Preparation and Photocatalytic Activity of Potassium- Incorporated Titanium Oxide Nanostructures Produced by the Wet Corrosion Process Using Various Titanium Alloys

Abstract

:1. Introduction

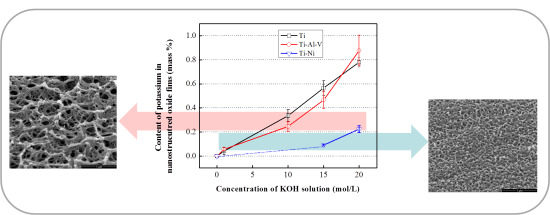

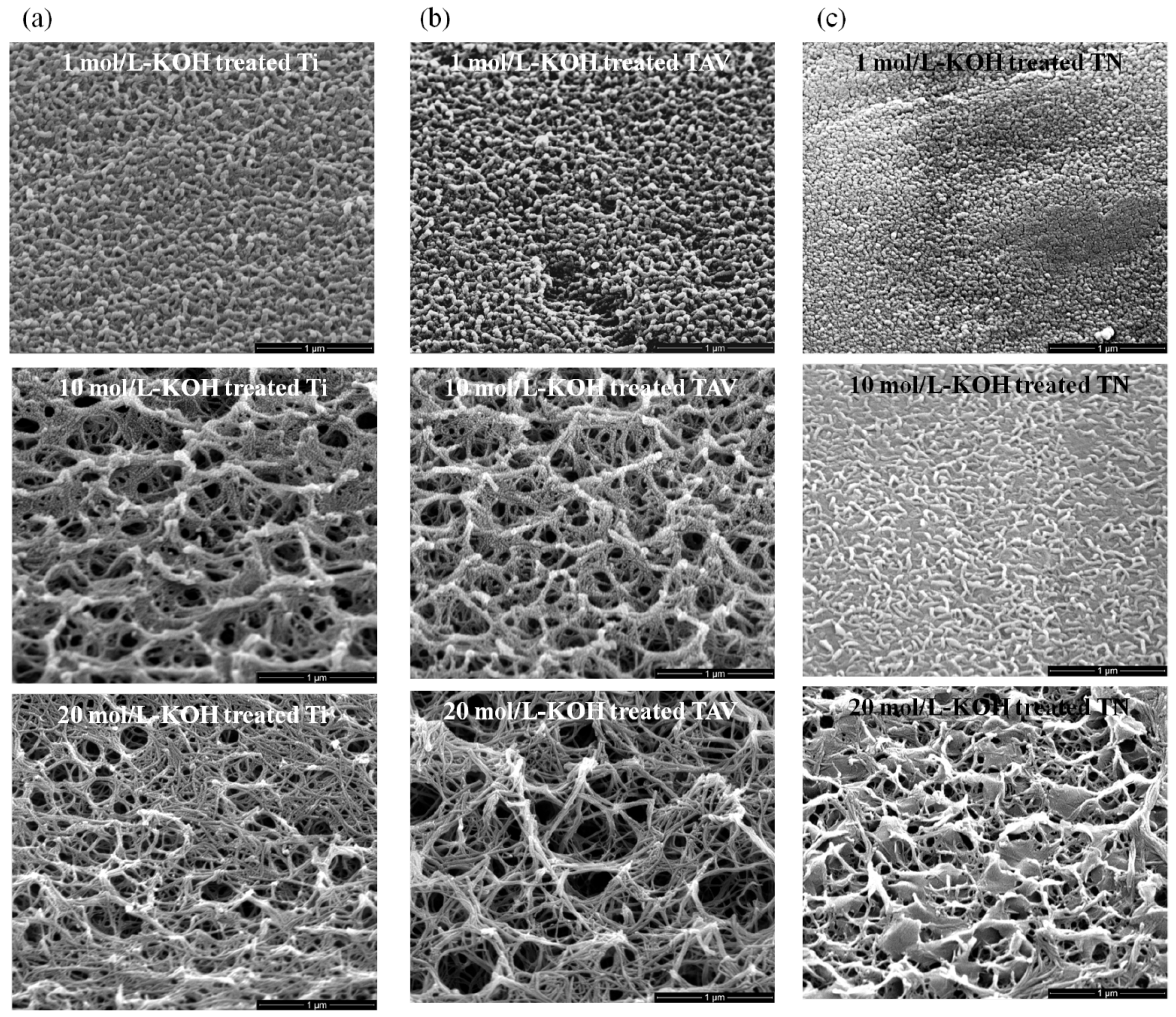

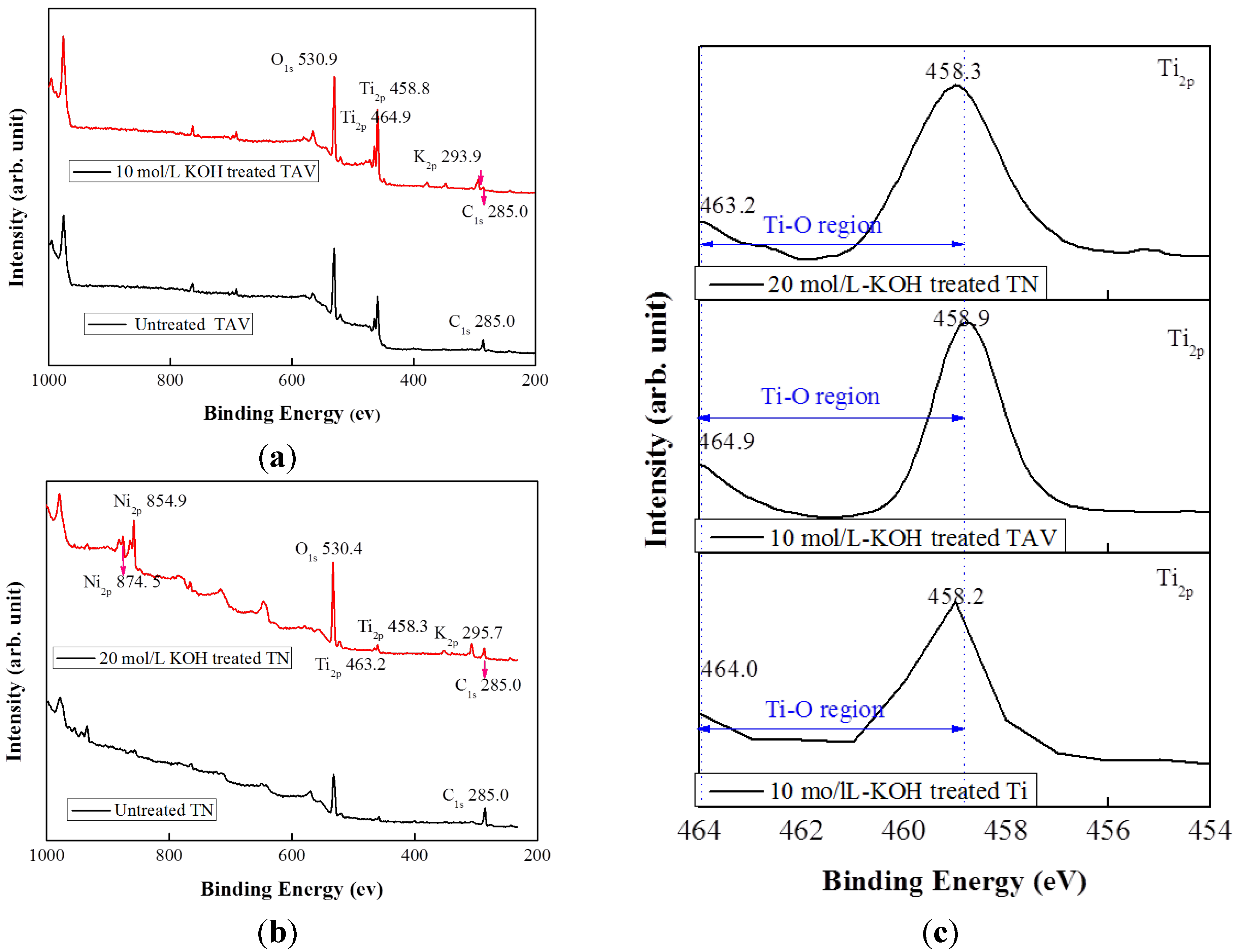

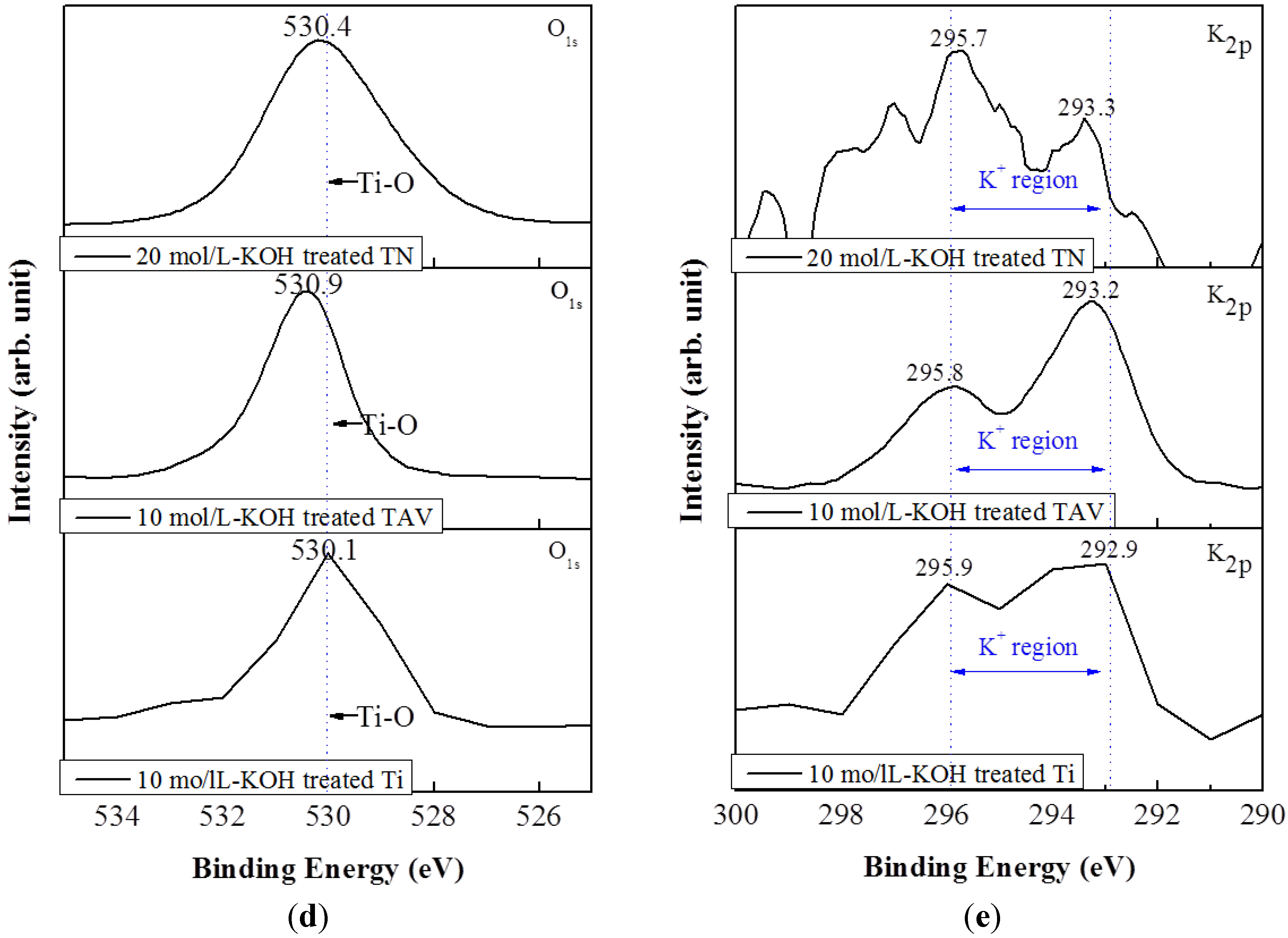

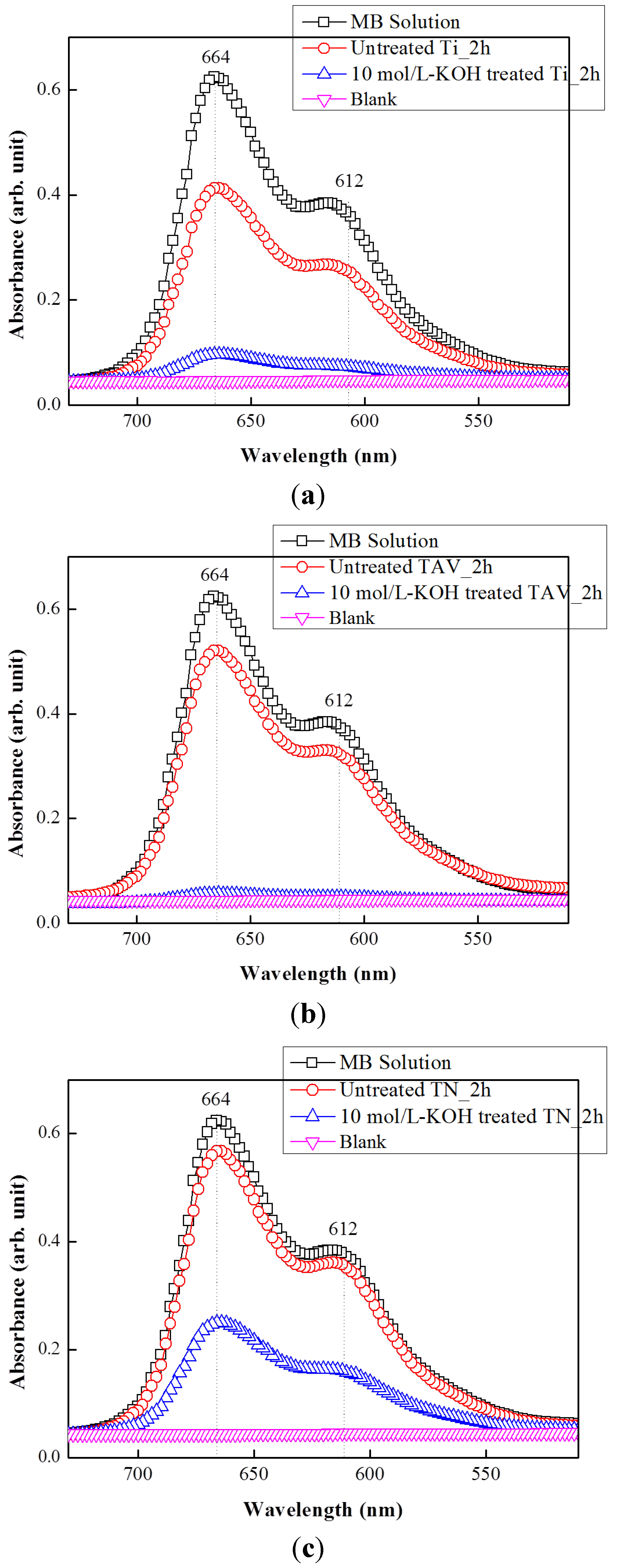

2. Results and Discussion

- (1)

- TiO2 + OH− = HTiO3−

- (2)

- Ti + 3OH− = Ti(OH)3+ + 4e−

- (3)

- Ti(OH)3+ + e− = TiO2·H2O +1/2H2

- (4)

- Ti(OH)3+ + OH− = Ti(OH)4

- (5)

- TiO2·nH2O + OH− = HTiO3−·nH2O

3. Experimental Section

