1. Introduction

In recent years, the rapid development of intelligent electronics and internet of things technologies has driven an increasingly urgent demand for high-speed and highly reliable memory devices in embedded systems [

1,

2]. Ferroelectric random access memory (FeRAM), with its non-volatility, low power consumption, and high read/write speed, has emerged as a promising candidate for next-generation memory applications [

3,

4]. Among FeRAM configurations, ferroelectric oxides [e.g., Pb(Zr,Ti)O

3] and their heterostructures have attracted extensive attention due to their high storage density and tunable interfacial coupling effects [

5,

6,

7]. Moreover, it has been shown that ferroelectric oxides can maintain stable ferroelectricity in ultrathin films even down to one-nanometer limit [

8]. However, the modulation of microstructural and physical properties in ultrathin ferroelectric oxide films remains not fully explored [

9,

10,

11,

12], thereby limiting their potential applications in modern nanoelectronics and optoelectronics [

13,

14,

15].

Femtosecond (fs) lasers, as ultrafast and ultra-intense energy carriers, enable high-precision micro-processing and induce phase changes in target materials within extremely short timescales [

16,

17,

18,

19]. Compared to longer laser pulses, fs lasers offer the key advantage of minimizing the heat-affected zone, which facilitates precise control of the microstructure features [

20,

21,

22,

23]. Previous studies have demonstrated that focused fs laser beams with fluence close to the ablation threshold can directly create craters, nano-bumps, jet-like structures, and complete material removal in various thin films [

24,

25,

26,

27]. Additionally, fs lasers have been widely applied in the fabrication of novel functional materials and the modulation of device performance [

16,

28,

29]. However, the dynamic microstructural and physical responses of ferroelectric oxide ultrathin films under fs laser pulse irradiation remain largely unexplored.

In this work, we report on the high-precision engineering of microstructure and ferroelectric/piezoelectric responses in Pb(Zr,Ti)O3 (PZT) ultrathin films using a single-pulse fs laser micromachining technique. Optical microscopy and atomic force microscopy (AFM) characterizations reveal a progressive evolution of microstructures with increasing fs laser pulse fluence. When employing laser fluence below 0.5 nJ, nano-concave arrays are achieved in PZT thin films, which are attributed to the fs laser peening effect. As the laser fluence increases to 1 nJ, nano-volcano structures emerge, while ablation occurs at a fluence of approximately 2 nJ. Additionally, single-point fs laser irradiation with fluence exceeding 2 nJ enables the formation of nano-cave structures with controlled depth and width in PZT/Pt/SiO2 multilayers, resulting from a combination of fs laser ablation and melting effects. Piezoresponse force microscopy (PFM) measurements demonstrate that the laser peening process significantly enhances the piezoelectric response while exerting minimal influence on the coercive field of PZT ultrathin films, which is attributed to the enhanced electromechanical energy transfer and compressive stresses distribution in PZT thin films with nano-concave structures induced by laser peening effect. Our study provides an ultrafast, non-contact, laser-based approach for precisely modulating the microstructure and physical properties of ferroelectric ultrathin films, offering new pathways for the development of next-generation high-performance non-volatile memory devices.

2. Results and Discussion

For the ferroelectric oxide layer, we worked with 50 nm thick PZT thin film deposited on SiO

