Photovoltaic Performance of Dye-Sensitized Solar Cells Containing ZnO Microrods

Abstract

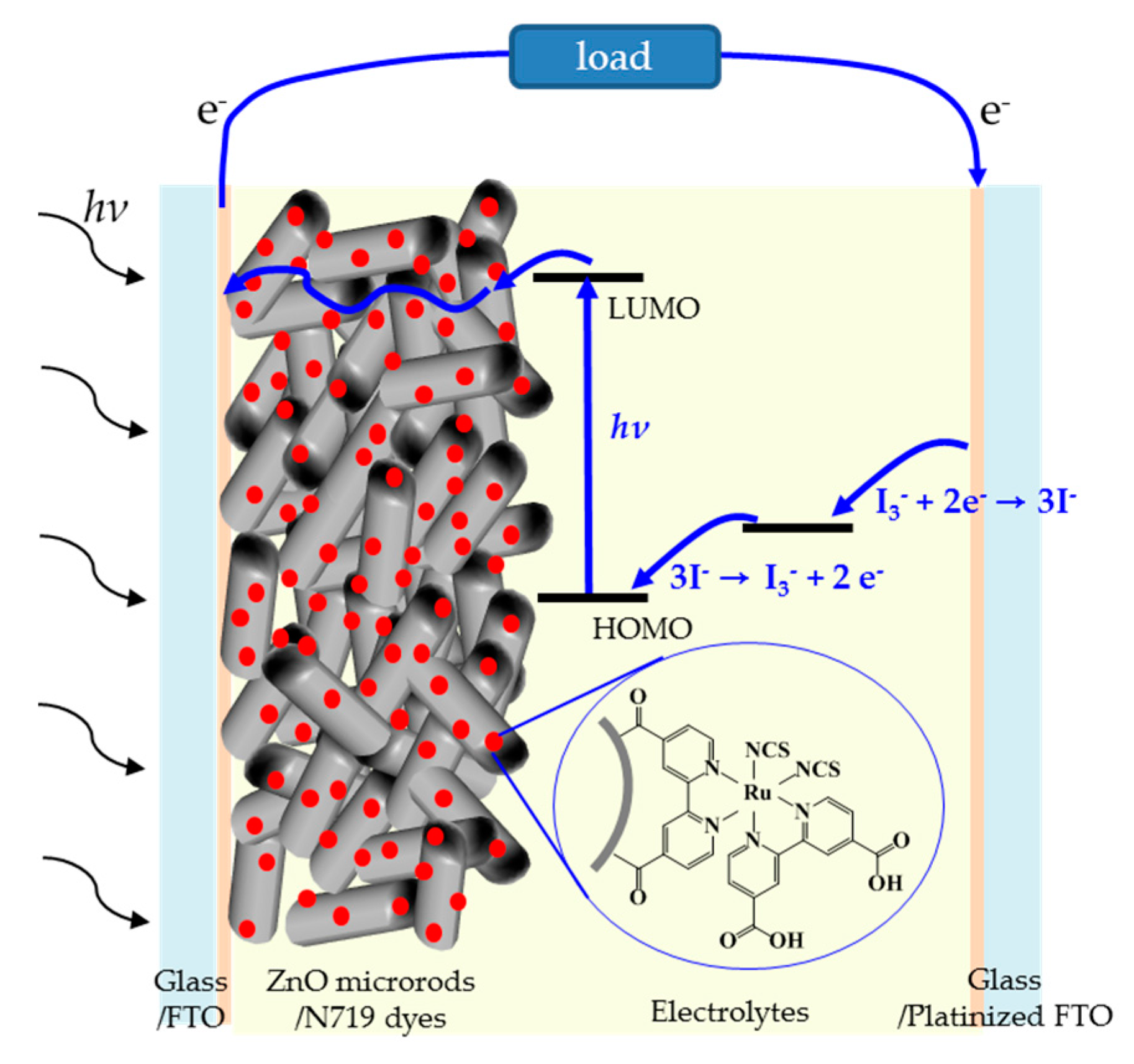

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of DSSCs

2.3. Measurements

3. Results and Discussion

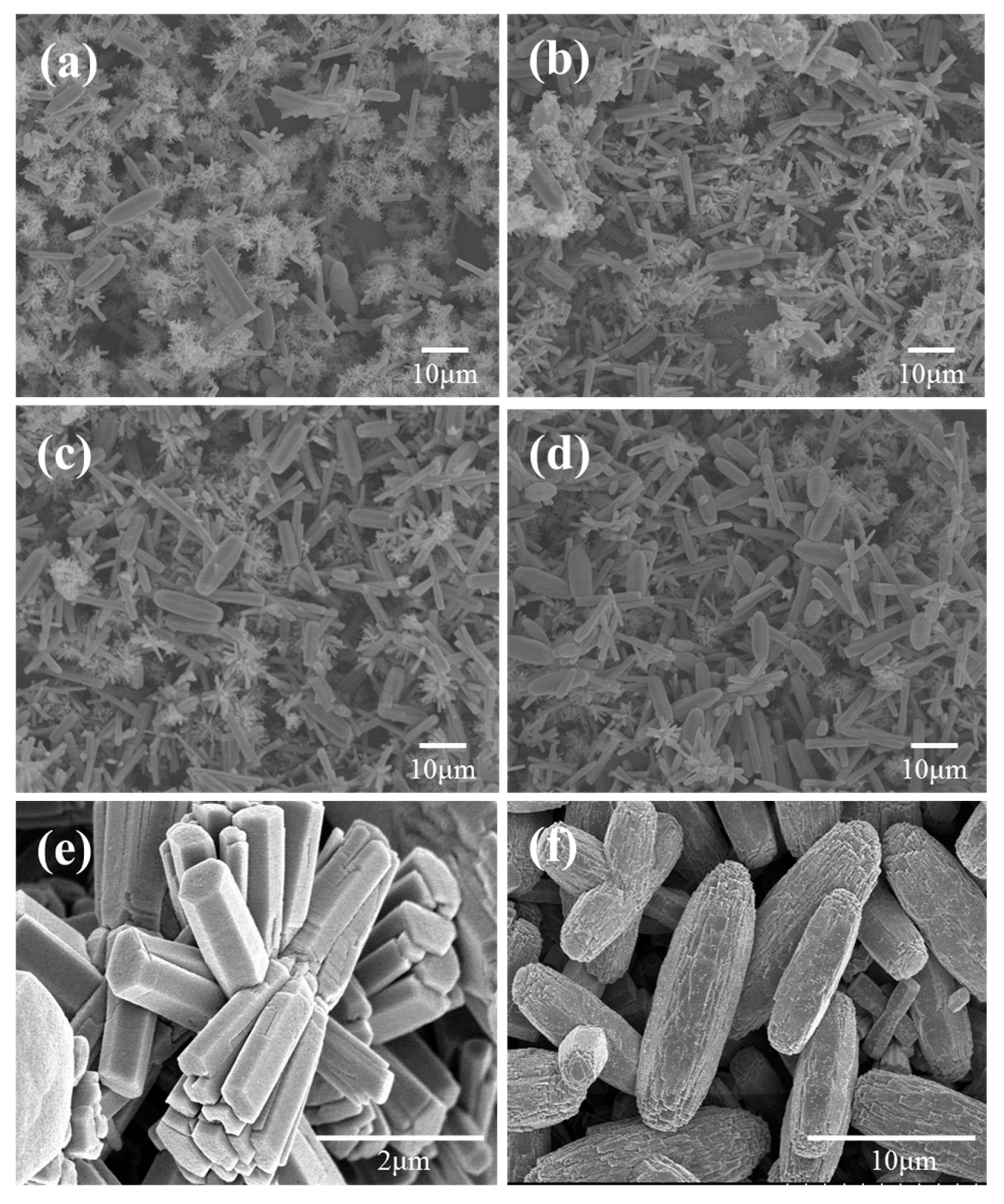

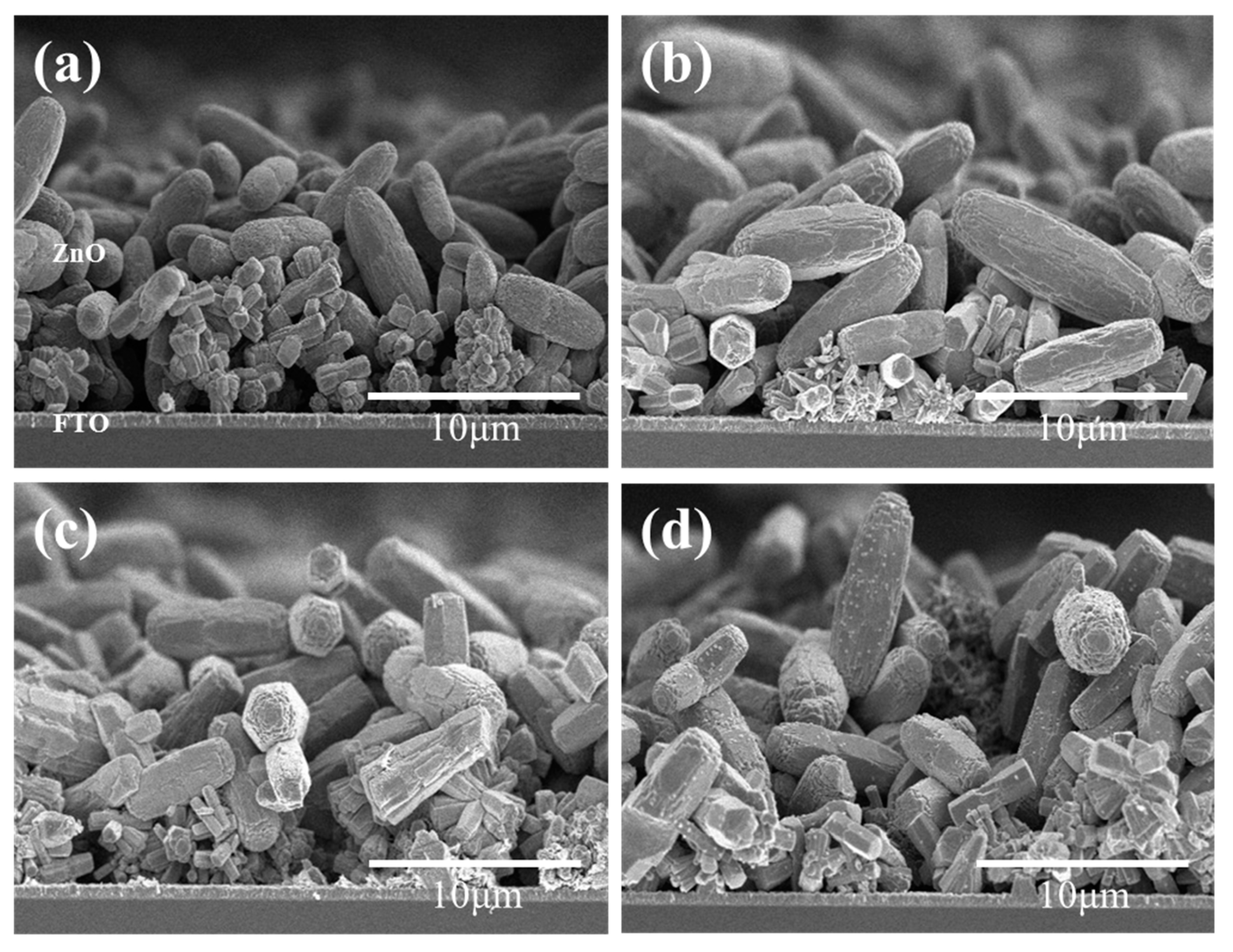

