High-Efficiency Strategy for Reducing Decomposition Potential of Lithium Formate as Cathode Prelithiation Additive for Lithium-Ion Batteries

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of B-LFM with Decreased Particle Size

2.3. Preparation of LiNi0.834Co0.11Mn0.056O2 (NCM834) Cathode Material

2.4. Preparation of LFM/Catalyst Composite Electrodes and Pure Conductive Additive Electrodes

2.5. Preparation of NCM/B-LFM/Catalyst Composite Electrodes and Graphite Electrodes

2.6. Material Characterization

3. Results

3.1. Impact of Conductive Additive on Delithiation Potential of LFM

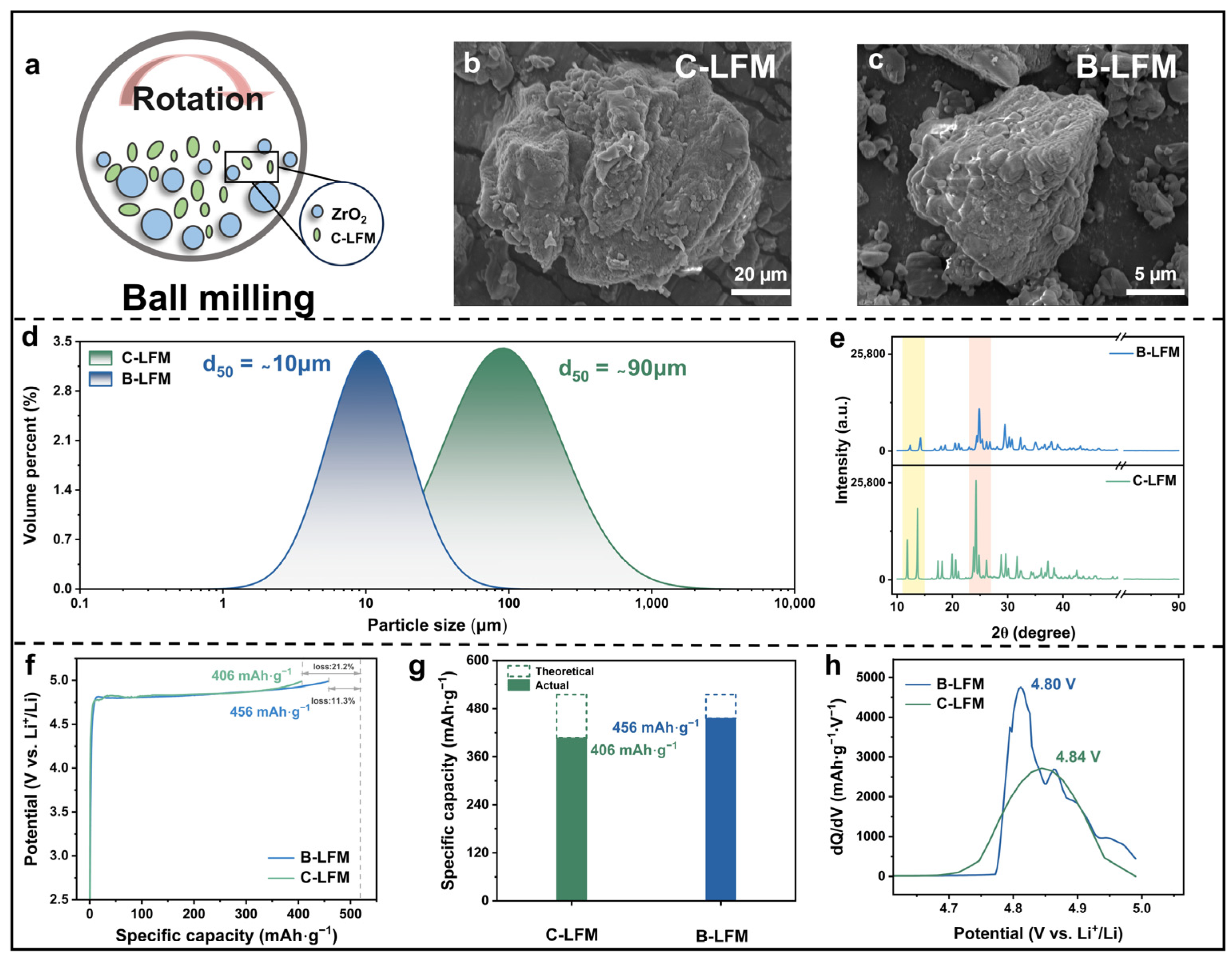

3.2. Impact of Particle Size on Delithiation Potential of LFM

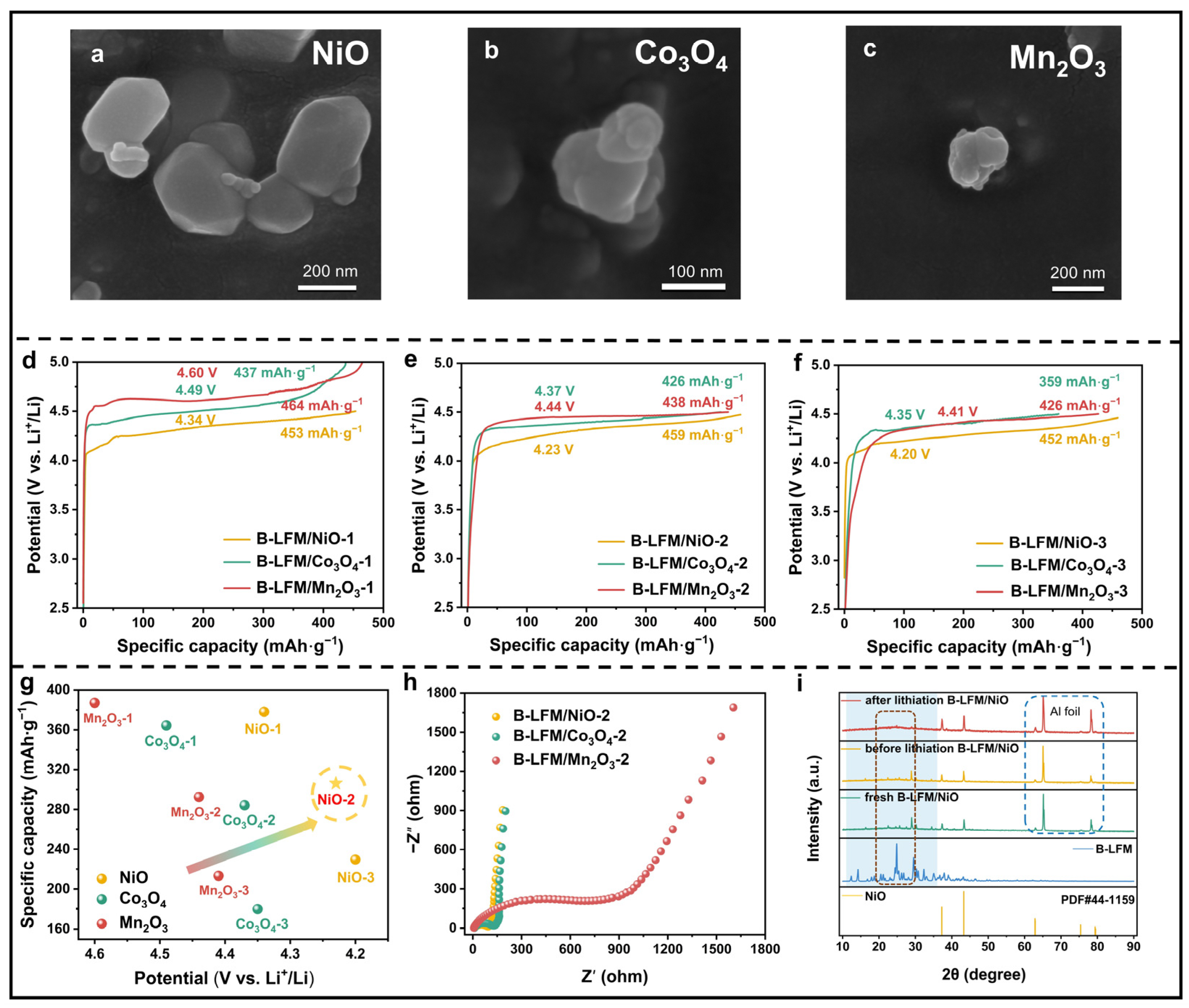

3.3. Impact of Catalyst on Delithiation Potential of LFM

3.4. Electrochemical Properties of Half Cell

3.5. Electrochemical Properties of Full Cell

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kebede, A.A.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. A comprehensive review of stationary energy storage devices for large scale renewable energy sources grid integration. Renew. Sustain. Energy Rev. 2022, 159, 112213. [Google Scholar] [CrossRef]

