Microstructure, Mechanical Properties at Room Temperature and High Temperature of Near-α Titanium Alloys Fabricated by Spark Plasma Sintering

Abstract

:1. Introduction

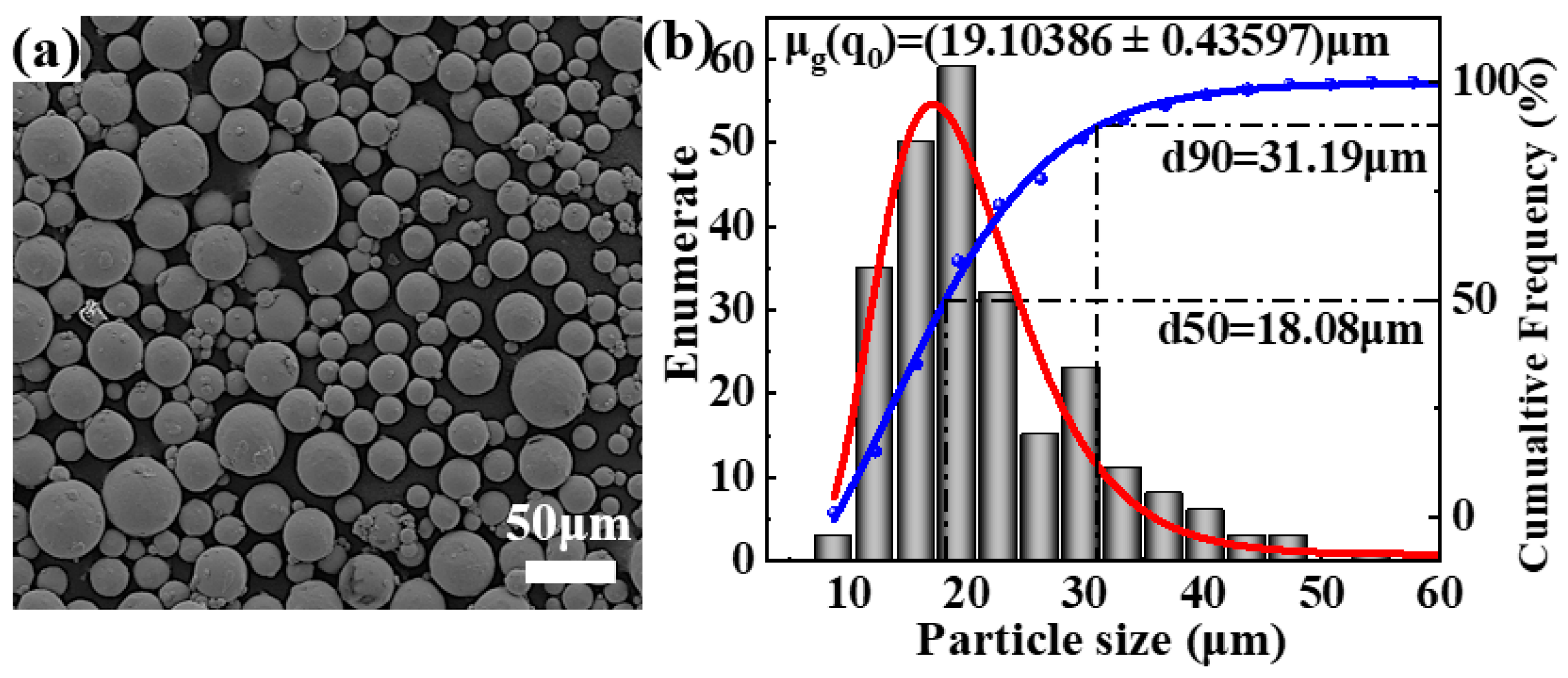