2 (285 nm)/Si substrate (

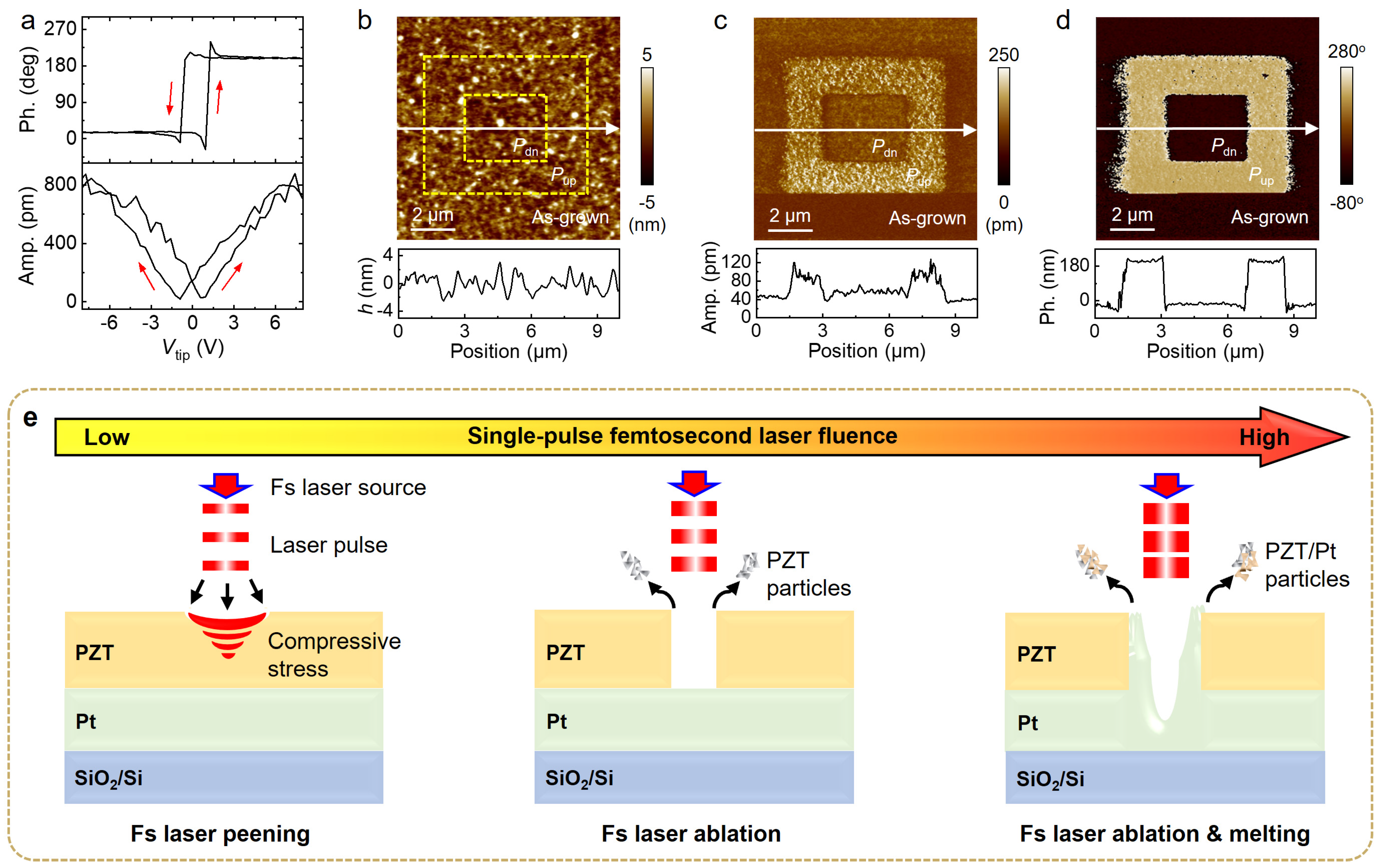

Figure S1 in Supplementary Materials), with a 150 nm thick Pt buffer layer serving as the bottom electrode. The PZT thin films were grown by magnetron sputtering, followed by rapid thermal annealing (see Methods) to improve the crystallinity of the perovskite phase. To analyze the intrinsic ferroelectric characteristics of PZT thin films, we performed PFM studies (see Methods).

Figure 1a displays the switching hysteresis of phase and amplitude responses taken on the as-grown PZT thin films, where the coercive voltages for the polarization-down (

Pdn) and polarization-up (

Pup) states are 0.78 V and −0.93 V, respectively.

Figure 1b shows the AFM image of the PZT thin film deposited on Pt/SiO

2/Si substrate, which exhibits relatively smooth surface with a root mean square of ~1.4 nm.

Figure 1c,d represent the PFM amplitude and phase images of the box-in-box domain structure written on the 50 nm PZT film by applying a DC bias voltage of ±10 V to the AFM tip, which exhibits uniform

Pdn and

Pup domain pattern. The above PFM characterizations confirm the exceptional polarization controllability and nanoscale domain engineering capability in the as-grown PZT ultrathin films.

