Nano-Silica Sol-Gel and Carbon Nanotube Coupling Effect on the Performance of Cement-Based Materials

Abstract

:1. Introduction

2. Results

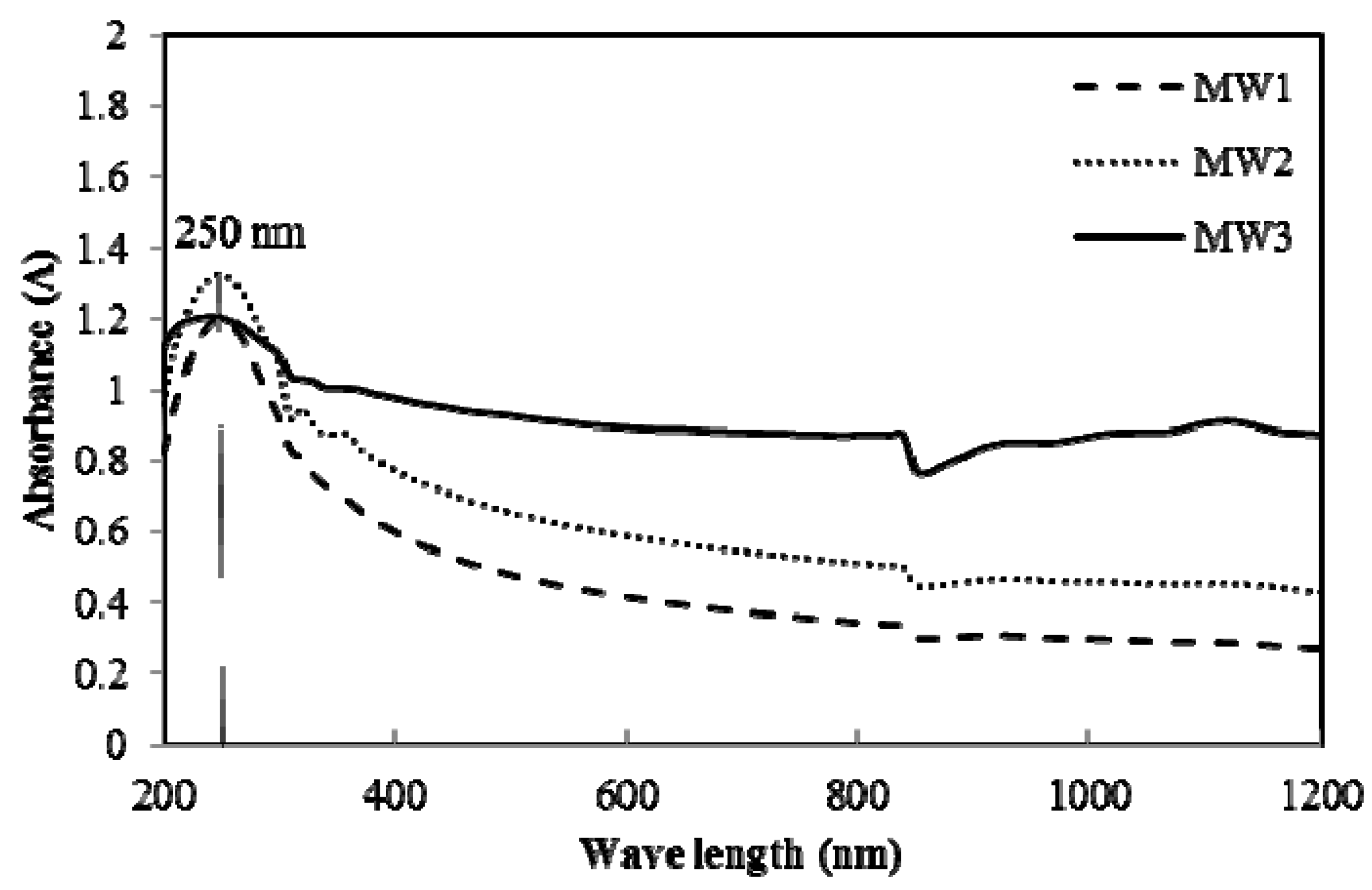

