Efficient Image Processing Technique for Detecting Spatio-Temporal Erosion in Boron Nitride Exposed to Iodine Plasma

Abstract

1. Introduction

| Technique | Accuracy | Spatial Resolution | Ease of Use | Notes |

|---|---|---|---|---|

| Cavity Ring-Down Spectroscopy (CRDS) [25] | High sensitivity to minute erosion species | No spatial resolution (volume-averaged concentration within the cavity) | Complex setup (requires active cavity alignment due to thermal drift) | Ideal for quantifying ablation rates; unsuitable for analysing fine surface morphology. |

| Optical Emission Spectroscopy (OES) | Moderate accuracy [25] | Line-of-sight only; spatial mapping requires multi-fibre setup [26] | Simple setup but requires precise plasma state knowledge for quantification | Real-time monitoring based on excited species emission; unsuitable for analysing fine surface morphology. |

| Quartz Crystal Microbalance (QCM) | High sensitivity to mass changes | No spatial resolution (measures a single point representing the average mass change on the crystal surface) | Simple setup; measures only deposition without identifying specific materials | Provides only surface-averaged data rather than localised measurements; unsuitable for analysing fine surface morphology. |

| Laser Profilometry [27,28] | Moderate to high (limited by laser line width and surface reflectivity) | Limited by laser spot size | Moderate setup (requires calibration and adjustment for different surface dimensions) | Contactless 3D surface reconstruction; affected by shadows, vibrations and thermal drift; suitable for analysing fine surface morphology |

| AFM-based Image Processing (Our technique) | High (nanometre-scale) | High (sub-micron to nanometre) | Simple setup (AFM only); post-processing required (can be automated) | Enables detailed visualisation and quantification of surface erosion evolution; well-suited for analysing fine surface morphology. |