2. Materials and Methods

2.1. Material

2.2. Preparation

2.3. Characterization

3. Results and Discussion

3.1. Relative Density

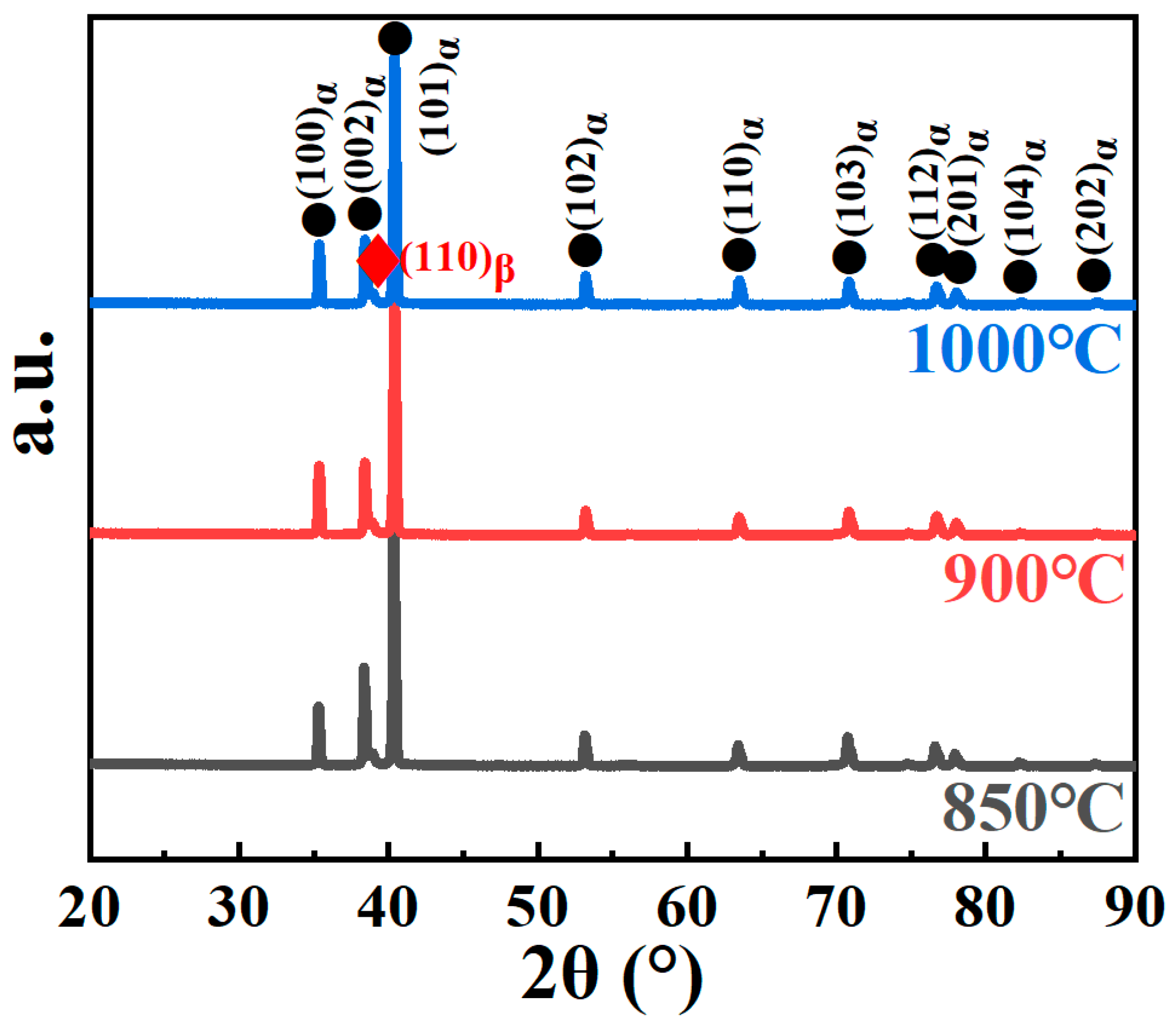

