Abstract

Submicron particles are widely used in industrial applications due to their unique physical and mechanical properties that enhance the performance of composite materials. In particular, boron carbide particles are valued for their exceptional hardness and high wear resistance and are especially valuable in protective coatings and aerospace applications. However, these particles can agglomerate, significantly impairing their effectiveness. When this occurs during the development of composite materials, physical and mechanical properties are negatively affected. In this paper, a chemical-free method using a non-destructive, open-system dry mechanical deagglomeration technique is developed, leaving the primary particles unaltered, while breaking up strong adhesions between primary particles resulting from the manufacturing process. This method was tested for the deagglomeration of as-received boron carbide submicron particles, with an average primary particle diameter of d50 = 300 nm, and its effect on particle size distribution is presented. Furthermore, X-ray diffraction and true density measurements were carried out on the raw powder. Submicron particles in the dry and as-received state were poured into an experimental mold without a dispersing agent or a protective atmosphere. Static pressure was applied up to 141 MPa to produce tablets at room temperature, finding that 70 MPa yielded the best results in terms of homogeneity, dispersibility, and reproducibility. In order to break apart the densified pressed tablets, ultrasonication was applied before running particle size measurements in the wet dispersed state. Using a tri-laser diffraction light scattering technique, it was determined that particle size distribution followed a Gaussian curve, indicating that this method is suitable to regain the primary submicron particles with uniform properties. It is also shown that applying ultrasound on the as-received powder alone failed to cause the complete deagglomeration of strongly adhering primary particles. These findings suggest that there is no significant wear on the primary particles and no alteration of their surface chemistry, due to the lack of any chemically supported mechanisms such as the alteration of surface charge or the adsorption of surfactants. Furthermore, as the static pressure exerts an immediate impact on all particles in the mold, there is a clear economical advantage in terms of a shorter processing time over other deagglomeration methods such as high shear mixing.

1. Introduction

Tribological properties are a major focus of many engineering applications, including aerospace [1,2], aircraft [3,4], automotive [5,6], mining [7], wagon engineering [8] and marine sectors [9]. These specific physical and mechanical requirements often exceed the capabilities of single-phase materials. Composite materials are a promising alternative to traditional materials due to their unique and extended range of low friction and high wear resistance in various tribosystems [10,11,12,13,14] and mechanical properties, like microhardness [15,16,17]. They are created by dispersing one or more solid phases in another solid matrix, e.g., by means of composite electroplating [15,18,19]. Dispersoids usually take the form of fibers, spheres, flakes and platelets. The use of materials based on conventional micrometer-sized particles leads to a limitation of the achievable physical and mechanical properties, sometimes conflicting with the requirements. The demand for specific mechanical properties requires a homogeneous distribution of non-agglomerated particles into the matrix. In the very first step, this requires agglomerate-free starting materials. Agglomeration itself is mainly a phenomenon observed in submicrometer particles, as their total energy by volume (bulk plus surface contributions) is higher than that of larger particles in the micrometer range, due to a much larger surface area. In agglomerates, primary particles are often held together mainly by van der Waals forces, as well as by mechanical interlocking due to shape-related entanglement [20,21]. These forces are relatively weak compared to chemical bonds, making the agglomerates susceptible to breakage into primary particles under shear force [22,23], without altering the latter. This reduces the quality of submicron powders and, thus, the properties of the end product, unless controlled deagglomeration occurs before further processing [24,25]. Nevertheless, to achieve certain properties of superhydrophobicity [26], or to find an alternative to conventional hard chromium electrodeposited layers [27], the use of reinforcing particles is a prospective option.

Boron carbide (B4C) particles are ideal for applications in extreme environments [28]. This ceramic is the third overall hardest material known (HV100 = 47 GPa) [29,30], with a high elastic modulus (≈450 GPa) [31], an excellent wear resistance [32], an exceptional chemical resistance [33], a high melting point of 2450 °C [34,35], and a low bulk density of 2.52 g/cm3 [34,35]. Because of these properties, B4C is a promising potential candidate for the development of advanced composites using composite metals [36,37,38,39], polymers [40,41,42,43] and ceramic [44,45,46] materials, additive manufacturing [47,48,49], powder metallurgy [50] and electrochemical/electroless composite layers [28,51,52,53,54,55,56,57,58]. When well-dispersed in a matrix, B4C nanoparticles not only enhance mechanical properties [55], but also increase the wear resistance [28,52,53,56,59,60,61] and hardness [51,52,54,56] of the composite. For example, the addition of B4C to epoxy resin up to 2 wt.% improves ballistic properties and enhances the matrix toughening and impact energy of the studied composite [43]. The finely tuned microstructure of the matrix and the homogenous dispersion of the B4C particles are credited with improved tensile strength [37], hardness [33], and compression strength [62], measured at AA-6061 and AA-2024, respectively. Introducing 1.5 wt.% of B4C (particle size ≈ 68 nm) increases Vickers hardness and tensile strength properties of Al-7150 matrix by approximately 22% and 90%, respectively, in comparison to the raw state of the Al-7150 alloy [38]. Particles of boron carbide with an average size of 1.5 µm were used as a reinforcement (without any additional treatment) for codeposition with electroless nickel (Ni-P) on the cast magnesium alloy AZ91D as a substrate for increasing wear and corrosion resistance [59].

These reinforcements can even be submicron-sized. Integrating even smaller submicron particles (particle size ≤ 1 µm) [52] would enable the improvement of the abrasion resistance of composite materials. However, reinforcements of this size are difficult to incorporate into the matrix, as submicron particles tend to agglomerate during processing [24,25].

Conventional methods for preventing reagglomeration and deagglomerating of particles include chemical [34,35] and mechanical approaches [63,64,65,66], respectively. The chosen pH value depends on the point of zero charge (PZC) [67] and can significantly affect properties, such as the colloidal stability, microstructure, and rheological nature of suspensions containing cellulose nanocrystals [68] and goethite nanopowder [69]. Chemical surfactants used to prevent reagglomeration of nanoparticles include cetyltrimethylammonium bromide (CTAB) [55,63,70], sodium dodecyl sulfate (SDS) [51,53,60,63,71,72,73,74], polyethylene glycol (PEG) [63,75,76,77], polyvinyl pyrrolidone (PVP) [23], hexadecyltrimethylammonium chloride (HTMAC) and dodecyl dimethyl benzyl ammonium chloride (DDBAC) [76], trileucine [78], and ammonium salt of polyacrylic acid [79]. However, chemical methods come with a major drawback, namely that the chemical additives can have detrimental effects on the composite production process.

Concerning further potential techniques, a lump breaker was utilized to crush an asphalt pavement into particles with d = 50 mm [80] and a powder crusher was used for grinding W and Zr particles [81]. In order to reduce coal size, different devices such as rotary beakers, roll crushers, hammer mills, impactors, tumbling mills, and roller mills were screened and reviewed [82]. The operational speed of the mentioned devices could be decreased down to 18 rpm, while maintaining a high enough power to reduce the particle size. The literature does not report on the deagglomeration of particles using one of these devices. As the main goal here is to deagglomerate as-received boron carbide into the primary particles without wearing the latter off, these methods were excluded from the current research.

To achieve the effective deagglomeration of nanoparticles mechanically, a number of instruments and methods have been developed, including ball milling, high-pressure homogenization, ultrasonication, and high-shear mixers. These are shown in Table 1.

The literature reports that sonication and centrifugation after cryo-milling procedures help deagglomerate two-dimensional h-BN nanopowder [66]. B4C dispersion has been achieved through chemical treatment followed by ball milling for 24 h [34,35]. Mechanical methods, such as ball milling, are easily available and inexpensive for deagglomerating particles, but they can be time consuming. Although the process of particle deagglomeration using ball milling is generally clean, it can produce fine particles that need to be controlled to minimize the environmental impact. The use of a high-shear mixer device enables the rapid deagglomeration of nanoparticle aggregates, resulting in a uniform and stable nanoparticle suspension; however, this technique is typically more cost-effective when applied to large-scale production [83].

In order to deagglomerate silica particles by shear stress, the study from Gerde et al. [84] applied dispersion to a suitable aerosol through the use of a high-pressure nozzle in the range of (1 MPa to 8 MPa). Such a pressure resulted in particle damage, followed by a significant reduction in particle size. This method of particle deagglomeration through the use of a high-pressure nozzle has been used in a number of studies with different pressures [21,78,85,86,87,88] or pressure with shock waves [89,90,91,92]. Heat treatment using the sparking plasma sintering method was used to deagglomerate raw detonation nanodiamond powder with d50 = 203 nm [76]. The powder was placed in a graphite mold with a diameter of 20 mm by using a heating temperature of 500 °C, a unidirectional pressure of 30 MPa (t = 5 min), and an argon gas protective atmosphere.

