Mechanical and Sorptivity Characteristics of Edge-Oxidized Graphene Oxide (EOGO)-Cement Composites: Dry- and Wet-Mix Design Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

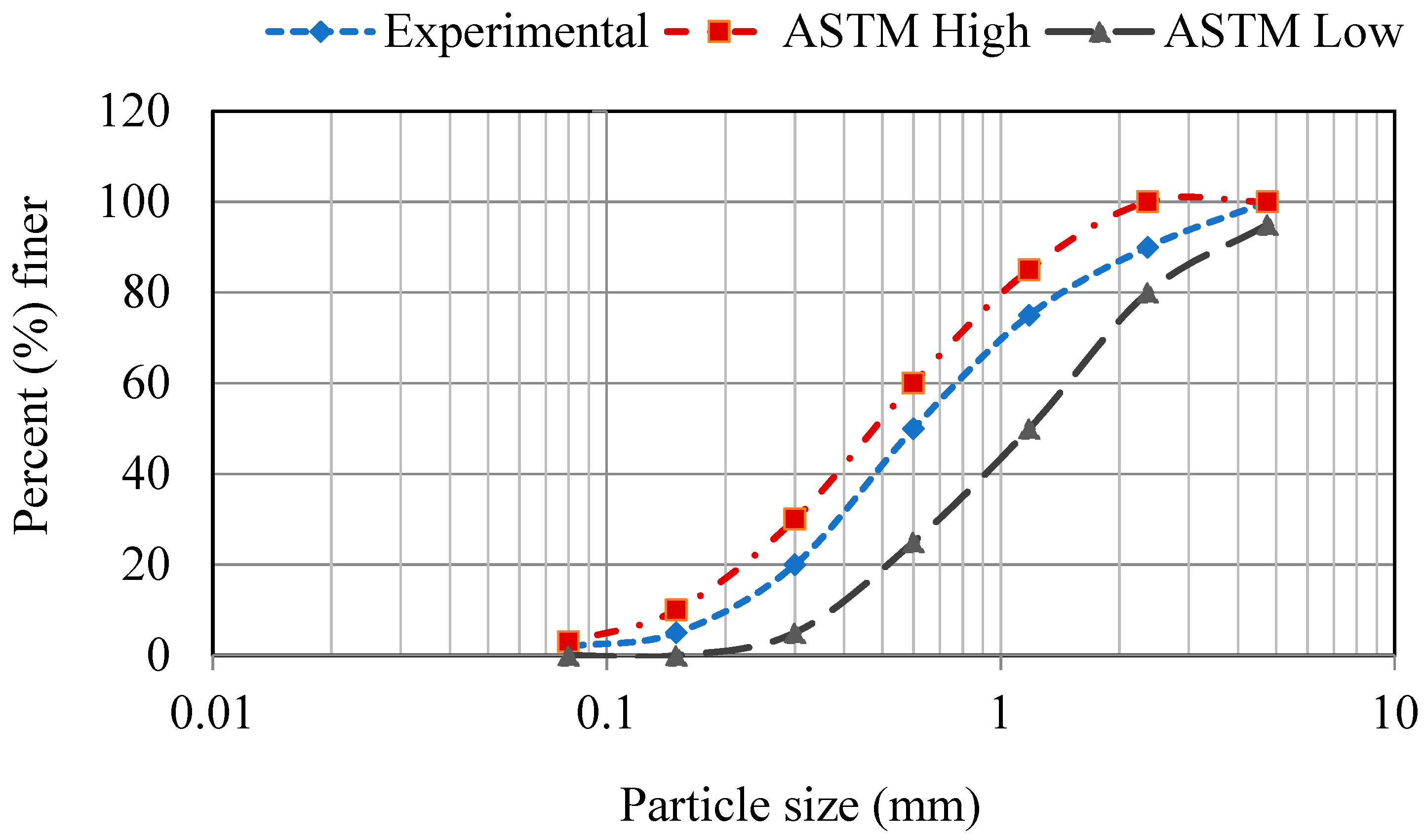

2.1.1. Cement and Fine Aggregate

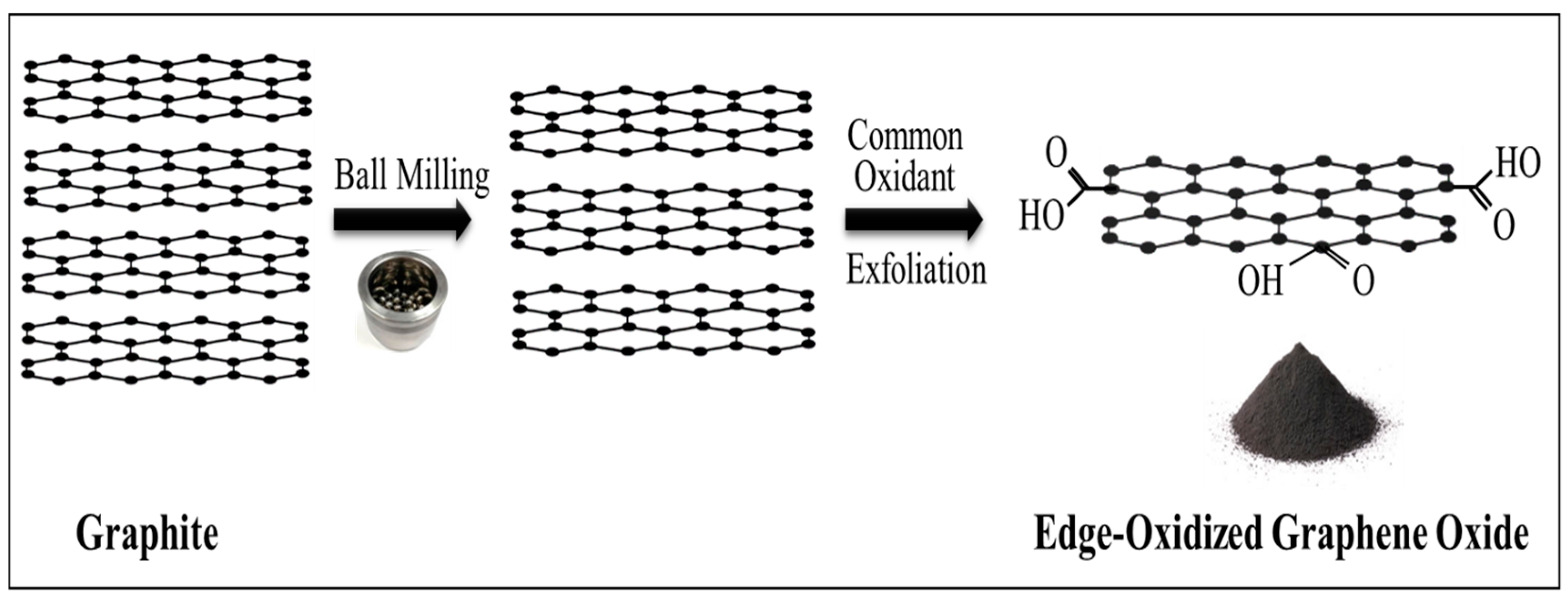