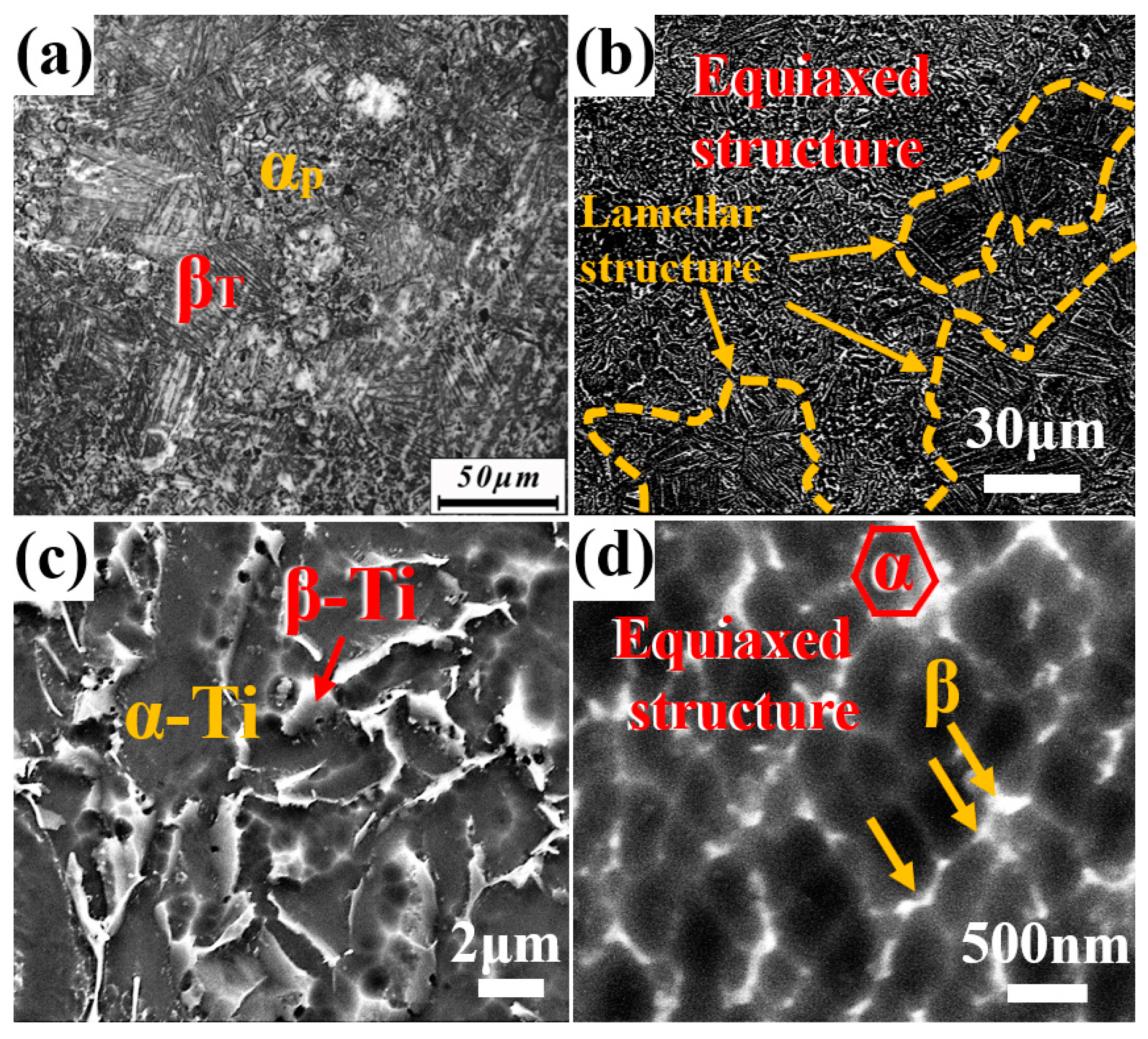

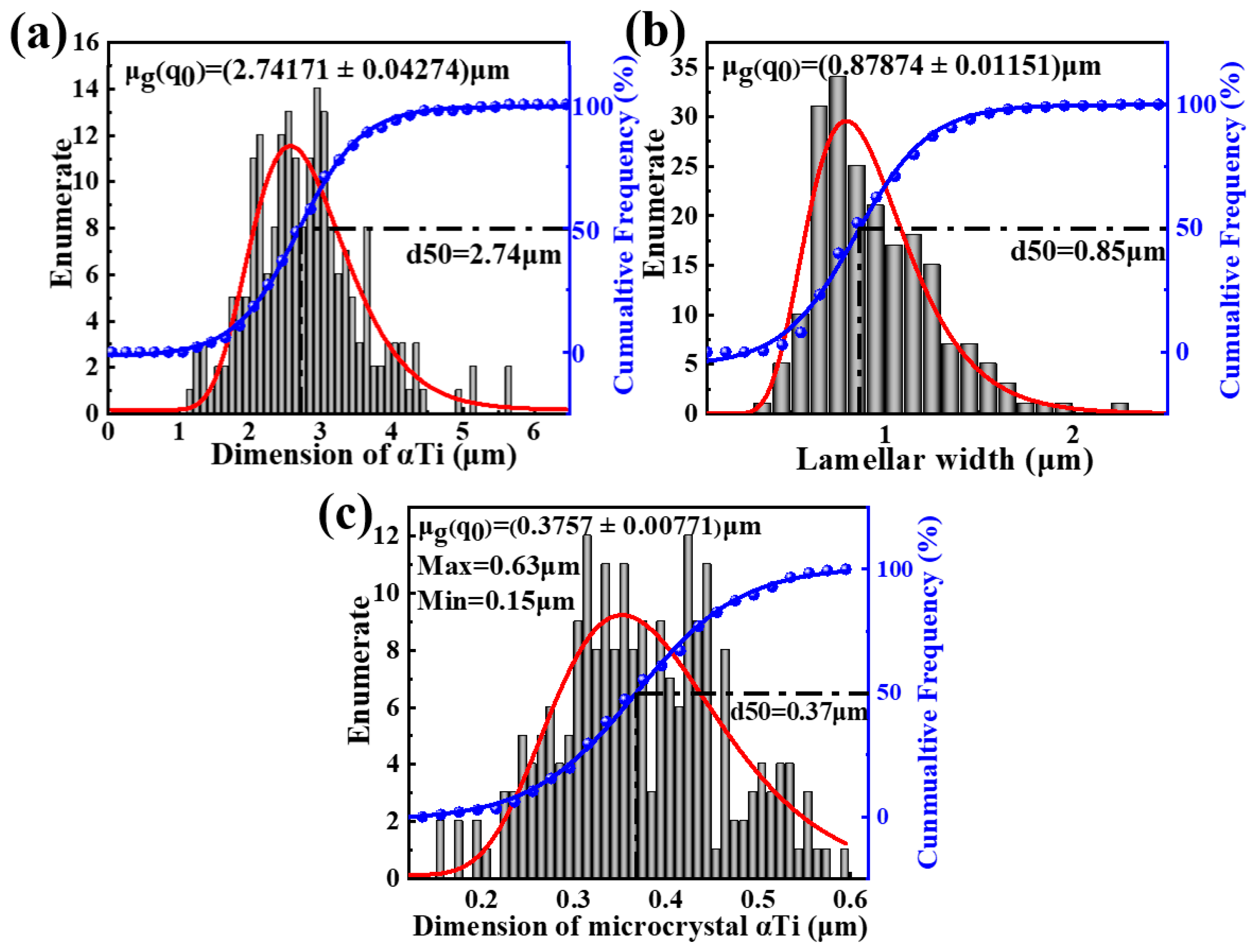

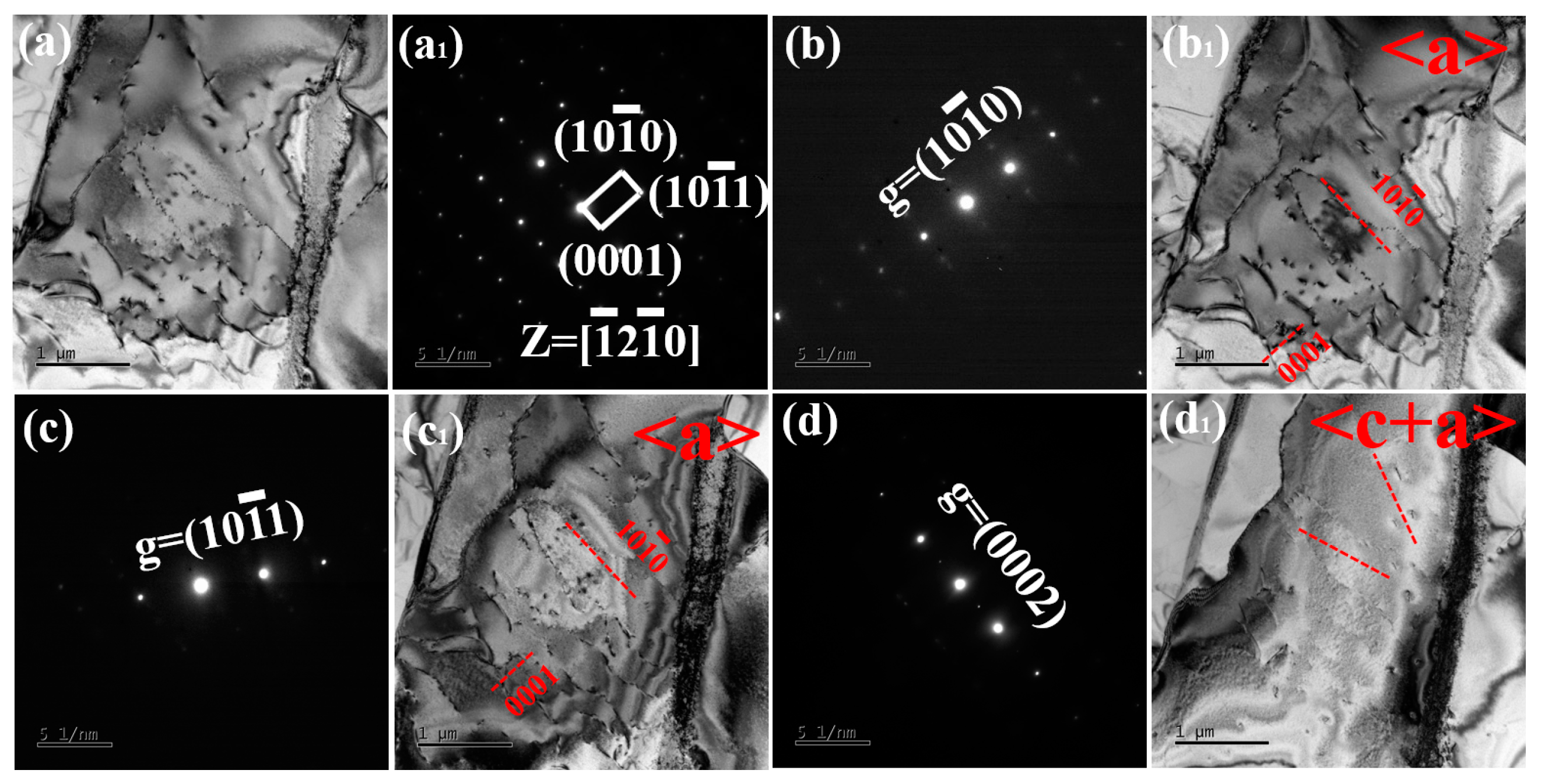

3.2. Microstructures

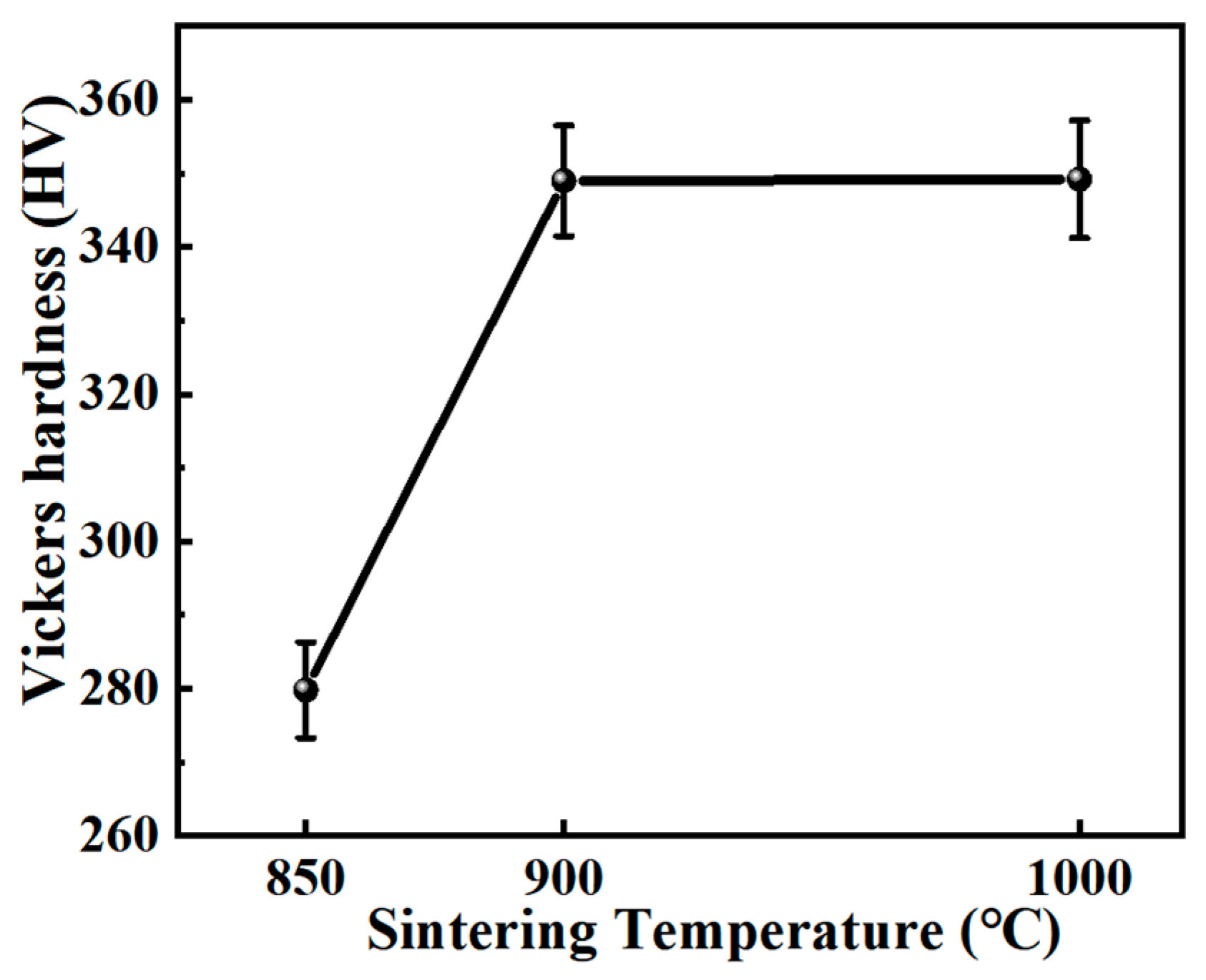

