Building Polyacryronitrile Fiber/Epoxy Resin (PANER) Interleaving Film to Strengthen Flexural and Compressive Performances of Laminated CFRP Composites

Abstract

1. Introduction

2. Preparation and Characterization of CFRP Composites

2.1. Raw Materials

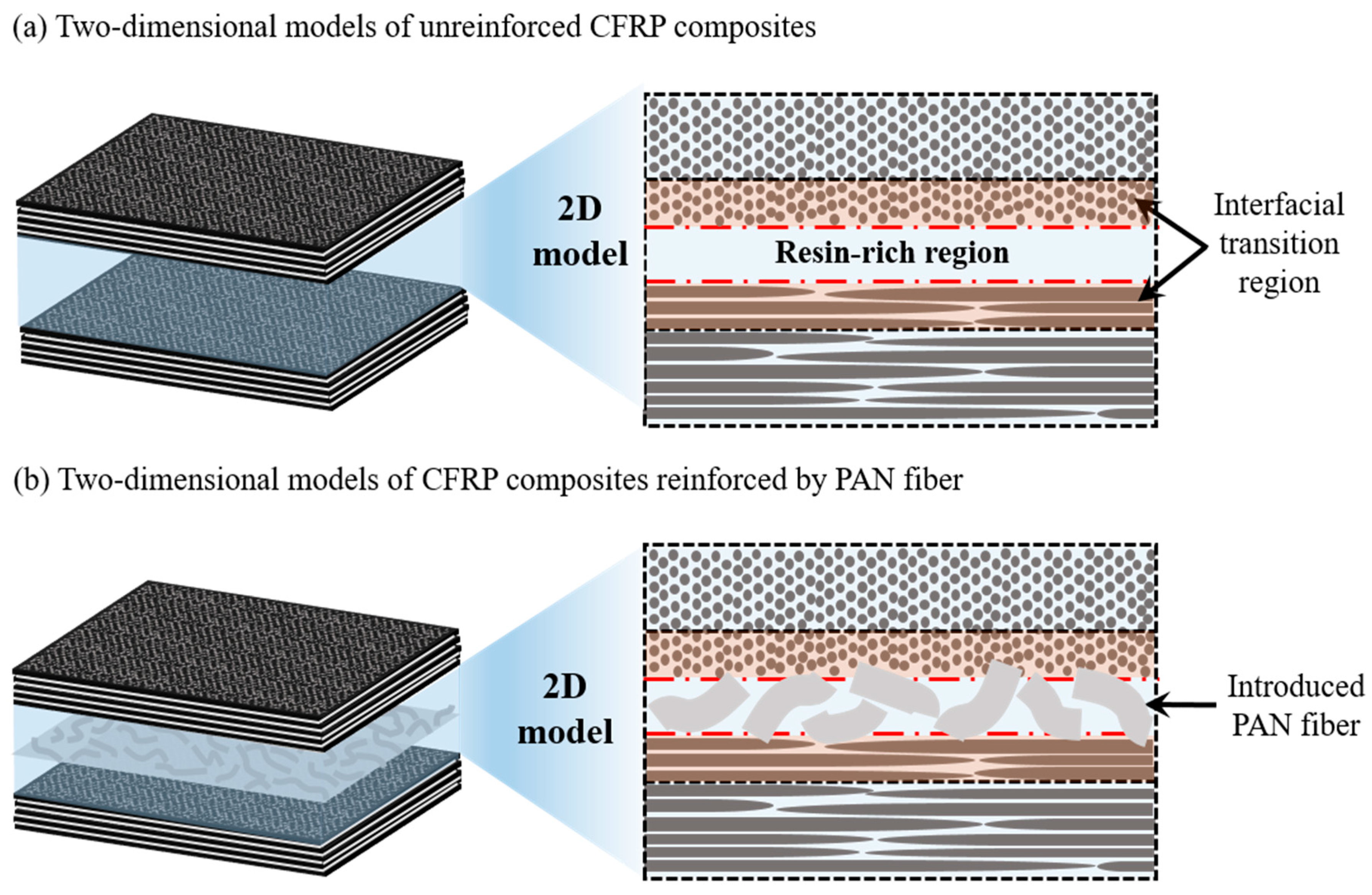

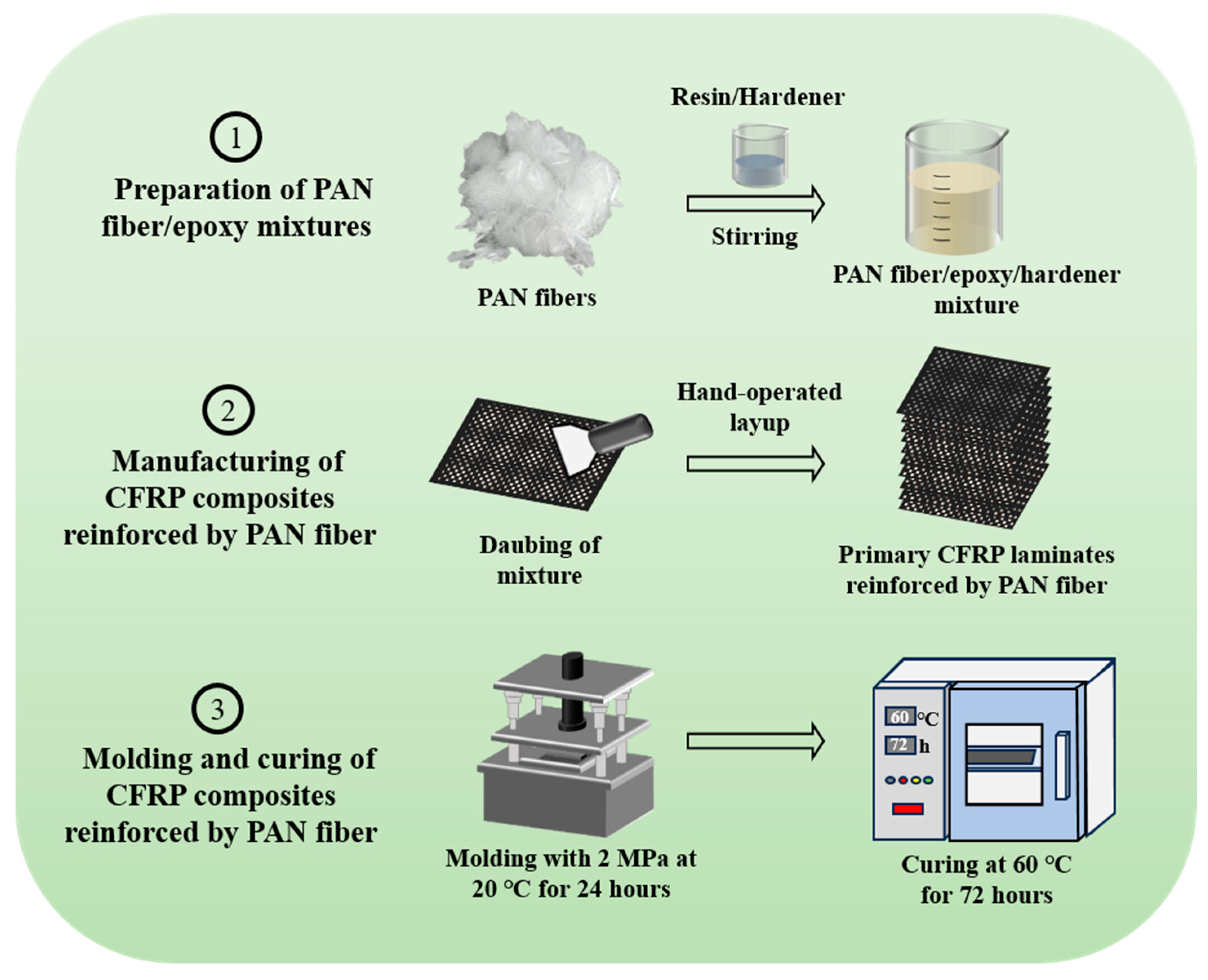

2.2. Preparation of CFRP Composites Reinforced by PAN Fiber

- (1)

- PAN/epoxy mixtures were first processed without the addition of hardener. In this step, the continuous PAN fibers were finely cut into short, discontinuous fibers, and then mixed with epoxy resin in various masses. The PAN ratio was varied as 1 wt.%, 2 wt.%, 3 wt.%, and 4 wt.%. By thoroughly stirring the PAN fibers into epoxy resin, a uniform and homogeneously viscous PAN/epoxy mixture was prepared.

- (2)

- After preparing the mixture, the process was followed by calculating and adding the hardener at a ratio of 1:5 relative to the epoxy resin content in the PAN/epoxy mixtures. Then, PAN/epoxy/hardener mixtures with varying masses of PAN fibers were daubed onto the carbon fiber fabric to design the primary CFRP laminated structure reinforced by PAN fibers.

- (3)

- The final CFRP composite structure was obtained after compression molding and curing. The prepared primary-laminated CFRP was placed under compression molding at 2 MPa for 24 h and then placed into the dry curing chamber at 60 °C for 72 h to obtain finally cured laminated CFRP composites. The detailed parameters of final CFRP composites reinforced by PAN fiber are presented in Table 2.

