Nanostructured Silver Found in Ancient Dacian Bracelets from Cehei Hoard—Salaj, Romania

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples Description and Preparation

2.2. Investigation Methods

3. Results

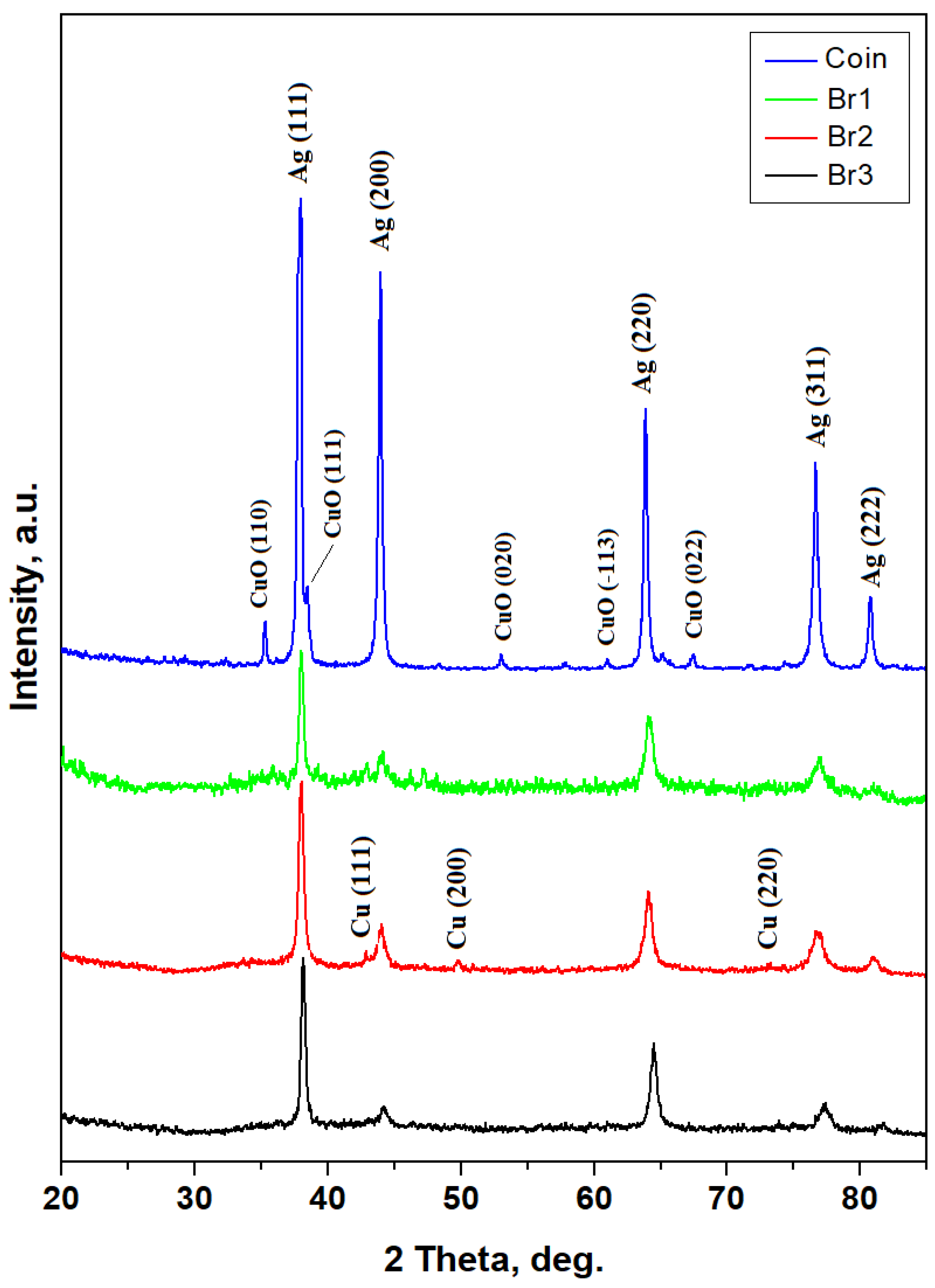

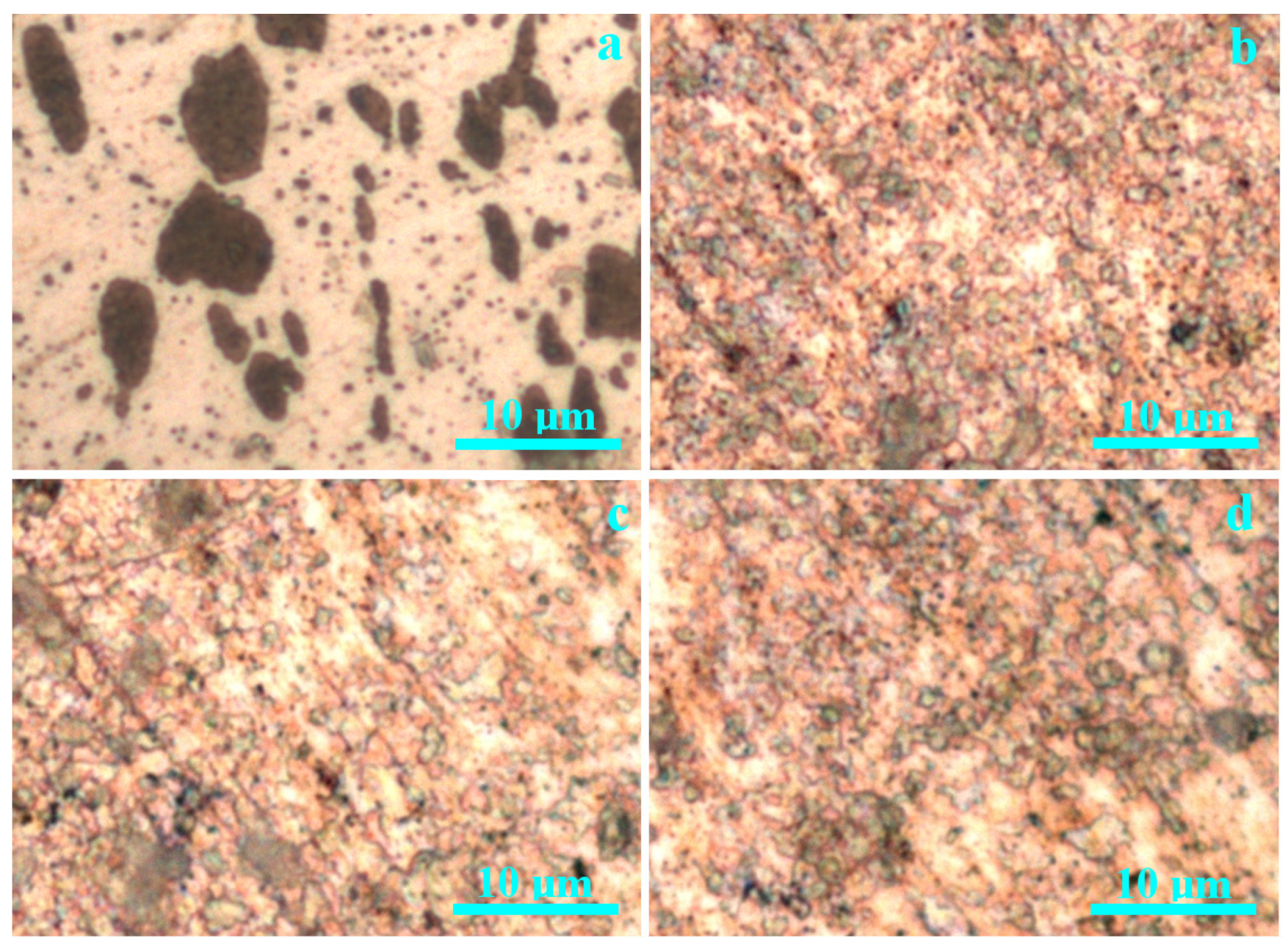

