Abstract

The effects of abrasion on the heating performance of carbon nanotube (CNT)/epoxy composites were investigated in terms of Joule’s heat, convective heat, and radiative heat under moderate-to-severe and localized abrasive conditions. While the overall heating behavior was characterized by the heating rate and the curvature of the transient response, a numerical solution of the heat equation was used to quantify convective and radiative heat transfers, incorporating the specific heat of each component, the convective heat transfer coefficient, and the Biot number. CNT reinforcement significantly improved wear resistance at a CNT concentration of 0.31 vol. %, but the presence of micro-voids led to a slight increase in wear rate with additional CNT inclusion. Using an equivalent circuit model, local and severe abrasion scenarios were analyzed to determine the variation in electrical conductivity with temperature at different degrees of abrasion, indicating the impact of scattering effects. This analysis provides valuable insights for estimating both wear resistance and the heating performance of self-heated surface materials, with potential applications in future space technologies.

1. Introduction

Incorporating carbon-based fillers into a polymeric matrix enhances the resulting composites with a broad spectrum of electrical and mechanical properties. Due to their high aspect ratio and conductivity, a small amount of the fillers enables the construction of percolation networks, demonstrating tunable composites from insulators to conductors [1,2], and they also reinforce other mechanical properties, such as tensile strength and Young’s modulus [3,4,5]. In addition to the tailorable properties of the composites, the solution-based synthesis method is effective in providing scalable composites with customizable dimensions and thicknesses of molds [6]. Such unique characteristics prompt the consideration of various applications by adjusting electrical resistance with carbon filler content and selecting appropriate polymers for each purpose. Using the flexibility of polymers with appreciable thermal and chemical resistance [5,7] when carbon fillers are dispersed in a polymeric matrix, flexible heaters can be developed to generate Joule heat using electrical current through fillers for various applications: carbon nanotube (CNT)/epoxy composites have been considered for de-icing because epoxy resin can be integrated into structures such as bridges, terraces, roofs, and helicopter rotor blades [8,9,10,11]; flexible carbon fiber composites can also be used for de-icing curved aircraft wings, as these are compatible with passenger aircraft such as the Airbus A350 XWB and Boeing 787, which primarily consist of carbon fiber-reinforced polymer composites [12,13,14]; and flexible CNT composites have been evaluated to provide thermal comfort for passengers in vehicle seats [15,16].

In particular, motivated by the Artemis project, which seeks to protect astronauts from harsh environments and to improve the capability of mission tasks to the Moon and potential advancements for Mars [17], materials used in extravehicular activity (EVA) systems must be lightweight as space exploration costs thousands of dollars per pound [18]. While other lightweight fillers, such as halloysite and boron nitride nanotubes, can provide flame retardancy and radiation shielding, respectively [19,20], CNT-based composites can offer tunable electrical conductivity, enabling both cosmic radiation shielding and temperature control through Joule heating [21,22]. Recently, although the material design is beneficial for thermoset materials for on-site repair in cold regions with less power consumption and without additional curing equipment [23,24,25], heat generation in tandem with abrasion problems has been reported during extravehicular activities (EVAs) [26]. For example, while the temperature of the lunar surface drops to 25 K without solar illumination, spacesuits, vehicles, and terrestrial habitats are exposed to micrometeoroid collisions as well as abrasion by lunar dust, which is much more severe than the weather on Earth [27]. As the electrostatic potential of the lunar dust varies from positive on the sun-facing side to negative on the opposite side depending on photoelectrons produced by solar wind and UV rays, an EVA object attracts dust due to the potential difference and subsequently experiences severe abrasion due to dust sharpness, which has been shaped without any wind or water erosion [28,29]. Indeed, NASA reported that the abrasion of EVA suits during an 8 h lunar-surface activity was more severe than 100 h usage abrasion of the training suits, meaning that the suits were limited to 75 h use [30]. Previously, lunar dust abrasion has been simulated by Taber wheels of up to 8000 cycles [30,31], and the abrasion of polymer composites has been investigated with a focus on the coefficient of friction and wear rate, namely an enhanced coefficient of friction and thermal conductivity due to interconnected fillers [32], lower coefficient of friction due to reduced hardness [33], wear rate related with surface porosity [34], and orientational effect of fillers on the coefficient of friction and wear rate [35].

However, previous studies remain insufficient for space applications based on further demands of required thermal and abrasive properties. As summarized in Table 1 [23,27], EVA suits have undergone more than 2500 h exposure [25], showing non-uniform abrasion to different parts [23,27,30]. Therefore, considering the flame retardancy, heating, and curing of the CNT/epoxy composite [5,7,23], this work investigates its heating performance under severe and local abrasions that may occur in application environments.

Table 1.

EVA suit applications with environmental conditions and required properties [23,27].

2. Materials and Methods

2.1. Fabrication of CNT/Epoxy Composites

Chemical vapor deposition (CVD)-grown CNTs were purchased to provide fillers with a length of 5–20 µm, diameter of 10–20 nm, and a density () of from NanoLab, Inc. (Waltham, MA, USA), and Smooth-On 690 was purchased from Easy Composites Ltd. (Staffordshire, UK) for epoxy matrix with a density () of . Thus, each volume fraction of CNTs () in the CNT/epoxy composites was obtained as , where and are the measured epoxy matrix mass and CNT filler mass, respectively.

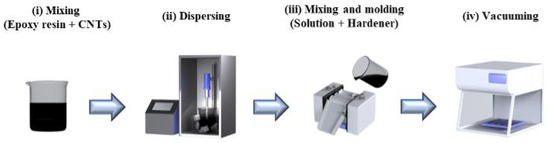

For dispersed CNT fillers within a polymeric matrix, the CNT/epoxy composite films were fabricated through the procedure as shown in Figure 1 [24,36]: (i) once the epoxy precursor ( 690: Part A) of 20 g was dissolved with acetone of 50 g in a beaker using a spatula, the desired amount of CNTs (0–2.44 vol. %) was added to the epoxy precursor/acetone solution; (ii) an ultrasonicator (Q700CA, Qsonica LLC, Newtown, CT, USA) was operated to disperse the CNTs in the solution in a pulsed mode of 90% amplitude for 30 min, while the epoxy precursor/acetone/CNTs mixture was surrounded with ice to prevent the evaporation of acetone; (iii) a 60 °C hot plate was used to evaporate the solvent for 24 h, and 6 g of curing agent ( 690: Part B) was added to the mixture using a 3-roll mill (TR 50M, Trilos, San Ramon, CA, USA), followed by molding; (iv) air bubbles in the films were removed in a vacuum chamber for 1 h.