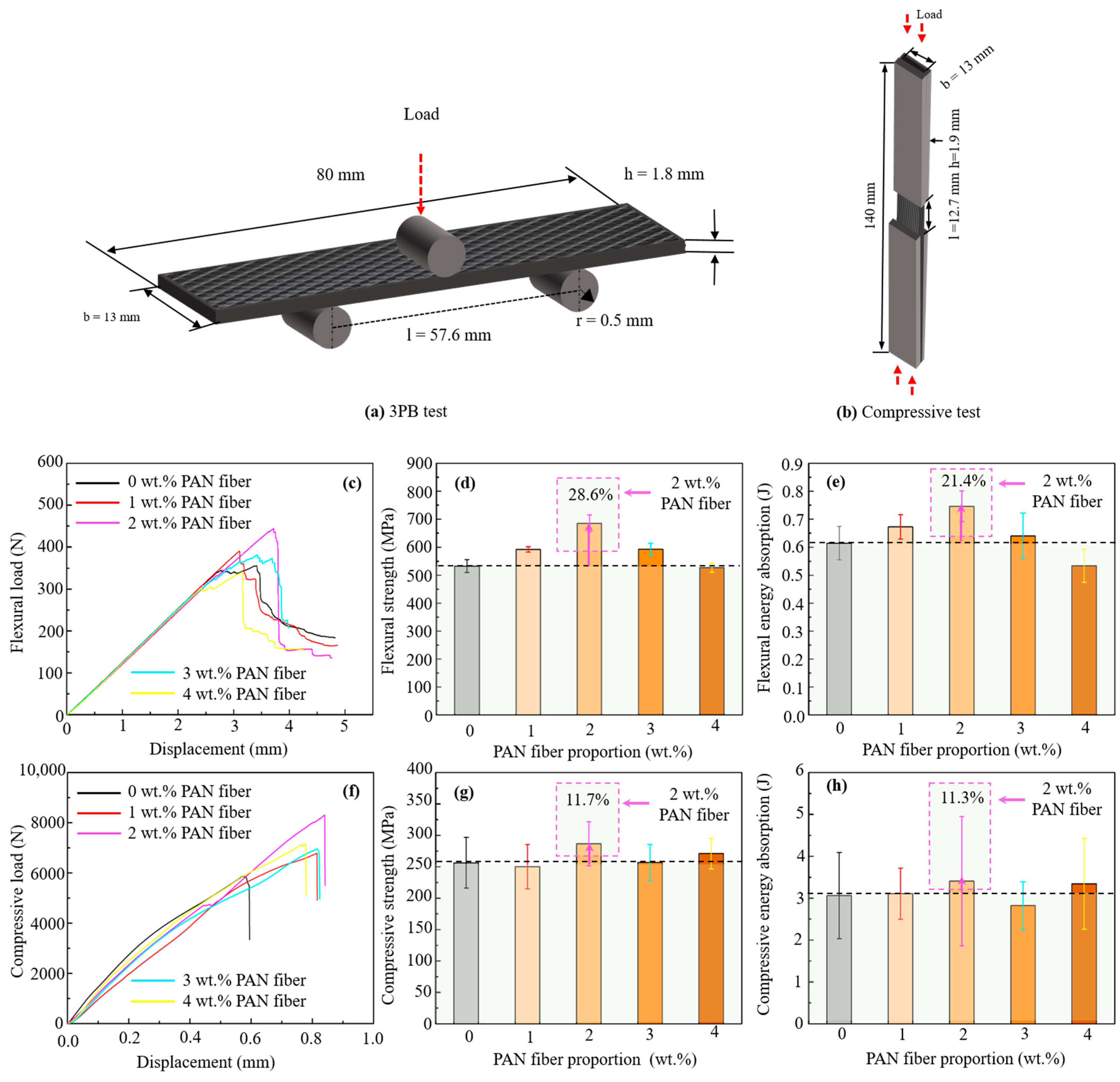

2.3. Tests and Characterizations of CFRP Composites Reinforced by PAN Fiber

3. Results and Discussions

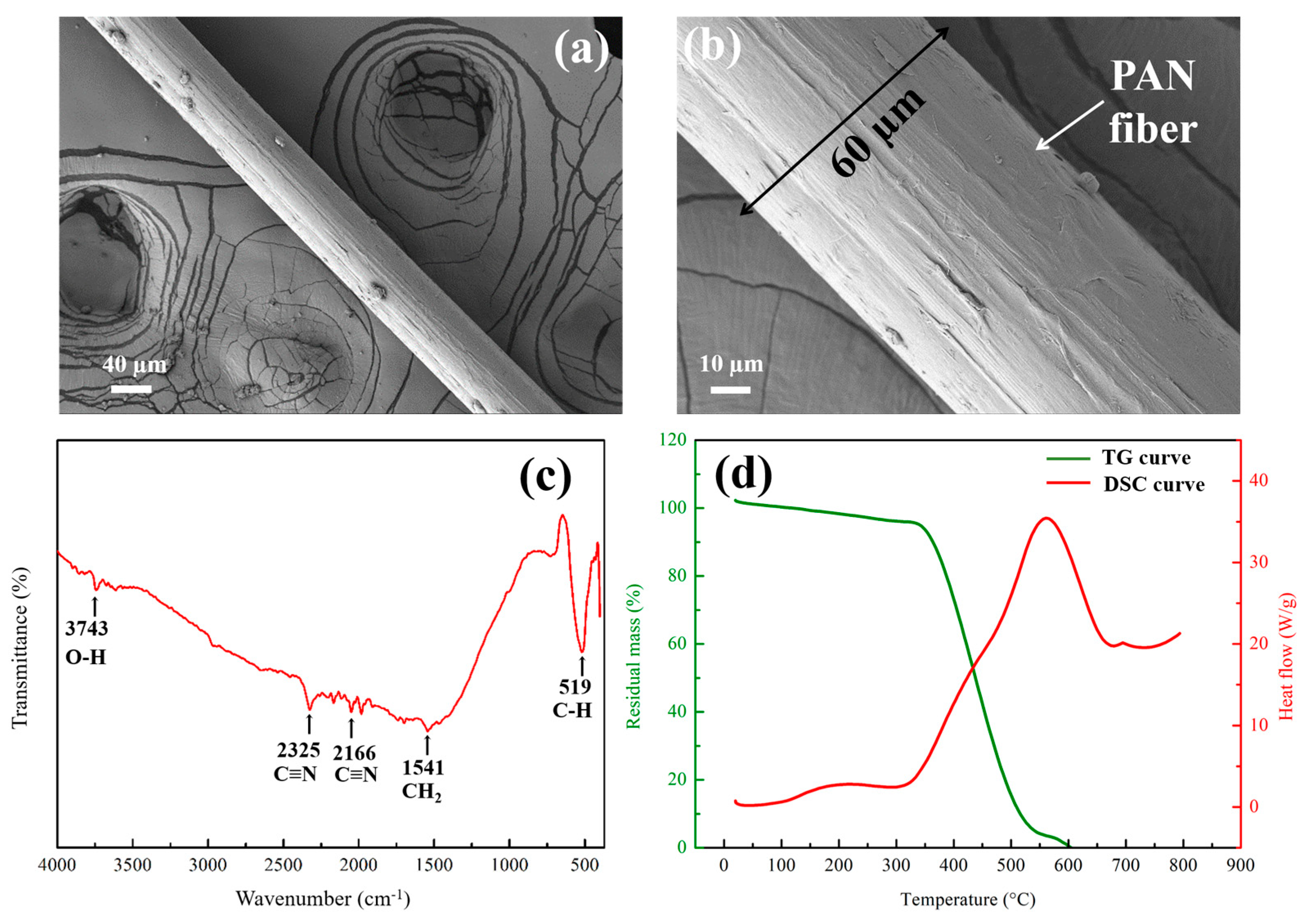

3.1. Microstructure, Chemical Composition, and Thermal Stability of PAN Fiber

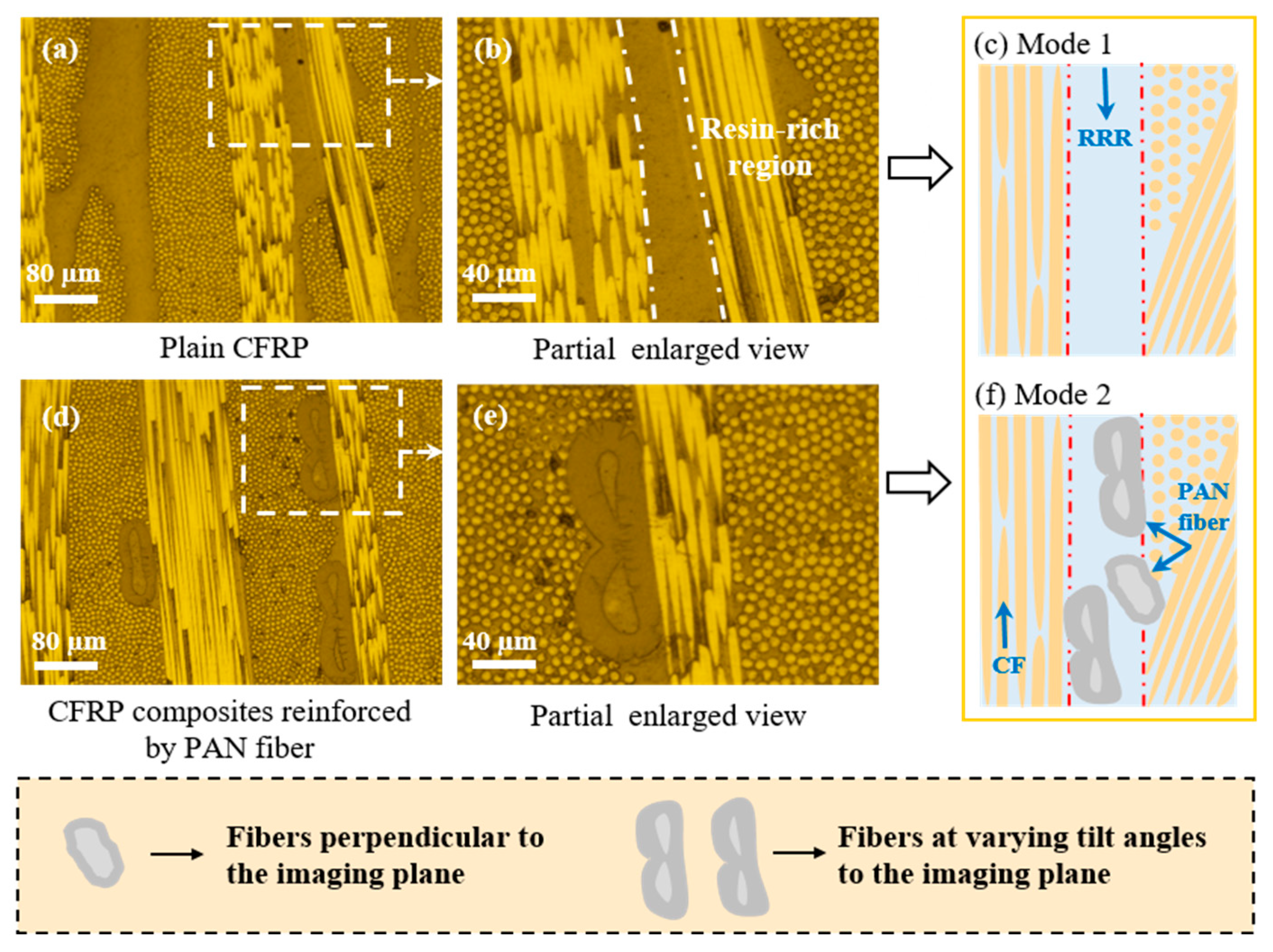

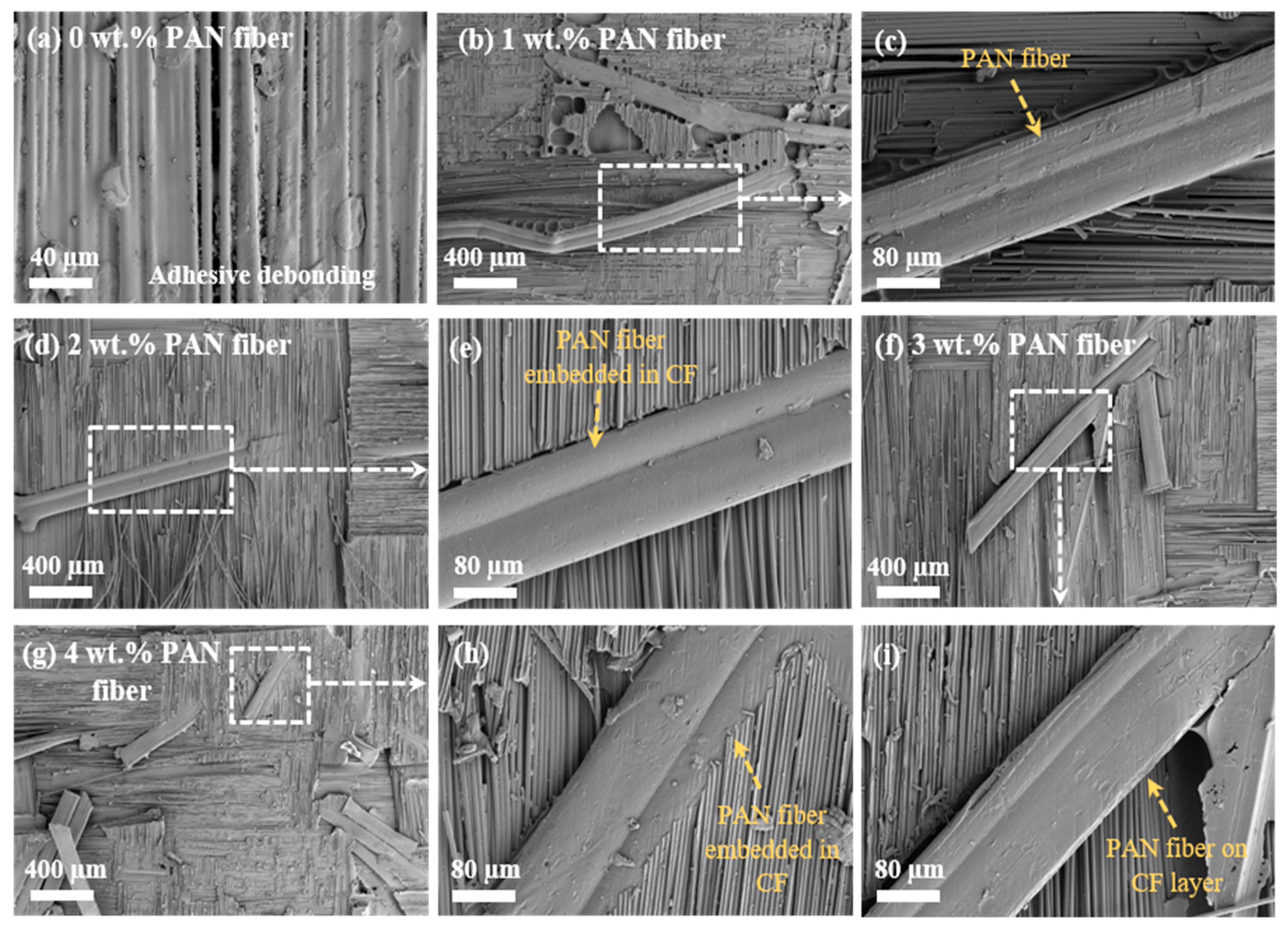

3.2. Interlayer Fiber Distributed Structure of Laminated CFRP Composites

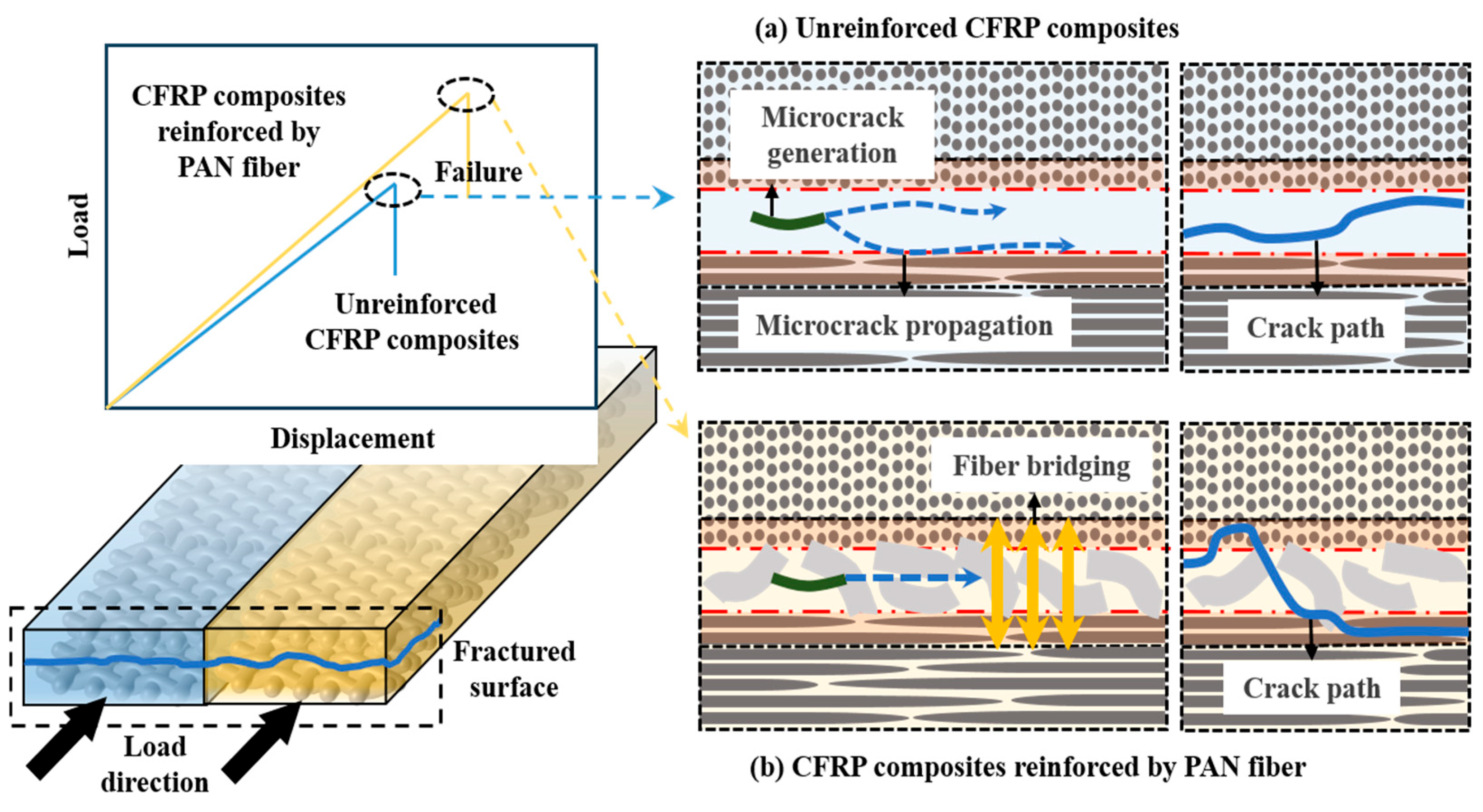

3.3. Flexural and Compressive Properties of CFRP Composites After Tests

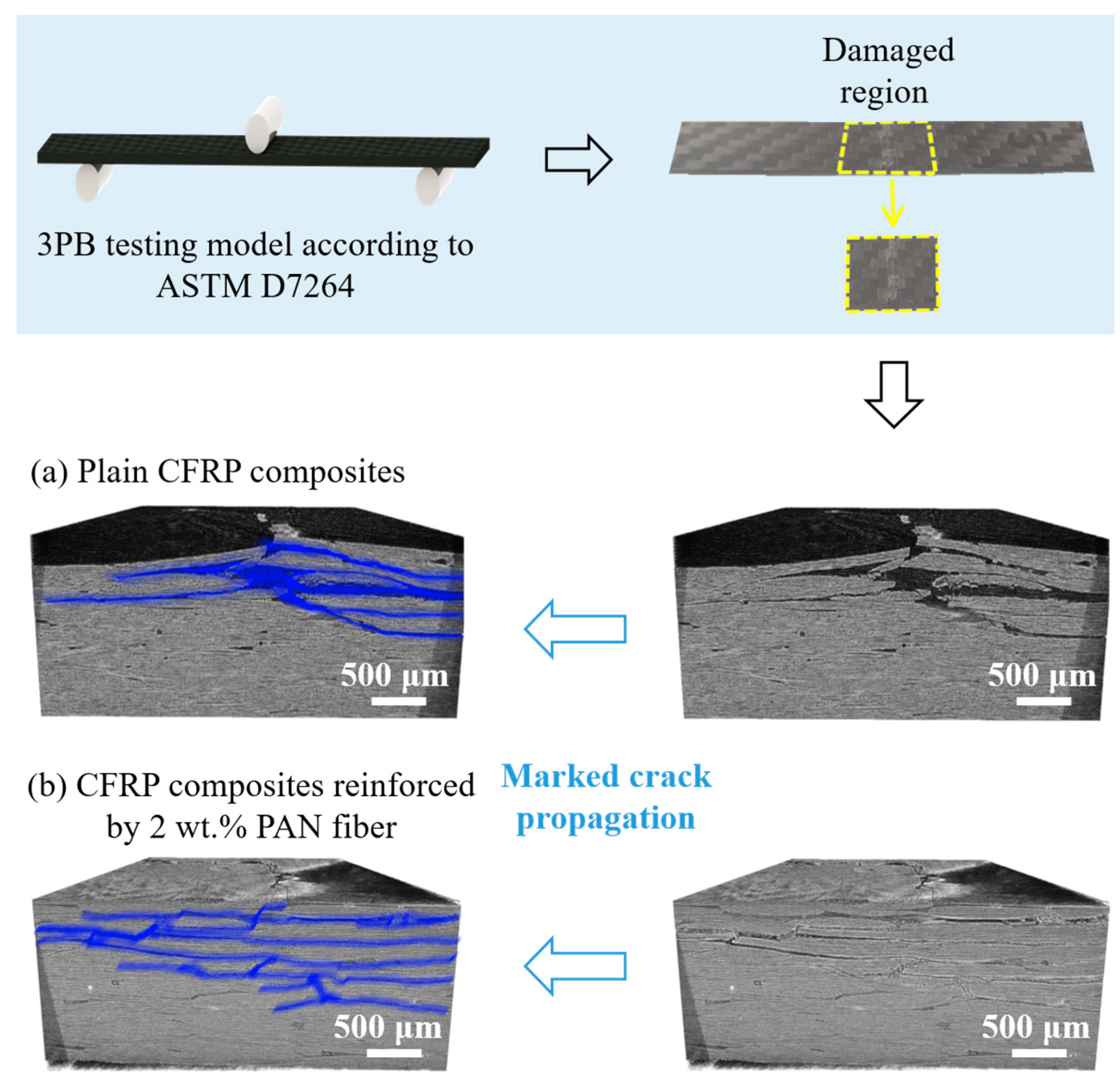

3.4. Fractured Surface Analysis

3.5. Microstructure Analysis of Damaged Surfaces of CFRP After 3PB

3.6. Contribution of PANER Interleaving Film in Improving CFRP Composites

4. Conclusions

- (1)

- PANER interleaving film was successfully prepared at the interlayer of CFRP composite; the fiber bridging behavior was also constructed between CF layers, which could improve the mechanical interlocking of CFRP laminates to hinder the crack generation and further propagation.

