Long Period Grating Modified with Quasi-2D Perovskite/PAN Hybrid Nanofibers for Relative Humidity Measurement

Abstract

1. Introduction

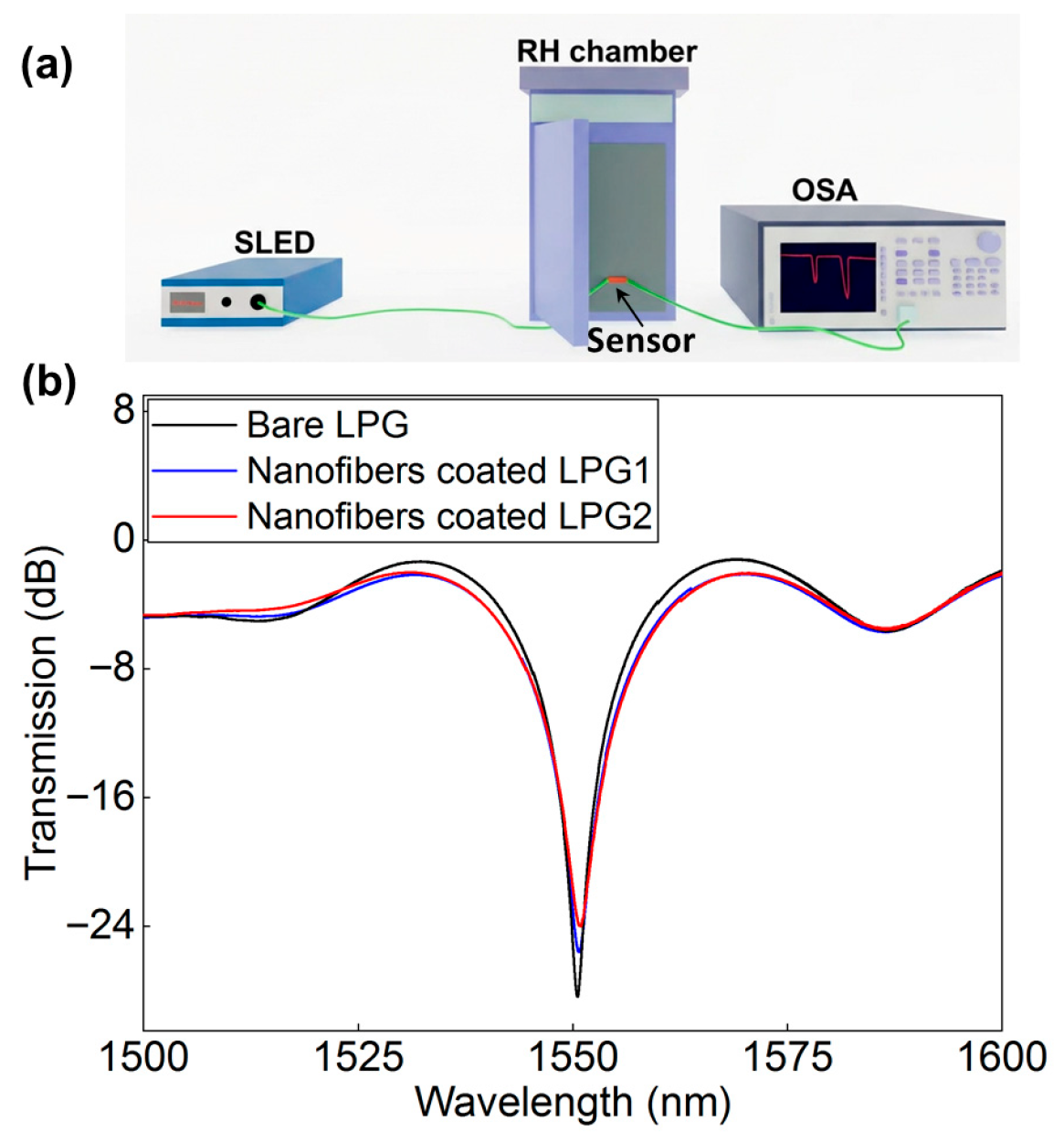

2. Materials and Characterization

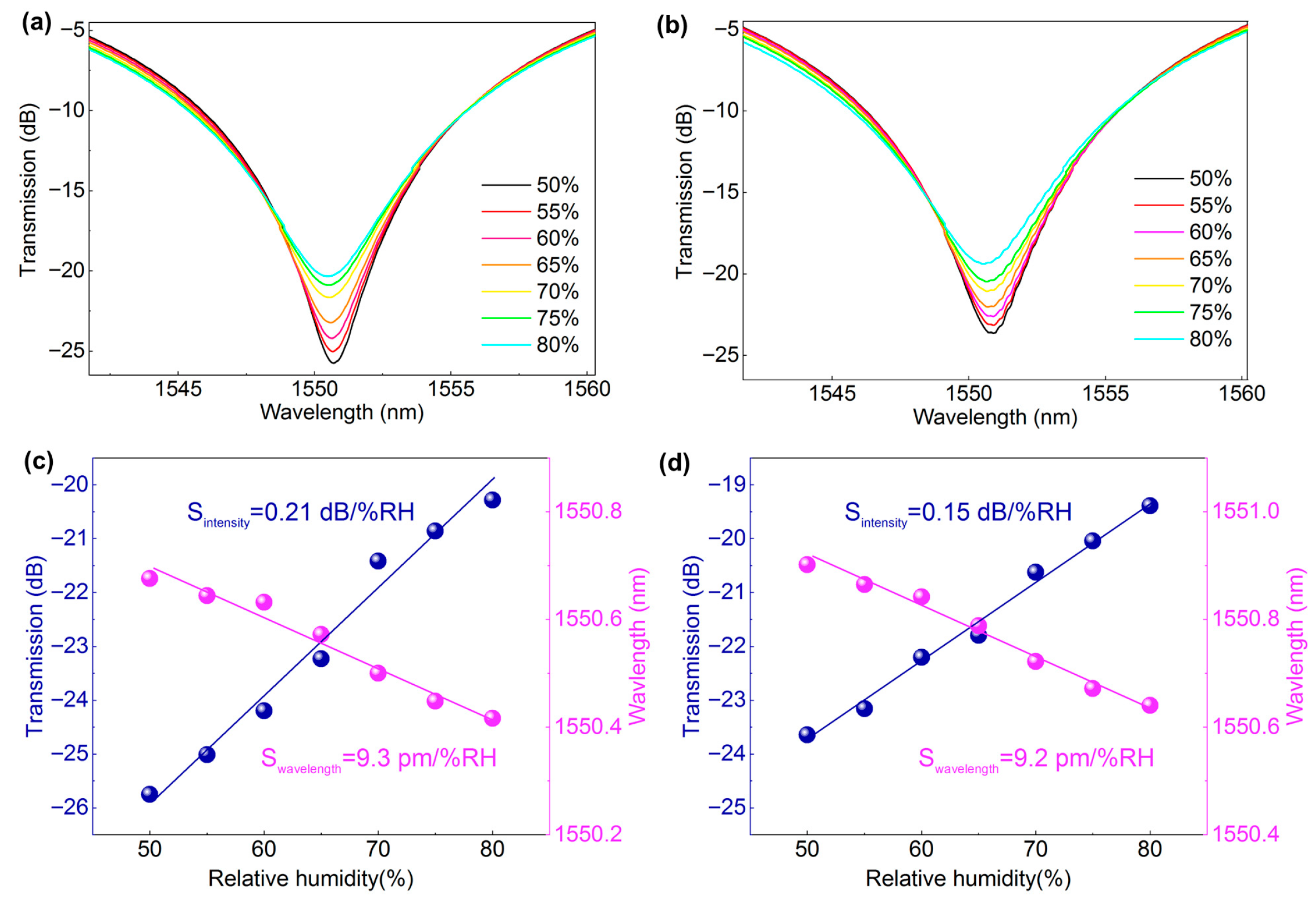

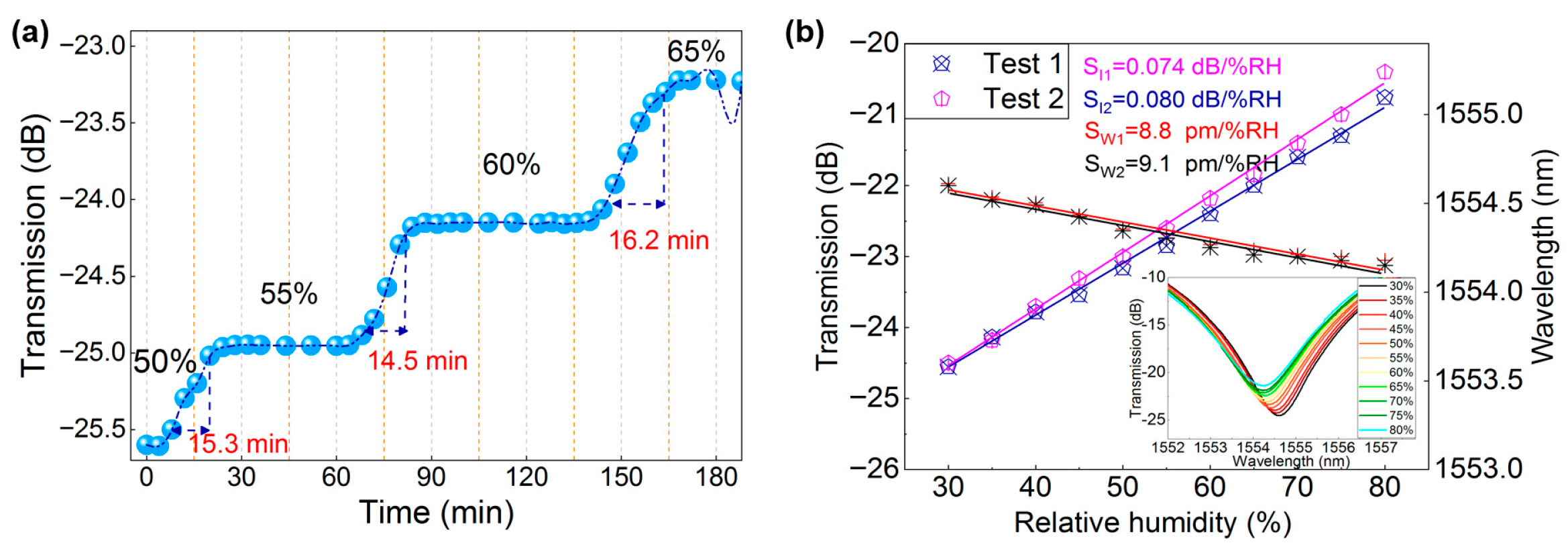

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jindal, R.; Tao, S.; Singh, J.P.; Gaikwad, P.S. High dynamic range fiber optic relative humidity sensor. Opt. Eng. 2002, 41, 1093–1096. [Google Scholar] [CrossRef]

