The Influence of the Defect Rate of Graphene on Its Reinforcing Capability Within High-Entropy Alloys

Abstract

1. Introduction

2. Materials and Methods

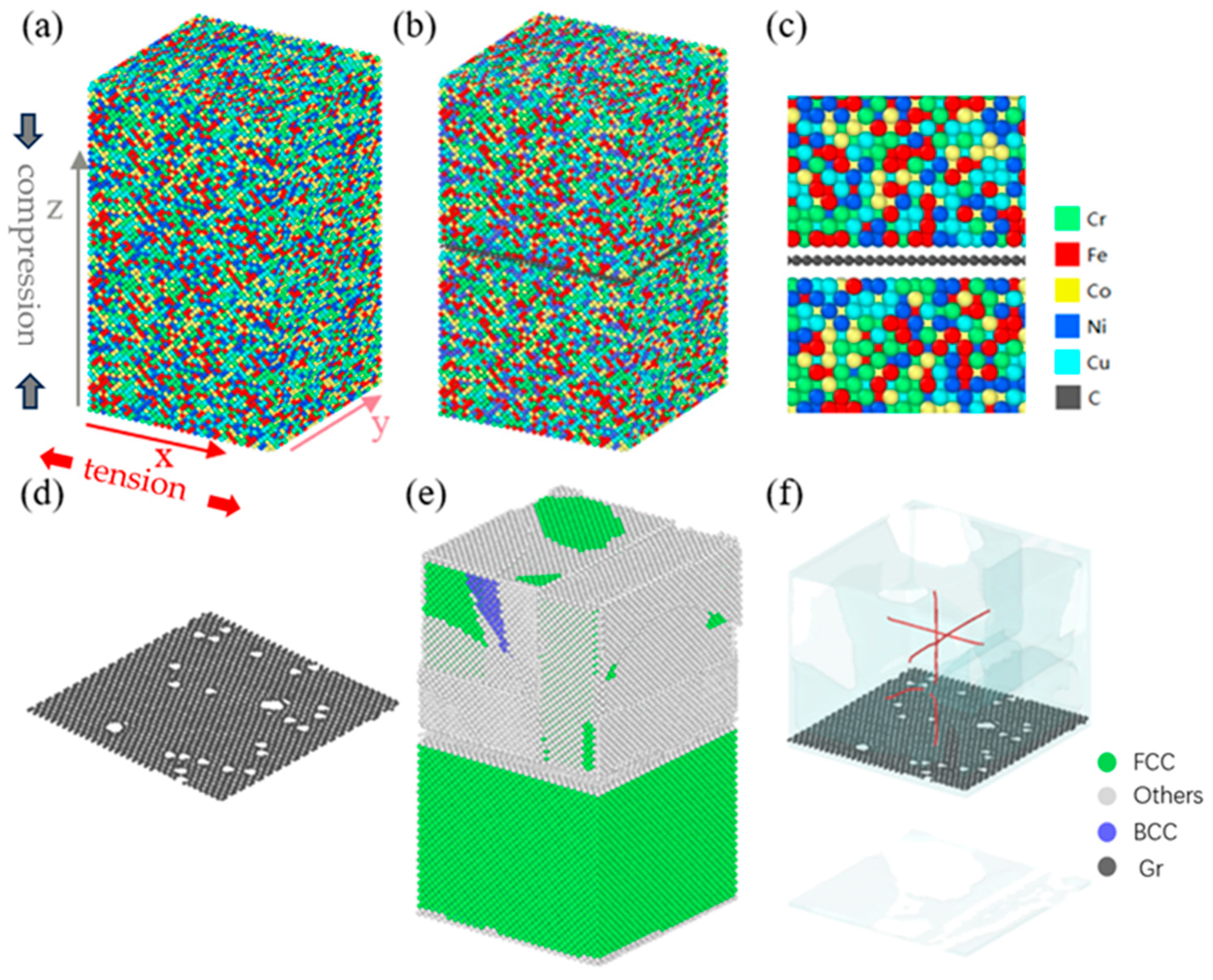

2.1. Modeling

2.2. Interatomic Potentials

2.3. Simulations

3. Results

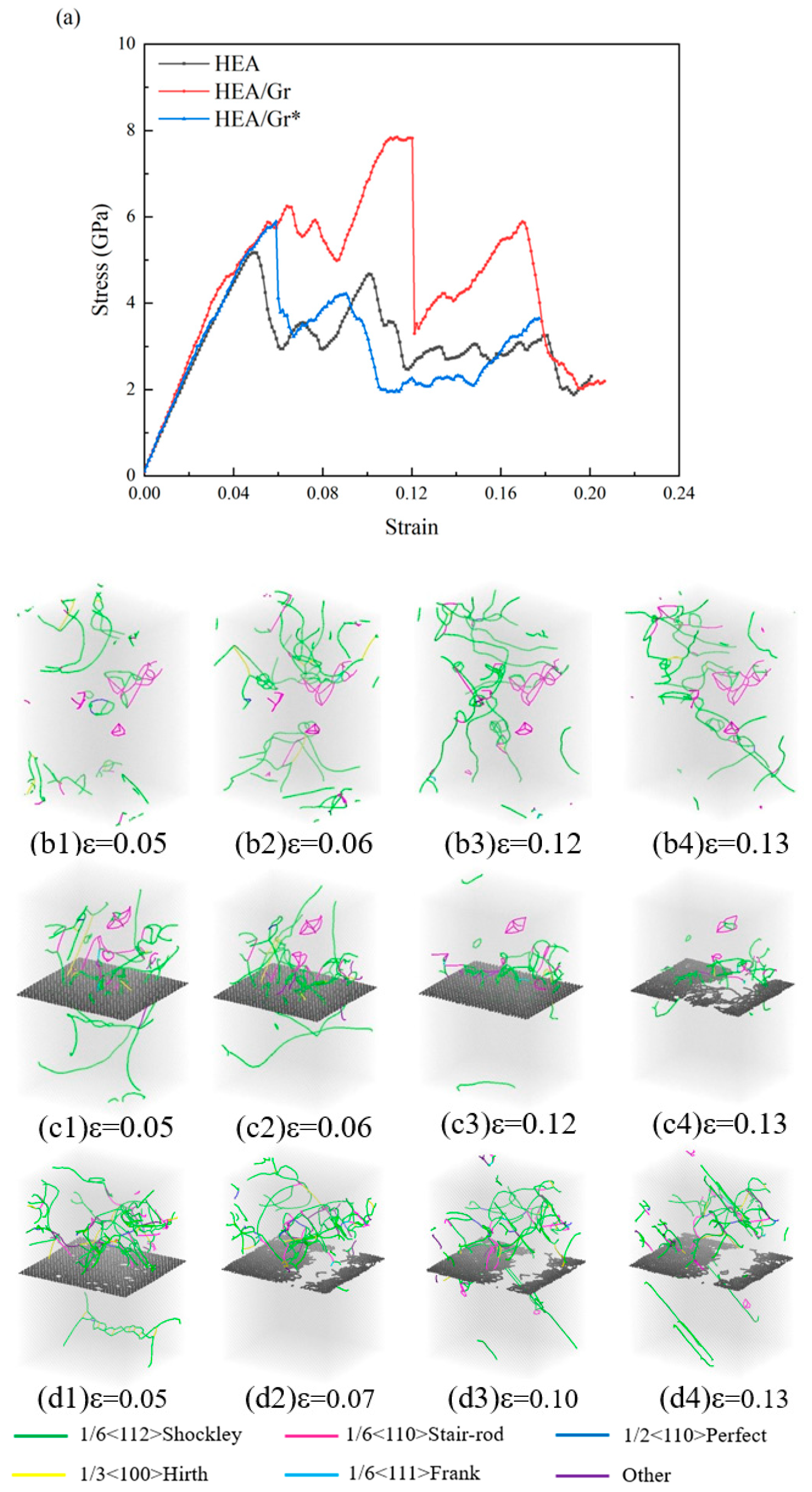

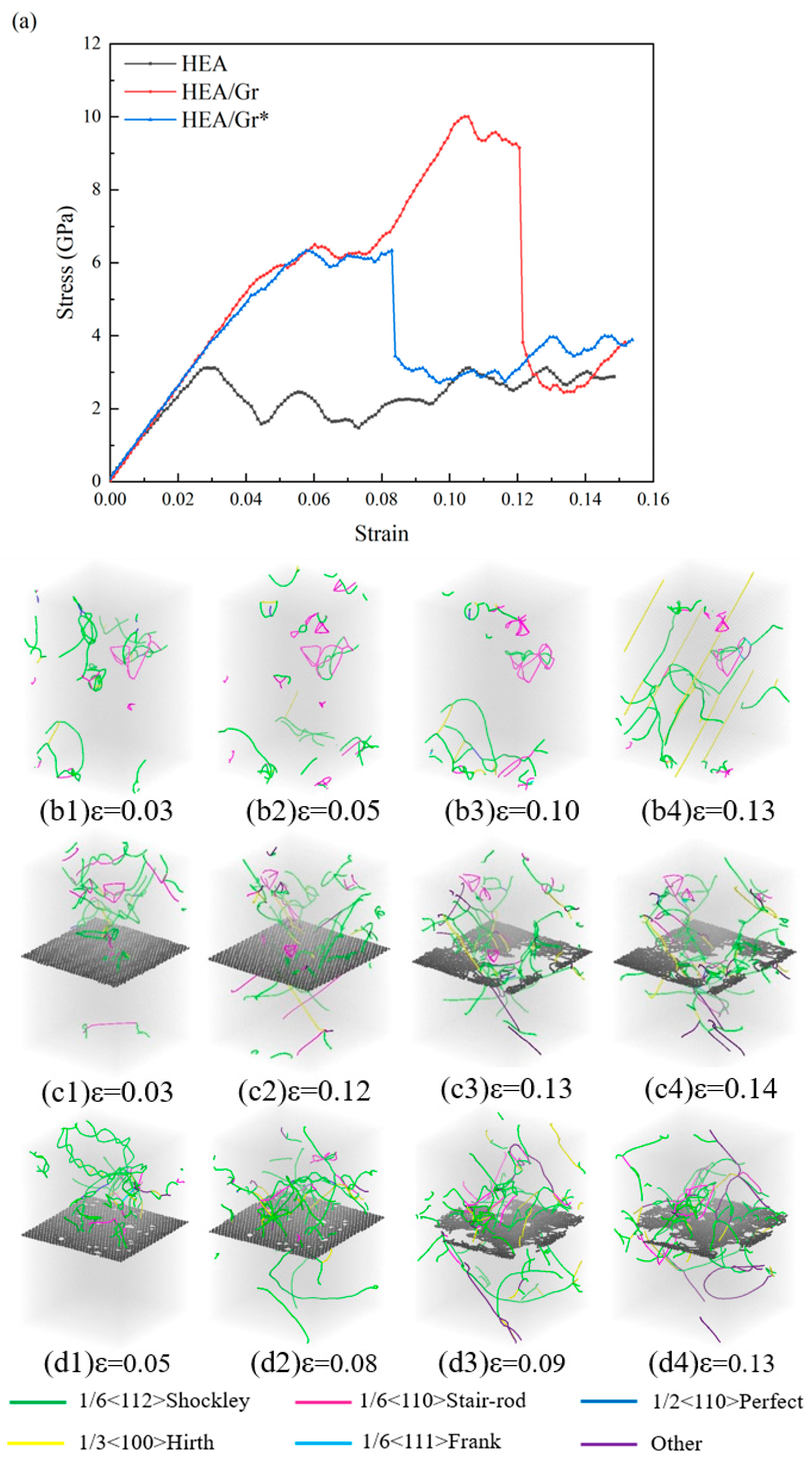

