Enhanced Resistive Switching and Conduction Mechanisms in Silk Fibroin-Based Memristors with Ag Nanoparticles for Bio-Neuromorphic Applications

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

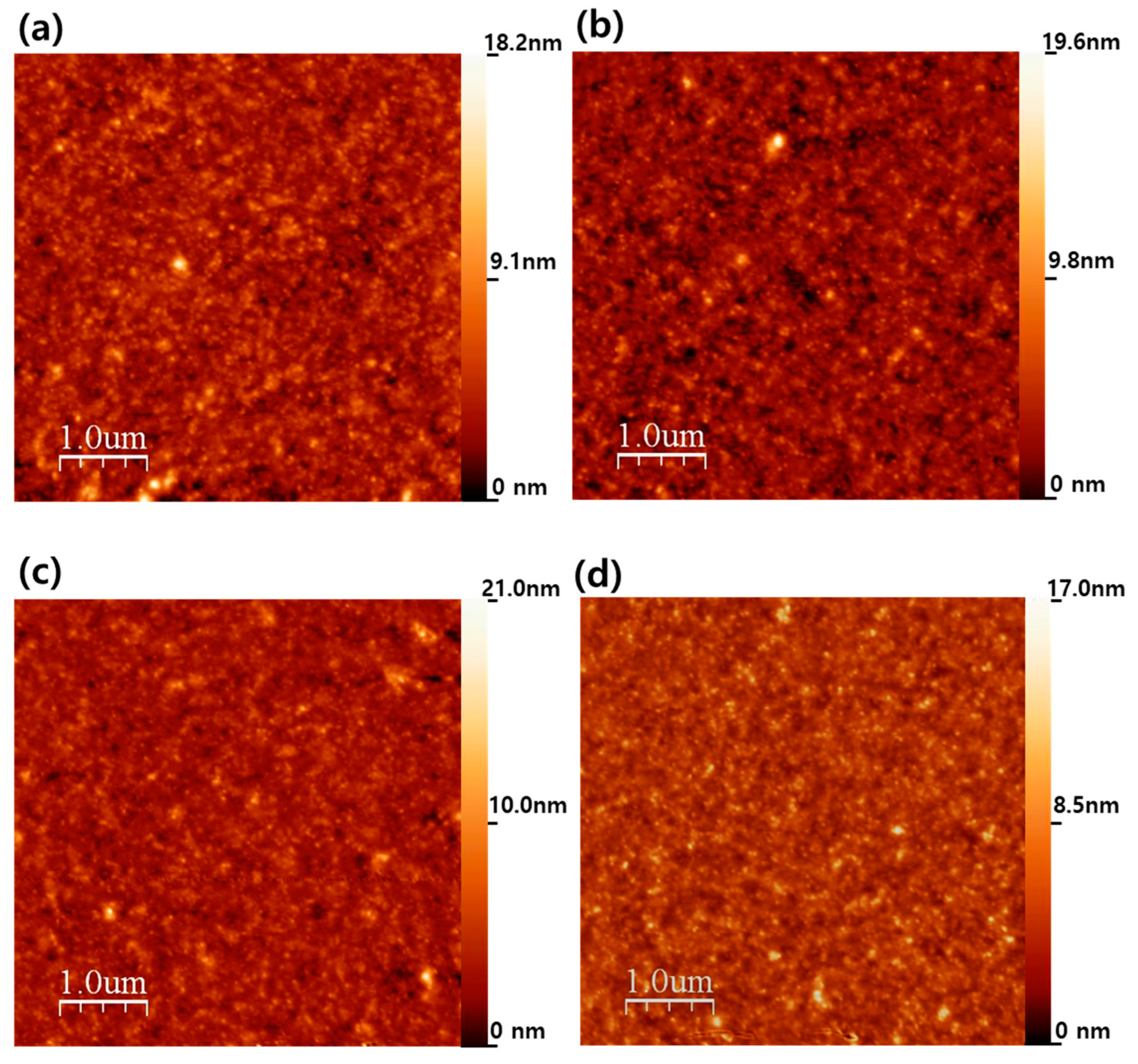

3.1. Surface Morphology and Film Characteristics of SF Films Incorporating Ag NPs