Table 1.

Conventional particle deagglomeration techniques.

Table 1.

Conventional particle deagglomeration techniques.

| Treatment Technique | Main Operational Principle | Applied Particle Primary Size/ Particle Size Distribution Method | Advantages | Disadvantages |

|---|---|---|---|---|

| Ultrasonic homogenizer | A probe emits ultrasonic waves into a liquid sample, creating cavitation for dispersion. | Porous SiO2 (d = 15–20 nm)/dynamic light scattering (DLS), employing a He–Ne laser [93]. | Fast, efficient, reliable, and capable of processing samples in volumes ranging from a few millilitres to several litres [94]. | Generates a large amount of heat, it suffers from high energy consumption, scalability issues [94], and reagglomeration [95]. |

| Al2O3 (d = 50 nm)/elemental mapping of scanning electron microscope (SEM) [96]. | ||||

| Boron nitride nanotubes with a diameter ranging from 5 nm to 10 nm/SEM, transmission electron microscope (TEM) [97]. | ||||

| Ultrasonic bath | Sample placed in a liquid bath; ultrasonic waves propagate uniformly through the medium. | TiB2 (d = 100–200 nm)/laser diffraction [98]. | It does not require physical contact with the particles, reducing contamination risks. | Some energy is lost as heat, reducing the overall efficiency compared to direct ultrasonic probes; causes reagglomeration [95]. |

| Hydrostatic pressure + ultrasonic treatment | Ultrasonic treatment using sonotrode under a hydrostatic pressure. | Multi-walled carbon nanotubes (MWCNT Ø 5 nm to 12 nm, L ≈ 50 µm)/DLS, SEM, and TEM [23]. | Non-thermal, retains material properties. | Requires specialized, high-pressure systems. |

| SiO2 (d = 12 nm)/polarization intensity differential scattering (PIDS) [99]. | ||||

| Ultrasonic jet dispersion | Water supply at a pressure of 400 MPa with nanosuspension. High-speed jet combined with ultrasonication directly impacts particle suspensions. |

| High-speed jet combined with ultrasonication directly impacts particle suspensions. | Requires specialized equipment and it is energy intensive. |

| RESS/REHPS * | High shear stress in the nozzle passing through the Mach disc in the freely expanding jet. | Al2O3 and TiO2 (d = 1–3 µm)/scanning mobility particle spectrometer, aerodynamic particle sizer, and SEM [21]. | Produces fine particles with no solvent residue. | High cost, limited scalability. |

| Shock waves | Shock-tube filled with argon. Agglomerates suspended in a gas phase by means of shock waves, pressure, and shear forces. | SiO2 (d = 40 nm), SiC (d = 1.5 µm)/laser particle size analyzer (Mie scattering principle) [91]. | Effective for hard agglomerates, non-contact method. | Equipment complexity, high energy consumption. |

| High-shear mixer | A rotor–stator assembly creates a high-speed shearing action in a suspension with particles. | SiO2 (d = 12 nm)/laser particle size analyzer (Mie scattering principle) [83]. | Suitable for low-/high-viscosity materials, scalable. | Can damage sensitive materials |

| + ultrasonication | TiO2 (d ≈ 25 µm)/laser diffraction and PIDS [22]. | + potential thermal issues. | ||

| Swirl airflow | Powder packing in a capsule, discharging to the vortex chamber for dispersion and deagglomeration through swirl airflow-induced capsule rotation. | Drug powders (d = 60–140 µm)/ numerical simulation [101]. | Simple design, low energy Requirements. | Limited control over fine particle sizes. |

| Planetary centrifugal force | Dual-axis mixing generates centrifugal and shearing forces in a container. | Graphene nanoplatelets with 8–15 nm thickness/digital optical microscope [102]. | Uniform mixing, suitable for viscous materials. | Limited throughput, high maintenance costs. |

| Ball milling | A container contains grinding balls and suspension roll on a roller–mixer. The high shear rate breaks particle clusters mechanically. | UO2–PuO2 (d = 100 nm)/dry route laser granulometer (Mie diffraction theory) [77]. | Versatility, efficiency, and safety for diverse sample processing needs are ensured by their ability to handle multiple samples, prevent cross-contamination, and reduce aerosolization [103]. | In a laboratory setting, this type of homogenization is limited in terms of sample size. A single tube will hold only a few grams or millilitres of the sample for processing [103]. |

| Zero-valent iron (d = 200 nm)/ laser diffraction and SEM [104]. | ||||

| Mechanically reducing solid particle size by intense agitation of a slurry of the material being milled and coarse milling media [105]. | Onion-like carbon ink (d = 30–300 nm, after treatment)/dynamic light scattering, Raman spectroscopy, TEM [73]. | |||

| Rotary kiln | Thermal treatment—a rotating inclined cylinder heats (600 °C) and tumbles powder continuously. | Graphite (d50 = 375 µm)/dynamic image analysis and dry sieving analysis [106]. | Handles large volumes, effective for heat-tolerant particles. | Energy-intensive, limited to thermally stable materials. |

* RESS/REHPS—rapid expansion of supercritical solutions/high-pressure suspensions.

Currently available methods often lead to highly and reproducibly deagglomerated particles. However, these methods are expensive [21,91,93,96,97,100,106] and can process only small particle quantities [21,103]; alternatively, they are low-cost but produce low-quality particles [102,103]. These particles potentially reagglomerate, ultimately resulting in a costly or substandard final product [82,94]. Even mechanical dispersion methods often require the use of chemical additives or heat treatment [76,106] to avoid reagglomeration in the dispersed state. It was particularly challenging to find relevant information in open-source literature on the operational and experimental costs of the methods mentioned in Table 1 for a quantitative comparison with our approach.

In this study, a mechanical method using shear force that is generated inside the press mold at room temperature under atmospheric conditions was developed and tested. This method was applied to disperse primary boron carbide submicron particles with a d50 of 300 nm. The method was tested, and a monomodal distribution curve was found after pressing with a holding time of 10 s, without altering the physical shape, wearing off the primary particles, or using chemical methods such as pH alteration or chemical surfactant addition. Furthermore, the static pressure in the mold has an immediate impact on all particles in the mold, a phenomenon that is advantageous over stochastic methods, which only treat a portion of the whole sample at a time. In combination with the comparatively short processing time of just 10 s, which is orders of magnitude shorter than that of alternative methods, such as stochastic shear mixing, a clear economical advantage can be expected.

2. Materials and Methods

Commercially available B4C particles (IHK 915, Industrie Keramik Hochrhein GmbH, Wutöschingen, Germany) with an announced d50 = 300 nm were utilized. The shape of the raw powder is irregular. The chemical composition and physical properties of the B4C particles are provided in Table 2 and Table 3, respectively, as stated in the manufacturer’s datasheet.

Table 2.

B4C submicron particle chemical composition.

Table 3.

Physical properties of B4C submicron particles.

X-ray diffraction (XRD) measurements were carried out on the raw boron carbide powder using a Seifert diffractometer (Sun XRD 3003, GE Sensing & Inspection GmbH, Alzenau, Germany) with three Meteor1D detectors. The X-ray diffractometer was equipped with a Co-tube (acceleration voltage = 50 kV, current = 5 mA, and Co Kα (λ = 1.78896 Å)) in the range of 2θ = [30°, 140°], at a step width of 0.02° and a step time of t = 30 s. True density for the raw powder was measured using gas pycnometer (Ultrapyc 5000 Micro, Anton Paar, FL, USA). The powder, with a volume of 0.5527 cm3, was placed into the test cylinder (volume = 4.5 cm3). The density measurements were performed across 15 runs at 20 °C in an argon-protective atmosphere with a supported pressure of 0.896 bar for 1 h 24 min.

To achieve mechanical deagglomeration using the method suggested here, and to measure the effectiveness of the particle deagglomeration, different forces (Table 4) were applied to the lower punch of the press mold filled with B4C particles using an upstroke hydraulic press (TP 400, Fontijne Holland BV, Vlaardingen, The Netherlands). The upstroke hydraulic press has a plate size of 320 mm × 320 mm, a hydraulic pressure of 200 bar, and a maximum pressure force of 400 kN. Forces ranging from 10 kN to 100 kN were applied, and these values were then converted into pressure values in megapascal (MPa) based on the diameter of the experimental press mold.

Table 4.

Applied parameters of the experimental samples.