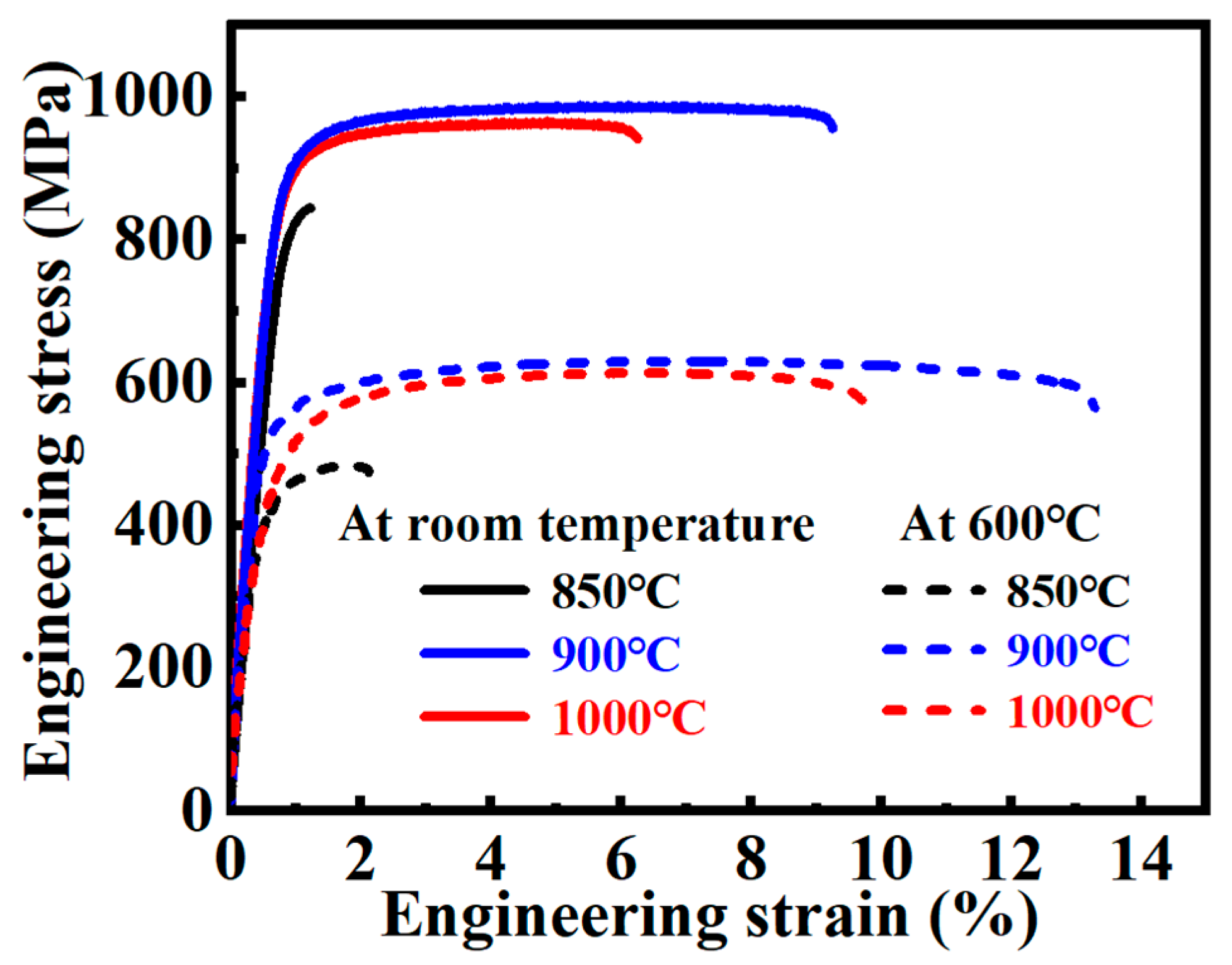

3.3. Mechanical Properties

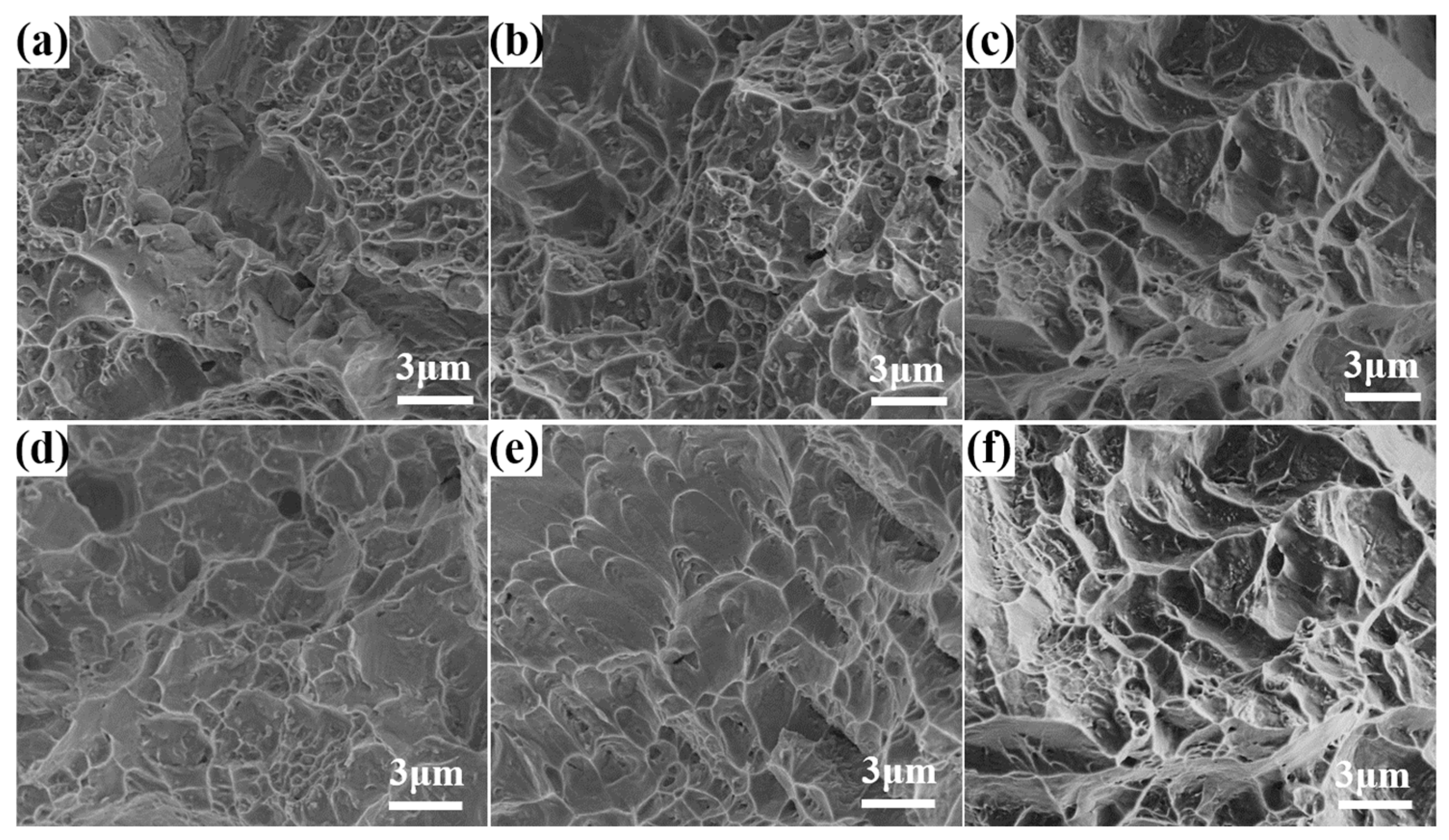

3.4. Fracture

4. Conclusions

- (1)

- With the increase in sintering temperature, the relative density of Ti60 alloy first increased and then tended to stabilize. After sintering at 850 °C, 900 °C, and 1000 °C, the relative densities of Ti60 alloy were 94.56%, 99.91%, and 99.99%, respectively.