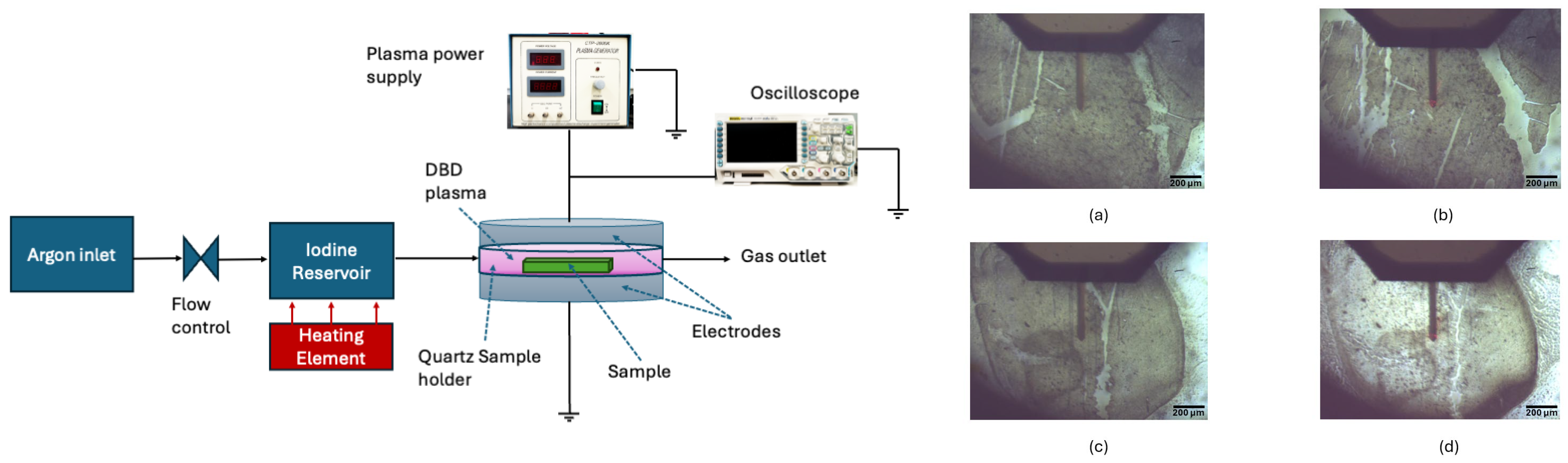

2. Materials and Methods

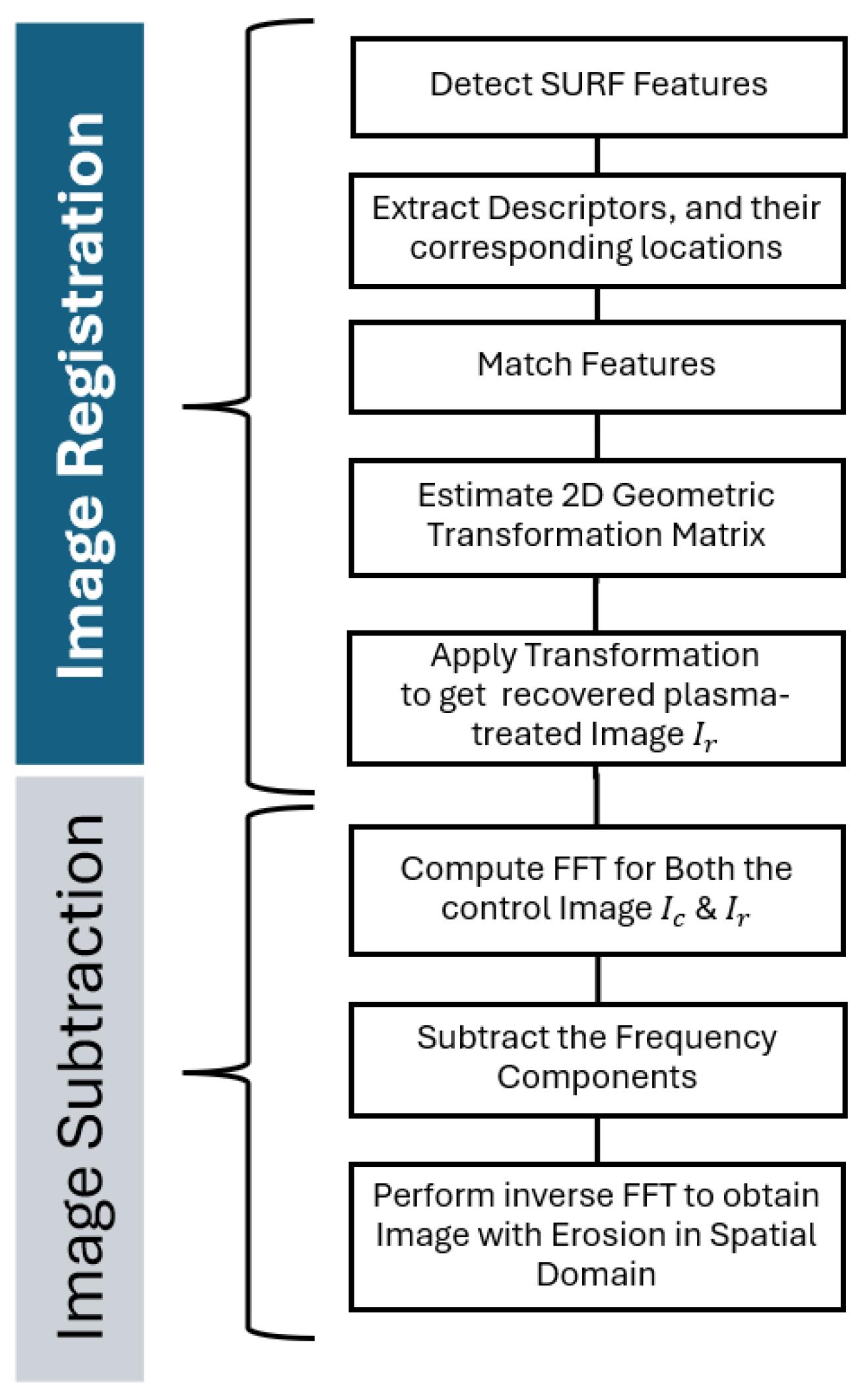

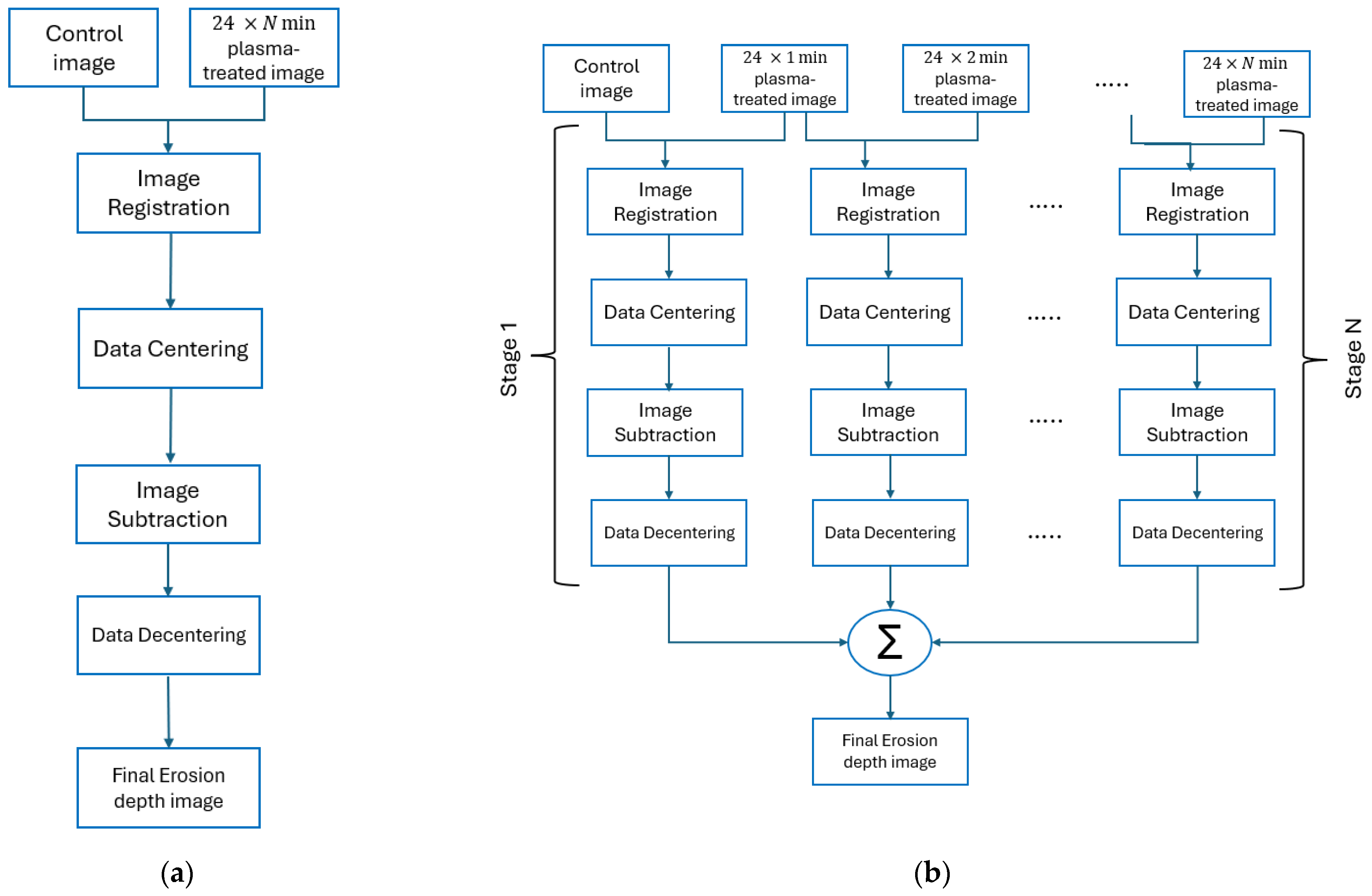

3. Image Processing Technique

3.1. Image Registration

3.2. Image Subtraction in Frequency Domain

3.3. Image Filtering

3.4. Direct and Indirect Methods

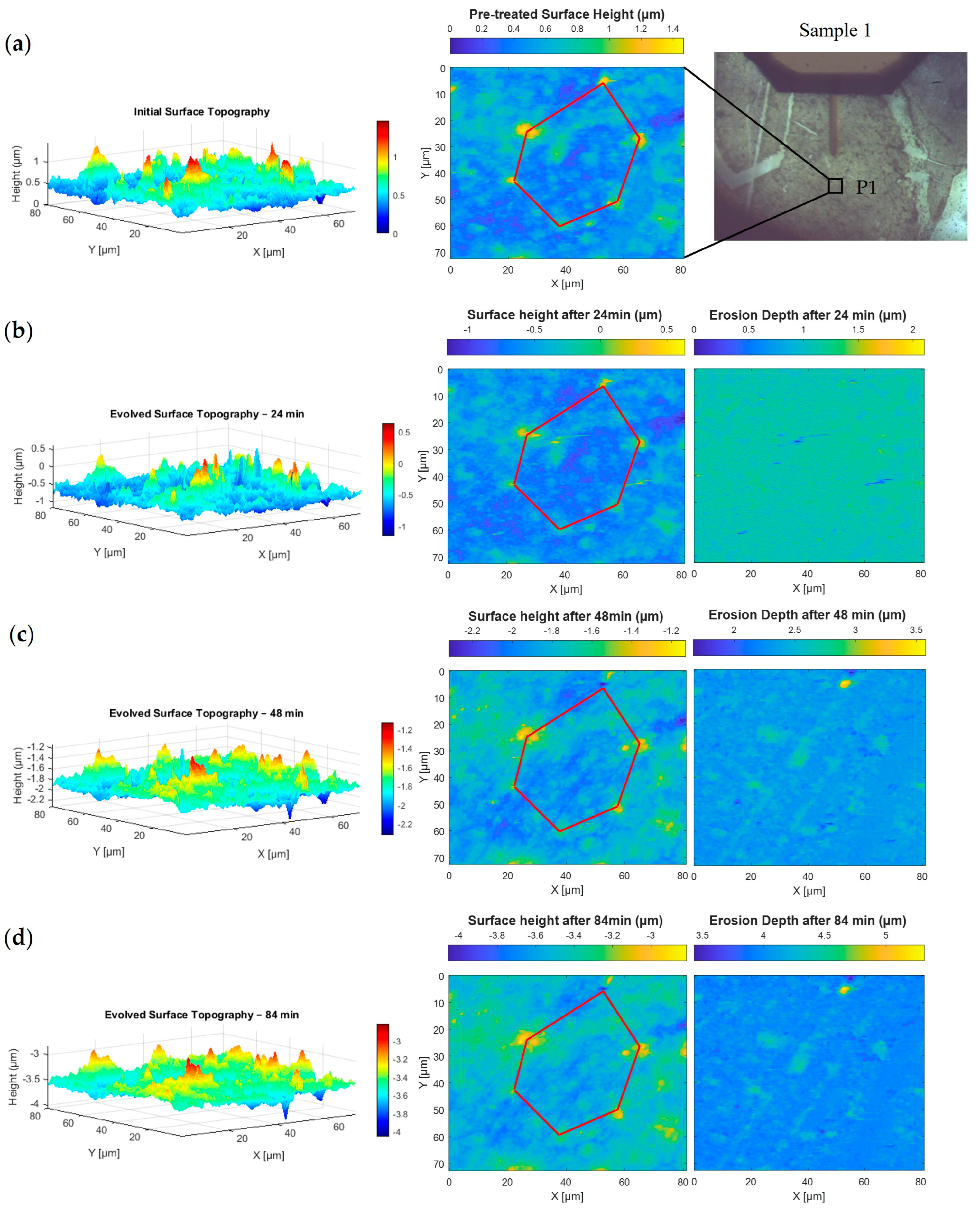

4. Results and Discussion

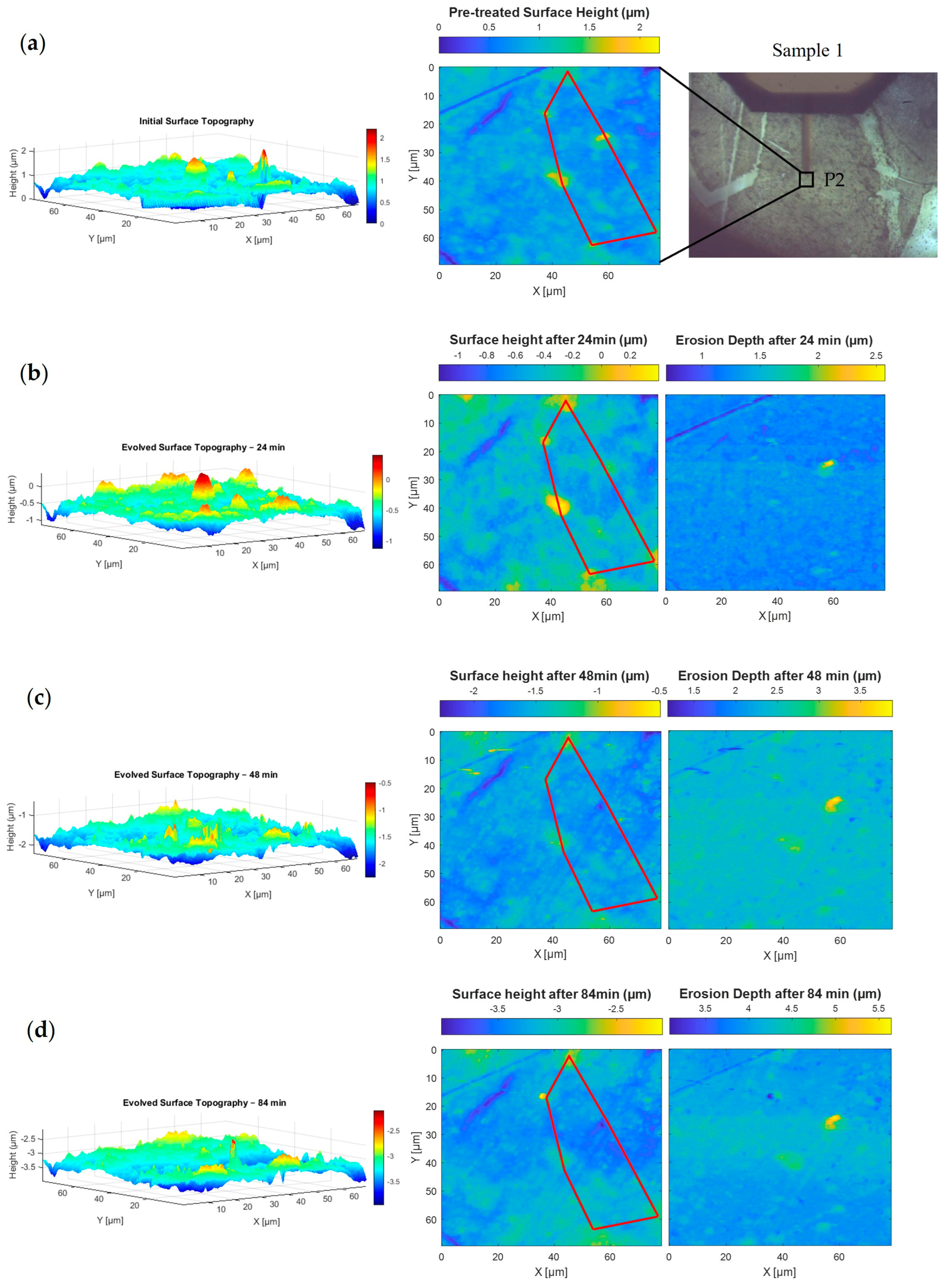

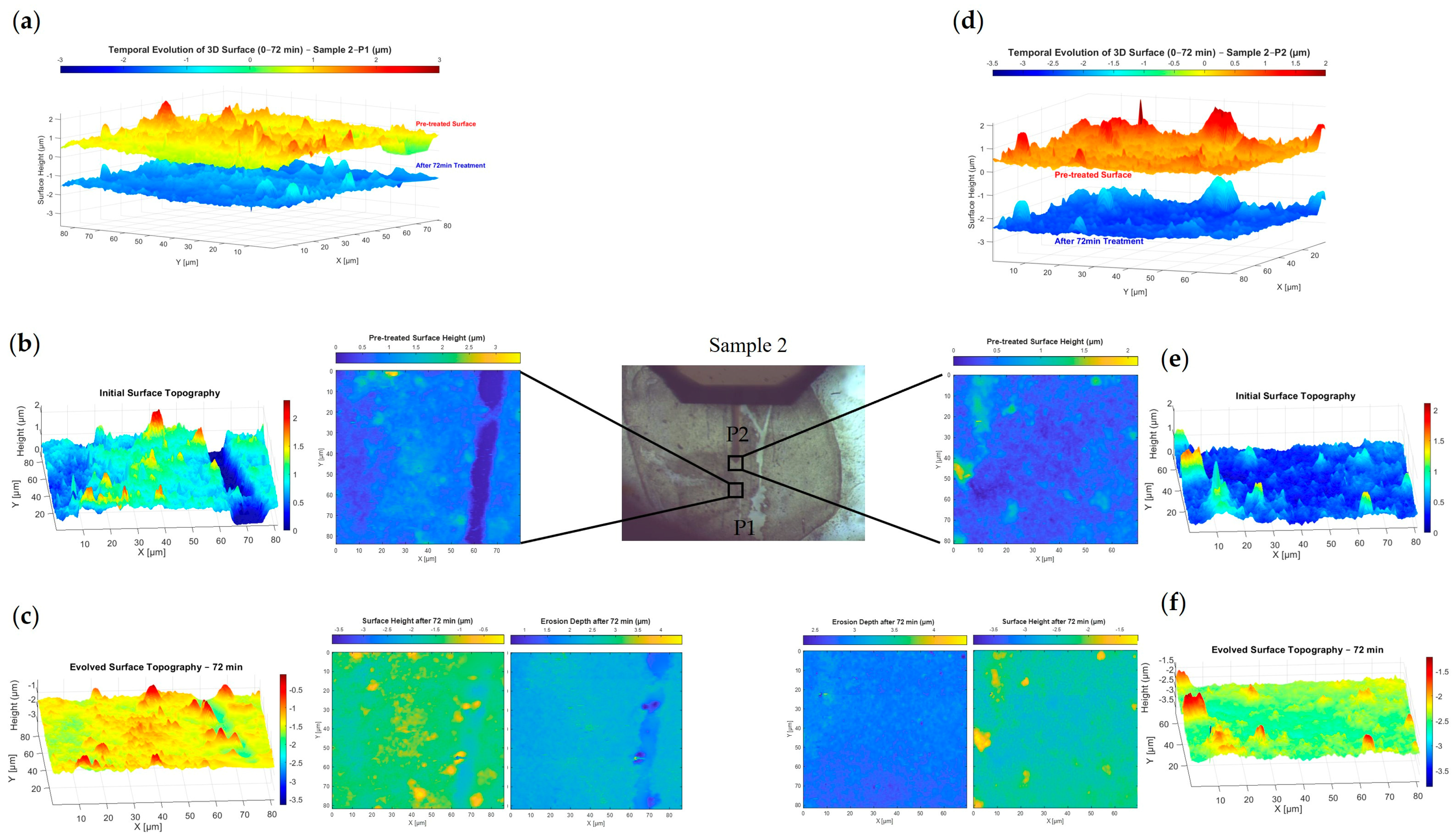

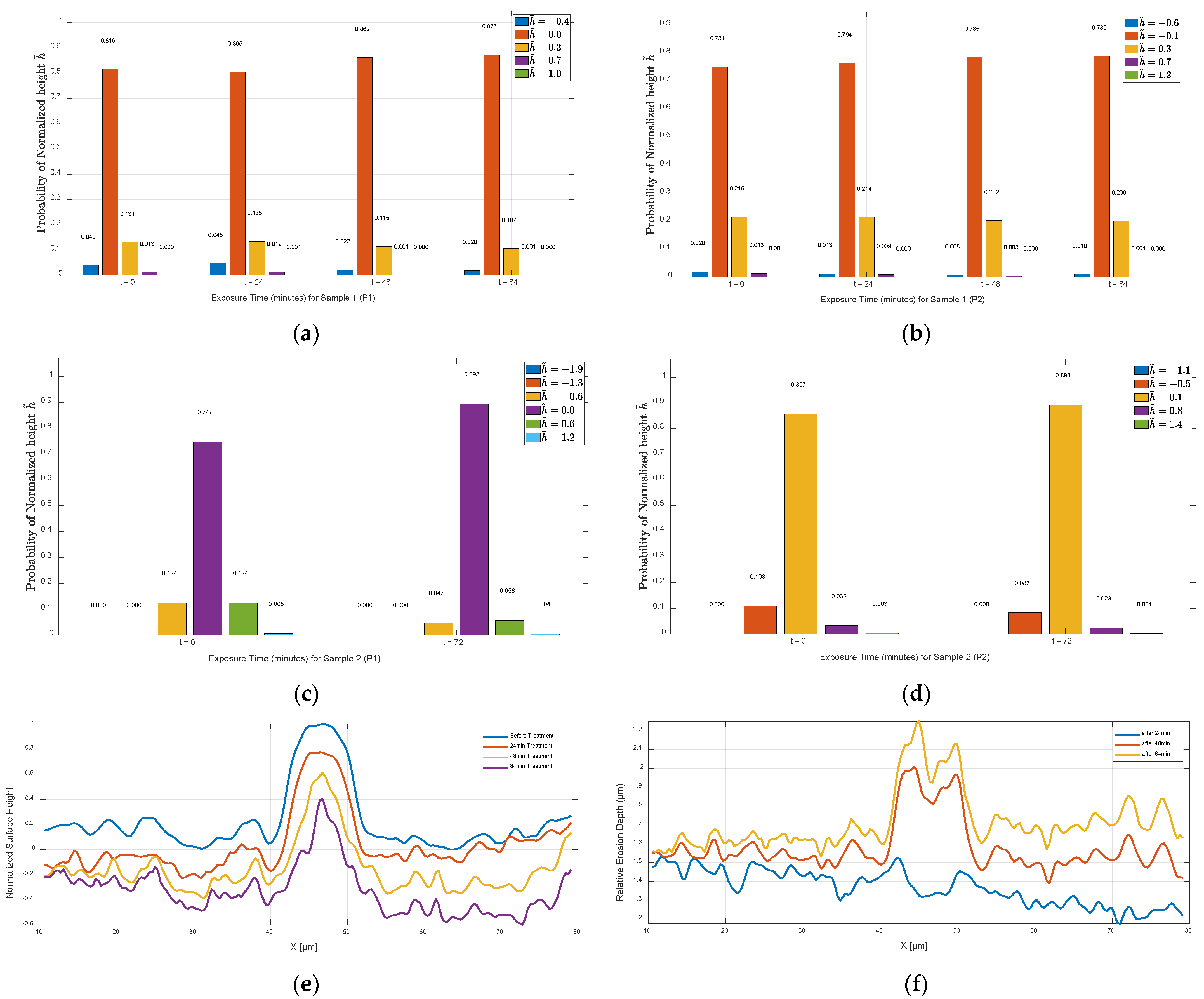

4.1. Surface Evolution Under Iodine Plasma

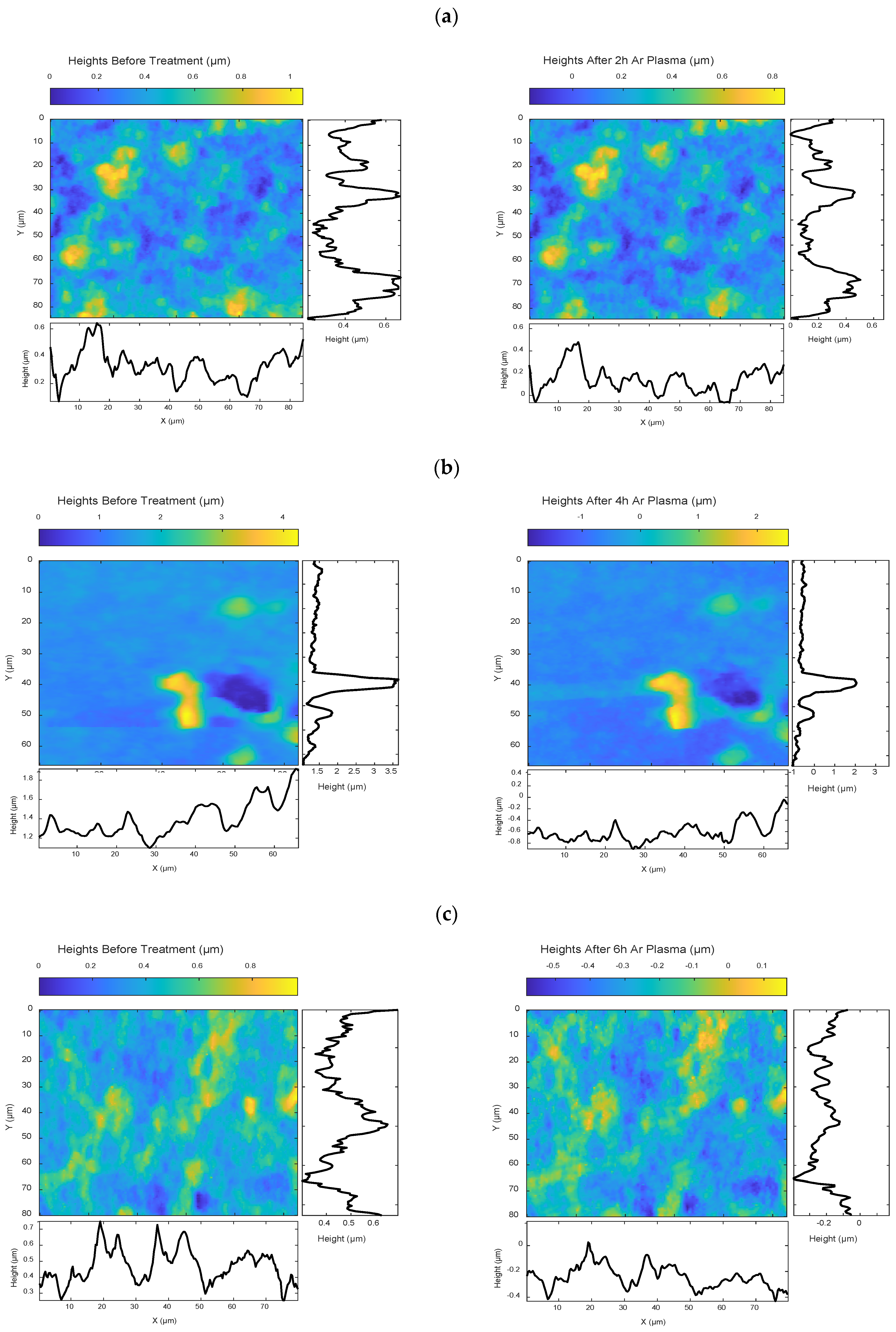

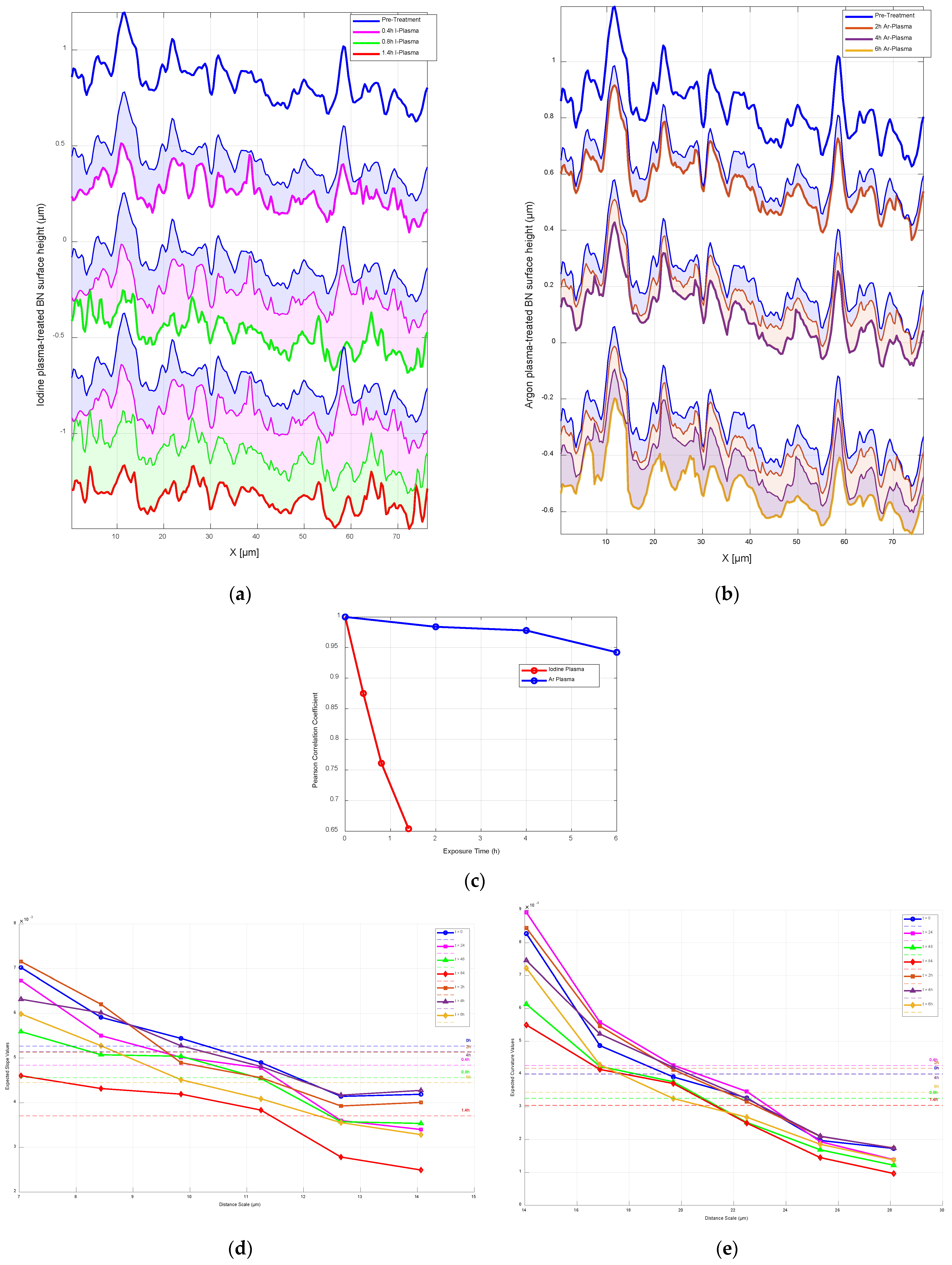

4.2. Surface Interaction with Iodine and Argon Plasma: A Comparative View

4.2.1. ANN-Based Surface Prediction

4.2.2. Localised Surface Response