Figure 1.

Fabrication procedure of the CNT/epoxy composites: (i) epoxy precursor/acetone/CNTs mixture; (ii) dispersing CNTs by ultrasonication; (iii) mixing curing agent in a 3-roll mill and molding specimens; (iv) removing air bubbles in a vacuum chamber.

2.2. Characterizations

Once the CNT/epoxy composites were prepared through the fabrication procedure, in order to minimize the contact resistance between the materials and tip probes for electrical measurements, RS PRO silver conductive paints (RS 186-3600) and copper foil tapes were applied to make electrodes at both ends of each specimen. The electrical resistance (R) of each specimen was obtained from the slope () of current–voltage (I–V) curves by applying V from −10 V to +10 V using multimeters depending on R: Tektronix Keithley 2700 (Beaverton, OR, USA) for G and Tektronix Keithley 2450 (Beaverton, OR, USA) for G [9], so that its electrical conductivity () was calculated as , where L is the length between the electrodes, W is the width, and d is the thickness of each specimen [37]. For the temperature coefficient of resistance (), R was measured at different temperatures using an environmental chamber (Lab Companion TE3-KE, Daejeon, Republic of Korea). Laser-flash analysis (NETZSCH LFA 447, Burlington, MA, USA) was used to determine thermal conductivity once both sides of the composites were coated with graphite spraying (Sprayon LU204, Cleveland, OH, USA) for better signal-to-noise ratio by eliminating reflection and enhancing absorption and emission [38].

In addition to the conductivity measurements, a DC power supply (Tektronix 2260B-800-1, Beaverton, OR, USA) was used to generate Joule heat through the specimens with mm, mm, and mm at room temperature. During the heating, their surface-temperature distributions were monitored using a thermal infrared (IR) camera (FLIR A655sc, Wilsonville, OR, USA), ensuring the temperature remained within the IR detector range [9].

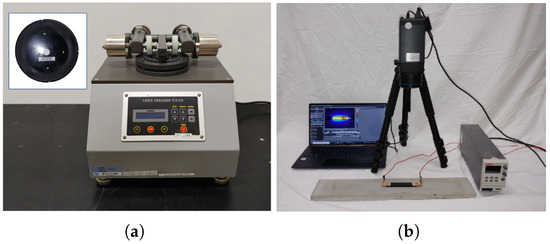

According to ASTM D 4060, the standard abrasion test method, abrasion resistance was evaluated for the 5 mm thick disk specimens with 95 mm diameter using a Taber abrasion tester (Standard Solution CT–5100) as shown in Figure 2a. Under 1 kg load of CS–17 abrasive wheel with a rotational speed of 80 rpm, the weight loss () was determined as the weight difference between before and after 2000 abrasion cycles to within 0.1 mg accuracy during 10,000 cycles of 1727.786 m sliding distance, and the wheel surface was scrubbed to remove any contaminants and to maintain consistent abrasion every 2000 cycles. Thus, the specific wear rate () was obtained as , where the sliding the density is , distance is L, and the applied load is F [31,35]. Furthermore, a 16 mm wide hand-sander was used to severely and locally abrade the specimens, and the reduced thickness of each abraded area was measured. Different abrasion experimental setups have been reported [39,40].

Figure 2.

Images of characterization methods: (a) abrasion test method with a Taber tester and (inset) a specimen of 9.5 cm diameter and 5 mm thickness, (b) Joule-heating method with a DC power supply and an IR camera.

The morphology of the specimens was examined using a scanning electron microscope (TESCAN MIRA3 FE-SEM, Brno, Czech Republic) at 15 kV on crosss-sections of the abraded areas after Pt coating with a sputter (QUORUM Q150 TS, Laughton, UK). The images were processed to evaluate porosity without any interaction or modification of the specimens [34]. This can also be obtained by gas adsorption or using water [41,42].

3. Results and Discussion

3.1. Electrical Percolation and Heating Performance

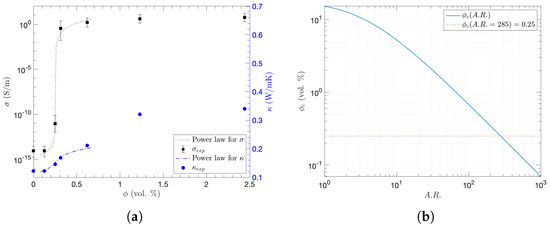

The average of multiple measurements was plotted with its error bars of the standard deviation at the corresponding of CNTs in each specimen in Figure 3a. As a sharp increase in was observed from 0.125 to 0.62 vol. % of , when is close to the electrical percolation threshold () [43], the power law was applied to analyze the percolation behavior of as follows [44,45,46]:

where s and t are the critical exponents for and , respectively. Thus, using the nonlinear least-square regression, of 0.25 vol. % was experimentally obtained with the universal and material independent t of 2.0 [47]. The effective conductivity at is related to , where is the resistance of the filler, is the resistance of the matrix, and [48,49]. Likewise, since thermal conductivity () was analyzed with the power relation, the same of 0.25 vol. % was obtained for thermal conduction as plotted in Figure 3a [46,49]. Since both and began to saturate at vol. %, it is unlikely that further enhancements will be observed with the addition of CNTs beyond vol. %. Moreover, although the aspect ratio () of the purchased CNTs initially ranged from 250 to 2000 with the provided length and diameter, it is necessary to estimate the effective for resultant CNT fillers in the polymeric matrix through the fabrication procedure, since the dispersion energy by ultrasonication reduces agglomerate size as well as break the CNTs, resulting in less length or [50,51]:

where the constant C is 1.4 for thin rods. As was plotted with in Figure 3b, the CNTs with of 285 constructed the percolation networks at vol. % after the material fabrication. After constructing percolation networks, as electrons can still hop across the interphase layer due to van der Waals interactions between CNTs [52], the thickness of the interphase layer would be

where is the maximum distance of the electron tunneling between close adjoining CNTs [53]. Considering = 1.8 nm [52,53,54,55], as = 0.4–0.8 nm with the obtained of 0.25 vol. % for vol. %, the both percolation networks and electron hopping contribute to the effective electrical conductivity of the composites for [52,56].

