Research Progress in Carbon Nanotube-Based Cold Cathode Electron Guns

Abstract

1. Introduction

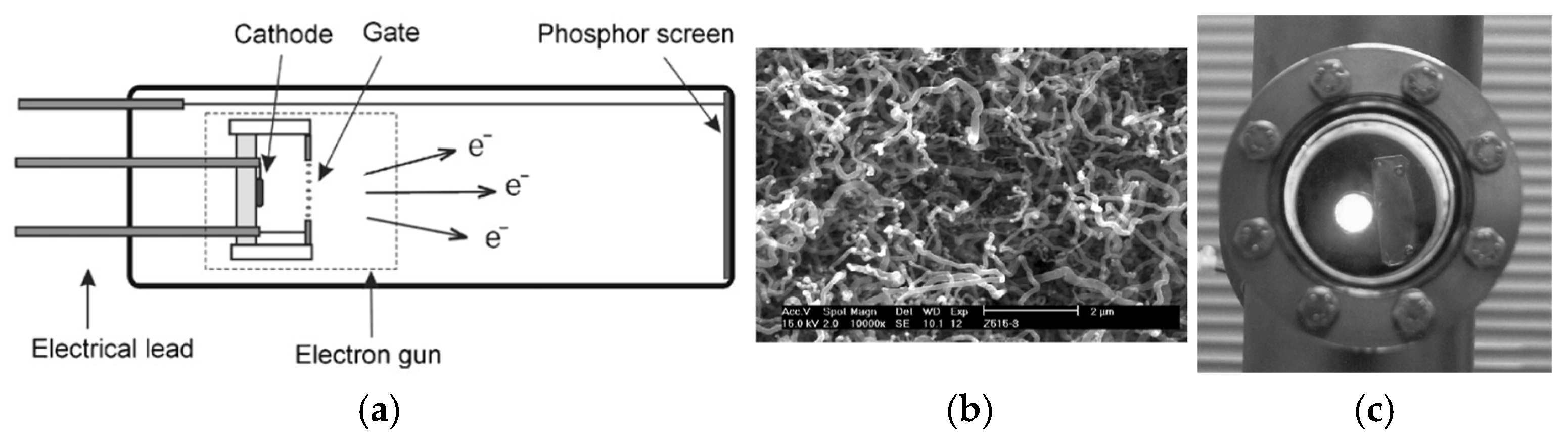

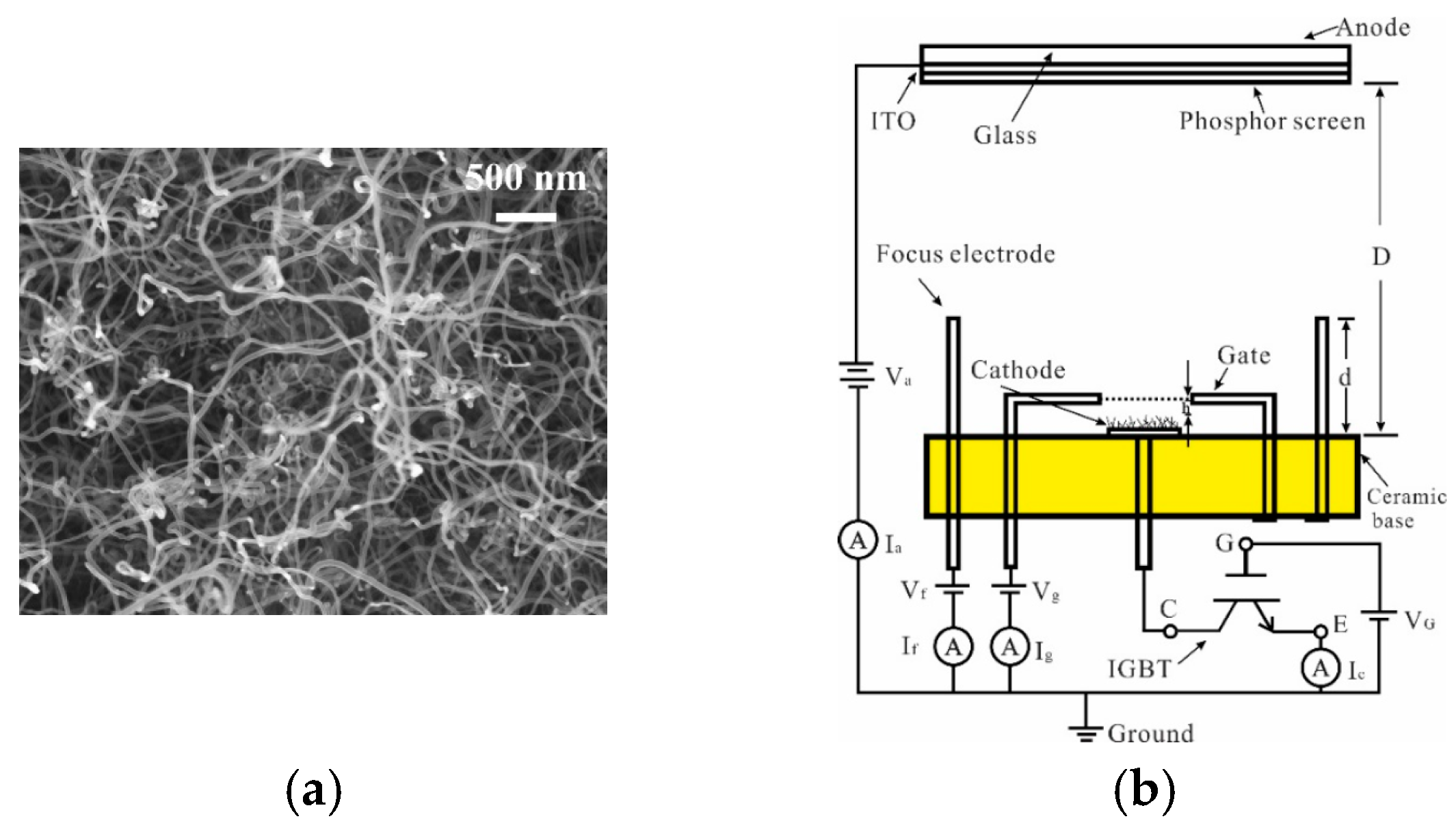

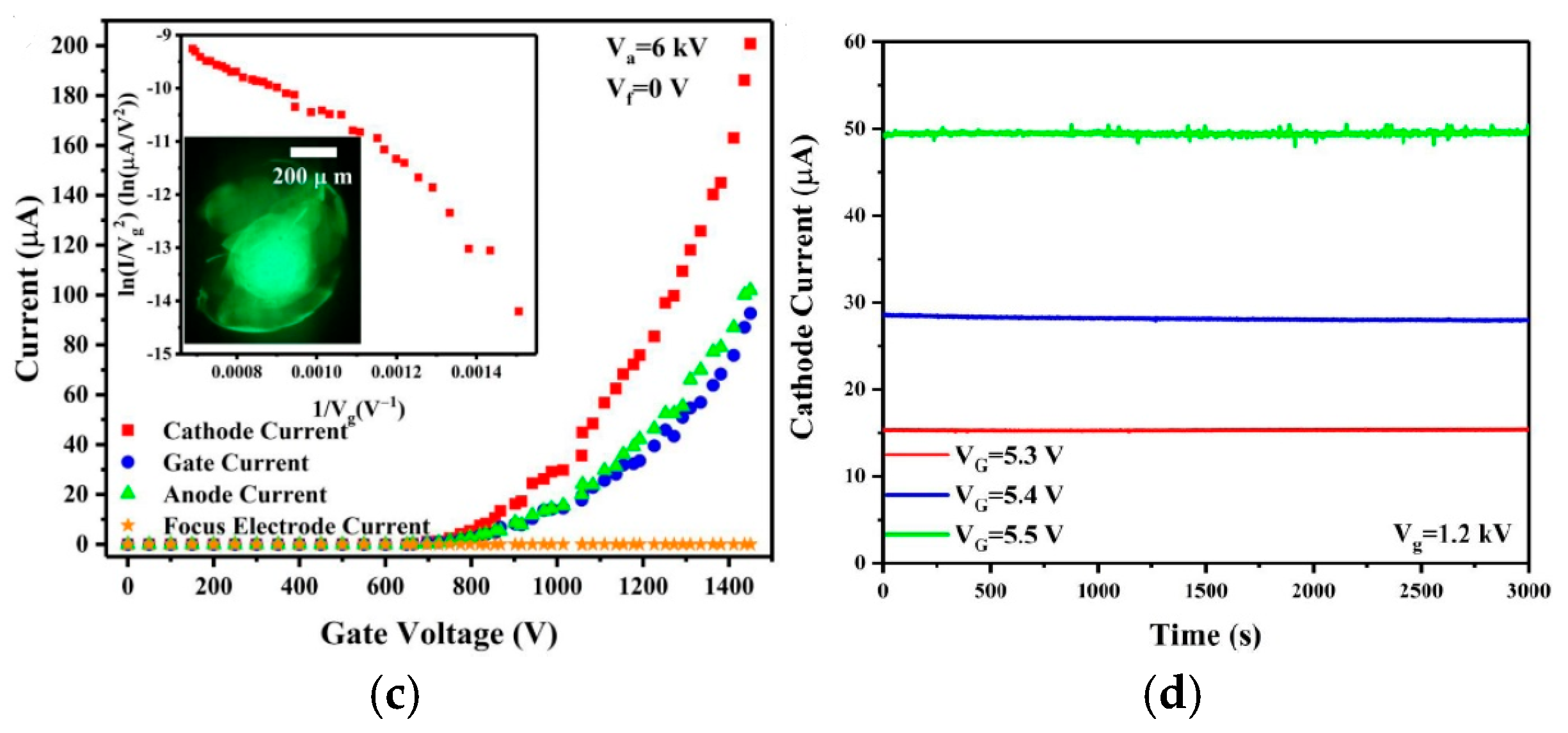

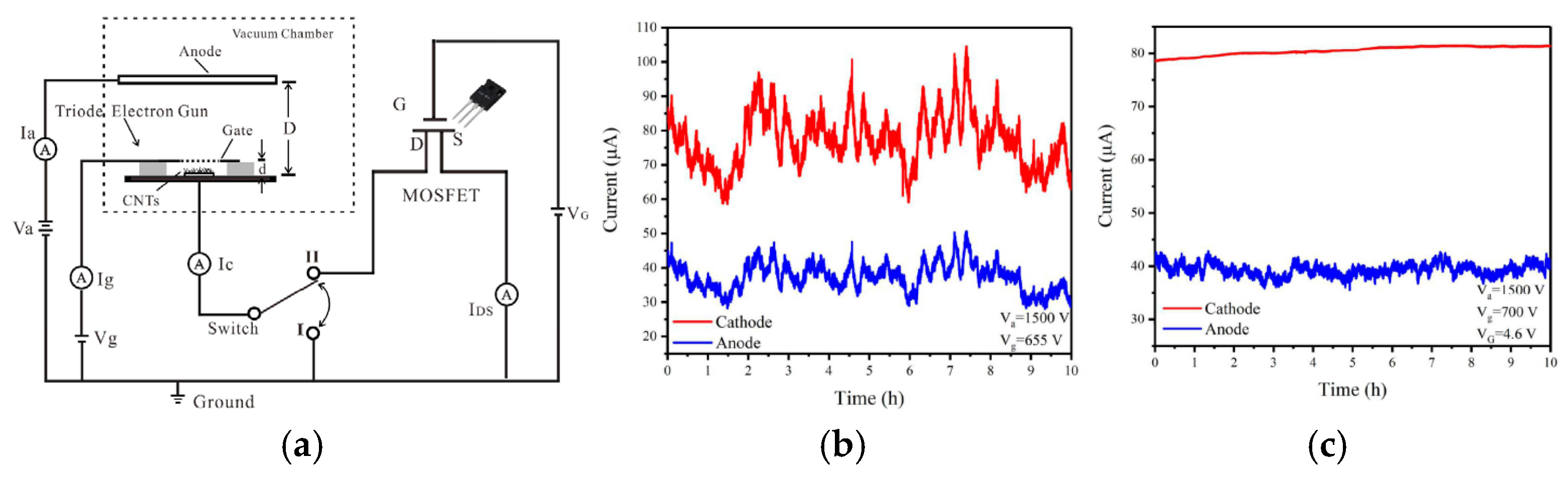

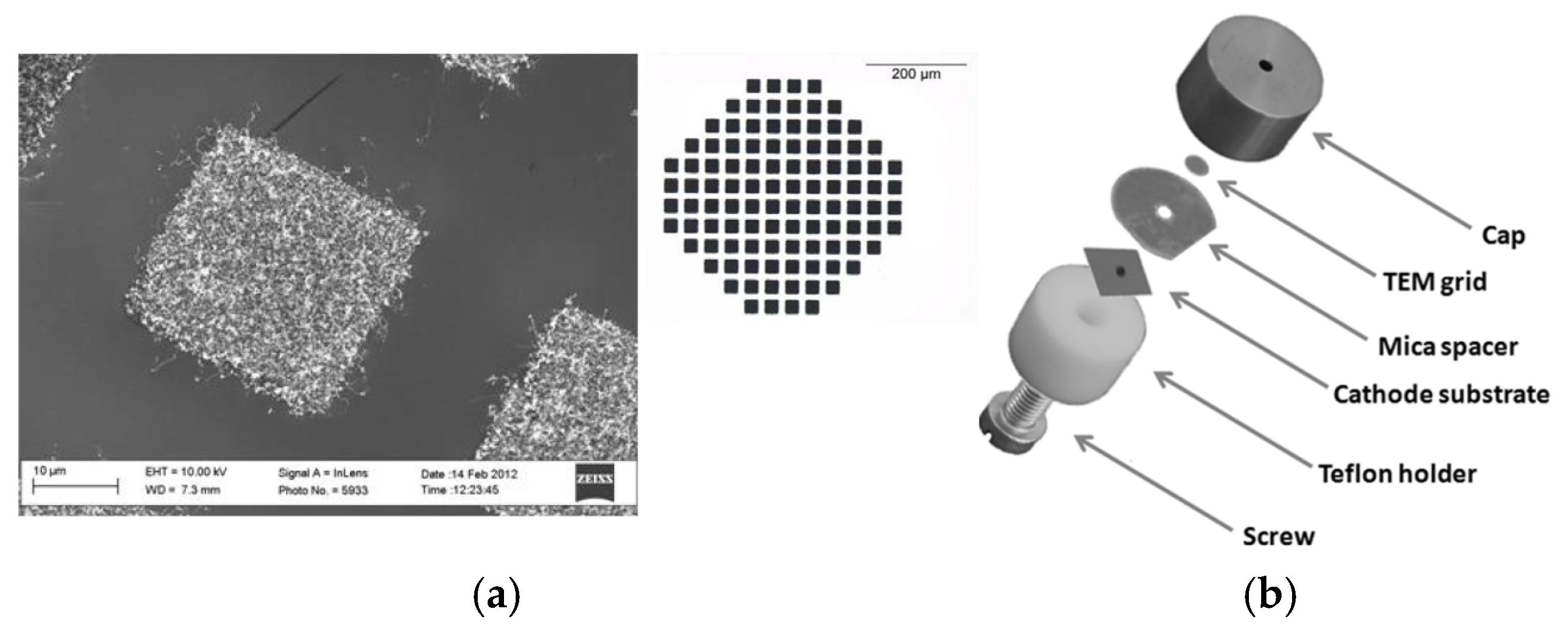

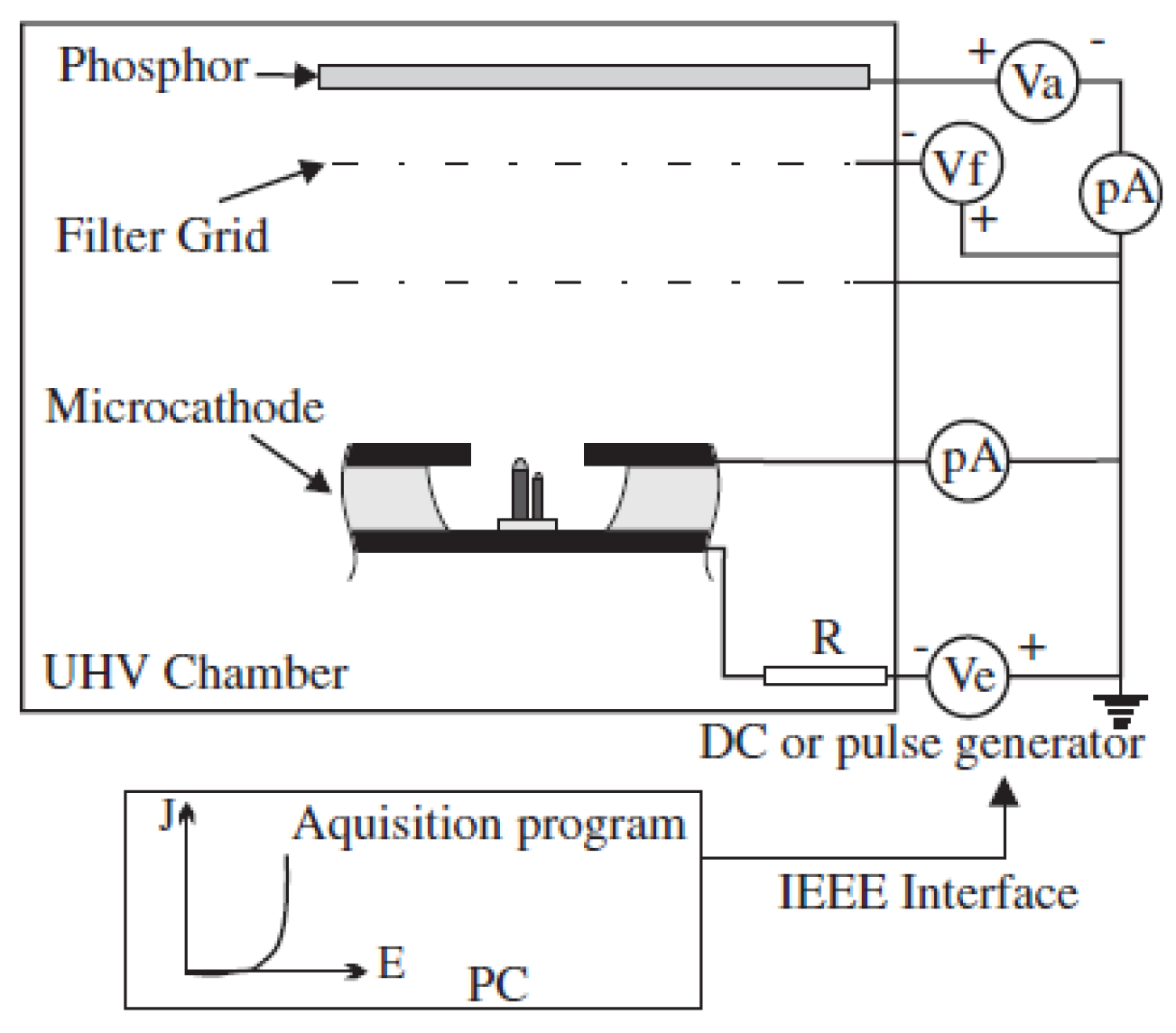

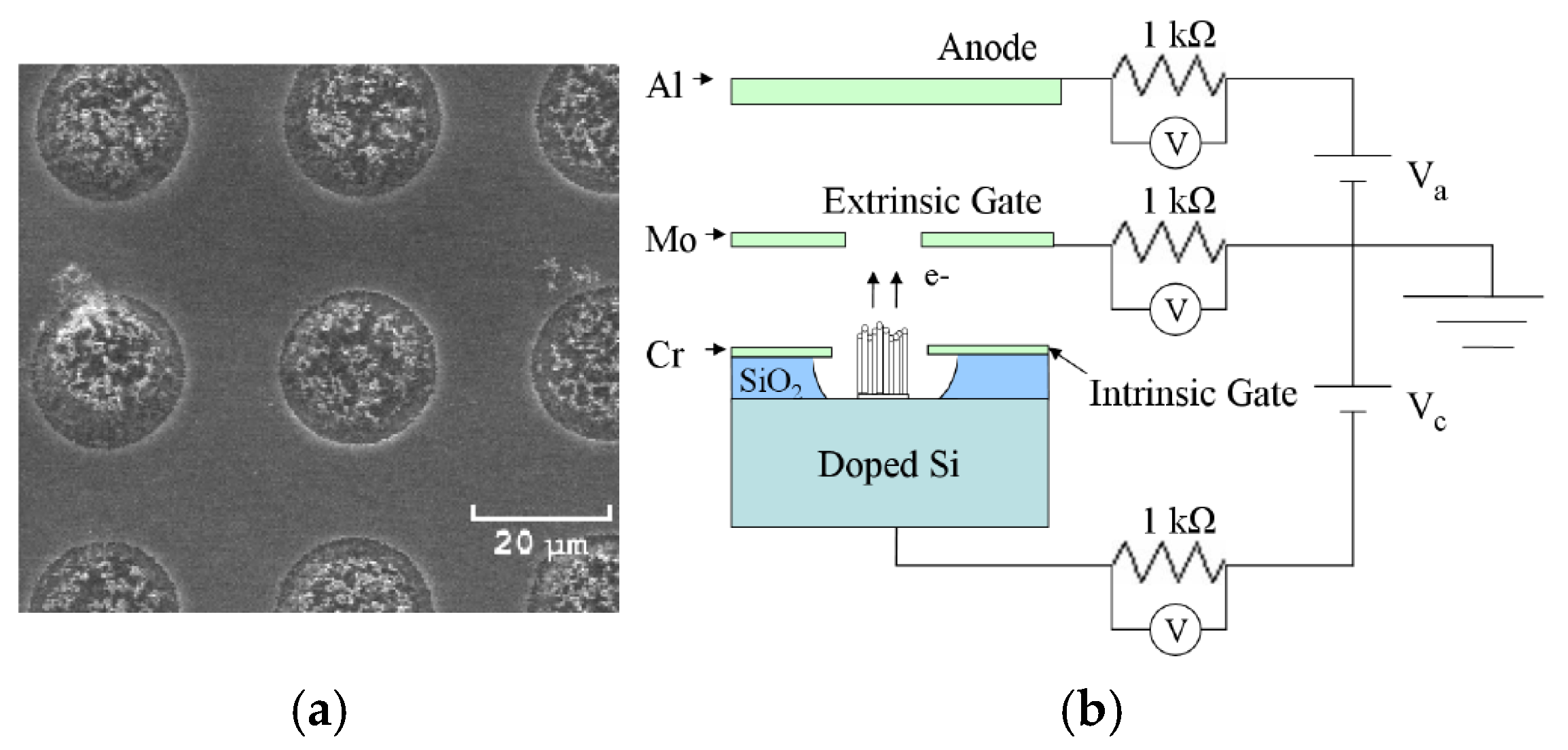

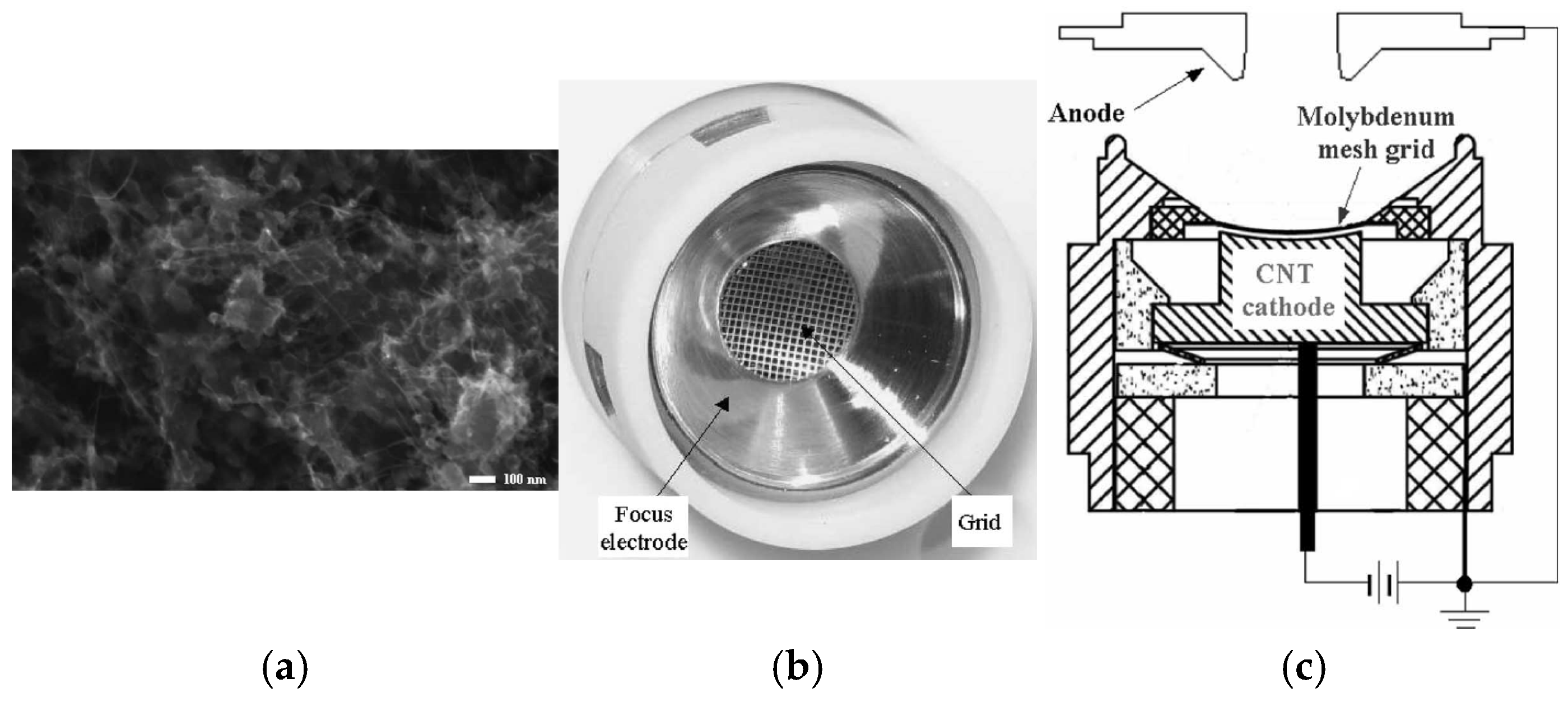

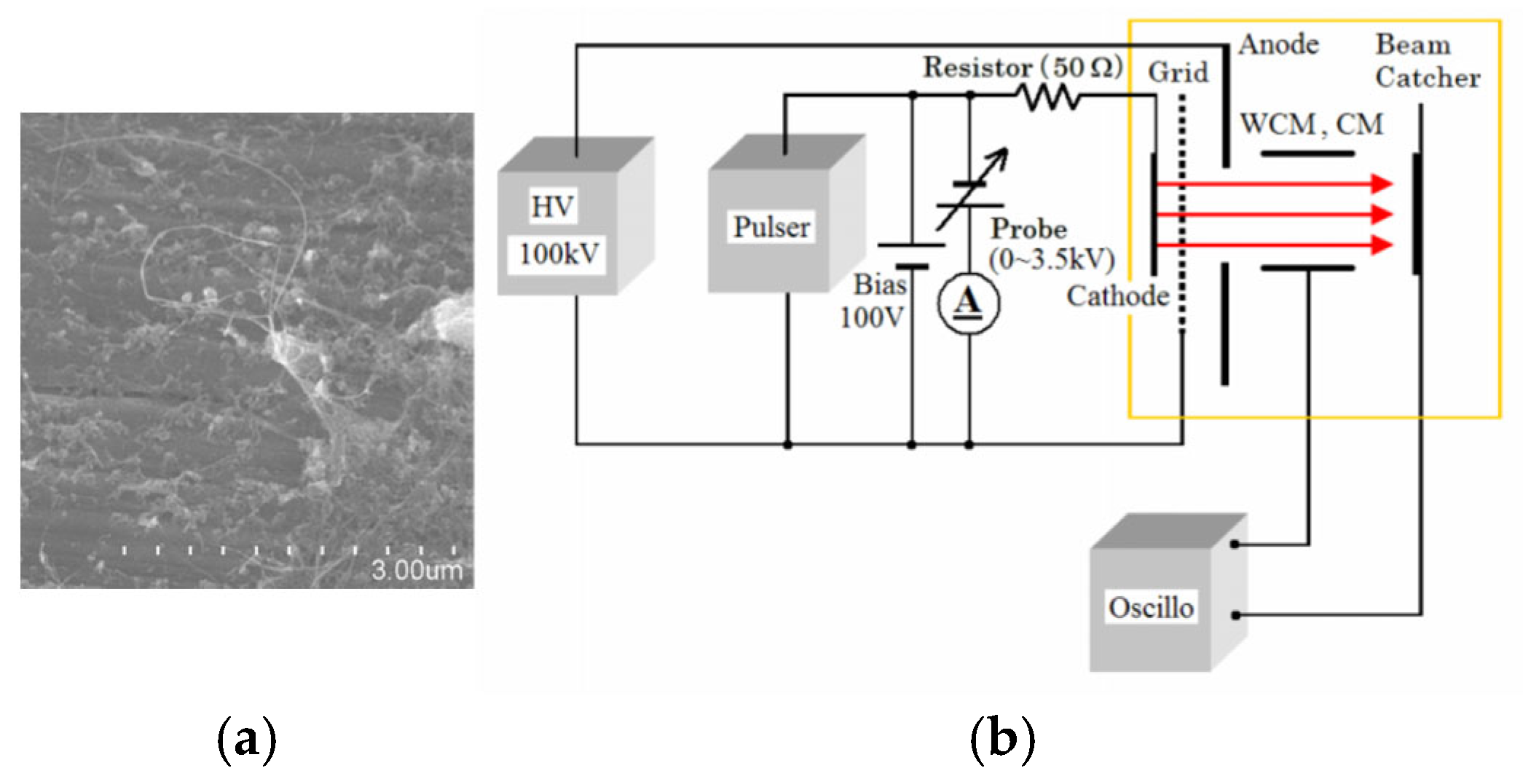

2. Cold Electron Gun Based on Disordered CNTs Film Emitter

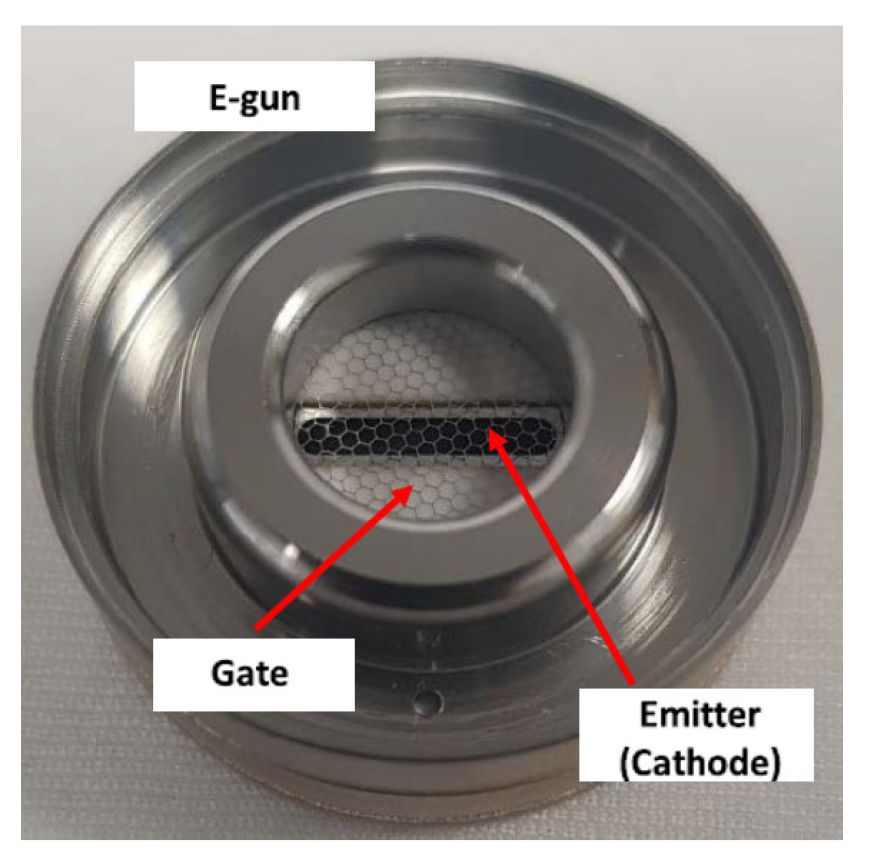

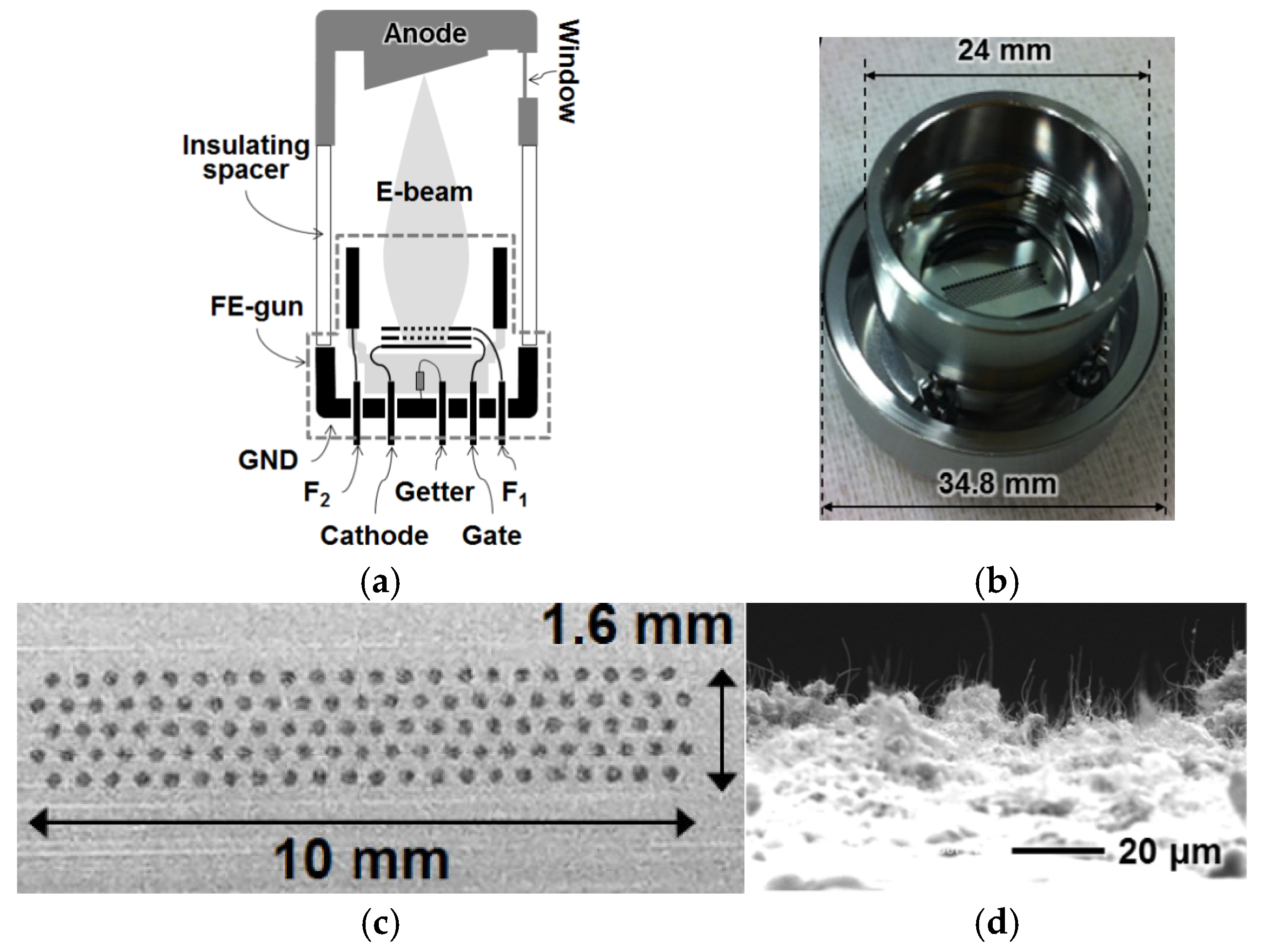

3. Cold Electron Gun Based on Aligned CNTs Emitter

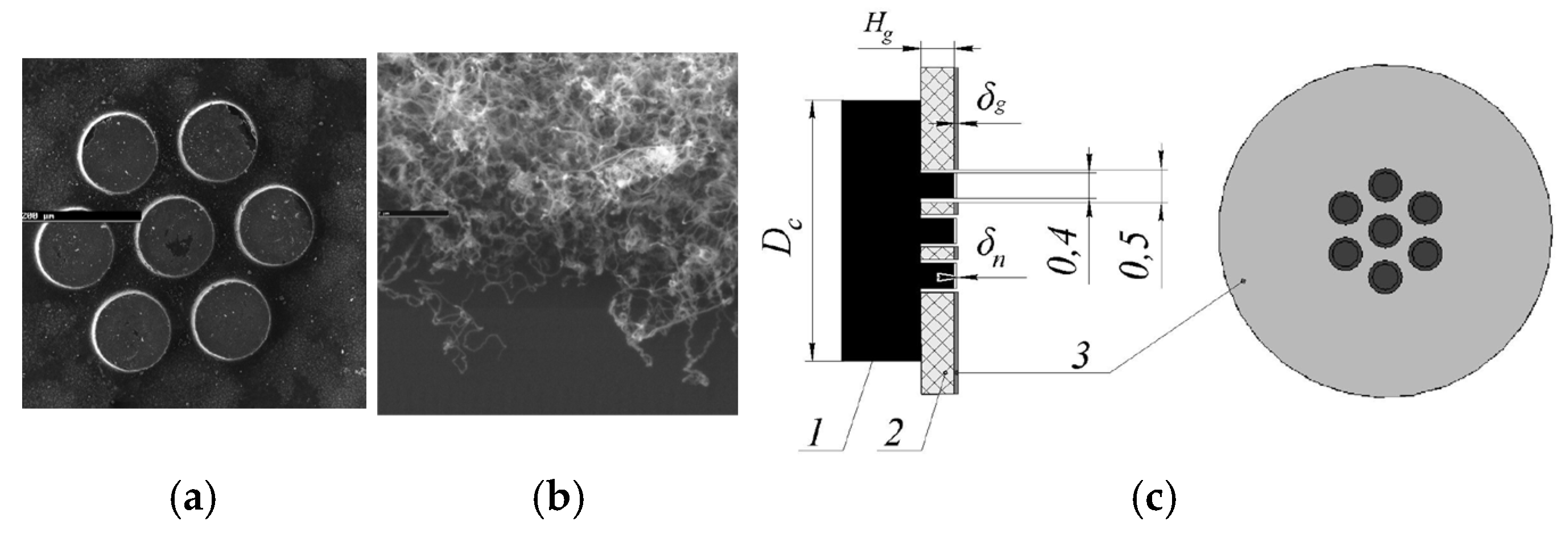

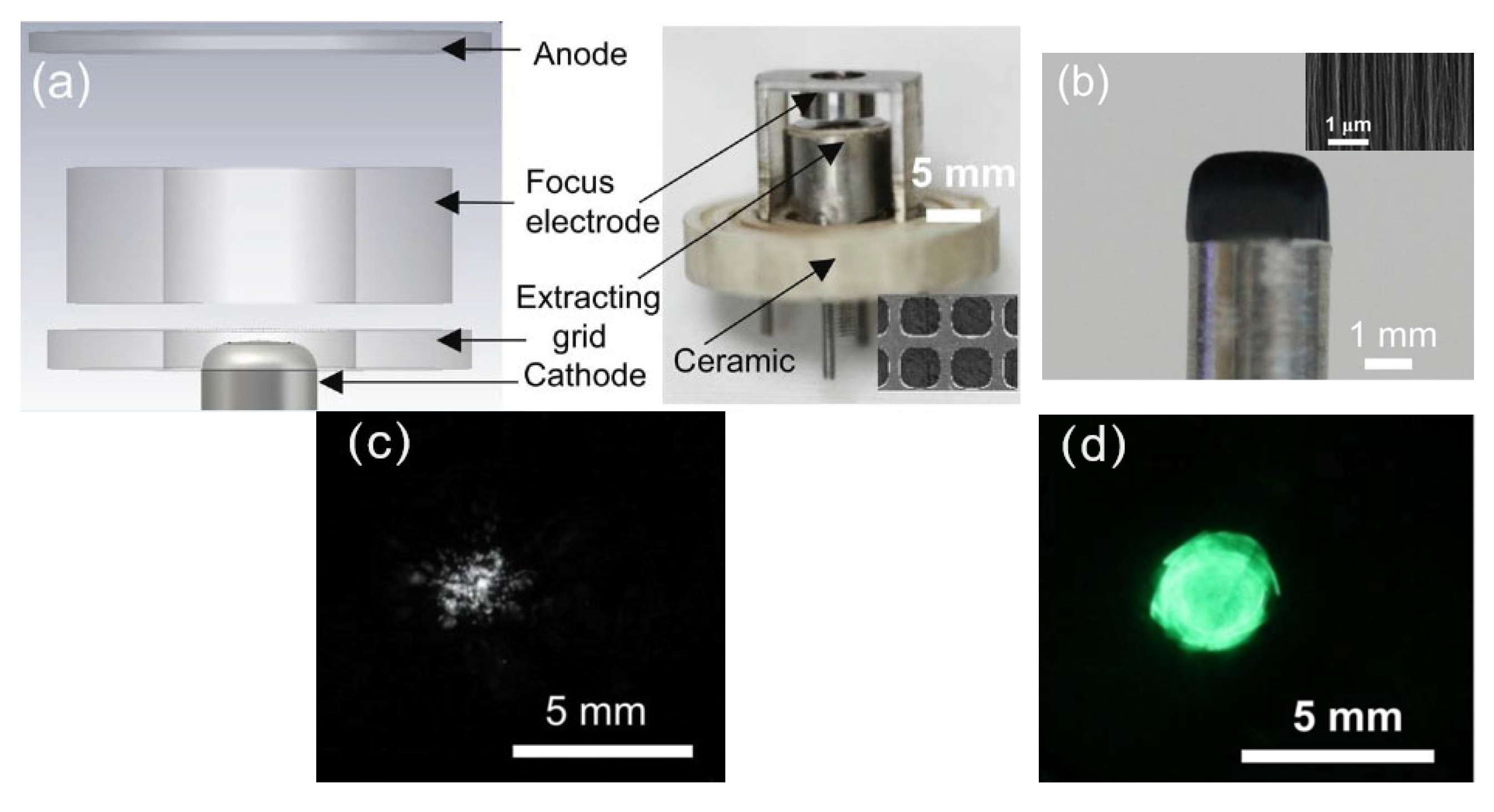

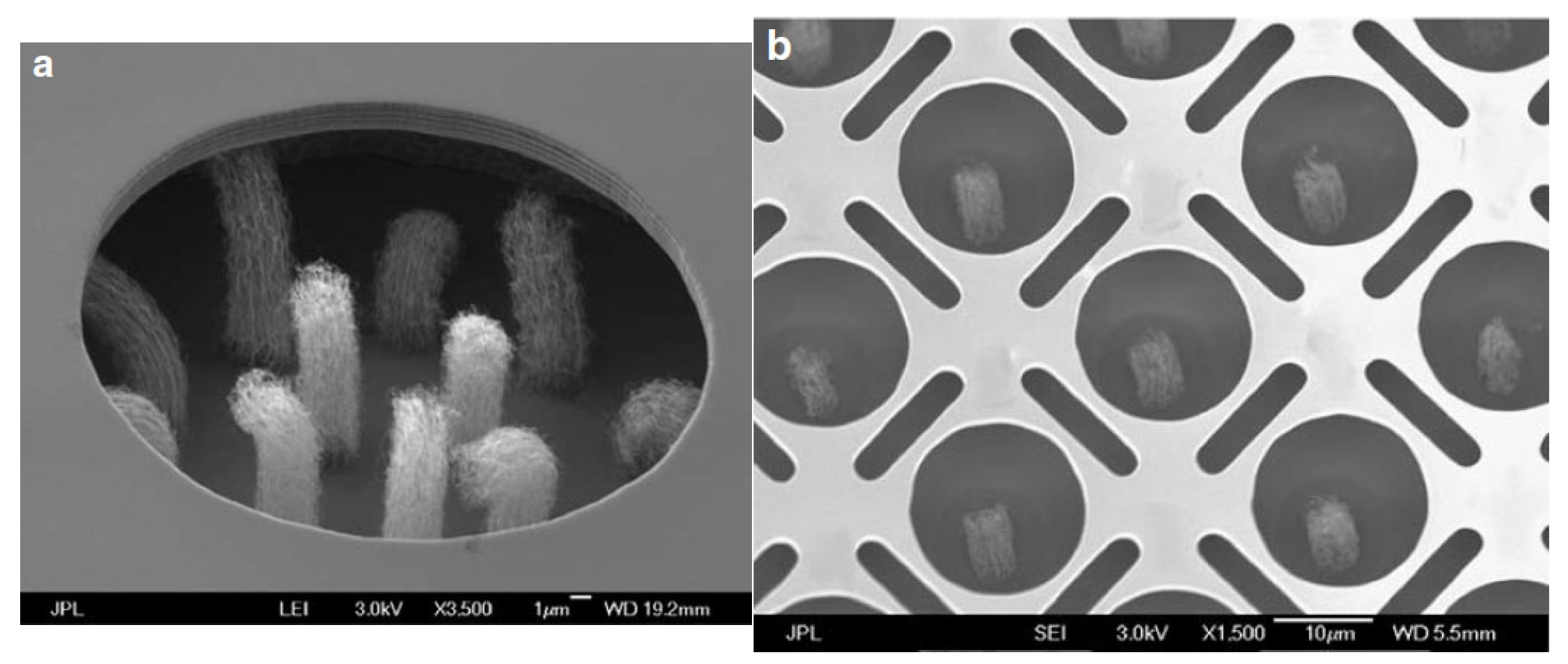

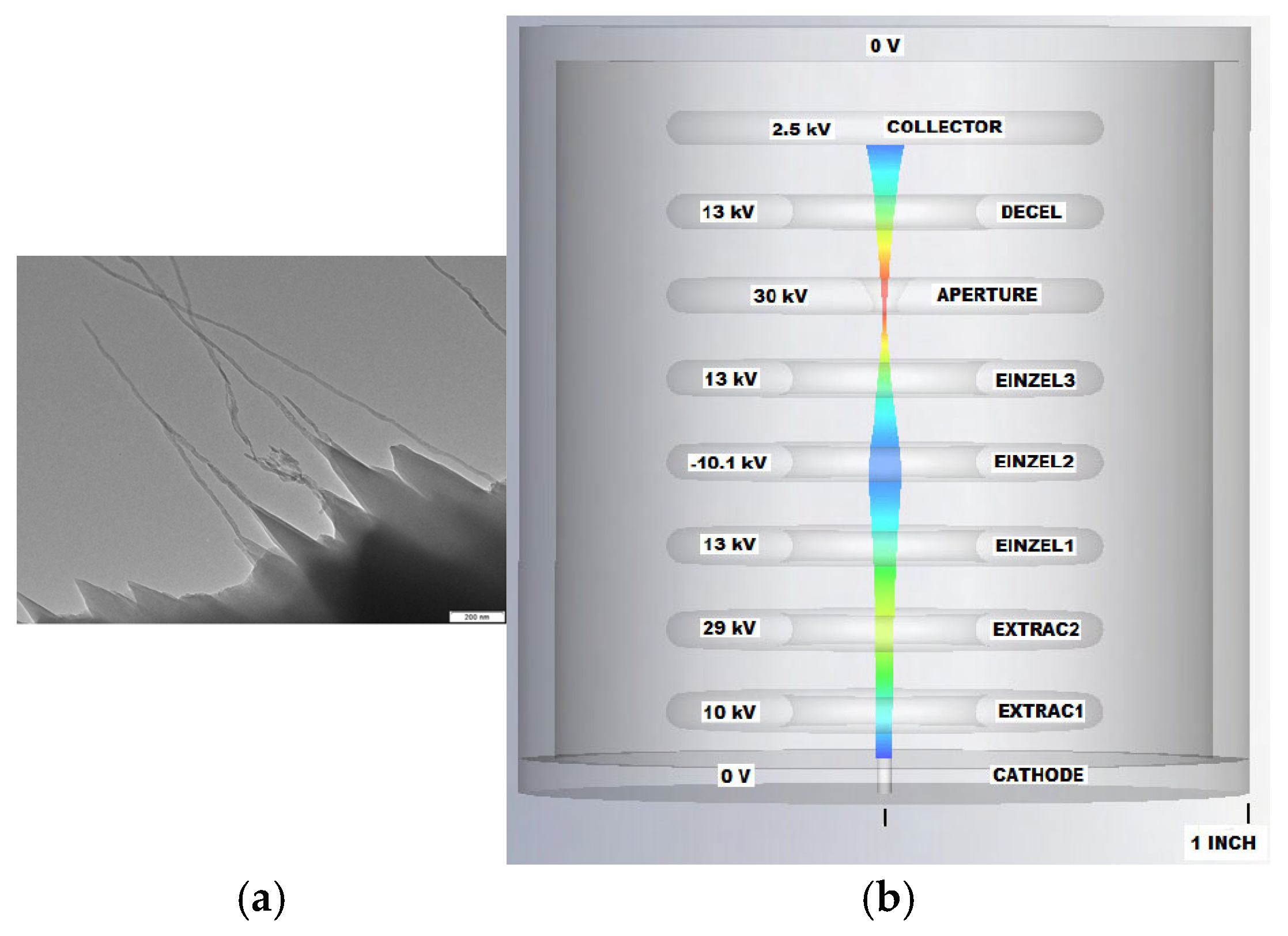

3.1. Cold Electron Gun Based on Single-Aligned CNTs Bundle Emitter

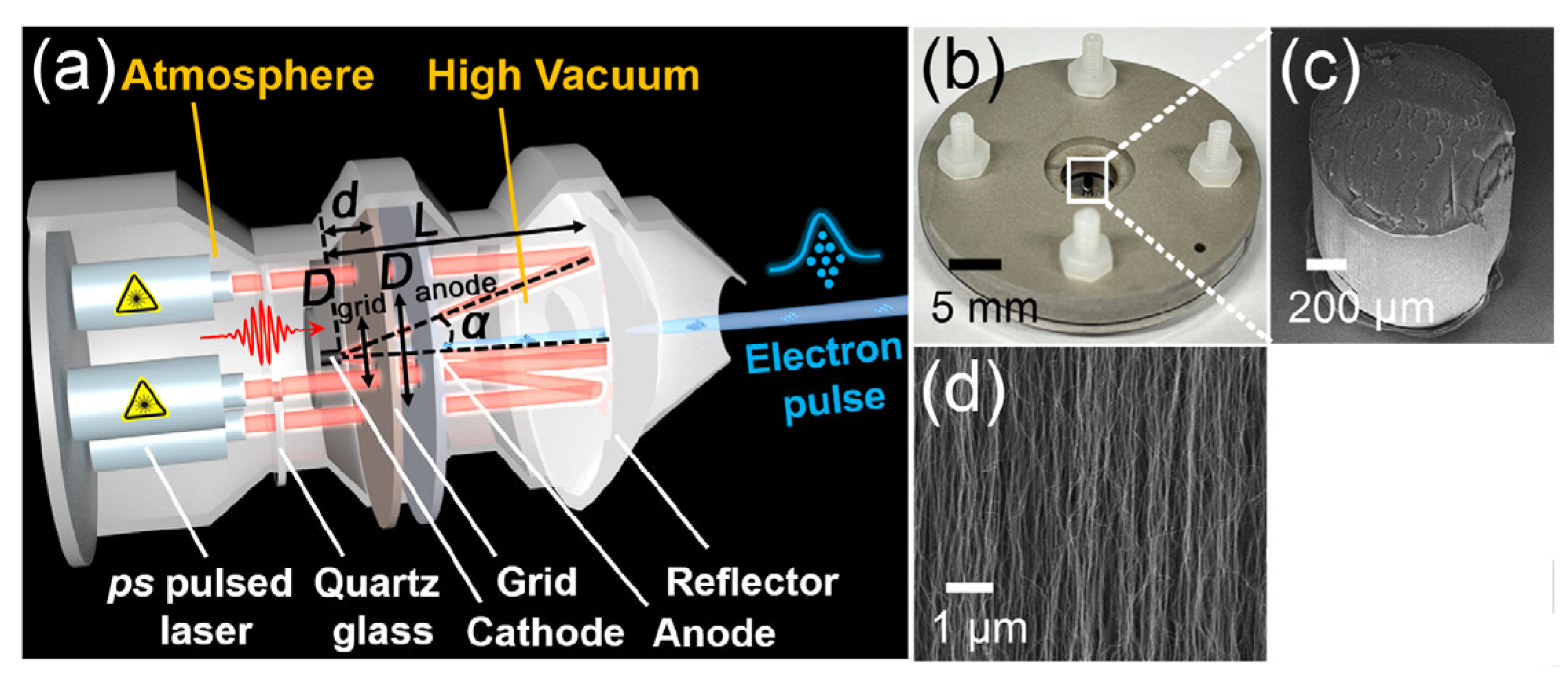

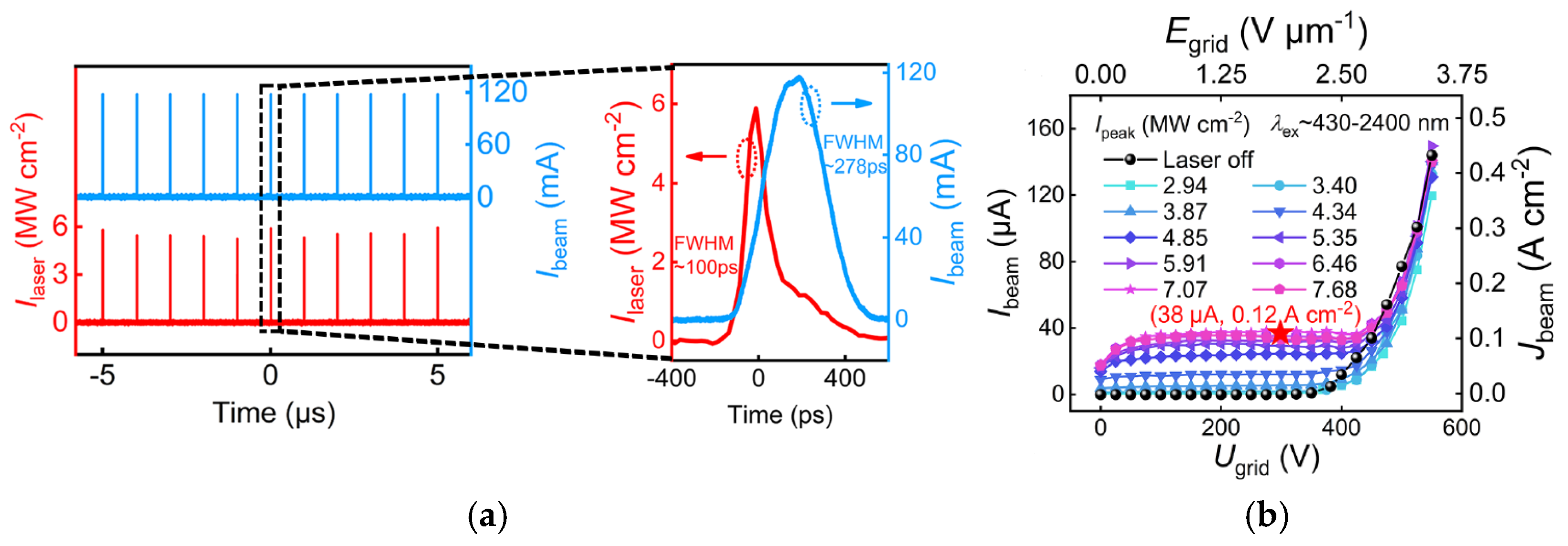

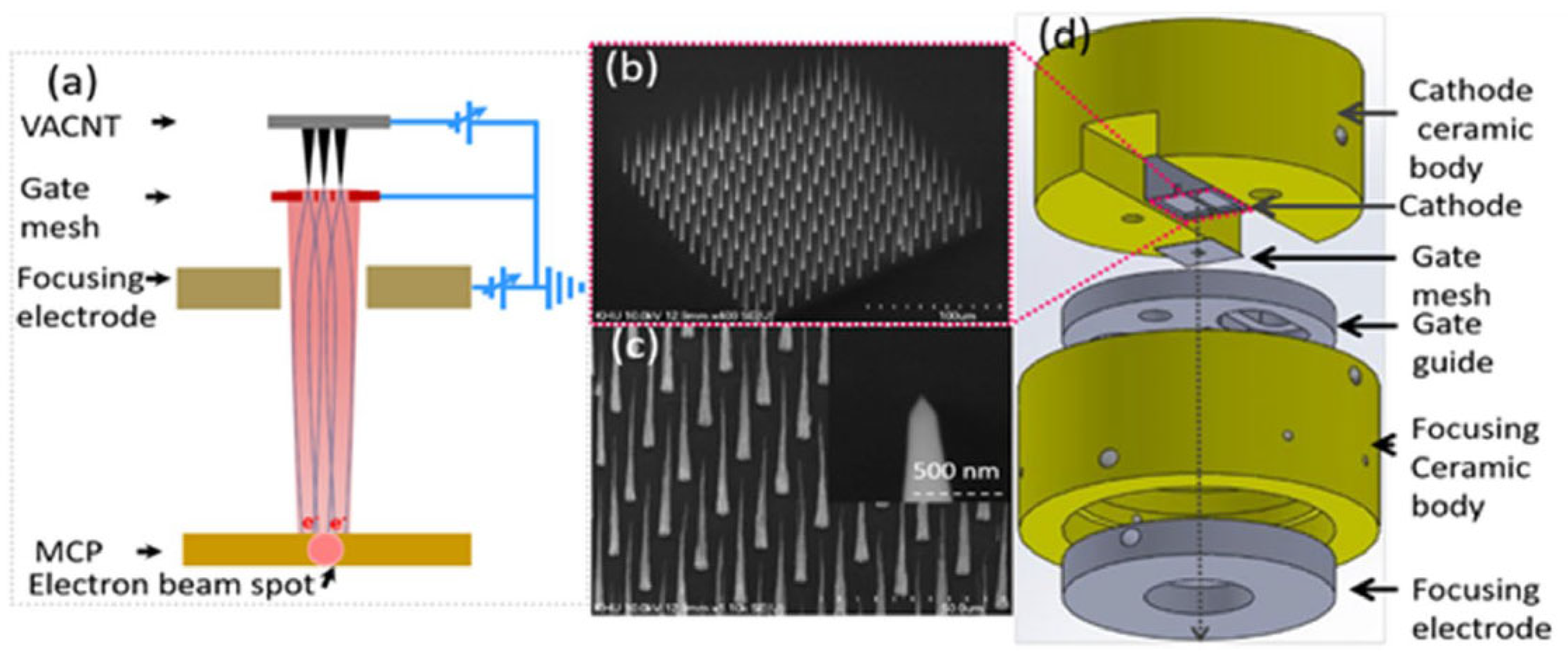

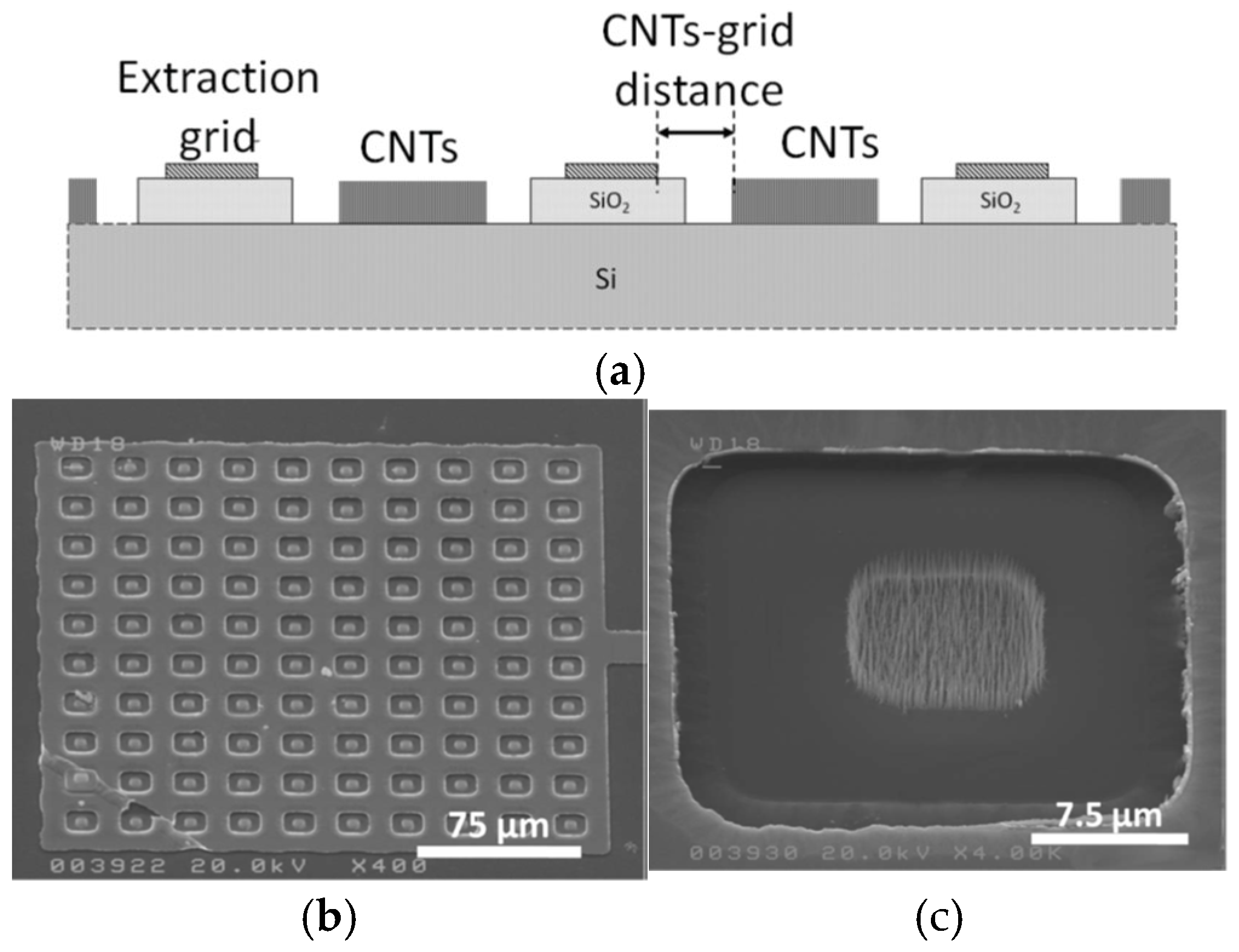

