Controlling the Mechanical Properties of Bulk Metallic Glasses by Superficial Dealloyed Layer

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

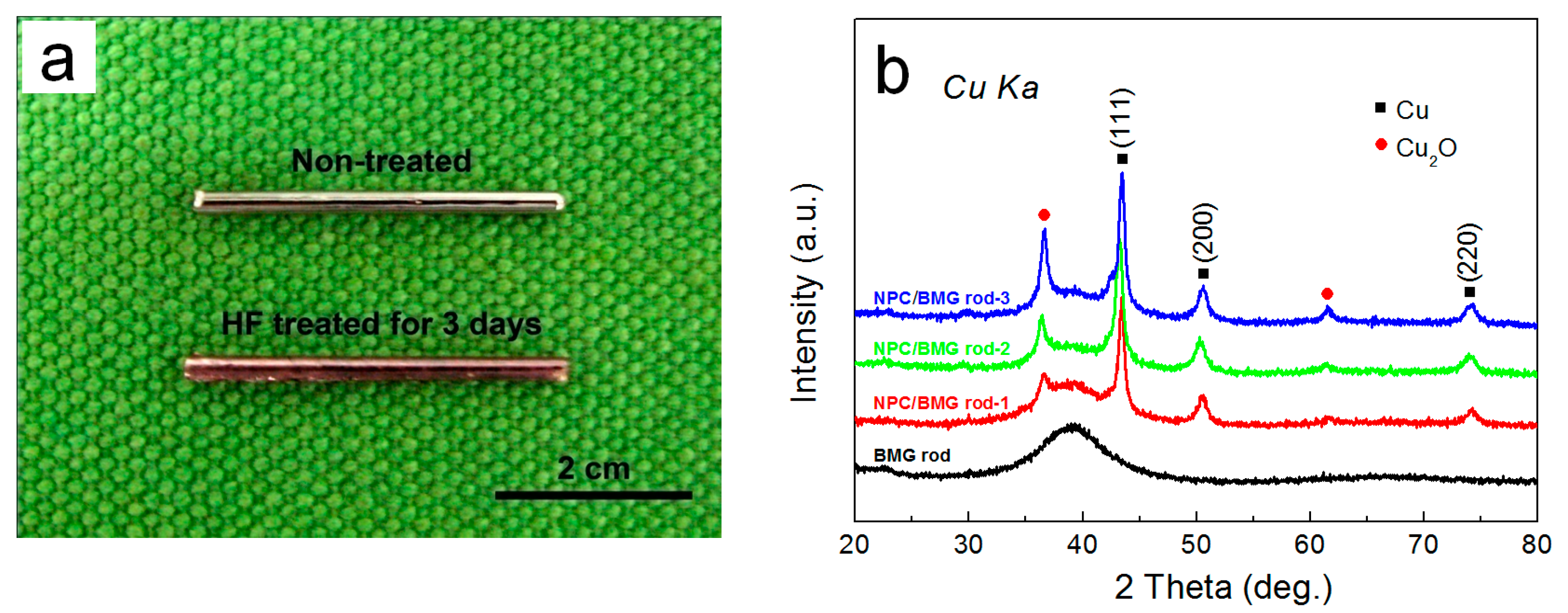

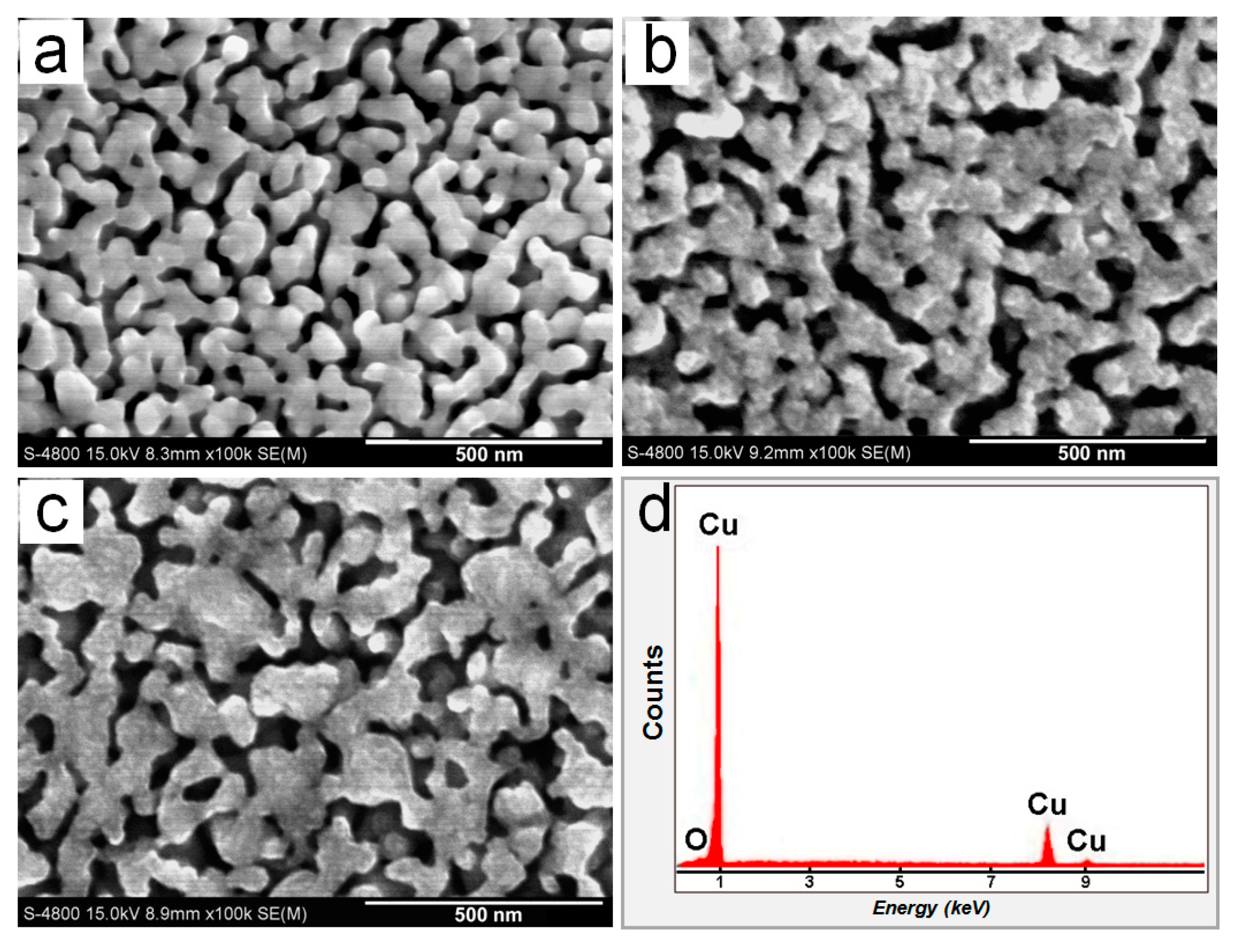