3.1. The Impact of Gr Vacancy Defects on the Tensile Performance

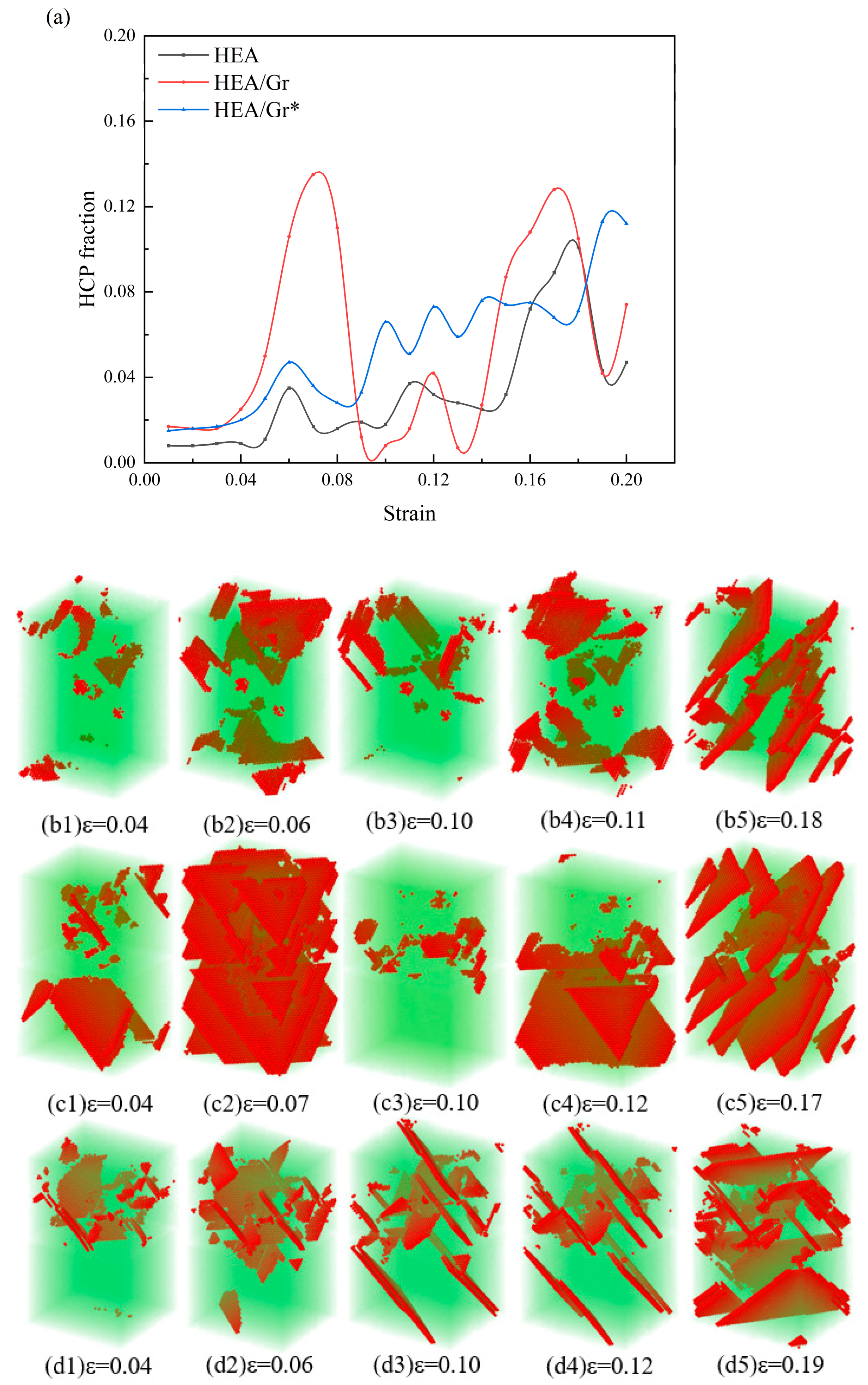

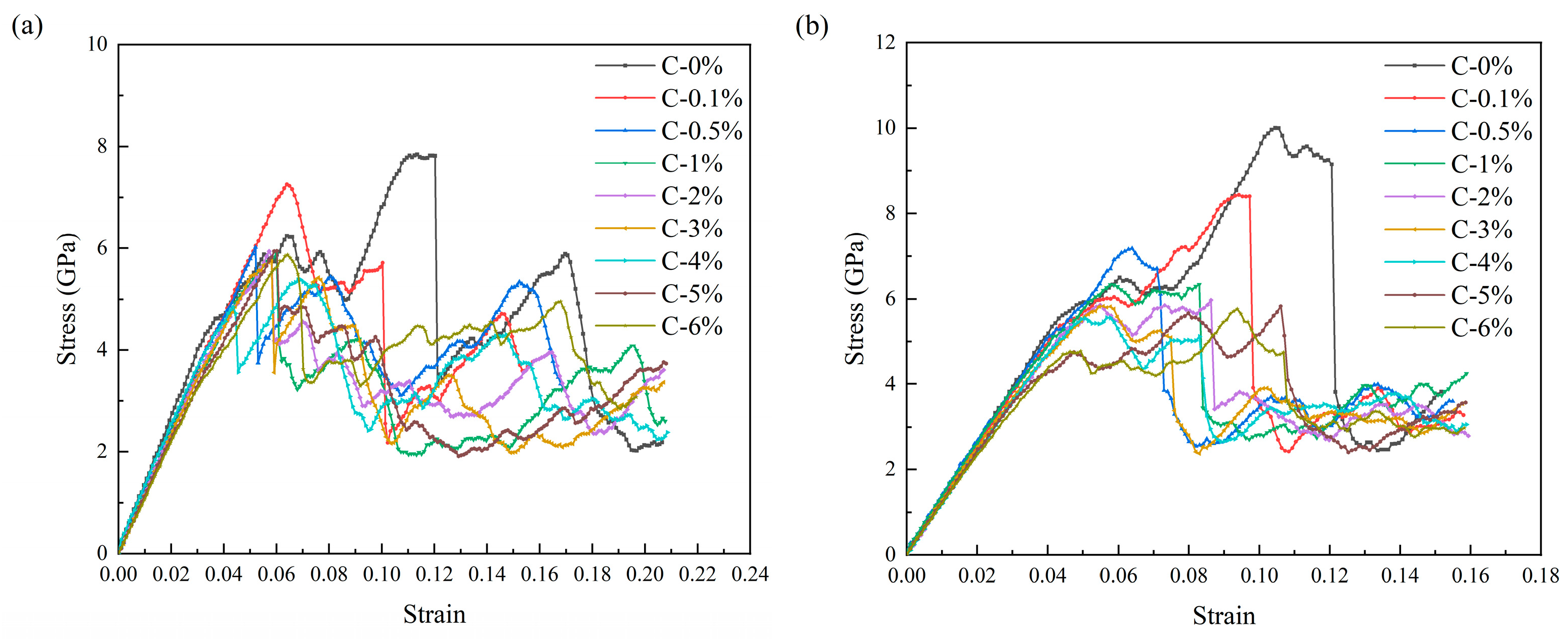

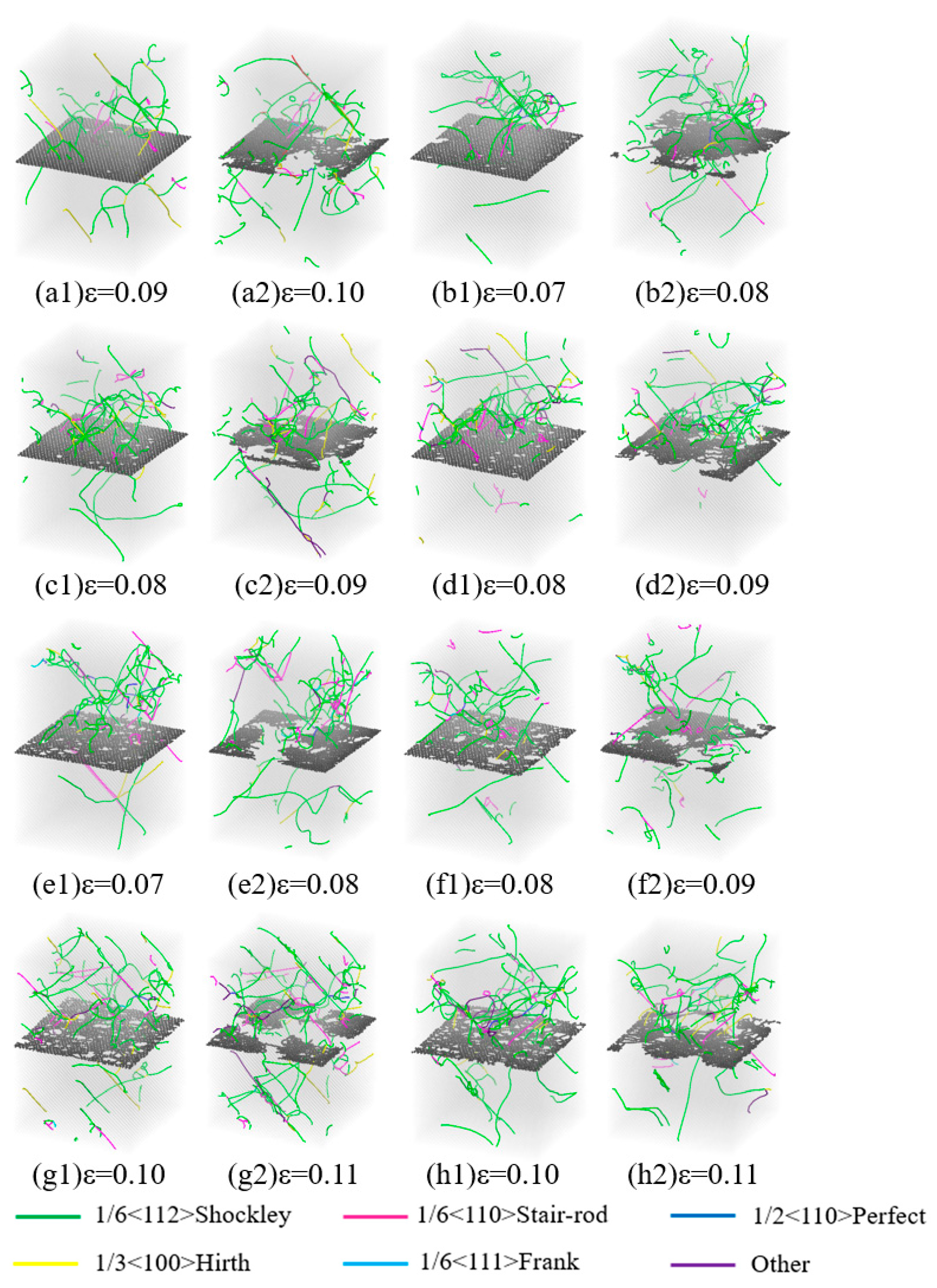

3.2. The Impact of Gr Vacancy Defects on the Compressive Performance

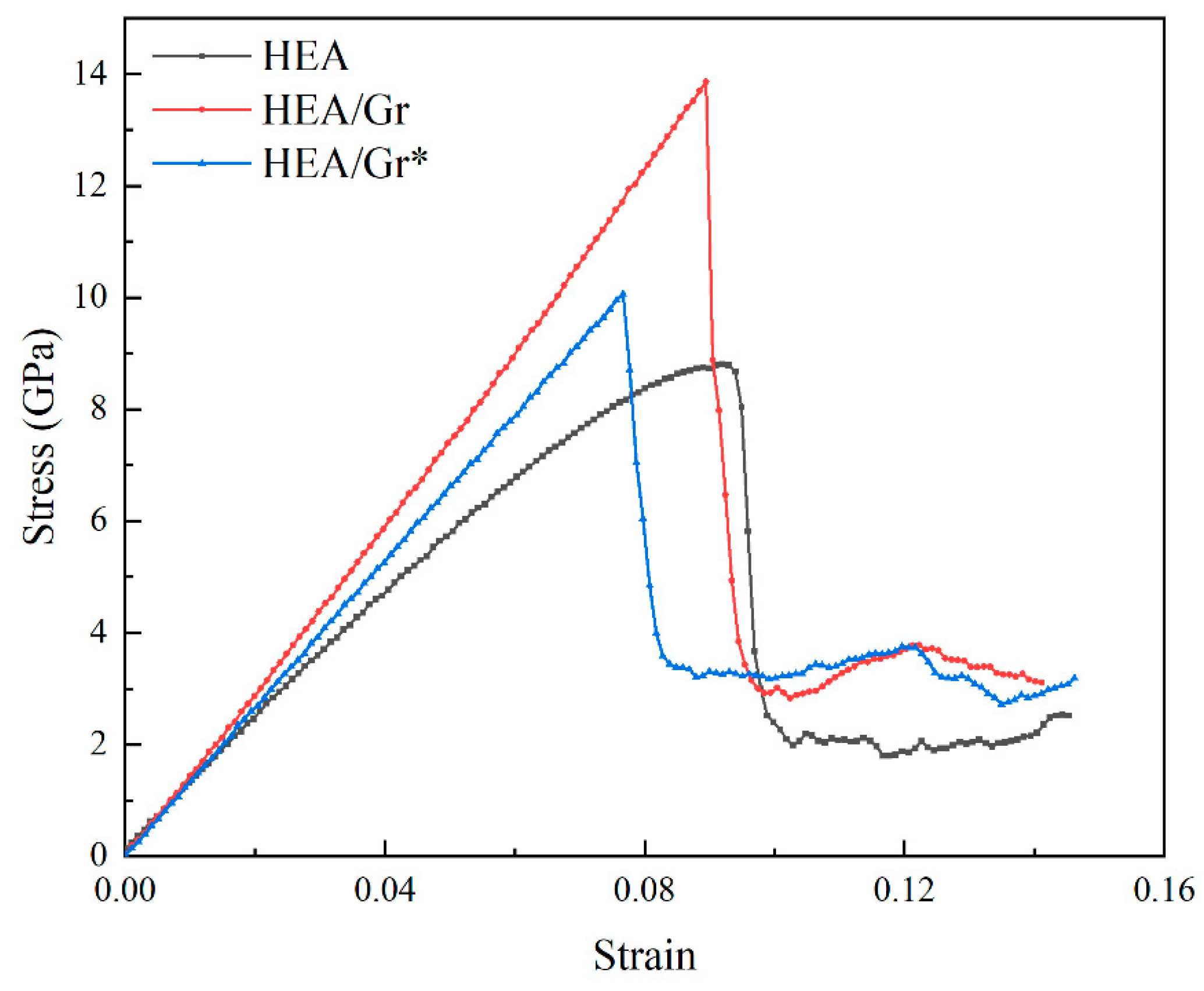

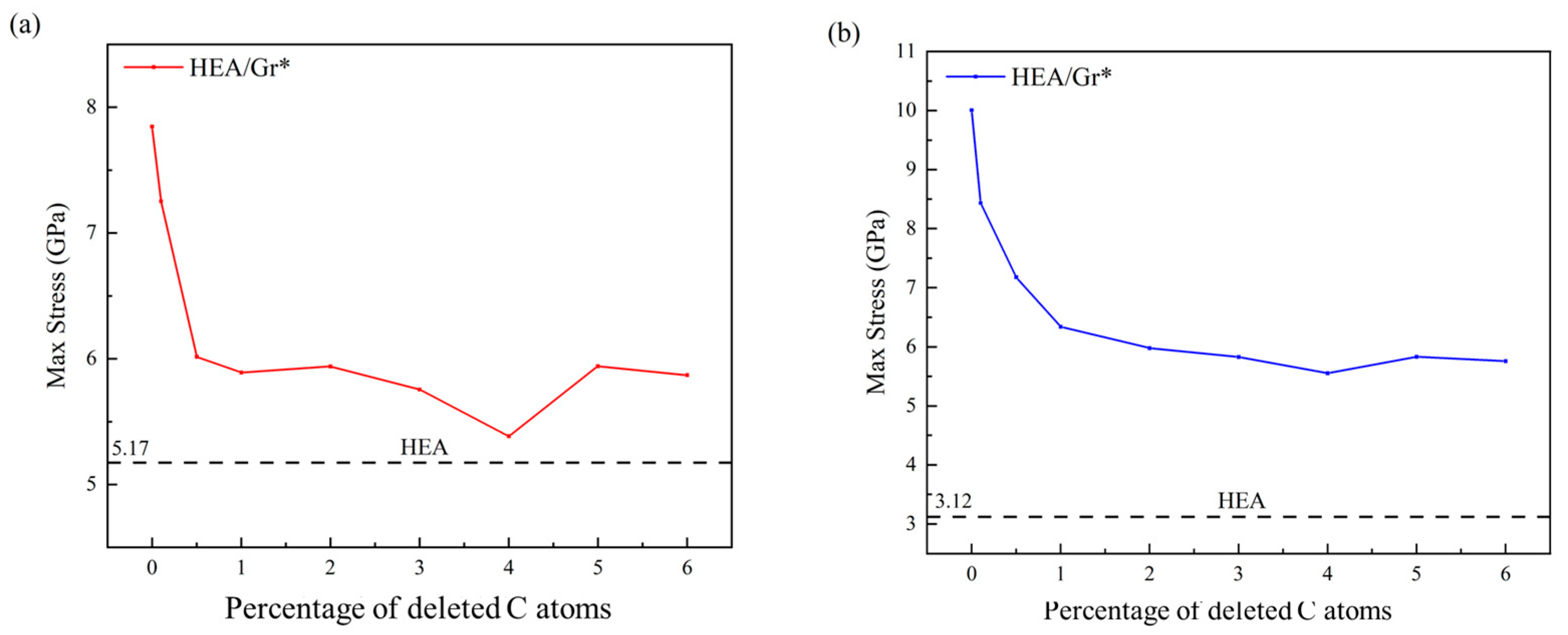

3.3. The Impact of Varying Quantities of Vacancy Defects on the Enhancement Effect

4. Conclusions

- (1)

- Vacancy defects can lead to a reduction in the strength of Gr, rendering it more susceptible to damage when it is required to bear loads. Compared to Gr without such defects, the strengthening effect is diminished. During simulations, the strain nodes associated with Gr failure occur prematurely, yet they still contribute to a certain degree of strengthening for the overall model. Research indicates that Gr* with a minimal amount of vacancy defects remains effective in blocking the movement of dislocations, altering the direction of dislocation propagation and increasing dislocation density. When confronted with initial dislocations, this can enhance the local yield stress of the model. Notably, in compression simulations conducted perpendicular to the graphene plane, Gr* plays a pivotal role in bolstering the flow stress of the model, even after the overall yield point has been reached.