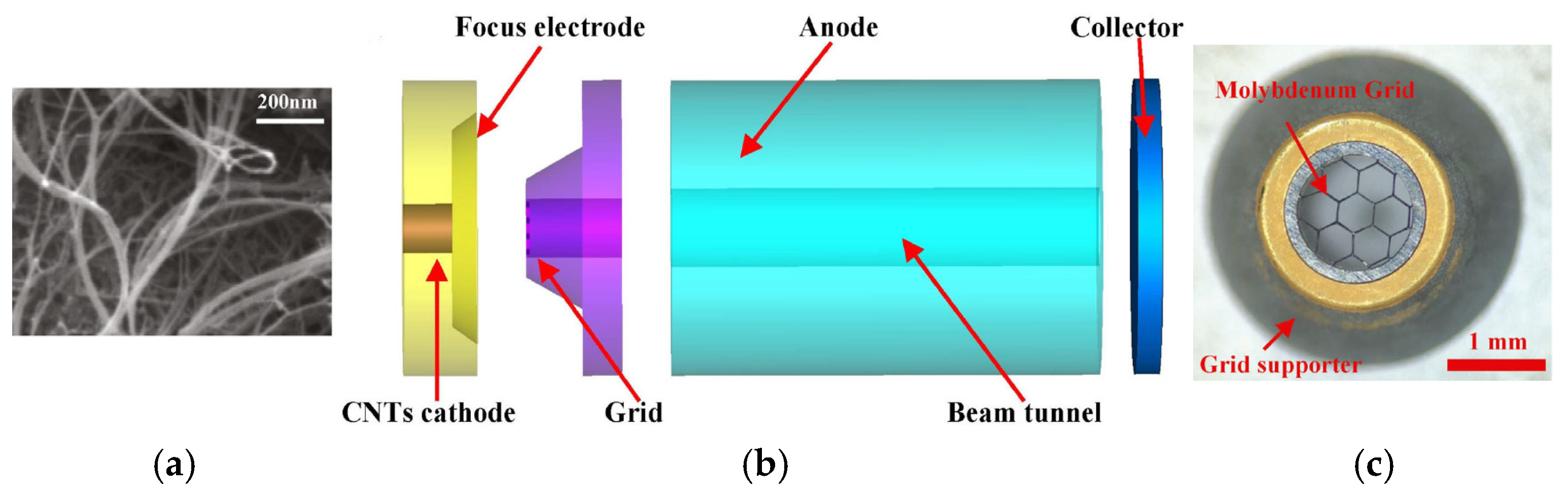

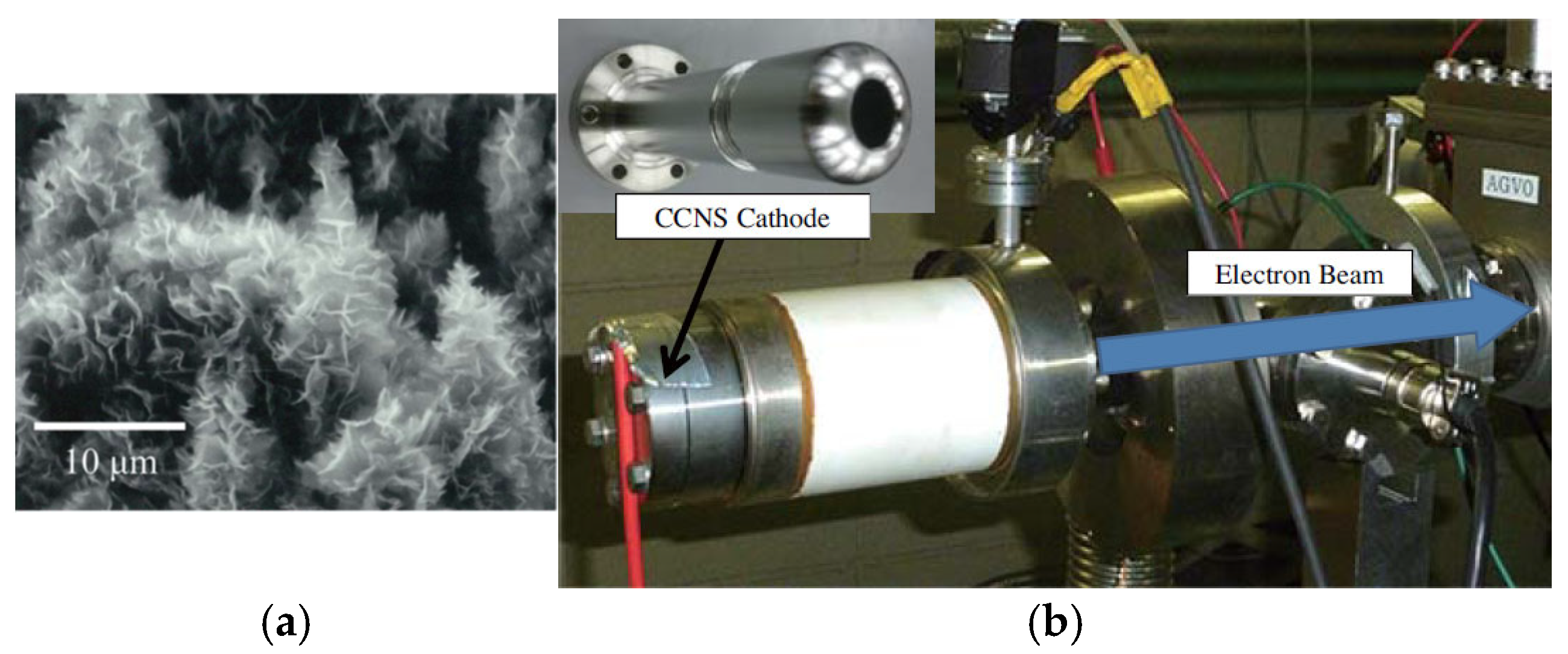

3.2. Cold Electron Gun Based on Aligned CNTs Arrays Emitter

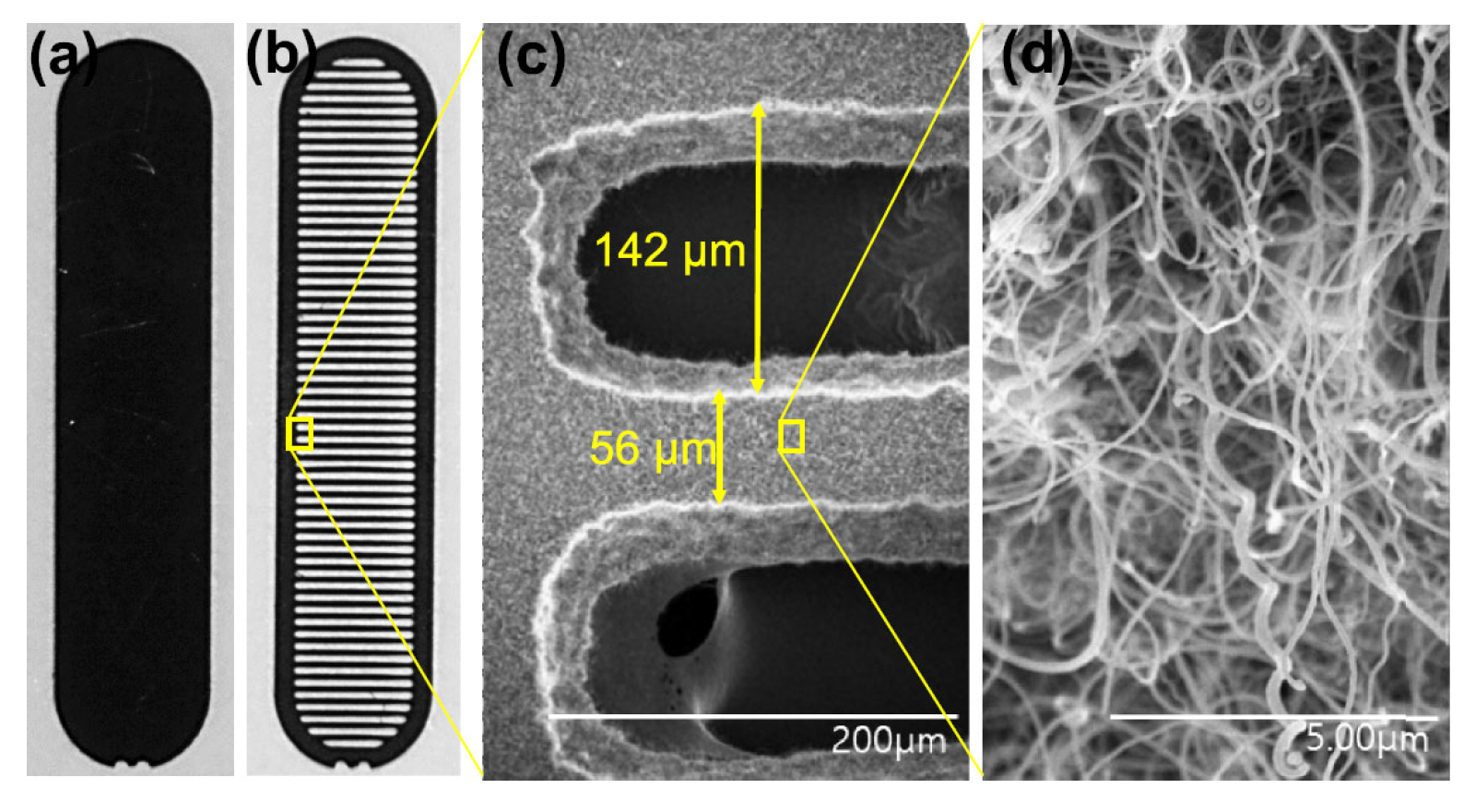

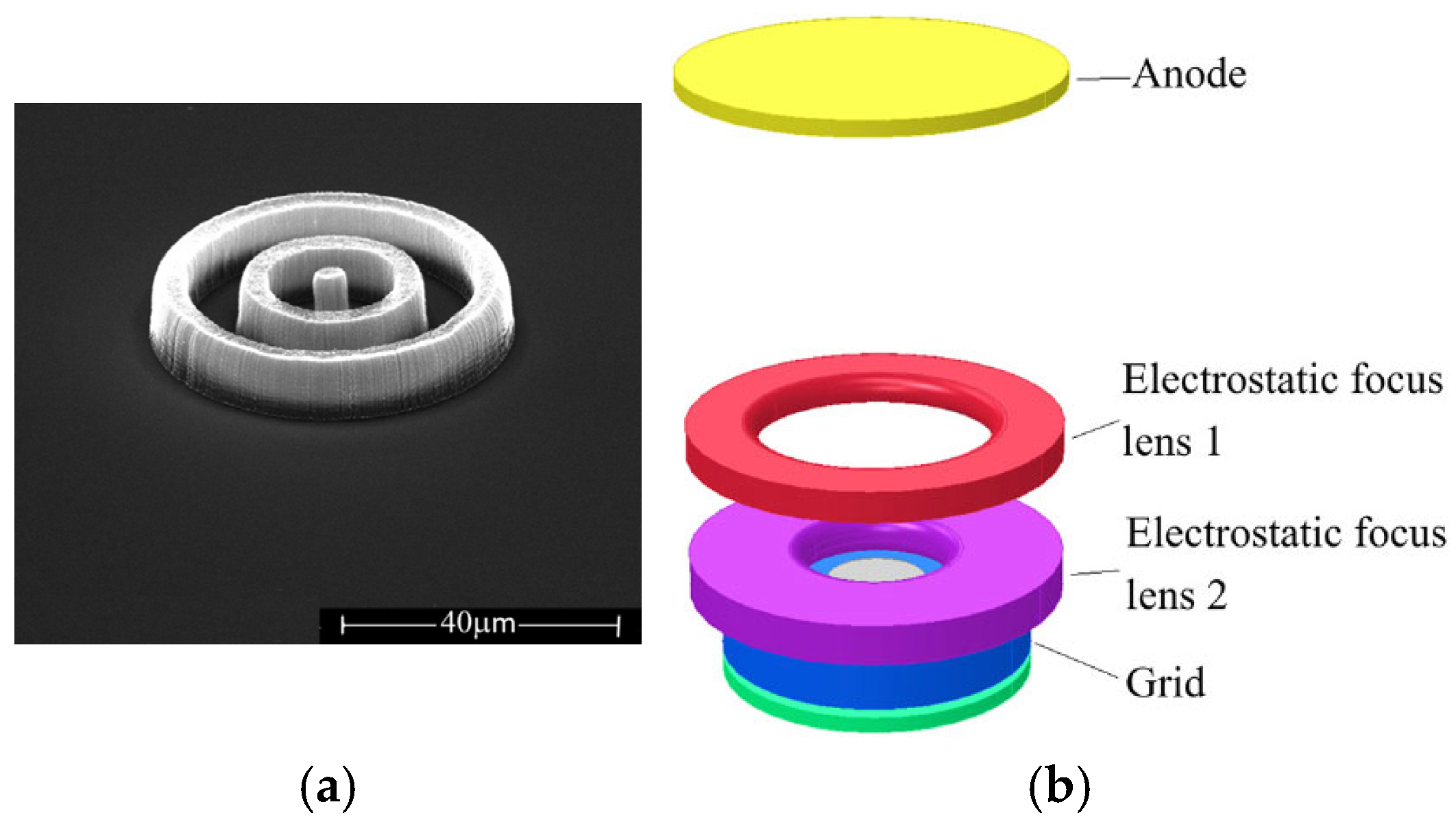

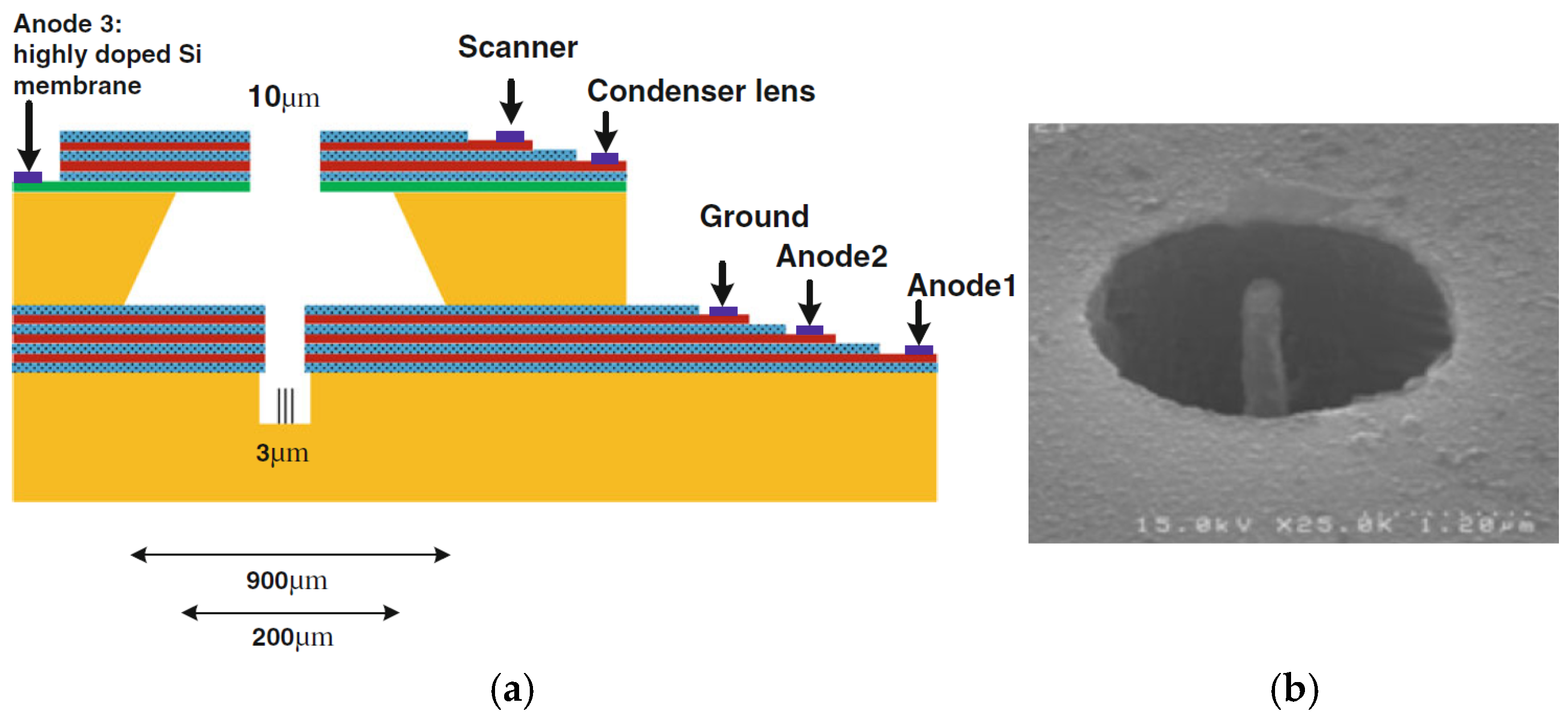

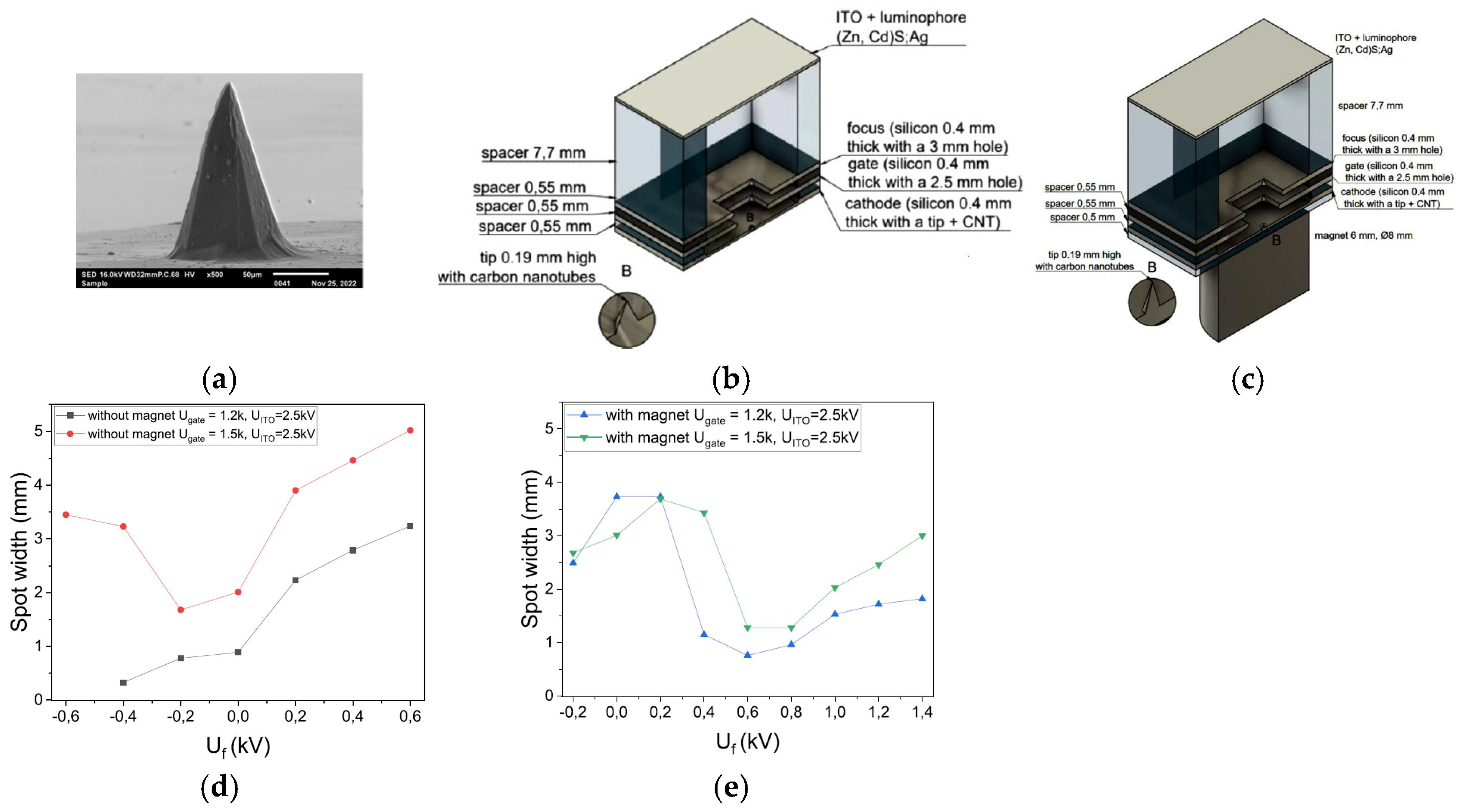

3.3. Aligned CNTs Cold Cathode Electron Gun Based on Micro-Fabrication Technique

4. Cold Cathode Electron Gun Based on CNTs Paste Emitter

5. Cold Cathode Electron Gun Based on Other Forms of CNT Emitters

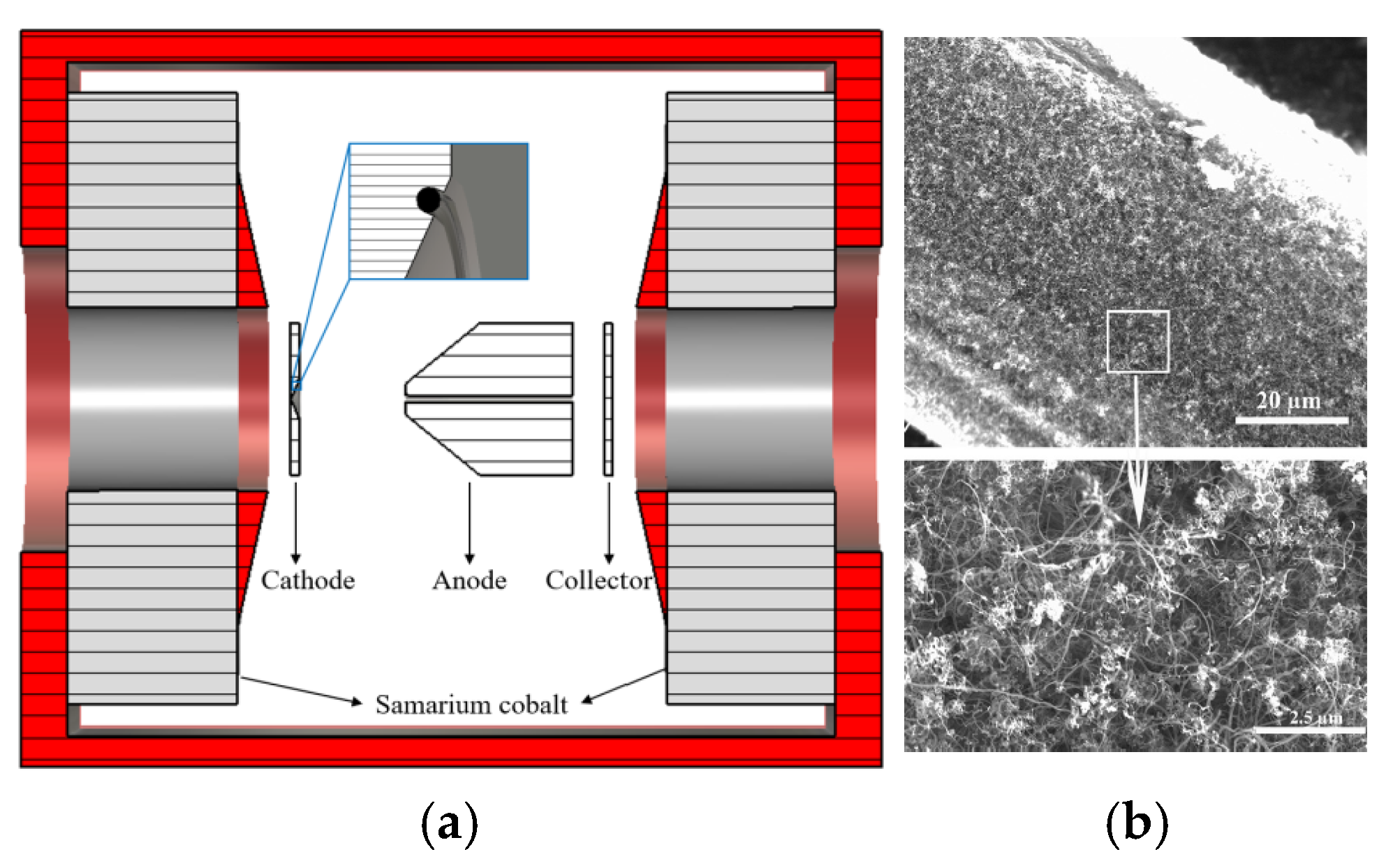

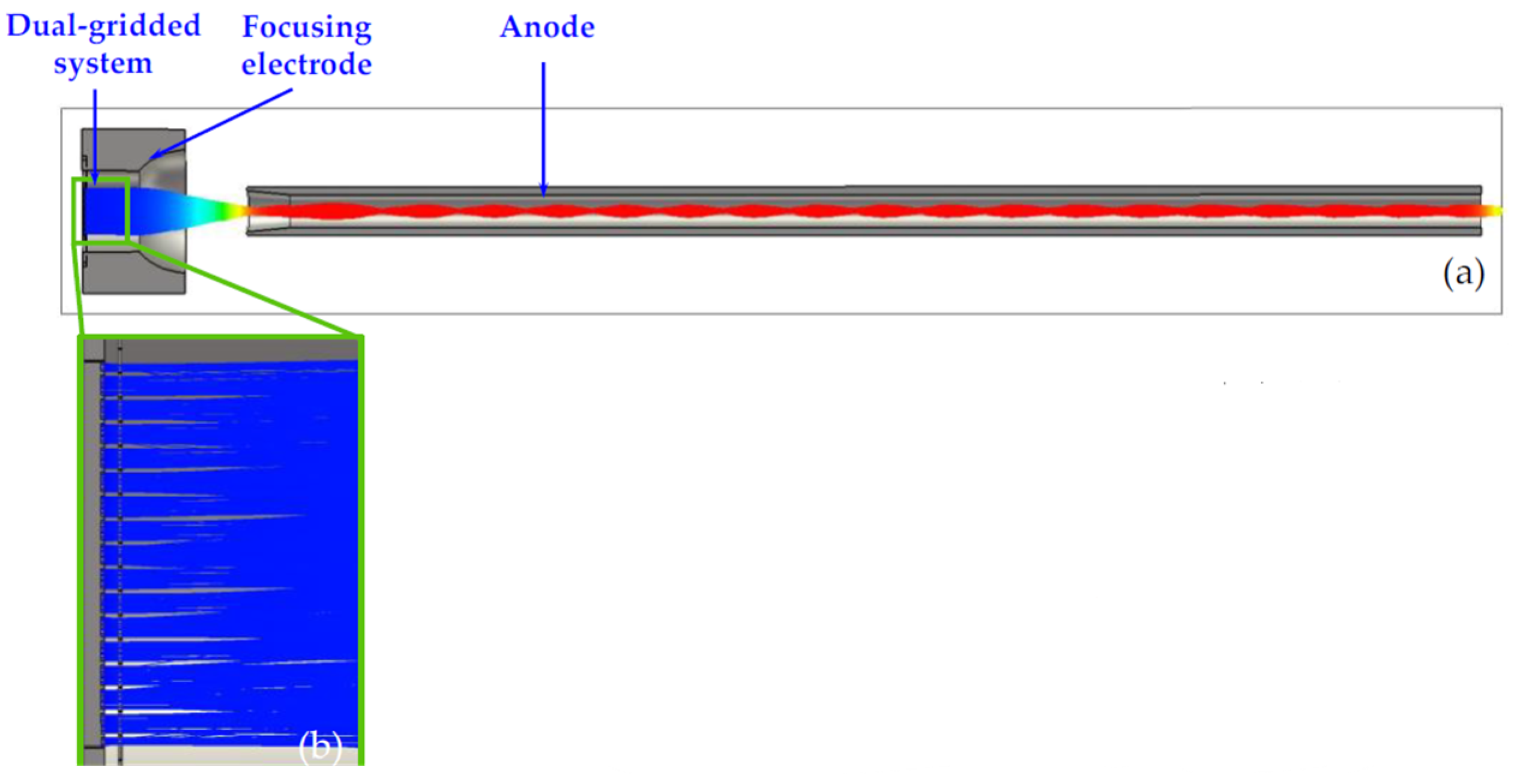

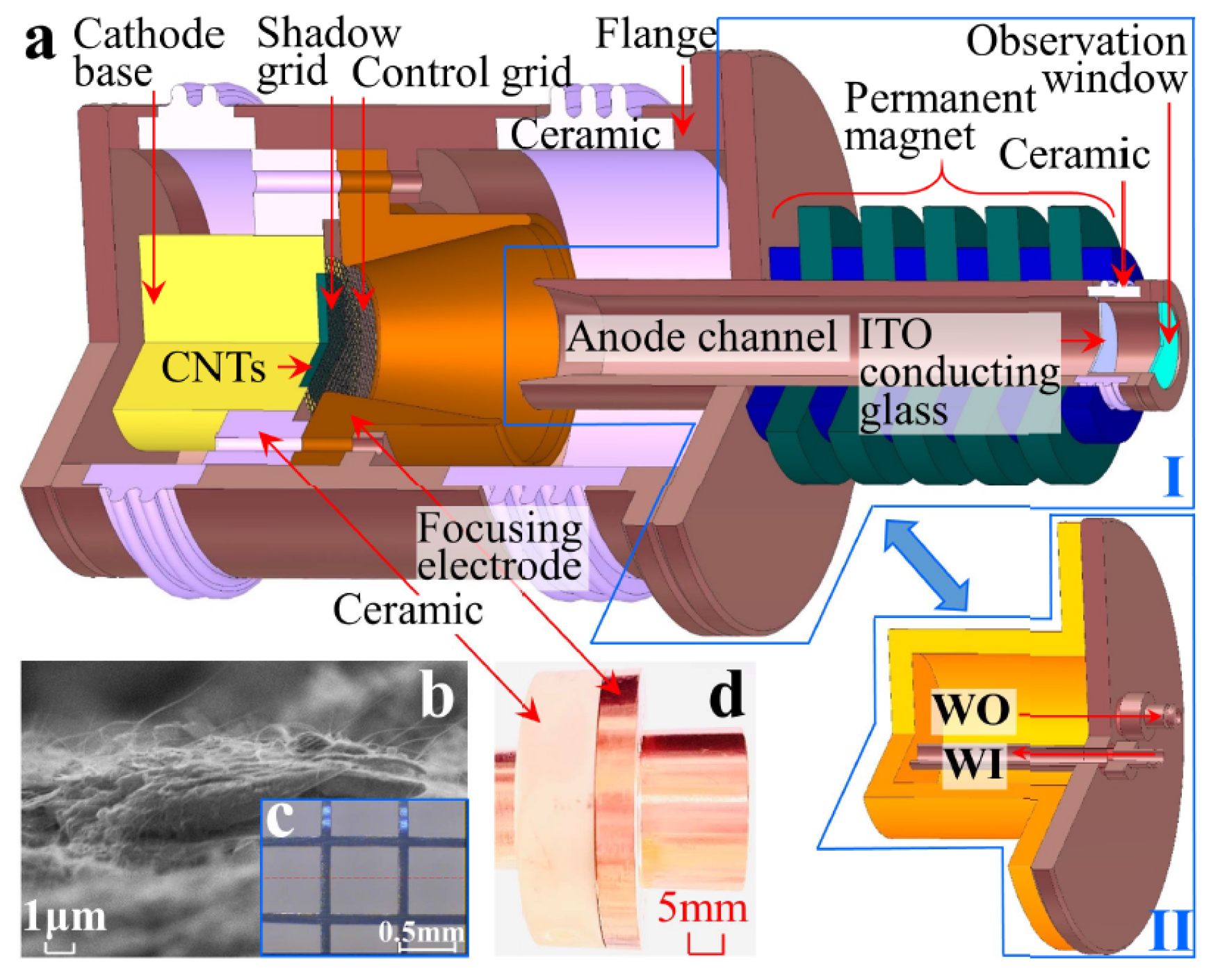

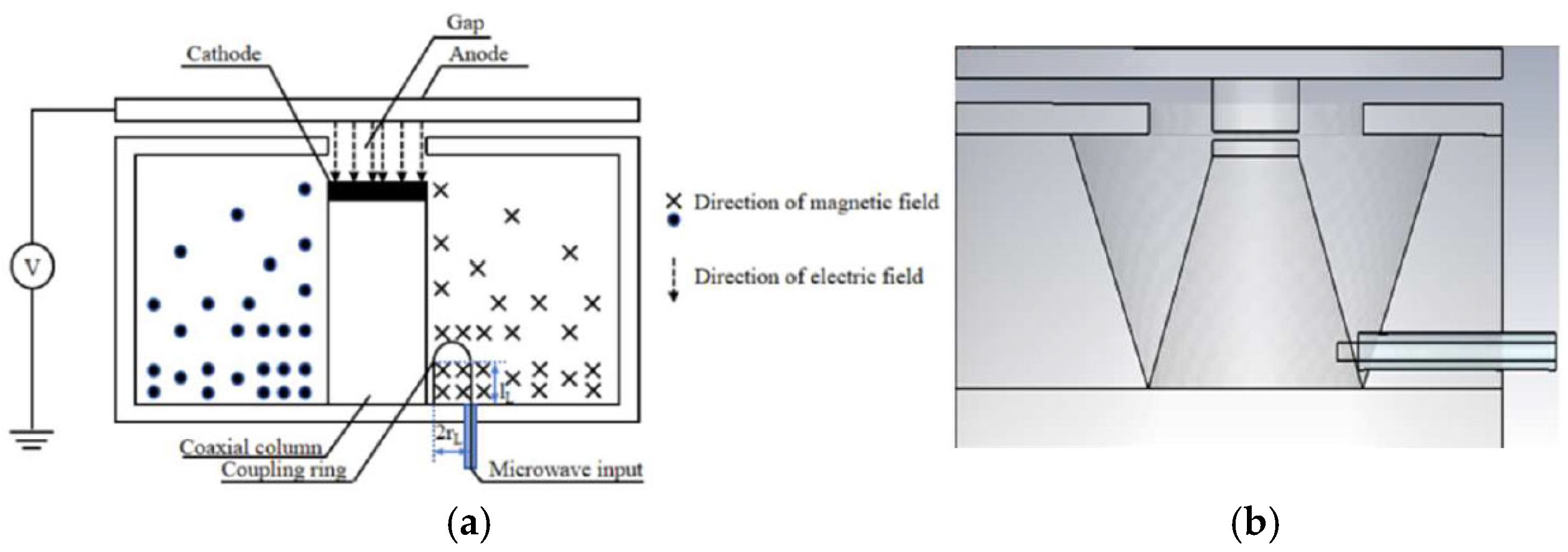

6. Microwave Electron Gun Based on CNT Cold Cathode

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Booske, J.H.; Dobbs, R.J.; Joye, C.D.; Kory, C.L.; Neil, G.R.; Park, G.S. Vacuum electronic high power terahertz sources. IEEE Trans. Terahertz Sci. Technol. 2011, 1, 54–75. [Google Scholar] [CrossRef]