3.1. Morphological Characteristics of ZnO Layers with Growth Time

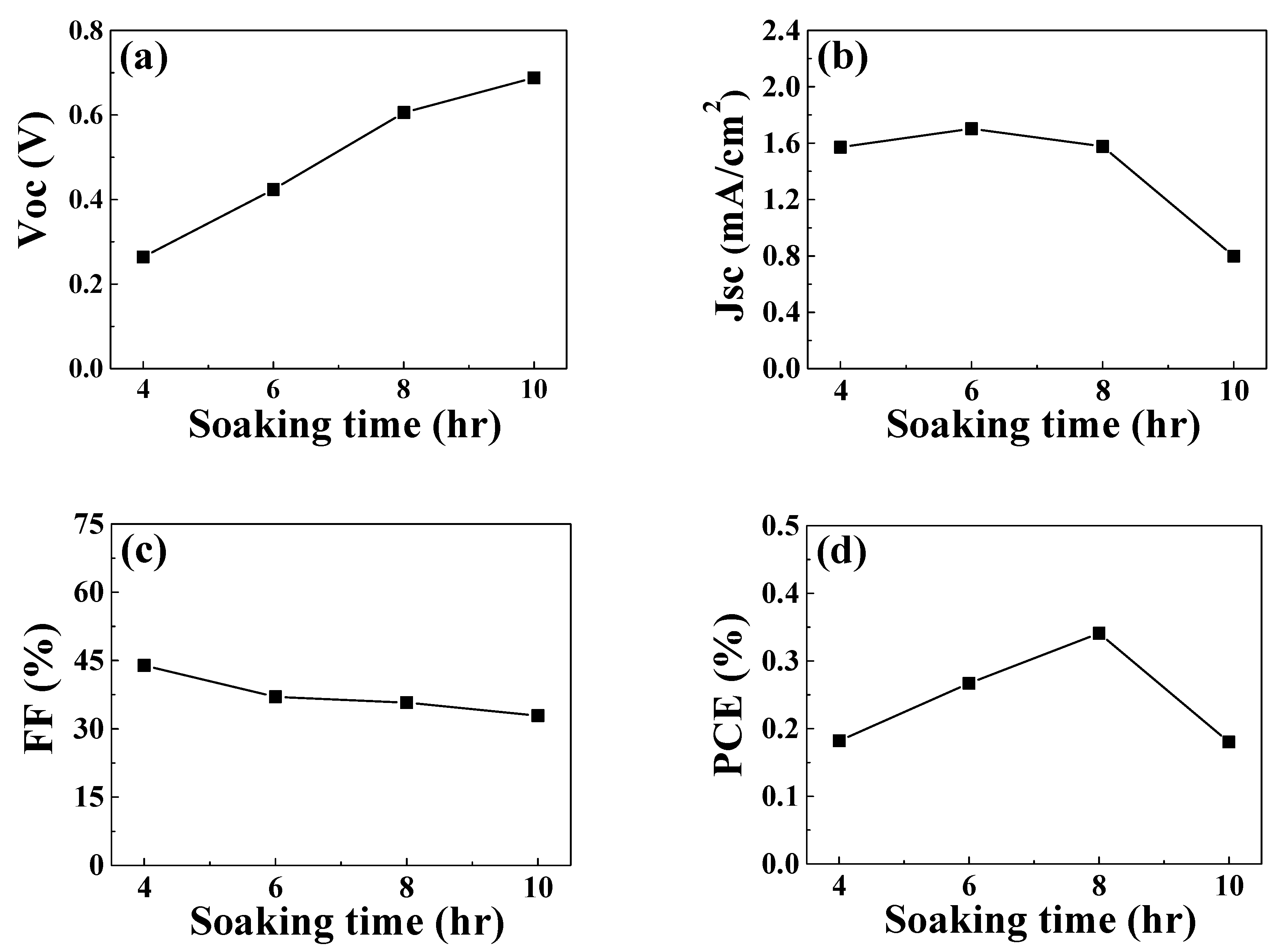

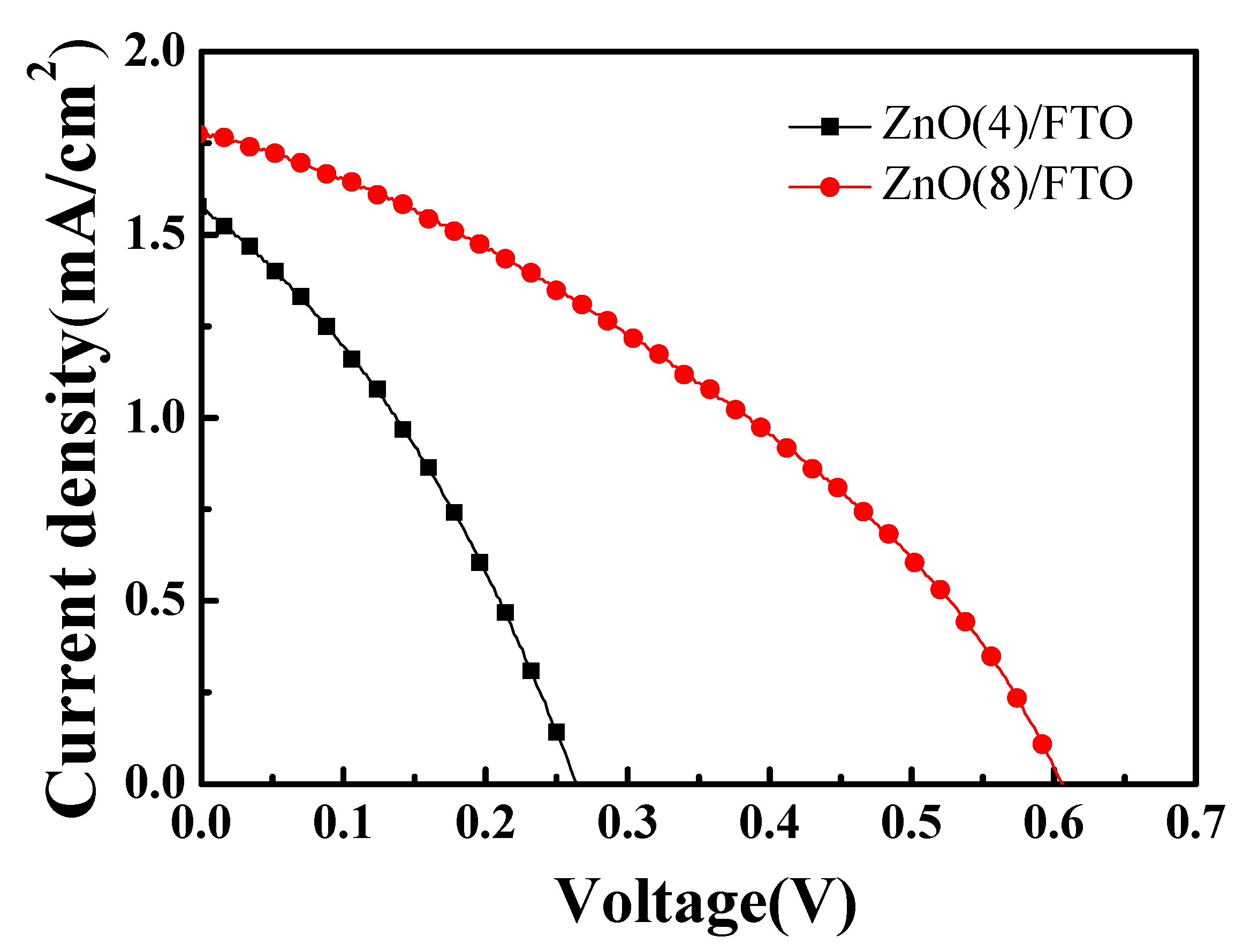

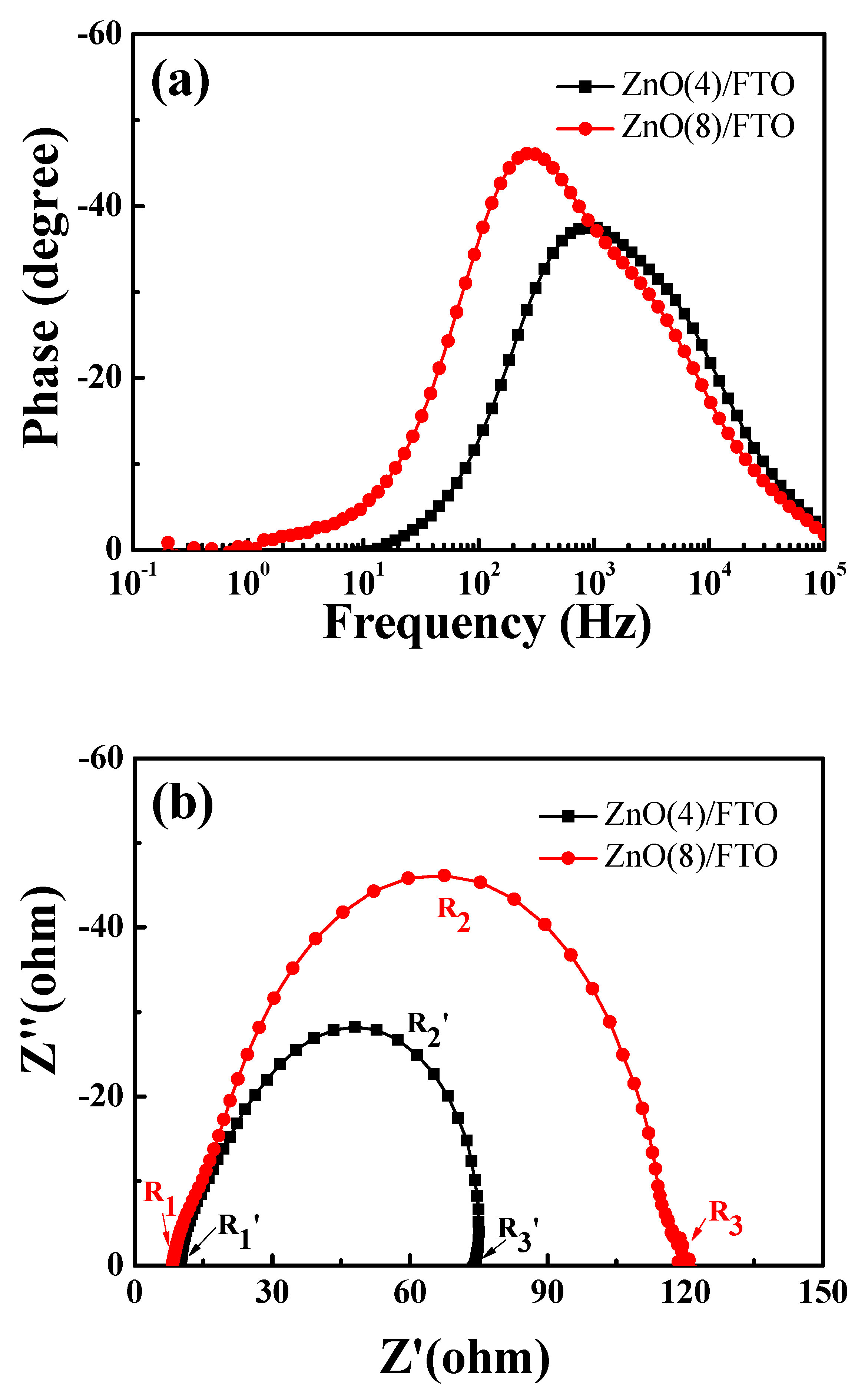

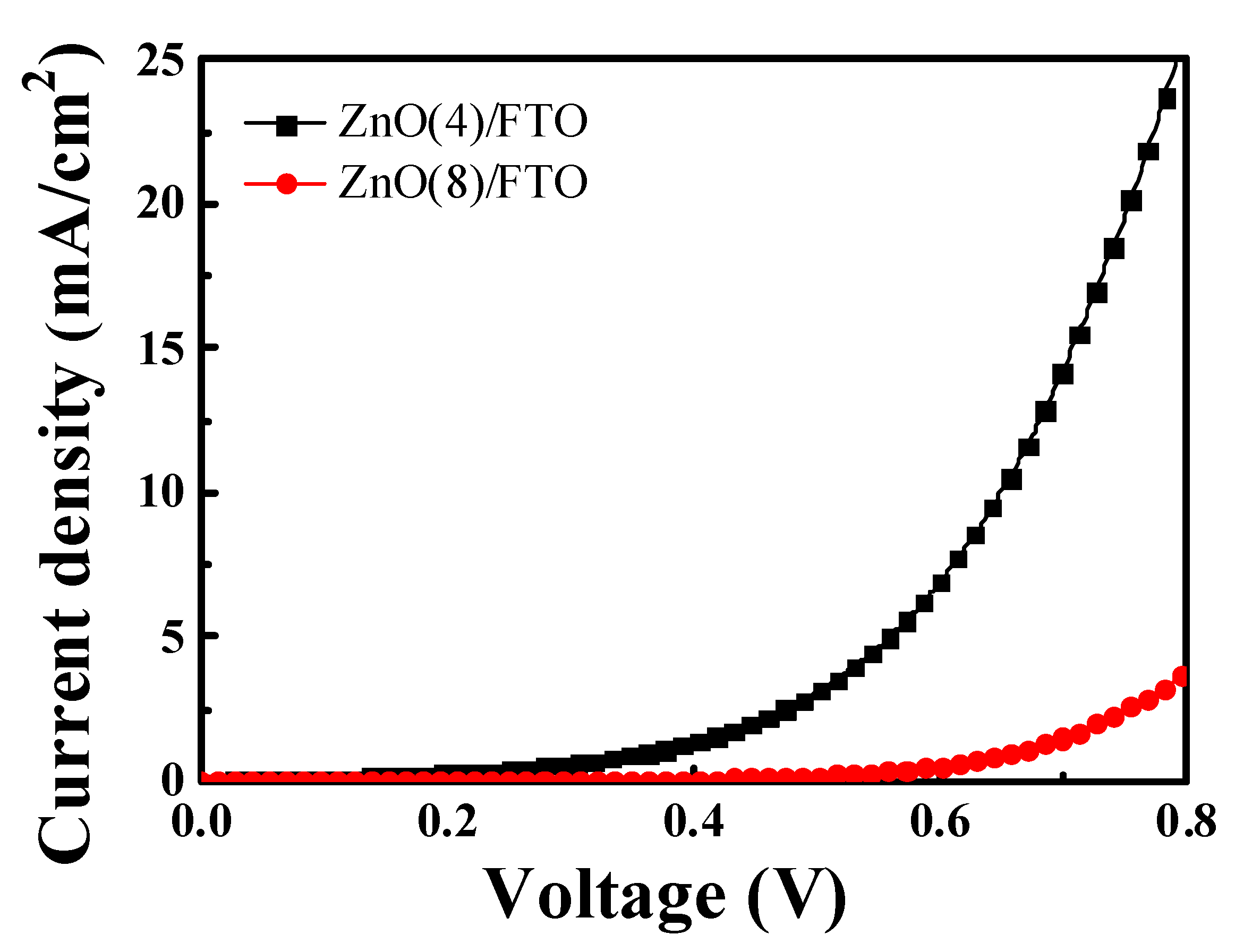

3.2. Photovoltaic Performance of DSSCs with ZnO Nanoflowers and Microrods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Sharma, K.; Sharma, V.; Sharma, S.S. Dye-Sensitized