Recent Prospects in the Inline Monitoring of Nanocomposites and Nanocoatings by Optical Technologies

Abstract

:1. Introduction

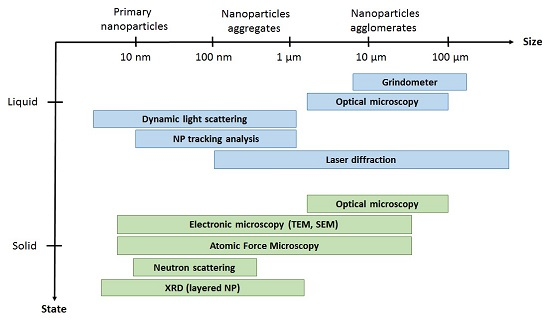

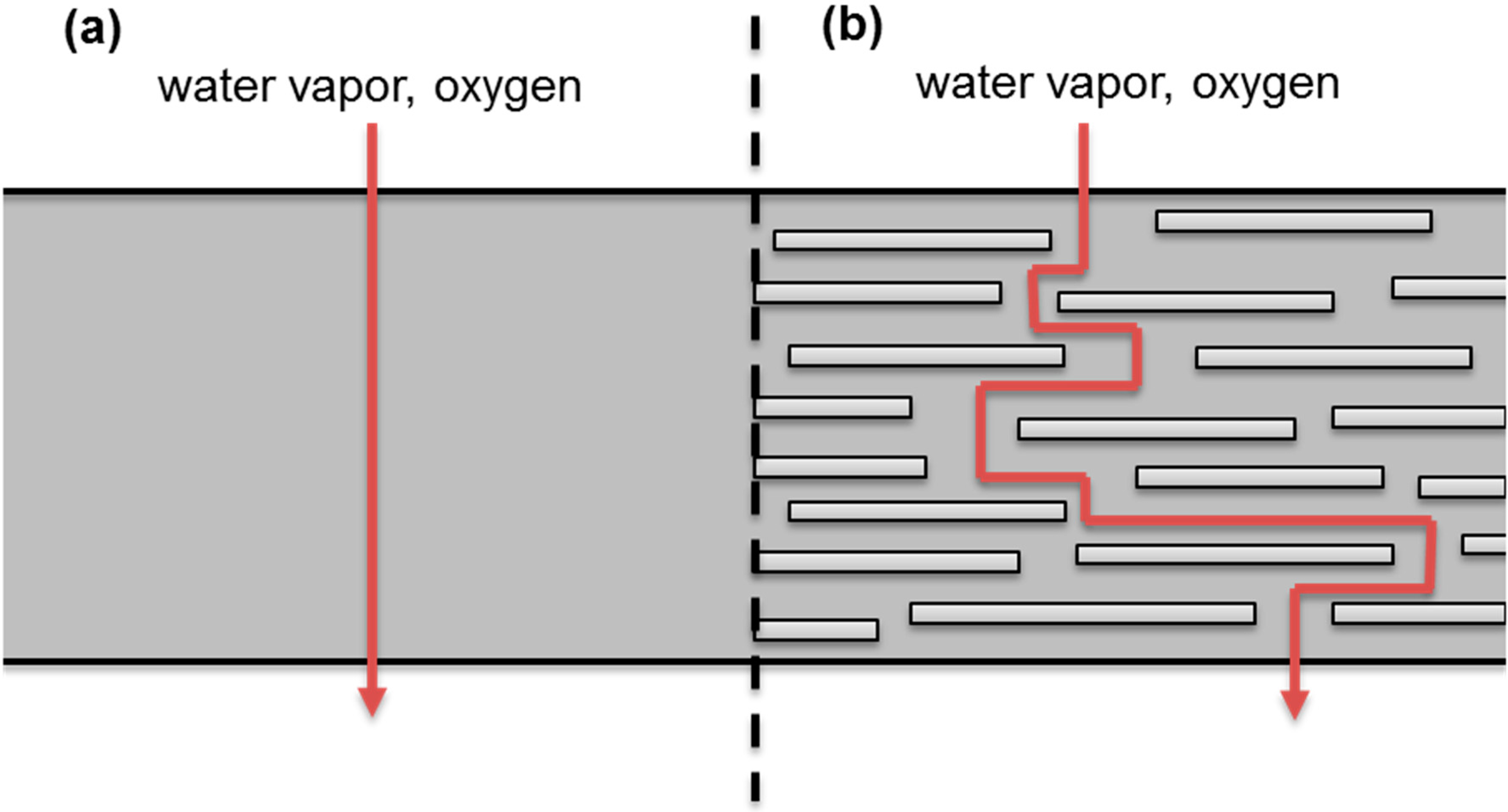

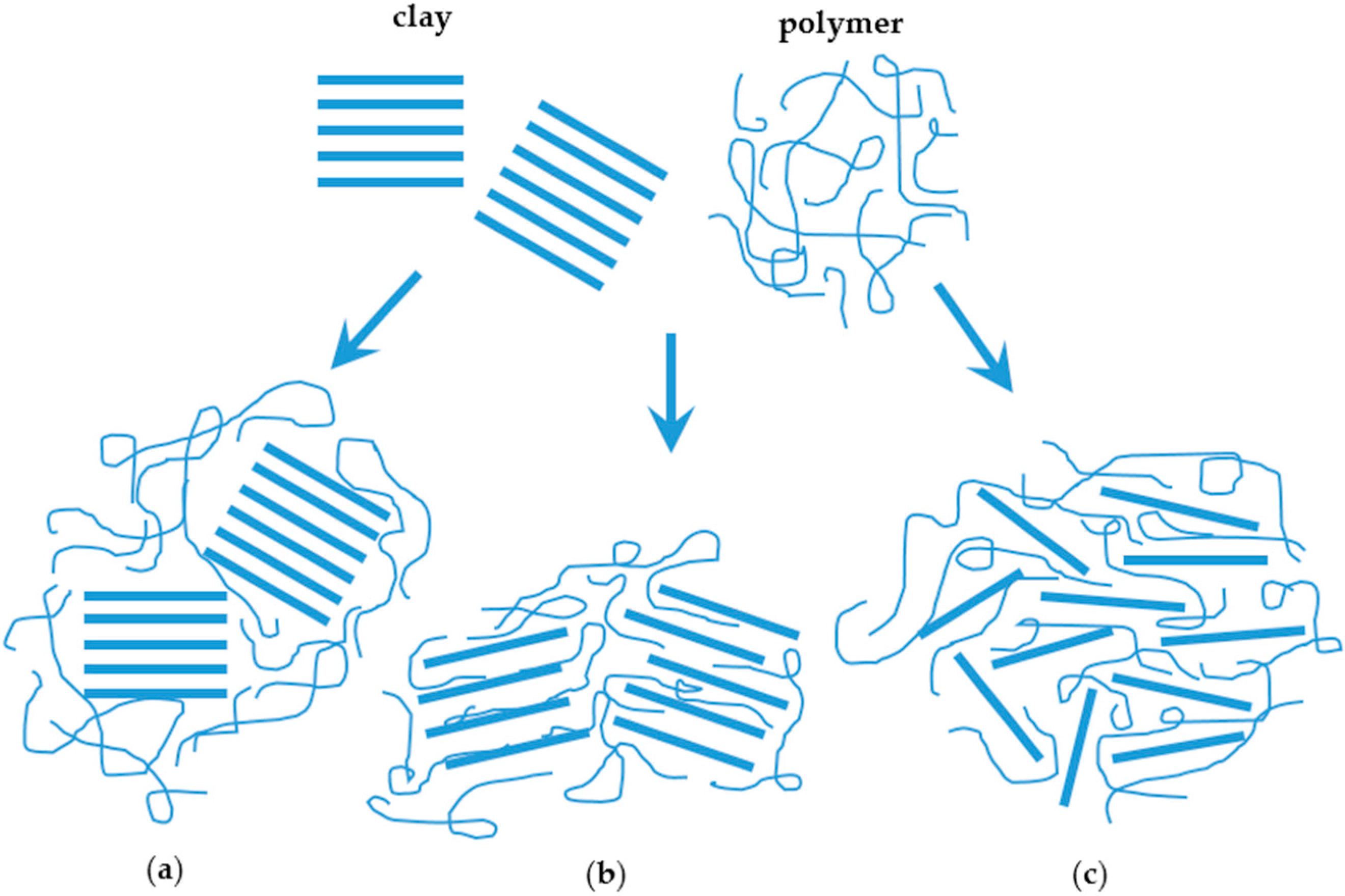

2. Nanoparticles Dispersion Monitoring

2.1. Background

2.2. Conventional Approaches

2.3. Inline Monitoring

3. Thickness Monitoring

3.1. Background

3.2. Conventional Approaches

3.3. Inline Monitoring

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Organization for Standardization (ISO). Nanotechnologies—Vocabulary. In Part 4: Nanostructured Materials; ISO: London, UK, 2011; Volume ISO/TS 80004-4:2011(en), Available online: https://www.iso.org/obp/ui/#iso:std:iso:ts:80004:-4:ed-1:v1:en (accessed on 25 July 2016).