Various laser-material interaction dynamics are considered to exist between single-pulse fs laser irradiation and PZT ultrathin films (

Figure 1e). As shown in

Figure 1e (left panel), during low-fluence single-pulse fs laser irradiation, high-energy photons induce a nonlinear ionization effect that liberates surface electrons from atomic confinement, resulting in the generation of transient high-density plasma. The rapid expansion of this plasma produces ultrahigh-pressure shock waves that significantly exceed the material’s yield strength, thereby inducing plastic deformation in the PZT layer [

30,

31]. This shock- peening effect is anticipated to enable surface modification of PZT thin films at nanoscale spatial resolution, such as the formation of nano-concave structures. When the single-pulse fs laser fluence approaches the critical threshold, ablation begins to occur, leading to the formation of nano-volcano (nano-cave) structures in the PZT thin film (

Figure 1e (middle panel)). Further increasing fs laser fluence beyond this threshold simultaneously triggers ablation in the PZT layer and melting in the Pt layer (

Figure 1e (right panel)), resulting in the formation of more complex nano-concave structures [

32,

33].

Based on the above assumption, we next employ a single-pulse fs laser micromachining technique for high-precision nano-engineering of PZT/Pt/SiO

2 multilayers, through which various nanostructures can be controllably fabricated.

Figure 2a schematically illustrates the fabrication of nanostructure arrays in the PZT thin films via single fs laser pulse scan. A fs laser beam with a wavelength of 1030 nm was focused onto the surfaces of the PZT thin films, with a high-precision electrically controlled sample stage enabling two-dimensional (2D) scanning for nanostructure array fabrication. The spacing of nanostructure array can be well controlled by adjusting the laser scanning speed.

Figure 2b,c and

Figure S2 show the optical and AFM images of PZT thin films by single fs laser pulse irradiation at different laser fluences (ranging from 0.2 nJ to 1 nJ) with a scanning pitch of approximately 0.96 μm. The white dashed circles represent fs laser pulse irradiation sites, and a distinct fluence-dependent nanostructure evolution is observed. When employing a weak laser fluence of 0.2 nJ, no apparent structural change is optically resolvable (

Figure 2(b1)). However, the corresponding AFM topography and cross-sectional profile analyses reveal periodic height modulation (

Figure 2(c1)), indicative of weak shock-peening effect induced by single-pulse fs laser irradiation [

34]. The laser shock-peening effect has been predominantly applied to enhance fatigue resistance in bulk and metallic materials such as stainless steel [

35]. Here, we for the first time, realize fs laser peening–induced nanostructure engineering in ferroelectric oxide ultrathin films.

Upon increasing the single-pulse fs laser fluence to 0.3 nJ, discernible surface modification emerges optically (

Figure 2(b2)), while AFM topography shows that the depth of depression intensifies (

Figure 2(c2)), confirming the enhancement of laser-peening effect. Remarkably, under 0.4–0.5 nJ single-pulse fs laser irradiation conditions, the shock-peening effect becomes more pronounced (

Figure 2(b3,b4)), which leads to the formation of relatively uniform and distinct nano-concave arrays in PZT thin films (

Figure 2(c3,c4)). It should be noted that few particulate-like protrusions are observed in nano-concave arrays with the same laser power applied, which can be explained by fs laser power fluctuation during the scanning process (see

Section 4). In contrast, under 1 nJ single-pulse fs laser irradiation, nano-volcano arrays are formed in the PZT thin film (

Figure 2(b5,c5)), which can be attributed to thermomechanical coupling effects involving radial migration and resolidification of molten material [

36]. Hence, 1 nJ is the critical transition threshold of PZT thin film between the shock peening–dominated regime (<1 nJ) and ablation-initiated regime (≥1 nJ).

Figure 2d quantitatively analyzes the dependence of nanostructure (nano-concave or nano-volcano) depth on fs laser fluence. Here, the depth is defined as the height difference in the modified zone between adjacent peak level and valley level. In the weak fluence region (0.2–0.5 nJ), the depth of nanostructures (nano-concaves) linearly increases, reflecting a highly fluence-dependent nonthermal shock-peening effect (left inset). With a relatively high fluence (~1 nJ), nano-volcano structures are formed and show significant depth fluctuation, suggesting that thermal ablation begins to occur beyond this threshold (right inset). The established fluence-dependent nanostructure evolution rules provide critical guidance for single-pulse fs laser high-precision nano-engineering in ferroelectric ultrathin films.