Figure 3.

Percolation behavior in the CNT/epoxy composites: (a) measured electrical conductivity () and thermal conductivity () as a function of CNT filler concentration () with the power-law relationship, (b) percolation threshold () as a function of CNT aspect ratio ().

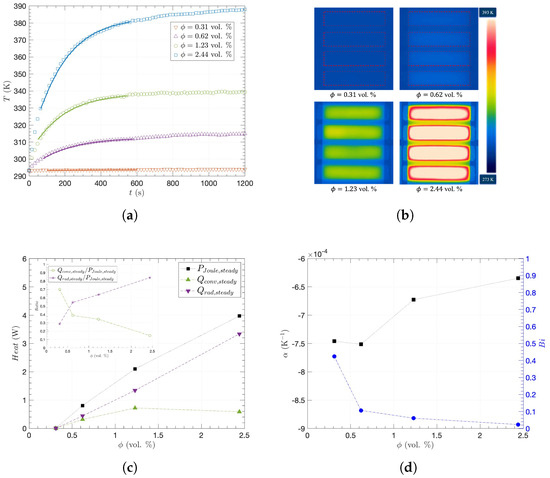

In addition, the percolating networks of the CNT fillers are the conducting pathways in which electrical current flows to generate Joule heat (), also referred to as resistive or ohmic heat, which describes the process of heat generation [57]. Figure 4 shows the heating performance in terms of time and temperature distribution for the CNT/epoxy composites with different CNT concentrations from 0.31 to 2.44 vol. % for S/m, which allows the investigation of their thermal properties with sufficient current flow given the low voltage difference for general heating elements [58]. As plotted in Figure 4a, the average temperature (T) of each specimen was monitored with elapsed time (t) by an IR camera. T rapidly increased at the beginning and then became saturated after around 600 s. Figure 4b illustrates thermal images when the specimens reached their steady states. The uniform distribution of temperature indicates the well-dispersed CNT fillers within the polymeric matrix. While the average and maximum are almost the same, about a 5 K difference was monitored between maximum and minimum temperatures of 2.44 vol. %, as the majority of the central area represents both the average and maximum temperatures in Figure 4b. Furthermore, when an electric current flows through a conductive specimen, increases T with t while convective heat () and radiative heat () are transferred to ambient environments [59,60,61]. Assuming that such energy conversion is conserved without any additional loss and that the internal temperature gradient is negligible due to simultaneous heating over the entire material through the percolating networks [57], the following heat equation can be written as follows:

where is the filler specific heat, is the filler mass, is the matrix specific heat, is the matrix mass, is the resistance at ambient temperature , is the temperature coefficient of resistance, h is the convective heat transfer coefficient, A is the area, is the emissivity, and is the Stefan–Boltzmann constant. Here, both the radiation coefficients of and are independent of environmental conditions, whereas h can be varied depending on space atmospheric environments, as shown in Table 1. Please note that Equation (4) was numerically solved in this study since it is impossible to find an analytical solution for general , whereas previous investigations have applied the Taylor expansion to for small temperature difference, [59,60]. Therefore, when at V, using experimental values of R, , , and T with t in Figure 4a for each specimen, J/kgK and 1140 J/kgK were obtained using the nonlinear least-square method and the numerical solution of Equation (4), while the ranges of = 133–496 J/kgK [61,62,63] and = 1025–1600 J/kgK [64,65,66,67] have been reported in the literature for the specific heats of CNT and epoxy, respectively, at room temperature. While there exist other methods to measure specific temperatures by preparing additional samples, the nonlinear least-square method offers a more straightforward approach to obtaining the specific heat from the same composite sample used to demonstrate heating performance. This eliminates the need to account for sample-to-sample variation, making the proposed method suitable for this study.

Figure 4.

Heating performance of the CNT/epoxy composites with different CNT concentrations: (a) the surface temperatures changing in time with the heat-equation model (solid lines), (b) the thermal images taken by an IR camera at steady state, (c) convective heat () and radiative heat () with the heat ratios (inset) to Joule heat () at steady state, (d) temperature coefficient of resistance () and Biot number () as a function of CNT filler concentration ().

Given those results, when it reaches the steady state, there is no temperature change with time: as the left-hand side of Equation (3) becomes zero, , and are plotted as a function of in Figure 4c, and higher with will generate higher and T. More specifically, as shown in the inset of Figure 4c, the ratio of increases with higher and decreases, because of the radiation term of in Equation (4), although was smaller than at vol. %. Figure 4d shows the temperature coefficient of resistance () with . The negative temperature coefficient (NTC) behavior and initial Joule heat reduce R and consequently contribute to higher Joule heat in Equation (4). Such NTC behavior would be considered to be the contribution of electron tunneling, whose transmission probability is inversely proportional to the distance between CNTs in relatively low or intermediate temperatures [68,69]. Furthermore, we have obtained the Biot number , where d is the characteristic length or specimen thickness, as shown in Figure 4d with the experimentally obtained in Figure 3a and h from Equation (4), which is 1.6–K for natural convection [60,70]. Please note that is the lowest at vol. %, indicating the most effective heat conduction relative to convection through the composites.