- Liu, J.; Huang, Z.; Fan, M.; Yang, J.; Xiao, J.; Wang, Y. Future energy infrastructure, energy platform and energy storage. Nano Energy 2022, 104, 107915. [Google Scholar] [CrossRef]

- Turner, J.M. The matter of a clean energy future. Science 2022, 376, 1361. [Google Scholar] [CrossRef]

- Zheng, Z.; Gao, H.; Ke, C.; Li, M.; Cheng, Y.; Peng, D.-L.; Zhang, Q.; Wang, M.-S. Constructing Robust Cross-Linked Binder Networks for Silicon Anodes with Improved Lithium Storage Performance. ACS Appl. Mater. Interfaces 2021, 13, 53818–53828. [Google Scholar] [CrossRef]

- Okubo, M.; Ko, S.; Dwibedi, D.; Yamada, A. Designing Positive Electrodes with High Energy Density for Lithium-Ion Batteries. J. Mater. Chem. A 2021, 9, 7407–7421. [Google Scholar] [CrossRef]

- Jin, C.; Huang, Y.; Li, L.; Wei, G.; Li, H.; Shang, Q.; Ju, Z.; Lu, G.; Zheng, J.; Sheng, O.; et al. A Corrosion Inhibiting Layer to Tackle the Irreversible Lithium Loss in Lithium Metal Batteries. Nat. Commun. 2023, 8269. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Zhang, X.; Li, C.; Wang, K.; Sun, X.; Ma, Y. Recent Advances in Prelithiation Materials and Approaches for Lithium-Ion Batteries and Capacitors. Energy Storage Mater. 2020, 32, 497–516. [Google Scholar] [CrossRef]

- Yan, C.; Xu, R.; Xiao, Y.; Ding, J.; Xu, L.; Li, B.; Huang, J. Toward Critical Electrode/Electrolyte Interfaces in Rechargeable Batteries. Adv. Funct. Mater. 2020, 30, 1909887. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, S.; Murakami, K.; Hwang, J.; Matsumoto, K. Intermediate-Temperature Operable Secondary Batteries. Accounts Mater. Res. 2025, 6. [Google Scholar] [CrossRef]

- Min, X.; Xu, G.; Xie, B.; Guan, P.; Sun, M.; Cui, G. Challenges of Prelithiation Strategies for next Generation High Energy Lithium-Ion Batteries. Energy Storage Mater. 2022, 47, 297–318. [Google Scholar] [CrossRef]

- Zou, K.; Song, Z.; Gao, X.; Liu, H.; Luo, Z.; Chen, J.; Deng, X.; Chen, L.; Zou, G.; Hou, H.; et al. Molecularly Compensated Pre-Metallation Strategy for Metal-Ion Batteries and Capacitors. Angew. Chem. Int. Ed. 2021, 60, 17070–17079. [Google Scholar] [CrossRef]

- Jin, L.; Shen, C.; Wu, Q.; Shellikeri, A.; Zheng, J.; Zhang, C.; Zheng, J.P. Pre-Lithiation Strategies for Next-Generation Practical Lithium-Ion Batteries. Adv. Sci. 2021, 8, 2005031. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Deng, Z.; Zhong, Y.; Xu, M.; Li, S.; Liu, X.; Zhou, Y.; Huang, K.; Shen, Y.; Huang, Y. Progress and Challenges of Prelithiation Technology for Lithium-ion Battery. Carbon Energy 2022, 4, 1107–1132. [Google Scholar] [CrossRef]

- Lu, J.; Wang, Y.; Qiao, Y.; Yang, S.; Cheng, X.; Yang, M.; Zhang, J.; Fu, Z. A High-Efficient Stable Surface-Prelithiated Li1.2Ni0.13Co0.13Mn0.54O2 Cathode Enabled by Sacrificial Lithium Nitrides for High-Energy-Density Lithium-Ion Batteries. Energy Storage Mater. 2024, 66, 103204. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Peng, J.; Cao, S.; Hu, H.; Chen, J.; Lei, Y.; Tang, Y.; Wang, X. Addressing the Initial Lithium Loss of Lithium-Ion Batteries by Introducing Pre-Lithiation Reagent Li5FeO4/C in the Cathode Side. Electrochim. Acta 2024, 481, 143918. [Google Scholar] [CrossRef]