Solar Cells: Fundamentals and Current Status. Nanoscale Res. Lett. 2018, 13, 381. [Google Scholar] [CrossRef] [PubMed]

- Berger, P.R.; Kim, M. Polymer solar cells: P3HT:PCBM and beyond. J. Renew. Sustain. Energy 2018, 10, 013508. [Google Scholar] [CrossRef]

- Wang, R.; Mujahid, M.; Duan, Y.; Wang, Z.K.; Xue, J.; Yang, Y. A Review of Perovskites Solar Cell Stability. Adv. Funct. Mater. 2019, 1808843. [Google Scholar] [CrossRef]

- O’Regan, B.; Grätzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 1991, 353, 737–740. [Google Scholar] [CrossRef]

- Anta, J.A.; Guillén, E.; Tena-Zaera, R. ZnO-based dye-sensitized solar cells. J. Phys. Chem. C 2012, 116, 11413–11425. [Google Scholar] [CrossRef]

- Vittal, R.; Ho, K.C. Zinc oxide based dye-sensitized solar cells: A review. Renew. Sustain. Energy Rev. 2017, 70, 920–935. [Google Scholar] [CrossRef]

- Bazazi, S.; Arsalani, N.; Khataee, A.; Tabrizi, A.G. Comparison of ball milling-hydrothermal and hydrothermal methods for synthesis of ZnO nanostructures and evaluation of their photocatalytic performance. J. Ind. Eng. Chem. 2018, 62, 265–272. [Google Scholar] [CrossRef]

- Lee, J.; Chae, J.; Nahm, K.; Kang, M. Synthesis of nanometer-sized hexagonal disk-shaped ZnO in formic acid using a hydrothermal method and its optical properties. J. Ind. Eng. Chem. 2009, 15, 645–648. [Google Scholar] [CrossRef]

