Abstract

The GaN-based green miniaturized light-emitting diode (mini-LED) is a key component for the realization of full-color display. Optimized passivation layers can alleviate the trapping of carriers by sidewall defects and are regarded as an effective way to improve the external quantum efficiency (EQE) efficiency of mini-LEDs. Since AlN has a closer lattice match to GaN compared to other heterogeneous passivation materials, we boosted the EQE of GaN-based green flip-chip mini-LEDs through the deposition of a lattice-compatible AlN passivation layer through atomic layer deposition (ALD) and a SiO2 passivation layer through plasma-enhanced chemical vapor deposition (PECVD). Benefiting from reduced sidewall nonradiative recombination, the EQE of the green flip-chip mini-LED with a composite ALD-AlN/PECVD-SiO2 passivation layer reached 34.14% at 5 mA, which is 34.6% higher than that of the green flip-chip mini-LED with a single PECVD-SiO2 passivation layer. The results provide guidance for the realization of high-performance mini-LEDs by selecting lattice-compatible passivation layers.

1. Introduction

GaN-based LEDs have attracted considerable attention due to their advantages, including high luminous efficiency, low energy consumption, and long operation lifetime [1,2,3,4,5]. However, due to mismatches in lattice constants and thermal expansion coefficients between GaN and sapphire substrate, there is a large number of threading dislocations in the epitaxial layer of GaN-based LEDs, leading to a decrease in emission efficiency [6]. Another major challenge contributing to efficiency degradation is related to Shockley–Read–Hall (SRH) recombination, which is caused by plasma-induced etching damage. According to previous studies, crystallographic defects, impurities, and dangling bonds were observed on the etched surface, which build trap states within the bandgap and thus act as SRH nonradiative recombination centers, leading to efficiency droop [7,8]. A range of techniques have been used to reduce etching damage, such as thermal annealing, chemical etching, H2 plasma treatment, and sidewall passivation layers [9,10,11,12,13,14]. Among the various techniques, sidewall passivation using dielectric materials is arguably the most promising for achieving high-performance mini-LEDs.

A sidewall passivation layer is generally grown by PECVD, which uses hydrogen-containing precursors and provides rapid deposition rates [15]. However, a passivation layer grown by PECVD is unable to completely cover the surface of the mini/micro-LED due to its poor step coverage ability. ALD uses self-limiting interactions between the precursor gas and the substrate surface, and thin films are deposited layer-by-layer through alternately introducing precursor gas [16,17]. Therefore, the growth thickness can be precisely controlled by ALD, which is more effective at depositing dense dielectric films compared to PECVD [18,19]. Heterogeneous materials including SiO2, Al2O3, and HfO2 have been adopted in previously reported passivation schemes. Deng et al. investigated the optical and electrical characteristics of green micro-LEDs with ALD-SiO2 passivation layers of different thicknesses [20]. Wong et al. used ALD to deposit 50 nm thick SiO2 as the passivation layer, achieving micro-LEDs with uniform light emission and low leakage current [21]. Lee et al. investigated the effect of ALD-Al2O3 (50 nm)/PECVD-SiO2 (250 nm) and PECVD-SiO2 (300 nm) passivation layers on the leakage current and EQE of GaN-based micro-LEDs [22]. Prechatavanich et al. analyzed the impact of SiO2, Al2O3, and HfO2 passivation layers on AlGaInP-based red micro-LEDs [23]. However, from the perspective of crystallography, it is more appropriate to use homogeneous materials or lattice-compatible materials as the passivation layer. A homogeneous GaN passivation layer is theoretically the superior candidate for GaN-based LEDs [24]. However, the low electrical resistivity of intrinsic GaN make it unsuitable as a passivation material in practice. Compared to other heterogeneous passivation layer materials (SiO2, Al2O3, HfO2), AlN has a closer lattice match to GaN [25], rendering it a potential passivation layer for GaN-based mini/micro-LEDs.