4.2.3. Scale-Based Surface Roughness Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Levchenko, I.; Xu, S.; Teel, G.; Mariotti, D.; Walker, M.L.R.; Keidar, M. Recent progress and perspectives of space electric propulsion systems based on smart nanomaterials. Nat. Commun. 2018, 9, 879. [Google Scholar] [CrossRef] [PubMed]

- Borrfors, A.N.; Harding, D.J.; Weissenrieder, J.; Ciaralli, S.; Hallock, A.; Brinck, T. Aromatic hydrocarbons as Molecular Propellants for Electric Propulsion Thrusters. J. Electr. Propuls. 2023, 2, 24. [Google Scholar] [CrossRef]

- Rafalskyi, D.; Martínez, J.M.; Habl, L.; Rossi, E.Z.; Proynov, P.; Boré, A.; Baret, T.; Poyet, A.; Lafleur, T.; Dudin, S.; et al. In-orbit demonstration of an iodine electric propulsion system. Nature 2021, 599, 411–415. [Google Scholar] [CrossRef] [PubMed]

- Levchenko, I.; Bazaka, K. Iodine powers low-cost engines for satellites. Nature 2021, 599, 373–374. [Google Scholar] [CrossRef]

- Jerman, G.A. Iodine Vapor Exposure Testing of Engineering Materials; Technical Report; NASA, Marshall Space Flight Center: Huntsville, AL, USA, 2022.

- Martínez, J.M.; Rafalskyi, D. Design and development of iodine flow control systems for miniaturized propulsion systems. CEAS Space J. 2021, 14, 91–107. [Google Scholar] [CrossRef]

- Szabo, J.J.; Robin, M.; Paintal, S.; Pote, B.; Hruby, V.; Freeman, C. Iodine Propellant Space Propulsion. In Proceedings of the 33rd International Electric Propulsion Conference, Washington, DC, USA, 6–10 October 2013. [Google Scholar] [CrossRef]

- Branam, R. Iodine Plasma (Electric Propulsion) Interaction with Spacecraft Materials; Technical Report. AFRL-AFOSR-VA-TR-2016-0381; Air Force Research Laboratory: Tuscaloosa, AL, USA, 2016. [Google Scholar]