- (2)

- Introducing varying quantities of vacancy defects into Gr* exerts diverse degrees of influence on its strengthening effect. Both the size and distribution of these defects play a pivotal role in shaping the deformation behavior of Gr*. A small yet concentrated number of vacancy defects renders the model more susceptible to damage, whereas a larger quantity of defects distributed uniformly enhances the stability and toughness of the model. When the concentration of vacancy defects in Gr* is low (C*>6%), Gr* struggles to maintain the stability of its structure, suffering damage during the relaxation phase. Consequently, the strengthening effect disappears in the elastic stage, and the model’s overall yield strength approaches that of pure HEA.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, C.; Song, G.; Gao, M.C.; Feng, R.; Chen, P.; Brechtl, J.; Chen, Y.; An, K.; Guo, W.; Poplawsky, J.D. Lattice distortion in a strong and ductile refractory high-entropy alloy. Acta Mater. 2018, 160, 158–172. [Google Scholar] [CrossRef]

- Chung, D.; Ding, Z.; Yang, Y. Hierarchical eutectic structure enabling superior fracture toughness and superb strength in CoCrFeNiNb0.5 eutectic high entropy alloy at room temperature. Adv. Eng. Mater. 2019, 21, 1801060. [Google Scholar] [CrossRef]

- Chou, Y.; Yeh, J.; Shih, H. The effect of molybdenum on the corrosion behaviour of the high-entropy alloys Co1.5CrFeNi1.5Ti0.5Mox in aqueous environments. Corros. Sci. 2010, 52, 2571–2581. [Google Scholar] [CrossRef]

- Yang, T.; Li, C.; Zinkle, S.J.; Zhao, S.; Bei, H.; Zhang, Y. Irradiation responses and defect behavior of single-phase concentrated solid solution alloys. J. Mater. Res. 2018, 33, 3077–3091. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Q.; Zhao, Y.; He, Q.; Lu, J.; Yang, Y. Elemental segregation in solid-solution high-entropy alloys: Experiments and modeling. J. Alloys Compd. 2016, 681, 167–174. [Google Scholar] [CrossRef]

- Wu, S.; Qiao, D.; Zhang, H.; Miao, J.; Zhao, H.; Wang, J.; Lu, Y.; Wang, T.; Li, T. Microstructure and mechanical properties of CxHf0.25NbTaW0.5 refractory high-entropy alloys at room and high temperatures. J. Mater. Sci. Technol. 2022, 97, 229–238. [Google Scholar] [CrossRef]

- Gao, Z.; Niu, Z.; Gao, Z.; Li, J.; Bai, G.; Ke, L.; Yu, Y.; Zhang, C. Microstructure and wear behavior of in-situ synthesized TiC-reinforced CoCrFeNi high entropy alloy prepared by laser cladding. Appl. Surf. Sci. 2024, 670, 160720. [Google Scholar] [CrossRef]

- Xu, H.; Zang, J.; Yuan, Y.; Zhou, Y.; Tian, P.; Wang, Y. In-situ assembly from graphene encapsulated CoCrFeMnNi high-entropy alloy nanoparticles for improvement corrosion resistance and mechanical properties in metal matrix composites. J. Alloys Compd. 2019, 811, 152082. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, X.; Sun, H.; Zhang, Y.; Fang, Y.; Shu, R. Microstructure and mechanical properties of bioinspired laminated CoCrFeNiMn high entropy alloy matrix composites reinforced with graphene. Mater. Sci. Eng. A 2022, 859, 144198. [Google Scholar] [CrossRef]

- Shi, Y.; Ye, W.; Hua, D.; Zhou, Q.; Huang, Z.; Liu, Y.; Li, S.; Guo, T.; Chen, Y.; Eder, S.J. Interfacial engineering for enhanced mechanical performance: High-entropy alloy/graphene nanocomposites. Mater. Today Phys. 2023, 38, 101220. [Google Scholar] [CrossRef]

- Ares, P.; Novoselov, K.S. Recent advances in graphene and other 2D materials. Nano Mater. Sci. 2022, 4, 3–9. [Google Scholar] [CrossRef]

- Ye, W.; Shi, Y.; Zhou, Q.; Xie, M.; Wang, H.; Bou-Saïd, B.; Liu, W. Recent advances in self-lubricating metal matrix nanocomposites reinforced by carbonous materials: A review. Nano Mater. Sci. 2024, 6, 701–713. [Google Scholar] [CrossRef]

- Zhou, C.; Qing, F.; Sun, X.; Wu, R.; Wang, H.; Wen, Q.; Li, X. Preparation of graphene-coated Cu particles with oxidation resistance by flash joule heating. Carbon 2024, 224, 119060. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Q.; Shi, Y.; Ye, W.; Lin, Y.; Wang, H. The deformation mechanism of graphene nanosheets embedded in high-entropy alloy upon sliding. Carbon 2024, 229, 119532. [Google Scholar] [CrossRef]

- Ye, W.; Zhou, Q.; Shi, Y.; Xie, M.; Chen, B.; Wang, H.; Liu, W. Robust wear performance of graphene-reinforced high entropy alloy composites. Carbon 2024, 224, 119040. [Google Scholar] [CrossRef]