Next, we explore the effect of single-pulse fs laser irradiation on the ferroelectric and piezoelectric responses in PZT ultrathin films using the PFM technique. PFM has been proven to be a reliable approach that can be used to quantitatively characterize the ferroelectric and piezoelectric properties of various ferroelectric materials in local areas [

37,

38,

39].

Figure 3a and

Figure S3 compare the switching hysteresis of PFM phase response taken on PZT nanostructure arrays fabricated with fs laser peening at different laser fluences, where similar phase hysteresis curves are detected.

Figure 3c quantitatively analyzes the dependence of coercive voltage (

VC) extracted from

Figure 3a and

Figure S3 on fs laser fluence. It is clear that the average

VC remains stable (~0.5 ± 0.1 V) across a wide laser fluence range of 0.2 nJ to 1.0 nJ. This indicates that the ferroelectric polarization switching energy barrier does not alter. Thus, we can conclude that the fs laser-peening process exerts minimal influence on the ferroelectric properties of PZT ultrathin films.

Figure 3b compares the switching hysteresis of PFM amplitude response taken from the same sample in

Figure 3a at different laser fluences. The dependence of maximum amplitude extracted from

Figure 3b and

Figure S3 on fs laser fluence is shown in

Figure 3d. It is found that, with increasing the laser fluence, the amplitude signal continuously increases, revealing significant enhancement of piezoelectric performance in PZT thin films.

The experimental results in

Figure 2 have shown that nano-concave structures can be formed in PZT thin films by single-pulse fs laser irradiation, which is mainly attributed to the fs laser peening effect. Laser peening is a mechanical (cold working) process, where short pulses hit the surface of a PZT thin film and shockwaves are generated. These shockwaves can plastically deform the film surface and compressive residual stresses extend into the internal structure of PZT thin films [

34,

40]. Therefore, the piezoelectric enhancement in PZT thin films with nano-concaves can be attributed to fs laser-peening induced microstructure engineering. On the one hand, the formation of nano-concave structures enhances the electromechanical energy transfer, thus leading to an enhancement of the piezoelectric response [

29]. On the other hand, the nano-concave structures enable a concentrated distribution of compressive stresses in the PZT thin films. The enhanced strain in the PZT thin films with nano-concave structures further promotes the enhancement of the piezoelectric response [

29].

To further confirm the effect of laser peening on the ferroelectric/piezoelectric responses in PZT thin films, we performed ferroelectric domain pattern writing in both laser-peened and un-peened regions.

Figure 3e shows the optical image of a PZT thin film partially processed with fs laser peening at a fluence of 0.5 nJ, where the upper half corresponds to the un-peened region, and the lower half represents the laser-peened region.

Figure 3f,g shows the PFM amplitude and phase images of the square domain structure written on the same region as in

Figure 3e by applying a bias voltage of ±10 V to the AFM tip. It is clear that both laser-peened and un-peened regions exhibit uniform

Pdn and

Pup domain pattern, thus confirming that fs laser peening does not suppress, but rather enhances the ferroelectric/piezoelectric responses of PZT thin films. The established fs laser fluence and property correlation offers new pathways for developing high-performance ferroelectric non-volatile memory devices.

The aforementioned discussion is mainly focused on the dynamic responses of PZT ultrathin films under fs laser irradiation at relatively low fluence levels (≤1 nJ), where complete ablation does not occur. In the following section, we investigate the impact of fs laser ablation on the microstructural characteristics of PZT thin films. It is predicted that complete ablation would occur at a fluence of 2 nJ, through which nano-cave structures could be obtained (

Figure 1e (middle panel)).

The scanning pitch plays an important role in the nanostructure array fabrication. In

Figure 4a–d, we designed nanostructure arrays to be formed in PZT thin film by single-pulse fs laser scan at different step sizes (ranging from 0.96 to 0.48 μm).