3.1. Preparation of Nanostructured Titanium Oxide Films with Ti, Ti–Al–V Alloy, and TiNi Alloy

| Metal | Composition (wt %) | ||||

|---|---|---|---|---|---|

| Ti | Al | V | Ni | Cu | |

| Ti | Bal. | ||||

| Ti–Al–V | Bal. | 6.45 | 4.16 | ||

| TiNi | Bal. | 50 | 5 | ||

3.2. Characterizations

3.3. Photocatalytic Activity Testing of the K-Incorporated nTOFs

4. Conclusions

Acknowledgments

Author Contributions

Supplementary Materials

Conflicts of Interest

References

- Wang, X.; Li, Y. Solution-based synthetic strategies for 1-D nanostructures. Inorg. Chem. 2006, 45, 7522–7534. [Google Scholar] [CrossRef] [PubMed]

- Du, G.H.; Chen, Q.; Han, P.D.; Yu, Y.; Peng, L.M. Potassium titanate nanowires: Structure, growth, and optical properties. Phys. Rev. B 2003, 67, 035323. [Google Scholar] [CrossRef]

- Bavykin, D.V.; Cressey, B.A.; Light, M.E.; Walsh, F.C. An aqueous, alkaline route to titanate nanotubes under atmospheric pressure conditions. Nanotechnology 2008, 19, 275604. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.T.; Um, M.H.; Kumazawa, H. Synthesis of titanate derivatives using ion-exchange reaction. J. Am. Ceram. Soc. 2000, 83, 1098–1102. [Google Scholar] [CrossRef]

- Yamg, Z.; Choi, D.; Kerisit, S.; Rosso, K.M.; Wang, D.; Zhang, J.; Graff, G.; Liu, J. Nanostructures and lithium electrochemical reactivity of lithium titanites and titanium oxides: A review. J. Power Sources 2009, 192, 588–598. [Google Scholar]

- Geng, H.-Z.; Kim, K.K.; So, K.P.; Lee, Y.S.; Chang, Y.; Lee, Y.H. Effect of acid treatment on carbon nanotube-based flexible transparent conducting films. J. Am. Chem. Soc. 2007, 129, 7758–7759. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Yudasaka, M.; Iijima, S. Dissociation of electrolytes in a nano-aqueous system within single-wall carbon nanotubes. J. Phys. Chem. B 2005, 109, 6037–6039. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Arai, S.; Endo, M. The preparation of multi-walled carbon nanotubes with a Ni-P coating by an electroless deposition process. Carbon 2005, 43, 1716–1721. [Google Scholar] [CrossRef]