3.1. Alloy Phases and Their Microstructural Constituents

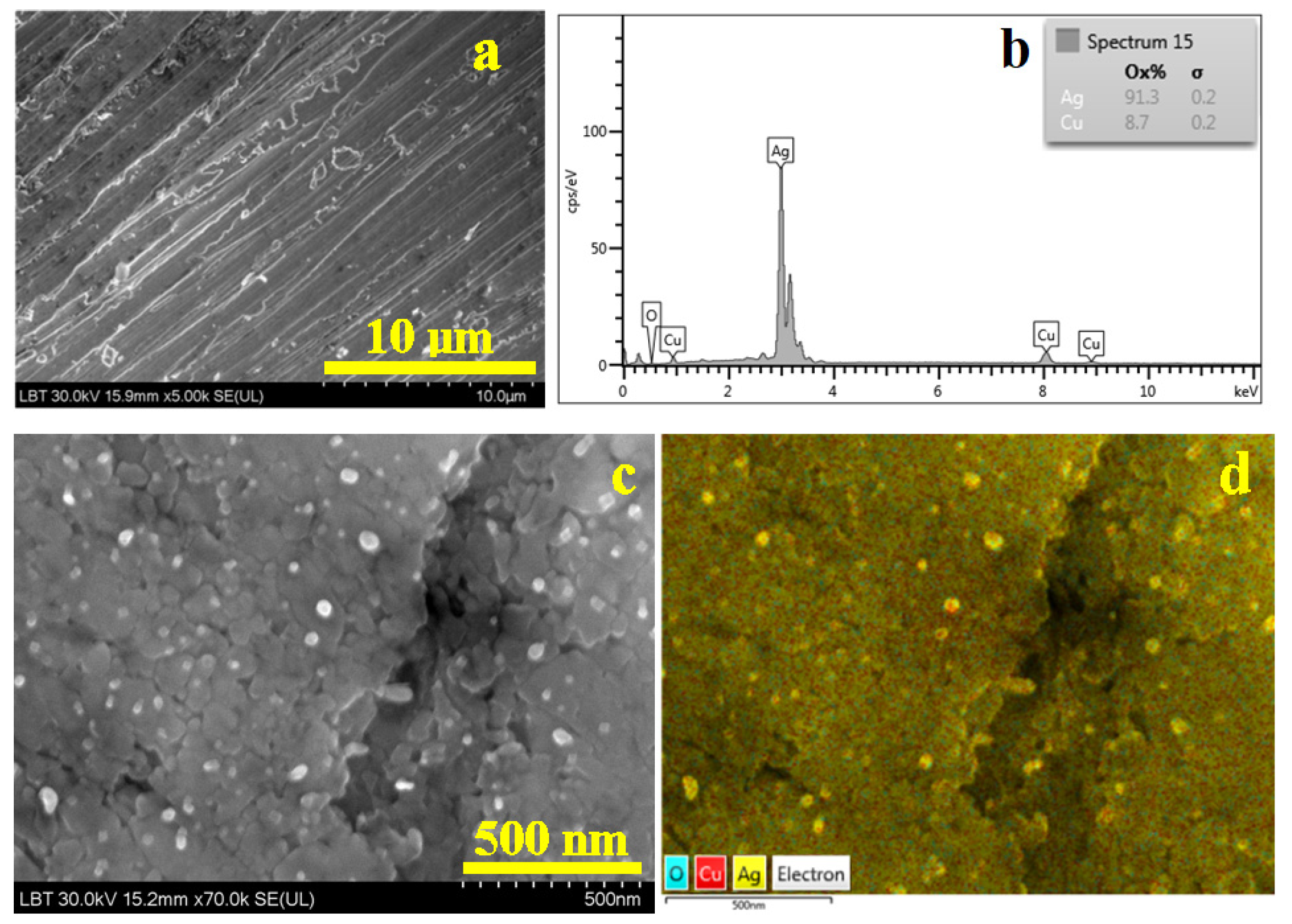

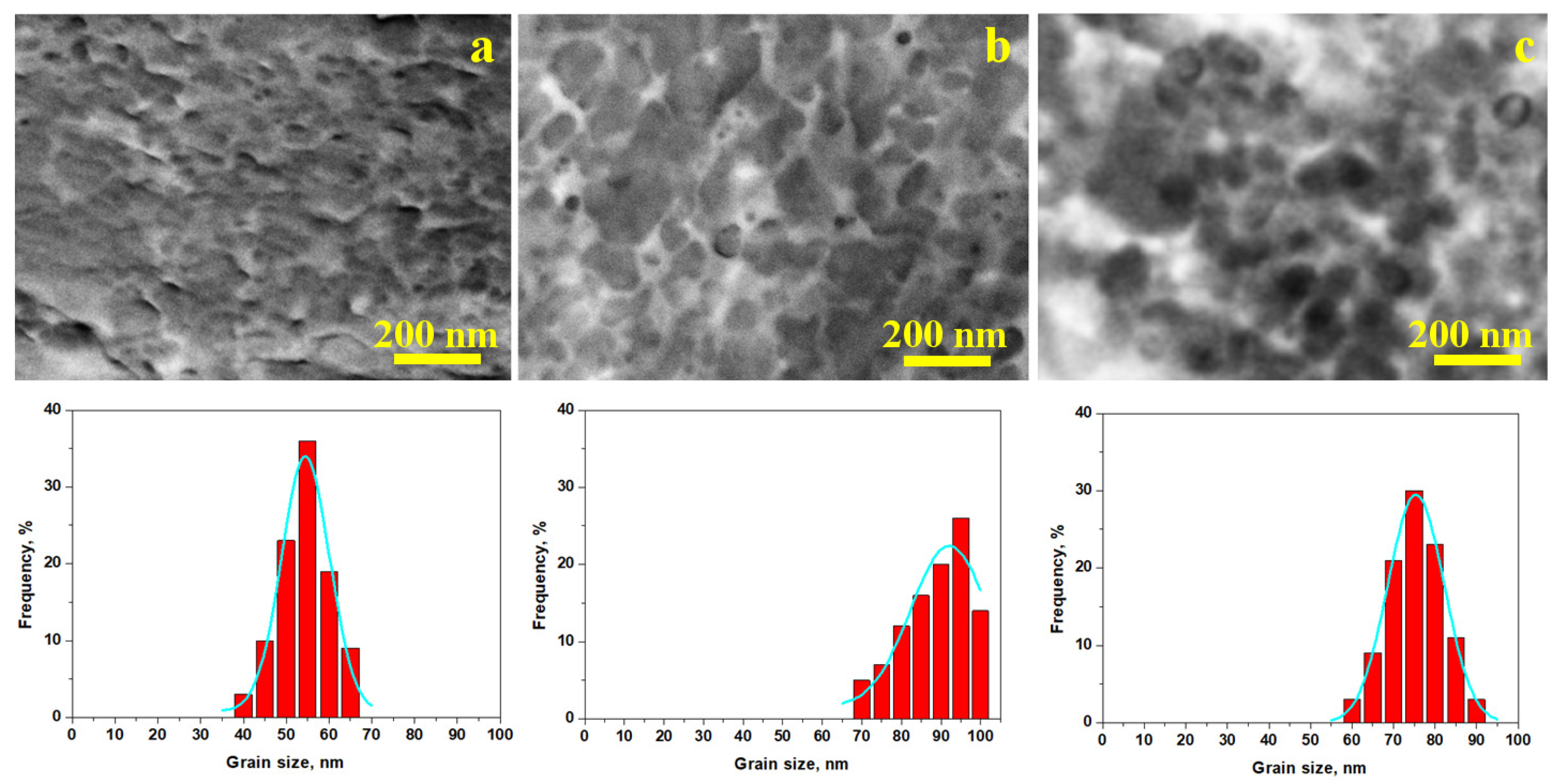

3.2. Sample’s Morphology and Nanostructure

3.3. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BSE | Backscatter Electron Image |