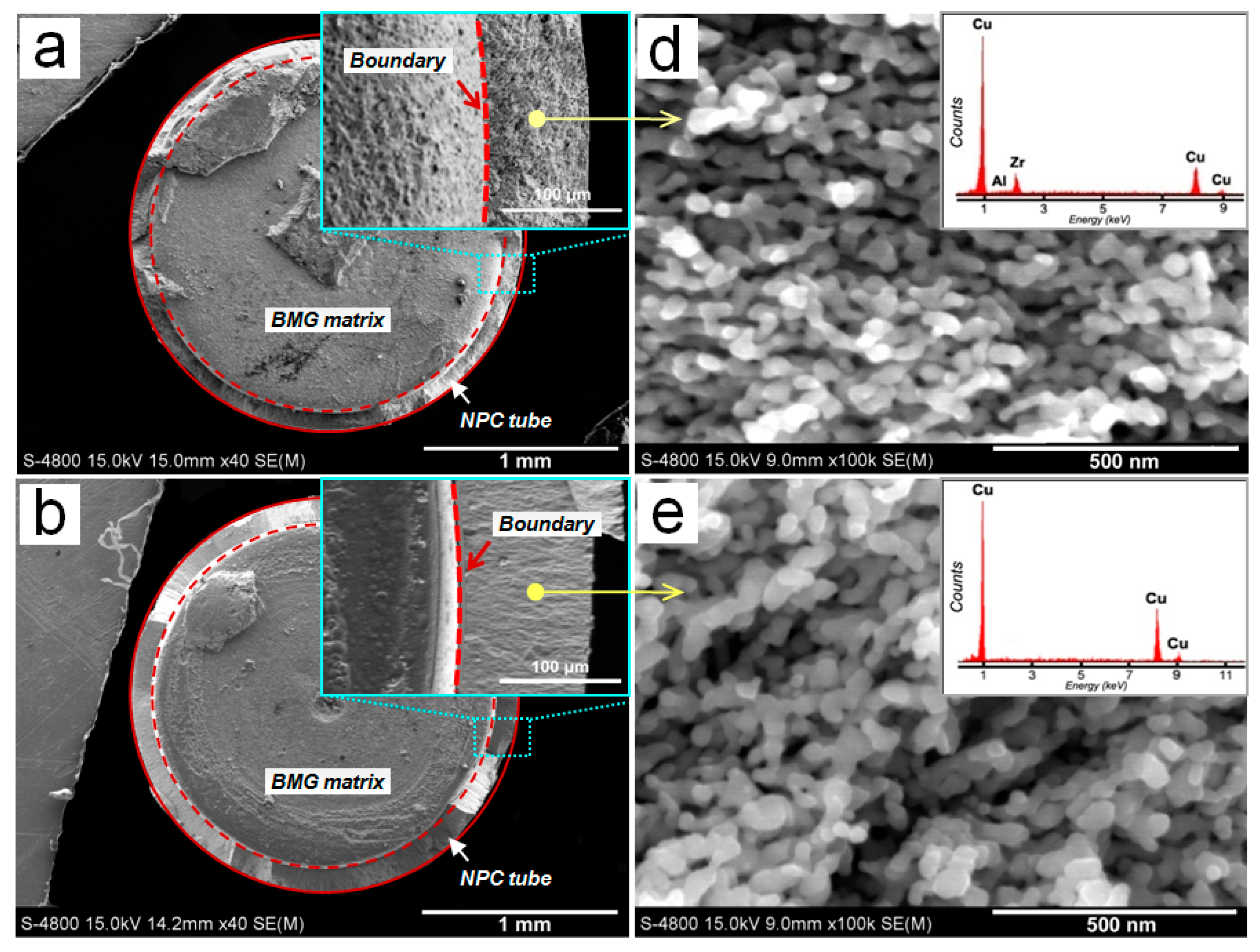

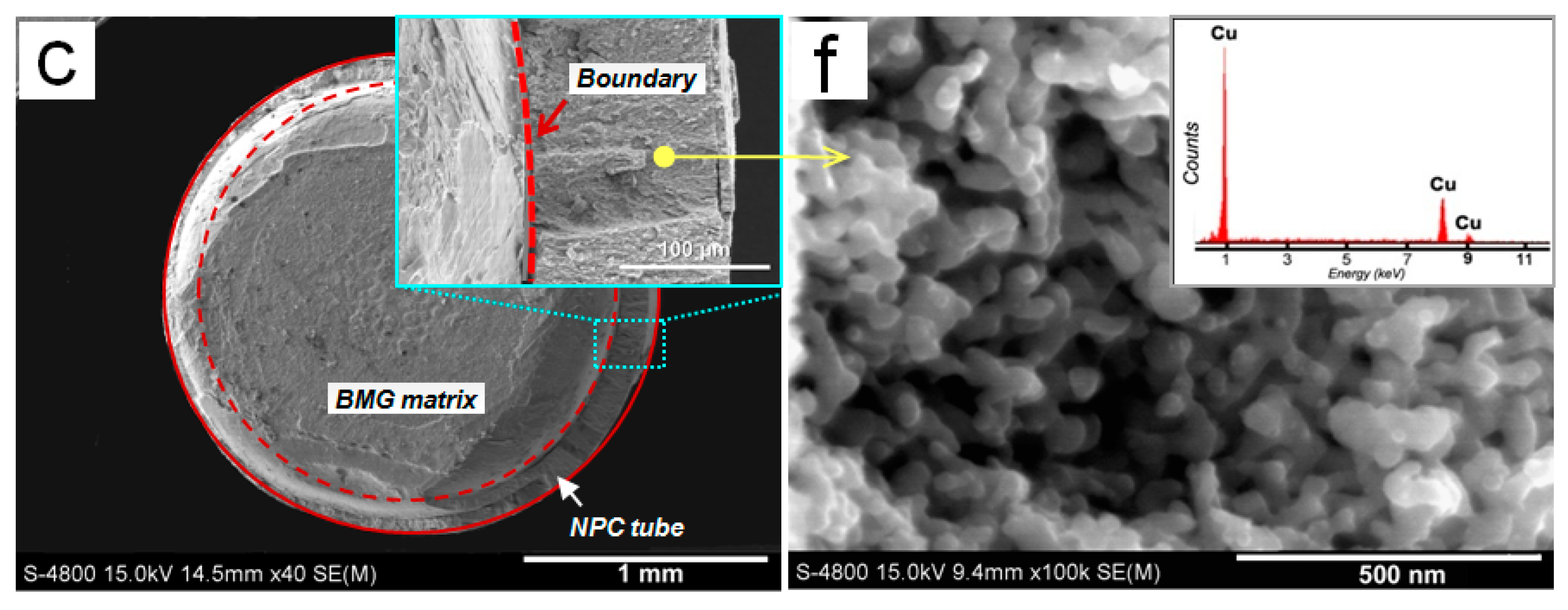

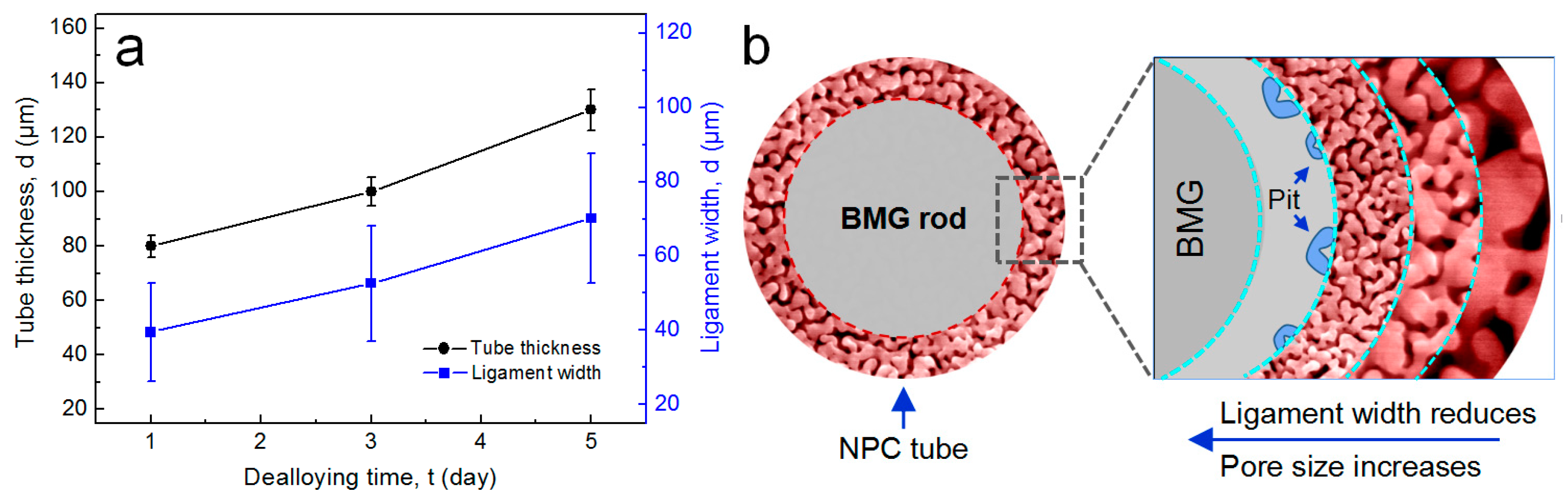

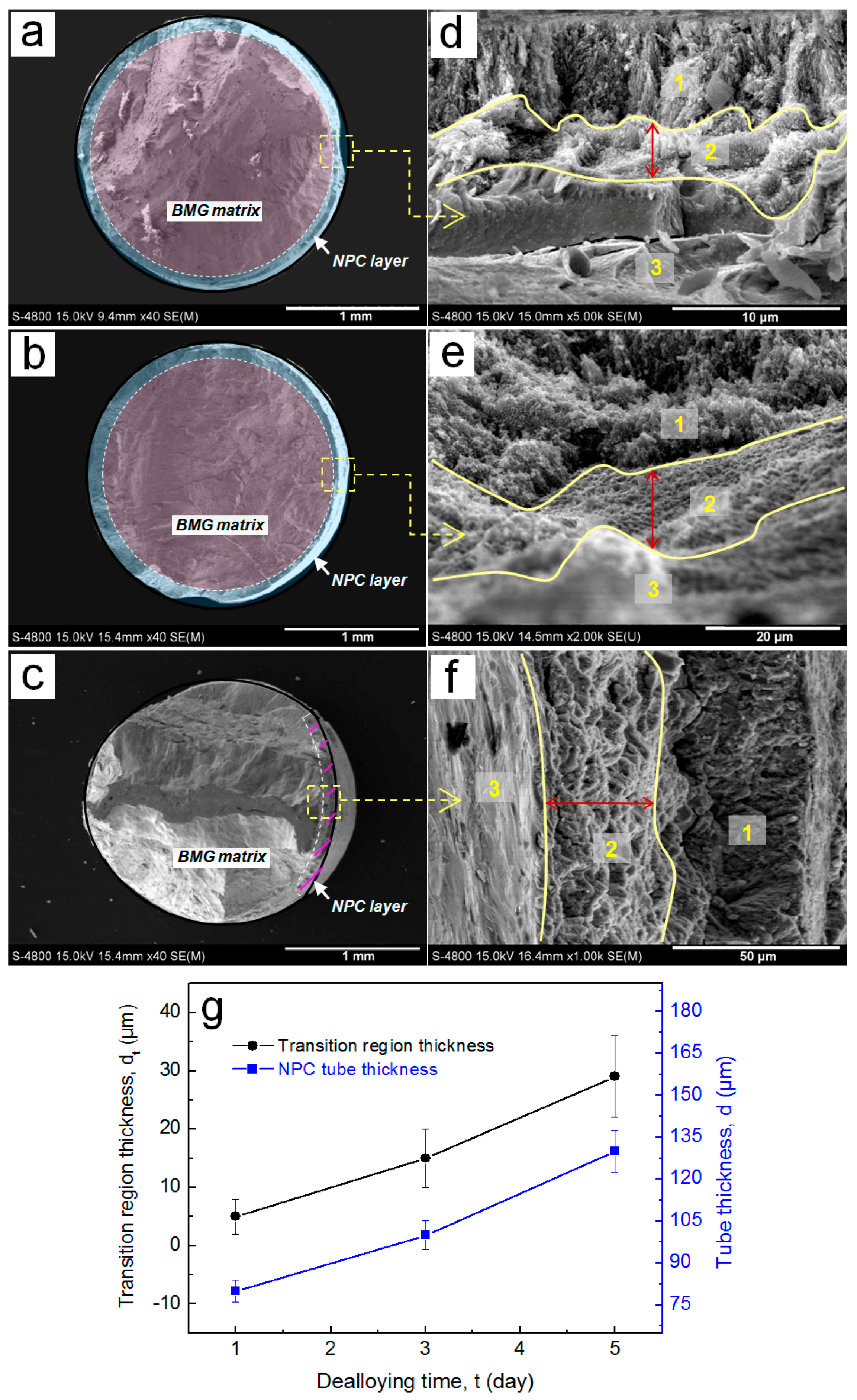

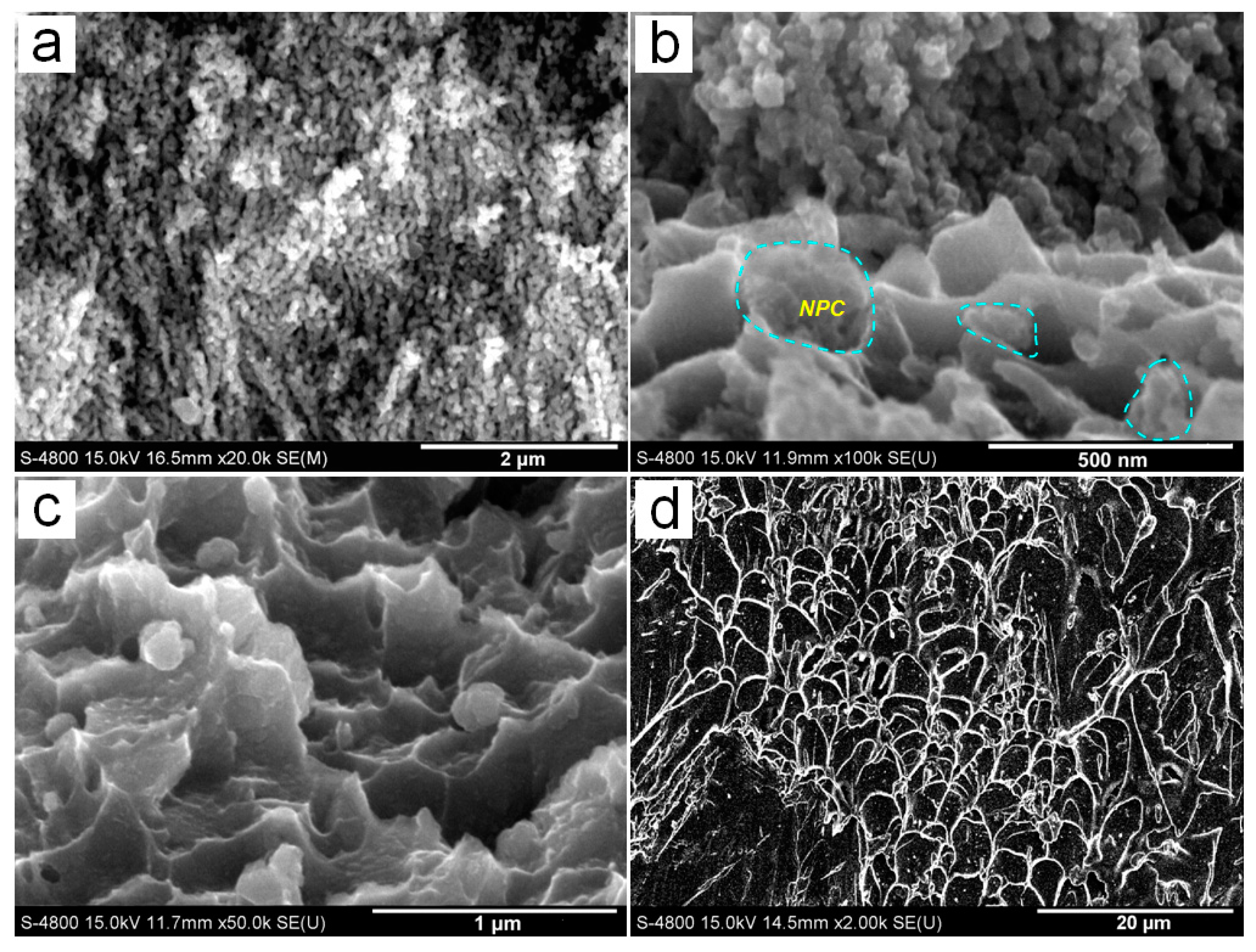