3.2. Optical Properties of SF Films Embedded with Ag NPs: PL and Reflectance Spectra Analysis

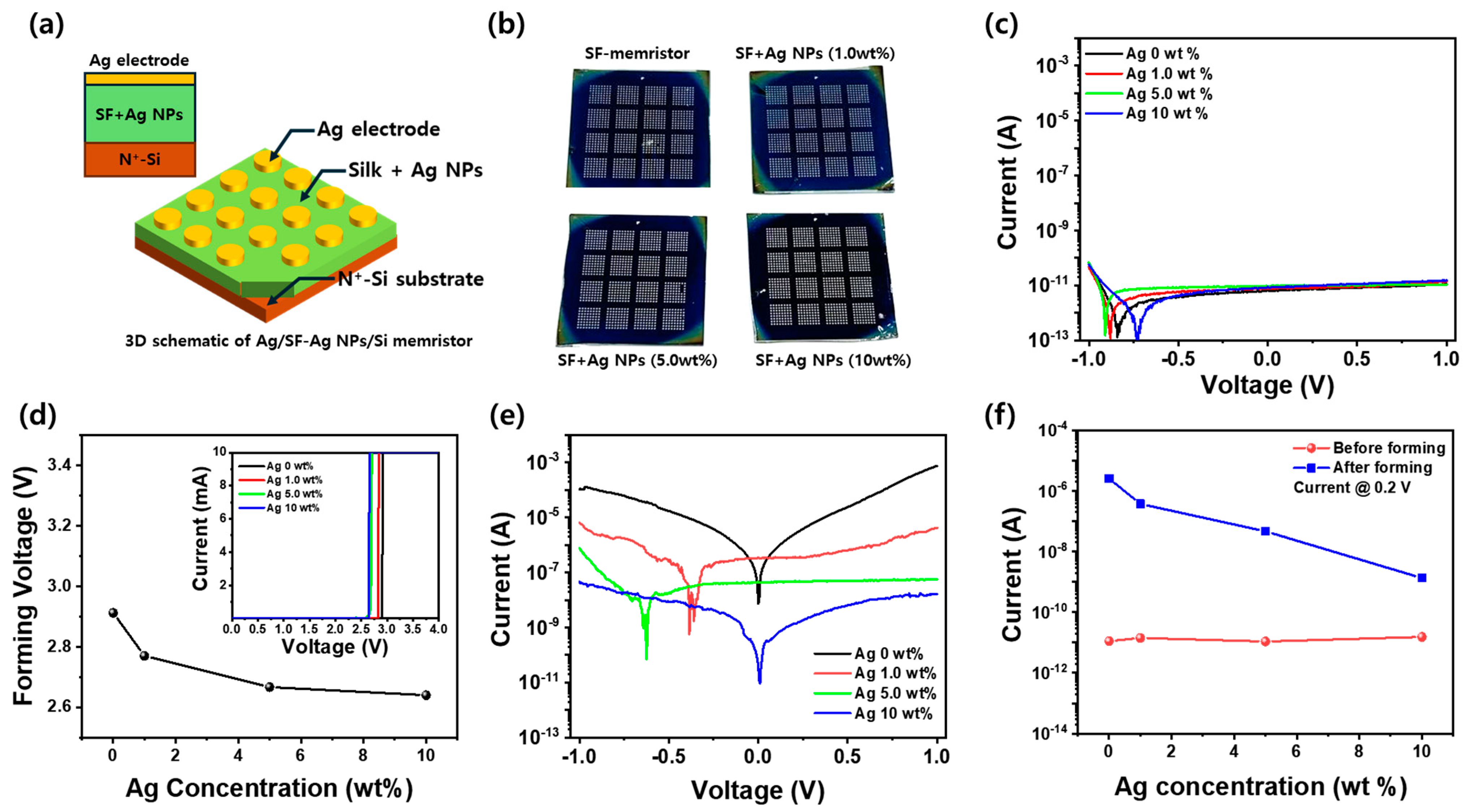

3.3. Electrical Characteristics of Ag/SF-Ag NP/Si Memristors: I-V Analysis Before and After Forming Process

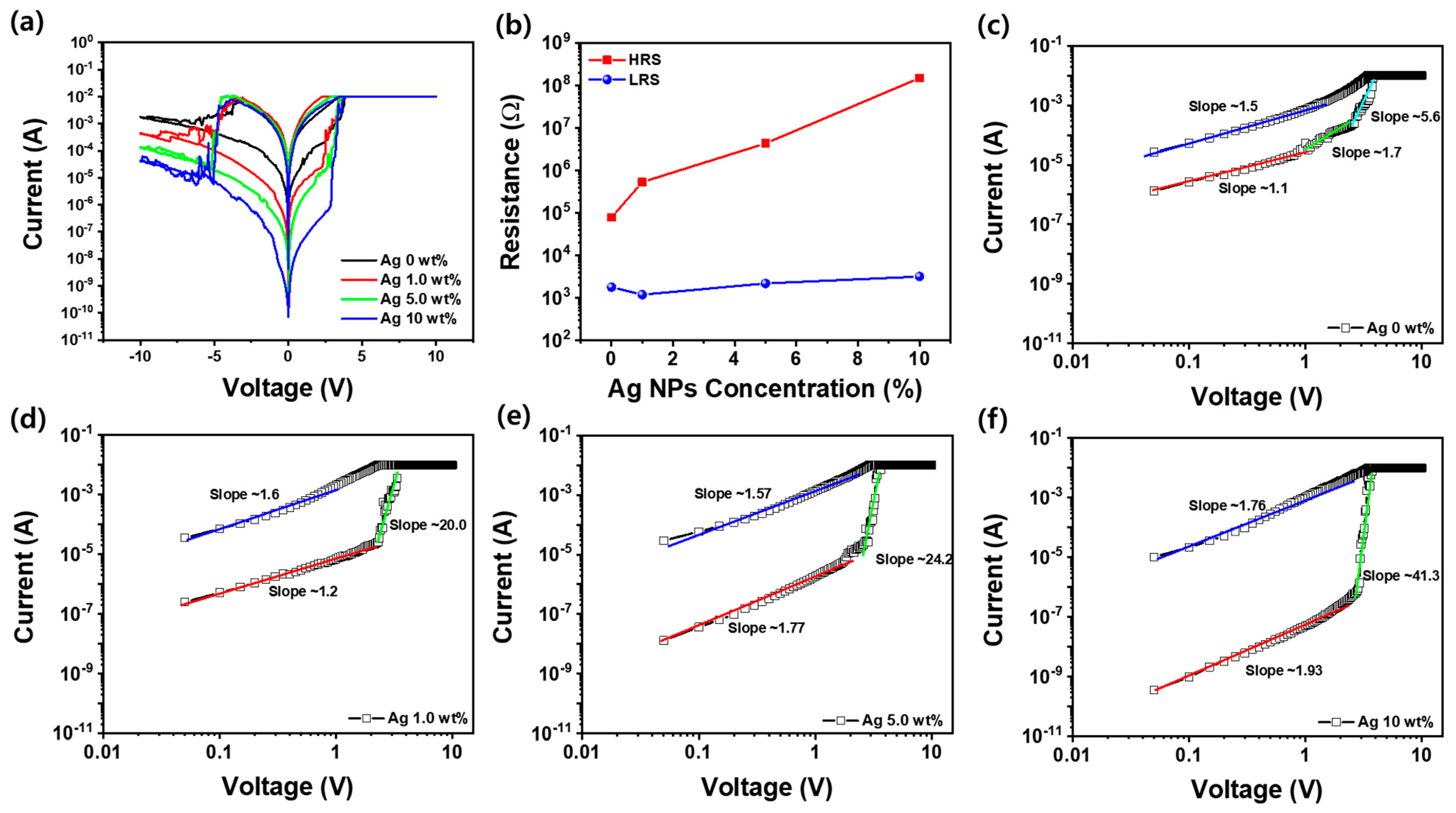