- Intrater, J. A review of: “Flame Retardant Polymer Nanocomposites, A. Morgan and C. Wilkie (Editors)”. Mater. Manuf. Process. 2008, 23, 220–221. [Google Scholar] [CrossRef]

- Arora, A.; Padua, G.W. Review: Nanocomposites in food packaging. J. Food Sci. 2010, 75, R43–R49. [Google Scholar] [CrossRef] [PubMed]

- Xiao, W.; Xu, J.B.; Liu, X.Y.; Hu, Q.L.; Huang, J.G. Antibacterial hybrid materials fabricated by nanocoating of microfibril bundles of cellulose substance with titania/chitosan/silver-nanoparticle composite films. J. Mater. Chem. B 2013, 1, 3477–3485. [Google Scholar] [CrossRef]

- Holder, K.M.; Spears, B.R.; Huff, M.E.; Priolo, M.A.; Harth, E.; Grunlan, J.C. Stretchable gas barrier achieved with partially hydrogen-bonded multilayer nanocoating. Macromol. Rapid Commun. 2014, 35, 960–964. [Google Scholar] [CrossRef] [PubMed]

- Noller, K.; Schmid, M.; Schöneweitz, C. Organic and Inorganic Nanolayers to Improve Barrier Properties; FlexPakRenew Workshop—Planet Friendly Packaging: Lyon, France, 2011. [Google Scholar]

- Schmid, M. Nanoscale Surface Modification—A Chemical Grafting Process for Improved Water Vapour Barrier Properties, 4th ed.; Workshop Green Chemistry and Nanotechnologies in Polymer Chemistry: Pisa, Italy, 2013; pp. 55–56. [Google Scholar]

- Schmid, M.; Benz, A.; Stinga, C.; Samain, D.; Zeyer, K.P. Fundamental investigations regarding barrier properties of grafted pvoh layers. Int. J. Polym. Sci. 2012, 2012. [Google Scholar] [CrossRef]

- Schmid, M.; Sängerlaub, S.; Miesbauer, O.; Jost, V.; Werthan, J.; Stinga, C.; Samain, D.; Stramm, C.; Noller, K.; Müller, K. Water repellence and oxygen and water vapor barrier of PVOH-coated substrates before and after surface esterification. Polymers 2014, 6, 2764–2783. [Google Scholar] [CrossRef]

- Li, Y.C.; Mannen, S.; Cain, A.C.; Grunlan, J.C. Flame retardant polymer/clay layer-by-layer assemblies on cotton fabric. Abstr. Papers Am. Chem. Soc. 2011, 241. [Google Scholar]

- Rahman, A.; Ashraf, A.; Xin, H.; Tong, X.; Sutter, P.; Eisaman, M.D.; Black, C.T. Sub-50-nm self-assembled nanotextures for enhanced broadband antireflection in silicon solar cells. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef] [PubMed]

- Halder, S.; Ghosh, P.; Goyat, M.; Ray, S. Ultrasonic dual mode mixing and its effect on tensile properties of SiO2-epoxy nanocomposite. J. Adhes. Sci. Technol. 2013, 27, 111–124. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Fagan, J.; Douglas, J.F.; Yamamoto, K.; Heckert, A.N.; Leigh, S.D.; Obrzut, J.; Du, F.; Lin-Gibson, S.; Mu, M. Relationship between dispersion metric and properties of PMMA/SWNT nanocomposites. Polymer 2007, 48, 4855–4866. [Google Scholar] [CrossRef]

- Lee, S.; Lee, B.; Kim, B.J.; Park, J.; Yoo, M.; Bae, W.K.; Char, K.; Hawker, C.J.; Bang, J.; Cho, J. Free-standing nanocomposite multilayers with various length scales, adjustable internal structures, and functionalities. J. Am. Chem. Soc. 2009, 131, 2579–2587. [Google Scholar] [CrossRef] [PubMed]

- Barreca, D.; Carraro, G.; Warwick, M.E.A.; Kaunisto, K.; Gasparotto, A.; Gombac, V.; Sada, C.; Turner, S.; Van Tendeloo, G.; Maccato, C.; et al. Fe2O3-TiO2 nanosystems by a hybrid PE-CVD/ALD approach: Controllable synthesis, growth mechanism, and photocatalytic properties. Crystengcomm 2015, 17, 6219–6226. [Google Scholar] [CrossRef]

- Ray, S.S.; Okamoto, M. Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar]

- Coates, P.D.; Barnes, S.E.; Sibley, M.G.; Brown, E.C.; Edwards, H.G.M.; Scowen, I.J. In-process vibrational spectroscopy and ultrasound measurements in polymer melt extrusion. Polymer 2003, 44, 5937–5949. [Google Scholar] [CrossRef]

- Alig, I.; Fischer, D.; Lellinger, D.; Steinhoff, B. Combination of NIR, Raman, ultrasonic and dielectric spectroscopy for in-line monitoring of the extrusion process. Macromol. Symp. 2005, 230, 51–58. [Google Scholar] [CrossRef]

- Barres, C.; Bounor-Legare, V.; Melis, F.; Michel, A. In-line near infrared monitoring of esterification of a molten ethylene-vinyl alcohol copolymer in a twin screw extruder. Polym. Eng. Sci. 2006, 46, 1613–1624. [Google Scholar] [CrossRef]

- Watari, M. A review of online real-time process analyses of melt-state polymer using the near-infrared spectroscopy and chemometrics. Appl. Spectrosc. Rev. 2014, 49, 462–491. [Google Scholar] [CrossRef]

- Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic-inorganic nanocomposites-A review. Prog. Polym. Sci. 2013, 38, 1232–1261. [Google Scholar] [CrossRef]