- Whaley, D.R.; Gannon, B.M.; Smith, C.R.; Armstrong, C.M.; Spindt, C.A. Application of field emitter arrays to microwave power amplifiers. IEEE Trans. Plasma Sci. 2000, 28, 727–747. [Google Scholar] [CrossRef]

- Kim, J.W.; Jeong, J.W. Great improvement in adhesion and uniformity of carbon nanotube field emitters through reactive nanometer-scale SiC fillers. Carbon 2015, 82, 245–253. [Google Scholar] [CrossRef]

- Liu, X.C.; Li, Y.X.; Xiao, J.F.; Zhao, J.Z.; Li, C.; Li, Z.J. Enhanced field emission stability of vertically aligned carbon nanotubes through anchoring for X-ray imaging applications. J. Mater. Chem. C 2023, 11, 2505. [Google Scholar] [CrossRef]

- Choi, Y.C.; Kang, J.T.; Park, S.; Shin, M.S.; Jeon, H.; Kim, J.W.; Jeong, J.W.; Song, Y.H. Preparation of a miniature carbon nanotube paste emitter for very high resolution X-ray imaging. Carbon 2016, 100, 302–308. [Google Scholar] [CrossRef]

- Saito, Y.; Uemura, S. Field emission from carbon nanotubes and its application to electron sources. Carbon 2000, 38, 169–182. [Google Scholar] [CrossRef]

- Zhan, R.Z.; Chen, J.; Deng, S.Z.; Xu, N.S. Fabrication of gated CuO nanowire field emitter arrays for application in field emission display. J. Vac. Sci. Technol. B 2010, 28, 558–561. [Google Scholar] [CrossRef]