- Hashimoto, A.; Suenaga, K.; Gloter, A.; Urita, K.; Iijima, S. Direct evidence for atomic defects in graphene layers. Nature 2004, 430, 870–873. [Google Scholar] [CrossRef]

- Kisielowski, C. Observing Atoms at Work by Controlling Beam-Sample Interactions. Adv. Mater. 2015, 27, 5838–5844. [Google Scholar] [CrossRef] [PubMed]

- Borowiak-Palen, E.; Mendoza, E.; Bachmatiuk, A.; Rummeli, M.H.; Gemming, T.; Nogues, J.; Skumryev, V.; Kalenczuk, R.J.; Pichler, T.; Silva, S.R.P. Iron filled single-wall carbon nanotubes—A novel ferromagnetic medium. Chem. Phys. Lett. 2006, 421, 129–133. [Google Scholar] [CrossRef]

- Gass, M.H.; Bangert, U.; Bleloch, A.L.; Wang, P.; Nair, R.R.; Geim, A.K. Free-standing graphene at atomic resolution. Nat. Nanotechnol. 2008, 3, 676–681. [Google Scholar] [CrossRef] [PubMed]

- Meyer, J.C.; Kisielowski, C.; Erni, R.; Rossell, M.D.; Crommie, M.F.; Zettl, A. Direct Imaging of Lattice Atoms and Topological Defects in Graphene Membranes. Nano Lett. 2008, 8, 3582–3586. [Google Scholar] [CrossRef]

- Sethurajaperumal, A.; Ravichandran, V.; Merenkov, I.; Ostrikov, K.K.; Varrla, E. Delamination and defects in graphene nanosheets exfoliated from 3D precursors. Carbon 2023, 213, 118306. [Google Scholar] [CrossRef]

- Robertson, A.W.; Allen, C.S.; Wu, Y.A.; He, K.; Olivier, J.; Neethling, J.; Kirkland, A.I.; Warner, J.H. Spatial control of defect creation in graphene at the nanoscale. Nat. Commun. 2012, 3, 1144. [Google Scholar] [CrossRef]

- Ansari, R.; Ajori, S.; Motevalli, B. Mechanical properties of defective single-layered graphene sheets via molecular dynamics simulation. Superlattices Microstruct. 2012, 51, 274–289. [Google Scholar] [CrossRef]

- Tapia, A.; Peón-Escalante, R.; Villanueva, C.; Avilés, F. Influence of vacancies on the elastic properties of a graphene sheet. Comput. Mater. Sci. 2012, 55, 255–262. [Google Scholar] [CrossRef]

- Fedorov, A.S.; Popov, Z.I.; Fedorov, D.A.; Eliseeva, N.S.; Serjantova, M.V.; Kuzubov, A.A. DFT investigation of the influence of ordered vacancies on elastic and magnetic properties of graphene and graphene-like SiC and BN structures. Phys. Status Solidi 2012, 249, 2549–2552. [Google Scholar] [CrossRef]

- Lopez-Polin, G.; Gomez-Navarro, C.; Gomez-Herrero, J. The effect of rippling on the mechanical properties of graphene. Nano Mater. Sci. 2022, 4, 18–26. [Google Scholar] [CrossRef]

- González, C.; Dappe, Y.J.; Dong, C.; Robinson, J.A.; Trampert, A.; Engel-Herbert, R. Atomic-scale characterization of defects in oxygen plasma-treated graphene by scanning tunneling microscopy. Carbon 2024, 227, 119260. [Google Scholar]

- Damasceno, D.; Rajapakse, R.; Mesquita, E.; Pavanello, R. Atomistic simulation of tensile strength properties of graphene with complex vacancy and topological defects. Acta Mech. 2020, 231, 3387–3404. [Google Scholar] [CrossRef]

- Sun, X.; Fu, Z.; Xia, M.; Xu, Y. Effects of vacancy defect on the tensile behavior of graphene. Theor. Appl. Mech. Lett. 2014, 4, 051002. [Google Scholar] [CrossRef]

- Zandiatashbar, A.; Lee, G.-H.; An, S.J.; Lee, S.; Mathew, N.; Terrones, M.; Hayashi, T.; Picu, C.R.; Hone, J.; Koratkar, N. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 2014, 5, 3186. [Google Scholar] [CrossRef]

- Fang, Z.; Xu, S.; Cao, R.; Jiao, M.; Liu, K.; Diao, Q.; Guan, S.; Jia, Y. Interfacial Adsorption Mechanisms of Arginine, Glutamic Acid, Aspartic Acid, and Valine on Magnesium and Magnesium Alloy Surfaces: A First-Principles Investigation. Coatings 2025, 15, 586. [Google Scholar] [CrossRef]

- Luo, H.; Ruan, Z.; Fan, T.; Zhang, Y.; Hu, T.; Yan, H. First-principles investigation of plane faults and thermodynamics in BCC (TiZrHf) 1-xMx (M= Nb, Mo, Ta) medium entropy alloys. Mater. Chem. Phys. 2025, 335, 130498. [Google Scholar] [CrossRef]

- Wei Wang, J.; Narayanan, S.; Yu Huang, J.; Zhang, Z.; Zhu, T.; Mao, S.X. Atomic-scale dynamic process of deformation-induced stacking fault tetrahedra in gold nanocrystals. Nat. Commun. 2013, 4, 2340. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, R.; Zhang, X.; Cao, T.; Xue, Y.; Li, X. Deformation mechanisms and remarkable strain hardening in single-crystalline high-entropy-alloy micropillars/nanopillars. Nano Lett. 2021, 21, 3671–3679. [Google Scholar] [CrossRef]

- Bhatt, M.D.; Kim, H.; Kim, G. Various defects in graphene: A review. RSC Adv. 2022, 12, 21520–21547. [Google Scholar] [CrossRef]

- Farkas, D.; Caro, A. Model interatomic potentials and lattice strain in a high-entropy alloy. J. Mater. Res. 2018, 33, 3218–3225. [Google Scholar] [CrossRef]