3.4. RS Characteristics and Conduction Mechanisms in Ag/SF-Ag NP/Si Memristors

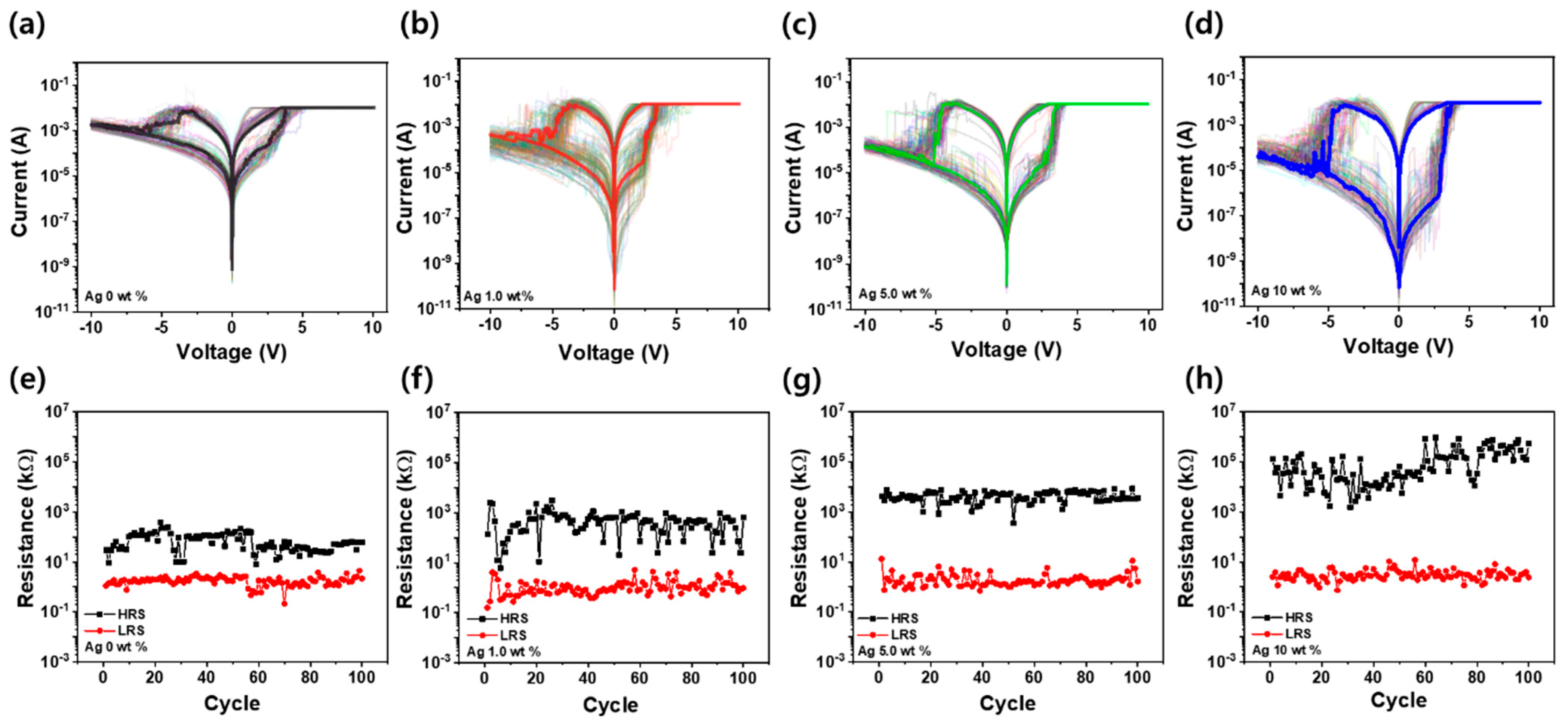

3.5. Stability and Reliability of RS Behavior in Ag/SF-Ag NP/Si Memristors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Wang, Z.; Midya, R.; Xia, Q.; Yang, J.J. Review of memristor devices in neuromorphic computing: Materials sciences and device challenges. J. Phys. D Appl. Phys. 2018, 51, 503002. [Google Scholar] [CrossRef]

- Duan, X.; Cao, Z.; Gao, K.; Yan, Y.; Sun, S.; Zhou, G.; Wu, Z.; Ren, F.; Sun, B. Memristor-based neuromorphic chips. Adv. Mater. 2024, 36, 2310704. [Google Scholar] [CrossRef]