In this work, we fabricated GaN-based green flip-chip mini-LEDs with different types of passivation layers (PECVD-SiO2, ALD-SiO2/PECVD-SiO2, ALD-AlN/PECVD-SiO2) and investigated the impact of deposition methods and passivation materials on the optical and electrical properties of green flip-chip mini-LEDs. By comparing the far-field angular emission pattern and near-field light-emitting intensity distributions of green flip-chip mini-LEDs with different passivation layers, we demonstrate the influence of the film quality and refractive index of the passivation materials on the light extraction efficiency (LEE) of green flip-chip mini-LEDs. Benefiting from reduced sidewall nonradiative recombination, the EQE of the green flip-chip mini-LED with a composite ALD-AlN/PECVD-SiO2 passivation layer was increased by 34.6% compared to that of the green flip-chip mini-LED with a single PECVD-SiO2 passivation layer.

2. Experimental

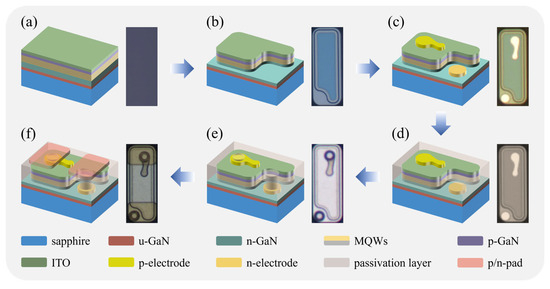

GaN-based LEDs were grown on a c-plane patterned sapphire substrate (PSS) by using a metal–organic chemical vapor deposition (MOCVD) system. Trimethylaluminum (TMAl), trimethylindium (TMIn), trimethylgallium (TMGa)/triethylgallium (TEGa), and ammonia (NH3) were used as Al, In, Ga, and N sources, respectively. Silane (SiH4) and bis (cyclopentadienyl) magnesium (CP2Mg) were used for n- and p-type doping, respectively. The LED epitaxial structure consisted of a 20 nm thick sputtered AlN nucleation layer, a 3.5 µm thick undoped GaN buffer layer (temperature = 1125 °C, pressure = 150 Torr, NH3 = 65,000 sccm, TMGa = 950 sccm), a 2 µm thick Si-doped n-GaN (temperature = 1100 °C, pressure = 150 Torr, TMGa = 650 sccm, NH3 = 45,000 sccm, Si-doping = 1.76 × 1019 cm−3), 9-period In0.24Ga0.76N (2.3 nm)/GaN (12 nm) multiple quantum wells (InGaN quantum well: temperature = 720 °C, pressure = 200 Torr, TEGa = 391 sccm, TMIn = 300 sccm, NH3 = 67,000 sccm; GaN barrier: temperature = 870 °C, pressure = 200 Torr, TEGa = 332 sccm, NH3 = 67,000 sccm), a 20 nm thick p-Al0.2Ga0.8N electron blocking layer (temperature = 955 °C, pressure = 100 Torr, TMGa = 605 sccm, TMAl = 444 sccm, NH3 = 60,000 sccm, Mg-doping = 6.57 × 1020 cm−3), and a 110 nm thick Mg-doped p-GaN layer (temperature = 965 °C, pressure = 200 Torr, TMGa = 605 sccm, NH3 = 60,000 sccm, Mg-doping = 2.89 × 1020 cm−3). For the fabrication of mini-LEDs, a 110 nm thick indium–tin oxide (ITO) layer was deposited on top of p-GaN via electron beam evaporation, followed by thermal annealing in O2 ambience at 550 °C for 20 min [Figure 1a]. The inductively coupled plasma (ICP) etching based on BCl3/Cl2 mixture gas was used to expose the n-GaN layer and define the mesa [Figure 1b]. Then, Cr/Al/Ti/Pt/Au metallization stacks were deposited on the ITO and exposed n-GaN layer [Figure 1c]. Next, an 800 nm thick SiO2 layer was deposited using PECVD, and Ti3O5 (54.8 nm)/SiO2 (89.1 nm) distributed Bragg reflector (DBR) stacks were sputtered on the SiO2 layer by electron beam evaporation [Figure 1d]. Afterwards, n- and p-electrode holes were formed by using ICP etching based on CHF3/Ar/O2 mixture gas [Figure 1e]. Cr/Al/Ti/Pt/Ti/Pt/Au metal stacks were then deposited as the n- and p-contact pads [Figure 1e]. Finally, LED wafers were diced into chips with dimensions of 165 µm × 70 µm. The current–voltage (I–V) curves and light output power (LOP) of the mini-LEDs were measured by a Everfine ATA-500 automatic temperature-controlled photoelectric analyzing system. The cross-sectional transmission electron microscopy (TEM) images were taken using FEI Talos F200X at 5 kV.