- Lee, H.R.; Kim, D.W.; Hwang, O.J.; Cho, B.; Park, K.C. Scanning electron imaging with vertically aligned carbon nanotube (CNT) based cold cathode electron beam (c-beam). Vacuum 2020, 182, 109696. [Google Scholar] [CrossRef]

- Yoo, S.T.; Park, K.C. Extreme ultraviolet lighting using carbon nanotube-based cold cathode electron beam. Nanomaterials 2022, 12, 4134. [Google Scholar] [CrossRef]

- Radauscher, E.J.; Gilchrist, K.H.; Di Dona, S.T.; Russell, Z.E.; Piascik, J.R.; Amsden, J.J.; Parker, C.B.; Stoner, B.R.; Glass, J.T. Improved Performance of Field Emission Vacuum Microelectronic Devices for Integrated Circuits. IEEE Trans. Electron Devices 2016, 63, 3753–3760. [Google Scholar] [CrossRef]

- Denbnovetsky, S.V.; Melnyk, I.V.; Melnyk, V.G.; Tugai, B.A.; Tuhai, S.B. High voltage glow discharge electron guns and its advanced application examples in electronic industry. In Proceedings of the 2016 International Conference Radio Electronics & Info Communications (UkrMiCo), Kiev, Ukraine, 11–16 September 2016; pp. 1–4. [Google Scholar]

