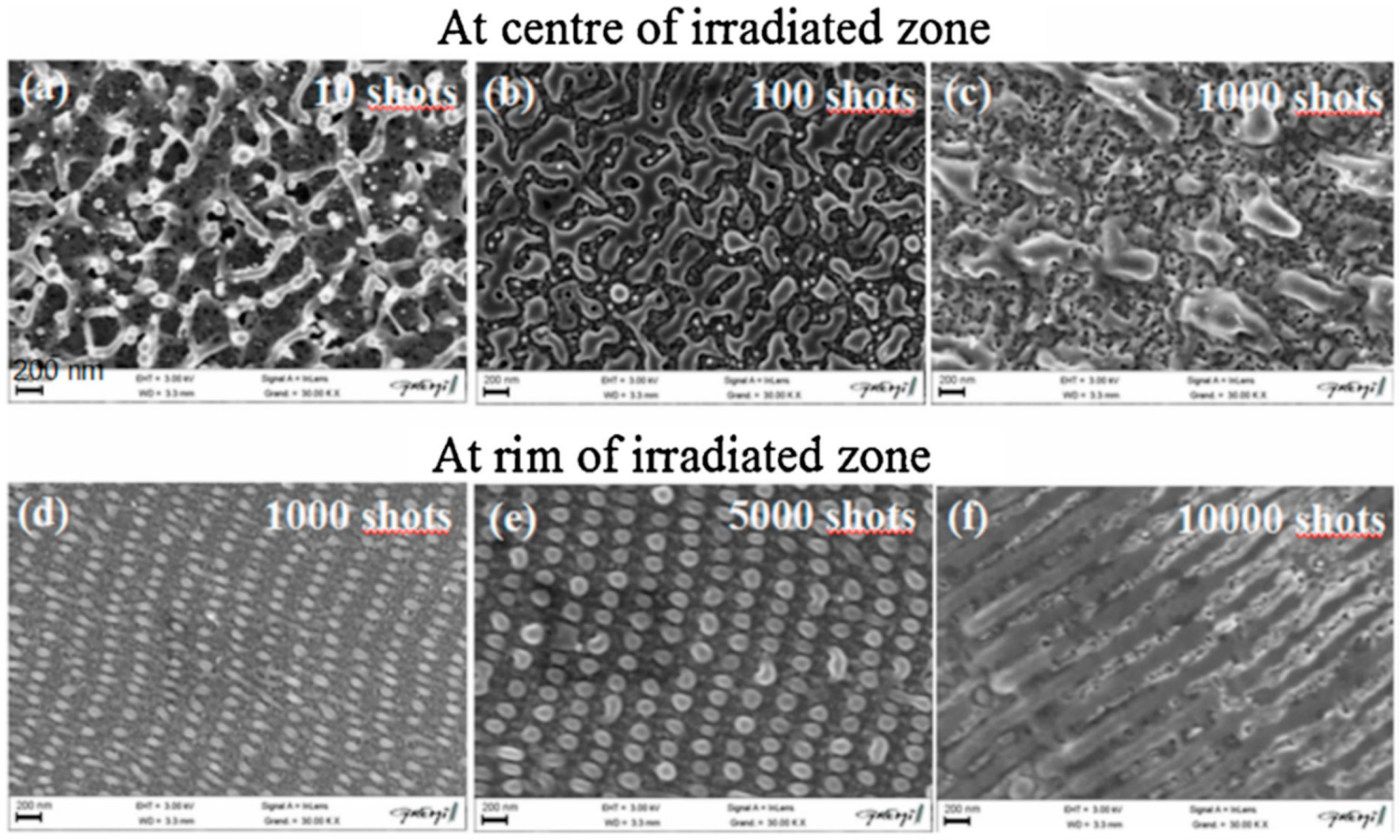

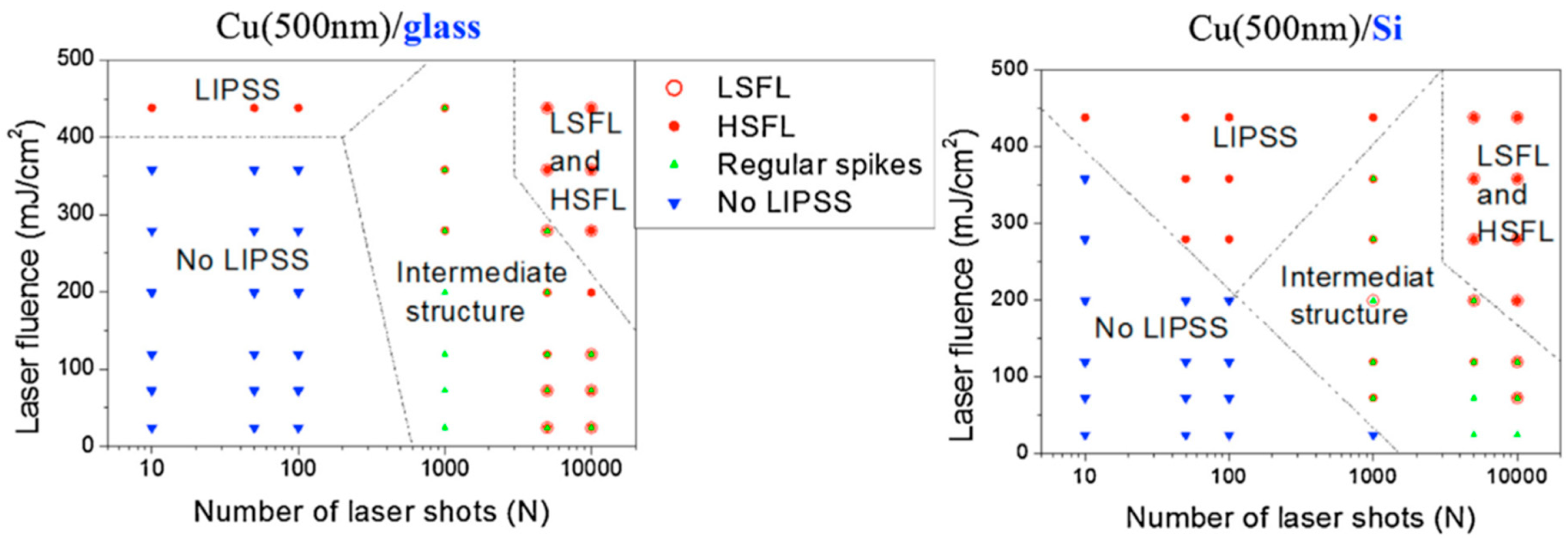

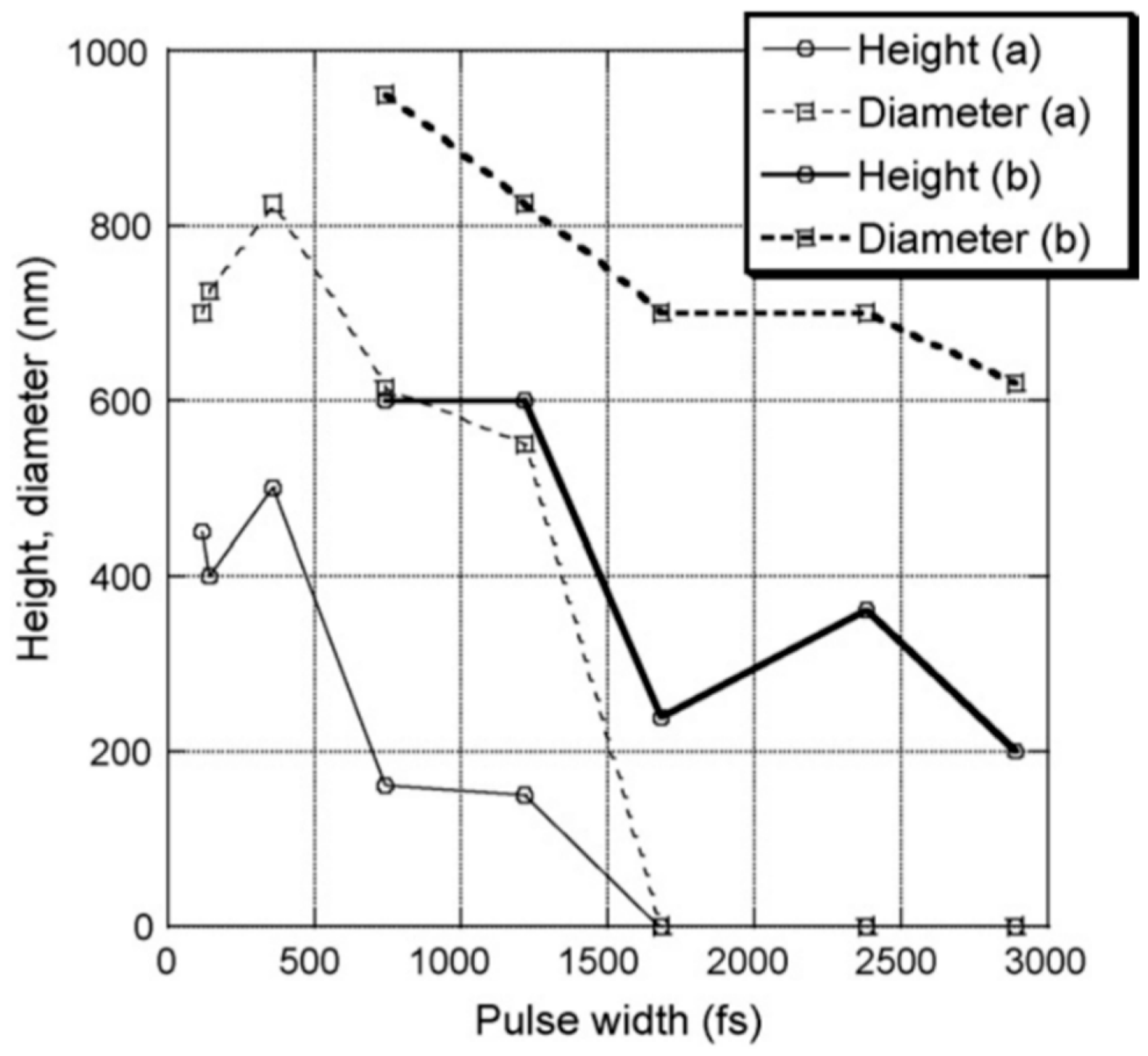