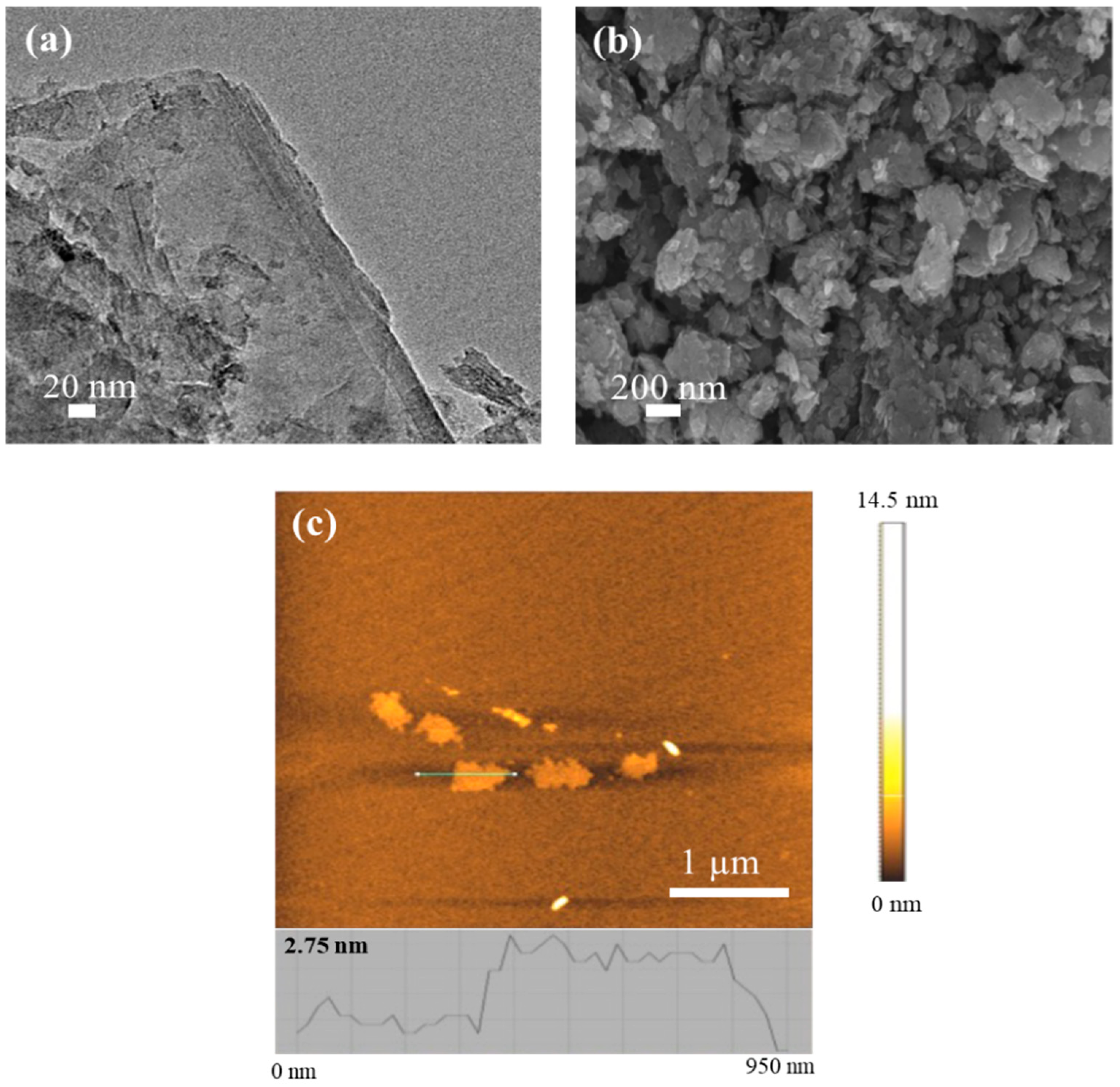

2.1.2. Edge-Oxidized Graphene Oxide (EOGO)

2.2. Preparation of Cement Paste and Mortar Specimens

2.3. Test Methods

2.3.1. Compressive and Flexural Strength Tests

2.3.2. Porosity Test

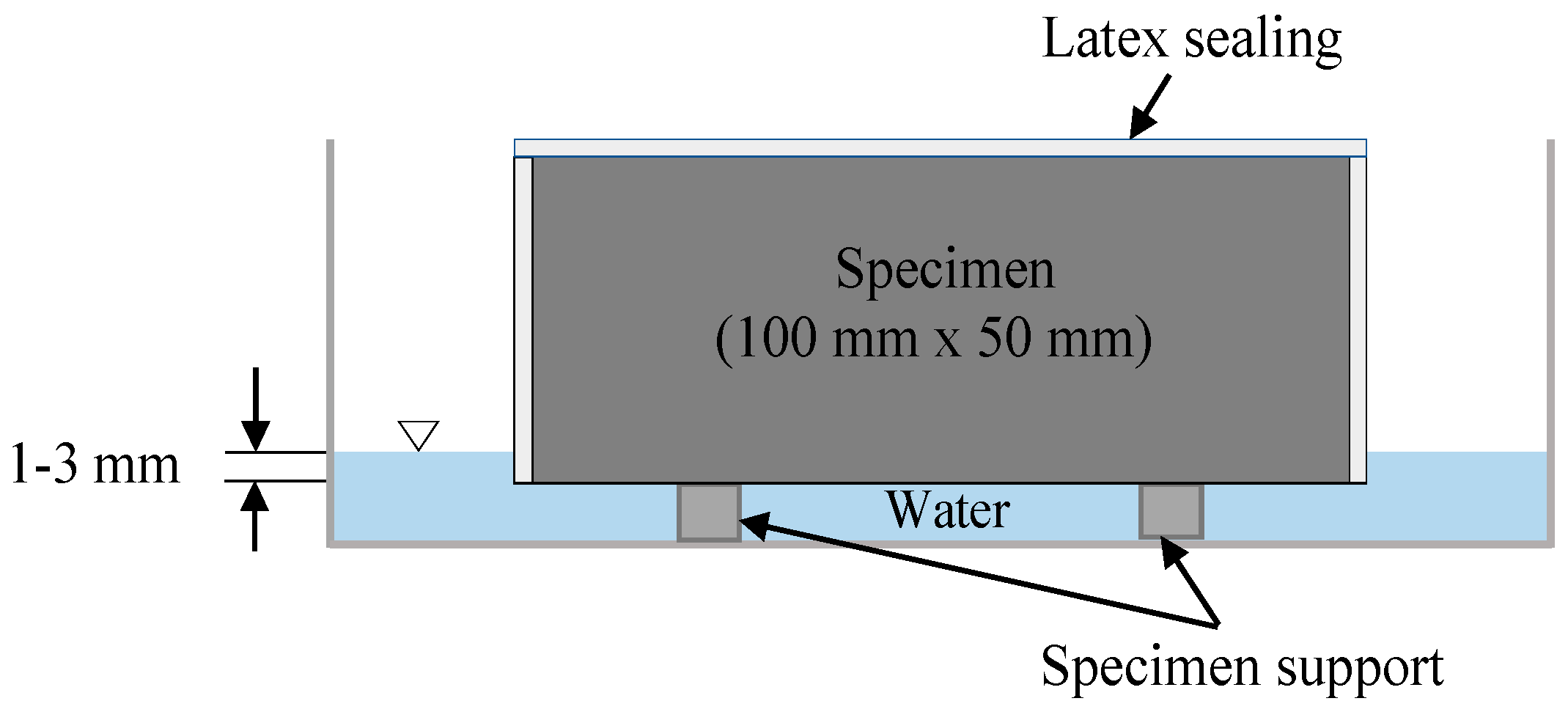

2.3.3. Water Sorptivity Test