- (2)

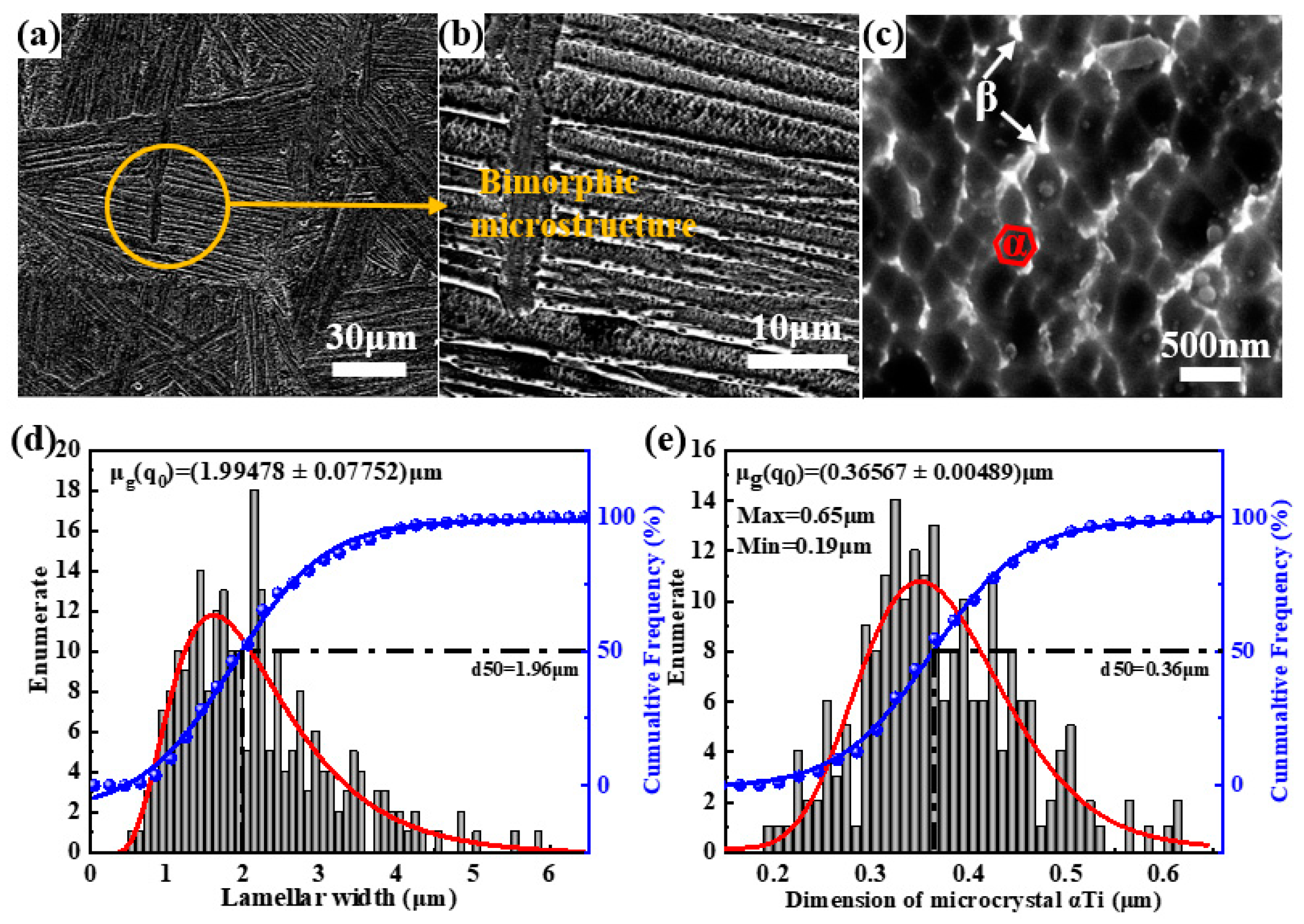

- At a sintering temperature of 900 °C, the microstructure of Ti60 alloy exhibits a bimodal characteristic, with approximately 20% equiaxed α phase, having an average size of 2.74 μm. The average width of the lamellar structure is 0.88 μm. Furthermore, within the lamellar structure, ultrafine equiaxed α phase and dispersed nanoscale β phase are observed, with average sizes of 375 nm and 80 nm, respectively.

- (3)