- Wu, S.; Yan, G.; Lian, Z.; Chen, X.; Zhou, B.; He, S. An open-cavity Fabry-Perot interferometer with PVA coating for simultaneous measurement of relative humidity and temperature. Sens. Actuators B Chem. 2016, 225, 50–56. [Google Scholar] [CrossRef]

- Li, C.; Yu, X.; Zhou, W.; Cui, Y.; Liu, J.; Fan, S. Ultrafast miniature fiber-tip Fabry–Perot humidity sensor with thin graphene oxide diaphragm. Opt. Lett. 2018, 43, 4719–4722. [Google Scholar] [CrossRef]

- Deng, S.; Meng, H.; Wang, X.; Fan, X.; Wang, Q.; Zhou, M.; Guo, X.; Wei, Z.; Wang, F.; Tan, C.; et al. Graphene oxide-film-coated splitting ratio adjustable Mach-Zehnder interferometer for relative humidity sensing. Opt. Express 2019, 27, 9232–9240. [Google Scholar] [CrossRef]

- Bariain, C.; Matias, I.R.; Arregui, F.J.; López-Amo, M. Optical fiber humidity sensor based on a tapered fiber coated with agarose gel. Sens. Actuators B Chem. 2000, 69, 127–131. [Google Scholar] [CrossRef]

- Wong, W.; Chan, C.; Chen, L.; Li, T.; Lee, K.; Leong, C. Polyvinyl alcohol coated photonic crystal optical fiber sensor for humidity measurement. Sens. Actuators B Chem. 2012, 174, 563–569. [Google Scholar] [CrossRef]