- Busek. Available online: https://www.busek.com/hall-thrusters (accessed on 24 April 2025).

- Mackey, J.; Frieman, J.D.; Ahern, D.M.; Gilland, J.H. Uncertainty in electric propulsion erosion measurements. In Proceedings of the AIAA Propulsion and Energy Forum and Exposition, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar] [CrossRef]

- Gildea, S.R.; Matlock, T.S.; Martínez-Sánchez, M.; Hargus, W.A. Erosion Measurements in a Low-Power Cusped-Field Plasma Thruster. J. Propuls. Power 2013, 29, 906–918. [Google Scholar] [CrossRef]

- Bundesmann, C.; Eichhorn, C.; Neumann, H.; Scholze, F.; Spemann, D.; Tartz, M.; Leiter, H.J.; Gnizdor, R.Y.; Scortecci, F. In situ erosion measurement tools for electric propulsion thrusters: Triangular laser head and telemicroscope. EPJ Tech. Instrum. 2022, 9, 1. [Google Scholar] [CrossRef]

- Misuri, T.; Vrebosch, T.; Pieri, L.; Andrenucci, M.; Tordi, M.; Marcuzzi, E.; Bartolozzi, M.; Renzetti, S.; González del Amo, J. Telemicroscopy and Thermography Diagnostic Systems for Monitoring Hall Effect Thrusters. In Proceedings of the 32nd International Electric Propulsion Conference, Wiesbaden, Germany, 11–15 September 2011; pp. 1–14. [Google Scholar]

- Gaeta, C.J.; Matossian, J.N.; Turley, R.S.; Beattie, J.R.; Williams, J.D.; Williamson, W.S. Erosion rate diagnostics in ion thrusters using laser-induced fluorescence. J. Propuls. Power 1993, 9, 369–376. [Google Scholar] [CrossRef]

- Duan, X.; Guo, D.; Cheng, M.; Yang, X.; Guo, N. Measurements of channel erosion of Hall thrusters by laser-induced fluorescence. J. Appl. Phys. 2020, 128, 183301. [Google Scholar] [CrossRef]