- Crewe, A.V. Electron Gun Using a Field Emission Source. Rev. Sci. Instrum. 1967, 39, 576–583. [Google Scholar] [CrossRef]

- Laszczyk, K.U. Field emission cathodes to form an electron beam prepared from carbon nanotube suspensions. Micromachines 2020, 11, 260. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.W.; Kang, J.T.; Choi, S.; Kim, J.W.; Ahn, S.; Song, Y.H. A digital miniature x-ray tube with a high-density triode carbon nanotube field emitter. Appl. Phys. Lett. 2013, 102, 023504. [Google Scholar] [CrossRef]

- Yuan, X.S.; Cole, M.T.; Zhang, Y.; Wu, J.Q.; Milne, W.I.; Yan, Y. Parametrically optimized carbon nanotube-coated cold cathode spindt arrays. Nanomaterials 2017, 7, 13. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Shukla, S.K.; Ravi, M.; Barik, R.K. A review of electron emitters for high-power and high-frequency vacuum electron devices. IEEE Trans. Plasma Sci. 2020, 48, 3446–3454. [Google Scholar] [CrossRef]

- Li, X.; Feng, J. Review of nanoscale vacuum devices. Electronics 2023, 12, 802. [Google Scholar] [CrossRef]

- Tang, H.; Liang, S.-D.; Deng, S.Z.; Xu, N.S. Comparison of field and thermionic emissions from carbon nanotubes. J. Phys. D Appl. Phys. 2006, 39, 5280–5284. [Google Scholar] [CrossRef]

- Allaham, M.M.; Forbes, R.G.; Mousa, M.S. Applying the field emission orthodoxy test to Murphy-Good plots. Jordan J. Phys. 2020, 13, 101–111. [Google Scholar] [CrossRef]

- Whaley, D.R.; Duggal, R.; Armstrong, C.M.; Bellew, C.L.; Holland, C.E.; Spindt, C.A. 100 W operation of a cold cathode TWT. IEEE Trans. Electron Devices 2009, 56, 896–905. [Google Scholar] [CrossRef]

- Li, Y.H.; Sun, Y.H.; Yeow, J.T.W. Nanotube field electron emission: Principles, development, and applications. Nanotechnology 2015, 26, 242001. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Xu, N.S.; Huang, H.J.; Ke, Y.L.; Li, B.H.; Chen, J.; She, J.C.; Deng, S.Z. Design and realization of microwave frequency multiplier based on field emission from carbon nanotubes cold-cathode. IEEE Trans. Electron Devices 2018, 65, 1146–1150. [Google Scholar] [CrossRef]