| EBSD | Electron Backscatter Diffraction |

| EDS | Energy Dispersive Spectroscopy |

| RIR | Relative Intensity Ratio |

| SEM | Scanning Electron Microscopy |

| SEI | Secondary Electron Image |

| TEM | Transmission Electron Microscopy |

| XRD | X-ray Diffraction |

References

- Dwivedi, D.; Mata, J.P. Archaeometallurgical investigation of ancient artefacts’ degradation phenomenon. NPJ Mater. Degrad. 2019, 3, 35. [Google Scholar] [CrossRef]

- Cosano, D.; Esquivel, D.; Tena, C.; Arrebola, J.R.R. Chemical analysis of archaeological metals found in a Roman burial site in Castro del Río (Córdoba, Spain). Next Mater. 2025, 8, 100721. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, D.; Zhang, L.; Liu, K.; Zhang, J.; Si, Y.; Chen, G.; Zhu, Q. Microstructural Evolution and Tensile Deformation Behavior of FeCoNiCrTi0.2 High-Entropy Alloys Regulated by Cold Rolling and Annealing. Metals 2025, 15, 1037. [Google Scholar] [CrossRef]

- da Silva, V.R.; Fjellvåg, Ø.S.; Švec, P.; Švec, P., Jr.; Hauback, B.C.; Deledda, S. The Effect of Mo and Al Substitution in Cryomilled and Cold-Rolled FeNi Alloys. Metals 2025, 15, 996. [Google Scholar] [CrossRef]

- Xie, Z.; Bi, Y.; Fan, Y.; Gao, C.; Zhang, X.; Feng, Y.; Zhou, D.; Dong, L. Finite Element Investigation of a Novel Cold-Formed Steel Shear Wall. Buildings 2024, 14, 1691. [Google Scholar] [CrossRef]

- Hang, H.; Gao, T.; Chen, J.; Li, X.; Song, H.; Huang, G. Investigation on Strain Hardening and Failure in Notched Tension Specimens of Cold Rolled Ti6Al4V Titanium Alloy. Materials 2022, 15, 3429. [Google Scholar] [CrossRef]

- Wadsworth, J. Archeometallurgy related to swords. Mater. Charact. 2015, 99, 1–7. [Google Scholar] [CrossRef]

- Yang, P.-H.; Chiu, M.-C.; Huang, H.-C.; Liang, C.-L. The behaviors and mechanisms of current-enhanced recrystallization and grain growth in as-rolled pure nickel during electrical annealing. Mater. Sci. Eng. A 2025, 946, 149173. [Google Scholar] [CrossRef]

- Liang, P.; Zhang, J.; Kong, N.; Li, H.; Zhu, H. The Microstructure Characteristics Evolution of Bulk High-Purity Silver for High Relief Application. Metals 2023, 13, 463. [Google Scholar] [CrossRef]

- Mandal, S.; Kumar, P.; Satpathy, B.; Das, K.; Das, S. Nanostructured metal oxide based coating for the protection and conservation of cultural heritage: A comprehensive review. J. Cult. Herit. 2024, 69, 94–112. [Google Scholar] [CrossRef]

- Plaza, N.Z.; Pingali, S.V.; Broda, M. The effect of organosilicon compounds on the nanostructure of waterlogged archeological oak studied by neutron and X-ray scattering. J. Cult. Herit. 2025, 71, 203–210. [Google Scholar] [CrossRef]