- Yun, S.; Mahata, C.; Kim, H.-W.; Kim, S. Artificial synapse characteristics of a ZnO-based memristor with a short-term memory effect. Appl. Surf. Sci. 2022, 579, 152164. [Google Scholar] [CrossRef]

- Huh, W.; Lee, D.; Lee, C.-H. Memristors Based on 2D Materials as an Artificial Synapse for Neuromorphic Electronics. Adv. Mater. 2020, 32, 2002092. [Google Scholar]

- Lee, H.J.; Kim, J.H.; Lee, S.H.; Noh, T.; Ahn, S.E.; Lee, S.-N. Ultraviolet to red wavelength-dependent gallium oxide memristor-based multi-level optoelectronic synapse device. J. Alloys Comps. 2025, 1017, 179053. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, H.J.; Kim, H.J.; Choi, J.; Oh, J.H.; Choi, D.C.; Byun, J.S.; Ahn, S.E.; Lee, S.-N. Oxide Semiconductor Memristor-Based Optoelectronic Synaptic Devices With Quaternary Memory Storage. Adv. Electron. Mater. 2024, 10, 2300863. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, J.H.; Lee, S.H.; Lee, S.-N. Ga2O3-Based Optoelectronic Memristor and Memcapacitor Synapse for In-Memory Sensing and Computing Applications. Nanomaterials 2024, 14, 1972. [Google Scholar] [CrossRef]

- Yang, X.; Taylor, B.; Wu, A.; Chen, Y.; Chua, L.O. Research Progress on Memristor: From Synapses to Computing Systems. IEEE Trans. Circuits Syst. I 2022, 26, 1845. [Google Scholar] [CrossRef]

- Jeong, D.S.; Kim, K.; Kim, S.; Choi, B.J.; Hwang, C.S. Memristors for Energy-Efficient New Computing Paradigms. Adv. Electron. Mater. 2016, 2, 1600090. [Google Scholar] [CrossRef]

- Lv, Z.; Zhu, S.; Wang, Y.; Ren, Y.; Luo, M.; Wang, H.; Zhang, G.; Zhai, Y.; Zhao, S.; Zhou, Y.; et al. Development of bio-voltage operated humidity-sensory neurons comprising self-assembled peptide memristor. Adv. Mater. 2024, 36, 2405145. [Google Scholar] [CrossRef]

- Lv, Z.; Xing, X.; Huang, S.; Wang, Y.; Chen, Z.; Gong, Y.; Zhou, Y.; Han, S.-T. Self-assembling crystalline peptide microrod for neuromorphic function implementation. Matter 2021, 4, 1702. [Google Scholar]

- Hota, M.K.; Bera, M.K.; Kundu, B.; Kundu, S.C.; Maiti, C.K. A natural silk fibroin protein-based transparent bio memristor. Adv. Funct. Mater. 2012, 22, 4493. [Google Scholar]

- Yong, J.; Hassan, B.; Liang, Y.; Ganesan, K.; Rajasekharan, R.; Evans, R.; Egan, G.; Kavehei, O.; Li, J.; Chana, G.; et al. A silk fibroin bio-transient soultion processable memristor. Sci. Rep. 2017, 7, 14731. [Google Scholar]

- Shivananda, C.S.; Rao, B.; Sangappa, B. Structural, thermal and electrical properties of silk fibroin–silver nanoparticles composite films. J. Mater. Sci. Mater. Electron. 2020, 31, 41. [Google Scholar]

- Xu, Z.; Shi, L.; Yang, M.; Zhu, L. Preparation and biomedical applications of silk fibroin-nanoparticles composites with enhanced properties—A review. Mater. Sci. Eng. C 2019, 95, 302. [Google Scholar]

- Zhu, B.; Wang, H.; Leow, W.R.; Cai, Y.; Loh, X.J.; Han, M.Y.; Chen, X. Silk fibroin for flexible electronic devices. Adv. Mater. 2016, 28, 4250. [Google Scholar]

- Zhao, K.; Wang, J.; Wu, Y.; Yu, X.; Cao, H.; Yang, X.; Ni, A.; Ge, Y.; Liu, Y.; Zhuang, S.; et al. Silk fibroin-based hydrogels with low hysteresis, self-adhesion, and tunable ionic conductivity for wearable devices. Int. J. Biol. Macromol. 2025, 306, 141597. [Google Scholar]