2.1. Characterization of Multi-Walled CNT (MWCNT) Dispersion in Aqueous Suspension

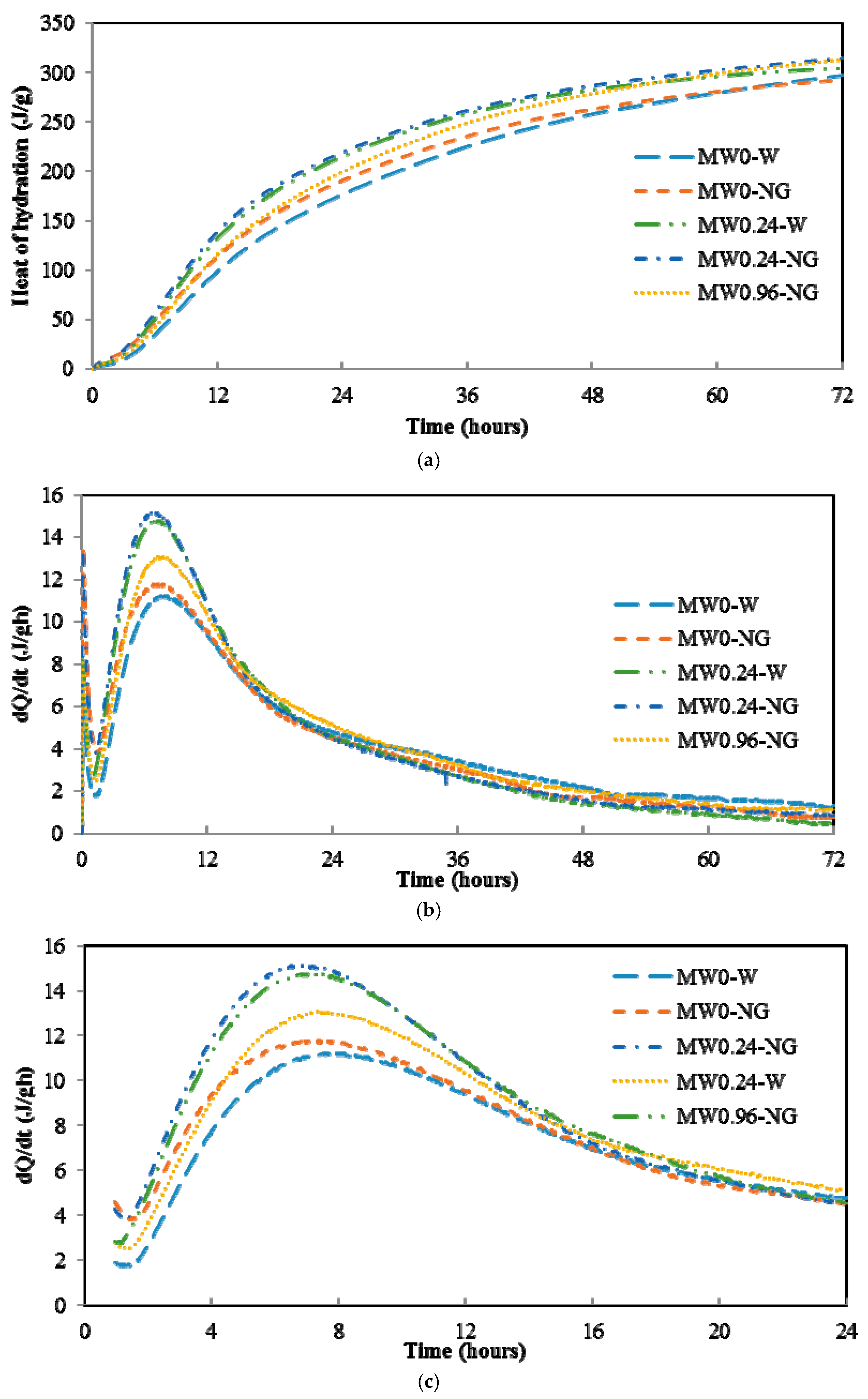

2.2. Heat of Hydration Test

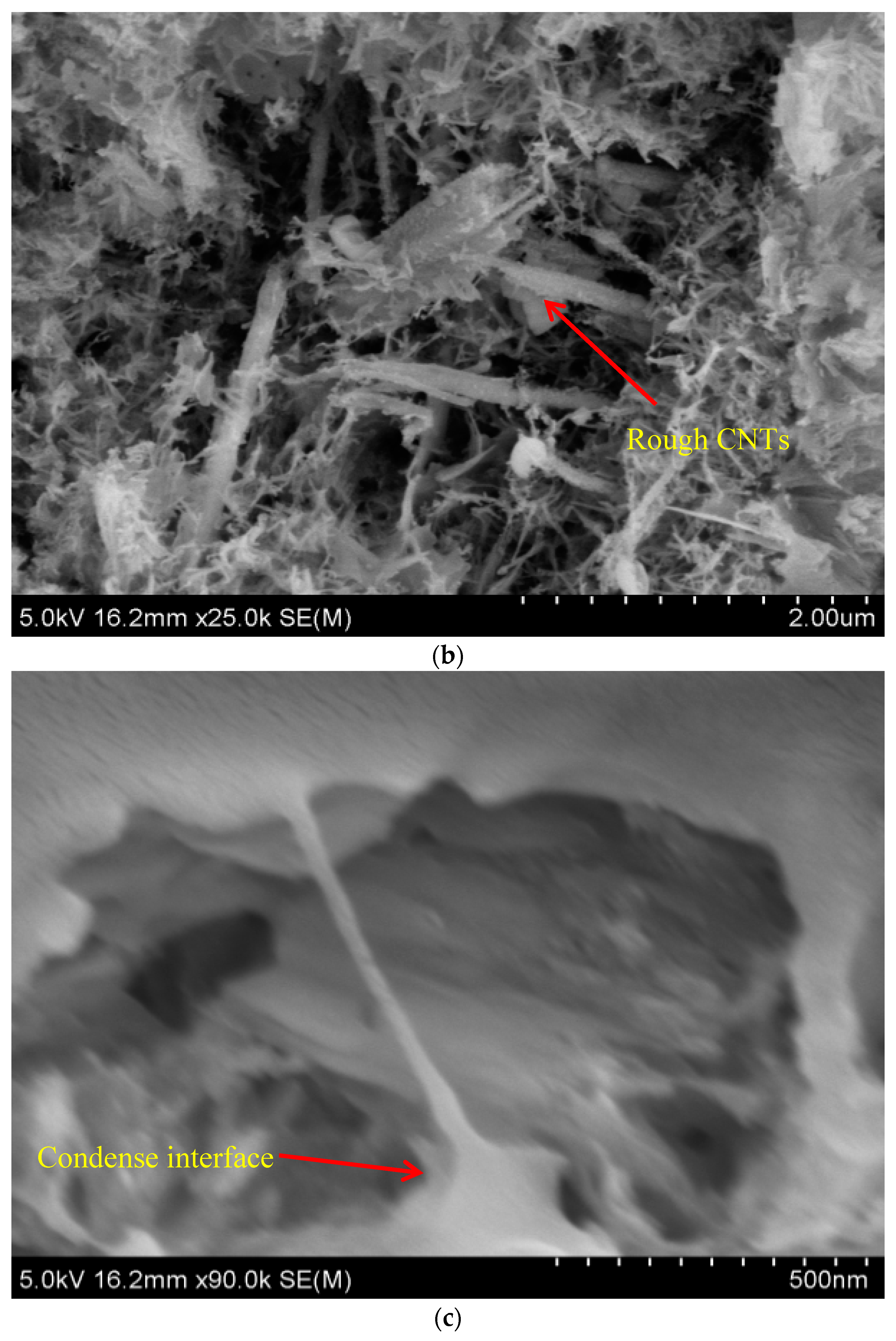

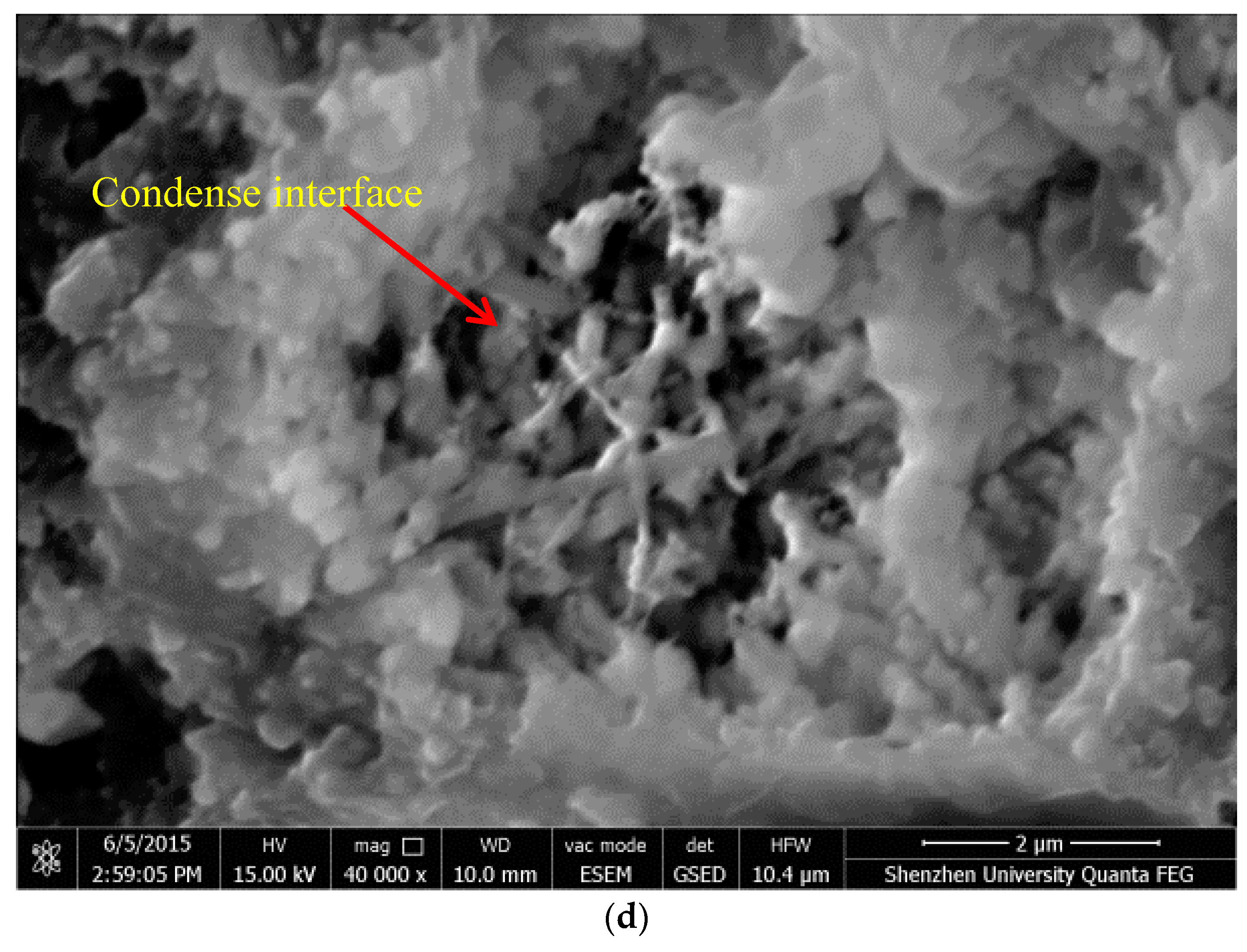