3.2. Abrasion Characterizations of CNT/Epoxy Composites

To characterize the degree of abrasion, the weight loss averages of the CNT/epoxy composites were primarily obtained in every 2000 abrasive cycles up to 10,000 cycles, as shown in Figure 5a. Overall, the addition of CNTs significantly enhanced abrasion resistance since the pure epoxy had a maximum weight loss of 321 mg after 10,000 abrasion cycles, whereas the 0.31 CNT vol. % showed a minimum weight loss () of 113 mg, or about 1/3 of the maximum. Such a difference in weight loss is attributed to Archard’s principle, in which hardness is inversely proportional to weight loss. Dispersed CNTs that interact with the epoxy matrix enhance resistance to deformation, leading to increased hardness [71]. Thus, the increased hardness of the composites by the CNT incorporation decreases the plowing effect and reduces the weight loss [72]. Additionally, once the epoxy was preferentially abraded in the CNT/epoxy composites due to local hardness difference, CNTs would be released to form a CNT layer on the surface, giving rise to self-lubrication or a lower coefficient of friction [35,73].

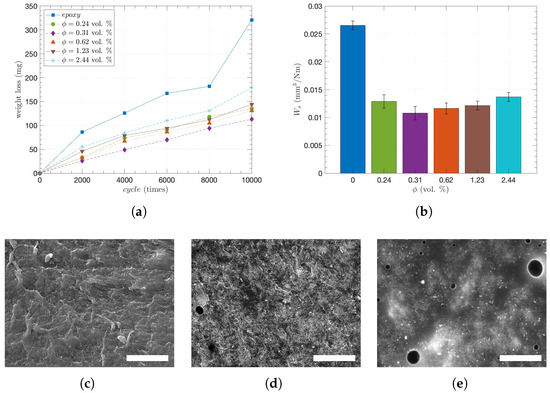

Figure 5.

Abrasion characteristics of the CNT/epoxy composites: (a) weight loss () in every 2000 cycles band (b) wear rate at 10,000 cycles with the different CNT concentrations, SEM images with m scale bars of the abraded surface with the CNT concentrations of (c) 0, (d) 1.23, and (e) 2.44 vol. %, respectively.

On the other hand, while the specific wear rate () significantly decreased with from 0 to 0.31 vol. %, it started to continuously increase with from 0.31 to 2.44 vol. %. When observing at 10,000 cycles with different CNT concentrations in Figure 5b, this is even more obvious: after showing the highest of /Nm at 0 vol. %, the showed the lowest of 0.0108 to /Nm at 0.31 and 2.44 vol. %, respectively. Such behavior occurs because of the inhomogeneous properties of composite materials when the CNT concentration exceeds the percolation threshold of . Even though the percolating networks were formed under the uniform distribution of CNTs, the further addition of CNTs induces local agglomeration, which leads to pores inside, and the interface between the CNT and the matrix is weakened [26,74]. Indeed, Figure 5c–e shows SEM images of the abraded surfaces for of 0, 1.23, and 2.44 vol. %, respectively. As a bigger and larger number of pores were observed, porosities of 0.34% and 1.93% were obtained by image-processing for = 1.23 and 2.44 vol. %, respectively [34]. Recently, an optimum porous microstructure of fiber-reinforced composites for wear resistance has been reported based on the relationship between porosity and wear rate. Furthermore, CNT inclusion slightly decreases hardness due to porosity and CNT agglomeration [32,34], which corresponds to this work. Moreover, as it has been considered that higher porosity contributes to reducing [34], Figure 3a shows that remains almost the same although increases from 1.23 to 2.44 vol. %. Therefore, such excess CNT fillers not only induce more pores but also lead to greater weight loss of the composites during abrasion due to the reduced hardness as well as limited .

3.3. Abrasion Effect on Heating Performance of the CNT/Epoxy Composites

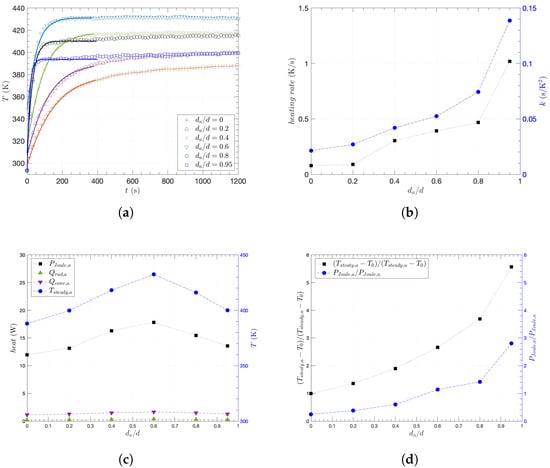

In addition to the general heating and abrasive behaviors of the composites, the local and severe abrasion effects on the heating performance of the composites were investigated with a degree of abrasion. Based on the previous observation of heating and wear performance, vol. % was chosen for further abrasion investigations due to the lowest , while remained relatively similar to different . Subsequently, for even more prolonged or severe abrasions, the degree of abrasion was defined as the reduced thickness ratio (), where d is the initial thickness and is the abraded thickness. As the thickness in the middle of the composite was reduced by abrasion, the temperature of the abraded area was monitored and analyzed with the numerical model of Equation (4) as shown in Figure 6a. Compared to the remaining unabraded area or the composite of = 0, the abraded area heated up faster with higher temperature at the same applied voltage of 20 V across the specimen. In particular, when , the temperature of the abraded area rapidly raised with the significant increase of slope, contributing to reaching a steady state within 200 s. For each plot in Figure 6a, therefore, such heating performance was quantified by the heating rate, as the average slope of temperature increased over the elapsed time, and the maximum curvature (k) is calculated as

Figure 6.

Heating characteristics of the abraded CNT/epoxy composites: (a) measured temperature in time for the abraded area with the heat-equation model (solid lines), (b) heating rate and curvature (k) with a degree of abrasion (), (c) convective heat () and radiative heat () at Joule heat () with steady-state temperature () as a function of , (d) temperature ratio with Joule heat ratio between the abraded and unabraded sections.