- Memarian, N.; Concina, I.; Braga, A.; Rozati, S.M.; Vomiero, A.; Sberveglieri, G. Hierarchically assembled ZnO nanocrystallites for high-efficiency dye-sensitized solar cells. Angew. Chem. Int. Ed. 2011, 50, 12321–12325. [Google Scholar] [CrossRef]

- Tsubomura, H.; Matsumura, M.; Nomura, Y.; Amamiya, T. Dye sensitised Zinc oxide: Aqueous electrolyte: Platinum photocell. Nature 1976, 261, 402–403. [Google Scholar] [CrossRef]

- Nayeri, F.D.; Soleimani, E.A.; Salehi, F. Synthesis and characterization of ZnO nanowires grown on different seed layers: The application for dye-sensitized solar cells. Renew. Energy 2013, 60, 246–255. [Google Scholar] [CrossRef]

- Chung, J.; Moon, H.; Bhang, S.H.; Kim, W.S.; Bong, K.W.; Yu, T. Aqueous-phase synthesis of single crystal ZnO nanobolts. J. Ind. Eng. Chem. 2016, 36, 59–65. [Google Scholar] [CrossRef]

- Umar, A.; Akhtar, M.S.; Almas, T.; Ibrahim, A.A.; Al-Assiri, M.S.; Masuda, Y.; Rahman, Q.I.; Baskoutas, S. Direct Growth of Flower-Shaped ZnO Nanostructures on FTO Substrate for Dye-Sensitized Solar Cells. Crystals 2019, 9, 405. [Google Scholar] [CrossRef]

- Nirmal Peiris, T.A.; Alessa, H.; Sagu, J.S.; Ahmad Bhatti, I.; Isherwood, P.; Upul Wijayantha, K.G. Effect of ZnO seed layer thickness on hierarchical ZnO nanorod growth on flexible substrates for application in dye-sensitised solar cells. J. Nanopart. Res. 2013, 15, 2115. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Y.; Su, M.; Xu, T.; Yang, H.; Bi, S.; Zhang, X.; Fang, Y.; Zhao, J. Design of Morphology-Controllable ZnO Nanorods/Nanopariticles Composite for Enhanced Performance of Dye-Sensitized Solar Cells. Nanomaterials 2019, 9, 931. [Google Scholar] [CrossRef] [PubMed]

- Peng, T.; Shi, W.; Wu, S.; Ying, Z.; Ri, J.H. Sea urchin-like TiO2 microspheres as scattering layer of nanosized TiO2 film-based dye-sensitized solar cell with enhanced conversion efficiency. Mater. Chem. Phys. 2015, 164, 238–245. [Google Scholar] [CrossRef]

- Zaban, A.; Greenshtein, M.; Bisquert, J. Determination of the electron lifetime in nanocrystalline dye solar cells by open-circuit voltage decay measurements. ChemPhysChem 2003, 4, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Darvishzadeh, P.; Babanezhad, M.; Ahmadi, R.; Gorji, N.E. Modeling the degradation/recovery of open-circuit voltage in perovskite and thin film solar cells. Mater. Des. 2017, 114, 339–344. [Google Scholar] [CrossRef]

- Alarcόn, H.; Hedlund, M.; Johansson, E.M.J.; Rensmo, H.; Hagfeldt, A.; Boschloo, G. Modification of Nanostructured TiO2 Electrodes by Electrochemical Al3+ Insertion: Effects on Dye-Sensitized Solar Cell Performance. J. Phys. Chem. C 2007, 111, 13267–13274. [Google Scholar] [CrossRef]

- Lee, K.E.; Gomez, M.A.; Charbonneau, C.; Demopoulos, G.P. Enhanced surface hydroxylation of nanocrystalline anatase films improves photocurrent output and electron lifetime in dye sensitized solar cell photoanodes. Electrochim. Acta 2012, 67, 208–215. [Google Scholar] [CrossRef]

- Kim, J.T.; Han, Y.S. Effects of surface-modified photoelectrode on the power conversion efficiency of dye-sensitized solar cells. Met. Mater. Int. 2014, 20, 571–575. [Google Scholar] [CrossRef]

- Sarker, S.; Seo, H.W.; Seo, D.W.; Kim, D.M. Electrochemical impedance spectroscopy of dye-sensitized solar cells with different electrode geometry. J. Ind. Eng. Chem. 2017, 45, 56–60. [Google Scholar] [CrossRef]

- Kim, K.S.; Song, H.; Nam, S.H.; Kim, S.M.; Jeong, H.; Kim, W.B.; Jung, G.Y. Fabrication of an Efficient Light-Scattering Functionalized Photoanode Using Periodically Aligned ZnO Hemisphere Crystals for Dye Sensitized Solar Cells. Adv. Mater. 2012, 24, 792–798. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Sun, B.; Qiu, L.; Caocen, H.; Li, Q.; Chen, X.; Yan, F.J. Efficient light-scattering functionalized TiO2 photoanodes modified with cyanobiphenyl-based benzimidazole for dye-sensitized solar cells with additive-free electrolytes. Mater. Chem. 2012, 22, 18380–18386. [Google Scholar] [CrossRef]