- Petean, I.; Pețan, A.; Pop, H.; Avram, S.E.; Tudoran, L.B.; Borodi, G. Nondestructive investigations of tin-rich bronze mirrors discovered in Dacian sites from Sălaj County—Romania. J. Archaeol. Sci. Rep. 2025, 67, 105424. [Google Scholar] [CrossRef]

- Constantinescu, B.; Bugoi, R.; Cojocaru, V.; Simon, R.; Grambole, D.; Munnik, F.; Oberländer-Târnoveanu, E. Elemental analysis through X-ray techniques applied in archeological gold authentication—The case of Transylvanian gold and of the Dacian bracelets. Spectrochim. Acta Part B At. Spectrosc. 2009, 64, 1198–1203. [Google Scholar] [CrossRef]

- Chirilă, E.; Matei, V.A. Tezaurul dacic de la Cehei. Acta Mvsei Porolissensis 1986, 10, 95–117. [Google Scholar]

- Pop, H. Tezaurul Cehei-Deluț. In Șimleu Silvaniei, jud. Sălaj în Aurul și Argintul Antic al României, Catalog de Expoziție; Marghitu, R.A., Ed.; Muzeul Național de Istorie a României: București, Romania, 2013; pp. 323–325. [Google Scholar]

- Liu, S.; Gong, Z.; Lu, H.; Zhang, W.; Ma, Y.; Yang, X.; Xie, Z.; Hu, G.; Hu, D. Optimizing Metallographic Etchants for Ancient Gold and Silver Materials. Metals 2022, 12, 1229. [Google Scholar] [CrossRef]

- Xiao, J.; Song, Y.; Li, Y. Comparison of Quantitative X-ray Diffraction Mineral Analysis Methods. Minerals 2023, 13, 566. [Google Scholar] [CrossRef]

- Farcas, I.A.; Dippong, T.; Petean, I.; Moldovan, M.; Filip, M.R.; Ciotlaus, I.; Tudoran, L.B.; Borodi, G.; Paltinean, G.A.; Pripon, E.; et al. Material Evidence of Sediments Recovered from Ancient Amphorae Found at the Potaissa Roman Fortress. Materials 2023, 16, 2628. [Google Scholar] [CrossRef] [PubMed]

- Avram, S.E.; Tudoran, L.B.; Borodi, G.; Petean, I. Microstructural Characterization of the Mn Lepidolite Distribution in Dark Red Clay Soils. Appl. Sci. 2025, 15, 6445. [Google Scholar] [CrossRef]

- Dippong, T.; Toloman, D.; Lazar, M.D.; Petean, I. Effects of Lanthanum Substitution and Annealing on Structural, Morphologic, and Photocatalytic Properties of Nickel Ferrite. Nanomaterials 2023, 13, 3096. [Google Scholar] [CrossRef]

- Hassanzadeh-Tabrizi, S.A. Precise calculation of crystallite size of nanomaterials: A review. J. Alloys Compd. 2023, 968, 171914. [Google Scholar] [CrossRef]

- Kibasomba, P.M.; Dhlamini, S.; Maaza, M.; Liu, C.-P.; Rashad, M.M.; Rayan, D.A.; Mwakikunga, B.W. Strain and grain size of TiO2 nanoparticles from TEM, Raman spectroscopy and XRD: The revisiting of the Williamson-Hall plot method. Results Phys. 2018, 9, 628–635. [Google Scholar] [CrossRef]

- Northover, S.M.; Northover, J.P. Microstructures of ancient and modern cast silver–copper alloys. Mater. Charact. 2014, 90, 173–184. [Google Scholar] [CrossRef]

- Liu, S.; Shi, M.; Zhou, Y.; Li, R.; Xie, Z.; Hu, D.; Zhang, M.; Hu, G. Scanning electrochemical cell microscopy: A powerful method to study the intergranular corrosions of archaeological silver artifacts. J. Cult. Herit. 2020, 46, 176–183. [Google Scholar] [CrossRef]