While the heating rate reflects how fast the temperature rises, the maximum curvature serves as an indicator of how efficiently each steady state is reached. Interestingly, the heating rate and k showed similar behavior in Figure 6b, as they continuously increased with in the beginning and rapidly increased after = 0.6, while the highest values of both were at = 0.95. This is not simply because of reduced mass or heat capacity of the abraded section, since both the corresponding resistance and voltage increased with less thickness at the same time. Thus, considering the environment when the composite is locally abraded when a constant voltage is applied across it, it is necessary to analyze thermal behavior using an appropriate model. On the other hand, whereas the temperature of the abraded section at the steady state () does not either continuously increase or decrease with , it is highest when = 0.6. As shown in Figure 6c, since the Joule heat at the abraded section () was dominant over convective heat at the abraded section () or radiative heat at the abraded section (), the highest corresponds to the highest at = 0.6, while primarily determined overall behavior of . Moreover, using the measured temperature of the abraded section () and temperature of the unabraded section () at steady state, as shown in Figure 7a, Figure 6d indicates that was more concentrated than the rest at the higher degree of abrasion, as both the temperature ratio and Joule heat ratio between the abraded and unabraded sections increased with .

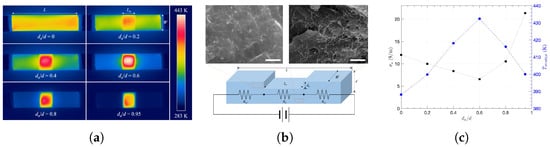

Figure 7.

Observations of CNT/epoxy composites: (a) IR images of the composite with , (b) the schematic of the locally abraded composite and its equivalent circuit diagram with SEM images showing CNT distribution before abrasion (upper left) and in the bottom side (upper right) of = 2.44 vol. %, both with m scale bars, (c) electrical conductivity () and steady-state temperature () of the abraded section.

Therefore, it is necessary to analyze in terms of material properties, including the unabraded section, since they are electrically connected to mutually influence the corresponding Joule heat:

where is the voltage, is the resistance, is the length, W is the width, and is the conductivity for the abraded section. is the resistance summation of the unabraded sections as according to the schematic and the equivalent circuit diagram in Figure 7a,b. Given the applied voltage (V) to the composite, the total resistance (R) increased with less thickness () or a higher degree of abrasion () so that the Joule heat of the entire composite decreased. However, since the voltage across the abraded section with is , increases with higher at the same V, and the corresponding Joule heat of the abraded section has the following relationship: According to Equation (5), showing the quadratic response of to external variable V, one can estimate higher at higher with constant , but Figure 7c shows that was not consistent with and it almost doubled at = 0.95 compared to others. However, increased is expected with a smaller thickness of . Although it has been previously reported that the electrical conductivity of graphene oxide/polymer composites significantly dropped with abrasive wear because of the deformation of the conducting network [29], decreased by only about half with in this work. The cross-sectional SEM images show CNT distributions of = 0 (upper left) and at = 0.95 (upper right) in Figure 7b. Therefore, the CNT/epoxy composites still have robust conducting networks against severe abrasion. Furthermore, while the highest contributed to the highest when = 0 in Figure 6c, generally tends to be the opposite of with as shown in Figure 7c, due to the scattering effect. At higher , more electrons would be scattered by phonons, resulting in reduced mobility and, consequently, lower [75,76]. Therefore, as we showed that the composites with local and severe abrasions can still be modeled and used for heating applications, one can consider that it is possible to practically predict both the abrasion degree and heating performance of the CNT composites under moderate-to-severe environments.

4. Conclusions

This study investigated the heating performance of CNT composites with a degree of abrasion for space applications and modeled the electro-thermo-mechanical behaviors in terms of the equivalent circuit. Highly conductive composites have been successfully prepared by dispersing CNTs in epoxy matrices, and the variations of electrical and thermal conductivities showed the percolation threshold at = 0.25 vol. % with the power-law relationship. Time-dependent heat generation was analyzed to obtain = 347 and 1140 J/kgK for CNT and epoxy, respectively, by the numerical solution of the heat equation, including Joule heat with convective and radiative heat losses. While the highest wear resistance was found at = 0.31 vol. %, the wear rate gradually increased with higher due to induced micro-voids. Further local and severe abrasion effects on heating performance were also analyzed to find the relationship between temperature and Joule heat based on the heat equation and the circuit model. Thus, this investigation provides the foundation for the design and analysis of CNT-polymer composites for self-heated surface materials in space applications, which are subjected to external loads or interactions with other environmental conditions, which are considered to be future work, like At. O exposure in low-Earth orbits [77]. By including other effects, the resistance-based method can still be useful for monitoring composite status in aircraft and for designing composite heaters, including multifunctional sensor and heater applications [13,16], and an optimal CNT concentration can be chosen to balance the required heat generation and weight loss by abrasion.

Author Contributions

Conceptualization, S.-H.J.; methodology, S.-H.J. and B.-W.K.; analysis, B.-W.K.; investigation, S.-H.J.; writing—original draft preparation, S.-J.L. and B.-W.K.; writing—review and editing, S.-H.J., B.-W.K. and H.Y.; visualization, S.-J.L. and B.-W.K.; supervision, S.-H.J.; project administration, S.-H.J. and B.-W.K.; funding acquisition, S.-H.J. and H.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science Foundation (NSF) under grants IIP #1738802, IIP #1941244, and U.S. Department of Agriculture NIFA #2021-67021-34201. This work was also supported by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (RS-2024-00407856).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

All authors declare no competing financial interest.

References

- Baughman, R.; Zakhidov, A.; Heer, W.D. Carbon nanotubes-the route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ma, P.; Chow, W.; To, C.; Tang, B.; Kim, J. Correlations between percolation threshold, dispersion state, and aspect ratio of carbon nanotubes. Adv. Funct. Mater. 2007, 17, 3207–3215. [Google Scholar] [CrossRef]

- Tjong, S. Structural and mechanical properties of polymer nanocomposites. Mater. Sci. Eng. R 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Wang, S. A review on enhancement of mechanical and tribological properties of polymer composites reinforced by carbon nanotubes and graphene sheet: Molecular dynamic simulations. Compos. Part B 2019, 160, 348–361. [Google Scholar] [CrossRef]

- Balguri, P.; Samuel, D.; Thumu, U. A review on mechanical properties of epoxy nanocomposites. Mater. Today Proc. 2021, 44, 346–355. [Google Scholar] [CrossRef]