- (2)

- The greatest flexural and compressive strength of CFRP composites was yielded by 2 wt.% PAN fiber, achieving 685.61 MPa and 286.66 MPa, respectively, and exhibiting 28.6% and 11.7% increments over the base strength.

- (3)

- The introduction of PAN fiber contributed to shifting the failure modes of the CFRP composites from delamination-dominated failure to crossing-multi-layer failure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Yang, S.; Cheng, Y.; Xiao, X.; Pang, H. Development and application of carbon fiber in batteries. Chem. Eng. J. 2020, 384, 123294. [Google Scholar] [CrossRef]

- Ahmad, F.; Al Awadh, M.; Noor, S. Optimum alternate material selection methodology for an aircraft skin. Chin. J. Aeronaut. 2023, 36, 476–488. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in fiber-reinforced polymer composites: A comprehensive analysis. Polymers 2023, 16, 2. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Mei, H.; Zhang, S.; Chen, H.; Zhou, H.; Zhai, X.; Cheng, L. Interfacial modification and enhancement of toughening mechanisms in epoxy composites with CNTs grafted on carbon fibers. Compos. Sci. Technol. 2016, 134, 89–95. [Google Scholar] [CrossRef]

- Zhao, M.; Meng, L.; Ma, L.; Ma, L.; Yang, X.; Huang, Y.; Ryu, J.E.; Shankar, A.; Li, T.; Yan, C.; et al. Layer-by-layer grafting CNTs onto carbon fibers surface for enhancing the interfacial properties of epoxy resin composites. Compos. Sci. Technol. 2018, 154, 28–36. [Google Scholar] [CrossRef]

- Feng, P.; Song, G.; Li, X.; Xu, H.; Xu, L.; Lv, D.; Zhu, X.; Huang, Y.; Ma, L. Effects of different “rigid-flexible” structures of carbon fibers surface on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites. J. Colloid Interface Sci. 2021, 583, 13–23. [Google Scholar] [CrossRef] [PubMed]