- Stadlmayr, R.; Szabo, P.S.; Biber, H.; Koslowski, H.R.; Kadletz, E.; Cupak, C.; Wilhelm, R.A.; Schmid, M.; Linsmeier, C.; Aumayr, F. A high temperature dual-mode quartz crystal microbalance technique for erosion and thermal desorption spectroscopy measurements. Rev. Sci. Instrum. 2020, 91, 125104. [Google Scholar] [CrossRef]

- Yamamoto, N.; Yalin, A.P.; Tao, L.; Smith, T.B.; Gallimore, A.D.; Arakawa, Y. Development of Real-Time Boron Nitride Erosion Monitoring System for Hall Thrusters by Cavity Ring-Down Spectroscopy. Trans. Jpn. Soc. Aeronaut. Space Sci. Space Technol. Jpn. 2009, 7, Pb_1–Pb_6. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, N.; Yokota, S.; Matsui, M.; Komurasaki, K.; Arakawa, Y. Measurement of erosion rate by absorption spectroscopy in a Hall thruster. Rev. Sci. Instrum. 2005, 76, 083111. [Google Scholar] [CrossRef]

- Balika, L.; Focsa, C.; Gurlui, S.; Pellerin, S.; Pellerin, N.; Pagnon, D.; Dudeck, M. Laser-induced breakdown spectroscopy in a running Hall Effect Thruster for space propulsion. Spectrochim. Acta Part B At. Spectrosc. 2012, 74-75, 184–189. [Google Scholar] [CrossRef]

- Lee, B.C.; Huang, W.; Tao, L.; Yamamoto, N.; Gallimore, A.D.; Yalin, A.P. A cavity ring-down spectroscopy sensor for real-time Hall thruster erosion measurements. Rev. Sci. Instrum. 2014, 85, 053111. [Google Scholar] [CrossRef]

- Gray, T.G.; Williams, G.J.; Kamhawi, H.; Frieman, J.D. Non-intrusive Characterization of the Wear of the HERMeS Thruster Using Optical Emission Spectroscopy. In Proceedings of the 36th International Electric Propulsion Conference, Vienna, Austria, 15–20 September 2019; pp. 1–15. [Google Scholar]

- Roman, H.E.; Cesura, F.; Maryam, R.; Levchenko, I.; Alexander, K.; Riccardi, C. The fractal geometry of polymeric materials surfaces: Surface area and fractal length scales. Soft Matter 2024, 20, 3082–3096. [Google Scholar] [CrossRef]

- Bazaka, O.; Bazaka, K.; Truong, V.K.; Levchenko, I.; Jacob, M.V.; Estrin, Y.; Lapovok, R.; Chichkov, B.; Fadeeva, E.; Kingshott, P.; et al. Effect of titanium surface topography on plasma deposition of antibacterial polymer coatings. Appl. Surf. Sci. 2020, 521, 146375. [Google Scholar] [CrossRef]

- Levchenko, I.; Bazaka, K.; Belmonte, T.; Keidar, M.; Xu, S. Advanced Materials for Next-Generation Spacecraft. Adv. Mater. 2018, 30, e1802201. [Google Scholar] [CrossRef]

- Huang, W.; Gallimore, A.D.; Smith, T.B.; Yalin, A.P. The Technical Challenges of using Cavity Ring-Down Spectroscopy to Study Hall Thruster Channel Erosion. In Proceedings of the 32nd International Electric Propulsion Conference, Wiesbaden, Germany, 11–15 September 2011; p. 030. [Google Scholar]

- Xi, W.; Zhu, X.-M.; Zheng, B.-W.; Wang, L. Synchronous monitoring of erosion product at different locations in the low-power Hall thruster plume using spectral measurement system. Vacuum 2025, 238, 114300. [Google Scholar] [CrossRef]

- Peterson, P.; Manzella, D.; Jacobson, D. Investigation of the Erosion Characteristics of a Laboratory Hall Thruster. In Proceedings of the 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 20–23 July 2003. [Google Scholar] [CrossRef]

- Misuri, T.; Milani, A.; Andrenucci, M. Development of a Telemicroscopy Diagnostic Apparatus and Erosion Modelling in Hall Effect Thrusters. In Proceedings of the 31st International Electric Propulsion Conference, Ann Arbor, MI, USA, 20–24 September 2009; pp. 1–14. [Google Scholar]

- Hu, Z.; Fan, Z.; Liu, C.; Wu, Y.; Wang, C. Geometrical patterns based cross-scale image registration for AFM and optical microscopy. In Proceedings of the 2019 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Zhenjiang, China, 4–8 August 2019; pp. 276–280. [Google Scholar] [CrossRef]

- Geldmann, C. Fine registration of SEM and AFM images using Monte Carlo simulations. In Proceedings of the 2013 IEEE International Conference on Automation Science and Engineering (CASE), Madison, WI, USA, 17–20 August 2013; pp. 813–818. [Google Scholar] [CrossRef]

- Wortmann, T. Registration of AFM and SEM Scans Using Local Features. Int. J. Optomechatron. 2011, 5, 249–270. [Google Scholar] [CrossRef]

- Wang, Y.; Kilpatrick, J.I.; Jarvis, S.P.; Boland, F.; Kokaram, A.; Corrigan, D. Automated Registration of Low and High Resolution Atomic Force Microscopy Images Using Scale Invariant Features. In Proceedings of the 2014 IEEE International Conference on Image Processing (ICIP), Paris, France, 27–30 October 2014; pp. 5866–5870. [Google Scholar]

- Fan, Y.; Chen, Q.; Kumar, S.A.; Baczewski, A.D.; Tram, N.V.; Ayres, V.M. Registration of tapping and contact mode atomic force microscopy images. In Proceedings of the 2006 6th IEEE Conference on Nanotechnology, Cincinnati, OH, USA, 17–20 July 2006; pp. 193–196. [Google Scholar] [CrossRef]

- Alard, C.; Lupton, R.H. A Method for Optimal Image Subtraction. Astrophys. J. 1998, 503, 325–331. [Google Scholar] [CrossRef]

- Hu, L.; Wang, L.; Chen, X.; Yang, J. Image Subtraction in Fourier Space. Astrophys. J. 2022, 936, 157. [Google Scholar] [CrossRef]

- Khalil, A.; Rahimi, A.; Luthfi, A.; Azizan, M.M.; Satapathy, S.C.; Hasikin, K.; Lai, K.W. Brain Tumour Temporal Monitoring of Interval Change Using Digital Image Subtraction Technique. Front. Public Health 2021, 9, 752509. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Zhang, S.; He, Z.; Guo, Y. The comparative study of three methods of remote sensing image change detection. In Proceedings of the 2009 17th International Conference on Geoinformatics, Fairfax, VA, USA, 12–14 August 2009; pp. 1–4. [Google Scholar] [CrossRef]

- NIST Chemistry WebBook. Available online: https://webbook.nist.gov/cgi/cbook.cgi?ID=C7553562&Mask=4&Type=ANTOINE&Plot=on# (accessed on 24 April 2025).