2.3. Morphology Observation

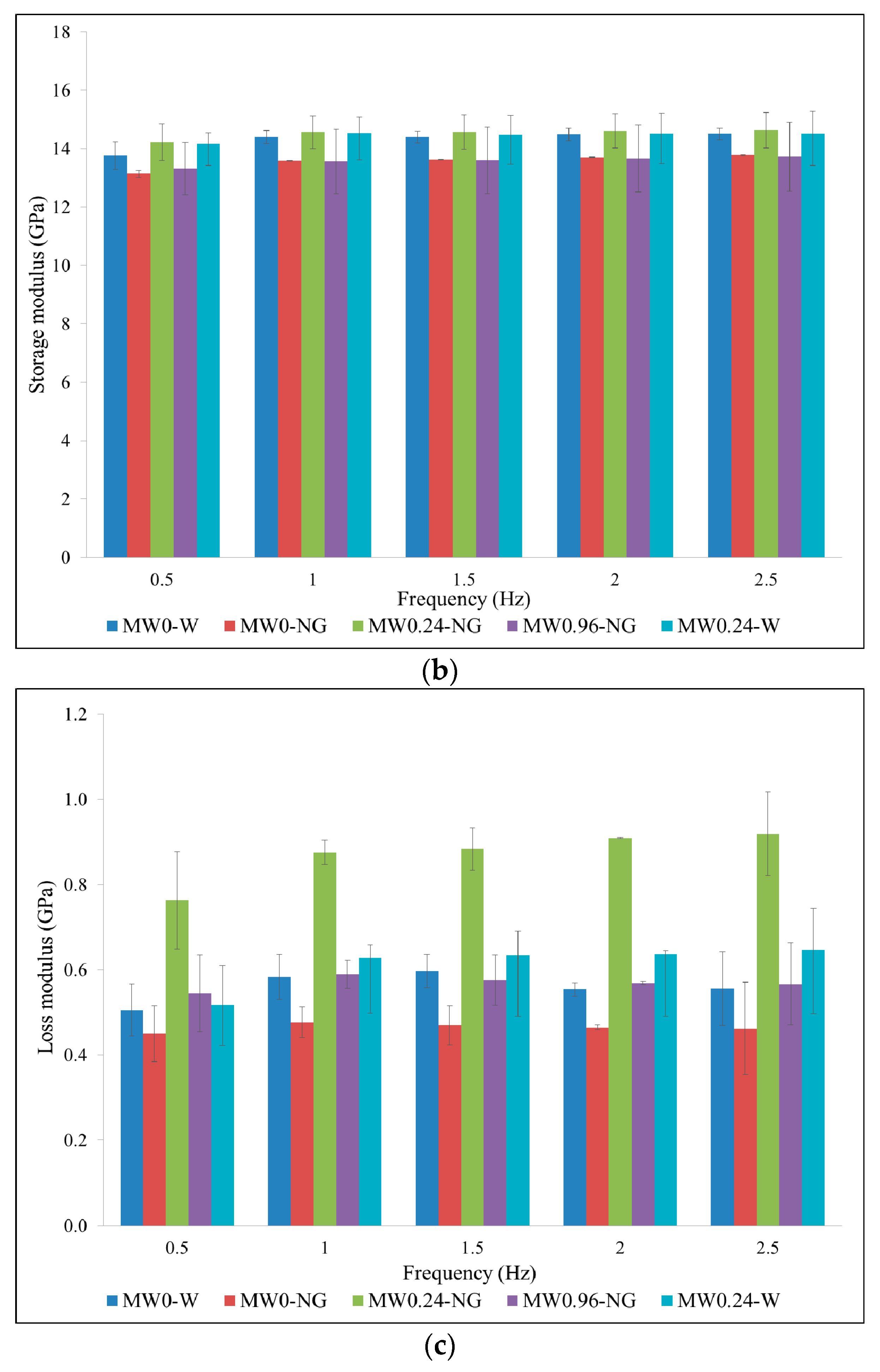

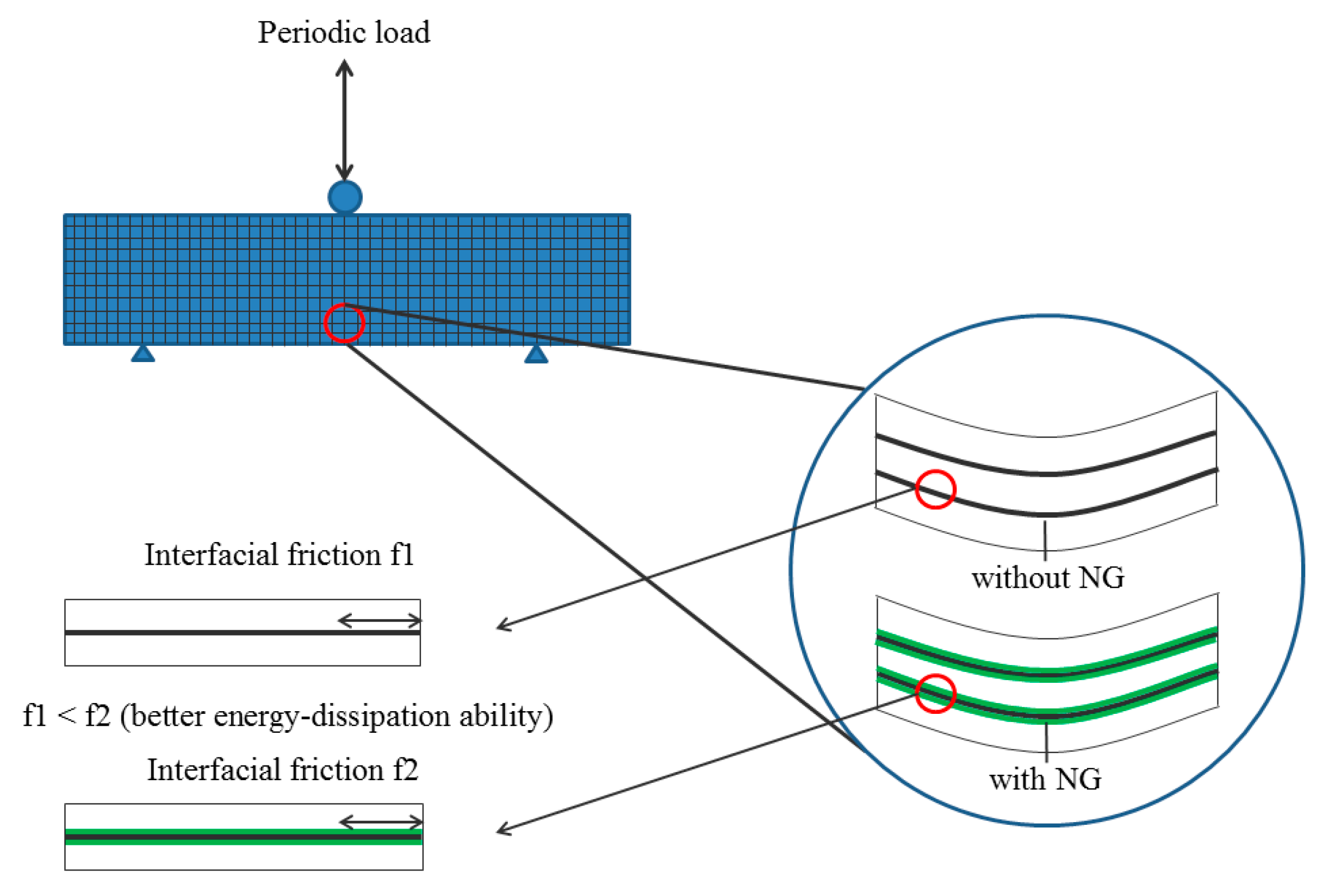

2.4. Damping Property

3. Discussions

4. Materials and Methods

4.1. Materials

4.2. Methods

4.2.1. Preparation of Aqueous Dispersion

4.2.2. Manufacture of CNTs/Cement Composite

- (a)

- Extra amount of water was added into the suspension and the composite was mixed at a high speed of 285 ± 10 r/min for 3 min;

- (b)

- The fresh pastes were cast into molds with dimension of 100 × 12 × 5 mm for DMA test;

- (c)

- The samples were demolded after 24 h and cured in a 20 °C and relative humidity of 95% environment until test.