- Choudalakis, G.; Gotsis, A.D. Permeability of polymer/clay nanocomposites: A review. Eur. Polym. J. 2009, 45, 967–984. [Google Scholar] [CrossRef]

- Duncan, T.V. Applications of nanotechnology in food packaging and food safety: Barrier materials, antimicrobials and sensors. J. Colloid Interface Sci. 2011, 363, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef]

- McAdam, C.P.; Hudson, N.E.; Liggat, J.J.; Pethrick, R.A. Synthesis and characterization of nylon 6/clay nanocomposites prepared by ultrasonication and in situ polymerization. J. Appl. Polym. Sci. 2008, 108, 2242–2251. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater. Sci. Eng. R 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Bertuoli, P.T.; Piazza, D.; Scienza, L.C.; Zattera, A.J. Preparation and characterization of montmorillonite modified with 3-aminopropyltriethoxysilane. Appl. Clay Sci. 2014, 87, 46–51. [Google Scholar] [CrossRef]

- Huskić, M.; Žigon, M.; Ivanković, M. Comparison of the properties of clay polymer nanocomposites prepared by montmorillonite modified by silane and by quaternary ammonium salts. Appl. Clay Sci. 2013, 85, 109–115. [Google Scholar] [CrossRef]

- Zhang, D.L. Processing of advanced materials using high-energy mechanical milling. Prog. Mater. Sci. 2004, 49, 537–560. [Google Scholar] [CrossRef]

- Xia, H.S.; Wang, Q. Preparation of conductive polyaniline/nanosilica particle composites through ultrasonic irradiation. J. Appl. Polym. Sci. 2003, 87, 1811–1817. [Google Scholar] [CrossRef]

- Usuki, A.; Kojima, Y.; Kawasumi, M.; Okada, A.; Fukushima, Y.; Kurauchi, T.; Kamigaito, O. Synthesis of nylon 6-clay hybrid. J. Mater. Res. 1993, 8, 1179–1184. [Google Scholar] [CrossRef]

- Messersmith, P.B.; Giannelis, E.P. Synthesis and characterization of layered silicate-epoxy nanocomposites. Chem. Mater. 1994, 6, 1719–1725. [Google Scholar] [CrossRef]

- Costantino, A.; Pettarin, V.; Viana, J.; Pontes, A.; Pouzada, A.; Frontini, P. Microstructure of PP/clay nanocomposites produced by shear induced injection moulding. In Proceedings of the 11th International Congress on Metallurgy & Materials Sam/Conamet, Rosario, Argentina, 18–21 October 2011; Volume 1, pp. 34–43.

- Kaynak, C.; Gunduz, H.O.; Isitman, N.A. Use of nanoclay as an environmentally friendly flame retardant synergist in polyamide-6. J. Nanosci. Nanotechnol. 2010, 10, 7374–7377. [Google Scholar] [CrossRef] [PubMed]

- Rhim, J.-W.; Ng, P.K.W. Natural biopolymer-based nanocomposite films for packaging applications. Crit. Rev. Food Sci. Nutr. 2007, 47, 411–433. [Google Scholar] [CrossRef] [PubMed]

- Bugnicourt, E.; Galy, J.; Gérard, J.; Boué, F.; Barthel, H. Structural investigations of pyrogenic silica–epoxy composites by small-angle neutron scattering and transmission electron microscopy. Polymer 2007, 48, 949–958. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, L. Interaction and properties of highly exfoliated soy protein/montmorillonite nanocomposites. Biomacromolecules 2006, 7, 1700–1706. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.A.; Rupp, J.E.P.; Suter, U.W. Gas permeation properties of polyethylene-layered silicate nanocomposites. J. Mater. Chem. 2005, 15, 1298–1304. [Google Scholar] [CrossRef]

- Cui, Y.; Kumar, S.; Kona, B.R.; van Houcke, D. Gas barrier properties of polymer/clay nanocomposites. RSC Adv. 2015, 5, 63669–63690. [Google Scholar] [CrossRef]

- Luo, Z.; Koo, J. Quantification of the layer dispersion degree in polymer layered silicate nanocomposites by transmission electron microscopy. Polymer 2008, 49, 1841–1852. [Google Scholar] [CrossRef]

- Hui, L.; Smith, R.; Wang, X.; Nelson, J.; Schadler, L. Quantification of particulate mixing in nanocomposites. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008; pp. 317–320.