- Xu, X.T.; Yuan, X.S.; Chen, Q.Y.; Cole, M.T.; Zhang, Y.; Xie, J.; Yin, Y.; Li, H.L.; Yan, Y. A low-voltage, premodulation terahertz oscillator based on a carbon nanotube cold cathode. IEEE Trans. Electron Devices 2020, 67, 1266–1269. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- de Heer, W.A.; Chatelain, A.; Ugarte, D. A CNT field-emission electron source. Science 1995, 27, 1179–1180. [Google Scholar] [CrossRef]

- Xu, N.S.; Huq, S.E. Novel cold cathode materials and applications. Mater. Sci. Eng. R Rep. 2005, 48, 47–189. [Google Scholar] [CrossRef]

- Yao, Z.; Kane, C.L.; Dekker, C. High-field electrical transport in single-wall carbon nanotubes. Phys. Rev. Lett. 2000, 84, 2941. [Google Scholar] [CrossRef]

- von Windheim, T.; Gilchrist, K.H.; Parker, C.B.; Hall, S.; Carlson, J.B.; Stokes, D.; Baldasaro, N.G.; Hess, C.T.; Scheick, L.; Rax, B.; et al. Proof-of-concept vacuum microelectronic nor gate fabricated using microelectromechanical systems and carbon nanotube field emitters. Micromachines 2023, 14, 973. [Google Scholar] [CrossRef]

- Li, C.; Zhou, X.; Zhai, F.; Li, Z.J.; Yao, F.R.; Qiao, R.X.; Chen, K.; Cole, M.T.; Yu, D.P.; Sun, Z.P.; et al. Carbon nanotubes as an ultrafast emitter with a narrow energy spread at optical frequency. Adv. Mater. 2017, 29, 6. [Google Scholar] [CrossRef]

- Cheng, H.M.; Li, F.M.; Su, G.; Pan, H.Y.; He, L.L.; Sun, X.; Dresselhaus, M.S. Large-scale and low-cost synthesis of single-walled carbon nanotubes by the catalytic pyrolysis of hydrocarbons. Appl. Phys. Lett. 1998, 72, 3282. [Google Scholar] [CrossRef]

- Wang, L.Z.; Wu, Y.T.; Jiang, J.; Tang, S.; Ke, Y.L.; Zhang, Y.; Deng, S.Z. Field-emission energy distribution of carbon nanotube film and single tube under high current. Nanomaterials 2024, 14, 888. [Google Scholar] [CrossRef]

- de Jonge, N.; Lamy, Y.; Schoots, K.; Oosterkamp, T.H. High brightness electron beam from a multi-walled carbon nanotube. Nature 2002, 420, 393–395. [Google Scholar] [CrossRef]

- Xiao, D.Y.; Du, H.H.; Sun, L.M.; Suo, X.C.; Wang, Y.R.; Zhang, Y.L.; Zhang, S.L.; Kuang, S.Y.; Hu, F.J.; Tu, L.C.; et al. Boosting the electron beam transmittance of field emission cathode using a self-charging gate. Nat. Commun. 2024, 15, 764. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Sun, G.; Zhang, X.; Zhang, X.; Cui, Z. Advancement in Carbon Nanotubes Optoelectronic Devices for Terahertz and Infrared Applications. Adv. Electron. Mater. 2024, 10, 2400124. [Google Scholar] [CrossRef]

- Tang, D.M.; Cretu, O.; Ishihara, S.; Zheng, Y.J.; Otsuka, K.; Xiang, R.; Maruyama, S.; Cheng, H.M.; Liu, C.; Golberg, D. Chirality engineering for carbon nanotube electronics. Nat. Rev. Electr. Eng. 2024, 1, 149–162. [Google Scholar] [CrossRef]

- Corbella, C.; Aijaz, A.; Kubart, T.; Lin, L.; Portal, S.; Keidar, M. Pulsed plasma vapour deposition of carbon materials: Advantages and challenges. Carbon 2025, 232, 119772. [Google Scholar] [CrossRef]

- Silan, J.; Niemann, D.L.; Ribaya, B.P.; Rahman, A.; Meyyappan, M.; Nguyen, C.V. Carbon nanotube pillar arrays for achieving high emission current densities. Appl. Phys. Lett. 2009, 95, 133111. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Mann, M.; Hasko, D.; Lei, W.; Wang, B.P.; Chu, D.P.; Pribat, D.; Amaratunga, G.A.J.; Milne, W.I. High emission current density, vertically aligned carbon nanotube mesh, field emitter array. Appl. Phys. Lett. 2010, 97, 113107. [Google Scholar] [CrossRef]

- Rodyakin, V.E.; Aksenov, V.N. Electron gun with an auto-emission cathode based on carbon nanotubes for a powerful extended interaction klystron of millimeter range. Bull. Russ. Acad. Sci. Phys. 2024, 88, 70–73. [Google Scholar] [CrossRef]

- Baughman, R.H.; Zakhidov, A.A.; de Heer, W.A. Carbon nanotubes–the route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef]

- Nojeh, A. Carbon nanotube electron sources: From electron beams to energy conversion and optophononics. ISRN Nanomater. 2014, 2014, 879827. [Google Scholar] [CrossRef]

- Lee, J.W.; Kim, Y.B.; Cho, Y.S.; Choi, J.W.; Lee, K.H.; Han, T.H.; Choi, H.S.; Gihm, S.H.; Jung, Y.S.; Kim, T.H.; et al. Optimizing field-emission devices: Advancements in stability and performance with well-oriented and dense integrated carbon nanotube assemblies. Carbon 2025, 233, 119845. [Google Scholar] [CrossRef]

- Zhang, Y.; Tan, Y.M.; Wang, L.Z.; Li, B.H.; Ke, Y.L.; Liao, M.X.; Xu, N.S.; Chen, J.; Deng, S.Z. Electron emission and structure stability of carbon nanotube cold cathode driven by millisecond pulsed voltage. Vacuum 2020, 172, 109071. [Google Scholar] [CrossRef]

- Sun, Y.N.; Yun, K.N.; Leti, G.; Lee, S.H.; Song, Y.H.; Lee, C.J. High-performance field emission of carbon nanotube paste emitters fabricated using graphite nanopowder filler. Nanotechnology 2017, 28, 065201. [Google Scholar] [CrossRef]

- Song, Y.J.; Li, J.; Yang, W.O. Thickness effect on field-emission properties of carbon nanotube composite cathode. IEEE Trans. Electron Devices 2019, 66, 716–721. [Google Scholar] [CrossRef]

- Jiang, J.; Ding, Y.; Qin, X.; Zhang, Y.; Ke, Y.; She, J.; Deng, S. A double-layer carbon-nanotube cold cathode with enhancing electron beam current. Diam. Relat. Mat. 2025, 153, 112099. [Google Scholar] [CrossRef]

- Shin, D.H.; Yun, K.N.; Jeon, S.G. High performance field emission of carbon nanotube film emitters with a triangular shape. Carbon 2015, 89, 404–410. [Google Scholar] [CrossRef]

- Cho, Y.; Song, H.; Choi, G.; Kim, D. A simple method to fabricate high-performance carbon nanotube field emitters. J. Electroceramics 2006, 17, 945–949. [Google Scholar] [CrossRef]

- Parveen, S.; Sarvar, M.; Zulfequar, M.; Ali, J. Carbon nanotubes as emerging field emitters: Influencing factors and remedies. J. Electron. Mater. 2025, 54, 1553–1571. [Google Scholar] [CrossRef]

- Nilsson, L.; Groening, O.; Emmenegger, C.; Kuettel, O.; Schaller, E.; Schlapbach, L.; Kind, H.; Bonard, J.M.; Kern, K. Scanning field emission from patterned carbon nanotube films. Appl. Phys. Lett. 2000, 76, 2071–2073. [Google Scholar] [CrossRef]

- Smith, R.C.; Silva, S.R.P. Maximizing the electron field emission performance of carbon nanotube arrays. Appl. Phys. Lett. 2009, 94, 133104. [Google Scholar] [CrossRef]

- Gautam, S.; Shah, P.V.; Jha, P.K.; Kumari, M.K.; Khaneja, M.K.; Kumar, P.K.; Rawat, J.S.; Chaudhary, P.K. Novel ring structure for minimisation of screening effect in carbon nanotube based field emitters. J. Exp. Nanosci. 2015, 10, 45–55. [Google Scholar] [CrossRef]

- Dionne, M.; Coulombe, S.; Meunier, J.-L. Screening effects between field-enhancing patterned carbon nanotubes: A numerical study. Trans. Electron Devices 2008, 55, 1298–1305. [Google Scholar] [CrossRef]

- Suh, J.S.; Jeong, K.S.; Lee, J.S.; Han, I. Study of the field-screening effect of highly ordered carbon nanotube arrays. Appl. Phys. Lett. 2002, 80, 2392. [Google Scholar] [CrossRef]

- Cole, M.T.; Teo, K.B.K.; Groening, O.; Gangloff, L.; Legagneux, P.; Milne, W.I. Deterministic cold cathode electron emission from carbon nanofibre arrays. Sci. Rep. 2014, 4, 4840. [Google Scholar] [CrossRef]

- Chouhan, V.; Noguchi, T.; Kato, S. Field emission from optimized structure of carbon nanotube field emitter array. J. Appl. Phys. 2016, 119, 134303. [Google Scholar] [CrossRef]

- Jeong, J.W.; Kim, J.W.; Kang, J.T.; Choi, S.; Ahn, S.; Song, Y.H. A vacuum-sealed compact x-ray tube based on focused carbon nanotube field-emission electrons. Nanotechnology 2013, 24, 085201. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.H.; Zoulkarneev, A.R.; Park, Y.J.; Chung, D.S.; Song, B.K.; Kang, H.S. Optimization of electron beam focusing for gated carbon nanotube field emitter arrays. IEEE Trans. Electron Devices 2005, 52, 2584–2590. [Google Scholar] [CrossRef]

- Lin, K.C.; Chen, H.W.; Juan, C.P.; Lai, R.L.; Hsu, Y.Y.; Cheng, H.C. Carbon-nanotube-based field emission devices with a self-focusing gate structure. J. Electrochem. Soc. 2008, 155, 38–41. [Google Scholar] [CrossRef][Green Version]

- Jiang, J.; Gao, J.K.; Liang, J.Z.; Ding, Y.L.; Ou, H.; Ke, Y.L.; She, J.C.; Zhang, Y.; Deng, S.Z. An on-chip carbon-nanotube field emission array with self-focusing on wafer. Carbon 2025, 238, 120206. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Yuan, X.S.; Zhang, Y.; Li, H.L.; Wang, B.; Yan, Y.; Lin, M. Study on a High Beam Transparency Gridded X-ray Electron Gun Based on Carbon Nanotube Cold Cathode. J. Nanoelectron. Optoelectron. 2018, 13, 1265–1270. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Zhao, L.; Li, Y.; Li, Z. Simulation and Optimization of CNTs Cold Cathode Emission Grid Structure. Nanomaterials 2023, 13, 50. [Google Scholar] [CrossRef]

- Ulisse, G.; Ciceroni, C.; Brunetti, F.; Di Carlo, A. Electrostatic beam focusing of carbon nanotubes electron source. IEEE Trans. Electron Devices 2014, 61, 2558–2563. [Google Scholar] [CrossRef]

- Jiang, R.; Liu, J.; Xu, D.; Li, Y.; Yang, K.; Zhao, J. A miniaturized single-wall carbon nanotubes field emission cathode with RF excited by coaxial resonant cavity. IEEE Trans. Electron Devices 2021, 68, 4681–4686. [Google Scholar] [CrossRef]

- Teo, K.B.K.; Minoux, E.; Hudanski, L.; Peauger, F.; Schnell, J.P.; Gangloff, L.; Legagneux, P.; Dieumegard, D.; Amaratunga, G.A.J.; Milne, W.I. Carbon nanotubes as cold cathodes. Nature 2005, 437, 968. [Google Scholar] [CrossRef] [PubMed]

- Chai, G.Y.; Chow, L. Electron emission from the side wall of an individual multiwall carbon nanotube. Carbon 2007, 45, 281–284. [Google Scholar] [CrossRef]

- Konishi, Y.; Hokushin, S.; Tanaka, H.; Pan, L.J.; Akita, S.; Nakayama, Y. Comparison of Field Emissions from Side Wall and Tip of an Individual Carbon Nanotube. Jpn. J. Appl. Phys. 2005, 44, 1648–1651. [Google Scholar] [CrossRef]

- Yuan, X.S.; Zhang, Y.; Cole, M.T.; Yan, Y.; Li, X.Y.; Parmee, R.; Wu, J.Q.; Xu, N.S.; Milne, W.I.; Deng, S.Z. A truncated-cone carbon nanotube cold-cathode electron gun. Carbon 2017, 120, 374–379. [Google Scholar] [CrossRef]

- Lim, J.; Gupta, A.P.; Yeo, S.J.; Kong, M.K.; Cho, C.G.; Kim, S.H. Design and fabrication of CNT-based e-gun using stripe-patterned alloy substrate for x-ray applications. IEEE Trans. Electron Devices 2019, 66, 5301–5304. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, X.; Deng, S.Z.; Xu, N.S. The application of carbon nanotubes in high-efficiency low power consumption field-emission luminescent tube. Ultramicroscopy 2003, 95, 153–156. [Google Scholar] [CrossRef]

- Bushuev, N.; Grigoriev, Y.; Bourtsev, A.; Schalaev, P.; Tarasov, E. Multibeam electron gun with gated carbon nanotube cathode. In Proceedings of the 2012 International Vacuum Nanoelectronics Conference (IVEC), Monterey, CA, USA, 24–26 April 2012; pp. 559–560. [Google Scholar]

- Yuan, X.S.; Zhang, Y.; Yang, H.; Li, X.Y.; Xu, N.S.; Deng, S.Z.; Yang, Y. A gridded high-compression-ratio carbon nanotube cold cathode electron gun. IEEE Electron Device Lett. 2015, 36, 399–401. [Google Scholar] [CrossRef]

- Yuan, X.S.; Zhu, W.W.; Zhang, Y.; Xu, N.S.; Yan, Y.; Wu, J.Q.; Shen, Y.; Chen, J.; She, J.C.; Deng, S.Z. A fully-sealed carbon-nanotube cold-cathode terahertz gyrotron. Sci. Rep. 2016, 6, 32936. [Google Scholar] [CrossRef]

- Li, X.H.; Chen, B.; Yuan, F.; Zhang, Y.; Deng, S.Z.; Feng, J.J. Beam test of a novel CNT cathode-based electron gun assembled in a TWT. IEEE Trans. Electron Devices 2019, 66, 2382–2388. [Google Scholar] [CrossRef]

- Guo, Y.J.; Wang, J.F.; Li, B.H.; Zhang, Y.; Deng, S.Z.; Chen, J. Achieving high current stability of gated carbon nanotube cold cathode electron source using IGBT modulation for X-ray source application. Nanomaterials 2022, 12, 1882. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.J.; Li, B.H.; Zhang, Y.; Deng, S.Z.; Chen, J. Characteristics of Carbon Nanotube Cold Cathode Triode Electron Gun Driven by MOSFET Working at Subthreshold Region. Nanomaterials 2024, 14, 1260. [Google Scholar] [CrossRef] [PubMed]

- Zu, Y.F.; Yuan, X.S.; Xu, X.T.; Chen, Q.Y.; Wang, B.; Li, H.L.; Yan, Y. Simulation study of annular beam electron optical system based on carbon nanotube cold cathode. In Proceedings of the 2022 23rd International Vacuum Electronics Conference (IVEC), Monterey, CA, USA, 25–29 April 2022; pp. 226–227. [Google Scholar]

- Yan, X.L.; Wu, Y.L.; Wang, B.S.; Zhang, Q.; Zheng, R.T.; Wu, X.L.; Cheng, G.A. Fabrication of carbon nanotube on nickel–chromium alloy wire for high-current field emission. Appl. Surf. Sci. 2018, 450, 38–45. [Google Scholar] [CrossRef]

- Kurilich, M.R.; Thapa, A.; Moilanen, A.; Miller, J.L.; Li, W.Z.; Neupane, S. Comparative study of electron field emission from randomly-oriented and vertically-aligned carbon nanotubes synthesized on stainless steel substrates. J. Vac. Sci. Technol. B 2019, 37, 041202. [Google Scholar] [CrossRef]

- Lee, H.R.; Kim, D.W.; Rodiansyah, A.; Cho, B.; Lim, J.; Park, K.C. Investigation of the effect of structural properties of a vertically standing cnt cold cathode on electron beam brightness and resolution of secondary electron images. Nanomaterials 2021, 11, 1918. [Google Scholar] [CrossRef]

- Li, J.P.; Zhang, Y.; Ke, Y.L.; Li, B.H.; Deng, S.Z. A cold cathode electron gun using convex carbon nanotube emitter. IEEE Trans. Electron Devices 2022, 69, 1457–1460. [Google Scholar] [CrossRef]