- Pan, D.; Zhao, N.; Wang, Q.; Jiang, S.; Ji, X.; An, L. Facile synthesis and characterization of luminescent TiO2 nanocrystals. Adv. Mater. 2005, 17, 1991–1995. [Google Scholar] [CrossRef]

- Chae, W.S.; Land, S.W.; Kim, Y.R. Templating route to mesoporous nanocrystalline titania nanofibers. Chem. Mater. 2005, 17, 3072–3074. [Google Scholar] [CrossRef]

- Hanley, T.L.; Luca, V.; Pickering, I.; Howe, R. Structure of titania sol-gel films: A study by X-ray absorption spectroscopy. J. Phys. Chem. B 2002, 106, 1153–1160. [Google Scholar] [CrossRef]

- Liu, Y.; Claus, R.O. Blue light emitting nanosized TiO2 colloids. J. Am. Chem Soc. 1997, 119, 5273–5274. [Google Scholar] [CrossRef]

- Liu, Y.; Lü, C.; Li, M.; Zhanh, L.; Yang, B. High refractive index organic–inorganic hybrid coatings with TiO2 nanocrystals. Colloid Surf. A 2008, 328, 67–72. [Google Scholar] [CrossRef]

- Jin, F.; Tong, H.; Shen, L.; Wang, K.; Chu, P.K. Micro-structural and dielectric properties of porous TiO2 films synthesized on titanium alloys by micro-arc discharge oxidization. Mater. Chem. Phys. 2006, 100, 31–33. [Google Scholar] [CrossRef]

- Nowotny, M.K.; Bogdanoff, P.; Dittrich, T.; Fiechter, S.; Fujishima, A.; Tributsch, H. Observations of p-type semiconductivity in titanium dioxide at room temperature. Mater. Lett. 2010, 64, 928–930. [Google Scholar] [CrossRef]

- Chu, D.; Yuan, X.; Qin, G.; Xu, M.; Zheng, P.; Lu, J.; Zha, L. Efficient carbon-doped nanostructured TiO2 (anatase) film for photoelectrochemical solar cells. J. Nanopart. Res. 2007, 10, 357–363. [Google Scholar] [CrossRef]

- Mali, S.S.; Desai, S.K.; Dalavi, D.S.; Betty, C.A.; Bhosale, P.N.; Patil., P.S. CdS-sensitized TiO2 nanocorals: Hydrothermal synthesis, characterization, application. Photochem. Photobiol. Sci. 2011, 10, 1652–1658. [Google Scholar] [CrossRef] [PubMed]

- Guilbault, G.G.; Kramer, D.N.; Cannon, P.L. Electrochemical determination of organophosphorus compounds. Anal. Chem. 1962, 34, 1437–1439. [Google Scholar] [CrossRef]

- Palecek, E. Past, present and future of nucleic acids electrochemistry. Talanta 2002, 56, 809–819. [Google Scholar] [CrossRef]

- Horvath, E.; Kukovecz, A.; Konya, Z.; Kiricsi, I. Hydrothermal conversion of self-assembled titanate nanotubes into nanowires in a revolving autoclave. Chem. Mater. 2007, 19, 927–931. [Google Scholar] [CrossRef]

- Wang, B.L.; Chen, Q.; Hu, J.; Li, H.; Hu, Y.F.; Peng, L.-M. Synthesis and characterization of large scale potassium titanate nanowires with good Li-intercalation performance. Chem. Phys. Lett. 2005, 406, 95–100. [Google Scholar] [CrossRef]

- Bavykin, D.V.; Carravetta, M.; Kulak, A.N.; Walsh, F.C. Application of magic-angle spinning NMR to examine the nature of protons in titanate nanotubes. Chem. Mater. 2010, 22, 2458–2463. [Google Scholar] [CrossRef]

- Lee, S.Y.; Matsuno, R.; Ishihara, K.; Takai, M. Electrical transport ability of nanostructured potassium-doped titanium oxide film. Appl. Phys. Express 2011, 4, 025803. [Google Scholar] [CrossRef]

- Malati, M.A.; Wong, W.K. Doping TiO2 for solar energy applications. Surf. Technol. 1984, 22, 305–322. [Google Scholar] [CrossRef]

- Wong, W.K.; Malati, M.A. Doped TiO2 for solar energy applications. Sol. Energy 1986, 36, 163–168. [Google Scholar] [CrossRef]