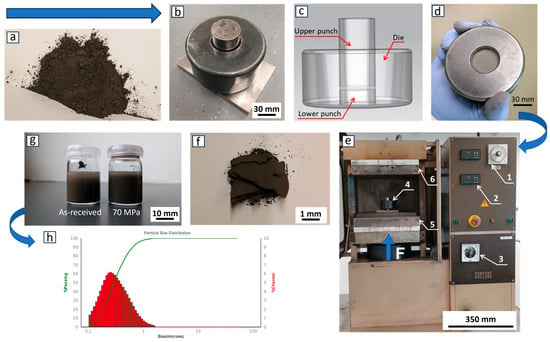

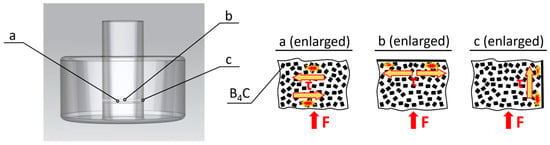

Figure 1 describes the various steps in the deagglomeration method for the boron carbide particles. The raw particles (Figure 1a), with a weight of 3 g, were poured into the experimental press mold (Figure 1b,c), with an internal diameter of 30 mm. Then, the forces presented in Table 4 were each applied to 10 sample groups (groups no. 4 through no. 13). Figure 1d shows the pressed particles in the press mold after applying a defined force for a holding time of 10 s. To investigate the influence of the applied force on the particles’ deagglomeration, three sample groups were used: the as-received sample (group no. 1) and the ultrasonicated sample without the application of pressure (groups no. 2 and no. 3). The experiments were performed in an open system in an upstroke hydraulic press (Figure 1e) at room temperature without the support of a protective gas. After mechanical dry pressing, the particles formed a tablet (Figure 1f) with a thickness of 0.8 mm. A part of this pressed-powder tablet (average weight of approximately 0.015 g) was transferred to a closed glass bottle, which was filled with 4 mL of deionized water. The dispersion was shaken well by hand before treatment in an ultrasonic bath (Figure 1g). The ultrasonic bath, containing a total volume of water of 5 L, was applied at 35 kHz (DT 514, Bandelin Sonorex, Berlin, Germany) to the experimental particles for 8 min at room temperature. It should be mentioned that this ultrasonic treatment was solely applied to break apart the pressed tablet, which was produced by the mechanical deagglomeration step itself, already containing solely primary particles, held together by the applied pressure, but showing no strong interparticle adhesion, as is typical for the agglomerates in the as-received powder. The particle size distribution is one of the most important parameters to evaluate particle dispersion quality. Therefore, particle size in deionized water was estimated using a tri-laser diffraction light scattering analyzer (S3500, Microtrac Retsch GmbH, Haan, Germany). This analyzer can detect particle sizes in the range of 0.02 µm to 2800 µm in a suspension. It was used in order to measure the particle size distribution after each mechanical deagglomeration and in the as-received reference state (Figure 1h). The duration of the applied built-in ultrasonics inside the laser diffraction analyzer was 1 min in the offline mode before performing particle size measurements. The total duration of the ultrasonic treatment before performing the measurements was 9 min. The laser diffraction analyzer supports three red lasers and its algorithms utilize Mie compensation and modified Mie calculations for the non-spherical particle wet method [107]. The measurements were reproduced three times for each sample. Data analyses adhered to DIN [108,109] standards for analyzing multimodal distributions.

Figure 1.

Schematic diagram of the process of dispersion and analysis of B4C submicron particles. (a) As-received particles, (b) photograph of the press mold, (c) 3D CAD render of the press mold, (d) powder in the mold after pressing, (e) hydraulic press—1. holding time control, 2. temperature control, 3. force control, 4. press mold, 5. lower plate, 6. upper plate, (f) pressed powder after release from the press mold, (g) ultrasonicated powders in deionized water (8 min), and (h) particle size distribution after the application of 70 MPa and ultrasonics (8 min + 1 min).

3. Results and Discussion

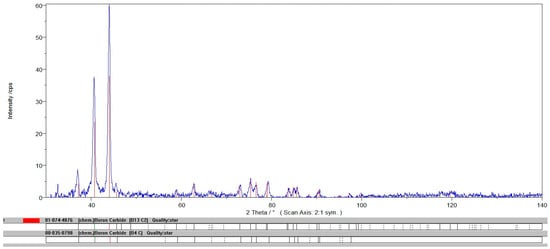

The XRD measurement (Figure 2) of the industrial B4C powder demonstrates additional peak positions of the boron-rich boron carbide phase B13C2 [110]. Shen et al. [111] observed that the B13C2 has a lower critical shear strength of 28.6 GPa compared to that of B4C, i.e., 46.7 GPa. However, B13C2 demonstrates a larger critical strain for amorphization, indicating that boron enrichment helps to reduce the amorphization in boron carbide. The elastic modulus of boron carbide material composition manufactured by chemical vapor deposition exhibited the maximum value: E = 475 GPa for B13C2 [112,113].

Figure 2.

XRD measurements for raw powder of boron carbide.

The B4C raw powder underwent true density measurements and demonstrated an average equal to 2.44 ± 0.02 g/cm3. The literature states that the bulk density of boron carbide increases linearly with carbon content within the homogeneity range of the phase and mentions that B13C2 density is 2.488 g/cm3 [112,114,115], in comparison to pure B4C which shows a density of 2.52 g/cm3 [112,114,115]. It should be mentioned that there is a reasonable difference in results between true and bulk density measurement methods. The bulk density encompasses the surface pores and internal voids of the volume [116], but true density excludes all voids or spaces within the volume, such as pores or gaps [117]. These results suggest that the investigated industrial boron carbide powder has a boron content of at least 78.3 wt.% [112,114,115].

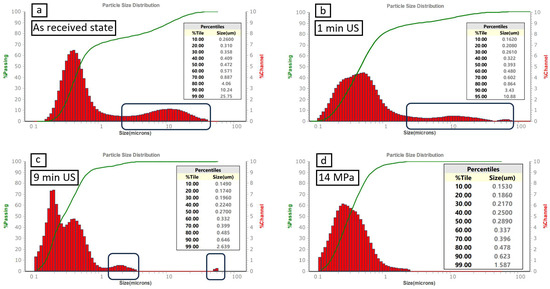

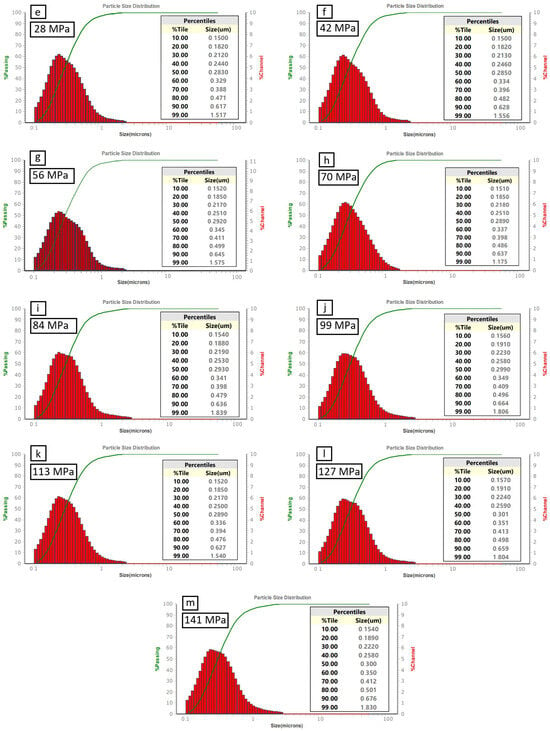

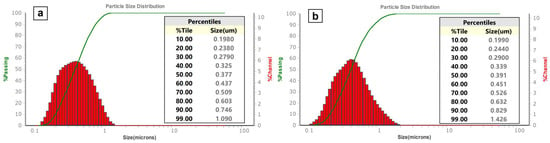

In the current study, the particle size distribution was analyzed using the laser diffraction method, which enabled us to evaluate the monomodal Gaussian nature of the average values of reproducible resulting curves (Figure 3). It is worth mentioning that the scale is logarithmic. The powder specific surface area indicates a range of 22–23 M2/cc, as stated in [118]. A comparison was made of different forces applied to assess their influence on the particle size distribution.

Figure 3.

Quantitative distributions of the size of boron carbide particles ultrasonicated and dispersed in deionized water: (a) as-received state, (b) after 1 min of ultrasonication, (c) after 8 min + 1 min of ultrasonication, after an applied pressure of (d) 14 MPa, (e) 28 MPa, (f) 42 MPa, (g) 56 MPa, (h) 70 MPa, (i) 84 MPa, (j) 99 MPa, (k) 113 MPa, (l) 127 MPa, and (m) 141 MPa.

The first three experimental groups (no. 1, no. 2, and no. 3) are shown in Figure 3a (as-received state), Figure 3b (ultrasonicated for 1 min), and Figure 3c (ultrasonicated for 9 min), respectively. The particle size distribution was significantly skewed, indicating a high degree of heterogeneity in particle size. This skew could be due to the presence of agglomerates (marked in black) in the raw powder, which could not be broken up fully via ultrasonication. Effective sonication requires high mechanical energy to overcome van der Waals forces, with dispersion limited by factors like amplitude, energy, duration, and solvent properties [119]. The lack of applied pressure demonstrated a high level of agglomeration, as evidenced by the broad and irregular curve obtained from the laser diffraction analysis.