- Knopp, A.; Scharr, G. Effect of z-pin surface treatment on delamination and debonding properties of z-pinned composite laminates. J. Mater. Sci. 2013, 49, 1674–1683. [Google Scholar] [CrossRef]

- Pingkarawat, K.; Mouritz, A. Improving the mode I delamination fatigue resistance of composites using z-pins. Compos. Sci. Technol. 2014, 92, 70–76. [Google Scholar] [CrossRef]

- Li, H.; Yu, Y.; Xu, X.; Chen, T.; Lu, W. Enhancing the fracture toughness of laminated composites through carbon nanotube belt stitching. Compos. Sci. Technol. 2021, 204, 108632. [Google Scholar] [CrossRef]

- Alaziz, R.; Saha, S.; Sullivan, R.W.; Tian, Z. Influence of 3-D periodic stitching patterns on the strain distributions in polymer matrix composites. Compos. Struct. 2021, 278, 114690. [Google Scholar] [CrossRef]

- Verma, K.K.; Padmakara, G.; Gaddikeri, K.M.; Ramesh, S.; Kumar, S.; Bose, S. The key role of thread and needle selection towards ‘through-thickness reinforcement’ in tufted carbon fiber-epoxy laminates. Compos. Part B Eng. 2019, 174, 106970. [Google Scholar] [CrossRef]