- Rophael, M.W.; Malati, M.A. The photocatalysed reduction of aqueous sodium carbonate using platinized titania. J. Photochem. Photobiol. A 1989, 46, 367–377. [Google Scholar] [CrossRef]

- Kudo, A.; Kondo, T. Photoluminescent and photocatalytic properties of layered caesium titanates, Cs2TinO2n+1 (n = 2,5,6). J. Mater. Chem. 1997, 7, 777–780. [Google Scholar] [CrossRef]

- Shibata, M.; Kudo, A.; Tanaka, A.; Domen, K.; Maruya, K.; Onishi, T. Photocatalytic activities of layered titanium compounds and their derivatives for H2 evolution from aqueous methanol solution. Chem. Lett. 1987, 113, 1017–1018. [Google Scholar] [CrossRef]

- Sato, T.; Yamamoto, Y.; Fujishiro, Y.; Uchida, S.J. Intercalation of iron oxide in layered H2Ti4O9 and H4Nb6O17: Visible-light induced photocatalytic properties. Chem. Soc. Faraday Trans. 1996, 92, 5089–5092. [Google Scholar] [CrossRef]

- Fujishima, A.; Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef] [PubMed]

- Hoyer, P. Semiconductor nanotube formation by a two-step template process. Adv. Mater. 1996, 8, 857–859. [Google Scholar] [CrossRef]

- Lakshmi, B.B.; Patrissi, C.J.; Martin, C.R. Sol-gel template synthesis of semiconductor oxide micro- and nanostructures. Chem. Mater. 1997, 9, 2544–2550. [Google Scholar] [CrossRef]

- Yuan, Z.Y.; Zhou, W.; Su, B.L. Hierarchical interlinked structure of titanium oxide nanofibers. Chem. Commun. 2002, 11, 1202–1203. [Google Scholar] [CrossRef]

- Masaki, N.; Uchida, S.; Yamane, H.; Sato, T. Hydrothermal synthesis of potassium titanates in Ti-KOH-H2O system. J. Mater. Sci. 2000, 35, 3307–3311. [Google Scholar] [CrossRef]

- Fu, Y.; Du, H.; Huang, W.; Zhang, S.; Hu, M. TiNi-based thin films in MEMS applications: A review. Sens. Actuators A 2004, 112, 395–408. [Google Scholar] [CrossRef]

- Krulevitch, P.; Lee, A.P.; Ramsey, P.B.; Trevino, J.C.; Hamilton, J.; Northrup, M.A. Thin film shape memory alloy microactuators. J. Microelectromech. Syst. 1996, 5, 270–282. [Google Scholar] [CrossRef]

- Castro, A.T.; Cuellar, E.L.; Mendez, U.O.; Yacaman, M. Crystal structure of TiNi nanoparticles obtained by Ar ion beam deposition. Mater. Sci. Eng. A 2008, 481 482, 476–478. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Takai, M.; Kim, H.M.; Ishihara, K. Preparation of nano-structured titanium oxide Film for biosensor substrate by wet corrosion process. Curr. Appl. Phys. 2009, 9, e266–e269. [Google Scholar] [CrossRef]

- Lee, S.Y.; Matsuno, R.; Ishihara, K.; Takai, M. Direct electron transfer with enzymes on nanofiliform titanium oxide films with electron-transport ability. Biosens. Bioelectron. 2013, 4, 289–293. [Google Scholar] [CrossRef] [PubMed]

- Hashmimoto, K.; Irie, H.; Fujushima, A. TiO2 photocatalysis: A historical overview and future prospects. Jpn. J. Appl. Phys. 2005, 44, 8269. [Google Scholar] [CrossRef]

- Das, P.P.; Mohapatra, S.K.; Misra, M. Photoelectrolysis of water using heterostructural composite of TiO2 nanotubes and nanoparticles. J. Phys. D 2008, 41, 245103. [Google Scholar] [CrossRef]

- Benoit, A.; Paramasivam, I.; Nah, Y.C.; Roy, P.; Schmuki, P. Decoration of TiO2 nanotube layers with WO3 nanocrystal for high-electrochromic activity. Electrochem. Commun. 2009, 11, 728–732. [Google Scholar] [CrossRef]

- Deng, L.; Wang, S.; Liu, D.; Zhu, B.; Huang, W.; Wu, S.; Zhang, S. Synthesis, characterization of Fe-doped TiO2 nanotubes with high photocatalytic activity. Catal. Lett. 2009, 129, 513–518. [Google Scholar] [CrossRef]

- Wang, J.; Lin, Z. Dye-sensitized TiO2 nanotube solar cells with markedly enhanced performance via rational surface engineering. Chem. Mater. 2010, 22, 579–584. [Google Scholar] [CrossRef]