- Cheng, F.; Ou, Y.; Liu, G.; Zhao, L.; Dong, B.; Wang, S.; Wen, S. Novel quasi-solid-state electrolytes based on electrospun poly(vinylidene fluoride) fiber membranes for highly efficient and stable dye-sensitized solar cells. Nanomaterials 2019, 9, 783. [Google Scholar] [CrossRef]

- Kim, J.T.; Lee, S.H.; Han, Y.S. Enhanced power conversion efficiency of dye-sensitized solar cells with Li2SiO3-modified photoelectrode. Appl. Surf. Sci. 2015, 333, 134–140. [Google Scholar] [CrossRef]

- Tian, H.; Hu, L.; Zhang, C.; Liu, W.; Huang, Y.; Mo, L.; Guo, L.; Sheng, J.; Dai, S. Retarded Charge Recombination in Dye-Sensitized Nitrogen-Doped TiO2 Solar Cells. J. Phys. Chem. C 2010, 114, 1627–1632. [Google Scholar] [CrossRef]

- Chen, S.G.; Chappel, S.; Diamant, Y.; Zaban, A. Preparation of Nb2O5 Coated TiO2 Nanoporous Electrodes and Their Application in Dye-Sensitized Solar Cells. Chem. Mater. 2001, 13, 4629–4634. [Google Scholar] [CrossRef]

- Diamant, Y.; Chen, S.G.; Melamed, O.; Zaban, A. Core-shell nanoporous electrode for dye sensitized solar cells: The effect of the SrTiO3 shell on the electronic properties of the TiO2 core. J. Phys. Chem. B 2003, 107, 1977–1981. [Google Scholar] [CrossRef]

- Hagfeldtt, A.; Boschloo, G.; Sun, L.; Kloo, L.; Petterson, H. Dye-sensitized solar cells. Chem. Rev. 2010, 110, 6595–6663. [Google Scholar] [CrossRef]

- Arkan, F.; Izadyar, M.; Nakhaeipour, A. The role of the electronic structure and solvent in the dye-sensitized solar cells based on Zn-porphyrins: Theoretical study. Energy 2016, 114, 559–567. [Google Scholar] [CrossRef]

- Lü, X.; Mou, X.; Wu, J.; Zhang, D.; Zhang, L.; Huang, F.; Xu, F.; Huang, S. Improved-performance dye-sensitized solar cells using Nb-doped TiO2 electrodes: Efficient electron injection and transfer. Adv. Funct. Mater. 2010, 20, 509–515. [Google Scholar] [CrossRef]

- Koide, N.; Islam, A.; Chiba, Y.; Han, L. Improvement of efficiency of dye-sensitized solar cells based on analysis of equivalent circuit. J. Photochem. Photobiol. A 2006, 182, 296–305. [Google Scholar] [CrossRef]

- Syrrokostas, G.; Leftheriotis, G.; Yianoulis, P. Effect of acidic additives on the structure and performance of TiO2 films prepared by a commercial nanopowder for dye-sensitized solar cells. Renew. Energy 2014, 72, 164–173. [Google Scholar] [CrossRef]

| Applied Photoelectrodes | Voc (mV) | Jsc (mA/cm2) | FF (%) | η (%) | Rse (Ωcm2) | Rsh (Ωcm2) |

|---|---|---|---|---|---|---|

| ZnO(4)/FTO | 0.264 | 1.572 | 43.94 | 0.182 | 97.8 | 345.7 |

| ZnO(8)/FTO | 0.606 | 1.577 | 35.77 | 0.341 | 131.4 | 973.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, S.I.; Sung, H.K.; Lee, S.-J.; Kim, W.H.; Kim, D.-H.; Han, Y.S. Photovoltaic Performance of Dye-Sensitized Solar Cells Containing ZnO Microrods. Nanomaterials 2019, 9, 1645. https://doi.org/10.3390/nano9121645

Cho SI, Sung HK, Lee S-J, Kim WH, Kim D-H, Han YS. Photovoltaic Performance of Dye-Sensitized Solar Cells Containing ZnO Microrods. Nanomaterials. 2019; 9(12):1645. https://doi.org/10.3390/nano9121645

Chicago/Turabian StyleCho, Seong Il, Hye Kyeong Sung, Sang-Ju Lee, Wook Hyun Kim, Dae-Hwan Kim, and Yoon Soo Han. 2019. "Photovoltaic Performance of Dye-Sensitized Solar Cells Containing ZnO Microrods" Nanomaterials 9, no. 12: 1645. https://doi.org/10.3390/nano9121645

APA StyleCho, S. I., Sung, H. K., Lee, S.-J., Kim, W. H., Kim, D.-H., & Han, Y. S. (2019). Photovoltaic Performance of Dye-Sensitized Solar Cells Containing ZnO Microrods. Nanomaterials, 9(12), 1645. https://doi.org/10.3390/nano9121645