- Zhang, L.; Jeong, S.; Reinsma, N.; Sun, K.; Maxwell, D.S.; Gionet, P.; Yu, T. Decomposition of Li2O2 as the Cathode Prelithiation Additive for Lithium-Ion Batteries without an Additional Catalyst and the Initial Performance Investigation. J. Electrochem. Soc. 2021, 168, 120520. [Google Scholar] [CrossRef]

- Liu, Y.; Lv, Y.; Li, N.; Jia, T.; Huang, S.; Cai, K.; Ouyang, Y.; Kang, F.; Cao, Y. LiF/Fe Composite for Ni-Rich Cathode Prelithiation: Synthesis, Bilayer Structured Electrode and Lithium Loss Compensation. Chem. Eng. J. 2024, 484, 149550. [Google Scholar] [CrossRef]

- Niu, F.; Qiu, L.; Chen, H.; Chen, X.; Kong, X.; Rong, Q.; Xiong, J.; Guo, Y.; Cai, Z.; Shen, S. Nanocatalysis in Cathode Pre-Lithiation for Lithium-Ion Batteries: Progress and Challenges. Nanoscale 2024, 16, 21294–21308. [Google Scholar] [CrossRef] [PubMed]

- Zhan, R.; Wang, X.; Chen, Z.; Seh, Z.W.; Wang, L.; Sun, Y. Promises and Challenges of the Practical Implementation of Prelithiation in Lithium-Ion Batteries. Adv. Energy Mater. 2021, 11, 2101565. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, J.; Huang, T.; Yu, A. Surface Coating Engineering of Prelithiation Cathode Additives for Lithium-Ion Batteries. Electrochem. Commun. 2024, 163, 107726. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, K.; Li, Y.; Li, Z.; Wu, C.; Pan, J.H. Engineering Nanostructure, Interface, and Prelithiation of Advanced Silicon-Based Lithium-Ion Battery Anodes. Energy Mater. Adv. 2025, 6. [Google Scholar] [CrossRef]

- Liu, B.; Liu, J.; Zhong, C.; Hu, W. Mg-doped, Carbon-coated, and Prelithiated SiOx as Anode Materials with Improved Initial Coulombic Efficiency for Lithium-ion Batteries. Carbon Energy 2024, 6, e421. [Google Scholar] [CrossRef]

- Jia, T.; Zhong, G.; Lv, Y.; Li, N.; Liu, Y.; Yu, X.; Zou, J.; Chen, Z.; Peng, L.; Kang, F.; et al. Prelithiation Strategies for Silicon-Based Anode in High Energy Density Lithium-Ion Battery. Green Energy Environ. 2023, 8, 1325–1340. [Google Scholar] [CrossRef]

- Bhujbal, A.V.; Ng, K.L.; Khazraei, S.; Bekou, J.; Riahi, A.R. Recent Advances in Prelithiation of Silicon Anode: Enhanced Strategy for Boosting Practicability of Li-Ion Battery. J. Electrochem. Soc. 2023, 170, 080506. [Google Scholar] [CrossRef]

- Jang, E.; Ryu, S.; Kim, M.; Choi, J.; Yoo, J. Silicon-Stabilized Lithium Metal Powder (SLMP) Composite Anodes for Fast Charging by in-Situ Prelithiation. J. Power Sources 2023, 580, 233326. [Google Scholar] [CrossRef]

- Huang, G.; Liang, J.; Zhong, X.; Liang, H.; Cui, C.; Zeng, C.; Wang, S.; Liao, M.; Shen, Y.; Zhai, T.; et al. Boosting the Capability of Li2C2O4 as Cathode Pre-Lithiation Additive for Lithium-Ion Batteries. Nano Res. 2023, 16, 3872–3878. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, Y.; Chen, J.; Yin, J.; Sun, Z.; Zeng, G.; Wu, X.; Chen, L.; Yu, X.; Luo, H.; et al. Lattice Engineering on Li2CO3-Based Sacrificial Cathode Prelithiation Agent for Improving the Energy Density of Li-ion Battery Full-Cell. Adv. Mater. 2024, 36, 2312159. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Martin, A.; Gnutzmann, M.M.; Adhitama, E.; Frankenstein, L.; Heidrich, B.; Winter, M.; Placke, T. Opportunities and Challenges of Li2C4O4 as Pre-Lithiation Additive for the Positive Electrode in NMC622||Silicon/Graphite Lithium Ion Cells. Adv. Sci. 2022, 9, 2201742. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhao, Y.; Gong, X.; Liu, J.; Wu, C.; Chen, B.; Zhan, H. Advancing Anode-Free Lithium Metal Battery via Environmentally Resilient Lithium Oxalate as a Low-Voltage Prelithiation Additive. ACS Appl. Energy Mater. 2025, 8, 1830–1837. [Google Scholar] [CrossRef]

