A Single-Layer Full-Color Diffractive Waveguide by Lithography

Abstract

1. Introduction

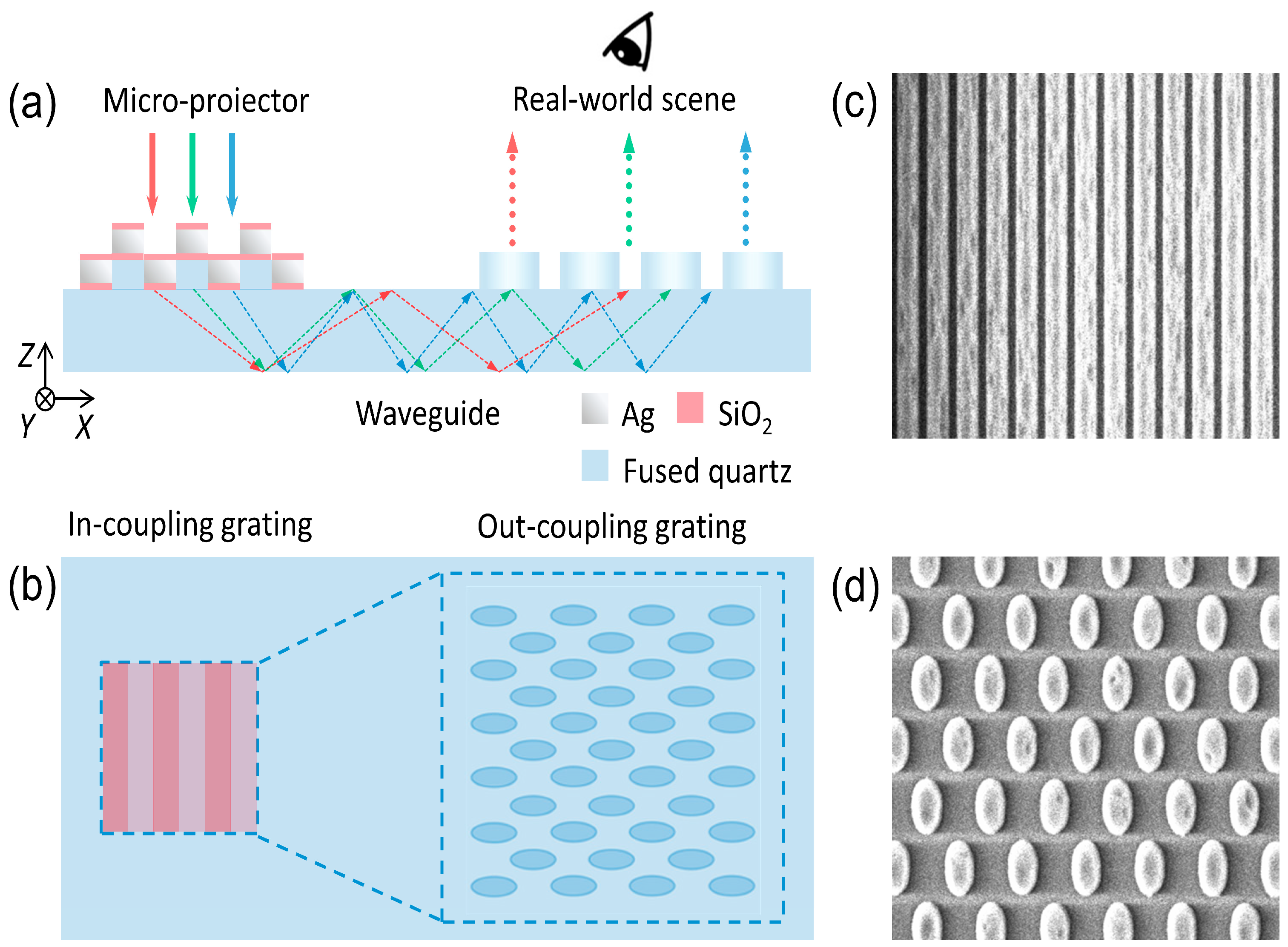

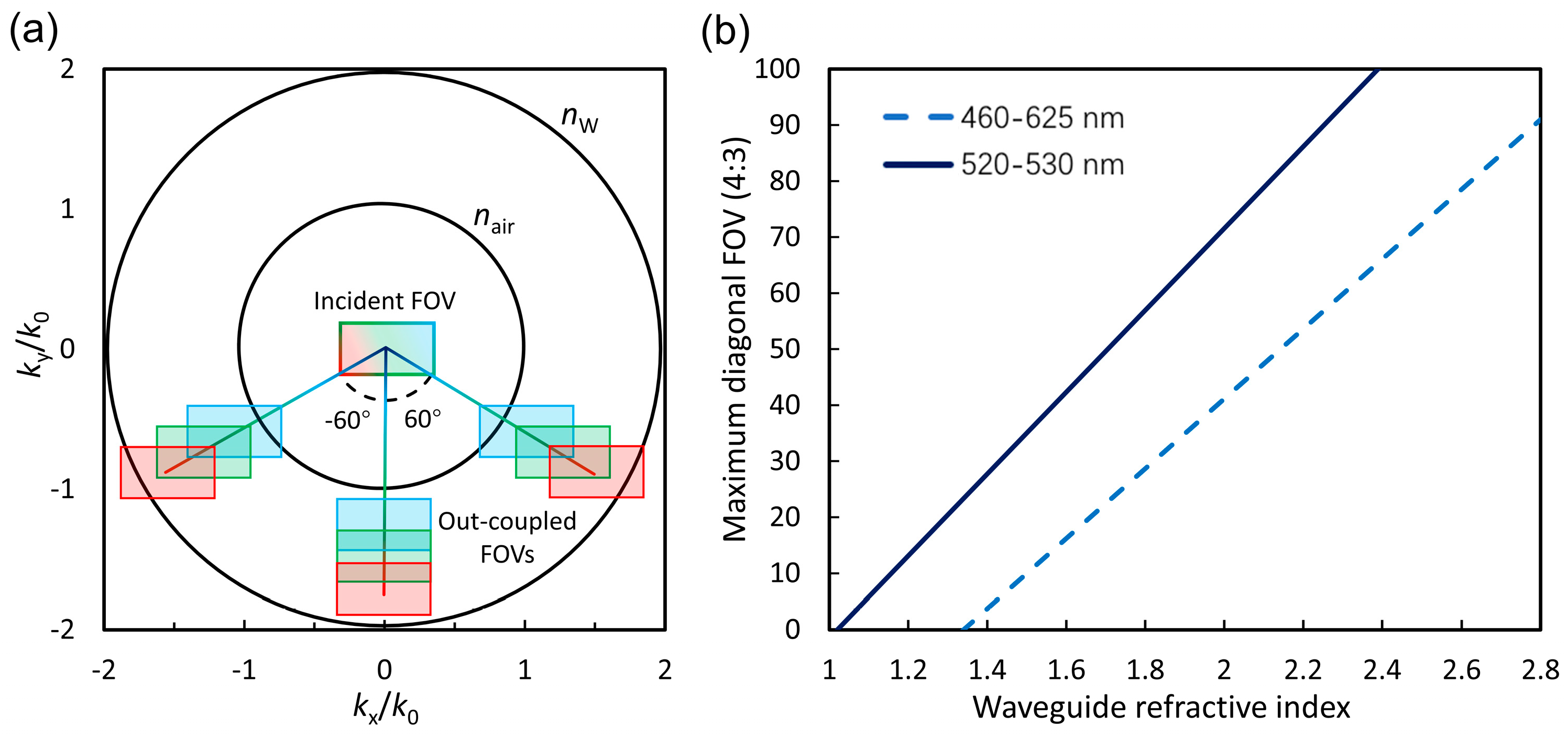

2. Theoretical Fundamentals of Diffractive Waveguide

3. Waveguide Design and Simulation

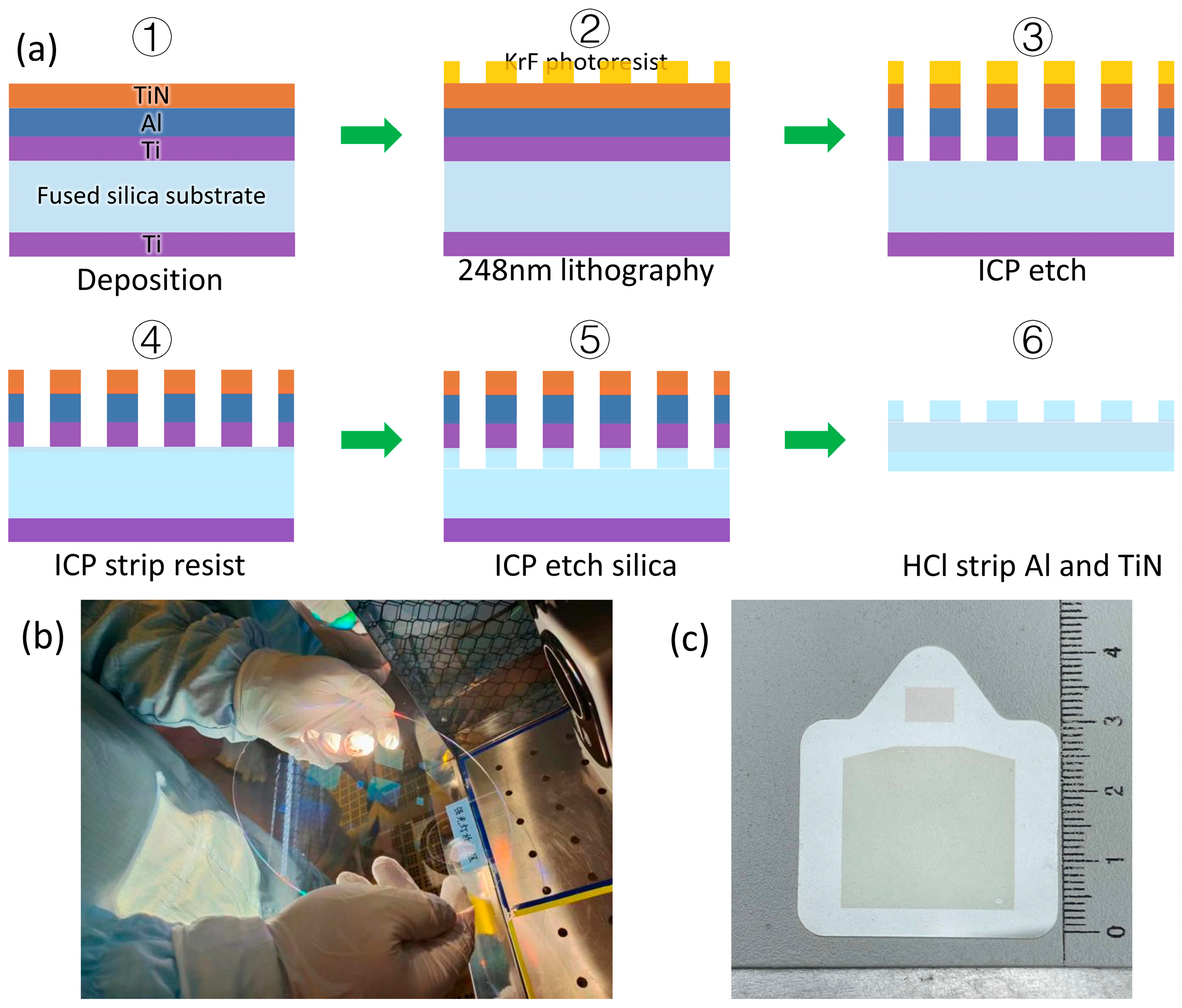

4. Fabrication and Measurement Experiments

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AR | Augmented Reality |

| NEDs | Near-Eye Displays |

| FOV | Field of View |

| RGB | Red, Green, Blue |

| TIR | Total Internal Reflection |

| SEM | Scanning Electron Microscopy |

| RCWA | Rigorous Coupled Wave Analysis |

| DUVL | Deep Ultraviolet Lithography |

| IC | Integrated Circuit |

| PECVD | Plasma-Enhanced Chemical Vapor Deposition |

| EBL | Electron Beam Lithography |

| PVD | Physical Vapor Deposition |

| DLP | Digital Light Processing |

| CMOS | Complementary Metal–Oxide-Semiconductor |

| NIL | Nanoimprint Lithography |

| Al | Aluminum |

| TiN | Titanium Nitride |

| SiO2 | Silicon Dioxide |

References

- Kress, B.; Saeedi, E.; Brac-de-la-Perriere, V. The segmentation of the HMD market: Optics for smart glasses, smart eyewear, AR and VR headsets. In Proceedings of the Photonics Applications for Aviation, Aerospace, Commercial, and Harsh Environments V, San Diego, CA, USA, 18–21 August 2014; SPIE: Bellingham, WA, USA, 2014; Volume 9202, pp. 107–120. [Google Scholar] [CrossRef]