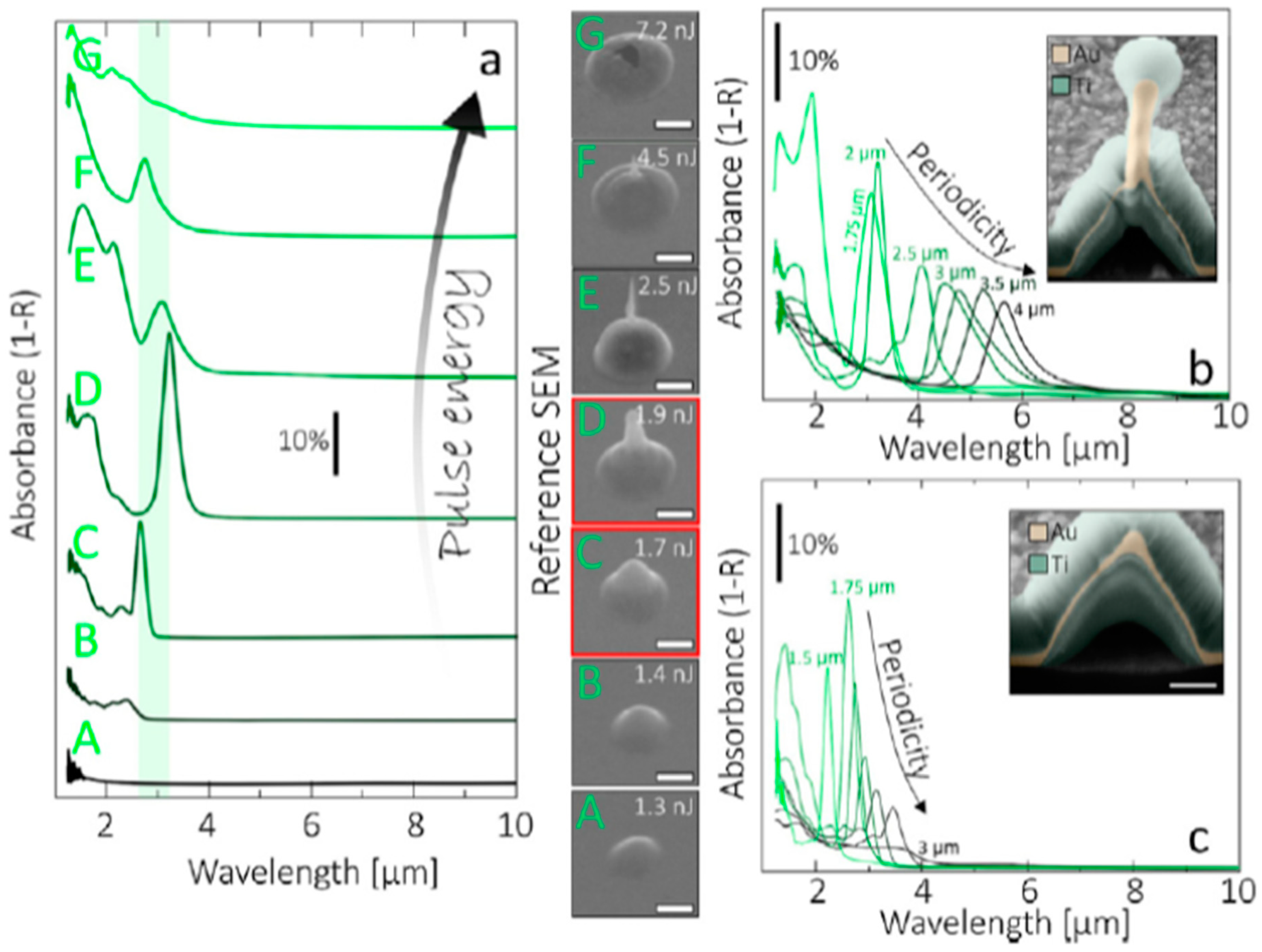

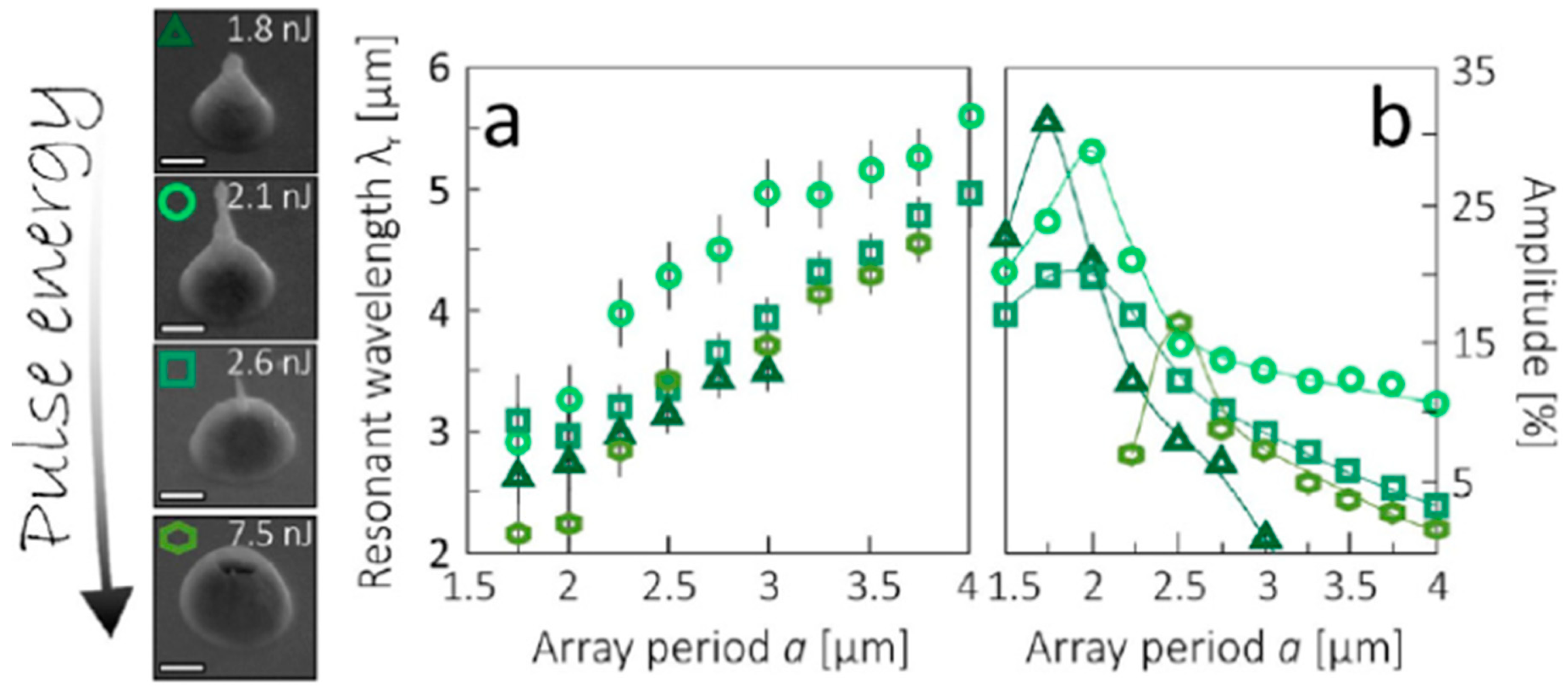

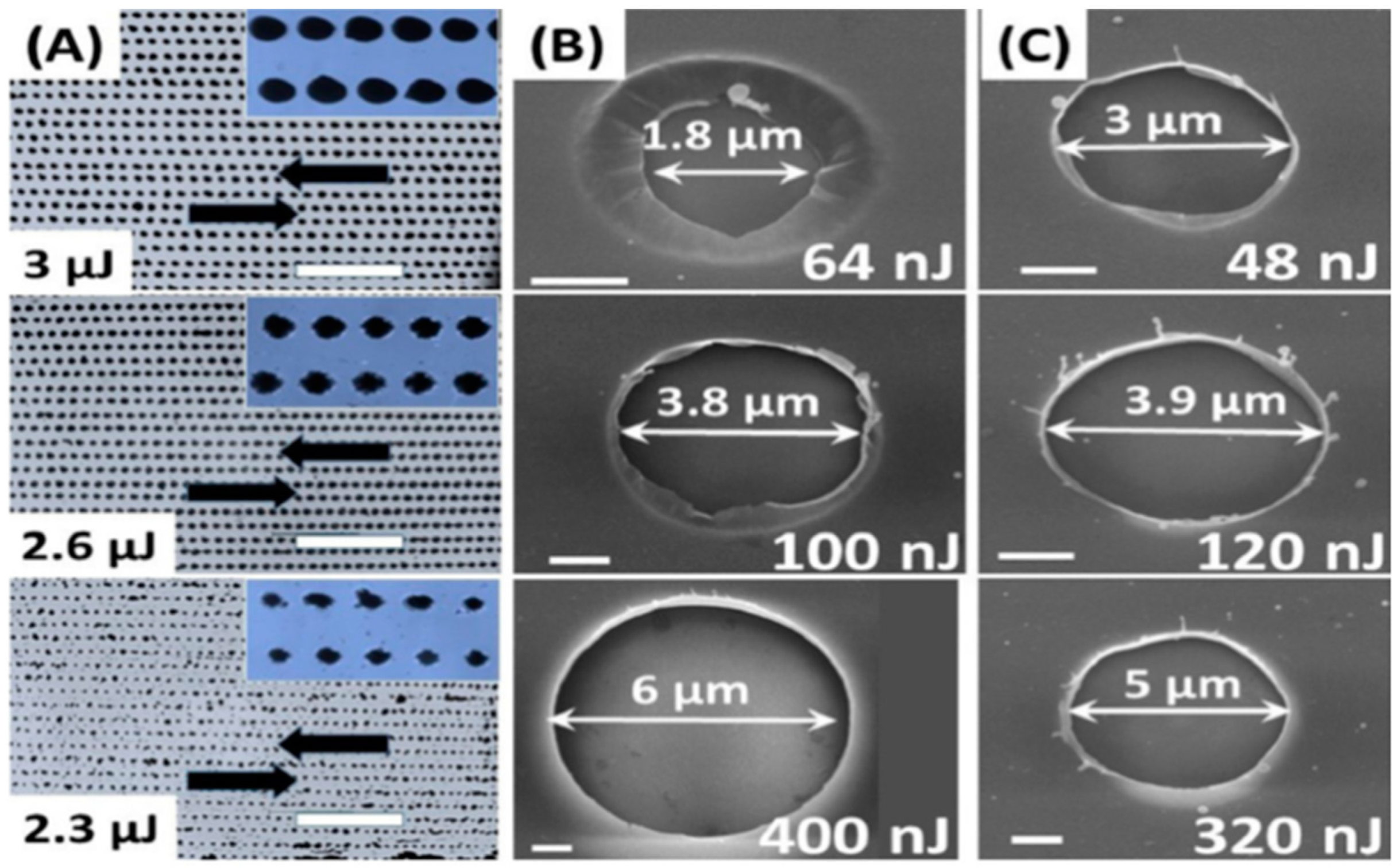