- Liu, J.; Lin, J.; Yin, Z.; Tong, Z.; Liu, J.; Wang, Z.; Zhou, Y.; Li, J. Electrocatalytic Decomposition of Lithium Oxalate-Based Composite Microspheres as a Prelithiation Additive in Lithium-Ion Batteries. Molecules 2024, 29, 2975. [Google Scholar] [CrossRef]

- Sim, E.-h.; Lee, S.W.; Lee, J.J.; Han, S.J.; Shin, J.H.; Lee, G.; Ko, S.; Lee, K.-Y.; Kim, Y.T. Effect of silicon carbide-based iron catalyst on reactor optimization for non-oxidative direct conversion of methane. J. Energy Chem. 2023, 81, 519–532. [Google Scholar] [CrossRef]

- Zhong, W.; Li, S.; Liu, M.; Wu, Q.; Zeng, Z.; Cheng, S.; Xie, J. Hierarchical Spherical Mo2C/N-doped Graphene Catalyst Facilitates Low-voltage Li2C2O4 Prelithiation. Nano Energy 2023, 115, 108757. [Google Scholar] [CrossRef]

- Barkaoui, S.; Wang, Y.; Zhang, Y.; Gu, X.; Li, Z.; Wang, B.; Baiker, A.; Li, G.; Zhao, Z. Critical Role of NiO Support Morphology for High Activity of Au/NiO Nanocatalysts in CO Oxidation. iScience 2024, 27, 110255. [Google Scholar] [CrossRef]

- Wenelska, K.; Dymerska, A.; Mijowska, E. Promotion of Borophene/NiO-Based Electrocatalyst for Oxygen Evolution Reaction. Chem. Eng. J. 2023, 476, 146714. [Google Scholar] [CrossRef]

- Abdel-Wahab, M.S.; El Emam, H.K.; El Rouby, W.M.A. Sputtered Cu-doped NiO thin films as an efficient electrocatalyst for methanol oxidation. RSC Adv. 2023, 13, 10818–10829. [Google Scholar] [CrossRef]

- Pan, S.; Yu, X.; Ling, Y.; Yang, Z. Stable and Efficient Hydrogen Evolution Reaction Catalyzed by NiO-Rh2P Heterostructure Electrocatalyst. Catal. Commun. 2022, 163, 106404. [Google Scholar] [CrossRef]

- Hua, W.-C.; Li, M.-Q.; Guo, Y.-L.; Chai, G.-T.; Liu, H.; Guo, Y.; Wang, L.; Zhan, W.-C. Catalytic Combustion of Vinyl Chloride Emissions over Co3O4 Catalysts with Different Crystallite Sizes. Rare Met. 2021, 40, 817–827. [Google Scholar] [CrossRef]

- Liu, W.; Men, Y.; Ji, F.; Shi, F.; Wang, J.; Liu, S.; Magkoev, T.T.; An, W. Boosting Catalytic Combustion of Ethanol by Tuning Morphologies and Exposed Crystal Facets of α-Mn2O3. Catalysts 2023, 13, 865. [Google Scholar] [CrossRef]

- Karami, Z.; Youssefi, M.; Raeissi, K.; Zhiani, M. Effect of the Morphology of Silver Layer on Electrical Conductivity and Electrochemical Performance of Silver/Reduced Graphene Oxide/Cotton Fabric Composite as a Flexible Supercapacitor Electrode. J. Energy Storage 2021, 42, 103042. [Google Scholar] [CrossRef]