- Wang, Z.; Li, J.; Shao, C.; Lin, X.; Yang, Y.; Chen, N.; Wang, Y.; Qu, L. Moisture power in natural polymeric silk fibroin flexible membrane triggers efficient antibacterial activity of silver nanoparticles. Nano Energy 2021, 90, 106529. [Google Scholar]

- Liu, R.; Bi, S.; Zhang, L.; Li, X.; Dai, K.; Wang, H.; Zhang, Z.; Gu, J. Flexible and antibacterial conductive hydrogels based on silk fibroin/polyaniline/AgNPs for motion sensing and wound healing promotion under electrical stimulation. J. Mater. Chem. B 2024, 12, 10346. [Google Scholar]

- Yang, H.; Wang, Z.; Guo, X.; Su, H.; Sun, K.; Yang, D.; Xiao, W.; Wang, Q.; He, D. Controlled Growth of Fine Multifilaments in Polymer-Based Memristive Devices Via the Conduction Control. ACS Appl. Mater. Interfaces 2020, 12, 34370. [Google Scholar]

- Jensen, T.R.; Malinsky, M.D.; Haynes, C.L.; Van Duyne, R.P. Nanosphere Lithography: Tunable Localized Surface Plasmon Resonance Spectra of Silver Nanoparticles. J. Phys. Chem. B 2000, 104, 10549. [Google Scholar]

- Malinsky, M.D.; Kelly, K.L.; Schatz, G.C.; Van Duyne, R.P. Nanosphere Lithography: Effect of Substrate on the Localized Surface Plasmon Resonance Spectrum of Silver Nanoparticles. J. Phys. Chem. B 2001, 105, 2343. [Google Scholar]

- Jiang, H.; Belkin, D.; Savelev, S.E.; Lin, S.; Wang, Z.; Li, Y.; Joshi, S.; Miday, R.; Li, C.; Rao, M.; et al. A novel true random number generator based on a stochastic diffusive memristor. Nat. Commun. 2017, 8, 882. [Google Scholar] [PubMed]

- Matsukatova, A.N.; Emelyanov, A.V.; Kulagin, V.A.; Vdovichenko, A.Y.; Minnekhanov, A.A.; Demin, V.A. Nanocomposite parylene-C memristors with embedded Ag nanoparticles for biomedical data processing. Org. Electron. 2022, 102, 106455. [Google Scholar]

- Li, D.; Ilyas, N.; Li, C.; Jiang, X.; Jiang, Y.; Li, W. Synaptic learning and memory functions in SiO2: Ag/TiO2 based memristor devices. J. Phys. D Appl. Phys. 2020, 53, 175102. [Google Scholar]

- Zhang, Y.; Fan, S.; Zhang, Y. Low-Power and Tunable-Performance Biomemristor Based on Silk Fibroin. ACS Biomater. Sci. Eng. 2021, 7, 3459. [Google Scholar]

- Zhao, M.; Wang, S.; Li, D.; Wang, R.; Li, F.; Wu, M.; Liang, K.; Ren, H.; Zheng, X.; Guo, C.; et al. Silk Protein Based Volatile Threshold Switching Memristors for Neuromorphic Computing. Adv. Electron. Mater. 2022, 8, 2101139. [Google Scholar]

- Shan, X.; Zhao, C.; Wang, X.; Wang, Z.; Fu, S.; Lin, Y.; Zeng, T.; Zhao, X.; Xu, H.; Zhang, X.; et al. Plasmonic Optoelectronic Memristor Enabling Fully Light-Modulated Synaptic Plasticity for Neuromorphic Vision. Adv. Sci. 2022, 9, 2104632. [Google Scholar]

- Han, J.; Shan, X.; Lin, Y.; Tao, Y.; Zhao, X.; Wang, Z.; Xu, H.; Liu, Y. Multi-Wavelength-Recognizable Memristive Devices via Surface Plasmon Resonance Effect for Color Visual System. Small 2023, 19, 2207928. [Google Scholar] [CrossRef]