- Ortega-Avilés, M.; Tenorio-Castilleros, D.; Segura-Venzor, I.L.; Miranda-Hernández, J.G.; Velasco, M.A. An archaeometallurgical study of Mixtec silver gold alloy foils from Tomb No. 7, Monte Alban, Oaxaca, México. Mater. Chem. Phys. 2020, 242, 122475. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.; Xia, E.; Chen, W.; He, X.; Tang, D. Effect of Solution and Aging Treatment on the Microstructural Evolution and Mechanical Properties of Cold-Rolled 2024 Aluminum Alloy Sheets. Coatings 2025, 15, 1139. [Google Scholar] [CrossRef]

- Liu, H.; Yang, Z.; Yang, Z.; Wu, Y.; Ju, J. Effect of Cold Rolling on Microstructure Evolution and Mechanical Properties of Zn-3Cu-1Mg-0.3Nd Alloy. Crystals 2025, 15, 769. [Google Scholar] [CrossRef]

- Kogtenkova, O.; Straumal, B.; Korneva, A.; Czeppe, T.; Wierzbicka-Miernik, A.; Faryna, M.; Zięba, P. Grain Boundary Complexions and Phase Transformations in Al- and Cu-Based Alloys. Metals 2019, 9, 10. [Google Scholar] [CrossRef]

- Uzonyi, I.; Bugoi, R.; Sasianu, A.; Kiss, A.Z.; Constantinescu, B.; Torbágyi, M. Characterization of Dyrrhachium silver coins by micro-PIXE method. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2000, 161–163, 748–752. [Google Scholar] [CrossRef]

- Arghir, G.; Petean, I.; Pripon, E.; Pascuta, P. On the mathematical algorithm of some ancient drachma minting time. Acta Tech. Napoc. Appl. Math. Mech. Eng. 2014, 57, 141–148. [Google Scholar]

- Marzano, A. Marine salt production in the Roman world: The salinae and their ownership. Quat. Sci. Rev. 2024, 336, 108776. [Google Scholar] [CrossRef]

- Chiarantini, L.; Benvenuti, M.; Bianchi, G.; Dallai, L.; Volpi, V.; Manca, R. Medieval Pb (Cu-Ag) Smelting in the Colline Metallifere District (Tuscany, Italy): Slag Heterogeneity as a Tracer of Ore Provenance and Technological Process. Minerals 2021, 11, 97. [Google Scholar] [CrossRef]

- Westner, K.J.; Klein, S.; Sergeev, D.; Müller, M. Temperature estimates of historical Pb-Ag smelting slags: A multi-methodological approach. J. Archaeol. Sci. Rep. 2022, 46, 103654. [Google Scholar] [CrossRef]

- Ning, Z.; Wang, Q.; Zhao, D.; Pei, W.; Wen, M. Structural Evolution of Bulk Silver during Cold Rolling and Annealing. Metals 2022, 12, 1525. [Google Scholar] [CrossRef]

- Angella, G.; Esfandiar Jahromi, B.; Vedani, M. A comparison between equal channel angular pressing and asymmetric rolling of silver in the severe plastic deformation regime. Mater. Sci. Eng. A 2013, 559, 742–750. [Google Scholar] [CrossRef]

- Weman, K. Chapter 11—Pressure welding methods. In Woodhead Publishing Series in Welding and Other Joining Technologies, Welding Processes Handbook, 2nd ed.; Weman, K., Ed.; Woodhead Publishing: Sawston, UK, 2012; pp. 119–132. [Google Scholar] [CrossRef]

- Yongbing, L. Pressure Welding. In ECPH Encyclopedia of Mining and Metallurgy; Xu, K., Ed.; Springer: Singapore, 2024. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Zhang, D.; Guo, X.; Du, J.; Wang, E. Effect of Sn Addition on Microstructural Evolution and Properties of Cu–Ag Alloys. JOM 2025. [Google Scholar] [CrossRef]