Experimental groups from no. 4 through no. 13 (from Figure 3d until Figure 3m) were subjected to different pressures, which, upon exceeding a certain threshold, led to monomodal particle distribution curves. The analysis reveals a narrowed, more Gaussian-like, uniform particle distribution curve for the processed powders compared to the raw one. Although the particle size distributions still exhibited some degree of symmetry, deviations from the ideal Gaussian shape were observed. These deviations could be attributed to agglomeration of boron carbide particles. Despite these deviations, the distributions retained some Gaussian characteristics, suggesting that the applied pressure still provides a degree of control over particle size. This indicates that the primary particle volume is distributed symmetrically around the monomodal mean total volume of the particles. It is worth mentioning that the ultrasonication step after pressing solely serves to break the loosely pressed primary particles apart, a step that is necessary to measure their size distribution.

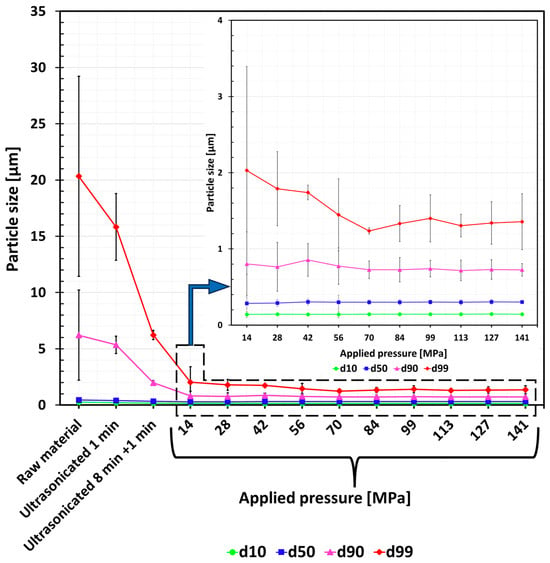

Applying a pressure of 70 MPa (experimental group no. 8) resulted in a monomodal particle distribution curve, with no further improvement in symmetry and shape when further increasing the pressure. A pressure of 70 MPa was chosen as the working point upon which further aspects such as reproducibility (Figure 3h) were investigated. Figure 4 shows particle size distribution curves for the pressed tablets no. 2 (Figure 4a) and no. 3 (Figure 4b). It demonstrates high reproducibility of the suggested dry pressing technique.

Figure 4.

Quantitative distributions of the size of boron carbide particles ultrasonicated and dispersed in deionized water after applying a pressure of 70 MPa to produce (a) tablet no. 2 and (b) tablet no. 3.

During the pressing process, boron carbide particles underwent shearing with forces (Figure 5) acting on the interparticle boundaries (Figure 5a) as well as the interfaces between particles and the upper and lower punch, respectively (Figure 5b), and between particles and the mold wall (Figure 5c). These forces contributed positively to the deagglomeration of particles, effectively reducing particle clusters and leading to a more uniform particle size distribution. As a comparison, the literature reports on pressure (30 MPa) applied in a heated press mold (500 °C–1300 °C) to deagglomerate nanodiamond particles followed by ultrasonication [76]. However, the authors did not mention the role of shear force in particle deagglomeration.

Figure 5.

Shear force acting on boron carbide particles during the pressing process.

The almost static nature of this method leads only to short movements, yet with a high force, so that the method is clearly able to provide the energy needed for deagglomeration without engaging in wear mechanisms, which would generally become more significant with longer relative movements. The latter would be a typical characteristic of, e.g., ball milling, which strongly enhances the risk of primary particle destruction. Another aspect in favor of the suggested method is the fact that particles are mainly interacting with each other, while only a minimal proportion comes into contact with either the mold wall or the punches. In this way, as the inter particle forces typical of agglomerates are still fairly below the strength of the primary particles, this method ideally addresses the described task.

Figure 6 compares the results of deagglomeration attempts and the differences between ultrasonication and mold pressing with various treatment times and pressures, respectively. While the average curves of three subsequent size measurements are presented in Figure 3, Figure 6 further provides the respective standard deviations. It demonstrates that applying static mechanical pressure resulted in full particle deagglomeration, once a certain threshold was exceeded. Consequently, increasing the force directly translates into a higher degree of particle deagglomeration (group no. 8–70 MPa), confirming the method’s effectiveness and adjustability. All experimental groups have almost the same values of d10 and d50, with a slight difference in d90. Furthermore, the largest differences in the values of d99 could be observed before and after applying pressure.

Figure 6.

Comparison of boron carbide particle mean size distribution after applying different deagglomeration methods and parameters, including standard deviations for three subsequent measurements.

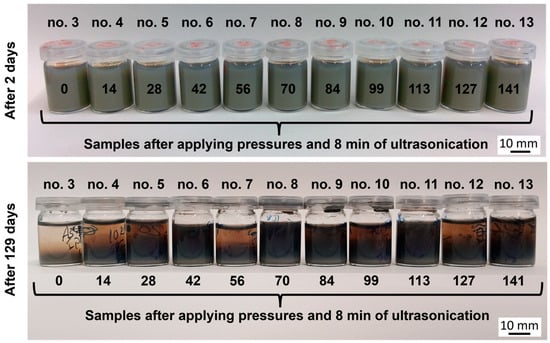

Figure 7 presents the experimental samples in glasses filled with boron carbide powders with different applied pressures (from 0 MPa through 141 MPa—experimental groups from no. 3 to no. 13, respectively) in deionized water, with the samples subsequently undergoing an ultrasonication process in an ultrasonication bath for 8 min. In semiquantitative sedimentation experiments, a resting period of 129 days compared to 2 days demonstrates only a minor difference in translucence due to particle sedimentation over time for samples that have been subjected to mechanical pressing and ultrasonication (samples no. 6, no. 8 and no. 9). In comparison, sample no. 3, with the raw material solely ultrasonicated (8 min), shows a significant degree of particle settling. Despite the ultrasonication, sample no. 3 obviously still contained unbroken agglomerates which showed a faster settling behavior due to their size. Primary particles of boron carbide have a low driving force to agglomerate in water and even in aqueous solutions with higher ionic strength, as their degree of van der Waals interaction is low. Therefore, the zeta potential developed in deionized water at pH = 7 is fully sufficient to prevent the primary particles from reagglomerating (the point of zero charge of B4C is between pH = 6 and pH = 8 [120]). What can be observed from Figure 7 is that, after a rest period of 129 days, all samples which were not fully deagglomerated in the treatment exhibited a faster speed of sedimentation, which led to a faster clearing of the above liquid phase. The explanation for this is that dispersions with the same volume and the same total particle content are best dispersed, in the sense that only primary particles are present, when the sedimented volume is at its lowest. This is because an ensemble of individual primary particles can pack more densely than they could if they were agglomerated.

Figure 7.

Boron carbide particles sedimented in deionized water after being left for 2 days and 129 days at room temperature, with different pressures and 8 min of ultrasonication subsequently applied.

4. Conclusions

An unconventional fast and cost-effective method for deagglomeration of boron carbide submicron particles was developed. It was proven that applying mechanical pressure on boron carbide particles in the dry state results in the deagglomeration of the latter. The particle size followed a monomodal Gaussian distribution curve, suggesting that this method fully restores the primary particles with consistent and uniform properties. Such a distribution is typically desired in materials science, as it ensures the highest degree of reproducibility when further processed. In future work, possible limitations of the presented method need to be identified, e.g., when treating brittle or soft particles which might either alter the primary particle size or lead to plastic deformation. However, to overcome this, these findings provide valuable guidance for optimizing the required pressures to achieve efficient and high-quality particles with minimum agglomeration. Additionally, the economic impact of the developed method has the advantage of rapid execution, which can lead to significant time savings in practical application, highlighting its potential in terms of cost-effectiveness.

Author Contributions

Conceptualization, M.E.; methodology, M.E.; formal analysis, M.E.; investigation, M.E.; writing—original draft preparation, M.E.; visualization, M.E.; writing—review and editing, T.S.; supervision, T.S.; project administration, T.S.; funding acquisition, T.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry of Education and Research (BMBF), funding number FKZ:13XP5195K. This publication was funded by Aalen University of Applied Sciences.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors of this manuscript wish to acknowledge Emanuel Wengenmayr from the Material Research Institute Aalen for their contribution in the form of XRD measurements, Andrea Bläsing for administrative support, and Taylor Rystrom for English editing.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, Y.; Liu, Z.-Q.; Wang, Y.-B. Development and Overview of Space Docking Mechanism. Recent Patents Eng. 2024, 19, E290124226390. [Google Scholar] [CrossRef]

- Sudarsi, R.; Sankaranarayanasamy, K.; Kenned, J.J. Effect of Carburization and Temperature on the Wear Behaviour of E16ncd13 Low Alloy Steel for Aerospace Applications. 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5090787 (accessed on 10 April 2025).