- Hui, C.; Wang, P.; Legrand, X. Improvement of tufting mechanism during the advanced 3-dimensional tufted composites manufacturing: To the optimisation of tufting threads degradation. Compos. Struct. 2019, 220, 423–430. [Google Scholar] [CrossRef]

- Huang, T.; Wang, Y.; Wang, G. Review of the mechanical properties of a 3D woven composite and its applications. Polym. Technol. Eng. 2017, 57, 740–756. [Google Scholar] [CrossRef]

- Li, Z.; Guo, L.; Zhang, L.; Wang, Q. In situ experimental investigation on the out-plane damage evolution of 3D woven carbon-fiber reinforced composites. Compos. Sci. Technol. 2018, 162, 101–109. [Google Scholar] [CrossRef]

- Wang, S.; Li, M.; Che, Z.; Wang, S.; Gu, Y.; Zhang, W. Balance interlaminar improvement and in-plane adverse impact of hexagonal semi-embedded fine Z-pin reinforced polymer composite. J. Mater. Res. Technol. 2022, 22, 1297–1306. [Google Scholar] [CrossRef]

- Mouritz, A. Review of z-pinned laminates and sandwich composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Cheng, F.; Hu, Y.; Yuan, B.; Hu, X.; Huang, Z. Transverse and longitudinal flexural properties of unidirectional carbon fiber composites interleaved with hierarchical Aramid pulp micro/nano-fibers. Compos. Part B Eng. 2020, 188, 107897. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, F.; Ji, Y.; Yuan, B.; Hu, X. Effect of aramid pulp on low temperature flexural properties of carbon fibre reinforced plastics. Compos. Sci. Technol. 2020, 192, 108095. [Google Scholar] [CrossRef]

- Zhou, H.; Du, X.; Liu, H.-Y.; Zhou, H.; Zhang, Y.; Mai, Y.-W. Delamination toughening of carbon fiber/epoxy laminates by hierarchical carbon nanotube-short carbon fiber interleaves. Compos. Sci. Technol. 2017, 140, 46–53. [Google Scholar] [CrossRef]

- Kumar, A.; Roy, S. Characterization of mixed mode fracture properties of nanographene reinforced epoxy and Mode I delamination of its carbon fiber composite. Compos. Part B: Eng. 2018, 134, 98–105. [Google Scholar] [CrossRef]

- Yuan, B.; Ye, M.; Hu, Y.; Cheng, F.; Hu, X. Flexure and flexure-after-impact properties of carbon fibre composites interleaved with ultra-thin non-woven aramid fibre veils. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105813. [Google Scholar] [CrossRef]

- Ou, Y.; Wu, L.; Yi, X.; Mao, D. Understanding Mode I interlaminar toughening of unidirectional CFRP laminates interleaved with aligned ultrathin CNT fiber veils: Thickness and orientation effects. Compos. Part B Eng. 2023, 254, 110578. [Google Scholar] [CrossRef]

- Oh, C.-B.; Kim, B.-J.; Lee, M.Y. Synergistic interlaminar strengthening of unidirectional carbon fiber-reinforced composites using carbon nanofiber-modified sizing on the surface of PET interleaves. Compos. Part B Eng. 2023, 264, 110929. [Google Scholar] [CrossRef]

- Coskun, T.; Tarih, Y.S.; Yar, A.; Gündoğdu, Ö.; Sahin, Ö.S. Influences of various thermoplastic veil interleaves upon carbon fiber-reinforced composites subjected to low-velocity impact. J. Thermoplast. Compos. Mater. 2024, 38, 1675–1693. [Google Scholar] [CrossRef]

- Quan, D.; Wang, G.; Zhao, G.; Alderliesten, R. On the interlayer toughening of carbon fibre/epoxy composites using surface-activated ultra-thin PEEK films. Compos. Struct. 2022, 303, 116309. [Google Scholar] [CrossRef]

- Shi, M.; Takahashi, S.; Takeno, A.; Nakai, A. Nanofiber veil applied in toughness enhancement of thermoplastic carbon fiber composites. J. Thermoplast. Compos. Mater. 2022, 36, 1631–1650. [Google Scholar] [CrossRef]

- Tarih, Y.S.; Coskun, T.; Yar, A.; Gundogdu, Ö.; Sahin, Ö.S. The influences of low-velocity impact loading on the vibration responses of the carbon/glass fiber-reinforced epoxy composites interleaved with various non-woven thermoplastic veils. J. Appl. Polym. Sci. 2023, 140, e53728. [Google Scholar] [CrossRef]

- Mahesh, V. Comparative study on low velocity impact response of carbon-fiber-reinforced polymer/ thermoplastic elastomer based fiber metal laminates with and without interleaving of elastomeric layer. J. Thermoplast. Compos. Mater. 2023, 37, 604–624. [Google Scholar] [CrossRef]

- Kausar, A. Polyacrylonitrile-based nanocomposite fibers: A review of current developments. J. Plast. Film Sheeting 2019, 35, 295–316. [Google Scholar] [CrossRef]

- Hiremath, N.; Bhat, S.; Boy, R.; Evora, M.C.; Naskar, A.K.; Mays, J.; Bhat, G. Carbon nanofibers based carbon–carbon composite fibers. Nanoscale Res. Lett. 2023, 18, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Palaniappan, S.K.; Aruchamy, K.; Bhuvaneshwaran, M.; Velayutham, T.; Manickaraj, K. Polyacrylonitrile fiber: Composites and applications. In Synthetic and Mineral Fibers, Their Composites and Applications; Elsevier: Amsterdam, The Netherlands, 2024; pp. 269–290. [Google Scholar]

- Alarifi, I.M.; Alharbi, A.; Khan, W.S.; Swindle, A.; Asmatulu, R. Thermal, electrical and surface hydrophobic properties of electrospun polyacrylonitrile nanofibers for structural health monitoring. Materials 2015, 8, 7017–7031. [Google Scholar] [CrossRef]

- Khan, H.; Kaur, J.; Naebe, M.; Hutchinson, S.; Varley, R.J. Continuous, pilot-scale production of carbon fiber from a textile grade PAN polymer. Mater. Today Commun. 2022, 31, 103231. [Google Scholar] [CrossRef]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, D.-C.J.M.; Buchmeiser, M.R. Carbon fibers: Precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef] [PubMed]

- ASTM D7264; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: New York, NY, USA, 2015.