- Kim, H.-M.; Takadama, H.; Miyaji, F.; Kokubo, T. Formation of bioactive functionally graded structure on Ti-6Al-4V alloy by chemical surface treatment. J. Mater. Sci. Mater. Med. 2000, 11, 555–559. [Google Scholar] [CrossRef] [PubMed]

- Moulder, J.F.; Stickle, W.F.; Sobol, P.E.; Bomben, K.E. Handbook of X-ray Photoelectron Spectroscopy; Perkin-Elmer: Oxford, UK, 1992. [Google Scholar]

- Asami, K.; Hashimoto, K.; Shimodaira, S. XPS determination of composition of alloy surfaces and surface oxide on mechanically polished iron-chromium alloys. Corros. Sci. 1997, 17, 713–723. [Google Scholar] [CrossRef]

- Jesus, J.C.; Gonzalez, I.; Quevedo, A.; Puerta, T. Thermal decomposition of nickel acetate tetrahydrate: An integrated study by TGA, QMS and XPS techniques. J. Mol. Catal. A 2005, 228, 283–291. [Google Scholar] [CrossRef]

- Matienzo, L.J.; Yin, L.I.; Grim, S.O.; Swartz, W.E. X-ray photoelectron spectroscopy of nickel compounds. Inorg. Chem. 1973, 12, 2762–2769. [Google Scholar] [CrossRef]

- Biju, V.; Khadar, M.A. Electronic structure of nanostructured nickel oxide using Ni2p XPS analysis. J. Nanopart. Res. 2002, 4, 247–253. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, L.; Yao, Y.; Ding, Y.; Shen, X. Ti2Ni Alloy: A potential candidate for hydrogen storage in nickel/metal hydride secondary batteries. Energy Environ. Sci. 2010, 3, 1316–1321. [Google Scholar] [CrossRef]

- Ali, A.M.; Hasegawa, S. Effect of hydrogen dilution on the growth of nanocrystalline silicon films at high temperature by using plasma-enhanced chemical vapor deposition. Thin Solid Films 2003, 437, 68–73. [Google Scholar] [CrossRef]

- Sakat, S.; Miyaji, F.; Fukumi, K. Structure of binary K2O-TiO2 and Cs2O-TiO2 glasses. J. Non Cryst. Solids 1989, 112, 64–68. [Google Scholar]

- Su, Y.; Balmer, M.L.; Bunker, B.C. Raman spectroscopic studies of silicotitanates. J. Phys. Chem. B 2000, 104, 8160–8169. [Google Scholar] [CrossRef]

- Liu, C.; Lu, X.; Yu, G.; Feng, X.; Zhang, Q.; Xu, Z. Role of an intermediate phase in solid state reaction of hydrous titanium oxide with potassium carbonate. Mater. Chem. Phys. 2005, 94, 401–407. [Google Scholar] [CrossRef]

- Bunker, B.C.; Peden, C.H. F.; Tallant, D.R.; Martinez, S.L.; Turner, G.L. Raman and NMR studies of hydrous sodium titanates. Mater. Res. Soc. Symp. Proc. 1998, 121, 105–110. [Google Scholar] [CrossRef]

- Miyaji, F.; Yoko, T.; Kozuka, H.; Sakka, S. Structure of Na2O·2TiO2 glass. J. Mater. Sci. 1991, 26, 248–252. [Google Scholar] [CrossRef]

- Ocana, M.; Garcia-Rpmps, J.V.; Serna, C.J. Low-temperature nucleation of rutile observed by raman spectroscopy during crystallization of TiO2. J. Am. Ceram. Soc. 1992, 75, 2010–2012. [Google Scholar] [CrossRef]

- Anderson, S.; Wadsley, A.A. The crystal structure of K2Ti2O5. Acta Chem. Scand. 1961, 15, 663–669. [Google Scholar] [CrossRef]

- Brus, L.E. Electron-electron and electron-hole interactions in small semiconductor crystallites: The size dependence of the lowest excited electronic state. J. Chem. Phys. 1984, 80, 4403–4409. [Google Scholar] [CrossRef]

- Kavan, L.; Gratzel, M.; Gilbert, S.E.; Klemenz, C.; Scheel, H.J. Electrochemical and photoelectorochemical investigation of single-crystal anatase. J. Am. Chem. Soc. 1996, 118, 6716–6723. [Google Scholar] [CrossRef]

- Bokhimi, X.; Morales, A.; Aguilar, M.; Toledo-Antonio, J.A.; Pedraza, F. Local order in titania polymorphs. Int. J. Hydrog. Energy 2001, 26, 1279–1287. [Google Scholar] [CrossRef]