3. Results

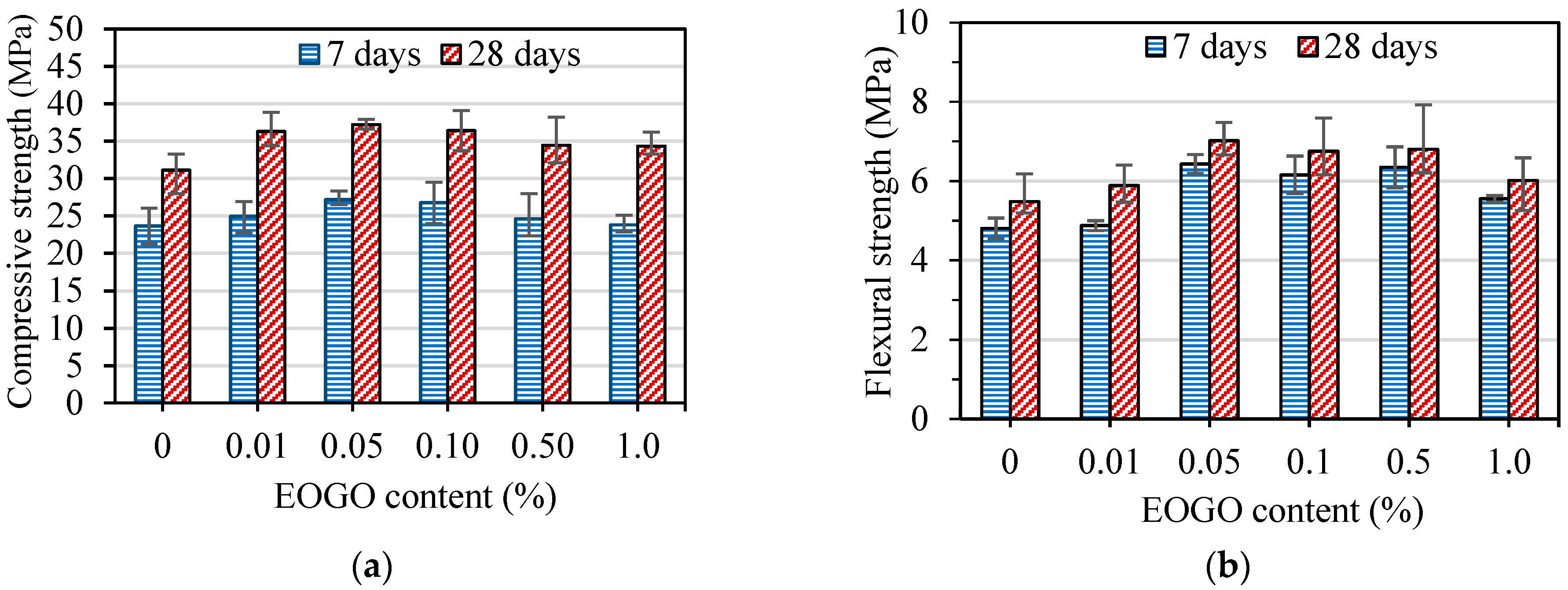

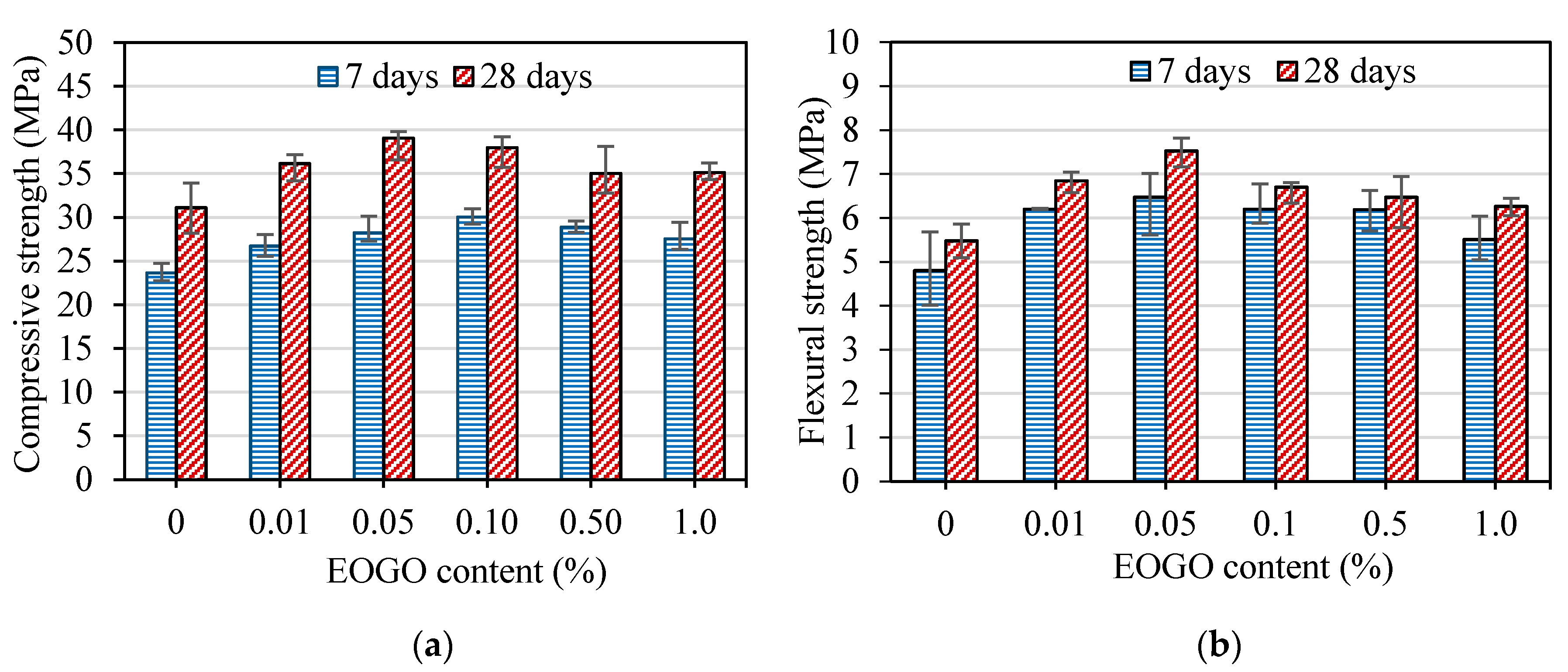

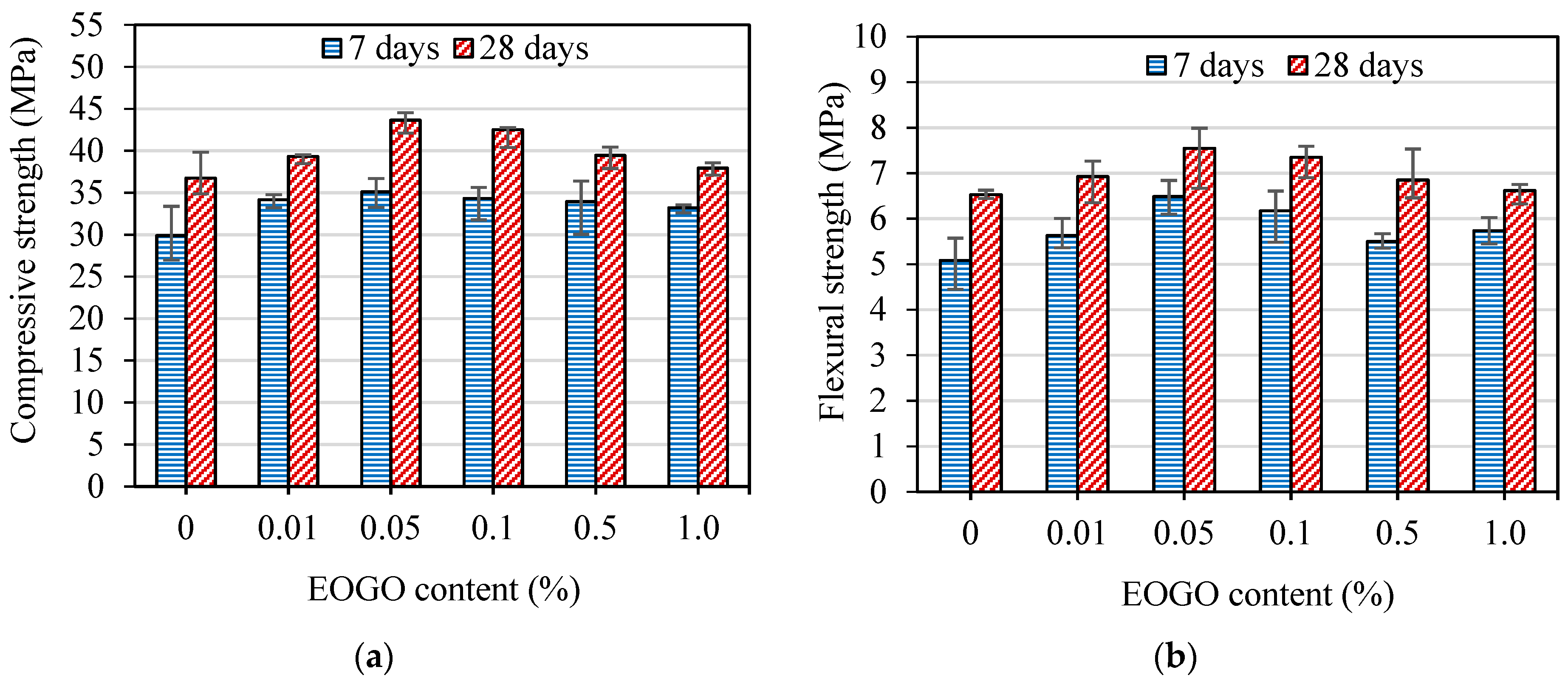

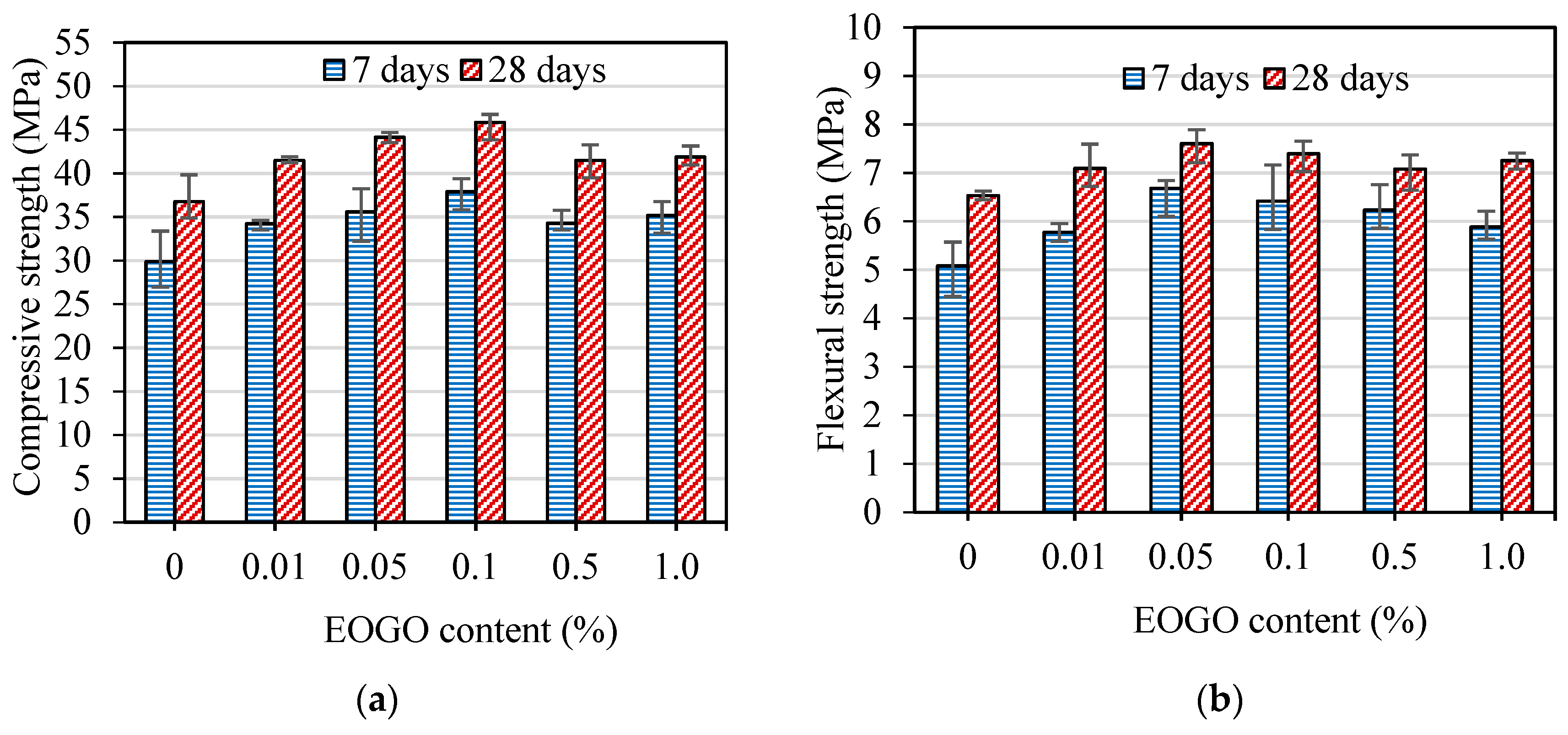

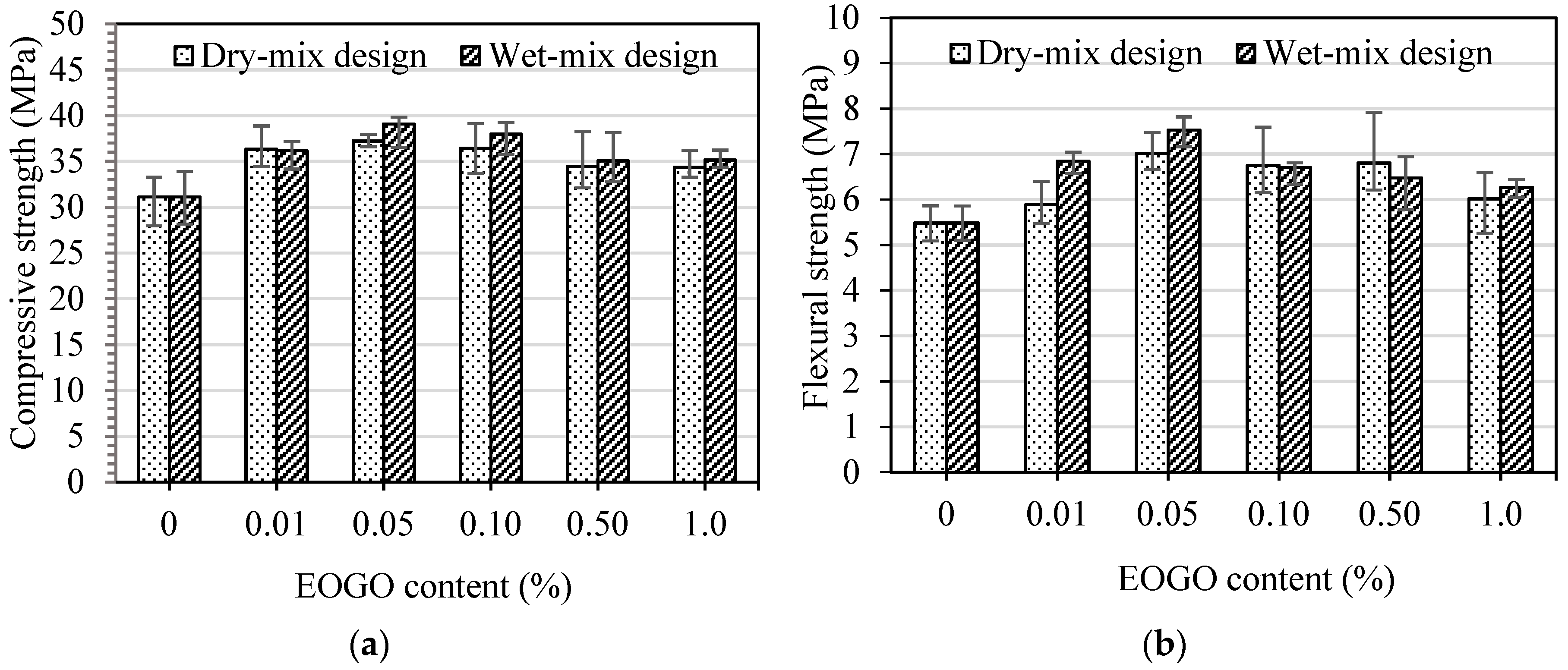

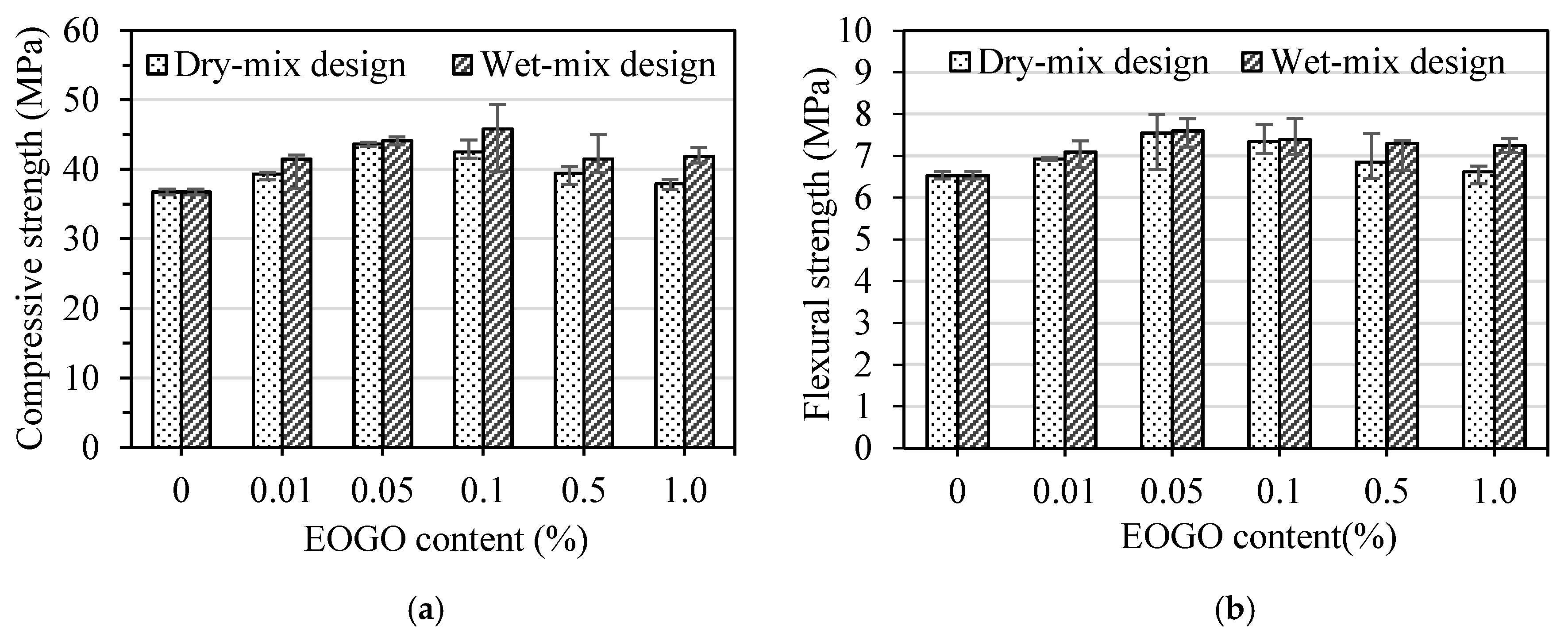