- Bugnicourt, E. Development of Sub-Micro Structured Composites Based on an Epoxy Matrix and Pyrogenic Silica: Mechanical Behavior Related to the Interactions and Morphology at Multi-Scale. Ph.D. Thesis, Institut National des Sciences Appliquées de Lyon, Villeurbanne, France, 2005. [Google Scholar]

- Battisti, A.; Skordos, A.A.; Partridge, I.K. Monitoring dispersion of carbon nanotubes in a thermosetting polyester resin. Compos. Sci. Technol. 2009, 69, 1516–1520. [Google Scholar] [CrossRef]

- Vermant, J.; Ceccia, S.; Dolgovskij, M.; Maffettone, P.; Macosko, C. Quantifying dispersion of layered nanocomposites via melt rheology. J. Rheol. 2007, 51, 429–450. [Google Scholar] [CrossRef]

- Xu, R. Light scattering: A review of particle characterization applications. Particuology 2015, 18, 11–21. [Google Scholar] [CrossRef]

- Gallego-Urrea, J.A.; Tuoriniemi, J.; Hassellöv, M. Applications of particle-tracking analysis to the determination of size distributions and concentrations of nanoparticles in environmental, biological and food samples. TrAC Trends Anal. Chem. 2011, 30, 473–483. [Google Scholar] [CrossRef]

- Ma, Z.; Merkus, H.G.; de Smet, J.G.; Heffels, C.; Scarlett, B. New developments in particle characterization by laser diffraction: Size and shape. Powder Technol. 2000, 111, 66–78. [Google Scholar] [CrossRef]

- Barbas, J.; Machado, A.; Covas, J. Evolution of dispersion along the extruder during the manufacture of polymer–organoclay nanocomposites. Chem. Eng. Sci. 2013, 98, 77–87. [Google Scholar] [CrossRef]

- McPeters, H.L.; Williams, S.O. In-line monitoring of polymer processes by near-infrared spectroscopy. Process Control Qual. 1992, 3, 75–83. [Google Scholar]

- Beyers, C.P.; Boelens, H.F.M.; Klumperman, L.; Westerhuis, J.A. In-line reaction monitoring of a methyl methacrylate and N,N-dimethylacrylamide copolymerization reaction using near-infrared spectroscopy. Appl. Spectrosc. 2004, 58, 863–869. [Google Scholar] [CrossRef] [PubMed]

- Fischer, D.; Sahre, K.; Abdelrhim, M.; Voit, B.; Sadhu, V.B.; Pionteck, J.; Komber, H.; Hutschenreuter, J. Process monitoring of polymers by in-line ATR-IR, NIR and Raman spectroscopy and ultrasonic measurements. C. R. Chim. 2006, 9, 1419–1424. [Google Scholar] [CrossRef]

- Moghaddam, L.; Rintoul, L.; Halley, P.J.; George, G.A.; Fredericks, P.M. In-situ monitoring by fibre-optic NIR spectroscopy and rheometry of maleic anhydride grafting to polypropylene in a laboratory scale reactive extruder. Polym. Test. 2012, 31, 155–163. [Google Scholar] [CrossRef]

- Rohe, T.; Becker, W.; Krey, A.; Nagele, H.; Kolle, S.; Eisenreich, N. In-line monitoring of polymer extrusion processes by NIR spectroscopy. J. Near Infrared Spectrosc. 1998, 1988, 325–332. [Google Scholar] [CrossRef]

- Fischer, D.; Muller, J.; Kummer, S.; Kretzschmar, B. Real time monitoring of morphologic and mechanical properties of polymer nanocomposites during extrusion by near infrared and ultrasonic spectroscopy. Polym. Spectrosc. 2011, 305. [Google Scholar] [CrossRef]

- Barbas, J.M.; Machado, A.V.; Covas, J.A. In-line near-infrared spectroscopy: A tool to monitor the preparation of polymer-clay nanocomposites in extruders. J. Appl. Polym. Sci. 2013, 127, 4899–4909. [Google Scholar] [CrossRef]

- Franzheim, O.; Stephan, M.; Rische, T.; Heidemeyer, P.; Burkhardt, U.; Kiani, A. Analysis of morphology development of immiscible blends in a twin screw extruder. Adv. Polym. Technol. 1997, 16, 1–10. [Google Scholar] [CrossRef]

- Sun, Z.; Jen, C.-K.; Yan, J.; Chen, M.-Y. Application of ultrasound and neural networks in the determination of filler concentration and dispersion during polymer extrusion processes. Polym. Eng. Sci. 2005, 45, 764–772. [Google Scholar] [CrossRef]

- Tatibouet, J.; Huneault, M. In-line ultrasonic monitoring of filler dispersion during extrusion. Int. Polym. Process. 2002, 17, 49–52. [Google Scholar] [CrossRef]

- Bridge, B.; Cheng, K. On-line ultrasonic monitoring of the extrusion of caco 3-filled polypropylene. J. Mater. Sci. Lett. 1987, 6, 219–222. [Google Scholar] [CrossRef]

- Villanueva, M.; Cabedo, L.; Gimenez, E.; Lagaron, J.; Coates, P.; Kelly, A. Study of the dispersion of nanoclays in a ldpe matrix using microscopy and in-process ultrasonic monitoring. Polym. Test. 2009, 28, 277–287. [Google Scholar] [CrossRef]

- Hart, J. Measuring food packaging materials. Photon. Spectra Mag. 2008, 42, 46. [Google Scholar]