- Jose, R.; Thavasi, V.; Ramakrishna, S. Metal oxides for dye-sensitized solar cells. J. Am. Ceram. Soc. 2009, 92, 289–301. [Google Scholar] [CrossRef]

- Hostetler, M.J.; Zhong, C.J.; Yen, B.K.H.; Anderegg, J.; Gross, S.M.; Evans, N.D.; Porter, M.; Murray, R.W. Stable, monolayer-protected metal alloy clusters. J. Am. Chem. Soc. 1998, 120, 9396–9397. [Google Scholar] [CrossRef]

- Sangpour, P.; Akhavan, O.; Moshfegh, A.Z. RF reactive co-sputtered Au-Ag alloy nanoparticles in SiO2 thin films. Appl. Surf. Sci. 2007, 253, 7438–7442. [Google Scholar] [CrossRef]

- Consadori, F.; Frindt, R.F. Crystal size effects on the exciton absorption spectrum of WSe2. Phys. Rev. B 1970, 2, 4893–4896. [Google Scholar] [CrossRef]

- Duan, C.-G.; Mei, W.N.; Liu, J.; Hardy, J.R. First-principles study on the optical properties of KNbO3. J. Phys. Condens. Matter. 2001, 13, 8189–8195. [Google Scholar] [CrossRef]

- Kang, X.W.; Chen, S.W. Photocatalytic reduction of methylene blue by TiO2 nanotube arrays: Effects of TiO2 crystalline phase. J. Mater. Sci. 2010, 45, 2696–2702. [Google Scholar] [CrossRef]

- Tan, B.; Wu, Y. High efficiency dye-sensitized solar cell based on novel TiO2 nanorod/nanoparticle bilayer electrode. J. Phys. Chem. B 2006, 110, 15932–15938. [Google Scholar] [CrossRef] [PubMed]

- Pavasupree, S.; Ngamsinlapasathian, S.; Nakajima, M.; Suzuki, Y.; Yoshikawa, S. Synthesis, characterization, photocatalytic activity and dye-sensitized solar cell performance of nanorods/nanoparticles TiO2 with mesoporous structur. J. Photochem. Photobiol. A 2006, 184, 163–169. [Google Scholar] [CrossRef]

- Torres-Martínez, C.L.; Kho, R.; Mian, O.I.; Mehra, R.K. Efficient photocatalytic degradation of environmental pollutants with mass-produced ZnS nanocrystals. J. Colloid Interface Sci. 2001, 240, 525–532. [Google Scholar] [CrossRef] [PubMed]

- Pouretedal, H.R.; Norozi, A.; Keshavarz, M.H.; Semnani, A. Nanoparticles of zinc sulfide doped with manganese, nickel and copper as nanophotocatalyst in the degradation of organic dyes. J. Hazard. Mater. 2009, 162, 674–681. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Nosaka, Y. Mechanism of the OH radical generation in photocatalysis with TiO2 of different crystalline types. J. Phys. Chem. C 2014, 118, 10824–10832. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.Y.; Lee, C.H.; Kim, D.Y.; Locquet, J.-P.; Seo, J.W. Preparation and Photocatalytic Activity of Potassium- Incorporated Titanium Oxide Nanostructures Produced by the Wet Corrosion Process Using Various Titanium Alloys. Nanomaterials 2015, 5, 1397-1417. https://doi.org/10.3390/nano5031397

Lee SY, Lee CH, Kim DY, Locquet J-P, Seo JW. Preparation and Photocatalytic Activity of Potassium- Incorporated Titanium Oxide Nanostructures Produced by the Wet Corrosion Process Using Various Titanium Alloys. Nanomaterials. 2015; 5(3):1397-1417. https://doi.org/10.3390/nano5031397

Chicago/Turabian StyleLee, So Yoon, Choong Hyun Lee, Do Yun Kim, Jean-Pierre Locquet, and Jin Won Seo. 2015. "Preparation and Photocatalytic Activity of Potassium- Incorporated Titanium Oxide Nanostructures Produced by the Wet Corrosion Process Using Various Titanium Alloys" Nanomaterials 5, no. 3: 1397-1417. https://doi.org/10.3390/nano5031397

APA StyleLee, S. Y., Lee, C. H., Kim, D. Y., Locquet, J.-P., & Seo, J. W. (2015). Preparation and Photocatalytic Activity of Potassium- Incorporated Titanium Oxide Nanostructures Produced by the Wet Corrosion Process Using Various Titanium Alloys. Nanomaterials, 5(3), 1397-1417. https://doi.org/10.3390/nano5031397