- Deluigi, O.R.; Pasianot, R.C.; Valencia, F.; Caro, A.; Farkas, D.; Bringa, E.M. Simulations of primary damage in a High Entropy Alloy: Probing enhanced radiation resistance. Acta Mater. 2021, 213, 116951. [Google Scholar] [CrossRef]

- Li, J.; Dong, L.; Dong, X.; Zhao, W.; Liu, J.; Xiong, J.; Xu, C. Study on wear behavior of FeNiCrCoCu high entropy alloy coating on Cu substrate based on molecular dynamics. Appl. Surf. Sci. 2021, 570, 151236. [Google Scholar] [CrossRef]

- Xie, H.; Ma, Z.; Zhao, H.; Ren, L. Atomic perspective of contact protection in graphene-coated high-entropy films. Tribol. Int. 2022, 174, 107748. [Google Scholar] [CrossRef]

- Zhang, H.; Siu, K.W.; Liao, W.; Wang, Q.; Yang, Y.; Lu, Y. In situ mechanical characterization of CoCrCuFeNi high-entropy alloy micro/nano-pillars for their size-dependent mechanical behavior. Mater. Res. Express 2016, 3, 094002. [Google Scholar] [CrossRef]

- Li, C.; Dedoncker, R.; Li, L.; Sedghgooya, F.; Zighem, F.; Ji, V.; Depla, D.; Djemia, P.; Faurie, D. Mechanical properties of CoCrCuFeNi multi-principal element alloy thin films on Kapton substrates. Surf. Coat. Technol. 2020, 402, 126474. [Google Scholar] [CrossRef]

- Li, Z.; Guo, Q.; Li, Z.; Fan, G.; Xiong, D.-B.; Su, Y.; Zhang, J.; Zhang, D. Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioinspired nanolaminated structure. Nano Lett. 2015, 15, 8077–8083. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, C.; Michal, G.; Li, J.; Wang, R. Strong strain hardening in graphene/nanotwinned metal composites revealed by molecular dynamics simulations. Int. J. Mech. Sci. 2021, 201, 106460. [Google Scholar] [CrossRef]

- Chien, S.-K.; Yang, Y.-T. A molecular dynamics study of the mechanical properties of graphene nanoribbon-embedded gold composites. Nanoscale 2011, 3, 4307–4313. [Google Scholar] [CrossRef]

- Guo, S.-J.; Yang, Q.-S.; He, X.; Liew, K. Modeling of interface cracking in copper–graphite composites by MD and CFE method. Compos. Part B Eng. 2014, 58, 586–592. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, P.; Wang, F. Graphene-boundary strengthening mechanism in Cu/graphene nanocomposites: A molecular dynamics simulation. Mater. Des. 2020, 190, 108555. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Yeom, M.S.; Shin, J.W.; Kim, H.; Cui, Y.; Kysar, J.W.; Hone, J.; Jung, Y.; Jeon, S. Strengthening effect of single-atomic-layer graphene in metal–graphene nanolayered composites. Nat. Commun. 2013, 4, 2114. [Google Scholar] [CrossRef] [PubMed]

- Santhapuram, R.R.; Muller, S.E.; Nair, A.K. Nanoscale bending properties of bio-inspired Ni-graphene nanocomposites. Compos. Struct. 2019, 220, 798–808. [Google Scholar] [CrossRef]

- Shuang, F.; Aifantis, K.E. Dislocation-graphene interactions in Cu/graphene composites and the effect of boundary conditions: A molecular dynamics study. Carbon 2021, 172, 50–70. [Google Scholar] [CrossRef]

- Xie, L.; Brault, P.; Thomann, A.-L.; Bauchire, J.-M. AlCoCrCuFeNi high entropy alloy cluster growth and annealing on silicon: A classical molecular dynamics simulation study. Appl. Surf. Sci. 2013, 285, 810–816. [Google Scholar] [CrossRef]

- Xie, H.; Ma, Z.; Zhang, W.; Zhao, H.; Ren, L. Strengthening effect of high-entropy alloys endowed by monolayer graphene. Mater. Today Phys. 2022, 27, 100800. [Google Scholar] [CrossRef]

- Pan, A.; Wang, W.; Xie, J.; Zhang, H.; Hao, S. Molecular dynamics simulations of interface structure and deformation mechanisms in metal/ceramic composites under tension. Mech. Mater. 2023, 184, 104688. [Google Scholar] [CrossRef]

- Cui, C.; Yu, Q.; Wang, W.; Xu, W.; Chen, L. Molecular dynamics study on tensile strength of twist grain boundary structures under uniaxial tension in copper. Vacuum 2021, 184, 109874. [Google Scholar] [CrossRef]

| Pair | (Å) | (eV) |

|---|---|---|

| Fe–C | 3.1000 | 0.050000 |

| Ni–C | 2.8520 | 0.230000 |

| Cr–C | 2.8680 | 0.037758 |

| Co–C | 2.8420 | 0.038281 |

| Cu–C | 3.0825 | 0.025780 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wang, H.; Zhang, C.; Zhang, C.; Zhang, X. The Influence of the Defect Rate of Graphene on Its Reinforcing Capability Within High-Entropy Alloys. Nanomaterials 2025, 15, 1177. https://doi.org/10.3390/nano15151177

Zhang X, Wang H, Zhang C, Zhang C, Zhang X. The Influence of the Defect Rate of Graphene on Its Reinforcing Capability Within High-Entropy Alloys. Nanomaterials. 2025; 15(15):1177. https://doi.org/10.3390/nano15151177

Chicago/Turabian StyleZhang, Xianhe, Hongyun Wang, Chunpei Zhang, Cun Zhang, and Xuyao Zhang. 2025. "The Influence of the Defect Rate of Graphene on Its Reinforcing Capability Within High-Entropy Alloys" Nanomaterials 15, no. 15: 1177. https://doi.org/10.3390/nano15151177

APA StyleZhang, X., Wang, H., Zhang, C., Zhang, C., & Zhang, X. (2025). The Influence of the Defect Rate of Graphene on Its Reinforcing Capability Within High-Entropy Alloys. Nanomaterials, 15(15), 1177. https://doi.org/10.3390/nano15151177