- Ahir, S.; Terentjev, E. Photomechanical actuation in polymer-nanotube composites. Nat. Mater. 2005, 4, 491–495. [Google Scholar] [CrossRef]

- Azeez, A.; Rhee, K.; Park, S.; Hui, D. Epoxy clay nanocomposites—Processing, properties and application: A review. Compos. Part B 2013, 45, 308–320. [Google Scholar] [CrossRef]

- Vertuccio, L.; Foglia, F.; Pantani, R.; Romero-Sanchez, M.; Calderon, B.; Guadagno, L. Carbon nanotubes and expanded graphite based bulk nanocomposites for de-icing applications. Compos. Part B 2021, 207, 108583. [Google Scholar] [CrossRef]

- Lee, S.J.; Jung, Y.J.; Cho, C.; Jang, S.H. Effect of Atmospheric Temperature on Epoxy Coating Reinforced with Carbon Nanotubes for De-Icing on Road Systems. Nanomaterials 2023, 13, 2248. [Google Scholar] [CrossRef]

- Jala, J.; Nowacki, B.; Mistewicz, K.; Gradon, P. Graphite-epoxy composite systems for Joule heating based de-icing. Cold Reg. Sci. Technol. 2023, 216, 104024. [Google Scholar] [CrossRef]

- Raji, A.; Varadhachary, T.; Nan, K.; Wang, T.; Lin, J.; Ji, Y.; Genorio, B.; Zhu, Y.; Kittrell, C.; Tour, J. Composites of graphene nanoribbon stacks and epoxy for Joule heating and deicing of surface. ACS Appl. Mater. Interfaces 2016, 8, 3551–3556. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Hawkins, S.; Falzon, B. An advanced anti-icing/de-icing system utilizing highly aligned carbon nanotube webs. Carbon 2018, 136, 130–138. [Google Scholar] [CrossRef]

- Fenta, E.W.; Mebratie, B.A. Advancements in carbon nanotube-polymer composites: Enhancing properties and applications through advanced manufacturing techniques. Heliyon 2024, 10, e36490. [Google Scholar] [CrossRef] [PubMed]

- Mucha, M.; Krzyzak, A.; Kosicka, E.; Coy, E.; Kościński, M.; Sterzyński, T.; Sałaciński, M. Effect of MWCNTs on Wear Behavior of Epoxy Resin for Aircraft Applications. Materials 2020, 13, 2696. [Google Scholar] [CrossRef]

- Grm, V.; Zave, D.; Drazic, G. A carbon-nanotubes-based heating fabric composite for automotive applications. Mater. Technol. 2020, 54, 761–768. [Google Scholar] [CrossRef]

- Park, Y.; Gwon, N.H.; Seong, W.K.; Kim, W. Heater-Integrated Flexible Piezoresistive Pressure Sensor Array for Smart-Car Seats. IEEE Sens. J. 2024, 24, 1255–1263. [Google Scholar] [CrossRef]

- Creech, S.; Guidi, J.; Elburn, D. Artemis: An overview of NASA’s activities to return humans to the Moon. In Proceedings of the 2022 IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2022; pp. 1–7. [Google Scholar]

- Gordon, G.D. Space Exploration: Mass Ratios for Different Missions. In Proceedings of the AIAA SPACE 2007 Conference & Exposition, Long Beach, CA, USA, 18–20 September 2007. [Google Scholar] [CrossRef]

- Kang, M.; Liu, Y.; Lin, W.; Liang, C.; Cheng, J. The thermal behavior and flame retardant performance of phase change material microcapsules with halloysite nanotube. J. Energy Storage 2023, 60, 106632. [Google Scholar] [CrossRef]

- Cheraghi, E.; Chen, S.; Yeow, J.T. Boron Nitride-Based Nanomaterials for Radiation Shielding: A Review. IEEE Nanotechnol. Mag. 2021, 15, 8–17. [Google Scholar] [CrossRef]

- Cha, J.H.; Jang, W.H.; Sarath Kumar, S.K.; Noh, J.E.; Choi, J.S.; Kim, C.G. Functionalized multi-walled carbon nanotubes/hydrogen-rich benzoxazine nanocomposites for cosmic radiation shielding with enhanced mechanical properties and space environment resistance. Compos. Sci. Technol. 2022, 228, 109634. [Google Scholar] [CrossRef]

- Liu, C.; Yin, H. Tailorable thermoelasticity of cubic lattice-based cellular and granular materials by prestress. Mater. Des. 2023, 233, 112223. [Google Scholar] [CrossRef]

- Ryan, E.; Seibers, Z.; Reynolds, J.; Shofner, M. Electrically conducting polymers and composites for applications in space exploration. J. Appl. Polym. Sci. 2024, 141, e55225. [Google Scholar] [CrossRef]

- Jang, S.H.; Kim, D.; Park, Y.L. Accelerated curing and enhanced material properties of conductive polymer nanocomposites by Joule heating. Materials 2018, 11, 1775. [Google Scholar] [CrossRef] [PubMed]

- Bond, D.; Goddard, B.; Singleterry, R.C., Jr.; y León, S.B. Evaluating the effectiveness of common aerospace materials at lowering the whole body effective dose equivalent in deep space. Acta Astronaut. 2019, 165, 68–95. [Google Scholar] [CrossRef]

- Mazumder, M.; Srirama, P.; Sharma, R.; Biris, A.; Hidetaka, I.; Trigwell, S.; Horenstein, M. Lunar and Martian dust dynamics. IEEE Ind. Appl. Mag. 2010, 16, 14–21. [Google Scholar] [CrossRef]

- Weiss, P.; Mohamed, M.; Gobert, T.; Chouard, Y.; Singh, N.; Chalal, T.; Schmied, S.; Schweins, M.; Stegmaier, T.; Gresser, G.; et al. Advanced materials for future lunar extravehicular activity space suit. Adv. Mater. Technol. 2020, 5, 2000028. [Google Scholar] [CrossRef]

- Jackson, T.; Farrell, W.; Zimmerman, M. Rover wheel charging on the lunar surface. Adv. Space Res. 2015, 55, 1710–1720. [Google Scholar] [CrossRef]

- Budzyń, D.; Zare-Behtash, H.; Cowley, A.; Cammarano, A. Implicit lunar dust mitigation technology: Compliant mechanisms. Acta Astronaut. 2023, 203, 146–156. [Google Scholar] [CrossRef]

- Gaier, J.; Meador, M.; Rogers, K.; Sheehy, B. Abrasion of Candidate Spacesuit Fabrics by Simulated Lunar Dust; Technical Report 2009-01-2473, SAE Technical Paper; NASA: Washington, DC, USA, 2009.