- Koper, G.J.M.; Vilcinskas, K. Anomalous thickness dependence of nano-composite layer-by-layer membranes. Colloids Surf. A 2014, 442, 2–5. [Google Scholar] [CrossRef]

- Schmid, M.; Dallmann, K.; Bugnicourt, E.; Cordoni, D.; Wild, F.; Lazzeri, A.; Noller, K. Properties of whey-protein-coated films and laminates as novel recyclable food packaging materials with excellent barrier properties. Int. J. Polym. Sci. 2012, 2012. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Bunch, J.S.; Verbridge, S.S.; Alden, J.S.; van der Zande, A.M.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Impermeable atomic membranes from graphene sheets. Nano Lett. 2008, 8, 2458–2462. [Google Scholar] [CrossRef] [PubMed]

- Leenaerts, O.; Partoens, B.; Peeters, F.M. Graphene: A perfect nanoballoon. Appl. Phys. Lett. 2008, 93. [Google Scholar] [CrossRef]

- NANOMASTER. Periodic Report Summary; UK, 2013; Available online: http://cordis.europa.eu/result/rcn/55964_de.html (accessed on 1 June 2016).

- Casiraghi, C.; Robertson, J.; Ferrari, A.C. Diamond-like carbon for data and beer storage. Mater. Today 2007, 10, 44–53. [Google Scholar] [CrossRef]

- Nine, M.J.; Cole, M.A.; Johnson, L.; Tran, D.N.; Losic, D. Robust superhydrophobic graphene-based composite coatings with self-cleaning and corrosion barrier properties. ACS Appl. Mater. Interfaces 2015, 7, 28482–28493. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Wan, J.; Zheng, Y.; Dong, W. Tuning photoconductive properties of organic–inorganic hybrid perovskite nanocomposite device via organic layer’s thickness. Mater. Lett. 2012, 76, 187–189. [Google Scholar] [CrossRef]

- Decker, J.J.; Meyers, K.P.; Paul, D.R.; Schiraldi, D.A.; Hiltner, A.; Nazarenko, S. Polyethylene-based nanocomposites containing organoclay: A new approach to enhance gas barrier via multilayer coextrusion and interdiffusion. Polymer 2015, 61, 42–54. [Google Scholar] [CrossRef]

- Podsiadlo, P.; Kaushik, A.K.; Arruda, E.M.; Waas, A.M.; Shim, B.S.; Xu, J.; Nandivada, H.; Pumplin, B.G.; Lahann, J.; Ramamoorthy, A.; et al. Ultrastrong and stiff layered polymer nanocomposites. Science 2007, 318, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Ling, Z.; Ren, C.E.; Zhao, M.Q.; Yang, J.; Giammarco, J.M.; Qiu, J.S.; Barsoum, M.W.; Gogotsi, Y. Flexible and conductive mxene films and nanocomposites with high capacitance. Proc. Natl. Acad. Sci. USA 2014, 111, 16676–16681. [Google Scholar] [CrossRef] [PubMed]

- Li, C.R.; Deng, H.T.; Wan, J.; Zheng, Y.Y.; Dong, W.J. Photoconductive properties of organic–inorganic hybrid perovskite (C6H13NH3)2(CH3NH3)m−1PbmI3m+1:TiO2 nanocomposites device structure. Mater. Lett. 2010, 64, 2735–2737. [Google Scholar] [CrossRef]

- Jeon, N.J.; Noh, J.H.; Kim, Y.C.; Yang, W.S.; Ryu, S.; Seok, S.I. Solvent engineering for high-performance inorganic–organic hybrid perovskite solar cells. Nat. Mater. 2014, 13, 897–903. [Google Scholar] [CrossRef] [PubMed]

- Ryan, O.H.; Marian, N.; Joop, S.; Albert, G. A parametric study of TiO2/CuInS2 nanocomposite solar cells: How cell thickness, buffer layer thickness, and TiO2 particle size affect performance. Nanotechnology 2007, 18. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Wu, H.; Li, C. Silver nanocomposite layer-by-layer films based on assembled polyelectrolyte/dendrimer. J. Colloid Interface Sci. 2005, 287, 604–611. [Google Scholar] [CrossRef] [PubMed]

- KLA-Tencor. KLA-Tencor Hrp-250. Available online: http://www.kla-tencor.com (accessed on 4 February 2016).

- Williams, D.B.; Carter, C.B. Transmission Electron Microscopy: A Textbook for Materials Science; Springer: New York, NY, USA, 2009. [Google Scholar]

- Sawyer, L.; Grubb, D.; Meyers, G.F. Polymer Microscopy; Springer: New York, NY, USA, 2008. [Google Scholar]

- Reboud, V.; Kehoe, T.; Kehagias, N.; Torres, C.M.S. Advances in nanoimprint lithography: 2-D and 3-D nanopatterning of surfaces by nanoimoprint lithography, morphological characterization, and photonic applications. In Nanotechnology: Volume 8: Nanostructured Surfaces; John Wiley & Sons: Weinheim, Germany, 2010. [Google Scholar]

- Hacker, C.A.; Diebold, A.C. Publication Citation: 2012 Updates to the International Technology Roadmap for Semiconductors (ITRS) Metrology Chapter; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013; pp. 96–100. [Google Scholar]

- Guidance for Industry Pat—A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance; U.S. Department of Health and Human Services, Food and Drug Administration: Rockville, MD, USA, 2004. Available online: http://www.fda.gov/downloads/Drugs/.../Guidances/ucm070305.pdf (accessed on 12 July 2016).