- Zschätzsch, D.; Benz, S.L.; Holste, K.; Vaupel, M.; Hey, F.G.; Kern, C.; Janek, J.; Klar, P.J. Corrosion of metal parts on satellites by iodine exposure in space. J. Electr. Propuls. 2022, 1, 14. [Google Scholar] [CrossRef]

- NIST. NIST Chemistry WebBook; National Institute of Standards and Testing (NIST): Gaithersburg, MD, USA, 1998. [CrossRef]

- Cho, S.; Yokota, S.; Komurasaki, K.; Arakawa, Y. Multilayer coating method for investigating channel-wall erosion in a hall thruster. J. Propuls. Power 2013, 29, 278–282. [Google Scholar] [CrossRef]

- Herbert, B.; Andreas, E.; Tinne, T.; Luc, V.G. Speeded-up robust features (SURF). Comput. Vis. Image Underst. 2008, 110, 346–359. [Google Scholar] [CrossRef]

- Zitová, B.; Flusser, J. Image registration methods: A survey. Image Vis. Comput. 2003, 21, 977–1000. [Google Scholar] [CrossRef]

- Muja, M.; Lowe, D.G. Fast approximate nearest neighbors with automatic algorithm configuration. In Proceedings of the 4th International Conference on Computer Vision Theory and Applications, Lisboa, Portugal, 5–8 February 2009; Volume 1, pp. 331–340. [Google Scholar] [CrossRef]

- Lowe, D.G. Distinctive image features from scale-invariant keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Leutenegger, S.; Chli, M.; Siegwart, R.Y. BRISK: Binary Robust invariant scalable keypoints. In Proceedings of the 2011 International Conference on Computer Vision, Barcelona, Spain, 6–13 November 2011; pp. 2548–2555. [Google Scholar] [CrossRef]

- Harris, C.; Stephens, M. A Combined Corner and Edge Detector. In Proceedings of the Alvey Vision Conference, Manchester, UK, 31 August–2 September 1988; pp. 23.1–23.6. [Google Scholar] [CrossRef]

- Rosten, E.; Drummond, T. Fusing points and lines for high performance tracking. In Proceedings of the 10th IEEE International Conference on Computer Vision, Beijing, China, 17–20 October 2005; Volume II, pp. 1508–1515. [Google Scholar] [CrossRef]

- Brown, L.G. A survey of image registration techniques. ACM Comput. Surv. 1992, 24, 325–376. [Google Scholar] [CrossRef]

- Sanders, W.C. Atomic Force Microscopy: Fundamental Concepts and Laboratory Investigations; CRC Press: Boca Raton, FL, USA, 2019; Volume 66. [Google Scholar] [CrossRef]

- Chen, S.W.W.; Pellequer, J.L. DeStripe: Frequency-based algorithm for removing stripe noises from AFM images. BMC Struct. Biol. 2011, 11, 7. [Google Scholar] [CrossRef]

- Nečas, D.; Klapetek, P. Gwyddion: An open-source software for SPM data analysis. Open Phys. 2012, 10, 181–188. [Google Scholar] [CrossRef]

- ThrustMe. Available online: https://www.thrustme.fr/iodine-propellant (accessed on 11 June 2025).

- Burden, F.; Winkler, D. Bayesian Regularization of Neural Networks. Methods Mol. Biol. 2008, 458, 23–42. [Google Scholar] [CrossRef]

- Moré, J.J. The Levenberg-Marquardt algorithm: Implementation and theory. In Numerical Analysis; Springer: Berlin/Heidelberg, Germany, 1978; pp. 105–116. [Google Scholar]

- Foresee, F.D.; Hagan, M.T. Gauss-Newton approximation to Bayesian learning. In Proceedings of the International Conference on Neural Networks (ICNN’97), Houston, TX, USA, 12 June 1997. [Google Scholar]

- Rogers, J.D.; Branam, R.D. Molybdenum erosion in iodine plasma at hollow cathode conditions. J. Vac. Sci. Technol. A 2024, 42, 023005. [Google Scholar] [CrossRef]

- Sanner, A.; Nöhring, W.G.; Thimons, L.A.; Jacobs, T.D.; Pastewka, L. Scale-dependent roughness parameters for topography analysis. Appl. Surf. Sci. Adv. 2022, 7, 100190. [Google Scholar] [CrossRef]

- Tian, Z.; Duan, X.; Yang, Z.; Ye, S.; Jia, D.; Zhou, Y. Microstructure and erosion resistance of in-situ SiAlON reinforced BN-SiO2 composite ceramics. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 315–320. [Google Scholar] [CrossRef]

| Durations | Space Conditions | Simulated Conditions | ||

|---|---|---|---|---|

| Iodine Partial Pressure (Pa) | Δt (Months) | Iodine Partial Pressure (Pa) | Δt (Mins) | |

| D1 | 0.1 | 12 | 2177 | 24 |

| D2 | 0.1 | 24 | 2177 | 48 |

| D3 | 0.1 | 36 | 2177 | 72 |

| D4 | 0.1 | 42 | 2177 | 84 |

| D1 | 0.1 | 12 | 2177 | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afifi, A.S.; Weerasinghe, J.; Prasad, K.; Levchenko, I.; Alexander, K. Efficient Image Processing Technique for Detecting Spatio-Temporal Erosion in Boron Nitride Exposed to Iodine Plasma. Nanomaterials 2025, 15, 961. https://doi.org/10.3390/nano15130961

Afifi AS, Weerasinghe J, Prasad K, Levchenko I, Alexander K. Efficient Image Processing Technique for Detecting Spatio-Temporal Erosion in Boron Nitride Exposed to Iodine Plasma. Nanomaterials. 2025; 15(13):961. https://doi.org/10.3390/nano15130961

Chicago/Turabian StyleAfifi, Ahmed S., Janith Weerasinghe, Karthika Prasad, Igor Levchenko, and Katia Alexander. 2025. "Efficient Image Processing Technique for Detecting Spatio-Temporal Erosion in Boron Nitride Exposed to Iodine Plasma" Nanomaterials 15, no. 13: 961. https://doi.org/10.3390/nano15130961

APA StyleAfifi, A. S., Weerasinghe, J., Prasad, K., Levchenko, I., & Alexander, K. (2025). Efficient Image Processing Technique for Detecting Spatio-Temporal Erosion in Boron Nitride Exposed to Iodine Plasma. Nanomaterials, 15(13), 961. https://doi.org/10.3390/nano15130961