Figure 1.

Fabrication steps of the GaN-based green flip-chip mini-LEDs with top-view micro-graphs of the mini-LEDs for each step: (a) epilayers of the green flip-chip mini-LEDs; (b) defining the mesa structure; (c) evaporation of the n-electrode and p-electrode; (d) deposition of the SiO2 passivation layer and evaporation of DBR; (e) formation of the n-electrode and p-electrode holes; (f) evaporation of the n-contact and p-contact pads.

For brevity, sample A is used to denote the green flip-chip mini-LED with a 920 nm thick PECVD-SiO2 passivation layer. Sample B is used to denote the green flip-chip mini-LED with a 120 nm thick ALD-SiO2 passivation layer and an 800 nm-thick PECVD-SiO2 passivation layer. Sample C is used to denote the green flip-chip mini-LED with a 120 nm thick ALD-AlN passivation layer and an 800 nm thick PECVD-SiO2 passivation layer.

3. Results and Discussion

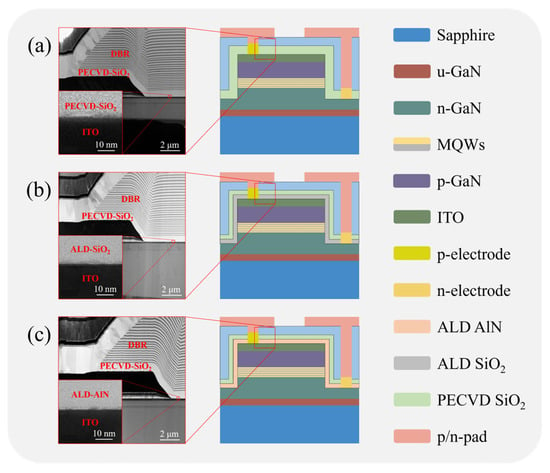

We compared the effects of three types of passivation layers on the optical and electrical performances of the green flip-chip mini-LEDs. Figure 2a–c show schematic illustration and cross-sectional TEM images of sample A, sample B, and sample C, respectively. Since it is difficult for electrons to penetrate the metal atoms in ITO, the ITO layer appears as a dark color in the TEM image. In Figure 2a, we can clearly observe a 920 nm thick PECVD-SiO2 passivation layer deposited on the top of the ITO layer. The ALD-SiO2 and ALD-AlN passivation layers deposited on the top of ITO can be clearly seen in Figure 2b,c. Adjacent to the ALD-SiO2 and ALD-AlN passivation layers, an 800 nm thick PECVD-SiO2 passivation layer can be obviously seen, as shown in Figure 2b,c. The Ti3O5/SiO2 DBR deposited on top of the PECVD-SiO2 passivation layer has a high reflectivity of up to 98.52% in the green wavelength, which can enhance the LEE of the green flip-chip mini-LEDs.

Figure 2.

Schematics and cross-sectional TEM images of green flip-chip mini-LEDs with different passivation layers. (a) Sample A with single PECVD-SiO2 passivation layer; (b) sample B with a composite ALD-SiO2/PECVD-SiO2 passivation layer; (c) sample C with a composite ALD-AlN/PECVD-SiO2 passivation layer.