- Li, J.P.; Zhang, Y.; Ke, Y.L.; Hong, T.Z.; Deng, S.Z. A carbon-nanotube cold-cathode reflex klystron oscillator: Fabrication @ X-band and returning electron beam realization. Electronics 2022, 11, 1231. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Jiang, J.; Zhang, Y.; Huang, Y.; Deng, S.Z. A Method of Shaping a Carbon Nanotube Pillar Emitter. In Proceedings of the 2024 37th International Vacuum Nanoelectronics Conference (IVNC), Brno, Czech Republic, 15–19 July 2024; pp. 1–2. [Google Scholar]

- Wang, L.Z.; Zhang, Y.; Hong, T.Z.; Wu, Y.T.; Ke, Y.L.; Deng, S.Z. Tailoring beam shape using a coplanar quadrupole focusing structure in carbon nanotube cold cathode electron gun. IEEE Trans. Electron Devices 2023, 70, 6553–6557. [Google Scholar] [CrossRef]

- Ren, J.B.; Zhang, Y.; Jiang, J.; Qin, X.Y.; Deng, S.Z. A sheet beam electron gun based on carbon nanotube cold cathode. IEEE Trans. Electron Devices 2024, 71, 3189–3193. [Google Scholar] [CrossRef]

- Ren, J.B.; Zhang, Y.; Ke, Y.L.; Jiang, J.; She, J.C.; Deng, S.Z. A W-band backward wave oscillator based on carbon nanotube cold cathode. IEEE Trans. Electron Devices 2025, 72, 859–865. [Google Scholar] [CrossRef]

- Han, D.; Shen, Y.; Xu, N.S.; Song, Z.Y.; Xu, P.B.; Tang, S.; Zhang, Y.; Chen, H.J.; Deng, S.Z. A picosecond pulsed cold-cathode electron gun for ultrafast electron characterization and high-frequency radiation source applications. IEEE Electron Device Lett. 2024, 45, 2197–2200. [Google Scholar] [CrossRef]

- Chen, K.; Yu, C.; Wang, X.W.; Zhou, S.H.; Wang, L.; Qu, Y.S.; Wang, A.W.; Xiao, F.; Li, Z.J.; Li, C.; et al. A carbon-nanotube-based electron source with a 0.3-eV energy spread and an unconventional time delay. Nat. Mater. 2025, 1–5. [Google Scholar] [CrossRef]

- Liao, C.Y.; Li, J.P.; Qin, X.Y.; Bo, Q.; Li, B.H.; Deng, S.Z.; Zhang, Y. Efficient fabrication of vertical carbon nanotube array cold cathode using laser cutting. In Proceedings of the 2021 34th International Vacuum Nanoelectronics Conference (IVNC), Lyon, France, 5–9 July 2021; pp. 1–2. [Google Scholar]

- Kang, J.S.; Hong, J.H.; Park, K.C. High-performance carbon-nanotube-based cold cathode electron beam with low-thermal-expansion gate electrode. J. Vac. Sci. Technol. B 2018, 36, 02C104. [Google Scholar] [CrossRef]

- Hong, N.T.; Koh, K.H.; Lee, S.; Minh, P.N.; Tam, N.; Khoi, P.H. Comparison of field-electron emission from different carbon nanotube array structures. J. Vac. Sci. Technol. B 2009, 27, 749–752. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Yuan, X.S.; Cole, M.T.; Zhang, Y.; Meng, L.; Yan, Y. Theoretical Study of a 0.22 THz Backward Wave Oscillator Based on a Dual-Gridded, Carbon-Nanotube Cold Cathode. Appl. Sci. 2018, 8, 2462. [Google Scholar] [CrossRef]

- Li, X.B.; Zhou, J.T.; Wu, Q.Y.; Liu, M.L.; Zhou, R.F.; Chen, Z.X. Fast microfocus x-ray tube based on carbon nanotube array. J. Vac. Sci. Technol. B 2019, 37, 051203. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, P.; Yu, S.; Wang, L.; Chen, Z. Fast microfocus cold cathode x-ray tube based on carbon nanotube array. In Proceedings of the 2023 24th International Vacuum Electronics Conference (IVEC), Chengdu, China, 25–28 April 2023; pp. 1–2. [Google Scholar]

- Adhikari, B.C.; Ketan, B.; Kim, J.S.; Yoo, S.T.; Choi, E.H.; Park, K.C. Beam trajectory analysis of vertically aligned carbon nanotube emitters with a microchannel plate. Nanomaterials 2022, 12, 4313. [Google Scholar] [CrossRef]

- Adhikari, B.C.; Ketan, B.; Patil, R.; Choi, E.H.; Park, K.C. Optimization of vertically aligned carbon nanotube beam trajectory with the help of focusing electrode in the microchannel plate. Sci. Rep. 2023, 13, 15630. [Google Scholar] [CrossRef]

- Pirio, G.; Legagneux, P.; Pribat, D.; Teo, K.B.K.; Chhowalla, M.; Amaratunga, G.A.J.; Milne, W.I. Fabrication and electrical characteristics of carbon nanotube field emission microcathodes with an integrated gate electrode. Nanotechnology 2002, 13, 1–4. [Google Scholar] [CrossRef]

- Manohara, H.M.; Toda, R.; Lin, R.; Liao, A.; Bronikowski, M.J.; Siegel, P.H. Carbon nanotube bundle array cold cathodes for THz vacuum tube sources. J. Infrared Millim. Terahertz Waves 2009, 30, 1338–1350. [Google Scholar] [CrossRef]

- Williams, L.T.; Walker, M.L.R.; Kumsomboone, V.S.; Ready, W.J. Experimental characterization of a carbon nanotube field emission cathode. In Proceedings of the 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Hartford, CT, USA, 21–23 July 2008. [Google Scholar] [CrossRef]

- Williams, L.T.; Walker, M.L.R.; Kumsomboone, V.S.; Ready, W.J. Experimental characterization of carbon nanotube field emission cathode lifetime. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, CO, USA, 2–5 August 2009. [Google Scholar]

- Williams, L.T.; Kumsomboone, V.S.; Ready, W.J.; Walker, M.L.R. Lifetime and failure mechanisms of an arrayed carbon nanotube field emission cathode. IEEE Trans. Electron Devices 2010, 57, 3163–3168. [Google Scholar] [CrossRef]

- Ulisse, G.; Brunetti, F.; Tamburri, E.; Orlanducci, S.; Cirillo, M.; Terranova, M.L. Carbon nanotube cathodes for electron gun. IEEE Trans. Electron Devices 2013, 34, 698–700. [Google Scholar] [CrossRef]

- Koohsorkhi, J.; Mohajerzadeh, S. Carbon nanotube based miniaturized electron gun and column assembly. Microsyst. Technol. 2013, 20, 325–336. [Google Scholar] [CrossRef]

- Lee, H.R.; Yang, H.H.; Park, K.C. CNT cold cathode electron beam (C-beam) for microscopy application. In Proceedings of the 2017 30th International Vacuum Nanoelectronics Conference (IVNC), Regensburg, Germany, 10–14 July 2017; pp. 160–161. [Google Scholar]

- Jiang, R.R.; Zeng, B.Q.; Liu, J.L.; Chai, X.; Chen, T.; Wu, Z.; Zhang, X.F.; Yang, K.Q. Enhanced field electron emission of single-walled carbon nanotubes prepared by imprinting technique. J. Alloys Compd. 2020, 816, 152669. [Google Scholar] [CrossRef]

- Ahn, Y.J.; Kim, S.J.; Jeong, J.W.; Park, S.R.; Kim, J.W.; Go, E.S.; Lee, J.W.; Kang, J.T.; Yun, K.N.; Choi, S.H.; et al. Overall control of field emission from carbon nanotube paste-emitters through macro-geometries for high-performance electron source applications. Carbon 2022, 189, 519–529. [Google Scholar] [CrossRef]

- Deng, S.Z.; Qian, F.; Chen, J.; Xu, N.S. The Frequency Characteristics of a lighting element using carbon nanotube-based composite cold-cathode. IEEE Trans. Electron Devices 2005, 52, 1504–1507. [Google Scholar] [CrossRef]

- Kim, H.J.; Choi, J.J.; Han, J.H.; Park, J.H.; Yoo, J.B. Design and field emission test of carbon nanotube pasted cathodes for traveling-wave tube applications. IEEE Trans. Electron Devices 2006, 53, 2674–2680. [Google Scholar] [CrossRef]

- Choi, H.Y.; Chang, W.S.; Kim, H.S.; Park, Y.H.; Kim, J.U. Acquisition of x-ray images by using a CNT cold emitter. Phys. Lett. A 2006, 357, 36–41. [Google Scholar] [CrossRef]

- Yang, G.; Rajaram, R.; Cao, G.; Sultana, S.; Liu, Z.; Lalush, D.; Lu, J.; Zhou, O. Stationary digital breast tomosynthesis system with a multi-beam field emission x-ray source array. In Proceedings of the Medical Imaging 2008: Physics of Medical Imaging, San Diego, CA, USA, 16–21 February 2008; Volume 6913, p. 69131A. [Google Scholar]

- Kim, J.W.; Shin, M.S.; Jeong, J.W.; Kang, J.T.; Choi, S.; Park, S.; Yeon, J.H.; Ahn, S.; Song, Y.H. Electrostatic Focusing Lens Module With Large Focusing Capability in Carbon Nanotube Emitter-Based X-Ray Sources. IEEE Electron Device Lett. 2015, 36, 396–398. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J.; Ji, D.X.; Xu, H.; Sun, M.; Wu, L.; Li, X.Y.; Wang, Q.L.; Zhang, X.B. Development of an electron gun based on CNT-cathode for traveling wave tube application. Vacuum 2021, 186, 110029. [Google Scholar] [CrossRef]

- Jiang, R.R.; Liu, J.L.; Zhao, P.Y.; Yang, K.Q.; Luongo, G.; Urban, F. Design of a Ka-Band Traveling Wave Tube Using Low Turn-On Field Emission Electron Source Made by Carbon Nanotubes. IEEE Trans. Plasma Sci. 2022, 50, 29–35. [Google Scholar] [CrossRef]

- Jiang, R.R.; Liu, J.L.; Wu, G.X.; Shi, N.J.; Liang, T.L.; Yu, M.; Zeng, B.Q.; Shi, J. Design of a miniaturized terahertz traveling wave tube with embedded single-walled carbon nanotubes cold cathode. Sci. Rep. 2025, 15, 15984. [Google Scholar] [CrossRef] [PubMed]

- Giubileo, F.; Di Bartolomeo, A.; Iemmo, L.; Luongo, G.; Urban, F. Field Emission from Carbon Nanostructures. Appl. Sci. 2018, 8, 526. [Google Scholar] [CrossRef]

- Behabtu, N.; Young, C.C.; Tsentalovich, D.E.; Kleinerman, O.; Wang, X.; Ma, A.W.K.; Bengio, E.A.; ter Waarbeek, R.F.; de Jong, J.J.; Hoogerwerf, R.E.; et al. Strong, light, multifunctional fibers of carbon nanotubes with ultrahigh conductivity. Science 2013, 339, 182–185. [Google Scholar] [CrossRef] [PubMed]

- Fairchild, S.B.; Zhang, P.; Park, J.H.; Back, T.C.; Marincel, D.; Huang, Z.Z. Carbon nanotube fiber field emission array cathodes. IEEE Trans. Plasma Sci. 2019, 47, 2032–2038. [Google Scholar] [CrossRef]

- Yahyazadeh, A.; Nanda, S.; Dalai, A.K. Carbon nanotubes: A review of synthesis methods and applications. Reactions 2024, 5, 429–451. [Google Scholar] [CrossRef]

- Shulaker, M.; Hills, G.; Patil, N.; Wei, H.; Chen, H.Y.; Wong, H.S.P.; Mitra, S. Carbon nanotube computer. Nature 2013, 501, 526–530. [Google Scholar] [CrossRef]

- Hughes, K.J.; Iyer, K.A.; Bird, R.E.; Ivanov, J.; Banerjee, S.; Georges, G.; Zhou, Q.A. Review of carbon nanotube research and development: Materials and emerging applications. ACS Appl. Nano Mater. 2024, 7, 18695–18713. [Google Scholar] [CrossRef]

- Gao, B.; Yue, G.Z.; Qiu, Q.; Cheng, Y.; Shimoda, H.; Fleming, L.; Zhou, O. Fabrication and electron field emission properties of carbon nanotube films by electrophoretic deposition. Adv. Mater. 2001, 13, 1770–1773. [Google Scholar] [CrossRef]

- Oh, S.J.; Zhang, J.; Cheng, H.; Shimoda, Y.; Zhou, O. Liquid-phase fabrication of patterned carbon nanotube field emission cathodes. Appl. Phys. Lett. 2004, 84, 3738–3740. [Google Scholar] [CrossRef]

- Calderón-Colón, X.; Geng, H.Z.; Gao, B.; An, L.; Cao, G.H.; Zhou, O. A carbon nanotube field emission cathode with high current density and long-term stability. Nanotechnology 2009, 20, 325707. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.S.; Chen, Q.Y.; Xu, X.T.; Cole, M.T.; Zhang, Y.; Chen, Z.X.; Yan, Y. A carbon nanotube-based hundred watt-level ka-band backward wave oscillator. IEEE Trans. Electron Devices 2021, 68, 2467–2472. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Yuan, X.S.; Xu, X.T.; Zhang, Y.; Cole, M.T. Development of a high-beam-transparency gridded electron gun based on a carbon nanotube cold cathode. IEEE Electron Device Lett. 2022, 43, 615–618. [Google Scholar] [CrossRef]

- Hozumi, Y.; Ohsawa, S.; Sugimura, T.; Ikeda, M. Development of field-emission electron gun from carbon nanotubes. In Proceedings of the LINAC 2004, Lübeck, Germany, 16–20 August 2004; pp. 651–653. [Google Scholar]

- Smith, B.C.; Hunt, C.E.; Carpenter, A.C. Field emission electron gun using a reticulated vitreous carbon cathode. In Proceedings of the 2010 International Vacuum Nanoelectronics Conference (IVNC), Palo Alto, CA, USA, 26–30 July 2010; pp. 38–39. [Google Scholar]

- Carpenter, A.C. High Current Field Emission Electron Source using a Reticulated Vitreous Carbon (RVC) Cathode. In Proceedings of the 2009 22nd International Vacuum Nanoelectronics Conference (IVNC), Hamamatsu, Japan, 20–24 July 2009; pp. 287–288. [Google Scholar]

- Cao, M.M.; Chacon, R.J.; Hunt, C.E. A field emission light source using a reticulated vitreous carbon (RVC) cathode and cathodoluminescent phosphors. J. Disp. Technol. 2011, 7, 467–472. [Google Scholar] [CrossRef]

- Kato, H.; O’Rourke, B.E.; Suzuki, R. Electron gun using coniferous carbon nano-structure. JJAP Conf. Proc. 2014, 2, 011302. [Google Scholar] [CrossRef]

- Kato, H.; O’Rourke, B.E.; Suzuki, R. Stable and high current density electron emission using coniferous carbon nano-structured emitter. Diam. Relat. Mat. 2015, 55, 41–44. [Google Scholar] [CrossRef]

- Urbański, P.; Szyszka, P.; Białas, M.; Grzebyk, T. Point field emission electron source with a magnetically focused electron beam. Ultramicroscopy 2024, 258, 113911. [Google Scholar] [CrossRef]

- Li, X.X.; Yuan, X.S.; Zhang, Y.; Yan, Y. Theoretical research on electron beam modulation in a field-emission cold cathode electron gun. Chin. Phys. B 2014, 23, 037901. [Google Scholar] [CrossRef]

- Yuan, X.S.; Wang, B.; Cole, M.T.; Zhang, Y.; Deng, S.Z.; Milne, W.I.; Yan, Y. Theoretical research on a multibeam-modulated electron gun based on carbon nanotube cold cathodes. IEEE Trans. Electron Devices 2016, 63, 2919–2924. [Google Scholar] [CrossRef]

- Xie, J.; Yuan, X.S.; Chen, Q.Y.; Yang, T.B.; Zhang, Y.; Wang, B.; Li, H.L.; Yan, Y.; Meng, L. Theoretical study of extended interaction frequency-locking oscillator based on carbon nanotube cold cathodes. IET Microw. Antennas Propag. 2018, 12, 1771–1774. [Google Scholar] [CrossRef]

- Li, J.X.; Zhang, Y.; Ke, Y.L.; Xu, N.S.; Deng, S.Z. A carbon nanotube cold cathode microwave electron gun. In Proceedings of the 2024 International Vacuum Nanoelectronics Conference (IVNC), Brno, Czech Republic, 15–19 July 2024; pp. 1–2. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Tu, Y.; Ma, D.; Yang, Y. Research Progress in Carbon Nanotube-Based Cold Cathode Electron Guns. Nanomaterials 2025, 15, 1403. https://doi.org/10.3390/nano15181403

Li J, Tu Y, Ma D, Yang Y. Research Progress in Carbon Nanotube-Based Cold Cathode Electron Guns. Nanomaterials. 2025; 15(18):1403. https://doi.org/10.3390/nano15181403

Chicago/Turabian StyleLi, Jiupeng, Yu Tu, Dewei Ma, and Yun Yang. 2025. "Research Progress in Carbon Nanotube-Based Cold Cathode Electron Guns" Nanomaterials 15, no. 18: 1403. https://doi.org/10.3390/nano15181403

APA StyleLi, J., Tu, Y., Ma, D., & Yang, Y. (2025). Research Progress in Carbon Nanotube-Based Cold Cathode Electron Guns. Nanomaterials, 15(18), 1403. https://doi.org/10.3390/nano15181403