- Cavallini, M.; Hemmatian, Z.; Riminucci, A.; Prezioso, M.; Morandi, V.; Murgia, M. Regenrable resistive switching in silicon oxide based nanojunction. Adv. Mater. 2012, 24, 1197. [Google Scholar]

- Wang, Z.; Yang, H.; Zhu, Z. Study on the blends of silk fibroin and sodium alginate: Hydrogen bond formation, structure and properties. Polymer 2019, 163, 144. [Google Scholar] [CrossRef]

- Shang, S.; Zhu, L.; Fan, J. Intermolecular interactions between natural polysaccharides and silk fibroin protein. Carbohydr. Polym. 2013, 93, 561. [Google Scholar] [CrossRef] [PubMed]

- Sionkowska, A.; Planecka, A. The influence of UV radiation on silk fibroin. Polym. Degrad. Stabil. 2011, 96, 523. [Google Scholar] [CrossRef]

- Li, X.; Qian, J.; Jiang, L.; He, S. Fluorescence quenching of quantum dots by gold nanorods and its application to DNA detection. Appl. Phys. Lett. 2009, 94, 063111. [Google Scholar] [CrossRef]

- Latha, S.; Asha, S.; Sindhu, P.; Parushuram, N.; Shilpa, M. Synthesis of anisotropic silver nanoparticles using silk fibroin: Characterization and antimicrobial properties. Mater. Res. Innov. 2019, 23, 79. [Google Scholar]

- Triana-Camacho, D.A.; D’Alessandro, A.; Bon, S.B.; Malaspina, R.; Ubertini, F.; Valentini, L. Piezoresistive, Piezocapacitive and Memcapacitive Silk Fibroin-Based Cement Mortars. Sensors 2024, 24, 7357. [Google Scholar] [CrossRef]

- Guo, D.Y.; Wu, Z.P.; An, Y.H.; Li, P.G.; Wang, P.C.; Chu, X.L.; Guo, X.C.; Zhi, Y.S.; Lei, M.; Li, H.; et al. Unipolar resistive switching behavior of amorphous gallium oxide thin films for nonvolatile memory applications. Appl. Phys. Lett. 2015, 106, 042105. [Google Scholar] [CrossRef]

- Ku, B.; Abbas, Y.; Sokolov, A.S.; Choi, C. Interface engineering of ALD HfO2-based RRAM with Ar plasma treatment for reliable and uniform switching behaviors. J. Alloys Compd. 2018, 735, 1181. [Google Scholar] [CrossRef]

- Li, H.X.; Li, Q.X.; Li, F.Z.; Liu, J.P.; Gong, G.D.; Zhang, Y.Q.; Leng, Y.B.; Sun, T.; Zhou, Y.; Han, S.T. Ni Single-Atoms Based Memristors with Ultrafast Speed and Ultralong Data Retention. Adv. Mater. 2023, 36, 2308153. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.; Lee, S.H.; Kim, T.; Min, K.; Lee, S.-N. Enhanced Resistive Switching and Conduction Mechanisms in Silk Fibroin-Based Memristors with Ag Nanoparticles for Bio-Neuromorphic Applications. Nanomaterials 2025, 15, 517. https://doi.org/10.3390/nano15070517

Choi J, Lee SH, Kim T, Min K, Lee S-N. Enhanced Resistive Switching and Conduction Mechanisms in Silk Fibroin-Based Memristors with Ag Nanoparticles for Bio-Neuromorphic Applications. Nanomaterials. 2025; 15(7):517. https://doi.org/10.3390/nano15070517

Chicago/Turabian StyleChoi, Jongyun, Seung Hun Lee, Taehun Kim, Kyungtaek Min, and Sung-Nam Lee. 2025. "Enhanced Resistive Switching and Conduction Mechanisms in Silk Fibroin-Based Memristors with Ag Nanoparticles for Bio-Neuromorphic Applications" Nanomaterials 15, no. 7: 517. https://doi.org/10.3390/nano15070517

APA StyleChoi, J., Lee, S. H., Kim, T., Min, K., & Lee, S.-N. (2025). Enhanced Resistive Switching and Conduction Mechanisms in Silk Fibroin-Based Memristors with Ag Nanoparticles for Bio-Neuromorphic Applications. Nanomaterials, 15(7), 517. https://doi.org/10.3390/nano15070517