- Guo, X.; Zang, F.; Zhu, Y.; Cao, D. Aircraft propeller erosion wear and aerodynamic characteristics. Acta Mech. Sin. 2024, 41, 524251. [Google Scholar] [CrossRef]

- Volosova, M.A.; Okunkova, A.A.; Kropotkina, E.Y.; Mustafaev, E.S.; Gkhashim, K.I. Wear Resistance of Ceramic Cutting Inserts Using Nitride Coatings and Microtexturing by Electrical Discharge Machining. Eng 2025, 6, 11. [Google Scholar] [CrossRef]

- Hatanaka, S.; Ogawa, Y.; Okubo, H.; Hanzawa, K.; Kajiki, R.; Yamaguchi, K.; Nakano, K. Correlation between friction and wear of rubber: An experimental approach based on the disconnections of Stribeck curves. Wear 2025, 562–563, 205623. [Google Scholar] [CrossRef]

- Kumaraswamy, J.; Bharath, L.; Anil, K.; Geetha, T.; Nagesh, R. Results in mechanical properties and wear behaviour of AA6061-Si3N4 composites. Results Surf. Interfaces 2025, 18, 100376. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, X.; Zhao, Z.; Zhang, L. Fabrication of Cu-Doped Diamond-like Carbon Film for Improving Sealing Performance of Hydraulic Cylinder of Shearers. C-J. Carbon Res. 2024, 10, 93. [Google Scholar] [CrossRef]

- Oldknow, K.; Stock, R.; Vollebregt, E. Effects of rail hardness on transverse profile evolution and computed contact conditions in a full-scale wheel-rail test rig evaluation. Wear 2025, 560–561, 205589. [Google Scholar] [CrossRef]

- Kim, S.; Shin, S. Improved unsteady fluid–structure interaction analysis using the dynamic mode decomposition on a composite marine propeller. Ocean Eng. 2025, 319, 120255. [Google Scholar] [CrossRef]

- Sun, N.; Hou, Z.; Jiang, Z.; Geng, J.; Xia, L. Facile modification of sepiolite and its application in wear-resistant and superhydrophobic epoxy coatings by mimicking the structure of shark skin. Appl. Clay Sci. 2025, 264, 107642. [Google Scholar] [CrossRef]

- Nie, M.; Jiang, P.; Li, X.; Zhu, D.; Yue, T.; Zhang, Z. Directed energy deposition combined with interlayer remelting for improving NiTi wear resistance by grain refinement. Tribol. Int. 2025, 202, 110300. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Wang, Y.; Chen, Z.; Liu, H.; Wang, X. Study on microstructure and sliding wear behavior of similar and dissimilar welded joints produced by laser-arc hybrid welding of wear-resistant steels. Wear 2025, 562–563, 205643. [Google Scholar] [CrossRef]

- Dalan, F.C.; Sobrinho, A.S.D.S.; Nishihora, R.K.; Santos, S.F.; Martins, G.V.; Cardoso, K.R. Effect of Nb and Ti additions on microstructure, hardness and wear properties of AlCoCrFeNi high-entropy alloy. J. Alloys Compd. 2025, 1010, 177117. [Google Scholar] [CrossRef]

- Chakraborti, A.; Das, S.K.; Sahoo, P. Tailoring the Tribomechanical and Corrosion Behavior of Reverse Pulse Deposited Ni–Co–P Coating Through Cobalt Content Modulation. J. Tribol. 2025, 147, 071401. [Google Scholar] [CrossRef]

- Hukumdar, O.; Kumlu, U.; Keskin, A.; Akar, M.A. Effect of TMAB and ZrC concentration on mechanical and morphological properties of Ni–B/ZrC composite electrodeposition. Mater. Test. 2024, 67, 17–35. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Oh, M.; Kobayashi, E.; Chen, C.-M.; Shen, Y.-A. Investigating microstructure and interfacial stability of Bi-enhanced Sn-9Zn alloy on electroplated Cu during aging. Mater. Sci. Semicond. Process. 2025, 186, 109046. [Google Scholar] [CrossRef]

- Ditenberg, I.A.; Smirnov, I.V.; Osipov, D.A.; Grinyaev, K.V. Structural-phase state and microhardness of the surfacing formed on a steel substrate by pulsed argon tungsten arc remelting of Cu-tube containing W-Ta-Mo-Nb-Zr-Cr-Ti powder mixture. Intermetallics 2025, 179, 108639. [Google Scholar] [CrossRef]

- Cheng, X.; Wei, K.; Li, H.; Teng, N.; Xu, S.; Chen, Q.; Gong, X.; He, Y.; Yan, S. A Ni-Cu/CuPP composite coating with good wear resistance and long-term corrosion resistance for seawater applications. Tribol. Int. 2025, 202, 110393. [Google Scholar] [CrossRef]

- Eiler, K.; Alcaide, F.; García-Lecina, E.; Sort, J.; Pellicer, E. Mesoporous Ni–Pt nanoparticles on Ni foam by electrodeposition: Dual porosity for efficient alkaline hydrogen evolution. Int. J. Hydrogen Energy 2025, 99, 448–457. [Google Scholar] [CrossRef]

- Pietraccini, M.; Glaude, P.-A.; Dufour, A.; Marmo, L.; Danzi, E.; Dufaud, O. A journey through space and time in the Godbert-Greenwald furnace: The evolution of a dust cloud particle size distribution. Process. Saf. Environ. Prot. 2024, 182, 509–526. [Google Scholar] [CrossRef]

- To, D.; Dave, R.; Yin, X.; Sundaresan, S. Deagglomeration of nanoparticle aggregates via rapid expansion of supercritical or high-pressure suspensions. AIChE J. 2009, 55, 2807–2826. [Google Scholar] [CrossRef]

- Krzosa, R.; Makowski, Ł.; Orciuch, W.; Adamek, R. Population Balance Application in TiO2 Particle Deagglomeration Process Modeling. Energies 2021, 14, 3523. [Google Scholar] [CrossRef]

- Yu, L.; Lin, Y.; Li, L.; Zong, H.; Zhou, Y.; Zhao, S.; Zhang, Z.; Grobert, N.; Maciejewska, B.M.; Qin, L. Understanding interfacial dynamics: Hydrostatic pressure-induced sono-dispersion of carbon nanotubes. Surf. Interfaces 2024, 51, 104740. [Google Scholar] [CrossRef]

- Hassanzadeh-Tabrizi, S. Mild oxidizing synthesis of non-agglomerated Fe2O3 nanoparticles for H2S gas sensing. Results Chem. 2024, 7, 101395. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting—Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Liu, J.; Guo, Y.; Wang, Z.; Xing, X.; Cui, G. Enhancement of superhydrophobicity in Ni-WS2-PTFE composite coatings via magnetic coupling electrodeposition. Surf. Coat. Technol. 2025, 497, 131731. [Google Scholar] [CrossRef]

- Chakraborty, S.; Langford, N.; Kohl, Y.; Varsou, D.-D.; Stokes, W.; Papaioannou, E.; Wien, S.; Berkesi, K.; Britton, A.; Ibrahim, B.; et al. Are Ni–SiC nanoparticle electroplated coatings a safer alternative to hard chromium? A comprehensive aging, toxicity, and in silico study to assess safety by design. Environ. Sci. Nano 2025, 12, 894–908. [Google Scholar] [CrossRef]

- Ebrahimian-Hosseinabadi, M.; Azari-Dorcheh, K.; Vaghefi, S.M. Wear behavior of electroless Ni–P–B4C composite coatings. Wear 2006, 260, 123–127. [Google Scholar] [CrossRef]

- Domnich, V.; Reynaud, S.; Haber, R.A.; Chhowalla, M. Boron Carbide: Structure, Properties, and Stability under Stress. J. Am. Ceram. Soc. 2011, 94, 3605–3628. [Google Scholar] [CrossRef]

- Niihara, K.; Nakahira, A.; Hirai, T. The Effect of Stoichiometry on Mechanical Properties of Boron Carbide. J. Am. Ceram. Soc. 1984, 67, C-13. [Google Scholar] [CrossRef]

- Hollenberg, G.W.; Walther, G. The Elastic Modulus and Fracture of Boron Carbide. J. Am. Ceram. Soc. 1980, 63, 610–613. [Google Scholar] [CrossRef]

- Rey, J.; Kapsa, P.; Male, G. Dry friction and wear of chemically vapour deposited boron carbide coatings. Surf. Coat. Technol. 1988, 36, 375–386. [Google Scholar] [CrossRef]

- Venkitachalapathy, K.; Manivannan, I.; Periandy, S.; Suresh, S.; Priya, M. (Eds.) Nano Boron Carbide Reinforcement in Al6061 Metal Matrix Composite; CRC Press: Boca Raton, FL, USA, 2025; Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/9781003606611-20/nano-boron-carbide-reinforcement-al6061-metal-matrix-composite-venkitachalapathy-manivannan-periandy-suresh-priya (accessed on 1 February 2025).