- Fischer-Bühner, J.; Bertoncello, R.; Basso, A.; Poliero, M. Silver Casting Revisited: The Alloy Perspective; The Bell Group, Inc.: Glasgow, UK, 2011. [Google Scholar]

- Gavrilă, C.C.; Lateş, M.T.; Grebenişan, G. Sustainable Approach to Metal Coin Canceling Methods, Using 3D Modeling and Finite Element Method Analysis. Sustainability 2024, 16, 2322. [Google Scholar] [CrossRef]

- Gavrilă, C.C.; Lateş, M.T. Metal coin error study using 3D modelling and FEM Analysis, Annals of the Oradea University. Fascicle Manag. Technol. Eng. 2019, 29, 3394. [Google Scholar] [CrossRef]

- Victoria-Hernández, J.; Jeong, Y.; Letzig, D. Role of recovery in the microstructure development and mechanical behavior of a ductile Mg-Zn-Nd-Y-Zr alloy: An analysis using EBSD data and crystal plasticity simulations. Int. J. Plast. 2025, 191, 104380. [Google Scholar] [CrossRef]

- Ji, Y.; Suo, H.; Ma, Z.; Huang, B.; Liu, J.; Zhang, Z.; Wang, Q. In-situ tensile analysis of microstructure evolution in Ni, Ni5W, and Ni9W using EBSD. J. Mater. Res. Technol. 2025, 36, 1475–1490. [Google Scholar] [CrossRef]

| Sample | Ag, wt.% | Crystallite Size, nm | |

|---|---|---|---|

| Scherrer | Williamson–Hall | ||

| Bracelet 1 | 91 | 5.22 | 50 |

| Bracelet 2 | 90 | 17.46 | 80 |

| Bracelet 3 | 95 | 8.49 | 70 |

| Sample | Ag, wt.% | Cu, wt.% | Grain Size, nm | |

|---|---|---|---|---|

| SEM | TEM | |||

| Drachma | 91.3 | 8.7 | 8000 | - |

| Bracelet 1 | 90.5 | 9.5 | 55 | 55 ± 15 |

| Bracelet 2 | 92.1 | 7.9 | 95 | 95 ± 25 |

| Bracelet 3 | 91.3 | 8.7 | 75 | 75 ± 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petean, I.; Pripon, E.; Pop, H.; Sarosi, C.; Paltinean, G.A.; Avram, S.E.; Ignat, N.; Tudoran, L.B.; Borodi, G. Nanostructured Silver Found in Ancient Dacian Bracelets from Cehei Hoard—Salaj, Romania. Nanomaterials 2025, 15, 1740. https://doi.org/10.3390/nano15221740

Petean I, Pripon E, Pop H, Sarosi C, Paltinean GA, Avram SE, Ignat N, Tudoran LB, Borodi G. Nanostructured Silver Found in Ancient Dacian Bracelets from Cehei Hoard—Salaj, Romania. Nanomaterials. 2025; 15(22):1740. https://doi.org/10.3390/nano15221740

Chicago/Turabian StylePetean, Ioan, Emanoil Pripon, Horea Pop, Codruta Sarosi, Gertrud Alexandra Paltinean, Simona Elena Avram, Nicoleta Ignat, Lucian Barbu Tudoran, and Gheorghe Borodi. 2025. "Nanostructured Silver Found in Ancient Dacian Bracelets from Cehei Hoard—Salaj, Romania" Nanomaterials 15, no. 22: 1740. https://doi.org/10.3390/nano15221740

APA StylePetean, I., Pripon, E., Pop, H., Sarosi, C., Paltinean, G. A., Avram, S. E., Ignat, N., Tudoran, L. B., & Borodi, G. (2025). Nanostructured Silver Found in Ancient Dacian Bracelets from Cehei Hoard—Salaj, Romania. Nanomaterials, 15(22), 1740. https://doi.org/10.3390/nano15221740