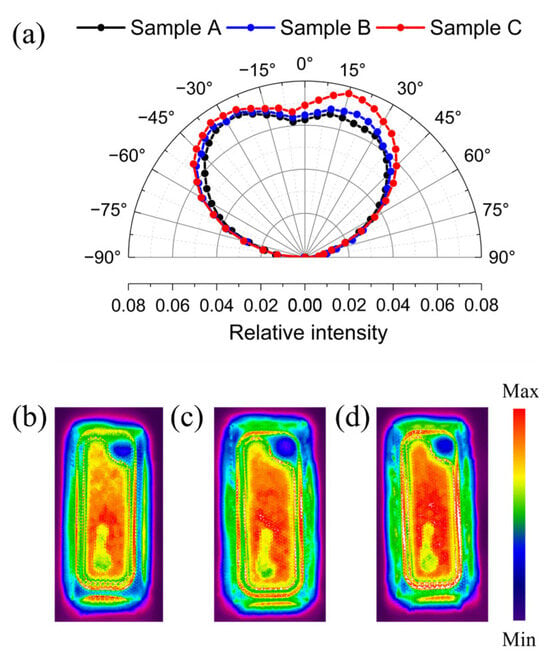

Figure 3a shows the far-field angular emission pattern of sample A, sample B, and sample C at an injection current of 5 mA. We find that sample B possess a higher emission intensity in comparison with sample A. This result reveals that the passivation effect of ALD-SiO2 on the sidewall is more effective in weakening the probability of carriers being captured by defect levels compared to PECVD-SiO2, thereby significantly reducing SRH nonradiative recombination and improving emission intensity [26]. Furthermore, it is found that the emission intensity of sample C is significantly improved in the side direction as compared to sample A and sample B. This result indicates that the lattice-compatible AlN passivation layer can more effectively enhance the LEE of the mini-LED compared to the SiO2 passivation layer. To further investigate the effects of the three types of passivation layers on the uniformity of the current distribution across InGaN/GaN multiple quantum wells’ (MQWs) active regions, we measured the near-field light-emitting intensity distributions of sample A, sample B, and sample C at 5 mA, as shown in Figure 3b–d. We can observe that sample C shows better uniformity and higher light-emitting intensity compared to sample A and sample B. The related mechanisms can be described as follows.

Figure 3.

(a) Far-field emission pattern of sample A, sample B, and sample C at 5 mA. Near-field light-emitting intensity distributions of (b) sample A, (c) sample B, and (d) sample C at 5 mA.

By neglecting the effects of multiple reflections between the dielectric layers, we can calculate the transmittance of the single SiO2 passivation layer and the composite AlN/SiO2 passivation layer using the following formula when light exits vertically from the inside of the chip [27]:

where T represents the transmittance, j = 2 corresponds to the single passivation layer case (SiO2), and j = 3 corresponds to the composite passivation layer case (AlN/SiO2). The refractive indices ni of GaN, AlN, SiO2, and air are 2.46, 2.16, 1.45, and 1.00, respectively. From Equation (1), the Fresnel power transmission can be calculated to be 90.2% for the single SiO2 passivation layer and 92.5% for the composite AlN/SiO2 passivation layer. Benefiting from higher transmittance, sample C with the composite ALD-AlN/PECVD-SiO2 passivation layer has a higher LEE compared to sample A and sample B, which is consistent with the conclusion obtained from Figure 3.

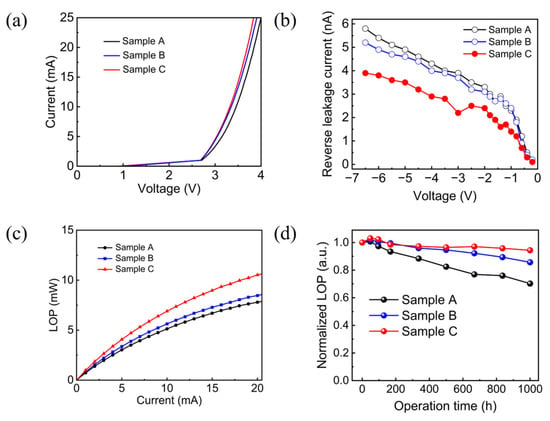

Figure 4a,b show the measured forward and reverse I–V characteristics of sample A, sample B, and sample C. At 5 mA, the forward voltages of sample A, sample B, and sample C are 3.15 V, 3.04 V and 3.03 V, respectively. Under the same injection current level, the forward voltage of the sample C is slightly lower than those of sample B and sample A. At a negative bias of −5 V, the reverse leakage currents of sample A, sample B, and sample C are 4.9 nA, 4.6 nA and 3.5 nA, respectively, as seen in Figure 4b. The leakage current of sample B is lower than that of sample A, revealing that the ALD-SiO2 passivation layer can effectively suppress the leakage current generated by surface defects compared to the PECVD-SiO2 passivation layer. This is attributable to the fact that ALD employs metal–organic precursors that are capable of ensuring optimal dielectric quality and yields precise thickness control at the atomic level. Figure 4c shows the LOP versus current characteristics of sample A, sample B, and sample C. Under a 5 mA injection current, the LOP values of sample A, sample B, and sample C are 3.03 mW, 3.37 mW, and 4.07 mW, respectively. The relationship between EQE and the LOP value can be calculated using the following formula:

where P represents the LOP value, e is the elementary charge, I is the injection current, h is the Planck constant, v is the photon frequency. From Equation (2), the EQE values of sample A, sample B, and sample C are 25.4%, 28.26%, and 34.14% respectively. Compared to sample A, the EQE of sample B and sample C increased by 7.7% and 34.6%, respectively. This is consistent with the results of the comparison of the near-field light-emitting intensity distributions in Figure 3b,d. Moreover, we investigated the optical degradation of the flip-chip mini-LEDs at a temperature of 85 °C and humidity of 85%, using an injection current of 5 mA. The intervals were fixed at 48h, 96h, 168h, 336h, 500h, 668h, 836h, and 1000h. As shown in Figure 4d, the LOPs of the flip-chip mini-LEDs increase during the initial aging stage, owing to the positive factors of Mg dopant activation and the annealing effect [2]. After 1000 h of aging, the LOPs of sample A and sample B showed degradations of 29.75% and 14.33%, respectively. Conversely, sample C exhibited an exceptional stability in optical performance. This improvement in stability allowed sample C with an ALD-AlN passivation layer to maintain 94.39% of its initial LOP after 1000 h of aging testing. The results indicate that the green flip-chip mini-LED with a lattice-compatible ALD-AlN passivation layer exhibits markedly smaller optical degradation and thus higher device reliability under harsh conditions.

Figure 4.

(a) I-V characteristics; (b) reverse I–V characteristics; (c) L–I characteristics, and (d) normalized LOP degradation after prolonged high-temperature and high-humidity aging test of sample A, sample B, and sample C.

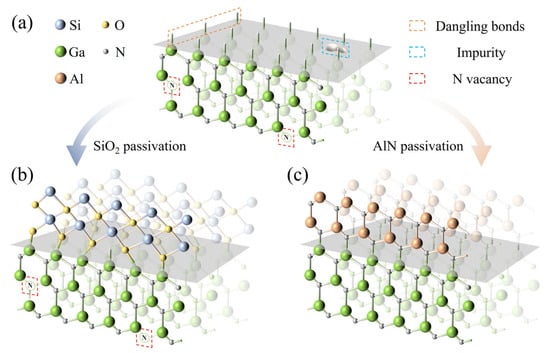

To interpret the difference between the SiO2 and AlN passivation layers in reducing the surface state density, atomic structure models of the sidewall surface before and after passivation are shown in Figure 5. After ICP etching, the exposed GaN sidewalls generated a large number of dangling bonds, impurity contaminations, and lattice defects [28,29,30], as shown in Figure 5a. These plasma damages increased the density of surface states, leading to increased SRH recombination rates and severe leakage current [31]. In addition, hybrid density-functional theory (DFT) calculations have demonstrated that N vacancies are the main lattice defects on the sidewalls of GaN-based LEDs and act as a midgap position for the SRH recombination [32]. Using SiO2 for sidewall passivation can remove impurity contaminations and saturate partially dangling bonds. However, the lattice mismatch between SiO2 and GaN introduces internal stress, and the SiO2 passivation layer cannot effectively eliminate surface N vacancies, as shown in Figure 5a. Instead, using AlN for sidewall passivation may be an effective way of eliminating nitrogen vacancies by acting as a nitrogen source [33]. Meanwhile, a lattice-compatible AlN passivation layer can significantly reduce the number of dangling bonds, thereby reducing leakage current and enhancing the stability of green flip-chip mini-LEDs, as shown in Figure 5c.

Figure 5.

Atomic structure models of the sidewall surface (a) before passivation, (b) after SiO2 passivation, and (c) after AlN passivation.

4. Conclusions

In summary, we have demonstrated that the green flip-chip mini-LED with a composite ALD-AlN/PECVD-SiO2 passivation layer had a higher light-emitting intensity and lower leakage current compared to the green flip-chip mini-LED with a single PECVD-SiO2 passivation layer. Benefiting from reduced sidewall nonradiative recombination, the EQE of the green flip-chip mini-LED with a composite ALD-AlN/PECVD-SiO2 passivation layer reached 34.14% at 5 mA, which is 34.6% higher than that of the green flip-chip mini-LED with a single PECVD-SiO2 passivation layer. In addition, burn-in tests show the significantly lower optical degradation and thus higher device reliability of the green flip-chip mini-LED with a composite ALD-AlN/PECVD-SiO2 passivation layer.