- Ryan, E.; Seibers, Z.; Reynolds, J.; Shofner, M. Surface-localized chemically modified reduced graphene oxide nanocomposites as flexible conductive surfaces for space applications. ACS Appl. Polym. Mater. 2023, 5, 5092–5102. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, J.; Li, Q.; Wu, H.; Guo, S.; Qiu, J. Constructing 3D interconnected CNTs network in PA6 composites with well-dispersed UHMWPE for excellent tribological and heat dissipation properties. Compos. Part B 2022, 246, 110252. [Google Scholar] [CrossRef]

- Arif, M.; Alhashmi, H.; Varadarajan, K.; Koo, J.; Hart, A.; Kumar, S. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced PEEK composites enabled via FFF additive manufacturing. Compos. Part B 2020, 184, 107625. [Google Scholar] [CrossRef]

- Li, C.; Fei, J.; Zhang, T.; Zhao, S.; Qi, L. Relationship between surface characteristics and properties of fiber-reinforced resin-based composites. Compos. Part B Eng. 2023, 249, 110422. [Google Scholar] [CrossRef]

- Man, Z.; Wang, H.; He, Q.; Kim, D.E.; Chang, L. Friction and wear behaviour of additively manufactured continuous carbon fibre reinforced PA6 composites. Compos. Part B 2021, 226, 109332. [Google Scholar] [CrossRef]

- Jang, S.; Yin, H. Effect of aligned ferromagnetic particles on strain sensitivity of multi-walled carbon nanotube/polydimethylsiloxane sensors. Appl. Phys. Lett. 2015, 106, 141903. [Google Scholar] [CrossRef]

- Rebeque, P.V.; Silva, M.J.; Cena, C.R.; Nagashima, H.N.; Malmonge, J.A.; Kanda, D.H.F. Analysis of the electrical conduction in percolative nanocomposites based on castor-oil polyurethane with carbon black and activated carbon nanopowder. Polym. Compos. 2019, 40, 7–15. [Google Scholar] [CrossRef]

- Tregenza, O.; Saha, M.; Hutasoit, N.; Hulston, C.; Palanisamy, S. An experimental evaluation of the thermal interface resistance between cold spray copper/laser-textured alumina bi-layered composites. Int. J. Heat Mass Transf. 2022, 188, 122606. [Google Scholar] [CrossRef]

- Bossa, N.; Sipe, J.; Berger, W.; Scott, K.; Kennedy, A.; Thomas, T.; Hendren, C.; Wiesner, M. Quantifying mechanical abrasion of MWCNT nanocomposites used in 3D printing: Influence of CNT content on abrasion products and rate of microplastic production. Environ. Sci. Technol. 2021, 55, 10332. [Google Scholar] [CrossRef]

- Schlagenhauf, L.; Chu, B.; Buha, J.; Nuesch, F.; Wang, J. Release of carbon nanotubes from an epoxy-based nanocomposite during an abrasion process. Environ. Sci. Technol. 2012, 46, 7366. [Google Scholar] [CrossRef]

- Kohlmeyer, R.R.; Lor, M.; Deng, J.; Liu, H.; Chen, J. Preparation of stable carbon nanotube aerogels with high electrical conductivity and porosity. Carbon 2011, 49, 2352–2361. [Google Scholar] [CrossRef]

- Molla-Abbasi, P.; Ghaffarian, S.R.; Danesh, E. Porous carbon nanotube/PMMA conductive composites as a sensitive layer in vapor sensors. Smart Mater. Struct. 2011, 20, 105012. [Google Scholar] [CrossRef]

- Shklovskii, B.; Efros, A. Electronic Properties of Doped Semiconductors; Springer: New York, NY, USA, 1984. [Google Scholar]

- Kirkpatrick, S. Percolation and Conduction. Rev. Mod. Phys. 1973, 45, 574. [Google Scholar] [CrossRef]

- Stauffer, D.; Aharony, A. Introduction to Percolation Theory; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Kim, B.W.; Park, S.H.; Bandaru, P. Anomalous decrease of the specific heat capacity at the electrical and thermal conductivity percolation threshold in nanocomposites. Appl. Phys. Lett. 2014, 105, 253108. [Google Scholar] [CrossRef]

- Vionnet-Menot, S.; Grimaldi, C.; Maeder, T.; Strässler, S.; Ryser, P. Tunneling-percolation origin of nonuniversality: Theory and experiments. Phys. Rev. B 2005, 71, 064201. [Google Scholar] [CrossRef]

- Straley, J. Critical exponents for the conductivity of random resistor lattices. Phys. Rev. B 1977, 15, 5733. [Google Scholar] [CrossRef]

- Kim, B.W.; Park, S.H.; Kapadia, R.; Bandaru, P. Evidence of percolation related power law behavior in the thermal conductivity of nanotube/polymer composites. Appl. Phys. Lett. 2013, 102, 243105. [Google Scholar] [CrossRef]

- Yang, Y.; Grulke, E. Thermal and rheological properties of carbon nanotube-in-oil dispersion. J. Appl. Phys. 2006, 99, 114307. [Google Scholar] [CrossRef]

- Ruan, B.; Jacobi, A. Ultrasonication effects on thermal and rheological properties of carbon nanotubes suspension. Nanoscale Res. Lett. 2012, 7, 127. [Google Scholar] [CrossRef]

- Feng, C.; Jiang, L. Micromechanics modeling of the electrical conductivity of carbon nanotube (CNT)—Polymer nanocomposites. Compos. Part A Appl. Sci. Manuf. 2013, 47, 143–149. [Google Scholar] [CrossRef]