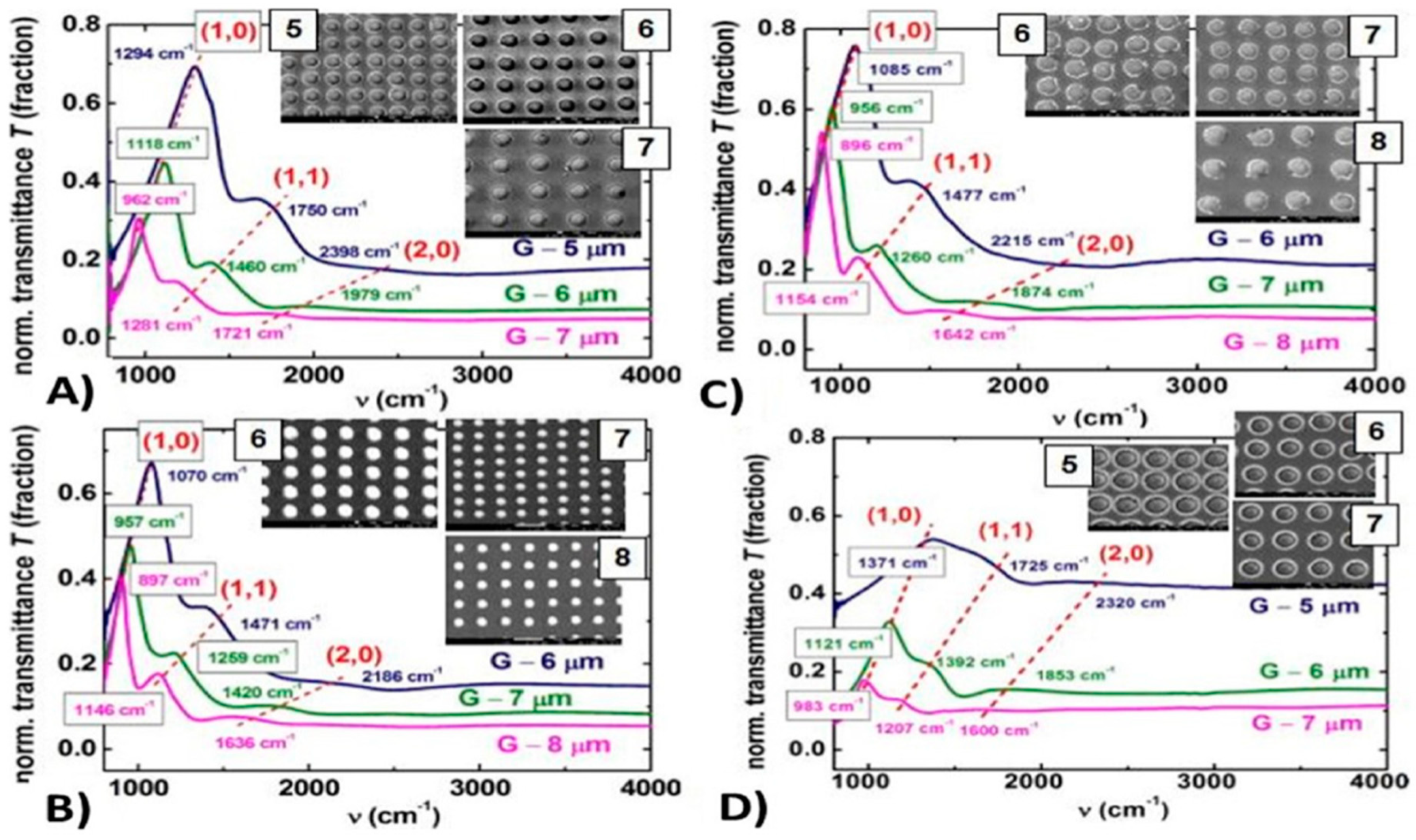

Now, we return to the case of nanostructuration of the deposited thin metal films: Huynh et al. [