3.1. Structural Hierarchy of NPC/BMG Composite Rods

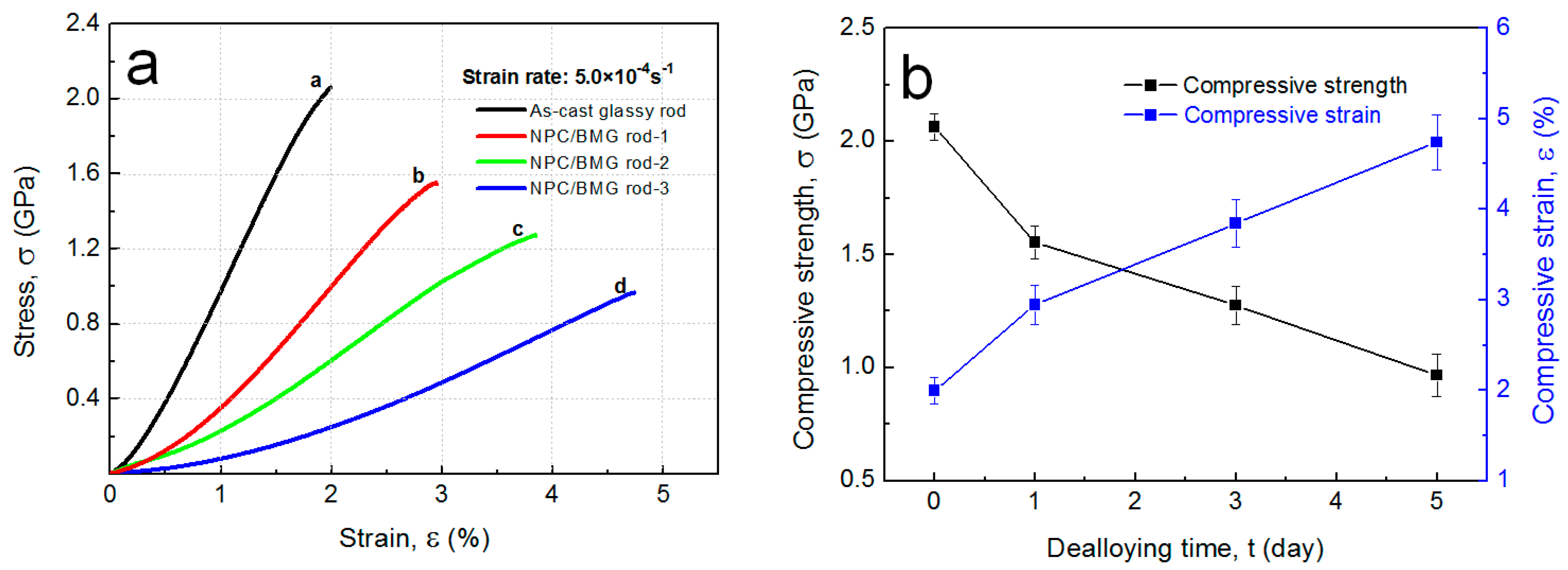

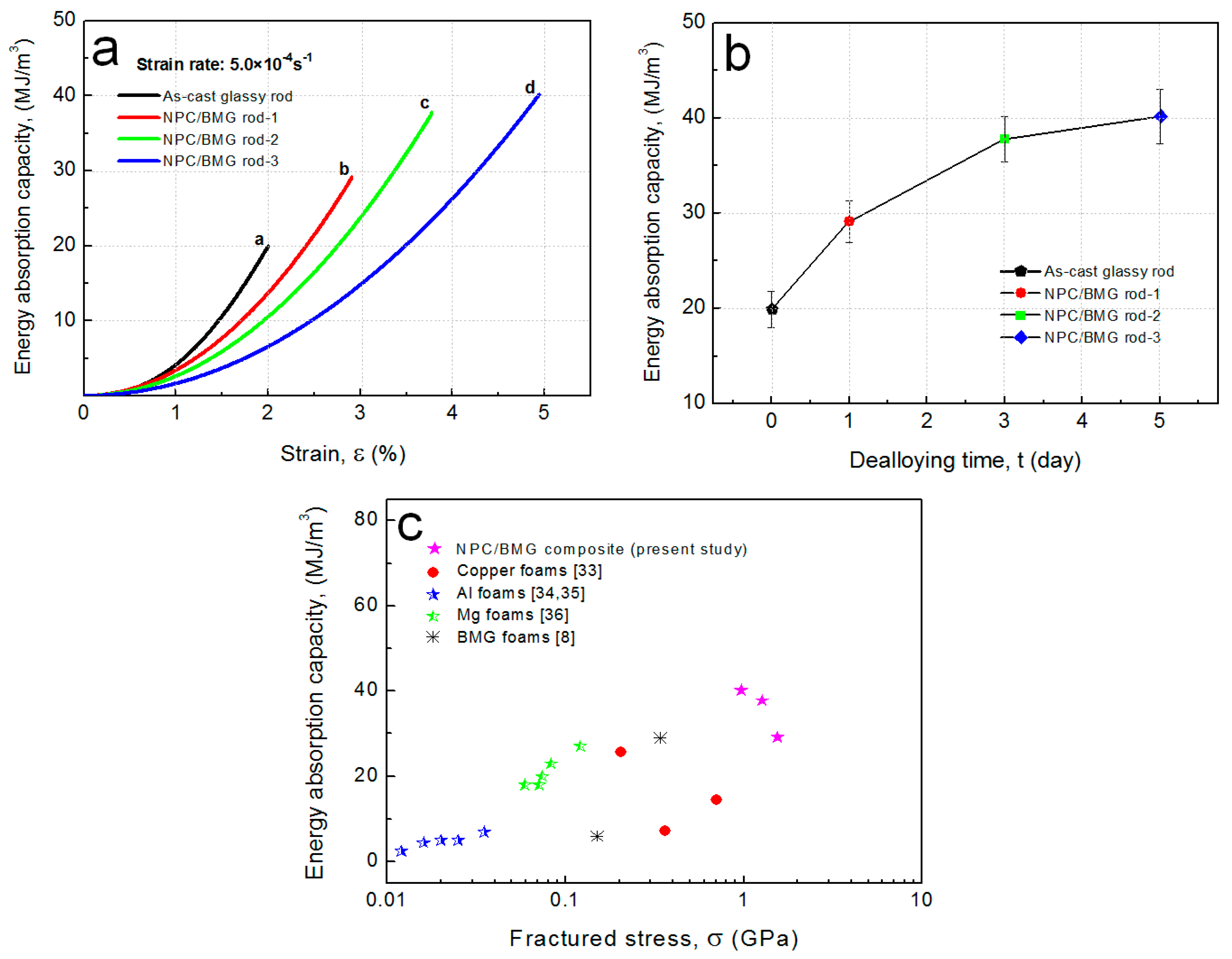

3.2. Mechanical Properties of NPC/BMG Composites

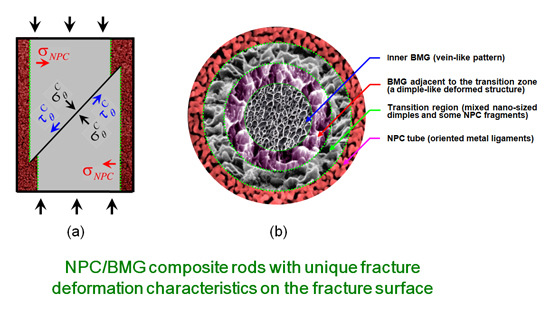