3.1. Effect of EOGO on the Mechanical Properties of Cement Paste and Mortar

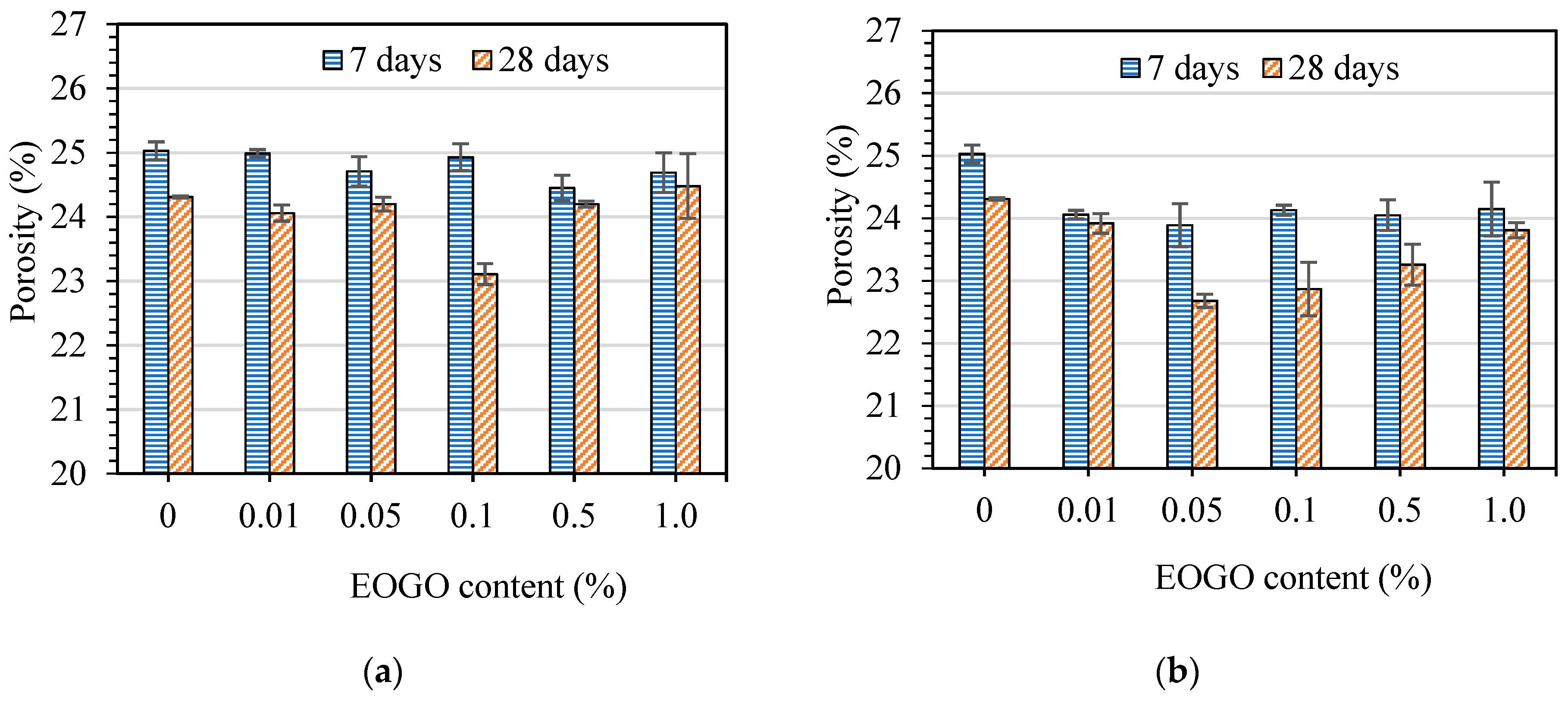

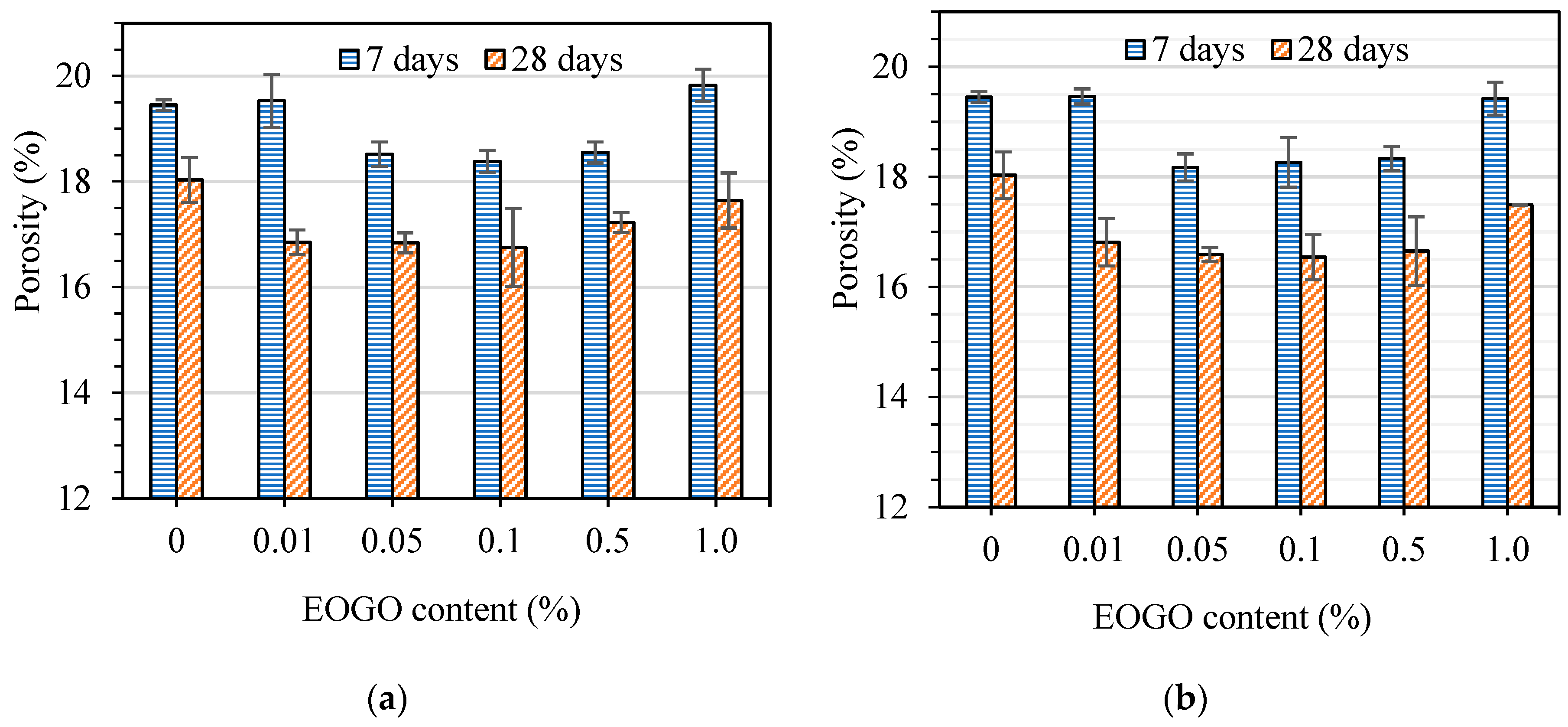

3.2. Effect of EOGO on the Porosity of Cement Paste and Mortar Specimens

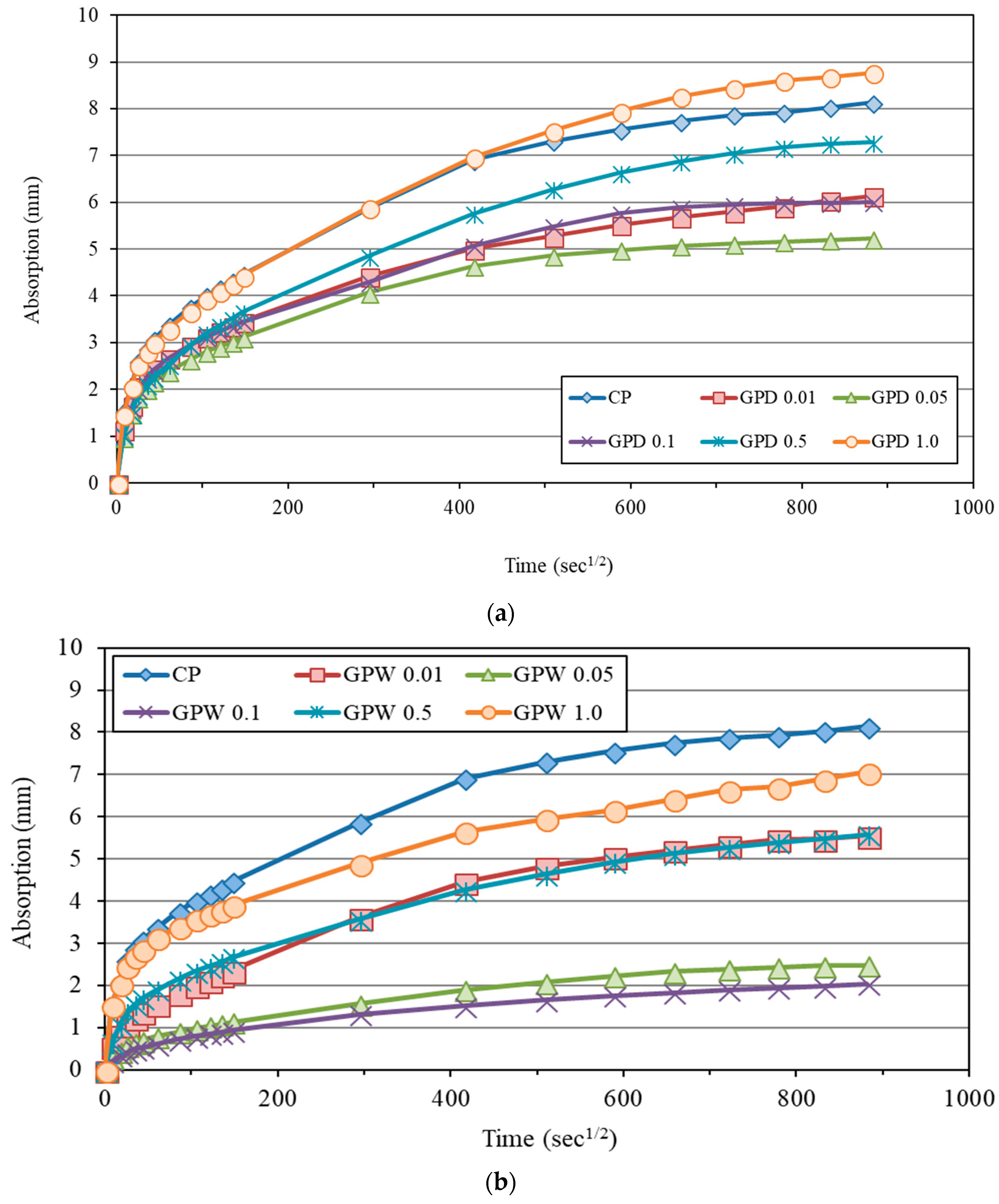

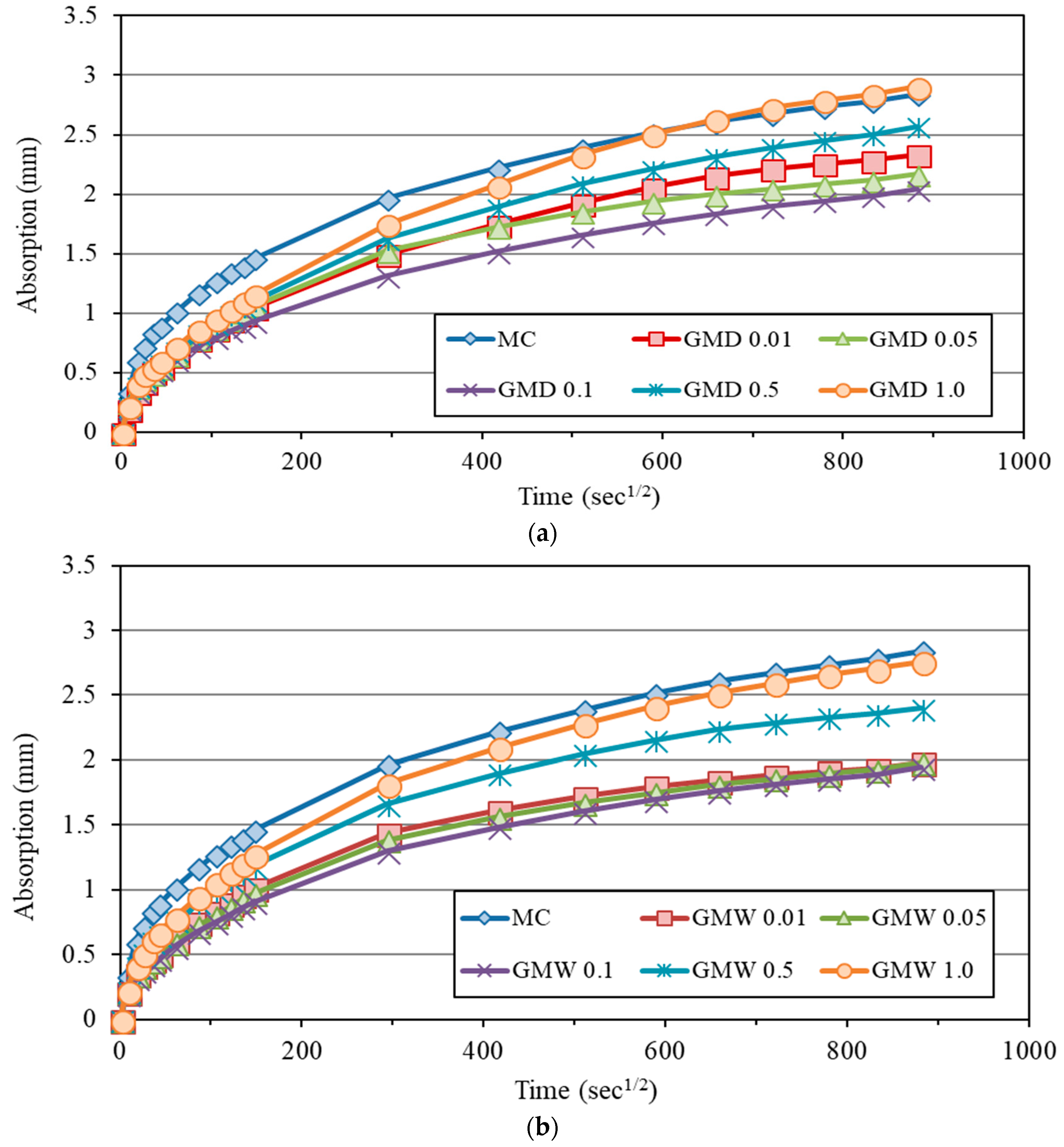