- Li, X.; Jiang, D.; Zhang, J.; Lin, Q.; Chen, Z.; Huang, Z. The dispersion of boron carbide powder in aqueous media. J. Eur. Ceram. Soc. 2013, 33, 1655–1663. [Google Scholar] [CrossRef]

- Costakis, W.J.; Rueschhoff, L.M.; Diaz-Cano, A.I.; Youngblood, J.P.; Trice, R.W. Additive manufacturing of boron carbide via continuous filament direct ink writing of aqueous ceramic suspensions. J. Eur. Ceram. Soc. 2016, 36, 3249–3256. [Google Scholar] [CrossRef]

- Kumar, R.V.; Reddappa, H.N.; Chandrashekar, A.; Paruti, B. Stir-cast Al2024-based composite reinforced with boron carbide and graphene particles: Mechanical and dry sliding wear characteristics. Eng. Rep. 2024, 6, e12850. [Google Scholar] [CrossRef]

- Ravi, B.; Naik, B.B.; Prakash, J.U. Characterization of Aluminium Matrix Composites (AA6061/B4C) Fabricated by Stir Casting Technique. Mater. Today Proc. 2015, 2, 2984–2990. [Google Scholar] [CrossRef]

- Kumar, D.; Seetharam, R.; Ponappa, K. Effects of graphene nano particles on interfacial microstructure and mechanical properties of Al7150/B4C hybrid nanocomposite fabricated by novel double ultrasonic two stage stir casting technique. J. Alloys Compd. 2024, 1008, 176686. [Google Scholar] [CrossRef]

- Krishnan, B.R.; Vellaichamy, R.; Sanjeevi, R.; Ramakrishnan, H.; Rajkumar, M.K. Experimental investigation of mechanical and metallurgical properties of LM25 aluminium alloy with boron carbide composite. Interactions 2025, 246, 23. [Google Scholar] [CrossRef]

- Vegari, A.; Abdisaray, A.; Mostafanejad, K.; Jabbari, N. High-density polyethylene (HDPE)-incorporated boron carbide and boric acid nanoparticles as a nanoshield of photoneutrons from medical linear accelerators. Int. J. Radiat. Biol. 2024, 100, 609–618. [Google Scholar] [CrossRef]

- Park, J.; Her, S.; Cho, S.; Woo, S.M.; Bae, S. Synthesis and characterization of Polyethylene/B4C composite, and its neutron shielding performance in cementitious materials: Experimental and simulation studies. Cem. Concr. Compos. 2022, 129, 104458. [Google Scholar] [CrossRef]

- Özcan, M.; Avcıoğlu, S.; Kaya, C.; Kaya, F. Boron carbide reinforced electrospun nanocomposite fiber mats for radiation shielding. Polym. Compos. 2023, 44, 4155–4167. [Google Scholar] [CrossRef]

- Magarajan, U.; Kumar, S.S.; Prabhu, L. Mechanical and ballistic studies of boron carbide filler reinforced glass fiber composites. Polym. Compos. 2024, 45, 14953–14965. [Google Scholar] [CrossRef]

- Dai, J.; Singh, J.; Yamamoto, N. Fabrication and characterization of FAST sintered micro/nano boron carbide composites with enhanced fracture toughness. J. Eur. Ceram. Soc. 2020, 40, 5272–5285. [Google Scholar] [CrossRef]

- Demir, E.; Mirzayev, M.; Abdurakhimov, B.; Mauyey, B.; Jabarov, S. Characterization of lattice parameter variations, defect dynamics, and surface morphology in Al2O3-B4C coatings on 321 stainless steel under swift heavy ion irradiation. Phys. E Low-Dimens. Syst. Nanostruct. 2025, 165, 116103. [Google Scholar] [CrossRef]

- Wang, H.; Zeng, Y.; Zhu, T.; Xu, Y.; Li, Y.; Fu, Z. Exceptional strength-toughness-hardness integrated B4C ceramics with synergistic reinforcement of nano-BN and in-situ ceramic phases. Compos. Part B Eng. 2025, 288, 111921. [Google Scholar] [CrossRef]

- Additive Manufacturing Process for Producing Aluminum-Boron Carbide Metal Matrix Composites. U.S. Patent US11898226B2, 13 February 2024. Available online: https://patents.google.com/patent/US11898226B2/en?oq=Additive+manufacturing+process+for+producing+aluminum-boron+carbide+metal+matrix+composites+(US11898226) (accessed on 14 March 2025).

- Stone, M.; Kolesnikov, A.; Fanelli, V.; May, A.; Bai, S.; Liu, J. Characterization of aluminum and boron carbide based additive manufactured material for thermal neutron shielding. Mater. Des. 2024, 237, 112463. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Mountakis, N.; Argyros, A.; Papadakis, V.; Moutsopoulou, A.; Rogdakis, K.; Kymakis, E. Optimization course of hexagonal boron carbide ceramic nanofiller content in polypropylene for material extrusion additive manufacturing: Engineering response, nanostructure, and rheology insights. Next Nanotechnol. 2024, 5, 100054. [Google Scholar] [CrossRef]

- Kosedag, E.; Ekici, R. Low-velocity impact behaviors of B4C/SiC hybrid ceramic reinforced Al6061 based composites: An experimental and numerical study. J. Alloys Compd. 2025, 1010, 177525. [Google Scholar] [CrossRef]

- He, T.; He, Y.; Li, H.; Su, Z.; Fan, Y.; He, Z. Fabrication of Ni-W-B4C composite coatings and evaluation of its micro-hardness and corrosion resistance properties. Ceram. Int. 2018, 44, 9188–9193. [Google Scholar] [CrossRef]

- McCrea, J.L.; Marcoccia, M. Electroformed Nanocrystalline Coatings: An Advanced Alternative to Hard Chromium Electroplating. Available online: https://apps.dtic.mil/sti/pdfs/ADA637483.pdf (accessed on 5 June 2024).

- Zhang, Y.; Zhang, S.; He, Y.; Li, H.; He, T.; Fan, Y.; Zhang, H. Mechanical properties and corrosion resistance of pulse electrodeposited Ni-B/B4C composite coatings. Surf. Coat. Technol. 2021, 421, 127458. [Google Scholar] [CrossRef]

- Fayyaz, O.; Yusuf, M.M.; Bagherifard, S.; Montemor, M.; Shakoor, R. Probing into the properties of B4C reinforced nickel phosphorus-based nanocomposite coating. J. Mater. Res. Technol. 2022, 20, 2323–2334. [Google Scholar] [CrossRef]

- Jiang, J.B.; Liu, W.D.; Zhang, L.; Zhong, Q.D.; Wang, Y.; Zhou, Q.Y. Electrodeposition and Hardness and Corrosion Resistance Propertie of Ni/Nano-B4C Composite Coatings. Adv. Mater. Res. 2012, 399–401, 2055–2060. [Google Scholar] [CrossRef]

- Bestetti, M.; Lecis, N.; Magagnin, L.; Pirovano, R.; Cavallotti, P.L. Alternatives to Coatings from Chromium VI Baths. 2002. Available online: https://sterc.org/pdf/sf2002/sf02r03.pdf (accessed on 18 November 2024).

- Bayatlı, A.; Şahin, E.F.; Kocabaş, M. Effect of boron carbide reinforcement on surface properties of electroless Ni–B and Ni–B–W coatings. Mater. Chem. Phys. 2023, 305, 127899. [Google Scholar] [CrossRef]

- Functionally Graded Abrasive Structure and Methods of Using and Making Same. U.S. Patent WO2024118120A1, 6 June 2024. Available online: https://patents.google.com/patent/WO2024118120A1/en (accessed on 18 November 2024).