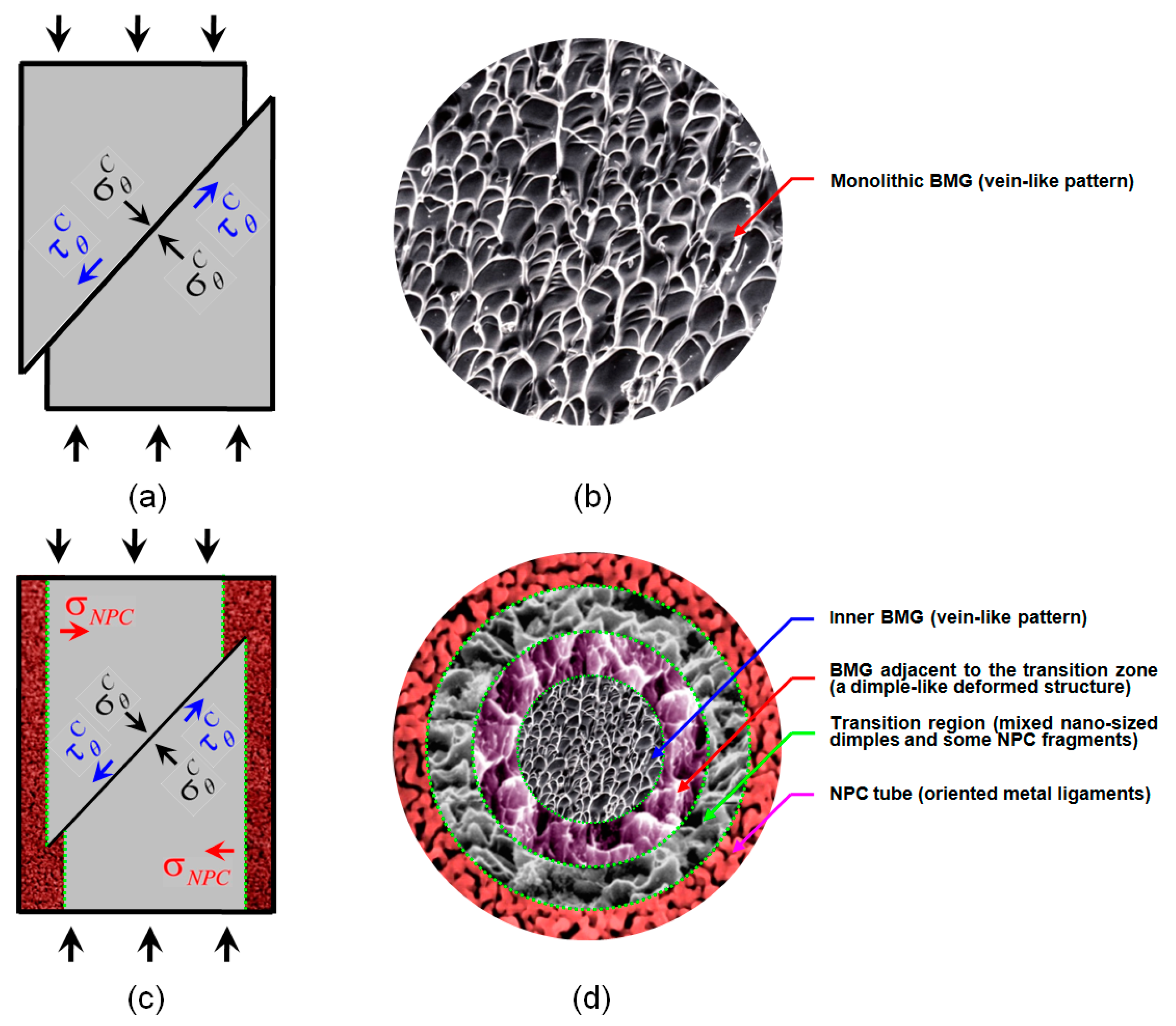

3.3. The Correlation of Microstructure and Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, T.H.; Ma, Y. Effect of applied stress on the mechanical properties of a Zr-Cu-Ag-Al bulk metallic glass with two different structure states. Materials 2017, 10, 711. [Google Scholar] [CrossRef] [PubMed]

- Greer, A.L.; Cheng, Y.Q.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Chu, Z.H.; Kato, H.; Xie, G.Q.; Yuan, G.Y.; Ding, W.J.; Inoue, A. Consolidation and mechanical properties of Cu46Zr42Al7Y5 metallic glass by spark plasma sintering. J. Non-Cryst. Solids 2012, 358, 1263–1267. [Google Scholar] [CrossRef]