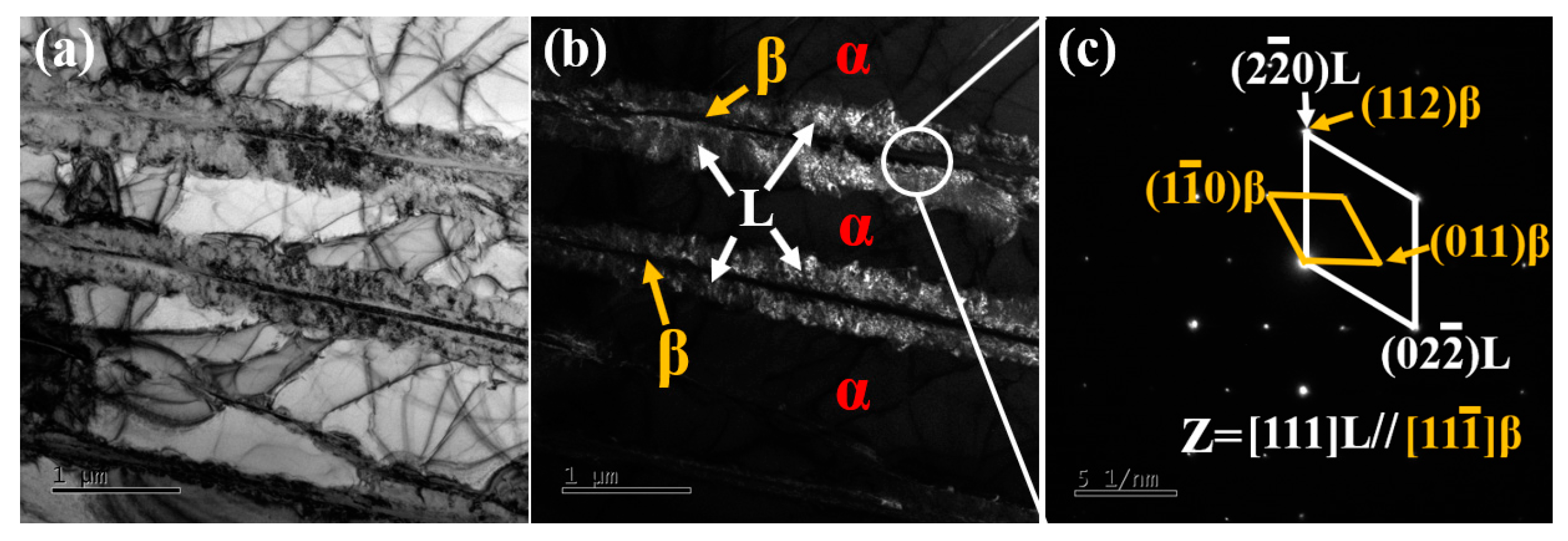

- When the sintering temperature is increased to 1000 °C, the Ti60 alloy exhibits a fully lamellar microstructure, with the lamellar width increasing to approximately 1.99 μm. Additionally, both the 900 °C and 1000 °C sintered Ti60 alloys display a symmetrically distributed L-phase interface layer at the α/β interface, with an orientation relationship described by (112)β//()L and []β//[111]L.

- (4)

- The Ti60 alloy sintered at 900 °C exhibits the best mechanical properties. Its Vickers hardness is 349 ± 7.5 HV, with a room-temperature yield strength, tensile strength, and elongation of 887 ± 15 MPa, 989 ± 10 MPa, and 9.2 ± 0.5%, respectively. At 600 °C, the yield strength, tensile strength, and elongation are 535 ± 15 MPa, 632 ± 10 MPa, and 13.0 ± 0.5%, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, Z.; Zhang, Z.; Cheng, X.; Wang, F.; Zhang, Y.; Li, S. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Ratzker, B.; Sokol, M. Exploring the capabilities of high-pressure spark plasma sintering (HPSPS): A review of materials processing and properties. Mater. Des. 2023, 233, 112238. [Google Scholar] [CrossRef]

- Borse, M.N.; Manokaran, M.; Yebaji, S.G.; Chopra, S.; Sourav, A.; Majumdar, B.; Babu, A.; Thangaraju, S. Development and characterization of a novel Y-Ti-O based aluminum nano-composite processed by high energy ball-milling and spark plasma sintering. Mater. Charact. 2022, 190, 112013. [Google Scholar] [CrossRef]

- Liu, J.; Li, F.; Yi, J.; Liu, Y.; Eckert, J.; Zuo, Q. Microstructure evolution and mechanical properties of functionally graded Fe–8Cr-xNi alloys fabricated by spark plasma sintering. Mater. Sci. Eng. A 2023, 866, 144648. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, J.; Wang, P.; Zhao, H.; Pang, J.; Li, X.; Zhang, J. Study of Bulk Amorphous and Nanocrystalline Alloys Fabricated by High-Sphericity Fe84Si7B5C2Cr2 Amorphous Powders at Different Spark-Plasma-Sintering Temperatures. Materials 2022, 15, 1106. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Z.; Liu, L.; Jia, X.; He, Y.; Li, X.; Cheng, X. In-situ manipulation of TiB whisker orientation and investigation of its high-temperature mechanical properties in titanium matrix composites. Compos. Part B Eng. 2024, 271, 111165. [Google Scholar] [CrossRef]

- Trzaska, Z.; Bonnefont, G.; Fantozzi, G.; Monchoux, J. Comparison of densification kinetics of a TiAl powder by spark plasma sintering and hot pressing. Acta Mater. 2017, 135, 1–13. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Wen, R.; Wang, G.; Zhang, X.; Mu, J.; Che, H.; Wang, W. Comparisons of the densification, microstructure and mechanical properties of boron carbide sintered by hot pressing and spark plasma sintering. Ceram. Int. 2018, 44, 2615–2619. [Google Scholar] [CrossRef]

- Xu, P.; Feng, Y.; Xu, B.; Chen, F.; Lin, Y. Disruption of oxide films during spark plasma sintering of micrometric-sized Al powders and its effect on microstructure and tensile properties of the consolidated Al. J. Alloy. Compd. 2017, 712, 822–832. [Google Scholar] [CrossRef]

- Savio, S.G.; Babu, D.A.; Ramakrishna, B.; Singh, S.; Vanitha, C. Influence of sintering process on microstructure and mechanical properties of alumina ceramics: Spark plasma and microwave hybrid sintering. Ceram. Int. 2024, 50, 11730–11742. [Google Scholar] [CrossRef]

- Kang, L.M.; Cai, Y.J.; Luo, X.C.; Li, Z.J.; Liu, X.B.; Wang, Z.; Li, Y.; Yang, C. Bimorphic microstructure in Ti-6Al-4V alloy manipulated by spark plasma sintering and in-situ press forging. Scr. Mater. 2021, 193, 43–48. [Google Scholar] [CrossRef]

- Hussein, M.A.; Suryanarayana, C.; Al-Aqeeli, N. Fabrication of nano-grained Ti–Nb–Zr biomaterials using spark plasma sintering. Mater. Des. 2015, 87, 693–700. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, G.; Zhang, J.; Wu, C.; Li, J.; Shen, Q.; Zhang, L. Phase transition, microstructure and mechanical properties of TC4 titanium alloy prepared by plasma activated sintering. J. Alloy. Compd. 2018, 714, 918–926. [Google Scholar] [CrossRef]