- Araghi, A.; Paydar, M. Electroless deposition of Ni–P–B4C composite coating on AZ91D magnesium alloy and investigation on its wear and corrosion resistance. Mater. Des. 2010, 31, 3095–3099. [Google Scholar] [CrossRef]

- Paydar, S.; Jafari, A.; Bahrololoom, M.E.; Mozafari, V. Influence of BN and B4C particulates on wear and corrosion resistance of electroplated nickel matrix composite coatings. Tribol. Mater. Surfaces Interfaces 2015, 9, 105–110. [Google Scholar] [CrossRef]

- Vasu, C.; Andhare, A.B.; Dumpala, R. Machinability and tool wear studies on AZ91/B4C metal matrix composites using uncoated and CVD diamond coated WC-Co turning inserts. Int. J. Refract. Met. Hard Mater. 2024, 119, 106538. [Google Scholar] [CrossRef]

- Zheng, R.; Hao, X.; Yuan, Y.; Wang, Z.; Ameyama, K.; Ma, C. Effect of high volume fraction of B4C particles on the microstructure and mechanical properties of aluminum alloy based composites. J. Alloys Compd. 2013, 576, 291–298. [Google Scholar] [CrossRef]

- Rachmaniar, S.; Nugraha, D.A.; Santjojo, D.J.D.H.; Tjahjanto, R.T.; Mufti, N.; Masruroh. Prevention of particle agglomeration in sol–gel synthesis of TiO2 nanoparticles via addition of surfactant. J. Nanopart. Res. 2024, 26, 45. [Google Scholar] [CrossRef]

- Kunjomana, A.G.; Bibin, J.; Athira, R.C.; Teena, M. Planetary Ball Milling and Tailoring of the Optoelectronic Properties of Monophase SnSe Nanoparticles. J. Electron. Mater. 2024, 53, 298–311. [Google Scholar] [CrossRef]

- Bhavesh, G.; Hariharan, P.; Dhinasekaran, D. Comparative study on the synthesis and characterization of Gd2Zr2O7 nanoparticles by mechanical milling and Co-precipitation techniques. Ceram. Int. 2024, 50, 27476–27485. [Google Scholar] [CrossRef]

- Sarma, S.S.; Padya, B.; Sarada, B.V.; Akhila, V.; Gowthami, C.; Krishna, P.V.; Joardar, J. Two-dimensional hexagonal boron nitride by cryo-milling: Microstructure and oxidation behavior at elevated temperature. J. Nanopart. Res. 2024, 26, 80. [Google Scholar] [CrossRef]

- Kosmulski, M. The pH dependent surface charging and points of zero charge. X. Update. Adv. Colloid Interface Sci. 2023, 319, 102973. [Google Scholar] [CrossRef] [PubMed]

- Bose, A.; Zakani, B.; Grecov, D. Influence of buffer on colloidal stability, microstructure, and rheology of cellulose nanocrystals in hyaluronic acid suspensions. J. Colloid Interface Sci. 2025, 678, 1194–1211. [Google Scholar] [CrossRef] [PubMed]

- Ding, P.; Pacek, A.W. Effect of pH on deagglomeration and rheology/morphology of aqueous suspensions of goethite nanopowder. J. Colloid Interface Sci. 2008, 325, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.-C.; Chou, C.-C.; Wang, H.-T.; Cheng, C.-H.; Hou, K.-H.; Ger, M.-D. Tribocorrosion study of electrodeposited Ni W alloy/BN(h) composited coatings for piston rings. Surf. Coat. Technol. 2022, 436, 128289. [Google Scholar] [CrossRef]

- Li, H.; He, Y.; He, T.; Qing, D.; Luo, F.; Fan, Y.; Chen, X. Ni-W/BN(h) electrodeposited nanocomposite coating with functionally graded microstructure. J. Alloys Compd. 2017, 704, 32–43. [Google Scholar] [CrossRef]

- Ünal, E.; Karahan, I. Production and characterization of electrodeposited Ni-B/hBN composite coatings. Surf. Coat. Technol. 2018, 333, 125–137. [Google Scholar] [CrossRef]

- Bauer, C.; Neff, T.; Day, A.; Krueger, A. Scalable Fabrication of Flexible Supercapacitor Electrodes Using Sustainable Water-Based Onion-like Carbon Inks. Batter. Supercaps 2024, 7, e202400203. [Google Scholar] [CrossRef]

- da Igreja, P.; Klump, D.; Bartsch, J.; Thommes, M. Reduction of submicron particle agglomeration via melt foaming in solid crystalline suspension. J. Dispers. Sci. Technol. 2024, 45, 307–316. [Google Scholar] [CrossRef]

- Diego, D.Z.; Gianluigi, S. Electroplating Bath Containing Trivalent Chromium and Process for Depositing Chromium. 2020. Available online: https://patents.google.com/patent/US20200308723A1/en (accessed on 18 November 2024).

- Zhou, Y.-M.; Liao, Y.-L.; Pan, X.-Y.; Zhao, X.; Zhang, F.-L.; Qin, H.-Q.; Zhang, Z.-J. Synthesis and lapping performance of a detonation nanodiamonds slurry by a SPS deagglomeration technology. Int. J. Refract. Met. Hard Mater. 2024, 118, 106433. [Google Scholar] [CrossRef]

- La Lumia, F.; Ramond, L.; Pagnoux, C.; Coste, P.; Lebreton, F.; Sevilla, J.; Bernard-Granger, G. Dense and homogeneous MOX fuel pellets manufactured using the freeze granulation route. J. Am. Ceram. Soc. 2020, 103, 3020–3029. [Google Scholar] [CrossRef]

- Heida, R.; Hagedoorn, P.; van Meel, M.C.; Prins, J.E.R.; Simonis, F.S.; Akkerman, R.; Huckriede, A.L.W.; Frijlink, H.W.; de Boer, A.H.; Hinrichs, W.L.J. Performance Testing of a Homemade Aerosol Generator for Pulmonary Administration of Dry Powder Formulations to Mice. Pharmaceutics 2023, 15, 1847. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.-C.; Lai, C.-H.; Li, C.-C. Dispersion stabilization of carbonyl iron particles and its applications in chemical mechanical planarization. Colloids Surfaces A Physicochem. Eng. Asp. 2024, 683, 133003. [Google Scholar] [CrossRef]

- Sukhija, M.; Coleri, E. A review on the incorporation of reclaimed asphalt pavement material in asphalt pavements: Management practices and strategic techniques. Road Mater. Pavement Des. 2025, 1–40. [Google Scholar] [CrossRef]

- Yao, G.; Chen, H.; Zhao, Z.-H.; Luo, L.-M.; Ma, Y.; Cheng, J.-G.; Zan, X.; Xu, Q.; Wu, Y.-C. The superior thermal stability and irradiation resistance capacities of tungsten composites synthesized by simple second-phase particle component modulation. J. Nucl. Mater. 2022, 561, 153522. [Google Scholar] [CrossRef]

- Bevan, R. Review of Industrial Size Reduction Equipment Used in the Processing of Coal. In Rotary Breakers, Roll Crushers, Hammer Mills, Impactors, Tumbling Mills, Roller Mills and Misc; Kennedy Van Saun Corp.: Danville, PA, USA, 1977. Available online: https://www.osti.gov/biblio/6707008 (accessed on 2 April 2025).

- Li, Z.; Xu, Z.; Wan, L.; Zhang, Z.; Liu, B. Nanoparticle deagglomeration driven by a high shear mixer and intensification of low-speed stirring in a viscous system. Chem. Eng. Process. Process. Intensif. 2025, 208, 110092. [Google Scholar] [CrossRef]

- Gerde, P.; Ewing, P.; Låstbom, L.; Ryrfeldt, Å.; Waher, J.; Lidén, G. A Novel Method to Aerosolize Powder for Short Inhalation Exposures at High Concentrations: Isolated Rat Lungs Exposed to Respirable Diesel Soot. Inhal. Toxicol. 2004, 16, 45–52. [Google Scholar] [CrossRef]

- Chow, M.Y.T.; Lam, J.K.W. Enhancing Pulmonary Drug Delivery: A Study on Mixed Particle Formulations. Available online: https://ddl-conference.com/ddl2024/conference-papers/enhancing-pulmonary-drug-delivery-a-study-on-mixed-particle-formulations/ (accessed on 1 March 2025).

- Xie, B.; Hassan-Naji, R.; Hall, D.A. Effects of process parameters on deposition behavior and mechanical properties of alumina coatings by aerosol deposition. J. Am. Ceram. Soc. 2025, 108, e20169. [Google Scholar] [CrossRef]

- Wu, Y.; Klauck, M.; Trollmann, K.; Allelein, H.-J. Influence of different thermodynamic parameters on variation across the aerosol size spectrum. Ann. Nucl. Energy 2024, 202, 110468. [Google Scholar] [CrossRef]

- Ye, Y.; Tu, C.; Zhang, Z.; Xu, R.; Bao, F.; Lin, J. Deagglomeration of airborne nanoparticles in a decelerating supersonic round jet. Adv. Powder Technol. 2021, 32, 1488–1501. [Google Scholar] [CrossRef]

- Strecker, J.J.F.; Roth, P. Particle Breakup in Shock Waves Studies by single Particle Light Scattering. Part. Part. Syst. Charact. 1994, 11, 222–226. [Google Scholar] [CrossRef]

- To, D. Deagglomeration and Mixing via the Rapid Expansion of High Pressure and Supercritical Suspensions. Ph.D. Thesis, New Jersey Institute of Technology, Newark, NJ, USA, 2011. Available online: https://digitalcommons.njit.edu/dissertations/265/ (accessed on 24 February 2025).