Figure 4e,i show the optical and AFM images of the nanostructure arrays fabricated in PZT thin film with a fluence of 2 nJ at a step size of 0.96 μm, confirming the achievement of uniform and periodic nano-cave structures. The corresponding high-magnified AFM image is shown in

Figure S4. The cross-sectional height profiles reveal that the average depth of nano-cave structure is 50 nm, which is in good agreement with the thickness of the PZT thin film. It is demonstrated that single-pulse fs laser irradiation possesses the capability for atomic-level, selective removal of ultrathin films in the (PZT/Pt/SiO

2) multilayer system.

When the step size is reduced to 0.8 μm (

Figure 4b), as expected, nanoscale rhombic arrays are formed in the PZT layer, as evidenced by optical microscopy and AFM topography characterizations (

Figure 4f,j). By reducing the step size to 0.64 μm (

Figure 4c), we achieve the complete removal of the PZT layer (

Figure 4g,k), without causing damage to the underlying Pt layer. This outcome can be attributed to the first-order overlap effect, which results in continuous spatial superposition of the fs laser beam. Concurrently, the accumulated equivalent pulse count within the overlapping region reaches approximately two pulses per unit area (

Figure 4c). This value is sufficient to meet the ablation threshold of the PZT layer while remaining below the damage threshold of the Pt layer. When the step size is further reduced to 0.48 μm (

Figure 4d), a secondary overlap effect occurs, increasing the pulse density to approximately three pulses per unit area. Under this condition, a remarkable increase in surface roughness is observed in the fs laser–scanned region (

Figure 4h,l), indicating that the Pt layer has been damaged. The aforementioned discovery provides a universally applicable fs laser-based methodology for high-precision “etching” of ferroelectric ultrathin films, demonstrating substantial potential for the nano-fabrication of integrated ferroelectric memory devices and piezoelectric micro-electromechanical systems.

Finally, we investigate the controllable modulation of microstructures in PZT-based heterostructures under single-point fs laser irradiation.

Figure 5a–i compare the AFM topographies of nanostructures fabricated on PZT/Pt/SiO

2 multilayers using a single fs laser pulse with fluence ranging from 2 nJ to 500 nJ. The insets in

Figure 5a–i show the corresponding optical images. In the relatively low fluence range (2 nJ to 10 nJ,

Figure 5a–c), nano-cave structures are formed due to the laser ablation effect. These structures exhibit nearly consistent depth (~50 nm), while their diameter increases progressively with increasing fluence. At this stage, the applied fluence exceeds the ablation threshold of the PZT layer but remains below the damage threshold of the Pt/SiO

2 substrate, enabling spatially selective removal of the PZT layer. In the medium-fluence range (30 nJ to 100 nJ), both AFM imaging and optical contrast (

Figure 5d–f) indicate that fs laser melting and ablation occur in the Pt layer. Specifically, at a fluence of 30 nJ, a molten protrusion appears at the center of the laser-irradiated region (

Figure 5d). This phenomenon is attributed to the Gaussian-type intensity profile of the laser beam [

41], where only the central region receives sufficient fluence to exceed the melting point of the Pt layer. When the fluence increases to 70–100 nJ (

Figure 5e,f), both ablation and melting processes occur in the Pt layer, resulting in the formation of nano-cavities at the central region. Concurrently, molten–solidified ring structures are observed in the peripheral area, which is attributed to the radial gradient of the laser energy distribution. In the high-fluence regime (200 nJ to 500 nJ), fs laser melting and ablation occur across the entire PZT/Pt/SiO

2 multilayer. At 200 nJ, the initial modification of the SiO

2 layer is observed. Upon increasing fluence to 300 nJ, a four-tier annular structure forms, consisting of an outermost PZT ablation zone, an intermediate Pt molten ring, an inner Pt ablation region, and a central SiO

2 etching pit. At 500 nJ, this hierarchical architecture stabilizes and expands in both width and depth.

Figure 5j displays the 3D height profiles of nano-cave structures fabricated in PZT/Pt/SiO

2 multilayer at different fs laser pulse fluences, offering a more intuitive understanding of the interaction between the fs laser and the multilayer system. In the lower energy regime, ablation of the PZT layer dominates the process, with the ablation diameter expanding as the laser fluence increases. When the fluence reaches a critical threshold, both the interaction depth and diameter increase abruptly.