- Zhu, K.; Cheng, X.; Zhao, Z.; Lu, C. High-sensitivity, high-resolution polymer fiber Bragg grating humidity sensor harnessing microwave photonic filtering response analysis. Opt. Lett. 2020, 45, 6603–6606. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, J.; He, X.; Yuan, J.; Wu, Q.; Liu, B. Long-period fiber grating based on side-polished optical fiber and its sensing application. IEEE Trans. Instrum. Meas. 2023, 72, 7001109. [Google Scholar] [CrossRef]

- Jing, L.; Liu, B.; Liu, D.; Liu, D.; Wang, F.; Guan, C.; Wang, Y.; Liao, C. Femtosend laser inscribed excessively tilted fiber grating for humidity sensing. Sensors 2024, 24, 342. [Google Scholar] [CrossRef]

- Mustaffa, S.N.; Rashid, A.R.A.; Jin, T.S.; Menon, P.S.; Razak, M.Z.A.; Markom, A.M. Metal Oxide Coated Optical Fiber for Humidity Sensing Application: A Review. IEEE Access 2023, 11, 126568–126600. [Google Scholar] [CrossRef]

- He, J.; Richardson, C.J.K.; Hu, X. Robust, high-sensitivity, and broadband long-period waveguide gratings on SOI for sensing applications. Photonics Res. 2022, 10, 2156–2165. [Google Scholar]

- Hossain, A.K.M.S.; Mozumder, S.M.R.H.; Paul, B.K. A comprehensive design of slotted circular photonic crystal fiber for extremely high relative sensitivity with low confinement loss. Opt. Commun. 2021, 479, 126092. [Google Scholar]

- Wang, B.; Han, B.; Wang, K.; Cao, S. Air vehicle humidity sensor based on PVA film humidity sensing principle. APL Mater. 2024, 12, 071116. [Google Scholar] [CrossRef]

- Tsai, Y.T.; Wu, C.W.; Tsai, L.; Chiang, C. Application of graphene oxide-based, long-period fiber grating for sensing relative humidity. J. Light. Technol. 2020, 39, 4124–4130. [Google Scholar] [CrossRef]

- Wang, F.; Wang, B.; Zhang, X.; Lu, M.; Zhang, Y.; Sun, C.; Peng, W. High sensitivity humidity detection based on Functional GO/MWCNTs hybrid nano-materials coated titled fiber Bragg grating. Nanomaterials 2021, 11, 1134. [Google Scholar] [CrossRef]

- Peng, J.; Zhou, J.; Sun, C.; Liu, Q. Optical fiber temperature and humidity dual parameter sensing based on fiber Bragg gratings and porous film. Sensors 2023, 23, 7587. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Gong, H.; He, X.; Xu, B.; Zhao, C. Simultaneous measurement of temperature and humidity based on phase-shifted fiber Bragg grating and Fabry–Perot. IEEE Sens. J. 2025, 25, 35974–35981. [Google Scholar] [CrossRef]

- Uto, K.; Liu, Y.; Mu, M.; Yamamoto, R.; Azechi, C.; Tenjimbayashi, M.; Kaeser, A.; Marliac, A.; Alam, M.; Sasai, J.; et al. Humidity-responsive polyvinyl alcohol/microcrystalline cellulose composites with shape memory features for hair-styling applications. Adv. Mater. Interfaces 2024, 11, 230027. [Google Scholar] [CrossRef]

- Feng, D.; Zheng, H.; Sun, H.; Li, J.; Xi, J.; Deng, L.; Guo, Y.; Jiang, B.; Zhao, J. SnO2/Polyvinyl alcohol nanofibers wrapped tilted fiber grating for high-sensitive humidity sensing and fast human breath monitoring. Sens. Actuators. B Chem. 2023, 388, 133807. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, L.; Wang, N.; Yu, T.; Sun, W.; Luo, N.; Feng, Y.; Liu, W.; Wang, D. Humidity-resistant triboelectric nanogenerator based on a swelling-resistant and antiwear PAN/PVA-CACL2 composite film for seawater desalination. Adv. Funct. Mater. 2024, 34, 2306702. [Google Scholar] [CrossRef]