4.3. Characterization of the Degree of MWCNT Dispersion

4.4. Calorimetry Test

4.5. Morphology Observation

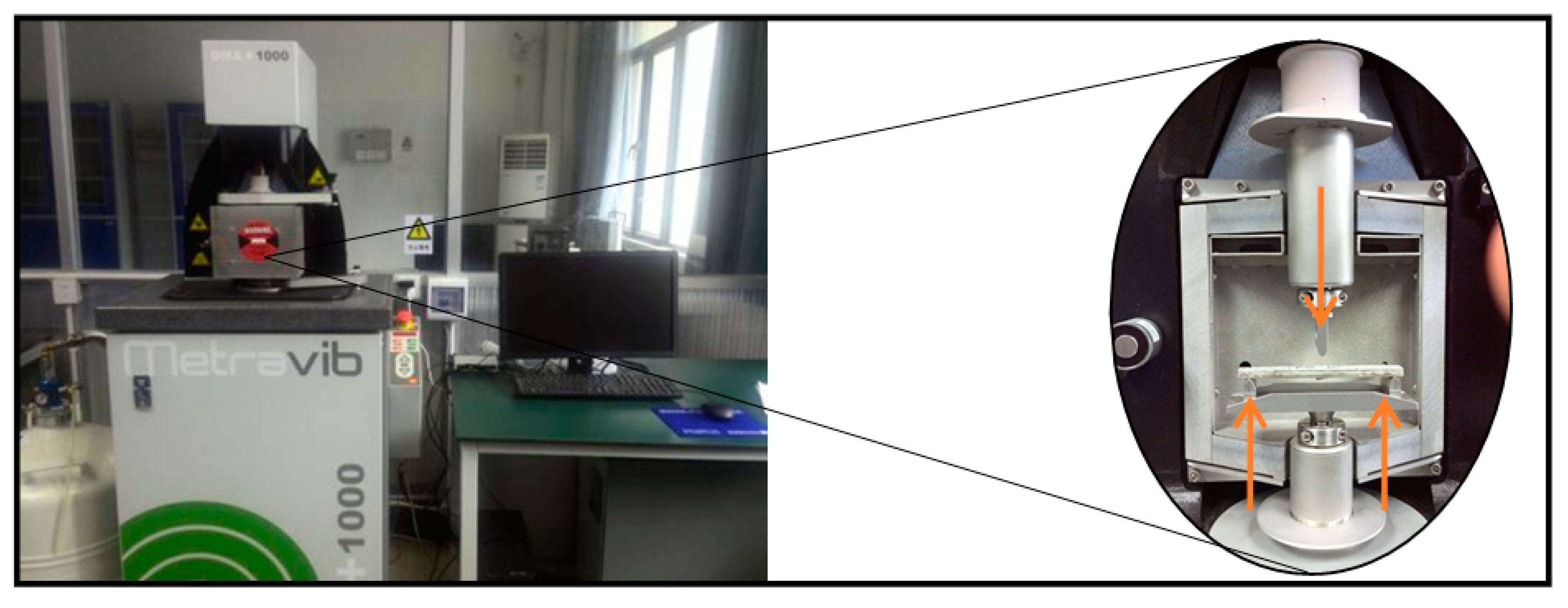

4.6. Dynamic Mechanical Analysis

5. Conclusions

- (a)

- For MWCNT dispersion in NS gel, the optimal dosage of MWCNTs in this study is 0.02% by weight of cement;

- (b)

- Addition of NS does not affect the dispersion of MWCNTs in aqueous suspension;

- (c)

- NS absorbs on the surface of MWCNTs and promotes the formation of hydration products on the surface of MWCNTs;

- (d)

- NS improves the interfacial adhesion between MWCNTs and cement matrix, leading to higher loss modulus and improved energy dissipation ability. The property enhancements in the MW0.24-NG sample were 48% and 66% higher than in the MW0.24-W and MW0-W samples, respectively.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Salvetat, J.P.; Bonard, J.M.; Thomson, N.H.; Kulik, A.J.; Forro, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Belytschko, T.; Xiao, S.P.; Schatz, G.C.; Ruoff, R.S. Atomistic simulations of nanotube fracture. Phys. Rev. B 2002, 65, 235430. [Google Scholar] [CrossRef]

- Kaushik, B.K.; Goel, S.; Rauthan, G. Future VLSI interconnects: Optical fiber or carbon nanotube—A review. Microelectron. Int. 2007, 24, 53–63. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Del Carmen Camacho, M.; Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Mechanical properties and durability of CNTs cement composites. Materials 2014, 7, 1640–1651. [Google Scholar] [CrossRef]

- Mendoza, O.; Sierra, G.; Tobón, J.I. Influence of super plasticizer and Ca(OH)2 on the stability of functionalized multi-walled carbon nanotubes dispersions for cement composites applications. Constr. Build. Mater. 2013, 47, 771–778. [Google Scholar] [CrossRef]