- Pribik, R.; Aslan, K.; Zhang, Y.; Geddes, C.D. Metal-enhanced fluorescence from chromium nanodeposits. J. Phys. Chem. C 2008, 112, 17969–17973. [Google Scholar] [CrossRef]

- Leaflet: Complete Process Control Solutions Roll-to-Roll. Available online: http://www.schwabinspection.com/download.php?File=L2RhdGEvd3d3Y3VzdC9uZTItNzM3Ny9odG1sL2Ntc19tZWRpYS9tb2R1bGVfb2IvMC81N18xX0xlYWZsZXRfUm9sbC10by1Sb2xsXzIwMTQtMDEucGRm&Filetype=pdf&Filename=Leaflet_Roll-to-Roll_2014–01.pdf (accessed on 4 February 2016).

- Brochure Easymeasure. Available online: http://www.drschenk.com/fileadmin/brochures/brochure_easymeasure_2015_01.pdf (accessed on 18 January 2016).

- Clean4Yield. Final Report Summary—Clean4yield (Contamination and Defect Control for Increased Yield for Large Scale R2R production of OPV and OLED); 2016. Available online: http://cordis.europa.eu/result/rcn/174103_en.html (accessed on 1 June 2016).

- Laumeier, T. C4Y—Innovative Inspection and Measurement Solutions. Available online: https://t.co/0oLbnPmqQC (accessed on 23 February 2016).

- Bosch, R.H.E.C.; Bloksma, F.L.; Huijs, J.M.M.; Verheijen, M.A.; Kessels, W.M.M. Surface infrared spectroscopy during low temperature growth of supported Pt nanoparticles by atomic layer deposition. J. Phys. Chem. C 2016, 120, 750–755. [Google Scholar] [CrossRef]

- Dufour, M.L.; Lamouche, G.; Detalle, V.; Gauthier, B.; Sammut, P. Low-coherence interferometry, an advanced technique for optical metrology in industry. In Proceedings of the 16th World Conference on NDT, Montreal, QC, Canada, 30 August–3 September 2004.

- Ignatovich, F.; Spaeth, M.; Solpietro, J.; Cotton, W.; Gibson, D. Measurement of film stacks in cell phones and tablets using white light interferometry. In Proceedings of the Association of International Metallizers Coaters and Laminators ( AIMCAL ) Web Coating & Handling Conference, Myrtle Beach, CA, USA, 19–22 October 2014; pp. 421–427.

- Merklein, T.M. High resolution measurement of multilayer structures. Appl. Opt. 1990, 29, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Tutorial: Advanced Thin-Film Measurement Systems. Available online: http://www.filmetrics.com/technology (accessed on 18 January 2016).

- Clean4Yield. Periodic Report Summary 1. 2014. Available online: http://cordis.europa.eu/result/rcn/141788_en.html (accessed on 1 June 2016).

- THIME. Final Report Summary. 2016. Available online: http://ec.europa.eu/transport/themes/its/doc/c-its-platform-final-report-january-2016.pdf (accessed on 15 June 2016).

- Şenay, V.; Özen, S.; Pat, S.; Korkmaz, Ş. Optical, morphological and mechanical properties of an Al–Al2O3 nanocomposite thin film grown by thermionic vacuum ARC. Int. J. Light Electr. Opt. 2016, 127, 3383–3387. [Google Scholar] [CrossRef]

- Jiang, P.; McFarland, M.J. Large-scale fabrication of wafer-size colloidal crystals, macroporous polymers and nanocomposites by spin-coating. J. Am. Chem. Soc. 2004, 126, 13778–13786. [Google Scholar] [CrossRef] [PubMed]

- Tompkins, H.G. A User’s Guide to Ellipsometry; Elsevier Science: St. Louis, MO, USA, 2012. [Google Scholar]

- Elton, N.J. The complex refractive index and reflectometry versus ellipsometry. Surfoptic Reflect. Tech. Paper 2007, 3, 1–11. [Google Scholar]

- Matković, A.; Beltaos, A.; Milićević, M.; Ralević, U.; Vasić, B.; Jovanović, D.; Gajić, R. Spectroscopic imaging ellipsometry and fano resonance modeling of graphene. J. Appl. Phys. 2012, 112. [Google Scholar] [CrossRef]