- Han, Y.; Inoue, A.; Kong, F.L.; Chang, C.T.; Shu, S.L.; Shalaan, E.; Al-Marzouki, F. Softening and good ductility for nanocrystal-dispersed amorphous Fe-Co-B alloys with high saturation magnetization above 1.7 T. J. Alloys Compd. 2016, 657, 237–245. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A.; Duan, G.; Lind, M.L.; Demetriou, M.D.; Johnson, W.L. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Ye, H.Y.; Shi, J.Y.; Yang, H.J.; Qiao, J.W. Dendrite size dependence of tensile plasticity of in situ Ti-based metallic glass matrix composites. J. Alloys Compd. 2014, 583, 593–597. [Google Scholar] [CrossRef]

- Cox, M.E.; Dunand, D.C. Anisotropic mechanical properties of amorphous Zr-based foams with aligned, elongated pores. Acta Mater. 2013, 61, 5937–5948. [Google Scholar] [CrossRef]

- Cox, M.E.; Kecskes, L.J.; Mathaudhu, S.N.; Dunand, D.C. Amorphous Hf-based foams with aligned, elongated pores. Mater. Sci. Eng. A 2012, 533, 124–127. [Google Scholar] [CrossRef]

- Chu, J.P.; Jang, J.S.C.; Huang, J.C.; Chou, H.S.; Yang, Y.; Ye, J.C.; Wang, Y.C.; Lee, J.W.; Liu, F.X.; Liaw, P.K.; et al. Thin film metallic glasses: Unique properties and potential applications. Thin Solid Films 2012, 520, 5097–5122. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.J.; Djemia, P.; Mompiou, F.; Abadias, G.; Raskinb, J.P.; Pardoen, T. Extrinsic mechanical size effects in thin ZrNi metallic glass films. Acta Mater. 2015, 90, 232–241. [Google Scholar] [CrossRef]

- Ghidelli, M.; Idrissi, H.; Gravier, S.; Blandin, J.J.; Raskin, J.P.; Schryvers, D.; Pardoen, T. Homogeneous flow and size dependent mechanical behavior in highly ductile Zr65Ni35 metallic glass films. Acta Mater. 2017, 131, 246–259. [Google Scholar] [CrossRef]

- Tian, L.; Cheng, Y.Q.; Shan, Z.W.; Li, J.; Wang, C.C.; Han, X.D.; Sun, J.; Ma, E. Approaching the ideal elastic limit of metallic glasses. Nat. Commun. 2012, 3, 609. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brothers, A.H.; Dunand, D.C. Plasticity and damage in cellular amorphous metals. Acta Mater. 2005, 53, 4427–4440. [Google Scholar] [CrossRef]

- Inoue, A.; Wada, T.; Wang, X.M. Bulk non-equilibrium alloys and porous glassy alloys with unique mechanical characteristics. Mater. Sci. Eng. A 2006, 442, 233–242. [Google Scholar] [CrossRef]

- Inoue, A.; Nishiyama, N.; Matsuda, T. Preparation of bulk glassy Pd40Ni10Cu30P20 alloy of 40 mm in diameter by water quenching. Mater. Trans. 1996, 37, 181–184. [Google Scholar] [CrossRef]

- Peker, A.; Johnson, W.L. A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 1993, 63, 2342–2344. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, T.; Nishiyama, N.; Ohba, K.; Masumoto, T. Preparation of 16 mm diameter rod of amorphous Zr65Al7.5Ni10Cu17.5 alloy. Mater. Trans. 1993, 34, 1234–1237. [Google Scholar] [CrossRef]

- Wada, T.; Qin, F.X.; Wang, X.M.; Inoue, A.; Yoshimura, M. Preparation of open-cell porous Zr-based bulk glassy alloy. Mater. Trans. 2007, 48, 2381–2384. [Google Scholar] [CrossRef]

- Wada, T.; Wang, X.M.; Kimura, H.; Inoue, A. Preparation of a Zr-based bulk glassy alloy foam. Scr. Mater. 2008, 59, 1071–1074. [Google Scholar] [CrossRef]

- Xie, G.Q.; Qin, F.X.; Zhu, S.L.; Louzguine-Luzgin, D.V. Corrosion behaviour of porous Ni-free Ti-based bulk metallic glass produced by spark plasma sintering in Hanks’ solution. Intermetallics 2014, 44, 55–59. [Google Scholar] [CrossRef]

- Inoue, A.; Wada, T.; Louzguine-Luzgin, D.V. Improved mechanical properties of bulk glassy alloys containing spherical pores. Mater. Sci. Eng. A 2007, 471, 144–150. [Google Scholar] [CrossRef]

- Demetriou, M.D.; Schramm, J.P.; Veazey, C.; Johnson, W.L.; Hanan, J.C.; Phelps, N.B. High porosity metallic glass foam: A powder metallurgy route. Appl. Phys. Lett. 2007, 91, 161903. [Google Scholar] [CrossRef]

- Brothers, A.H.; Prine, D.W.; Dunand, D.C. Acoustic emissions analysis of damage in amorphous and crystalline metal foams. Intermetallics 2006, 14, 857–865. [Google Scholar] [CrossRef]

- Qin, C.L.; Wang, C.Y.; Hu, Q.F.; Wang, Z.F.; Zhao, W.M.; Inoue, A. Hierarchical nanoporous metal/BMG composite rods with excellent mechanical properties. Intermetallics 2016, 77, 1–5. [Google Scholar] [CrossRef]

- Wang, Z.F.; Fei, P.Y.; Xiong, H.Q.; Qin, C.L.; Zhao, W.M.; Liu, X.Z. CoFe2O4 nanoplates synthesized by dealloying method as high performance Li-ion battery anodes. Electrochim. Acta 2017, 252, 295–305. [Google Scholar] [CrossRef]

- Fu, C.Q.; Xu, L.J.; Dan, Z.H.; Makino, A.; Hara, N.; Qin, F.X.; Chang, H. Structural inheritance and redox performance of nanoporous electrodes from nanocrystalline Fe85.2B10-14P0-4Cu0.8 alloys. Nanomaterials 2017, 7, 141. [Google Scholar] [CrossRef] [PubMed]