- Han, B.; Yang, Z.; Shi, X.; Yu, X. Transport properties of carbon-nanotube/cement composites. J. Mater. Eng. Perform. 2013, 22, 184–189. [Google Scholar] [CrossRef]

- Li, W.W.; Ji, W.M.; Liu, Y.; Xing, F.; Liu, Y.K. Damping property of a cement-based material containing carbon nanotube. J. Nanomater. 2015, 16, 418. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Isfahani, F.T.; Li, W.; Redaelli, E. Dispersion of multi-walled carbon nanotubes and its effects on the properties of cement composites. Cem. Concr. Compos. 2016, 74, 154–163. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Li, W.W.; Ji, W.M.; Wang, Y.C.; Liu, Y.; Shen, R.X.; Xing, F. Investigation on the mechanical properties of a cement-based material containing carbon nanotube under drying and freeze-thaw conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K.; Penttala, V. Surface decoration of carbon nanotubes and mechanical properties of cement/carbon nanotube composites. Adv. Cem. Res. 2008, 20, 65–74. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Wernik, J.M.; Meguid, S.A. On the mechanical characterization of carbon nanotube reinforced epoxy adhesives. Mater. Des. 2014, 59, 19–32. [Google Scholar] [CrossRef]

- Ntim, S.A.; Sae-Khow, O.; Witzmann, F.A.; Mitra, S. Effects of polymer wrapping and covalent functionalization on the stability of MWCNTs in aqueous dispersions. J. Colloid Interface Sci. 2011, 355, 383–388. [Google Scholar] [CrossRef] [PubMed]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xu, S.J.; Xiao, B.L.; Xue, P.; Wang, W.G.; Ma, Z.Y. Effect of ball-milling time on mechanical properties of carbon nanotubes reinforced aluminum matrix composites. Compos. A Appl. Sci. Manuf. 2012, 43, 2161–2168. [Google Scholar] [CrossRef]

- Sun, Z.; Nicolosi, V.; Rickard, D.; Bergin, S.D.; Aherne, D.; Coleman, J.N. Quantitative evaluation of surfactant-stabilized single-walled carbon nanotubes: Dispersion quality and its correlation with zeta potential. J. Phys. Chem. C 2008, 112, 10692–10699. [Google Scholar] [CrossRef]

- Frankland, S.J.V.; Caglar, A.; Brenner, D.W.; Griebel, M. Molecular simulation of the influence of chemical cross-links on the shear strength of carbon nanotube-polymer interfaces. J. Phys. Chem. B 2002, 106, 3046–3048. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Kim, S.M.; Bani-Hani, K.A.; Al-Nuaimi, N.; Senouci, A. Finite element simulation of single carbon nanotube pull-outs from a cementitious nanocomposite material using an elastic-plastic-damage and cohesive surface models. Int. J. Theor. Appl. Multiscale Mech. 2014, 3, 31–57. [Google Scholar] [CrossRef]

- Schadler, L.S.; Giannaris, S.C.; Ajayan, P.M. Load transfer in carbon nanotube eposy composites. Appl. Phys. Lett. 1998, 73, 3842–3844. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Hu, Y.; Luo, D.; Li, P.; Li, Q.; Sun, G. Fracture toughness enhancement of cement paste with multi-walled carbon nanotubes. Constr. Build. Mater. 2014, 70, 332–338. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Tyson, B.M.; Yazdanbakhsh, A.; Grasley, Z. Mechanical properties of nanocomposite cement incorporating surface-treated and untreated carbon nanotubes and carbon nanofibers. J. Nanomech. Micromech. 2011, 2, 1–6. [Google Scholar] [CrossRef]

- Stynoski, P.; Mondal, P.; Marsh, C. Effects of silica additives on fracture properties of carbon nanotube and carbon fiber reinforced Portland cement mortar. Cem. Concr. Compos. 2015, 55, 232–240. [Google Scholar] [CrossRef]

- Sanchez, F.; Ince, C. Microstructure and macroscopic properties of hybrid carbon nanofiber/silica fume cement composites. Compos. Sci. Technol. 2009, 69, 1310–1318. [Google Scholar] [CrossRef]

- Makar, J.M.; Chan, G.W. Growth of Cement Hydration Products on Single-Walled Carbon Nanotubes. J. Am. Ceram. Soc. 2009, 92, 1303–1310. [Google Scholar] [CrossRef]

- Makar, J.; Margeson, J.; Luh, J. Carbon nanotube/cement composites-early results and potential applications. In Proceedings of the 3rd Conference on Construction Materials: Performance, Innovations and Structural Implications, Vancouver, BC, Canada, 22–24 August 2005. [Google Scholar]

- Duan, Z.; Luo, J. Effect of multi-walled carbon nanotubes on the vibration-reduction behavior of cement. In Proceedings of the International Conference on Smart Materials and Nanotechnology in Engineering, Harbin, China, 1–4 July 2007; pp. 64230R-1–64230R-6. [Google Scholar]