- Wei, K.; Zhou, T.; Jiang, Y.; Sun, C.; Liu, Y.; Li, S.; Liu, S.; Fu, X.; Hu, C.; Tian, S.; et al. Perovskite heteroepitaxy for high-efficiency and stable pure-red LEDs. Nature 2025, 638, 949–956. [Google Scholar] [CrossRef]

- Wang, C.; He, B.; Hui, W.; Su, Z.; Chen, L.; Du, W.; Zhang, L.; Zhang, J.; Fu, M.; Wang, H.; et al. Controlling water for enhanced homogeneities in perovskite solar cells with remarkable reproducibility. Adv. Funct. Mater. 2024, 34, 2403690. [Google Scholar] [CrossRef]

- Berhe, T.; Su, W.; Chen, C.; Pan, C.; Cheng, J.; Chen, H.; Tsai, M.; Chen, L.; Dubale, A.; Hwang, B. Organometal halide perovskite solar cells: Degradation and stability. Energ. Environ. Sci. 2016, 9, 323–356. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F.; Zhong, C.; Dong, X.; Tong, L. Fiber optic relative humidity sensor based on the tilted fiber Bragg grating coated with graphene oxide. Appl. Phys. Lett. 2016, 109, 031107. [Google Scholar] [CrossRef]

- Jiang, B.; Zhao, J. Nanomaterial-functionalized tilted fiber gratings for optical modulation and sensing (Invited). J. Light. Technol. 2023, 41, 4103–4113. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, P.; Yang, Q.; Wu, J.; Zhao, J.; Jiang, B. Generation of Multiple and Ultra-High Slope Fano-Like Resonances via MZI and Cascaded Fiber Gratings. Opt. Lasers Eng. 2024, 194, 109223. [Google Scholar] [CrossRef]

- Erdogan, T. Cladding-mode resonances in short- and long-period fiber grating filters. J. Opt. Soc. Amer. A 1997, 14, 1760–1773. [Google Scholar] [CrossRef]

- Koyamada, Y. Numerical analysis of core-mode to radiation-mode coupling in long-period fiber gratings. IEEE Photon. Technol. Lett. 2001, 13, 308–310. [Google Scholar] [CrossRef]

- Li, H.; Hu, S.; Wang, H.; Zhang, X.; Tong, Y.; Qi, H.; Guo, P.; Zhao, G.; Gao, J.; Liu, P.; et al. Control of n-Phase distribution in quasi two-dimensional perovskite for efficient blue light-emitting diodes. ACS Appl. Mater. Inter. 2023, 15, 9574–9583. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, Y.; Deng, J. Chiral Helical Polymer/Perovskite Hybrid Nanofibers with Intense Circularly Polarized Luminescence. ACS Nano 2021, 15, 7463–7471. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, J.; Li, M.; Zhang, Q. Ultra-High Sensitivity Humidity Sensor Based on a Graphene-Oxide-Coated Step-Index Fiber Surface Core-Mode Interferometer. Sens. Actuators Rep. 2024, 7, 100204. [Google Scholar]

- Zhang, W.; Li, X.; Chen, H.; Wang, Y. Ultra-Sensitive Humidity Sensor Based on Harmonic Vernier Effect in Parallel Fabry–Perot Interferometers with PVA/Graphene Quantum Dots Coating. Opt. Express. 2024, 32, 7957–7970. [Google Scholar]

- Li, S.; Zhang, F.; Wu, T.; Zhou, Y. A Temperature-Insensitive Humidity Sensor Based on a Tapered Coreless Fiber MZI Coated with Fe2O3 Nanorods and Cascaded with an FBG. IEEE Sens. 2024, 24, 18471–18479. [Google Scholar]

- Wang, L.; Sun, K.; Zhao, D.; Ma, R. A Compact Humidity Sensor Probe Based on a Tapered Multimode Fiber Michelson Interferometer Coated with Calcium Alginate Hydrogel. J. Opt. Soc. Am. B 2024, 41, 1234–1240. [Google Scholar]

- Chen, X.; Liu, Y.; Wang, S.; Xu, Z. Fast-Response and Highly Sensitive Humidity Sensor Based on a GO-PVA Coated Fiber Bragg Grating. J. Optoelectron. Laser. 2024, 35, 123–130. [Google Scholar]