- Qin, C.L.; Wang, Z.F.; Liu, H.; Liu, L.; Wang, H.; Ding, J.; Zhao, W.M. Monolithic nanoporous copper with novel electrochemical properties fabricated by dealloying Cu-Zr(-Al) metallic glasses. Mater. Sci. Forum 2014, 783–786, 1925–1930. [Google Scholar] [CrossRef]

- Luo, X.K.; Li, R.; Huang, L.; Zhang, T. Nucleation and growth of nanoporous copper ligaments during electrochemical dealloying of Mg-based metallic glasses. Corros. Sci. 2013, 7, 100–108. [Google Scholar] [CrossRef]

- Wang, Z.F.; Liu, J.Y.; Qin, C.L.; Liu, L.; Zhao, W.M.; Inoue, A. Fabrication and new electrochemical properties of nanoporous Cu by dealloying amorphous Cu-Hf-Al alloys. Intermetallics 2015, 56, 48–55. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, W. Formation, thermal stability and mechanical properties of Cu-Zr-Al bulk glassy alloys. Mater. Trans. 2002, 43, 2921–2925. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, W.; Zhang, T.; Kurosaka, K. High-strength Cu-based bulk glassy alloys in Cu-Zr-Ti and Cu-Hf-Ti ternary systems. Acta Mater. 2001, 49, 2645–2652. [Google Scholar] [CrossRef]

- Hyun, S.K.; Nakajima, H. Anisotropic compressive properties of porous copper produced by unidirectional solidification. Mater. Sci. Eng. A 2003, 340, 258–264. [Google Scholar] [CrossRef]

- Liu, J.A.; Qu, Q.X.; Liu, Y.; Li, R.G.; Liu, B. Compressive properties of Al-Si-SiC composite foams at elevated temperatures. J. Alloys Compd. 2016, 676, 239–244. [Google Scholar] [CrossRef]

- Xia, X.C.; Feng, H.; Zhang, X.; Zhao, W.M. The compressive properties of closed-cell aluminum foams with different Mn additions. Mater. Des. 2013, 51, 797–802. [Google Scholar] [CrossRef]

- Li, Q.Y.; Jiang, G.F.; Dong, J.; Hou, J.W.; He, H.G. Damping behavior and energy absorption capability of porous magnesium. J. Alloys Compd. 2016, 680, 522–530. [Google Scholar] [CrossRef]

- Wang, K.; Kobler, A.; Kübel, C.; Jelitto, H.; Schneider, G.; Weissmüller, J. Nanoporous-gold-based composites: Toward tensile ductility. NPG Asia Mater. 2015, 7. [Google Scholar] [CrossRef]

- Wang, K.; Weissmüller, J. Composites of nanoporous gold and polymer. Adv. Mater. 2013, 25, 1280–1284. [Google Scholar] [CrossRef] [PubMed]

- Andrews, E.W.; Gibson, L.J. On notch-strengthening and crack tip deformation in cellular metals. Mater. Lett. 2002, 57, 532–536. [Google Scholar] [CrossRef]

- Xi, X.K.; Zhao, D.Q.; Pan, M.X.; Wang, W.H.; Wu, Y.; Lewandowski, J.J. Fracture of brittle metallic glasses: Brittleness or plasticity. Phys. Rev. Lett. 2005, 94, 125510. [Google Scholar] [CrossRef] [PubMed]

- Suh, J.Y.; Conner, R.D.; Kim, C.P.; Demetriou, M.D.; Johnson, W.L. Correlation between fracture surface morphology and toughness in Zr-based bulk metallic glasses. J. Mater. Res. 2010, 25, 982–990. [Google Scholar] [CrossRef]

- Wu, F.F.; Zhang, Z.F.; Mao, S.X. Size-dependent shear fracture and global tensile plasticity of metallic glasses. Acta. Mater. 2009, 57, 257–266. [Google Scholar] [CrossRef]

- Wright, W.J.; Hufnagel, T.C.; Nix, W.D. Free volume coalescence and void formation in shear bands in metallic glass. J. Appl. Phys. 2003, 93, 1432–1437. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elastic moduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Eckert, J.; Schultz, L. Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass. Acta. Mater. 2003, 51, 1167–1179. [Google Scholar] [CrossRef]

- Liu, C.T.; Heatherly, L.; Horton, J.A.; Easton, D.S.; Carmichael, C.A.; Wright, J.L.; Schneibel, J.H.; Yoo, M.H.; Chen, C.H.; Inoue, A. Test environments and mechanical properties of Zr-base bulk amorphous alloys. Metall. Mater. Trans. 1998, 29, 1811–1820. [Google Scholar] [CrossRef]

- Wright, W.J.; Saha, R.; Nix, W.D. Deformation mechanisms of the Zr40Ti14Ni10Cu12Be24 bulk metallic glass. Mater. Trans. 2001, 42, 642–649. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Li, M.; Zhu, M.; Wang, H.; Qin, C.; Zhao, W.; Wang, Z. Controlling the Mechanical Properties of Bulk Metallic Glasses by Superficial Dealloyed Layer. Nanomaterials 2017, 7, 352. https://doi.org/10.3390/nano7110352

Wang C, Li M, Zhu M, Wang H, Qin C, Zhao W, Wang Z. Controlling the Mechanical Properties of Bulk Metallic Glasses by Superficial Dealloyed Layer. Nanomaterials. 2017; 7(11):352. https://doi.org/10.3390/nano7110352

Chicago/Turabian StyleWang, Chaoyang, Man Li, Mo Zhu, Han Wang, Chunling Qin, Weimin Zhao, and Zhifeng Wang. 2017. "Controlling the Mechanical Properties of Bulk Metallic Glasses by Superficial Dealloyed Layer" Nanomaterials 7, no. 11: 352. https://doi.org/10.3390/nano7110352

APA StyleWang, C., Li, M., Zhu, M., Wang, H., Qin, C., Zhao, W., & Wang, Z. (2017). Controlling the Mechanical Properties of Bulk Metallic Glasses by Superficial Dealloyed Layer. Nanomaterials, 7(11), 352. https://doi.org/10.3390/nano7110352