56] performed similar experiments by Magkaki et al. [

109], however, by irradiating Cu films deposited on glass and silicon substrates. In particular, in this case, the authors deposited 500 nm-thick Cu films on glass or Si substrates by magnetron sputtering and processed the films by a 42 ps-pulsed laser with a wavelength of 266 nm, a fluence ranging from 20 to 500 mJ/cm

2 and the number of pulses ranging from 10 to 10000 and reaching the highly controlled production of periodic surface nano-patterns useful for several applications [

123,

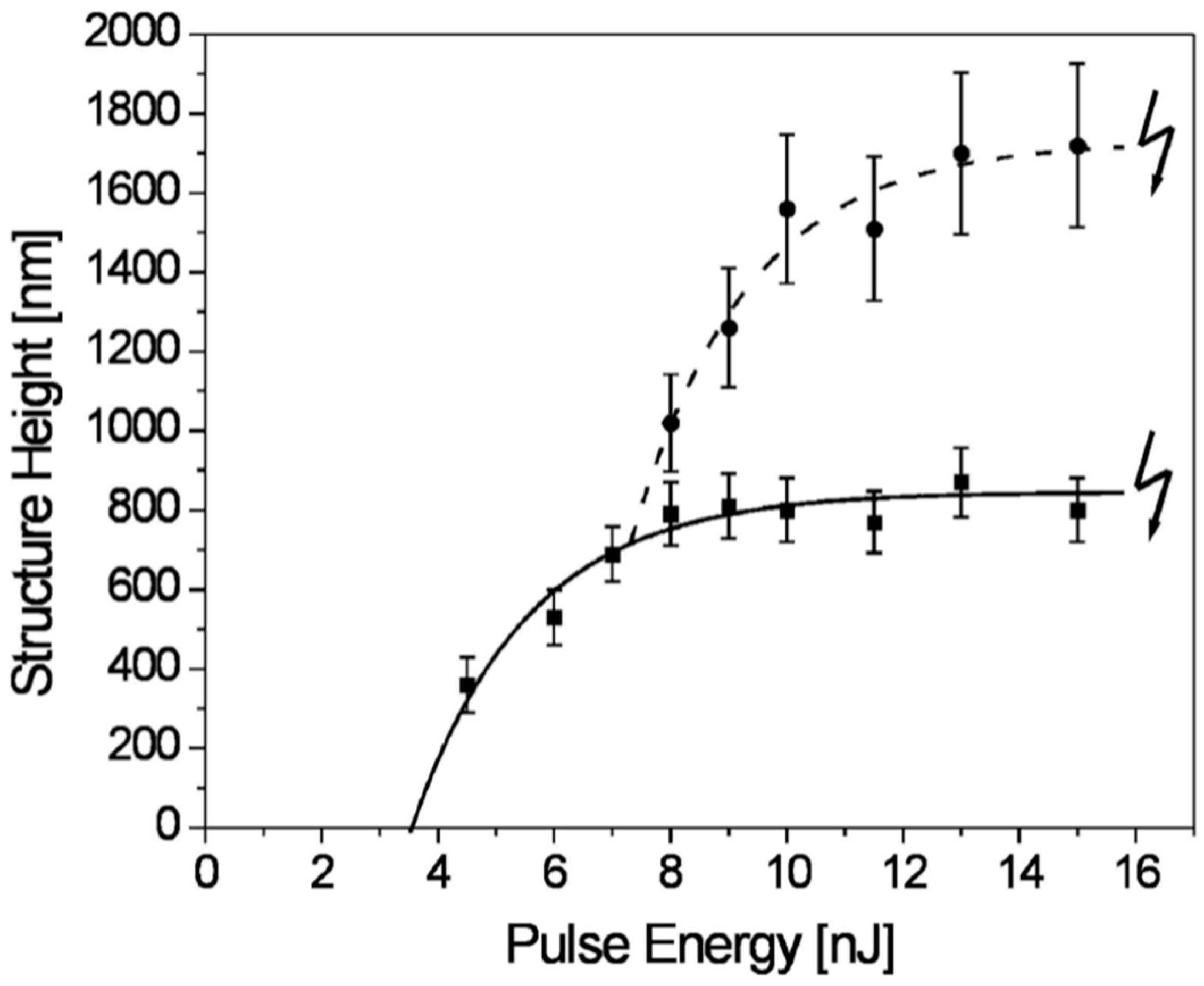

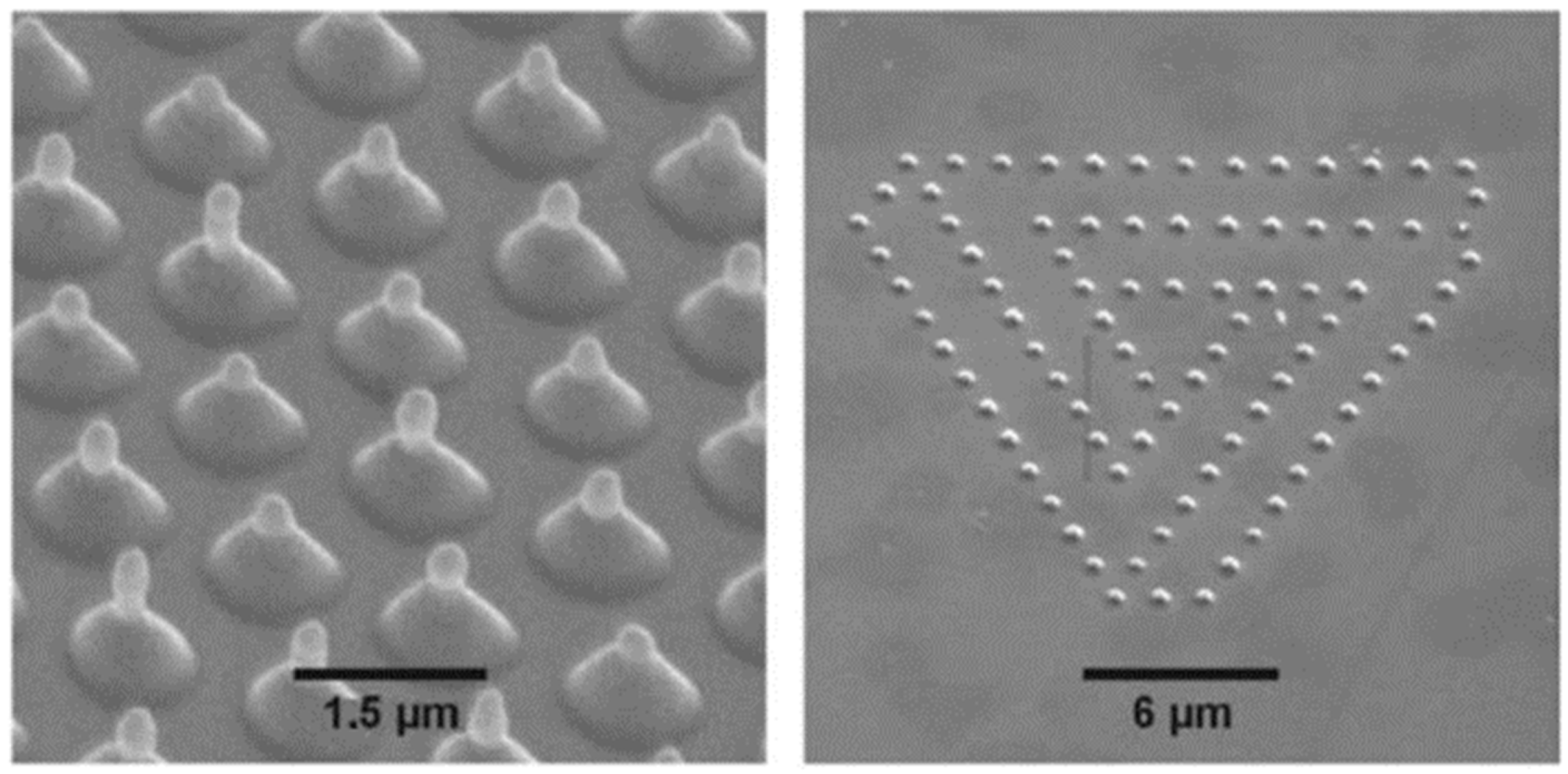

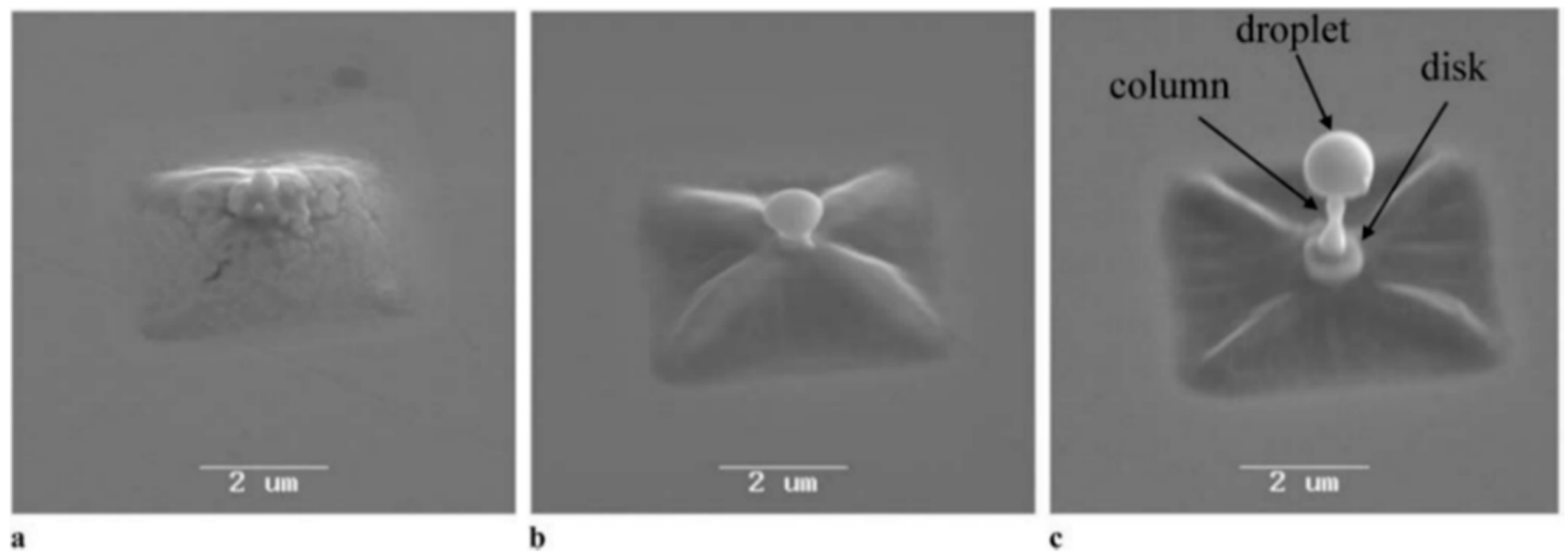

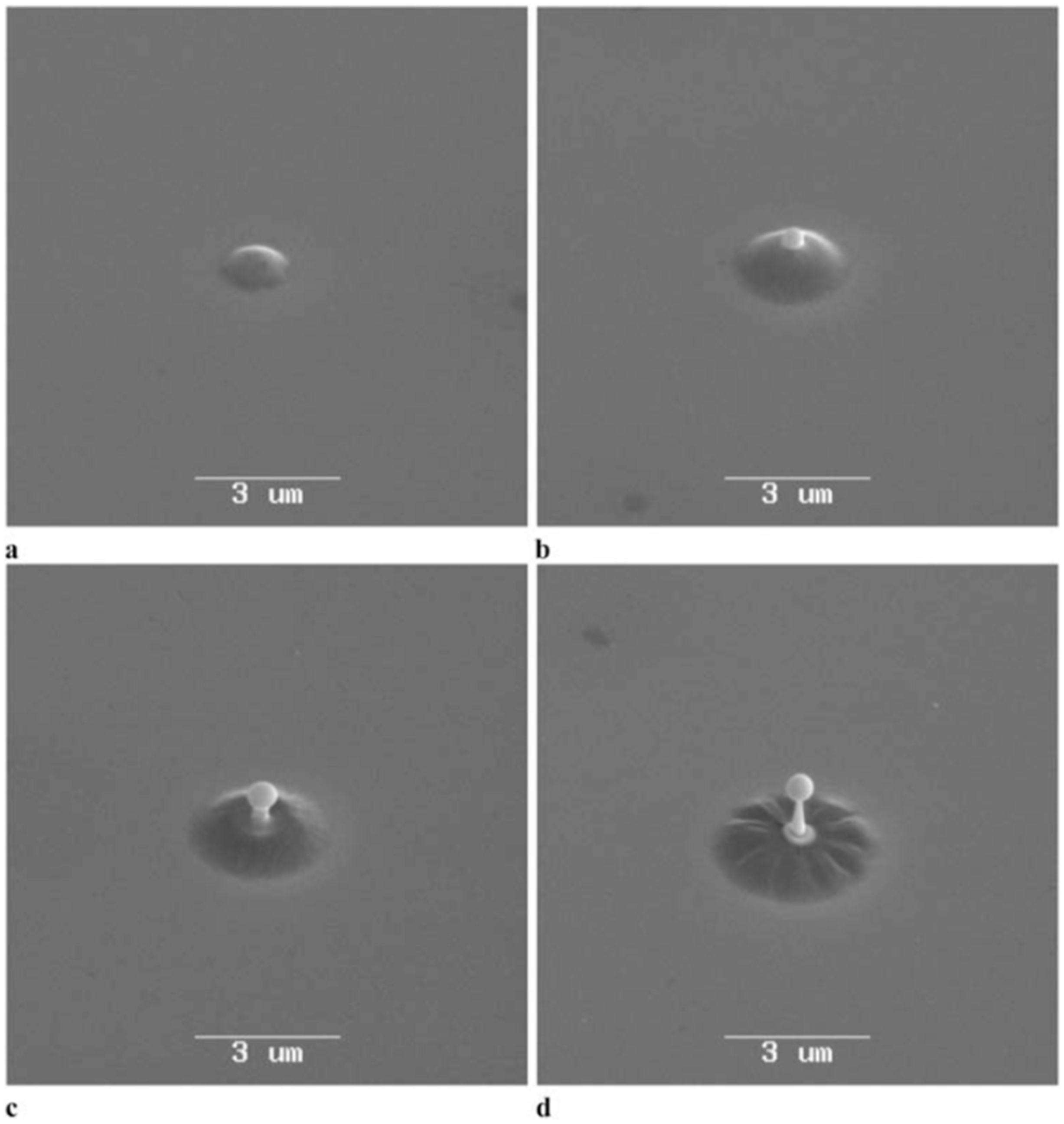

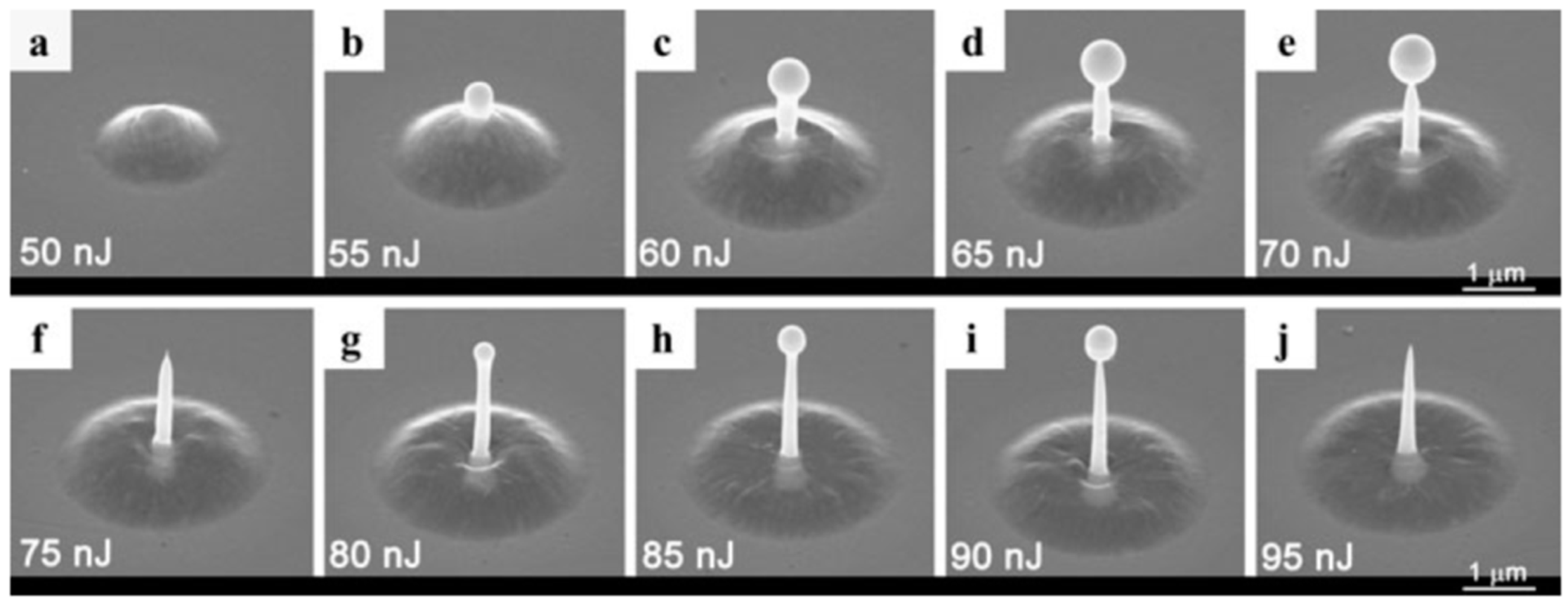