- Li, H.; Zhang, R.; Yang, L.; Liu, J. A Wide-Range and Stable Optical Fiber Humidity Sensor Based on a Chitosan/PVA/Carbon Nanopowder Coated FBG. Acta Opt. Sin. 2024, 44, 0506001. [Google Scholar]

- Wang, Q.; Sun, L.; Ma, X.; Li, F. Millisecond-Level Response Humidity Sensor Based on a C60-Lys Coated Tilted Fiber Bragg Grating for Respiratory Monitoring. Chin. Opt. Lett. 2024, 22, 010602. [Google Scholar]

- Xu, K.; He, J.; Lin, W.; Ding, Y. A Fast-Response Optical Fiber Humidity Sensor Based on SiO2-Capped ZnO Quantum Dots for Respiratory and Acoustic Sensing. Appl. Opt. 2024, 63, 2319–2326. [Google Scholar]

- Zhou, M.; Xie, G.; Cai, H.; Dong, L. A Linearly Fast-Response Optical Fiber Humidity Sensor Based on a Carbomer-Coated Biconical Weakly-Coupled Structure. Phys. Scr. 2024, 99, 055510. [Google Scholar]

| Structure | Sensing Material | Sensitivity | Response/Recovery Time | Refs. |

|---|---|---|---|---|

| Step-index fiber surface core-mode interferometer | Graphene Oxide (GO) | 707.3 pm/%RH | 4.8 s/8.4 s | [31] |

| Parallel FPIs (Harmonic Vernier effect) | PVA-Graphene Quantum Dots (GQDs) | 7.3343 nm/%RH | / | [32] |

| Tapered coreless fiber MZI (cascaded with FBG) | Fe2O3 nanorods | 0.3332 nm/%RH | / | [33] |

| Tapered multimode fiber Michelson probe | Calcium Alginate hydrogel | 0.31015 nm/%RH | / | [34] |

| FBG | Chitosan/PVA/Carbon Nanopowder | 57.7 pm/%RH | 420 s/540 s | [35] |

| FBG | Polyimide (PI) | 5.5 pm/%RH | / | [36] |

| Tilted FBG | Fullerene derivative (C60-Lys) | 0.080 dB/%RH | 40 ms/41 ms | [37] |

| Plastic-clad silica fiber | SiO2-capped ZnO QDs | 46.2 mV/%RH | 2.0 s/2.5 s | [38] |

| Biconical weakly coupled structure | Carbomer | −0.28 dB/%RH | 208 ms/464 ms | [39] |

| LPG | Quasi-2D Perovskite/PAN Hybrid Nanofibers | 18.2 pm/%RH and 0.21 dB/%RH | 980 s | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Feng, D.; Zhang, C.; Haider, S.I.; Tian, J.; Wu, J.; Liu, F.; Jiang, B. Long Period Grating Modified with Quasi-2D Perovskite/PAN Hybrid Nanofibers for Relative Humidity Measurement. Nanomaterials 2026, 16, 99. https://doi.org/10.3390/nano16020099

Feng D, Zhang C, Haider SI, Tian J, Wu J, Liu F, Jiang B. Long Period Grating Modified with Quasi-2D Perovskite/PAN Hybrid Nanofibers for Relative Humidity Measurement. Nanomaterials. 2026; 16(2):99. https://doi.org/10.3390/nano16020099

Chicago/Turabian StyleFeng, Dingyi, Changjiang Zhang, Syed Irshad Haider, Jing Tian, Jiandong Wu, Fu Liu, and Biqiang Jiang. 2026. "Long Period Grating Modified with Quasi-2D Perovskite/PAN Hybrid Nanofibers for Relative Humidity Measurement" Nanomaterials 16, no. 2: 99. https://doi.org/10.3390/nano16020099

APA StyleFeng, D., Zhang, C., Haider, S. I., Tian, J., Wu, J., Liu, F., & Jiang, B. (2026). Long Period Grating Modified with Quasi-2D Perovskite/PAN Hybrid Nanofibers for Relative Humidity Measurement. Nanomaterials, 16(2), 99. https://doi.org/10.3390/nano16020099