- ASTM D6641; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Com-Pression (CLC) Test Fixture. ASTM International: New York, NY, USA, 2016.

- Hu, Y.; Han, G.; Cheng, F.; Hu, X. Thickness effect on flexural strengths of laminar carbon fibre composites. Thin-Walled Struct. 2023, 186, 110690. [Google Scholar] [CrossRef]

- Yang, G.; Cheng, F.; Zuo, S.; Zhang, J.; Xu, Y.; Hu, Y.; Hu, X.; Wei, Y.; Gou, G. Constructing quasi-vertical fiber bridging behaviors of aramid pulp at interlayer of laminated basalt fiber reinforced polymer composites to improve flexural performances. Chin. J. Aeronaut. 2023, 36, 477–488. [Google Scholar] [CrossRef]

- Yang, G.; Lyu, Y.; Cheng, F.; He, J.; Zuo, S.; Huang, W.; Hu, Y.; Hu, X.; Chen, X. A low-cost and high-strength basalt/carbon fiber reinforced polymer improved by imitating tree-root micro/nano aramid short fiber. Chin. J. Aeronaut. 2024, 37, 526–538. [Google Scholar] [CrossRef]

| Raw Materials | Physical Properties | Manufacturer |

|---|---|---|

| Carbon fiber fabric | Density 1.76 g/cm3, tensile strength 3530 MPa and modulus 230 GPa | Shanghai Longchi Construction Technology Co., Ltd., Shanghai, China |

| PAN fiber | Density 1.18 g/cm3, tensile strength 800 MPa, modulus 16 GPa, and melting point 220–260 °C | Zibo Qiaotu Engineering Materials Co., Ltd., Shandong, China |

| Epoxy resin | 105 Epoxy Resin, toxic (boiling point higher than 204 °C) | West System, bay city, MI, USA |

| Hardener | 206 slow hardener, colorless or light yellow transparent liquid, toxic | West System, bay city, MI, USA |

| Specimen Group | PAN Fiber Mass Proportion (wt.%) in Mixture | Additive Amount in Each Interlayer (g/m2) | Thickness (mm) | Thickness Increment of Each Interlayer (μm) |

|---|---|---|---|---|

| Plain CFRP | 0 | 0 | 1.96 | 0 |

| 1-PAN/CFRP | 1 | 1.42 | 2 | 4.4 |

| 2-PAN/CFRP | 2 | 2.84 | 1.99 | 3.3 |

| 3-PAN/CFRP | 3 | 4.26 | 2.02 | 6.6 |

| 4-PAN/CFRP | 4 | 5.7 | 2.04 | 8.8 |

| Specimens | Plain CFRP | 1-PAN/CFRP | 2-PAN/CFRP | 3-PAN/CFRP | 4-PAN/CFRP | |

|---|---|---|---|---|---|---|

| PAN fiber mass proportion (wt.%) | 0 | 1 | 2 | 3 | 4 | |

| Flexural strength (MPa) | Average | 532.76 | 592.65 | 685.61 | 592.76 | 527.57 |

| Standard derivation | 23.25 | 9.60 | 29.17 | 21.19 | 16.73 | |

| Energy absorption (J) | Average | 0.61 | 0.67 | 0.74 | 0.63 | 0.53 |

| Standard derivation | 0.05 | 0.04 | 0.05 | 0.08 | 0.05 | |

| Compressive strength (MPa) | Average | 256.46 | 250.04 | 286.66 | 256.79 | 270.98 |

| Standard derivation | 40.47 | 35.41 | 35.01 | 28.77 | 24.21 | |

| Energy absorption (J) | Average | 3.06 | 3.1 | 3.4 | 2.82 | 3.34 |

| Standard derivation | 1.03 | 0.61 | 1.54 | 0.57 | 1.08 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashfaq, S.; He, J.; Lyu, Y.; Cheng, F.; Yuan, X.; Liang, X.; Shi, S.; Lomakin, E.; Bondarchuk, D.; Tojiyev, R.; et al. Building Polyacryronitrile Fiber/Epoxy Resin (PANER) Interleaving Film to Strengthen Flexural and Compressive Performances of Laminated CFRP Composites. Nanomaterials 2025, 15, 1576. https://doi.org/10.3390/nano15201576

Ashfaq S, He J, Lyu Y, Cheng F, Yuan X, Liang X, Shi S, Lomakin E, Bondarchuk D, Tojiyev R, et al. Building Polyacryronitrile Fiber/Epoxy Resin (PANER) Interleaving Film to Strengthen Flexural and Compressive Performances of Laminated CFRP Composites. Nanomaterials. 2025; 15(20):1576. https://doi.org/10.3390/nano15201576

Chicago/Turabian StyleAshfaq, Sidra, Jiaxin He, Yanan Lyu, Fei Cheng, Xiang Yuan, Xueling Liang, Shuying Shi, Evgeny Lomakin, Daria Bondarchuk, Rasuljon Tojiyev, and et al. 2025. "Building Polyacryronitrile Fiber/Epoxy Resin (PANER) Interleaving Film to Strengthen Flexural and Compressive Performances of Laminated CFRP Composites" Nanomaterials 15, no. 20: 1576. https://doi.org/10.3390/nano15201576

APA StyleAshfaq, S., He, J., Lyu, Y., Cheng, F., Yuan, X., Liang, X., Shi, S., Lomakin, E., Bondarchuk, D., Tojiyev, R., Liu, H., Hu, X., & Chen, X. (2025). Building Polyacryronitrile Fiber/Epoxy Resin (PANER) Interleaving Film to Strengthen Flexural and Compressive Performances of Laminated CFRP Composites. Nanomaterials, 15(20), 1576. https://doi.org/10.3390/nano15201576