3.3. Effect of EOGO on Water Sorptivity of Cement Paste and Mortar

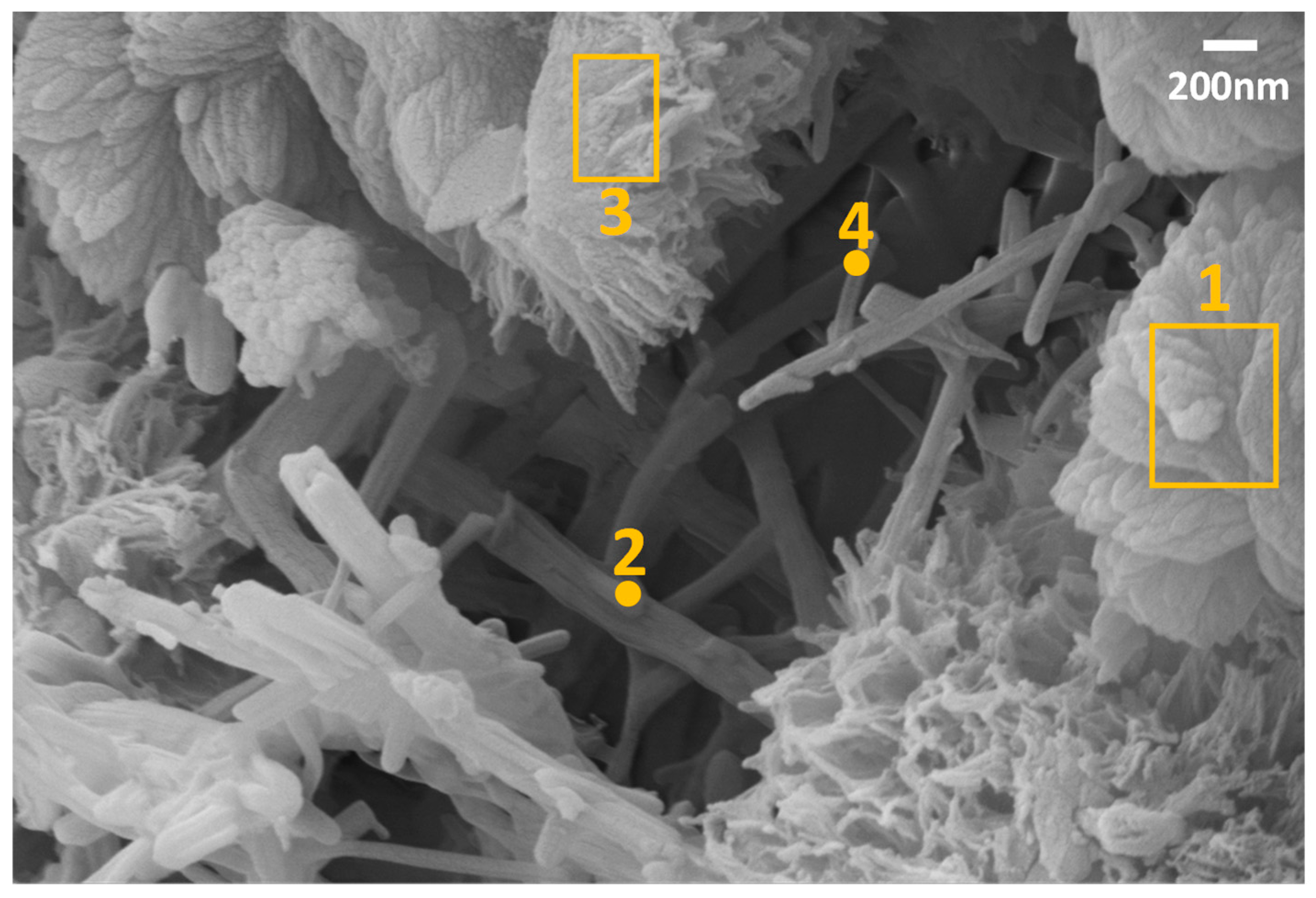

3.4. Scanning Electronic Microscopy (SEM) and Energy Dispersive Spectroscopy (EDS) Analysis

4. Discussion

5. Conclusions

- (1)

- The mechanical properties of all EOGO-cement composites were improved over the control cement composite specimens for both dry and wet-mix designs. It was observed that EOGO-cement composite with 0.05% exhibited the highest strengths at 7 and 28 days. EOGO-composites prepared by the dry- and wet-mix designs show a slight difference in strength.