Author Contributions

Conceptualization, S.Z.; data curation, J.S., L.S., and S.C.; writing—original draft preparation, J.S.; writing—review and editing, S.Z., J.S., and L.M.; validation, S.Z., L.S., and Q.Z.; software, J.S. and Q.Z.; visualization, J.S., S.C., L.M., and J.J.; supervision, J.J., C.J., J.H., K.W., and S.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Wuhan Joint Innovation Laboratory of Advanced Display Industry (Grant 2024010902040449), the Science and Technology Major Project of Hubei Province (2024BAA004), the Science and Technology Major Project of Wuhan (2024010702020024), the Key Research and Development Program of Hubei Province (2023BAB137), the National Key R&D Program of China (Grant Nos. 2022YFB3603603 and 2021YFB3600204), the National Natural Science Foundation of China (Grant Nos. 52475601 and 52075394), the Knowledge Innovation Program of Wuhan-Basic Research, the National Youth Talent Support Program, and the Fundamental Research Funds for the Central Universities.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Author Jingjing Jiang and Shengjun Zhou were employed by the company Wuhan JingWei Technology Co., Ltd. Author Conglong Jin, Jiahui Hu and Kuosheng Wen were employed by the company Jiangxi SMTC Semiconductor Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yang, G.; Chang, J.; Zhao, J.; Tong, Y.; Xie, F.; Wang, J.; Zhang, Q.; Huang, H.; Yan, D. Investigation of light output performance for gallium nitride-based light-emitting diodes grown on different shapes of patterned sapphire substrate. Mater. Sci. Semicond. Process. 2015, 33, 149–153. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Yan, H.; Chen, Z.; Liu, Y.; Liu, S. Highly efficient GaN-based high-power flip-chip light-emitting diodes. Opt. Express 2019, 27, A669–A692. [Google Scholar] [CrossRef]

- Guo, W.; Chen, N.; Lu, H.; Su, C.; Lin, Y.; Chen, G.; Lu, Y.; Zheng, L.; Peng, Z.; Kuo, H.C. The Impact of Luminous Properties of Red, Green, and Blue Mini-LEDs on the Color Gamut. IEEE Trans. Electron. Devices 2019, 66, 2263–2268. [Google Scholar] [CrossRef]

- Fan, B.; Zhao, X.; Zhang, J.; Sun, Y.; Yang, H.; Guo, L.J.; Zhou, S. Monolithically Integrating Ⅲ-Nitride Quantum Structure for Full-Spectrum White LED via Bandgap Engineering Heteroepitaxial Growth. Laser Photonics Rev. 2023, 17, 2200455. [Google Scholar] [CrossRef]

- Shi, L.; Cui, S.; Zhang, Z.; Jiang, J.; Sun, Y.; Liu, S.; Zhou, S. Toward Wide-Angle Ⅲ-Nitride Miniaturized LEDs: Device Engineering and Photon Extraction Strategy. Laser Photonics Rev. 2025, 2401723. [Google Scholar] [CrossRef]

- Touré, A.; Halidou, I.; Benzarti, Z.; Fouzri, A.; Bchetnia, A.; El Jani, B. Characterization of low Al content AlXGa1-XN epitaxial films grown by atmospheric-pressure MOVPE. Phys. Status Solidi A 2012, 209, 977–983. [Google Scholar] [CrossRef]

- Olivier, F.; Daami, A.; Licitra, C.; Templier, F. Shockley-Read-Hall and Auger non-radiative recombination in GaN based LEDs: A size effect study. Appl. Phys. Lett. 2017, 111, 022104. [Google Scholar] [CrossRef]

- Ley, R.T.; Smith, J.M.; Wong, M.S.; Margalith, T.; Nakamura, S.; DenBaars, S.P.; Gordon, M.J. Revealing the importance of light extraction efficiency in InGaN/GaN microLEDs via chemical treatment and dielectric passivation. Appl. Phys. Lett. 2020, 116, 251104. [Google Scholar] [CrossRef]