- Stenina, I.; Minakova, P.; Kulova, T.; Yaroslavtsev, A. Electrochemical Properties of LiFePO4 Cathodes: The Effect of Carbon Additives. Batteries 2022, 8, 111. [Google Scholar] [CrossRef]

- Jeong, M.H.; Kim, J.; Ham, D.W.; Kim, J.; Phiri, I.; Ryou, S.-Y. Stabilization of Li[NixMnyCo1-x-y]O2 Structure Using a Mixture of Super-P and Vapor-Grown Carbon Fiber as Conducting Additives. J. Ind. Eng. Chem. 2025, 143, 410–415. [Google Scholar] [CrossRef]

- Choi, J.H.; Choi, S.; Embleton, T.J.; Ko, K.; Saqib, K.S.; Ali, J.; Jo, M.; Hwang, J.; Park, S.; Kim, M.; et al. The Effect of Conductive Additive Morphology and Crystallinity on the Electrochemical Performance of Ni-Rich Cathodes for Sulfide All-Solid-State Lithium-Ion Batteries. Nanomaterials 2023, 13, 3065. [Google Scholar] [CrossRef]

- Bläubaum, L.; Röder, F.; Nowak, C.; Chan, H.S.; Kwade, A.; Krewer, U. Impact of Particle Size Distribution on Performance of Lithium-Ion Batteries. ChemElectroChem 2020, 7, 4755–4766. [Google Scholar] [CrossRef]

- Saelor, S.; Kongjan, P.; Prasertsan, P.; Mamimin, C.; O-Thong, S. Enhancing the Efficiency of High Solid Anaerobic Digestion of Empty Fruit Bunches under Thermophilic Conditions by Particle Size Reduction and Co-Digestion with Palm Oil Mill Effluent. Carbon Resour. Convers. 2025, 8, 100262. [Google Scholar] [CrossRef]

- Rao, R.R.; Bucci, A.; Corby, S.; Moss, B.; Liang, C.; Gopakumar, A.; Stephens, I.E.L.; Lloret-Fillol, J.; Durrant, J.R. Unraveling the Role of Particle Size and Nanostructuring on the Oxygen Evolution Activity of Fe-Doped NiO. ACS Catal. 2024, 14, 11389–11399. [Google Scholar] [CrossRef] [PubMed]

- Choi, C.; Yoon, S.; Jung, Y. Shifting the Scaling Relations of Single-Atom Catalysts for Facile Methane Activation by Tuning the Coordination Number. Chem. Sci. 2021, 12, 3551–3557. [Google Scholar] [CrossRef]

- Lou, D.; Song, G.; Xu, K.; Zhang, Y.; Zhu, K. The Oxidation Performance of a Carbon Soot Catalyst Based on the Pt-Pd Synergy Effect. Energies 2024, 17, 1737. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Yin, T.; Liu, Z.; Wu, Q.; Wang, Y.; Zou, K.; Ning, T.; Tan, L.; Li, L. High-Efficiency Strategy for Reducing Decomposition Potential of Lithium Formate as Cathode Prelithiation Additive for Lithium-Ion Batteries. Nanomaterials 2025, 15, 1225. https://doi.org/10.3390/nano15161225

Guo Y, Yin T, Liu Z, Wu Q, Wang Y, Zou K, Ning T, Tan L, Li L. High-Efficiency Strategy for Reducing Decomposition Potential of Lithium Formate as Cathode Prelithiation Additive for Lithium-Ion Batteries. Nanomaterials. 2025; 15(16):1225. https://doi.org/10.3390/nano15161225

Chicago/Turabian StyleGuo, Yaqin, Ti Yin, Zeyu Liu, Qi Wu, Yuheng Wang, Kangyu Zou, Tianxiang Ning, Lei Tan, and Lingjun Li. 2025. "High-Efficiency Strategy for Reducing Decomposition Potential of Lithium Formate as Cathode Prelithiation Additive for Lithium-Ion Batteries" Nanomaterials 15, no. 16: 1225. https://doi.org/10.3390/nano15161225

APA StyleGuo, Y., Yin, T., Liu, Z., Wu, Q., Wang, Y., Zou, K., Ning, T., Tan, L., & Li, L. (2025). High-Efficiency Strategy for Reducing Decomposition Potential of Lithium Formate as Cathode Prelithiation Additive for Lithium-Ion Batteries. Nanomaterials, 15(16), 1225. https://doi.org/10.3390/nano15161225