Perfluoropolyether (PFPE) Intermediate Molds for High-Resolution Thermal Nanoimprint Lithography

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

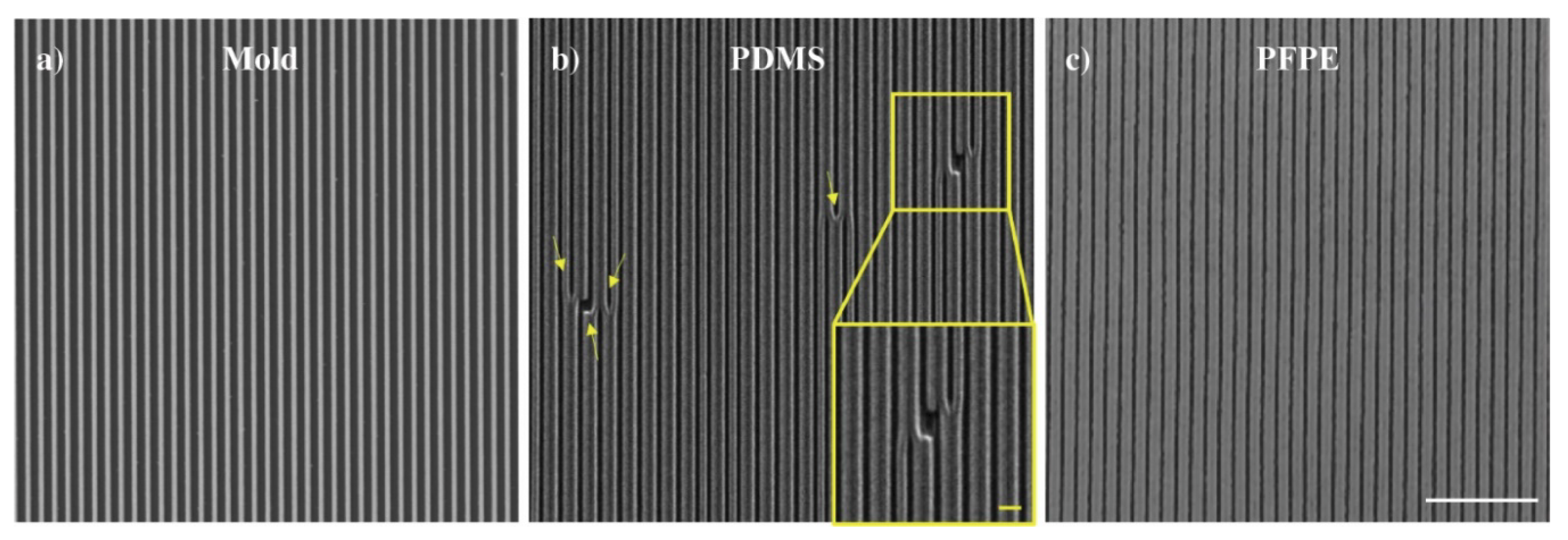

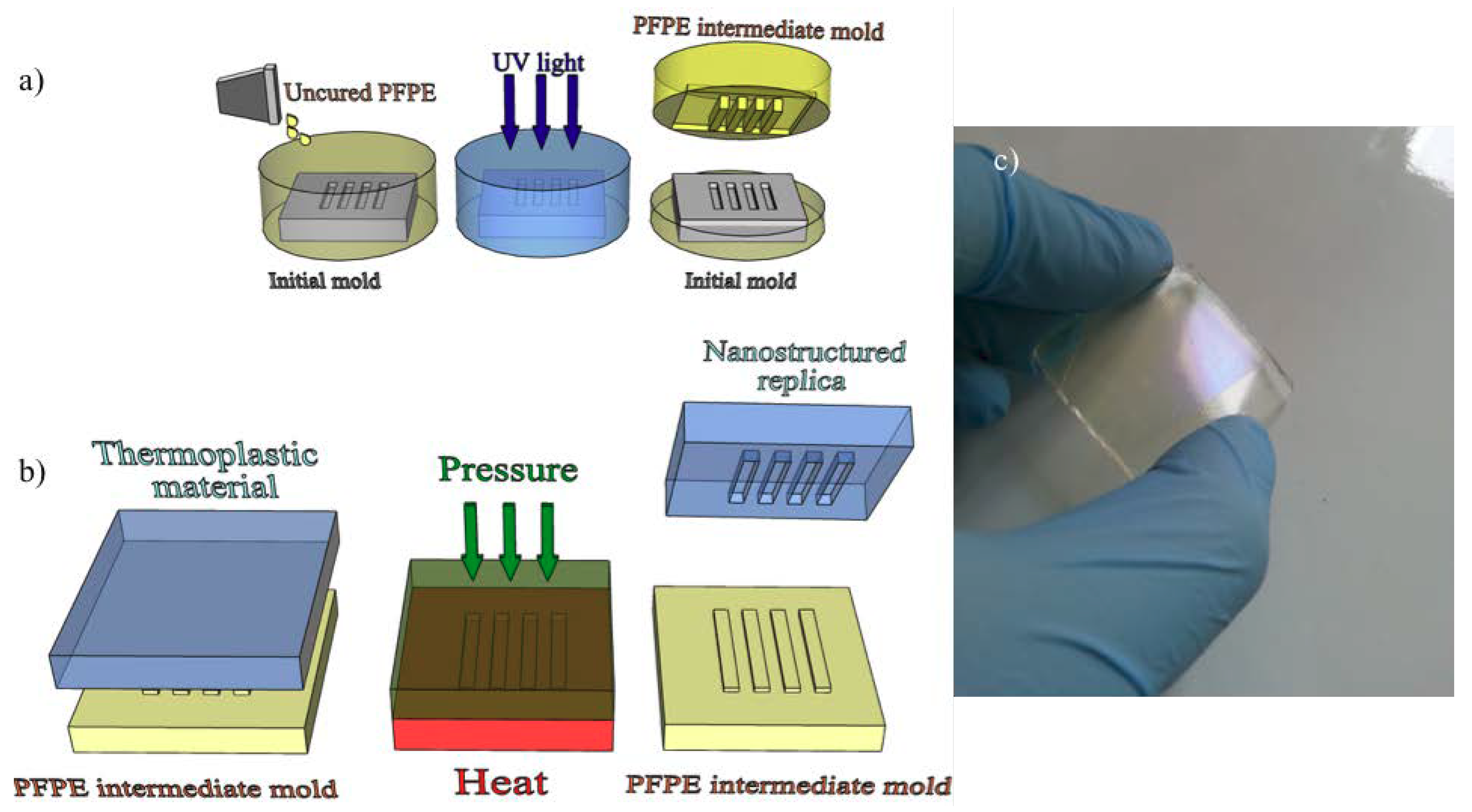

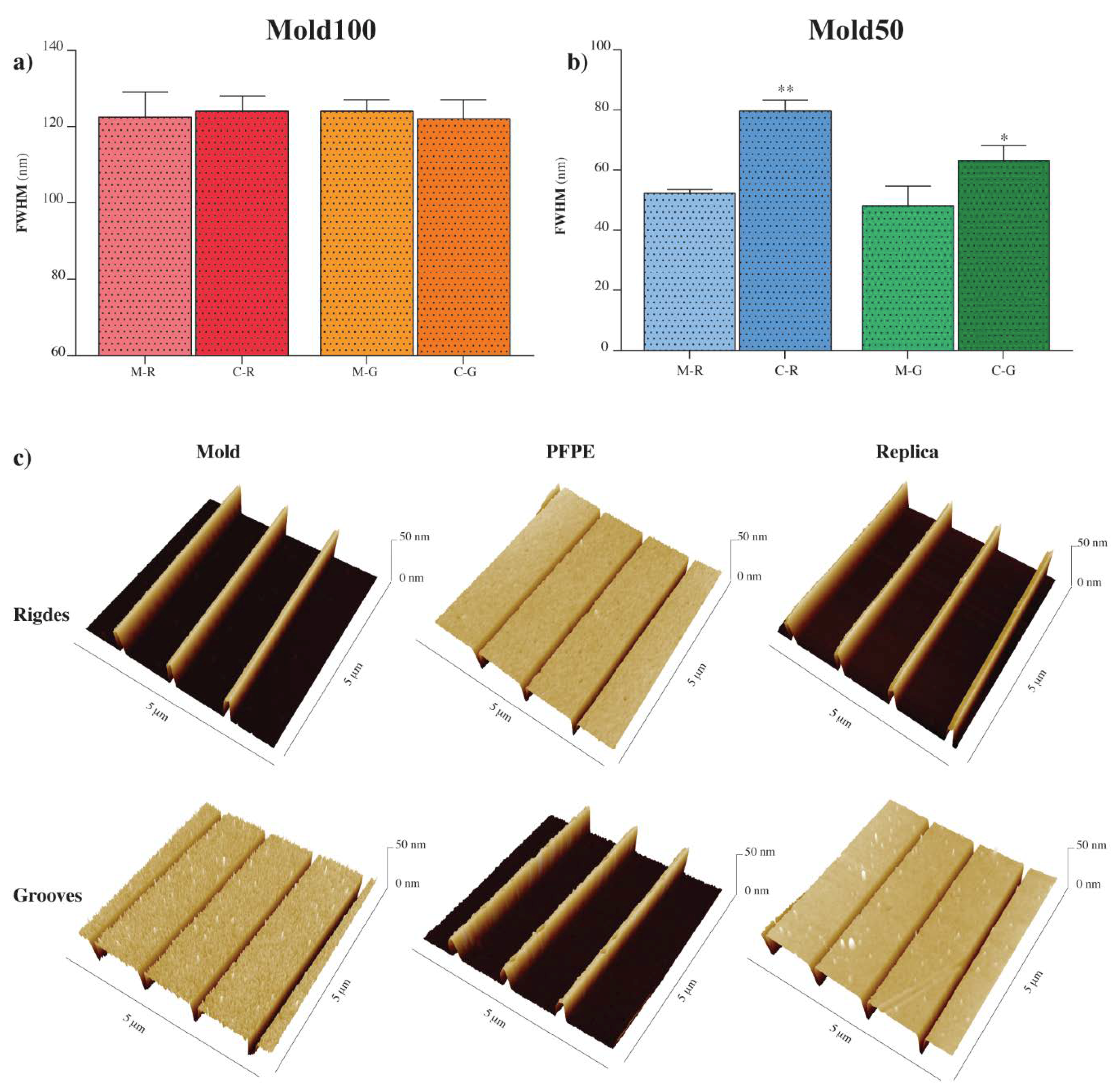

3.1. Step 1: PFPE Intermediate Mold Fabrication and Characterization

3.2. Step 2: COC Thermal Nanoimprinting via PFPE Intermediate Molds

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chou, S.; Krauss, P.; Renstrom, P. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114. [Google Scholar] [CrossRef]

- Chou, S.; Krauss, P.; Renstrom, P. Imprint Lithography with 25-Nanometer Resolution. Science 1996, 272, 85–87. [Google Scholar] [CrossRef]

- Heidari, B. Apparatus for Pattern Replication with Intermediate Stamp. US Patent 767,012,7B2, 2 March 2010. [Google Scholar]

- Kwon, B.; Kim, J.H. Importance of Molds for Nanoimprint Lithography: Hard, Soft, and Hybrid Molds. J. Nanosci. 2016. [Google Scholar] [CrossRef]

- Guo, L. Nanoimprint Lithography: Methods and Material Requirements. Adv. Mater. 2017, 19, 495–513. [Google Scholar] [CrossRef]