- Cheng, D.; Duan, J.; Chen, H.; Wang, H.; Li, D.; Wang, Q.; Hou, Q.; Yang, T.; Hou, W.; Wang, D.; et al. Freeform OST-HMD system with large exit pupil diameter and vision correction capability. Photonics Res. 2022, 10, 21–32. [Google Scholar] [CrossRef]

- Osmanis, K.; Zabels, R.; Ozols, A.; Narels, M.; Gertners, U.; Rūtenbergs, K.; Osmanis, I. Accommodation corrected 3D displays using spatial volume demultiplexer chip. In Proceedings of the Digital Optical Technologies 2019, Munich, Germany, 24–26 June 2019; SPIE: Bellingham, WA, USA, 2019; Volume 11062, pp. 131–140. [Google Scholar]

- Wang, Q.; Cheng, D.; Hou, Q.; Gu, L.; Wang, Y. Design of an ultra-thin, wide-angle, stray-light-free near-eye display with a dual-layer geometrical waveguide. Opt. Express 2020, 28, 35376–35394. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Fang, F. Design of a large field-of-view two-dimensional geometrical waveguide. Results Opt. 2021, 5, 100147. [Google Scholar] [CrossRef]

- Shishova, M.; Zherdev, A.; Odinokov, S.; Venediktov, V.; Lushnikov, D.; Kim, Y. Selective Couplers Based on Multiplexed Volume Holographic Gratings for Waveguide Displays. Photonics 2021, 8, 232. [Google Scholar] [CrossRef]

- Gu, Y.; Weng, Y.; Wei, R.; Shen, Z.; Wang, C.; Zhang, L.; Zhang, Y. Holographic Waveguide Display With Large Field of View and High Light Efficiency Based on Polarized Volume Holographic Grating. IEEE Photonics J. 2022, 14, 7003707. [Google Scholar] [CrossRef]

- Moharam, M.G.; Gaylord, T.K. Diffraction analysis of dielectric surface-relief gratings. J. Opt. Soc. Am. 1982, 72, 1385–1392. [Google Scholar] [CrossRef]

- Xiong, J.; Hsiang, E.-L.; He, Z.; Zhan, T.; Wu, S.-T. Augmented reality and virtual reality displays: Emerging technologies and future perspectives. Light Sci. Appl. 2021, 10, 216. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Zhao, Z.; Shi, X.; Li, X.; Wang, B.; Xue, Z.; Li, S. Optimization of gratings in a diffractive waveguide using relative-direction-cosine diagrams. Opt. Express 2021, 29, 36720–36733. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, Q.; Li, Y.; Yang, Z.; Wang, Z.; Liang, H.; Wu, S.-T. Waveguide-based augmented reality displays: Perspectives and challenges. eLight 2023, 3, 24. [Google Scholar] [CrossRef]

- Hsiao, F.-L.; Chen, P.-C.; Peng, Y.-H.; Su, W.-C.; Lin, W.-K.; Tsai, Y.-P. Analysis of surface relief grating waveguide based on finite element method. In Proceedings of the Photonic Fiber and Crystal Devices: Advances in Materials and Innovations in Device Applications XVII, San Diego, CA, USA, 20 August 2023; SPIE: Bellingham, WA, USA, 2023; Volume 12682, pp. 31–36. [Google Scholar]

- Li, Z.; Gao, C.; Li, H.; Wu, R.; Liu, X. Angular uniformity improvement of diffractive waveguide display based on region geometry optimization. Appl. Opt. 2024, 63, 2494–2502. [Google Scholar] [CrossRef]

- Ding, Y.; Gu, Y.; Yang, Q.; Yang, Z.; Huang, Y.; Weng, Y.; Zhang, Y.; Wu, S.-T. Breaking the in-coupling efficiency limit in waveguide-based AR displays with polarization volume gratings. Light Sci. Appl. 2024, 13, 185. [Google Scholar] [CrossRef]