- Saberi, M.; Moradi, A.; Ansari, R.; Hassanzadeh-Aghdam, M.K.; Jamali, J. Developing an efficient analytical model for predicting the electrical conductivity of polymeric nanocomposites containing hybrid carbon nanotube/carbon black nanofillers. Compos. Part A Appl. Sci. Manuf. 2024, 185, 108374. [Google Scholar] [CrossRef]

- Li, C.; Thostenson, E.T.; Chou, T.W. Dominant role of tunneling resistance in the electrical conductivity of carbon nanotube—Based composites. Appl. Phys. Lett. 2007, 91, 223114. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Kuronuma, Y.; Narita, F. Modeling and characterization of the electrical conductivity of carbon nanotube-based polymer composites. Polymer 2011, 52, 3852–3856. [Google Scholar] [CrossRef]

- Deng, F.; Zheng, Q.S. An analytical model of effective electrical conductivity of carbon nanotube composites. Appl. Phys. Lett. 2008, 92, 071902. [Google Scholar] [CrossRef]

- Chien, A.T.; Cho, S.; Joshi, Y.; Kumar, S. Electrical conductivity and Joule heating of polyacrylonitrile/carbon nanotube composite fibers. Polymer 2014, 55, 6896. [Google Scholar] [CrossRef]

- Krause, B.; Pötschke, P.; Ilin, E.; Predtechenskiy, M. Melt mixed SWCNT-polypropylene composites with very low electrical percolation. Polymer 2016, 98, 45–50. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, H.; Wang, R.; Wang, X.; Zhai, H.; Wang, T.; Jin, Q.; Sun, J. Highly stretchable and conductive copper nanowire based fibers with hierarchical structure for wearable heaters. ACS Appl. Mater. Interfaces 2016, 8, 32925. [Google Scholar] [CrossRef]

- Vollmer, M. Newton’s law of cooling revisited. Eur. J. Phys. 2009, 30, 1063. [Google Scholar] [CrossRef]

- Yi, W.; Lu, L.; Zhang, D.L.; Pan, Z.; Xie, S. Linear specific heat of carbon nanotubes. Phys. Rev. B 1999, 59, R9015. [Google Scholar] [CrossRef]

- Lu, L.; Yi, W.; Zhang, D. 3ω method for specific heat and thermal conductivity measurements. Rev. Sci. Instrum. 2001, 72, 2996. [Google Scholar] [CrossRef]

- Masarapu, C.; Henry, H.; Wei, B. Specific heat of aligned multiwalled carbon nanotubes. Nanotechnology 2005, 16, 1490. [Google Scholar] [CrossRef]

- Kim, H.; Park, K.; Lee, D. A study on the epoxy resin concrete for the ultra-precision machine tool bed. J. Mater. Process. Technol. 1995, 48, 649. [Google Scholar] [CrossRef]

- Baller, J.; Becker, N.; Ziehmer, M.; Thomassey, M.; Zielinski, B.; Müller, U.; Sanctuary, R. Interaction between silica nanoparticles and an epoxy resin before and during network formation. Polymer 2009, 50, 3211. [Google Scholar] [CrossRef]

- Hubert, H. Aspect Flow and Compaction of Laminated Composite Shapes During Cure. Ph.D. Thesis, The University of British Columbia, Kelowna, BC, Canada, 1996. [Google Scholar]

- Li, C.; Medvedev, G.; Lee, E.W.; Kim, J.; Caruthers, J.; Strachan, A. Molecular dynamics simulations and experimental studies of the thermomechanical response of an epoxy thermoset polymer. Polymer 2012, 53, 4222. [Google Scholar] [CrossRef]

- Gong, S.; Zhu, Z.; Li, Z. Electron tunnelling and hopping effects on the temperature coefficient of resistance of carbon nanotube/polymer nanocomposites. Phys. Chem. Chem. Phys. 2017, 19, 5113. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.; Thostenson, E.; Schumacher, T. Comparative study of the thermoresistive behavior of carbon nanotube-based nanocomposites and multiscale hybrid composites. Compos. Part B 2021, 222, 1090068. [Google Scholar] [CrossRef]

- Conti, R.; Gallitto, A.A.; Fiordilino, E. Measurement of the convective heat-transfer coefficient. Phys. Teach. 2014, 52, 109. [Google Scholar] [CrossRef]

- Bisht, A.; Dasgupta, K.; Debrupa, L. Effect of graphene and CNT reinforcement on mechanical and thermomechanical. J. Appl. Polym. Sci. 2018, 135, 46101. [Google Scholar] [CrossRef]

- Jang, S.; Li, L. Self-sensing carbon nanotube composites exposed to glass transition temperature. Materials 2020, 13, 259. [Google Scholar] [CrossRef]

- Jacobs, O.; Xu, W.; Schädel, B.; Wu, W. Wear behaviour of carbon nanotube reinforced epoxy resin composites. Tribol. Lett. 2006, 23, 65. [Google Scholar] [CrossRef]

- Tang, P.; Zhang, R.; Shi, R.; Bin, Y. Synergetic effects of carbon nanotubes and carbon fibers on electrical and self-heating properties of high-density polyethylene composites. J. Mater. Sci. 2015, 50, 1565–1574. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.; García, A.; Sánchez, M.; Ureña, A. Electrical Transport Mechanisms in Graphene Nanoplatelet Doped Polydimethylsiloxane and Application to Ultrasensitive Temperature Sensors. ACS Appl. Mater. Interfaces 2023, 15, 22377–22394. [Google Scholar] [CrossRef]

- Luo, S.; Liu, T. SWCNT/Graphite Nanoplatelet Hybrid Thin Films for Self-Temperature-Compensated, Highly Sensitive, and Extensible Piezoresistive Sensors. Adv. Mater. 2013, 25, 5650–5657. [Google Scholar] [CrossRef]

- Parkhomenko, I.; Vlasukova, L.; Parfimovich, I.; Komarov, F.; Novikov, L.; Chernik, V.; Zhigulin, D. Atomic oxygen exposure effect on carbon nanotubes/epoxy composites for space systems. Acta Astronaut. 2023, 204, 124–131. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).