- Bietsch, A.; Michel, B. Conformal contact and pattern stability of stamps used for soft lithography. J. Appl. Phys. 2000, 88, 4310. [Google Scholar] [CrossRef]

- Tucher, N.; Höhn, O.; Hauser, H.; Müller, C.; Bläsi, B. Characterizing the degradation of PDMS stamps in nanoimprint lithography. Microelectron. Eng. 2017, 180, 40–44. [Google Scholar] [CrossRef]

- Barbero, D.R.; Saifullah, M.S.M.; Hoffmann, P.; Mathieu, H.; Jörg, D.; Anderson, G.A.; Jones, C.; Welland, M.E.; Steiner, U. High Resolution Nanoimprinting with a Robust and Reusable Polymer Mold. Adv. Funct. Mater. 2007, 17, 2419–2425. [Google Scholar] [CrossRef]

- Weiss, D.N.; Meyers, S.T.; Keszler, D.A. All-inorganic thermal nanoimprint process. J. Vacu. Sci. Technol. B Nanotechnol. Microelectron. 2010, 28, 823–828. [Google Scholar] [CrossRef]

- Greer, A.I.M.; Vasiev, I.; Della-Rosa, B.; Gadegaard, N. Fluorinated ethylene–propylene: A complementary alternative to PDMS for nanoimprint stamps. Nanotechnology 2016, 27, 155301–1553019. [Google Scholar] [CrossRef] [PubMed]

- Williams, S.S.; Retterer, S.; Lopez, R.; Ruiz, R.; Samulski, E.T.; DeSimone, J.M. High-resolution PFPE-based molding techniques for nanofabrication of high-pattern density, sub-20 nm features: A fundamental materials approach. Nano Lett. 2010, 10, 1421–1428. [Google Scholar] [CrossRef] [PubMed]

- Scheirs, J. High performance polymers for diverse applications. In Modern Fluoropolymers; John Wiley & Sons, Inc.: New York, NY, USA, 1997. [Google Scholar]

- Ameduri, B.; Boutevin, B.; Kostov, G. Fluoroelastomers: Synthesis, properties and applications. Prog. Polym. Sci. 2001, 26, 105–187. [Google Scholar] [CrossRef]

- Liang, C.; Lin, C.; Cheng, T.; Shieh, J.; Lin, H. Nanoimprinting of Flexible Polycarbonate Sheets with a Flexible Polymer Mold and Application to Superhydrophobic Surfaces. Adv. Mater. Interfaces 2015, 2, 1500030. [Google Scholar] [CrossRef]

- Con, C.; Zhang, J.; Jahed, Z.; Tsui, T.; Yavuz, M.; Cui, B. Thermal nanoimprint lithography using fluoropolymer mold. Microelectron. Eng. 2012, 98, 246–249. [Google Scholar] [CrossRef]

- Meneghello, A.; Antognoli, A.; Sonato, A.; Zacco, G.; Ruffato, G.; Cretaio, E.; Romanato, F. Label-Free Efficient and Accurate Detection of Cystic Fibrosis Causing Mutations Using an Azimuthally Rotated GC-SPR Platform. Anal. Chem. 2014, 86, 11773–11778. [Google Scholar] [CrossRef] [PubMed]

- Shilton, R.; Travagliati, M.; Beltram, F.; Cecchini, M. Microfluidic pumping through miniaturized channels driven by ultra-high frequency surface acoustic waves. Appl. Phys. Lett. 2014, 105, 074106. [Google Scholar] [CrossRef]

- Dell’Anna, R.; Masciullo, C.; Iacob, E.; Barozzi, M.; Giubertoni, D.; Böttger, R.; Cecchini, M.; Pepponi, G. Multiscale structured germanium nanoripples as templates for bioactive surfaces. RSC Adv. 2017, 7, 9024–9030. [Google Scholar] [CrossRef] [Green Version]