- Dingemans, G.; Van de Sanden, M.C.M.; Kessels, W.M.M. Influence of the Deposition Temperature on the c-Si surface Passivation by Al2O3 Films Synthesized by ALD and PECVD. Electrochem. Solid-State Lett. 2009, 13, H76. [Google Scholar] [CrossRef]

- Cha, H.; Chang, H.S. Passivation performance improvement of ultrathin ALD-Al2O3 film by chemical oxidation. Vacuum 2018, 149, 180–184. [Google Scholar] [CrossRef]

- Tian, P.; McKendry, J.J.D.; Gong, Z.; Guilhabert, B.; Watson, I.M.; Gu, E.; Chen, Z.; Zhang, G.; Dawson, M.D. Size-dependent efficiency and efficiency droop of blue InGaN micro-light emitting diodes. Appl. Phys. Lett. 2012, 101, 231110. [Google Scholar] [CrossRef]

- Park, J.H.; Pristovsek, M.; Cai, W.; Cheong, H.; Tanaka, A.; Furusawa, Y.; Han, D.P.; Seong, T.Y.; Amano, H. Impact of Sidewall Conditions on Internal QuantumEfficiency and Light Extraction Efficiency of Micro-LEDs. Adv. Opt. Mater. 2023, 11, 2303128. [Google Scholar]

- Hang, S.; Zhang, M.; Zhang, Y.; Chu, C.; Zhang, Y.; Zheng, Q.; Li, Q.; Zhang, Z.H. Artificially formed resistive ITO/p-GaN junction to suppress the current spreading and decrease the surface recombination for GaN-based micro-light emitting diodes. Opt. Express 2021, 29, 31201–31211. [Google Scholar] [CrossRef]

- Zhuang, Z.; Iida, D.; Velazquez-Rizo, M.; Ohkawa, K. Ultra-small InGaN green micro-light-emitting diodes fabricated by selective passivation of p-GaN. Opt. Lett. 2021, 46, 5092–5095. [Google Scholar] [CrossRef]

- Hsu, Y.H.; Lin, X.D.; Lin, Y.H.; Wuu, D.S.; Horng, R.H. Performance comparison of flip-chip blue-light microLEDs with various passivation. Discov. Nano 2024, 19, 129. [Google Scholar] [CrossRef]

- Wong, M.S.; Lee, C.; Myers, D.J.; Hwang, D.; Kearns, J.A.; Li, T.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. Size-independent peak efficiency of Ⅲ-nitride micro-light-emitting-diodes using chemical treatment and sidewall passivation. Appl. Phys. Express 2019, 12, 097004. [Google Scholar] [CrossRef]

- Lai, S.; Lin, W.; Chen, J.; Lu, T.; Liu, S.; Lin, Y.; Lu, Y.; Lin, Y.; Chen, Z.; Kuo, H.C.; et al. The impacts of sidewall passivation via atomic layer deposition on GaN-based flip-chip blue mini-LEDs. J. Phys. D Appl. Phys. 2022, 55, 374001. [Google Scholar] [CrossRef]

- Yeh, Y.W.; Lin, S.H.; Hsu, T.C.; Lai, S.; Lee, P.T.; Lien, S.Y.; Wuu, D.S.; Li, G.; Chen, Z.; Wu, T.; et al. Advanced Atomic Layer Deposition Technologies for Micro-LEDs and VCSELs. Nanoscale Res. Lett. 2021, 16, 164. [Google Scholar] [CrossRef]

- Huang Chen, S.W.; Shen, C.C.; Wu, T.; Liao, Z.Y.; Chen, L.F.; Zhou, J.R.; Lee, C.F.; Lin, C.H.; Lin, C.C.; Sher, C.W.; et al. Full-color monolithic hybrid quantum dot nanoring micro light-emitting diodes with improved efficiency using atomic layer deposition and nonradiative resonant energy transfer. Photonics Res. 2019, 7, 416–422. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, J.; Li, S.; Huang, H.; Liu, Z.; Yan, Z.; Lai, S.; Zheng, L.; Yang, T.; Chen, Z.; et al. The impacts of SiO2 atomic-layer-deposited passivation layer thickness on GaN-based green micro-LEDs. Semicond. Sci. Technol. 2024, 39, 045004. [Google Scholar] [CrossRef]