- (2)

- For both dry and wet-mix designs, the addition of EOGO has a slight effect on the total porosity of cement composites. However, the addition of EOGO in cement composites can significantly refine the pore structure of cement composites according to the sorptivity results. There is a significant improvement of EOGO-cement composite in sorptivity. These sorptivity results indicate that the addition of EOGO results in the discontinuation of capillary pores in the cement matrix, thus leading to improvement in the durability of the cement composites. It was found that EOGO-cement composite with 0.05% mostly showed the greatest improvement in sorptivity.

- (3)

- The petrographic analyses (SEM/EDS) show that EOGO is mostly found in C–S–H which is the main hydration product and is primarily responsible for the strength of cement composite. This observation indicates that EOGO may bridge the C–S–H groups whereby the strength of the EOGO-cement composite can be improved.

- (4)

- The comparison between dry and wet-mix design methods shows that using the wet-mix design method shows slightly better improvement in the mechanical properties, total porosity, and water sorptivity of cement composites compared with the dry-mix design due to the better exfoliation and dispersion of EOGO flakes in the cement matrix. Nevertheless, the dry-mix design method has also significant effects on the mechanical and sorptivity characteristics of cement composites where the optimum content of EOGO (0.05%) increased the compressive and flexural strengths at 28 days of cement paste by around 20% and 28%, respectively. Both the compressive and flexural strengths at 28 days of mortar increased by around 19%. In addition, the sorptivity of cement paste and mortar decreased by approximately 48% and 40%, respectively. Thus, the dry-mix design is a practical, feasible, and economical method for EOGO-cement composites, and can be implemented in the concrete industry.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: Harlow, UK, 2011. [Google Scholar]

- Silvestre, J.; Silvvester, N.; de Brito, J. Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 2015, 20, 455–485. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Musso, S.; Tulliani, J.M.; Ferro, G.; Tagliaferro, A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K.; Penttala, V. Surface decoration of carbon nanotubes and mechanical properties of cement/carbon nanotube compositese. Adv. Cem. Res. 2008, 20, 65–73. [Google Scholar] [CrossRef]

- Lv, S.; Liu, J.; Sun, T.; Ma, Y.; Zhou, Q. Effect of GO nanosheets on shapes of cement hydration crystals and their formation process. Constr. Build. Mater. 2014, 64, 231–239. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lu, C.; Liu, B.; Zhang, K.; Li, C. Influence of graphene oxide additions on the microstructure and mechanical strength of cement. New Carbon Mater. 2015, 30, 349–356. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide-cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Tong, T.; Fan, Z.; Liu, Q.; Wang, S.; Tan, S.; Yu, Q. Investigation of the effects of graphene and graphene oxide nanoplatelets on the micro- and macro-properties of cementitious materials. Constr. Build. Mater. 2016, 106, 102–114. [Google Scholar] [CrossRef]

- Gong, K.; Asce, S.M.; Pan, Z.; Korayem, A.H.; Ph, D.; Qiu, L.; Li, D.; Collins, F.; Wang, C.M.; Duan, W.H.; Asce, A.M. Reinforcing effects of graphene oxide on portland cement paste. J. Mater. Civ. Eng. 2014, 27, 1–6. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Brunet, J.P.L.; Li, L.; Karpyn, Z.T.; Kutchko, B.G.; Strazisar, B.; Bromhal, G. Dynamic evolution of cement composition and transport properties under conditions relevant to geological carbon sequestration. Energy Fuels 2013, 27, 4208–4220. [Google Scholar] [CrossRef]

- De La Varga, I.; Spragg, R.P.; Di Bella, C.; Castro, J.; Bentz, D.P.; Weiss, J. Fluid transport in high volume fly ash mixtures with and without internal curing. Cem. Concr. Compos. 2014, 45, 102–110. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The fluid transport properties of HCWA-DSF hybrid supplementary binder mortar. Compos. Part B Eng. 2014, 56, 681–690. [Google Scholar] [CrossRef]

- Zhang, S.P.; Zong, L. Evaluation of relationship between water absorption and durability of concrete materials. Adv. Mater Sci. Eng. 2014, 2014, 650373. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Zdravkov, B.D.; Čermák, J.J.; Šefara, M.; Janků, J. Pore classification in the characterization of porous materials: A perspective. Cent. Eur. J. Chem. 2007, 5, 385–395. [Google Scholar]

- Nochaiya, T.; Chaipanich, A. Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl. Surf. Sci. 2011, 257, 1941–1945. [Google Scholar] [CrossRef]

- Han, B.; Yang, Z.; Shi, X.; Yu, X. Transport properties of carbon-nanotube/cement composites. J. Mater. Eng. Perform. 2013, 22, 184–189. [Google Scholar] [CrossRef]

- Kim, H.K.; Nam, I.W.; Lee, H.K. Enhanced effect of carbon nanotube on mechanical and electrical properties of cement composites by incorporation of silica fume. Compos. Struct. 2014, 107, 60–69. [Google Scholar] [CrossRef]

- Blair, R.G.; Chagoya, K.; Biltek, S.; Jackson, S.; Sinclair, A.; Taraboletti, A.; Restrepo, D.T. The scalability in the mechanochemical syntheses of edge functionalized graphene materials and biomass-derived chemicals. Faraday Discuss. 2014, 170, 223–233. [Google Scholar] [CrossRef] [PubMed]

- Garmor Inc. Available online: http://garmortech.com/technology.htm (accessed on 9 July 2015).

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Gao, Y.; Ren, X.; Tan, X.; Hayat, T.; Alsaedi, A.; Chen, C. Insights into key factors controlling GO stability in natural surface waters. J. Hazard. Mater. 2017, 335, 56–65. [Google Scholar] [CrossRef] [PubMed]

- ASTM International. Standard Specification for Portland Cement; ASTM C150/C150M-18; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. Standard Specification for Concrete Aggregates; ASTM C33/C33M-18; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Hummers, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- ASTM International. Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency; ASTM C305-14; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTM C109/C109M-16a; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM International. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM C348-14; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM International. Standard Test Method for Density and Void Content of Hardened Pervious Concrete; ASTM C1754/C1754M-12; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM International. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes; ASTM C1585-13; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Zhou, C.; Li, F.; Hu, J.; Ren, M.; Wei, J.; Yu, Q. Enhanced mechanical properties of cement paste by hybrid graphene oxide/carbon nanotubes. Constr. Build. Mater. 2017, 134, 336–345. [Google Scholar] [CrossRef]

- Bastos, G.; Faustino Patiño-Barbeito, F.; Patiño-Cambeiro, F.; Armesto, J. Nano-inclusions applied in cement-matrix composites: A review. Materials 2016, 9, 1015. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the mechanical properties and microstructure of graphene nanoplatelet-cement composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Cho, B.H.; Alharbi, Y.; Khawaji, M.; Mclnnis, M.; Nam, B.H. Optimized Mix Design for Graphene Oxide Nano ake (GONF)-Cement Composite. In Proceedings of the Transportation Research Board 97th Annual Meeting, Washington, DC, USA, 7–11 January 2018; TRB: Washington, DC, USA, 2018. [Google Scholar]

- Lv, S.; Ting, S.; Liu, J.; Zhou, Q. Use of graphene oxide nanosheets to regulate the microstructure of hardened cement paste to increase its strength and toughness. CrystEngComm 2014, 16, 8508. [Google Scholar] [CrossRef]

- e Silva, R.A.; de Castro Guetti, P.; da Luz, M.S.; Rouxinol, F.; Gelamo, R.V. Enhanced properties of cement mortars with multilayer graphene nanoparticles. Constr. Build. Mater. 2017, 149, 378–385. [Google Scholar] [CrossRef]