- Yu, N.; Capasso, F. Flat optics with designer metasurfaces. Nat. Mater. 2014, 13, 139–150. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Lin, P.; Huang, Y.-W.; Park, J.-S.; Chen, W.T.; Shi, Z.; Qiu, C.-W.; Cheng, J.-X.; Capasso, F. Meta-optics achieves RGB-achromatic focusing for virtual reality. Sci. Adv. 2021, 7, eabe4458. [Google Scholar] [CrossRef]

- Chang, S.; Guo, X.; Ni, X. Optical metasurfaces: Progress and applications. Annu. Rev. Mater. Res. 2018, 48, 279–302. [Google Scholar] [CrossRef]

- Kamali, S.M.; Arbabi, E.; Arbabi, A.; Faraon, A. A review of dielectric optical metasurfaces for wavefront control. Nanophotonics 2018, 7, 1041–1068. [Google Scholar] [CrossRef]

- Byrnes, S.J.; Lenef, A.; Aieta, F.; Capasso, F. Designing large, high-efficiency, high-numerical-aperture, transmissive meta-lenses for visible light. Opt. Express 2016, 24, 5110–5124. [Google Scholar] [CrossRef]

- Su, V.-C.; Chu, C.H.; Sun, G.; Tsai, D.P. Advances in optical metasurfaces: Fabrication and applications. Opt. Express 2018, 26, 13148–13182. [Google Scholar] [CrossRef]

- Baracu, A.M.; Avram, M.A.; Breazu, C.; Bunea, M.-C.; Socol, M.; Stanculescu, A.; Matei, E.; Thrane, P.C.V.; Dirdal, C.A.; Dinescu, A. Silicon metalens fabrication from electron beam to UV-nanoimprint lithography. Nanomaterials 2021, 11, 2329. [Google Scholar] [CrossRef]

- Hu, T.; Zhong, Q.; Li, N.; Dong, Y.; Xu, Z.; Fu, Y.H.; Li, D.; Bliznetsov, V.; Zhou, Y.; Lai, K.H. CMOS-compatible a-Si metalenses on a 12-inch glass wafer for fingerprint imaging. Nanophotonics 2020, 9, 823–830. [Google Scholar] [CrossRef]

- Park, J.-S.; Zhang, S.; She, A.; Chen, W.T.; Lin, P.; Yousef, K.M.; Cheng, J.-X.; Capasso, F. All-glass, large metalens at visible wavelength using deep-ultraviolet projection lithography. Nano Lett. 2019, 19, 8673–8682. [Google Scholar] [CrossRef]

- Li, N.; Xu, Z.; Dong, Y.; Hu, T.; Zhong, Q.; Fu, Y.H.; Zhu, S.; Singh, N. Large-area metasurface on CMOS-compatible fabrication platform: Driving flat optics from lab to fab. Nanophotonics 2020, 9, 3071–3087. [Google Scholar] [CrossRef]

- Brière, G.; Ni, P.; Héron, S.; Chenot, S.; Vézian, S.; Brändli, V.; Damilano, B.; Duboz, J.-Y.; Iwanaga, M.; Genevet, P. An etching-free approach toward large-scale light-emitting metasurfaces. Adv. Opt. Mater. 2019, 7, 1801271. [Google Scholar] [CrossRef]

- Moon, S.-W.; Kim, Y.; Yoon, G.; Rho, J. Recent progress on ultrathin metalenses for flat optics. Iscience 2020, 23, 101877. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Li, Y.; Wu, F.; Li, H.; Yang, H.; Wang, M.; Zheng, Z. A Single-Layer Full-Color Diffractive Waveguide by Lithography. Nanomaterials 2026, 16, 6. https://doi.org/10.3390/nano16010006

Li Y, Wu F, Li H, Yang H, Wang M, Zheng Z. A Single-Layer Full-Color Diffractive Waveguide by Lithography. Nanomaterials. 2026; 16(1):6. https://doi.org/10.3390/nano16010006

Chicago/Turabian StyleLi, Yong, Fei Wu, Huihui Li, Haitao Yang, Mengguang Wang, and Zhenrong Zheng. 2026. "A Single-Layer Full-Color Diffractive Waveguide by Lithography" Nanomaterials 16, no. 1: 6. https://doi.org/10.3390/nano16010006

APA StyleLi, Y., Wu, F., Li, H., Yang, H., Wang, M., & Zheng, Z. (2026). A Single-Layer Full-Color Diffractive Waveguide by Lithography. Nanomaterials, 16(1), 6. https://doi.org/10.3390/nano16010006