- Matković, A.; Ralević, U.; Chhikara, M.; Jakovljević, M.M.; Jovanović, D.; Bratina, G.; Gajić, R. Influence of transfer residue on the optical properties of chemical vapor deposited graphene investigated through spectroscopic ellipsometry. J. Appl. Phys. 2013, 114. [Google Scholar] [CrossRef]

- Logothetidis, S.; Georgiou, D.; Laskarakis, A.; Koidis, C.; Kalfagiannis, N. In-line spectroscopic ellipsometry for the monitoring of the optical properties and quality of roll-to-roll printed nanolayers for organic photovoltaics. Sol. Energy Mater. Sol. Cells 2013, 112, 144–156. [Google Scholar] [CrossRef]

- Logothetidis, S. Method for in-Line Determination of Film Thickness and Quality during Printing Processes for the Production of Organic Electronics. U.S. Patent 20140039822 A1, 6 February 2012. [Google Scholar]

- Stchakovsky, M.; Gaillet, M. Characterization of Barrier Layers by Spectroscopic Ellipsometry for Packaging Applications; Horiba: UK, 2014; Available online: http://www.horiba.com/fileadmin/uploads/Scientific/Documents/TFilm/Application_Notes/Characterization_of_Barrier_Layers_by_Spectroscopic_Ellipsometry_for_Packaging_Applications.pdf (accessed on 1 June 2016).

- Moretti, E.; Pizzol, G.; Fantin, M.; Enrichi, F.; Scopece, P.; Nuñez, N.O.; Ocaña, M.; Benedetti, A.; Polizzi, S. Deposition of silica protected luminescent layers of Eu:GdvO4 nanoparticles assisted by atmospheric pressure plasma jet. Thin Solid Films 2016, 598, 88–94. [Google Scholar] [CrossRef]

- Venkatasamy, V.; Jayaraju, N.; Cox, S.M.; Thambidurai, C.; Happek, U.; Stickney, J.L. Optimization of CdTe nanofilm formation by electrochemical atomic layer epitaxy (EC-ALE). J. Appl. Electrochem. 2006, 36, 1223–1229. [Google Scholar] [CrossRef]

- Schmid, M.; Kainz, D.; Miesbauer, O. Optinanopro. Verarbeitung und Monitoring neuartiger Nanomaterialien in Produktionslinien für Verpackungen, Automobile und Solarmodule. Rundsch. Fleischhyg. Lebensm. 2016, 2, 45–47. [Google Scholar]

| Chemical Dispersion Strategies | Physical Dispersion Strategies |

|---|---|

| Surface modification of nanoparticles - to enhance matrix/nanoparticles compatibility - to covalently react them with the continuous phase | Mechanical mixing by: - application of high shear - high energy ball milling - extrusion |

| Sonication | |

| In situ polymerisation | Orientation by: - application of compression/shear in one direction - electromagnetic fields |

| Characterization Technique | Type | Information Provided |

|---|---|---|

| XRD | Direct | Exfoliation degree of layered nanomaterials |

| TEM | Direct | Filler size, shape and distribution |

| SEM | Direct | Filler size, shape and distribution |

| AFM | Direct | Filler size, shape and distribution |

| SANS | Direct | Fractal organization of amorphous particles |

| Melt Rheology | Indirect | Degree of dispersion |

| Gas permeation | Indirect | Degree of dispersion |

| Offline Technique | In Situ or Inline Technique | |

|---|---|---|

| Absolute thickness | - Profilometry | - Low coherence interferometry |

| - Cross-section SEM | - Ellipsometry | |

| - Cross-section TEM | - Spectral reflectance | |

| Relative thickness | - Quartz microbalance | |

| - Machine vision based | ||

| - Optical absorption spectroscopy |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bugnicourt, E.; Kehoe, T.; Latorre, M.; Serrano, C.; Philippe, S.; Schmid, M. Recent Prospects in the Inline Monitoring of Nanocomposites and Nanocoatings by Optical Technologies. Nanomaterials 2016, 6, 150. https://doi.org/10.3390/nano6080150

Bugnicourt E, Kehoe T, Latorre M, Serrano C, Philippe S, Schmid M. Recent Prospects in the Inline Monitoring of Nanocomposites and Nanocoatings by Optical Technologies. Nanomaterials. 2016; 6(8):150. https://doi.org/10.3390/nano6080150

Chicago/Turabian StyleBugnicourt, Elodie, Timothy Kehoe, Marcos Latorre, Cristina Serrano, Séverine Philippe, and Markus Schmid. 2016. "Recent Prospects in the Inline Monitoring of Nanocomposites and Nanocoatings by Optical Technologies" Nanomaterials 6, no. 8: 150. https://doi.org/10.3390/nano6080150

APA StyleBugnicourt, E., Kehoe, T., Latorre, M., Serrano, C., Philippe, S., & Schmid, M. (2016). Recent Prospects in the Inline Monitoring of Nanocomposites and Nanocoatings by Optical Technologies. Nanomaterials, 6(8), 150. https://doi.org/10.3390/nano6080150