- Al-Muhit, B.A.; Nam, B.H.; Zhai, L.; Zuyus, J. Investigation on the mechanical, microstructural and electrical properties of graphene oxide-cement composite. In Proceedings of the Transportation Research Board 94th Annual Meeting, Washington, DC, USA, 11–15 January 2015; TRB: Washington, DC, USA, 2015. [Google Scholar]

- An, J.; McInnis, M.; Chung, W.; Nam, B. Feasibility of Using Graphene Oxide Nanoflake (GONF) as Additive of Cement Composite. Appl. Sci. 2018, 8, 419. [Google Scholar] [CrossRef]

- Sant, G.; Bentz, D.; Weiss, J. Capillary porosity depercolation in cement-based materials: Measurement techniques and factors which influence their interpretation. Cem. Concr. Res. 2011, 41, 854–864. [Google Scholar] [CrossRef]

- Henkensiefken, R.; Nantung, T.; Weiss, J. Saturated lightweight aggregate for internal curing in low w/c mixtures: Monitoring water movement using x-ray absorption. Strain 2011, 47, 432–441. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.M.; Li, W.G.; Li, C.Y.; Sanjayan, J.G.; Duan, W.H.; Li, Z. Effects of graphene oxide agglomerates on workability, hydration, microstructure and compressive strength of cement paste. Constr. Build. Mater. 2017, 145, 402–410. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentic-Hall, Pearson Education: Bergen County, NJ, USA, 2003. [Google Scholar]

- Horszczaruk, E.; Mijowska, E.; Kalenczuk, R.J.; Aleksandrzak, M.; Mijowska, S. Nanocomposite of cement/graphene oxide—Impact on hydration kinetics and Young’s modulus. Constr. Build. Mater. 2015, 78, 234–242. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

| Contents | CaO | SiO2 | SO3 | Al2O3 | Fe2O3 | Insoluble Residue | Loss on Ignition |

|---|---|---|---|---|---|---|---|

| (%) | 64.90 | 21.49 | 0.70 | 4.21 | 3.50 | 1.10 | - |

| Material | Chemical Composition | Physical Properties | |||

|---|---|---|---|---|---|

| Carbon (%) | Oxygen (%) | Density (g/cm3) | Surface Area (m2/g) | Mean Particle Size (nm) | |

| EOGO | 90–96 | 5–10 | ~1.0 | 200–300 | 400–500 |

| Specimen ID | w/c Ratio | Water (mL) | Cement (g) | Sand (g) | EOGO (g) |

|---|---|---|---|---|---|

| CP | 0.5 | 1750 | 3500 | - | - |

| GPD 0.01 | 0.5 | 1750 | 3500 | - | 0.35 |

| GPD 0.05 | 0.5 | 1750 | 3500 | - | 1.75 |

| GPD 0.1 | 0.5 | 1750 | 3500 | - | 3.5 |

| GPD 0.5 | 0.5 | 1750 | 3500 | - | 17.5 |

| GPD 1.0 | 0.5 | 1750 | 3500 | - | 35 |

| GPW 0.01 | 0.5 | 1750 | 3500 | - | 0.35 |

| GPW0.05 | 0.5 | 1750 | 3500 | - | 1.75 |

| GPW 0.1 | 0.5 | 1750 | 3500 | - | 3.5 |

| GPW 0.5 | 0.5 | 1750 | 3500 | - | 17.5 |

| GPW 1.0 | 0.5 | 1750 | 3500 | - | 35 |

| CM | 0.45 | 780 | 1686 | 4215 | - |

| GMD 0.01 | 0.45 | 780 | 1686 | 4215 | 0.1686 |

| GMD 0.05 | 0.45 | 780 | 1686 | 4215 | 0.843 |

| GMD 0.1 | 0.45 | 780 | 1686 | 4215 | 1.686 |

| GMD 0.5 | 0.45 | 780 | 1686 | 4215 | 8.43 |

| GMD 1.0 | 0.45 | 780 | 1686 | 4215 | 16.86 |

| GMW 0.01 | 0.45 | 780 | 1686 | 4215 | 0.1686 |

| GMW0.05 | 0.45 | 780 | 1686 | 4215 | 0.843 |

| GMW 0.1 | 0.45 | 780 | 1686 | 4215 | 1.686 |

| GMW 0.5 | 0.45 | 780 | 1686 | 4215 | 8.43 |

| GMW 1.0 | 0.45 | 780 | 1686 | 4215 | 16.86 |

| Samples | Initial Sorptivity (mm/s1/2) | Reduction Compared to CP (%) | Secondary Sorptivity (mm/s1/2) | Difference with CP (%) |

|---|---|---|---|---|

| CP | 0.0183 | - | 0.0035 | - |

| GPD 0.01 | 0.0147 | −19.7 | 0.0028 | −20.0 |

| GPD 0.05 | 0.0130 | −29.0 | 0.0018 | −48.6 |

| GPD 0.1 | 0.0140 | −23.5 | 0.0027 | −22.9 |

| GPD 0.5 | 0.0170 | −7.1 | 0.0040 | +14.3 |

| GPD 1.0 | 0.0183 | 0 | 0.0042 | +20.0 |

| GPW0.01 | 0.0118 | −35.5 | 0.0030 | −14.3 |

| GPW0.05 | 0.0054 | −70.5 | 0.0015 | −57.1 |

| GPW 0.1 | 0.0048 | −73.8 | 0.0012 | −65.7 |

| GPW 0.5 | 0.0126 | −31.1 | 0.0033 | −5.7 |

| GPW 1.0 | 0.0146 | −20.2 | 0.0034 | −2.9 |

| Samples | Initial Sorptivity (mm/s1/2) | Reduction Compared to CM (%) | Secondary Sorptivity (mm/s1/2) | Difference with CM (%) |

|---|---|---|---|---|

| CM | 0.007 | - | 0.0014 | - |

| GMD 0.01 | 0.0057 | −22.8 | 0.0013 | −7.7 |

| GMD 0.05 | 0.0055 | −27.3 | 0.001 | −40.0 |

| GMD 0.1 | 0.0047 | −48.9 | 0.0011 | −27.3 |

| GMD 0.5 | 0.0058 | −20.7 | 0.0016 | +12.5 |

| GMD 1.0 | 0.0061 | −14.8 | 0.0019 | +26.3 |

| GMW0.01 | 0.0054 | −29.6 | 0.0011 | −27.3 |

| GMW0.05 | 0.0047 | −48.9 | 0.0009 | −55.6 |

| GMW 0.1 | 0.0051 | −37.3 | 0.001 | −40.0 |

| GMW 0.5 | 0.0062 | −12.9 | 0.0012 | −16.7 |

| GMW 1.0 | 0.0069 | −1.4 | 0.0016 | +12.5 |

| Shots | C (%) | O (%) | Al (%) | Si (%) | S (%) | Ca (%) | Pd (%) | Au (%) | Total (%) | Probable Compounds |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 (Area) | 12.43 | 30.05 | - | 3.17 | - | 50.93 | - | 3.42 | 100 | C–S–H+EOGO |

| 2 (Point) | 5.29 | 31.98 | 4.39 | 6.82 | 4.63 | 46.89 | - | - | C–S–H+Ettringite+EOGO | |

| 3 (Area) | 15.56 | 39.99 | 0.86 | 10.15 | - | 25.74 | 4.56 | 3.15 | Jannite+EOGO | |

| 4 (Point) | - | 13.70 | 2.58 | 9.23 | 5.47 | 69.01 | - | - | Ettringite |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alharbi, Y.; An, J.; Cho, B.H.; Khawaji, M.; Chung, W.; Nam, B.H. Mechanical and Sorptivity Characteristics of Edge-Oxidized Graphene Oxide (EOGO)-Cement Composites: Dry- and Wet-Mix Design Methods. Nanomaterials 2018, 8, 718. https://doi.org/10.3390/nano8090718

Alharbi Y, An J, Cho BH, Khawaji M, Chung W, Nam BH. Mechanical and Sorptivity Characteristics of Edge-Oxidized Graphene Oxide (EOGO)-Cement Composites: Dry- and Wet-Mix Design Methods. Nanomaterials. 2018; 8(9):718. https://doi.org/10.3390/nano8090718

Chicago/Turabian StyleAlharbi, Yousef, Jinwoo An, Byoung Hooi Cho, Mohammad Khawaji, Wonseok Chung, and Boo Hyun Nam. 2018. "Mechanical and Sorptivity Characteristics of Edge-Oxidized Graphene Oxide (EOGO)-Cement Composites: Dry- and Wet-Mix Design Methods" Nanomaterials 8, no. 9: 718. https://doi.org/10.3390/nano8090718

APA StyleAlharbi, Y., An, J., Cho, B. H., Khawaji, M., Chung, W., & Nam, B. H. (2018). Mechanical and Sorptivity Characteristics of Edge-Oxidized Graphene Oxide (EOGO)-Cement Composites: Dry- and Wet-Mix Design Methods. Nanomaterials, 8(9), 718. https://doi.org/10.3390/nano8090718