Figure 5k,i quantitively analyze the dependence of nano-cave structure depth and width on fs laser pulse fluence, respectively. It can be observed that below 100 nJ, both depth and width exhibit gradual increases, whereas above 100 nJ, exponential growth is evident. This indicates that the penetration depth and interaction area in the multilayer system do not scale linearly with fs laser fluence. By precisely adjusting the fs laser fluence, nano-cave structures with controlled depth and width can be fabricated in PZT/Pt/SiO

2 multilayers.

4. Methods

Preparation of PZT Thin Films: Ferroelectric PZT thin films were deposited by radio-frequency (RF) sputtering method (TRP450, SKY Technology Development Co., Ltd., Shenyang, China) on the Pt/Ti-coated SiO2/Si substrates, followed by rapid thermal annealing (OTF-1200X-4-RTP, Hefei Kejing Materials Technology Co., Ltd., Heifei, China). First, Pt/Ti/SiO2/Si substrates were prepared by sputtering 20 nm Ti and then 150 nm Pt onto SiO2 (285 nm)/Si substrate. Second, PZT thin films were deposited using RF sputtering with a PbZr0.48Ti0.52O3 target. The deposition was carried out at 200 °C, with a gas flow of 70 sccm Ar and 0.5 sccm O2, under a working pressure of 1 Pa. The power of PbZr0.48Ti0.52O3 target (ZhongNuo Advanced Material Technology Co., Ltd., Beijing, China) was fixed at 67 W. The thickness of PZT film was controlled through the sputtering time. Third, rapid thermal annealing treatment was performed. Specifically, the sample was put into a rapid thermal furnace in an O2 environment. The temperature was increased to 650 °C with a heating rate of 10.5 °C/s, kept at 650 °C for 8 min, and then cooled to room temperature naturally.

AFM and PFM Measurements: The morphologies and thicknesses of the PZT thin films were measured using an AFM system (MFP-3D Origin, Oxford Instruments, Oxford, UK) with an AFM tip (Micromesh HQ:NSC14, k = 5) working in AC mode. PFM measurements were carried out using the same AFM system with a Pt-coated AFM tip (Micromesh HQ:NSC18, k = 2.8) in DART mode. For domain writing, a DC bias of ±10 V was applied to the AFM tip and the PZT thin films were grounded. For PFM imaging, a small AC voltage was applied to the AFM tip. All PFM phase and amplitude hysteresis loop measurements were conducted using the same Pt-coated AFM tip and under the same experimental conditions (resonant peak of AFM tip: 460 kHz; scanning voltage range: −8 V to 8 V; scanning frequency: 0.2 Hz).

Fs Laser Processing: Fs laser processing was conducted using a laser system with a wavelength of 1030 nm and a pulse duration of 138 fs (YC-FL-20-2000-IR, Hangzhou Yacto Technology Co., Ltd., Hangzhou, China). The laser output was linearly polarized, its power was controlled using a half-wave plate and a Glan prism. To enable high-resolution processing, the laser beam was focused onto the sample using an objective lens (100× magnification, working distance: 1 mm, NA = 0.9), achieving a focused spot size of approximately 0.63 μm. The samples were mounted on an electrically controlled three-axis sample stage and processed in ambient air. The system allowed for precise control of scanning speed and trajectory for micromachining applications. Laser parameters, such as pulse energy, were optimized based on the material and processing conditions to ensure effective micromachining and patterning results. All laser experiments were performed at a repetition rate of 1 kHz. For single-pulse irradiation, a signal generator was used to deliver a synchronization signal to the laser, and the laser was triggered at the rising edge of the signal. For scanning experiments, the laser operated continuously at 1 kHz while the focal spot diameter was matched with the translational speed of the three-dimensional stage. The laser stability was characterized at a repetition rate of 100 kHz, where the average power was 0.5 mW and the long-term stability value was 0.3% over a continuous test of approximately 14 h. In addition, the root-mean-square power fluctuation was measured to be less than 0.7%.