- Brandt, O.; Rajathurai, A.M.; Roth, P. First observations on break-up of particle agglomerates in shock waves. Exp. Fluids 1987, 5, 86–94. [Google Scholar] [CrossRef]

- Kellenberger, M.; Johansen, C.; Ciccarelli, G.; Zhang, F. Dense particle cloud dispersion by a shock wave. Shock Waves 2013, 23, 415–430. [Google Scholar] [CrossRef]

- Strach, A.; Dulski, M.; Wasilkowski, D.; Matus, K.; Dudek, K.; Podwórny, J.; Rawicka, P.; Grebnevs, V.; Waloszczyk, N.; Nowak, A.; et al. Multifaceted Assessment of Porous Silica Nanocomposites: Unraveling Physical, Structural, and Biological Transformations Induced by Microwave Field Modification. Nanomaterials 2024, 14, 337. [Google Scholar] [CrossRef] [PubMed]

- Exploring the Power and Potential of Ultrasonic Homogenizers [Online]. Available online: https://nanografi.com/blog/exploring-the-power-and-potential-of-ultrasonic-homogenizers-nanografi-/ (accessed on 3 January 2025).

- Nguyen, V.S.; Rouxel, D.; Hadji, R.; Vincent, B.; Fort, Y. Effect of ultrasonication and dispersion stability on the cluster size of alumina nanoscale particles in aqueous solutions. Ultrason. Sonochem. 2011, 18, 382–388. [Google Scholar] [CrossRef]

- Javdani, A.; Najafabadi, M.A. Achieving Homogeneous Distribution and Dispersion of Al2O3np Nanoparticles within 316L Matrix for Production of Metal Matrix Nanocomposites via Blended Powder Semisolid Forming. Arab. J. Sci. Eng. 2024, 49, 10669–10685. [Google Scholar] [CrossRef]

- John, D.; Sukumaran, A.K.; Mohammed, S.M.A.K.; Orikasa, K.; Lou, L.; Nisar, A.; Paul, T.; Lama, A.; Park, C.; Chu, S.; et al. Cold-Sprayed Boron-Nitride-Nanotube-Reinforced Aluminum Matrix Composites with Improved Wear Resistance and Radiation Shielding. Adv. Eng. Mater. 2024, 26, 2401490. [Google Scholar] [CrossRef]

- Čekerevac, D.; Bajić, D.; Perković, S.; Fidanovski, B.; Marinković, J.; Pejović, V.; Rigueiro, C.; Pereira, E.; Santiago, A. Impact resistance of aramid honeycomb tandem sandwich composites reinforced with TiB2. Compos. Adv. Mater. 2024, 33, 26349833241257960. [Google Scholar] [CrossRef]

- Sauter, C.; Emin, M.; Schuchmann, H.; Tavman, S. Influence of hydrostatic pressure and sound amplitude on the ultrasound induced dispersion and de-agglomeration of nanoparticles. Ultrason. Sonochem. 2008, 15, 517–523. [Google Scholar] [CrossRef]

- Galinovskiy, A.L.; Htet, K.M.; Provatorov, A.S. Ultra-Jet as a Tool for Dispersing Nanosuspensions. Polym. Sci. Ser. D 2020, 13, 209–213. [Google Scholar] [CrossRef]

- Zhu, Q. Optimizing Powder Dispersion in Dry Powder Inhalers: A CFD-DEM Investigation of Drug Formulation, Device Design and Electrostatic Charging. Ph.D. Thesis, University of New South Wales, Sydney, Australia, 2024. [Google Scholar] [CrossRef]

- Bergseth, Z.; Qi, X.; Wang, X. A study on graphene nanoplatelet dispersion methods and their effects on coating abrasion resistance and surface properties. Prog. Org. Coat. 2024, 189, 108352. [Google Scholar] [CrossRef]

- O’Driscoll, A. Bead Mill Homogenizers Versus Ultrasonic Homogenizers (Sonicators). 2019. Available online: https://homogenizers.net/blogs/blog/bead-mill-homogenizers-versus-ultrasonic-homogenizers-sonicators (accessed on 27 December 2024).

- Li, L.; Shi, Y.; Zhang, S.; Wei, M.; Li, S.; Zhang, W.-X. Enhanced breakage of the aggregates of nanoscale zero-valent iron via ball milling. Sci. Total. Environ. 2024, 946, 174399. [Google Scholar] [CrossRef] [PubMed]

- Sadler, L.Y.; Stanley, D.A.; Brooks, D.R. Attrition mill operating characteristics. Powder Technol. 1975, 12, 19–28. [Google Scholar] [CrossRef]

- Martinez, G. Variation in Graphite Removal from Spent EV Black Mass. Master Thesis, Luleå University of Technology, Luleå, Sweden, 2024. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:ltu:diva-109965 (accessed on 27 December 2024).

- S3500—Laserbeuger für Partikelgrößenbestimmung—Microtrac. Available online: https://www.microtrac.de/de/produkte/partikel-groesse-form-analyse/laserbeugung/s3500/ (accessed on 15 February 2025).

- Partikelgrößenverteilung: Partikelanalysatoren: Microtrac. Available online: https://www.microtrac.de/de/wissen/partikelgroessenverteilung/ (accessed on 18 February 2025).

- ISO 9276-2:2014(en); Representation of Results of Particle Size Analysis—Part 2: Calculation of Average Particle Sizes/Diameters and Moments from Particle Size Distributions. ISO: Geneva, Switzerland, 2014. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:9276:-2:ed-2:v1:en (accessed on 16 February 2025).

- Zhang, S.; Lu, W.; Wang, C.; Shen, Q.; Zhang, L. Synthesis and characterization of B13C2 boron carbide ceramic by pulsed electric current sintering. Ceram. Int. 2012, 38, 895–900. [Google Scholar] [CrossRef]

- Shen, Y.; Yang, M.Y.; Goddard, W.A.; An, Q. Strengthening boron carbide by doping Si into grain boundaries. J. Am. Ceram. Soc. 2022, 105, 2978–2989. [Google Scholar] [CrossRef]

- Thévenot, F. Boron carbide—A comprehensive review. J. Eur. Ceram. Soc. 1990, 6, 205–225. [Google Scholar] [CrossRef]

- Rey, J.; Male, G.; Kapsa, P.; Loubet, J.L. Boron carbide coatings: Correlation between mechanical properties and LPCVD parameters values. Le J. de Phys. Colloq. 1989, 50, C5-311–C5-321. [Google Scholar] [CrossRef]

- Bouchacourt, M. Etudes sur la Phase Carbure de Bore. Corrélations Propriétés-Composition. Ph.D. Thesis, Institut Polytechnique de Grenoble, Saint-Martin-d’Hères, France, 1982. Available online: https://theses.hal.science/tel-01177071 (accessed on 2 April 2025).

- Bouchacourt, M.; Thevenot, F. The properties and structure of the boron carbide phase. J. Less Common Met. 1981, 82, 227–235. [Google Scholar] [CrossRef]

- Xu, W.; Yao, J.; Wang, T.; Wang, F.; Li, J.; Gong, Y.; Zhang, Y.; Wu, J.; Sun, M.; Han, L. Study on the Correlation Between Mechanical Properties, Water Absorption, and Bulk Density of PVA Fiber-Reinforced Cement Matrix Composites. Buildings 2024, 14, 3580. [Google Scholar] [CrossRef]

- Rodríguez-Ramírez, J.; Méndez-Lagunas, L.; López-Ortiz, A.; Torres, S.S. True Density and Apparent Density During the Drying Process for Vegetables and Fruits: A Review. J. Food Sci. 2012, 77, R146–R154. [Google Scholar] [CrossRef]

- Plantz, P.E. Explanation of Data Reported be Microtrac Instruments: Provided by: Microtrac Inc. Particle Size Measuring. Available online: http://www.vahitech.com/Assets/MicrotracDataExplinationSheet.pdf (accessed on 20 February 2025).

- Ayan, U.; Mohoppu, M.; Sebastian, J.A.; Shreyan, B.R.; Toragall, V.B.; Maniruzzaman, M.; Al-Ostaz, A.; Werfel, T.; Villacorta, B.S. Polylactic Acid/Polybutylene Adipate Terephthalate-Carbon Nanotube Nanobiocomposites with a Segregated Toughening Morphology Yielding Large Ductility for Biocompatible Materials. ACS Appl. Nano Mater. 2025, 8, 1537–1556. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D.; Lin, Q. Aqueous processing of boron carbide powders. J. Ceram. Soc. Jpn. 2008, 116, 681–684. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).