- Masciullo, C.; Dell’Anna, R.; Tonazzini, I.; Böttger, R.; Pepponi, G.; Cecchini, M. Hierarchical thermoplastic rippled nanostructures regulate Schwann cell adhesion, morphology and spatial organization. Nanoscale 2017, 9, 14861–14874. [Google Scholar] [CrossRef] [PubMed]

- Meucci, S.; Tonazzini, I.; Beltram, F.; Cecchini, M. Biocompatible noisy nanotopographies with specific directionality for controlled anisotropic cell cultures. Soft Matter 2012, 8, 1109–1119. [Google Scholar] [CrossRef]

- Park, J.K.; Cho, S.H. Flexible gratings fabricated in polymeric plate using femtosecond laser irradiation. Opt. Lasers Eng. 2011, 49, 589–593. [Google Scholar] [CrossRef]

- Johnston, I.D.; McCluskey, D.K.; Tan, C.K.L.; Tracey, M.C. Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering. J. Micromech. Microeng. 2014, 24, 35017–35034. [Google Scholar] [CrossRef]

- Cho, H.; Kim, J.; Bang, H.J.W.; Hyun, M.S.; Bae, Y.; Ha, L.; Kim, D.Y.; Kang, S.M.; Park, T.J.; Seo, S.; et al. Replication of flexible polymer membranes with geometry-controllable nano-apertures via a hierarchical mould-based dewetting. Nat. Commun. 2014, 5, 3137. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, K.S.; Kim, J.H.; Lee, H.J.; Lee, S.R. Tribology issues in nanoimprint lithography. J. Mech. Sci. Technol. 2010, 24, 5–12. [Google Scholar] [CrossRef]

- Truong, T.T.; Lin, R.; Jeon, S.; Lee, H.H.; Maria, J.; Gaur, A.; Hua, F.; Meinel, I.; Rogers, J.A. Soft Lithography Using Acryloxy Perfluoropolyether Composite Stamps. Langmuir 2007, 5, 2898–2905. [Google Scholar] [CrossRef] [PubMed]

- Vitale, A.; Merlo, S.; Rizza, G.; Melilli, G.; Sangermano, M. UV Curing of Perfluoropolyether Oligomers Containing Graphene Nanosheets to Enhance Water-Vapor Barrier properties. Macromol. Chem. Phys. 2014, 215, 1588–1592. [Google Scholar] [CrossRef]

- Rolland, J.P.; Hagberg, E.C.; Denison, G.M.; Carter, K.R.; De Simone, J.M. High-Resolution Soft Lithography: Enabling Materials for Nanotechnologies High-resolution soft lithography: Enabling materials for nanotechnologies. Angew. Chem. Int. Ed. 2004, 43, 5796–5799. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masciullo, C.; Sonato, A.; Romanato, F.; Cecchini, M. Perfluoropolyether (PFPE) Intermediate Molds for High-Resolution Thermal Nanoimprint Lithography. Nanomaterials 2018, 8, 609. https://doi.org/10.3390/nano8080609

Masciullo C, Sonato A, Romanato F, Cecchini M. Perfluoropolyether (PFPE) Intermediate Molds for High-Resolution Thermal Nanoimprint Lithography. Nanomaterials. 2018; 8(8):609. https://doi.org/10.3390/nano8080609

Chicago/Turabian StyleMasciullo, Cecilia, Agnese Sonato, Filippo Romanato, and Marco Cecchini. 2018. "Perfluoropolyether (PFPE) Intermediate Molds for High-Resolution Thermal Nanoimprint Lithography" Nanomaterials 8, no. 8: 609. https://doi.org/10.3390/nano8080609

APA StyleMasciullo, C., Sonato, A., Romanato, F., & Cecchini, M. (2018). Perfluoropolyether (PFPE) Intermediate Molds for High-Resolution Thermal Nanoimprint Lithography. Nanomaterials, 8(8), 609. https://doi.org/10.3390/nano8080609