- Guchhait, P.K.; Bhandari, S.; Singh, S.; Rahaman, M. Study on the effect of nanosilica particles on morphology, thermo-mechanical and electrical properties of liquid polysulfide modified epoxy hybrid nanocomposites. Int. J. Plast. Technol. 2011, 15, 150–162. [Google Scholar] [CrossRef]

- Chandra, R.; Singh, S.P.; Gupta, K. Damping studies in fiber-reinforced composites—A review. Compos. Struct. 1999, 46, 41–51. [Google Scholar] [CrossRef]

- Rastogi, R.; Kaushal, R.; Tripathi, S.K.; Sharma, A.L.; Kaur, I.; Bharadwaj, L.M. Comparative study of carbon nanotube dispersion using surfactants. J. Colloid Interface Sci. 2008, 328, 421–428. [Google Scholar] [CrossRef] [PubMed]

- Rausch, J.; Zhuang, R.C.; Mäder, E. Surfactant assisted dispersion of functionalized multi-walled carbon nanotubes in aqueous media. Compos. A Appl. Sci. Manuf. 2010, 41, 1038–1046. [Google Scholar] [CrossRef]

| Notation | MWCNTs (g) | Water (mL) | NG (mL) |

|---|---|---|---|

| MW1 | 0.24 | 100 | 0 |

| MW2 | 0.24 | 0 | 100 |

| MW3 | 0.96 | 0 | 100 |

| Notation | 0 h | 3 h | 12 h | 24 h | 48 h | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | ΔA | A | ΔA | A | ΔA | A | ΔA | A | ΔA | |

| MW1-W | 1.20 | 0 | 1.19 | 1% | 1.18 | 2% | 1.18 | 2% | 1.17 | 3% |

| MW2-NG | 1.33 | 0 | 1.34 | −1% * | 1.37 | −4% * | 1.36 | −3% * | 1.32 | 0 |

| MW3-NG | 1.20 | 0 | 0.32 | 73% | 0.30 | 75% | 0.29 | 76% | 0.29 | 76% |

| Notation | Cement (g) | MWCNTs (g) | Water (mL) | NG (mL) |

|---|---|---|---|---|

| MW0-W | 1200 | 0 | 480 | 0 |

| MW0-NG | 1188 | 0 | 372 | 120 |

| MW0.24-W | 1200 | 0.24 (0.02%) | 480 | 0 |

| MW0.24-NG | 1188 | 0.24 (0.02%) | 372 | 120 |

| MW0.96-NG | 1188 | 0.96 (0.08%) | 372 | 120 |

| Notation | MW0-W | MW0-NG | MW0.24-W | MW0.24-NG | MW0.96-NG |

|---|---|---|---|---|---|

| Heat (J/g) | 296.97 | 292.4 (−1.54%) | 313.13 (+5.44%) | 314.36 (+5.86%) | 304.28 (+2.46%) |

| Notation | Diameter | Length | Purity | Specific Surface Area | –COOH | Making Method |

|---|---|---|---|---|---|---|

| MWCNTs | 10–20 nm | 10–30 μm | >95% | >120 m2/g | 2 wt % | CVD |

| Notation | SiO2/gel | Na2O | pH | Density | Average Diameter |

|---|---|---|---|---|---|

| NG | 10% | 0.18% | 8.3 | 1.04 g/cm3 | 14 nm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Ji, W.; Torabian Isfahani, F.; Wang, Y.; Li, G.; Liu, Y.; Xing, F. Nano-Silica Sol-Gel and Carbon Nanotube Coupling Effect on the Performance of Cement-Based Materials. Nanomaterials 2017, 7, 185. https://doi.org/10.3390/nano7070185

Li W, Ji W, Torabian Isfahani F, Wang Y, Li G, Liu Y, Xing F. Nano-Silica Sol-Gel and Carbon Nanotube Coupling Effect on the Performance of Cement-Based Materials. Nanomaterials. 2017; 7(7):185. https://doi.org/10.3390/nano7070185

Chicago/Turabian StyleLi, Weiwen, Weiming Ji, Forood Torabian Isfahani, Yaocheng Wang, Gengying Li, Yi Liu, and Feng Xing. 2017. "Nano-Silica Sol-Gel and Carbon Nanotube Coupling Effect on the Performance of Cement-Based Materials" Nanomaterials 7, no. 7: 185. https://doi.org/10.3390/nano7070185

APA StyleLi, W., Ji, W., Torabian Isfahani, F., Wang, Y., Li, G., Liu, Y., & Xing, F. (2017). Nano-Silica Sol-Gel and Carbon Nanotube Coupling Effect on the Performance of Cement-Based Materials. Nanomaterials, 7(7), 185. https://doi.org/10.3390/nano7070185