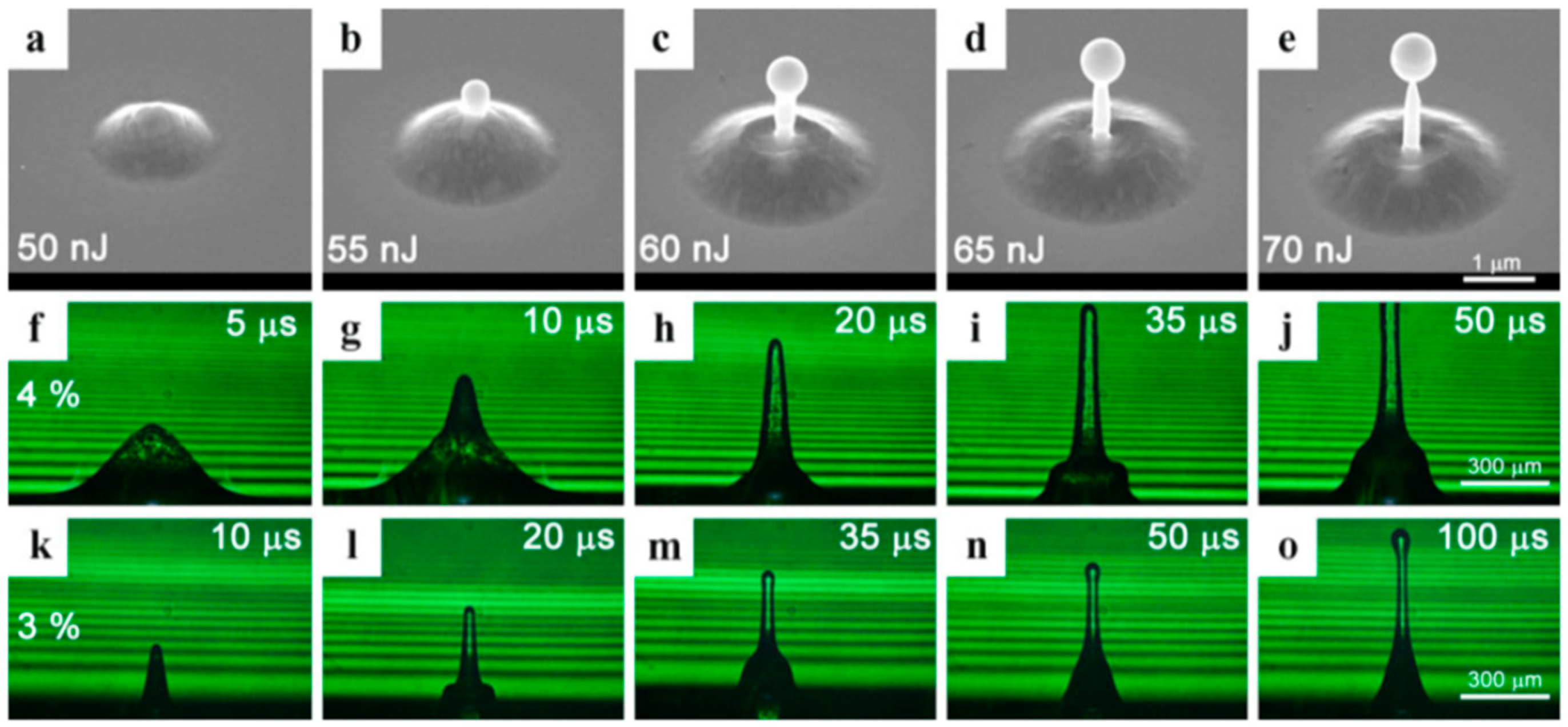

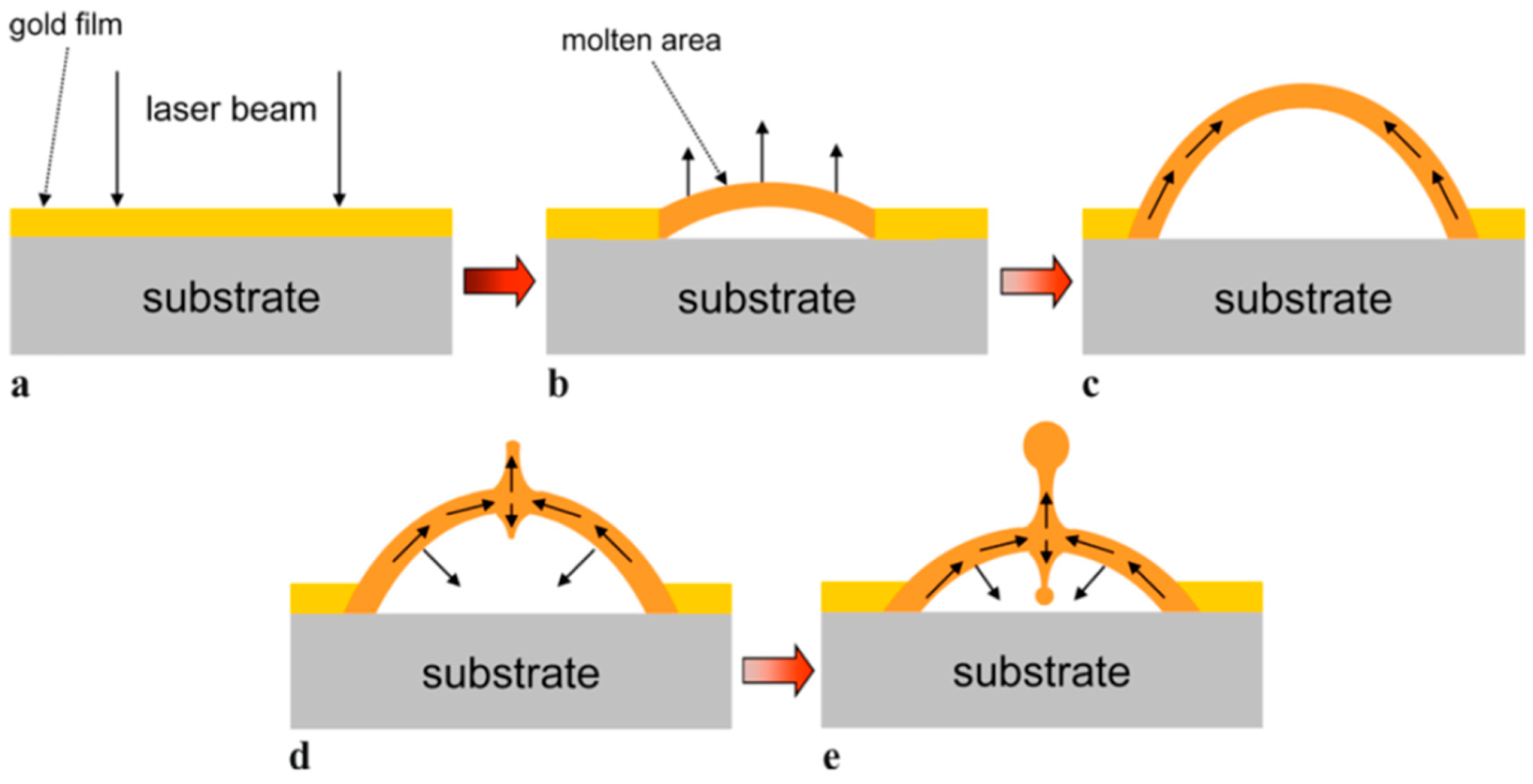

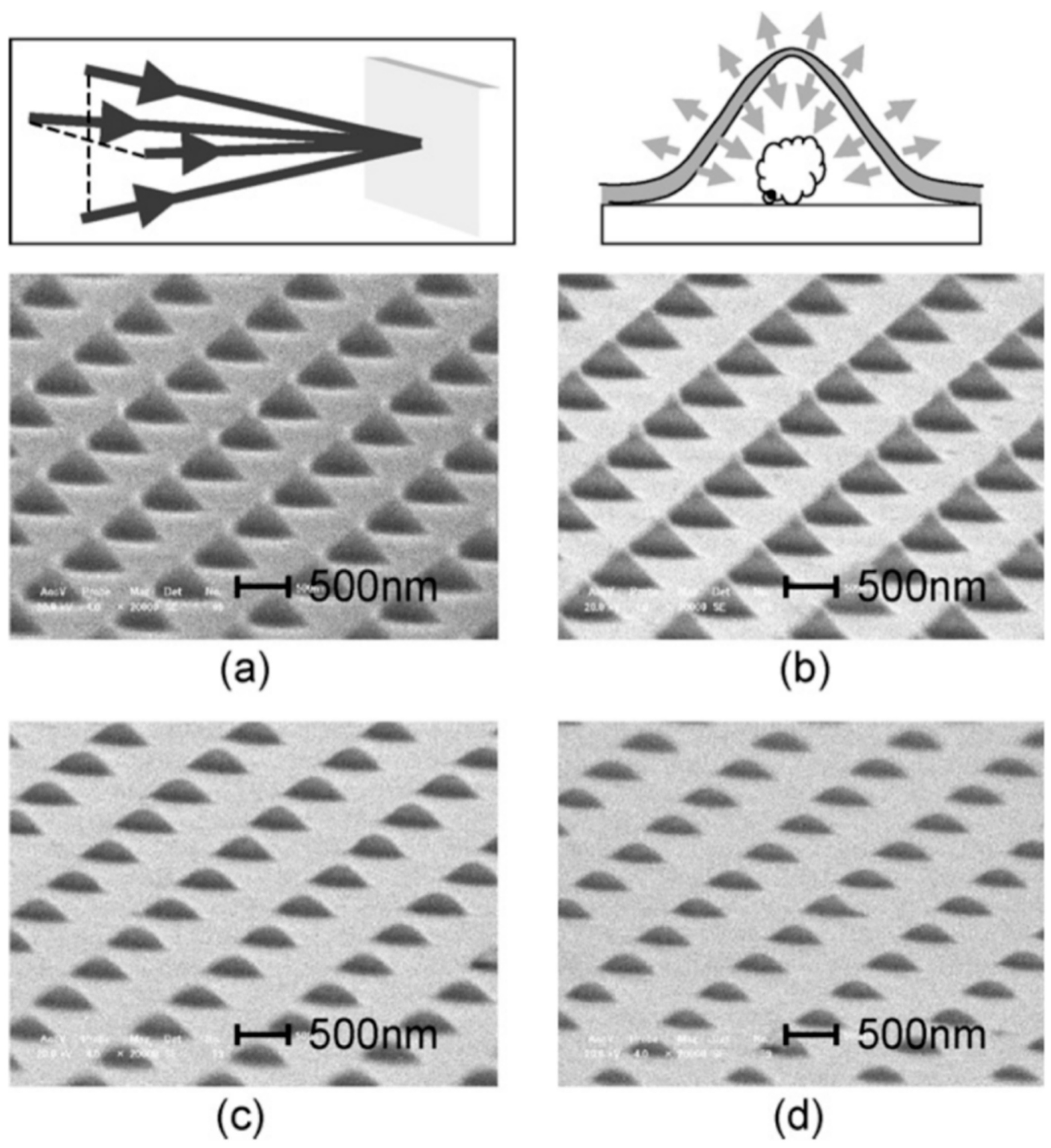

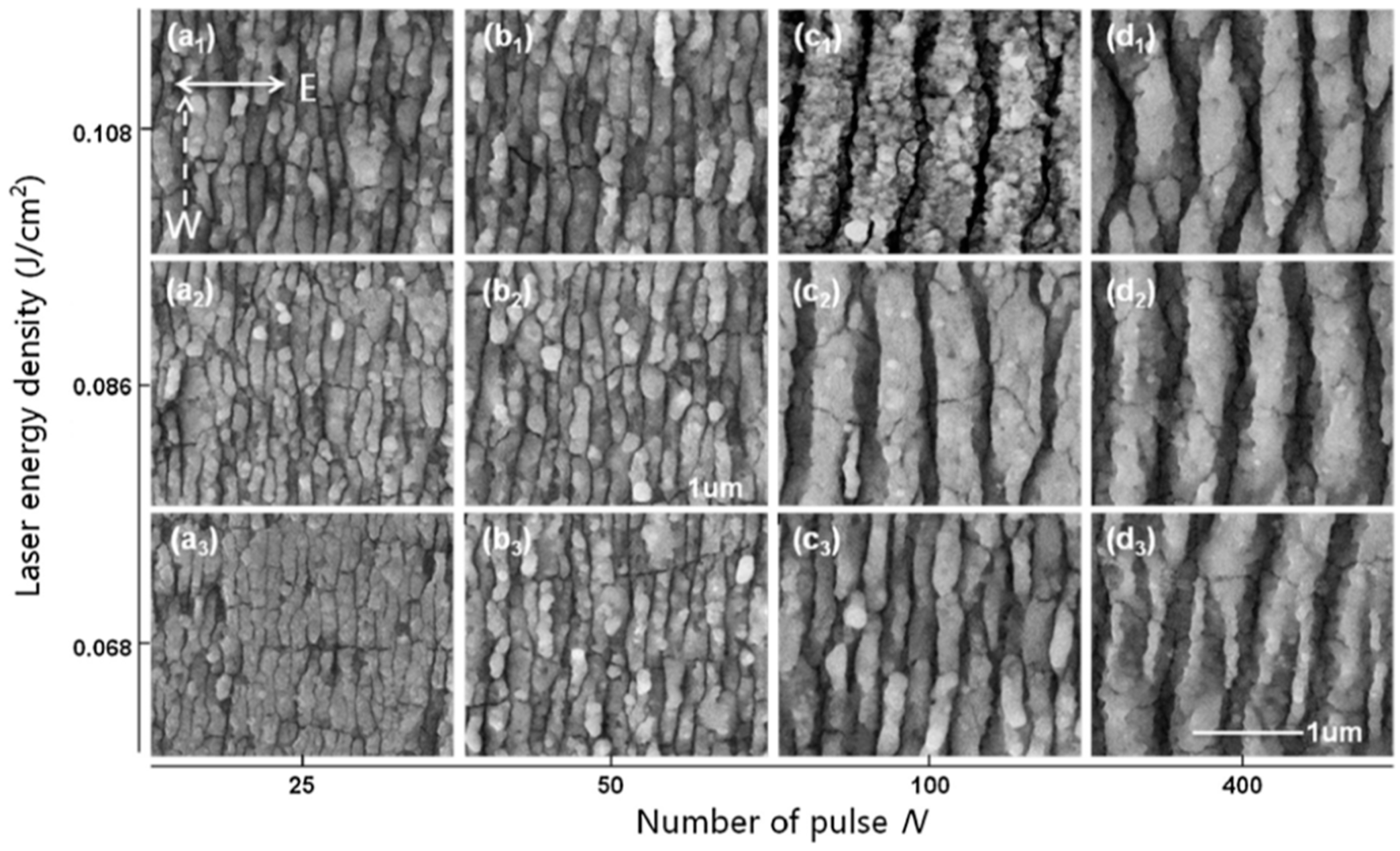

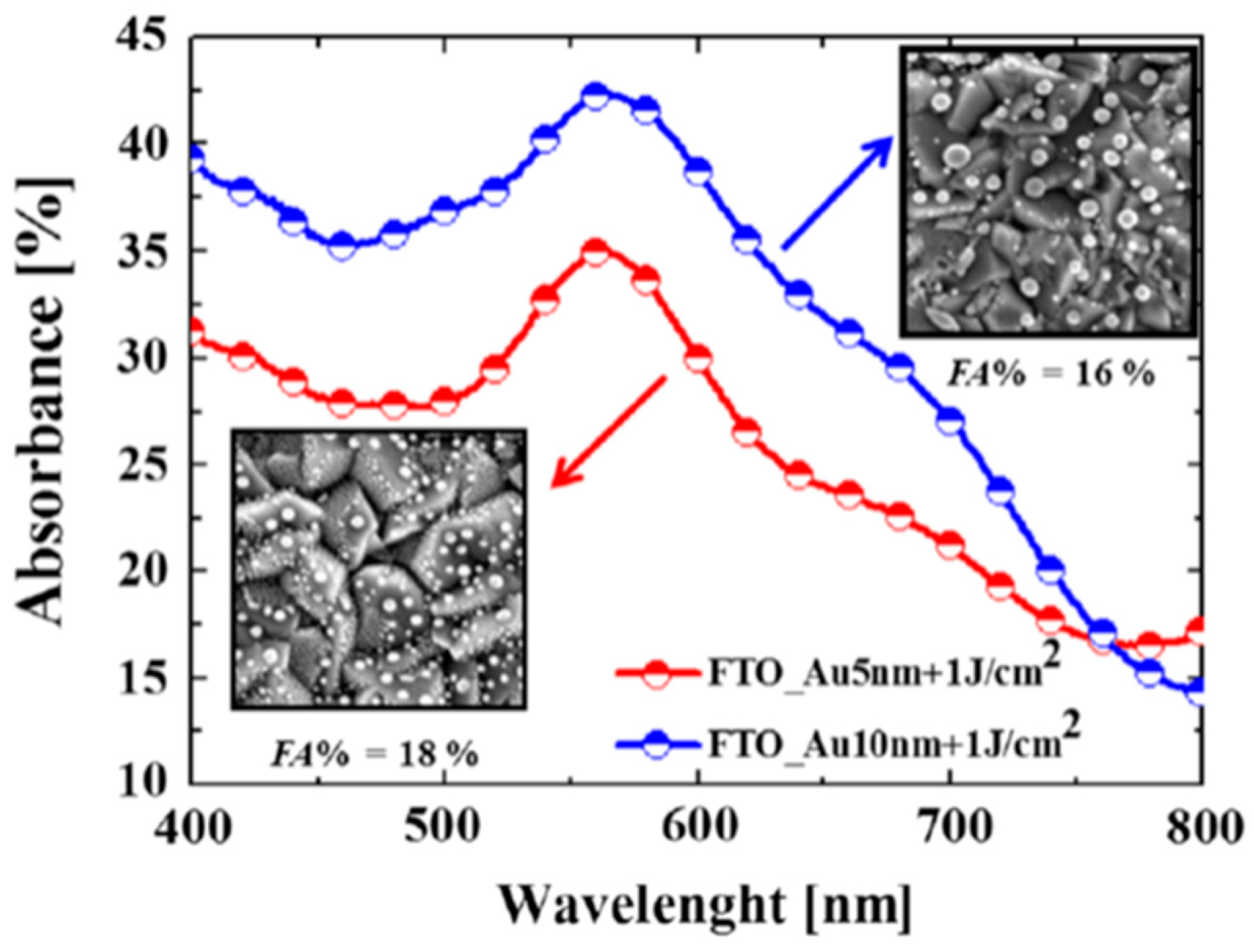

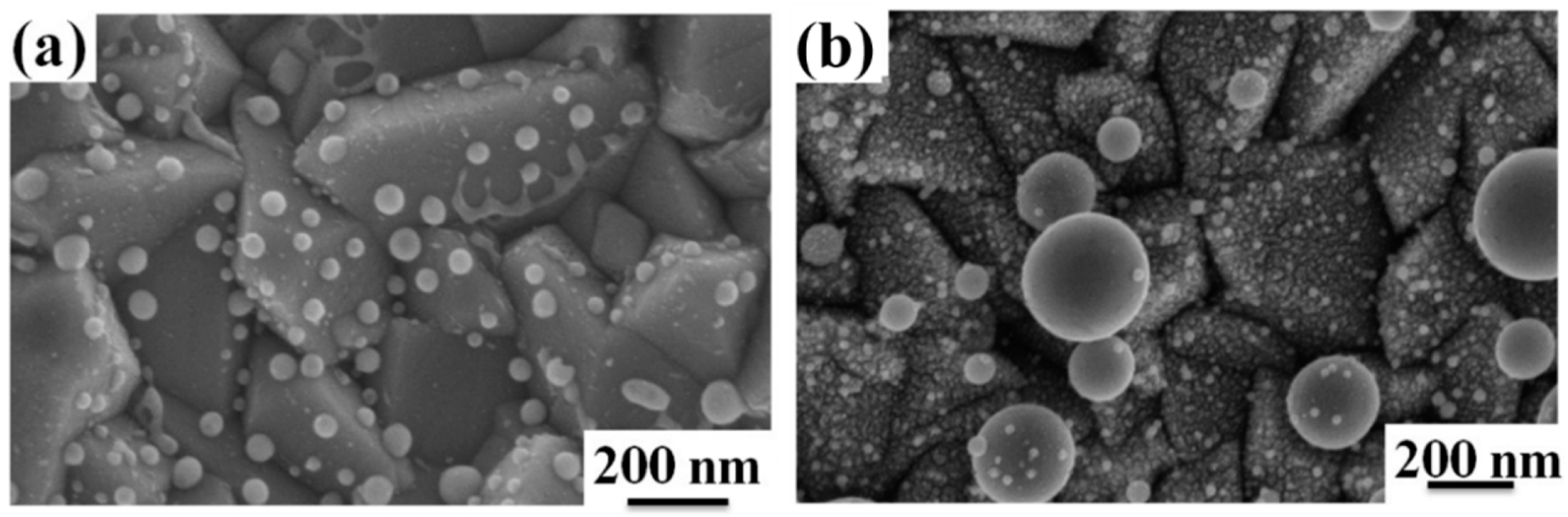

124]. The authors studied the surface morphologies of the irradiated regions by scanning electron microscopy to understand the mechanism of the laser-induced periodic surface structures’ formation. Overall, the experimental results of Huynh et al. [