- Laptev, A.M.; Bram, M.; Garbiec, D.; Räthel, J.; van der Laan, A.; Beynet, Y.; Huber, J.; Küster, M.; Cologna, M.; Guillon, O. Tooling in Spark Plasma Sintering Technology: Design, Optimization, and Application. Adv. Eng. Mater. 2024, 26, 2301391. [Google Scholar] [CrossRef]

- Singh, G.; Ramamurty, U. Boron modified titanium alloys. Prog. Mater. Sci. 2020, 111, 100653. [Google Scholar] [CrossRef]

- Zhao, E.; Sun, S.; Zhang, Y. Recent advances in silicon containing high temperature titanium alloys. J. Mater. Res. Technol. 2021, 14, 3029–3042. [Google Scholar] [CrossRef]

- Narayana, P.L.; Kim, S.; Hong, J.; Reddy, N.S.; Yeom, J. Tensile properties of a newly developed high-temperature titanium alloy at room temperature and 650 °C. Mater. Sci. Eng. A 2018, 718, 287–291. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, J.; Tang, B.; Kou, H.; Wang, J.; Wang, X.; Wang, S.; Wang, Q.; Chen, Z.; Li, J. Microstructural evolution and FCC twinning behavior during hot deformation of high temperature titanium alloy Ti65. J. Mater. Sci. Technol. 2020, 49, 56–69. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Compos. Part A Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Huang, L.; An, Q.; Geng, L.; Wang, S.; Jiang, S.; Cui, X.; Zhang, R.; Sun, F.; Jiao, Y.; Chen, X.; et al. Multiscale Architecture and Superior High-Temperature Performance of Discontinuously Reinforced Titanium Matrix Composites. Adv. Mater. 2021, 33, e2000688. [Google Scholar] [CrossRef]

- Su, Y.; Hao, G.; Fan, H.; Zhai, Y.; Kong, F.; Wang, X.; Chen, Y. Study on rolling of a new near-α titanium alloy: Microstructure refinement and dual-scale silicides evolution. J. Alloy. Compd. 2021, 852, 156867. [Google Scholar] [CrossRef]

- Xu, Y.; Fox, K.; Rugg, D.; Dunne, F.P.E. Cyclic plasticity and thermomechanical alleviation in titanium alloys. Int. J. Plast. 2020, 134, 102753. [Google Scholar] [CrossRef]

- Sakamoto, T.; Akiyama, H.; Tange, S.; Takebe, H. Age hardening of Si-bearing near-α titanium alloy Ti–6Al–2.75Sn–4Zr–0.4Mo–0.45Si (Ti-1100) with two kinds of initial phases. Mater. Trans. 2023, 64, 2246–2253. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Wang, Q.J.; Liu, J.R.; Yang, R. Effect of heat treatment on the crystallographic orientation evolution in a near-α titanium alloy Ti60. Acta. Mater. 2017, 131, 305–314. [Google Scholar] [CrossRef]

- Chen, C.; Shang, D.; Xiao, N.; Li, X.; Sha, A.; Li, J.; Tang, Z.; Han, Z.; Guo, Y.; Li, D. Fatigue life prediction of Ti60 titanium alloy under very high cycle loading at different temperatures. Int. J. Fatigue 2023, 176, 107838. [Google Scholar] [CrossRef]

- Jia, R.; Zeng, W.; He, S.; Gao, X.; Xu, J. The analysis of fracture toughness and fracture mechanism of Ti60 alloy under different temperatures. J. Alloy. Compd. 2019, 810, 151899. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti–6Al–4V via electron beam melting. Acta. Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Zhuang, Z.; Jing, C.; Shuai, G.; Hua, T.; Xin, L. Influence of α/β interface phase on the tensile properties of laser cladding deposited Ti–6Al–4V titanium alloy. J. Mater. Sci. Technol. 2017, 33, 675–681. [Google Scholar] [CrossRef]

| Sintering Temperature | Relative Density |

|---|---|

| 850 °C | 94.56% |

| 950 °C | 99.91% |

| 1000 °C | 99.99% |

| Material | Sintering Temperature | Test Temperature | YS (MPa) | UTS (MPa) | Elongation(%) |

|---|---|---|---|---|---|

| Ti60 | 850 °C | 25 °C | 816 ± 15 | 846 ± 20 | 1.2 ± 0.5 |

| 600 °C | 424 ± 10 | 483 ± 15 | 2.1 ± 0.5 | ||

| 900 °C | 25 °C | 887 ± 15 | 989 ± 10 | 9.2 ± 0.5 | |

| 600 °C | 535 ± 15 | 632 ± 10 | 13.0 ± 0.5 | ||

| 1000 °C | 25 °C | 878 ± 10 | 962 ± 10 | 6.1 ± 0.5 | |

| 600 °C | 511 ± 10 | 614 ± 10 | 9.6 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, Z.; Jia, X.; He, Y.; Zhou, J.; Sun, Y.; Cheng, X. Microstructure, Mechanical Properties at Room Temperature and High Temperature of Near-α Titanium Alloys Fabricated by Spark Plasma Sintering. Nanomaterials 2025, 15, 293. https://doi.org/10.3390/nano15040293

Wang Q, Zhang Z, Jia X, He Y, Zhou J, Sun Y, Cheng X. Microstructure, Mechanical Properties at Room Temperature and High Temperature of Near-α Titanium Alloys Fabricated by Spark Plasma Sintering. Nanomaterials. 2025; 15(4):293. https://doi.org/10.3390/nano15040293

Chicago/Turabian StyleWang, Qiang, Zhaohui Zhang, Xiaotong Jia, Yangyu He, Jinzhao Zhou, Yuanhao Sun, and Xingwang Cheng. 2025. "Microstructure, Mechanical Properties at Room Temperature and High Temperature of Near-α Titanium Alloys Fabricated by Spark Plasma Sintering" Nanomaterials 15, no. 4: 293. https://doi.org/10.3390/nano15040293

APA StyleWang, Q., Zhang, Z., Jia, X., He, Y., Zhou, J., Sun, Y., & Cheng, X. (2025). Microstructure, Mechanical Properties at Room Temperature and High Temperature of Near-α Titanium Alloys Fabricated by Spark Plasma Sintering. Nanomaterials, 15(4), 293. https://doi.org/10.3390/nano15040293