- Wong, M.S.; Hwang, D.; Alhassan, A.I.; Lee, C.; Ley, R.; Nakamura, S.; DenBaars, S.P. High efficiency of Ⅲ-nitride micro-light-emitting diodes by sidewall passivation using atomic layer deposition. Opt. Express 2018, 26, 21324–21331. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.H.; Lee, J.H.; Park, J.S.; Seong, T.Y.; Amano, H. Improving the Leakage Characteristics and Efficiency of GaN-based Micro-Light-Emitting Diode with Optimized Passivation. ECS J. Solid State Sci. Technol. 2020, 9, 055001. [Google Scholar] [CrossRef]

- Prechatavanich, N.; Wu, M.J.; Yee, C.K.; Sutheebanjerd, T.; Tseng, Y.T.; Yang, Y.C.; Lee, C.A.; Lin, K.H.; Wu, C.H. Sidewall defect suppression of 620 nm AlGaInP-based red µLED devices using HfO2 ALD passivation. Opt. Lett. 2025, 50, 313–316. [Google Scholar] [CrossRef]

- Chen, D.; Wang, Z.; Hu, F.C.; Shen, C.; Chi, N.; Liu, W.; Zhang, D.V.; Lu, H.L. Improved electro-optical and photoelectric performance of GaN-based micro-LEDs with an atomic layer deposited AlN passivation layer. Opt. Express 2021, 29, 36559–36566. [Google Scholar] [CrossRef]

- Zhou, S.; Liao, Z.; Sun, K.; Zhang, Z.; Qian, Y.; Liu, P.; Du, P.; Jiang, J.; Lv, Z.; Qi, S. High-Power AlGaN-Based Ultrathin Tunneling Junction Deep Ultraviolet Light-Emitting Diodes. Laser Photonics Rev. 2023, 18, 2300464. [Google Scholar] [CrossRef]

- Lee, T.Y.; Huang, Y.M.; Chiang, H.; Chao, C.L.; Hung, C.Y.; Kuo, W.H.; Fang, Y.H.; Chu, M.T.; Wu, C.I.; Lin, C.C.; et al. Increase in the efficiency of Ⅲ-nitride micro LEDs by atomic layer deposition. Opt. Express 2022, 30, 18552–18561. [Google Scholar] [CrossRef]

- Deng, Y.; Li, D.; Dai, Y.; Lin, Z.; Lin, Y.; Liu, Z.; Chen, X.; Kuo, H.C.; Chen, Z.; Lai, S.; et al. Competitive mechanism between light extraction efficiency and sidewall passivated effect in the green micro-LEDs with varied thickness of Al2O3 layer. Nanotechnology 2025, 36, 155201. [Google Scholar] [CrossRef]

- Liu, Z.; Cao, H.; Tang, X.; Liu, T.; Lu, Y.; Jiang, Z.; Xiao, N.; Li, X. Advanced technologies in InGaN micro-LED fabrication to mitigate the sidewall effect. Light: Sci. Appl. 2025, 14, 64. [Google Scholar] [CrossRef]

- Son, K.R.; Murugadoss, V.; Kim, K.H.; Kim, T.G. Investigation of sidewall passivation mechanism of InGaN-based blue microscale light-emitting diodes. Appl. Surf. Sci. 2022, 584, 152612. [Google Scholar] [CrossRef]

- Zhu, J.; Takahashi, T.; Ohori, D.; Endo, K.; Samukawa, S.; Shimizu, M.; Wang, X.L. Near-Complete Elimination of Size-Dependent Efficiency Decrease in GaN Micro-Light-Emitting Diodes. Phys. Status Solidi A 2019, 216, 1900380. [Google Scholar] [CrossRef]

- Yan, J.; Lu, W.; Li, J.; Huang, K.; Kang, J.; Zhang, R. Enhancing the Performance of Micro LEDs via Lightweight Atomic Charge-Matching Passivation. Adv. Opt. Mater. 2025, 2500796. [Google Scholar] [CrossRef]

- Kim, P.H.; Jeon, S.H.; Jang, J.H.; Han, S.; Kang, Y. Impact of Ga and N Vacancies at the GaN m-Plane on the Carrier Dynamics of Micro-Light-Emitting Diodes. Phys. Rev. Appl. 2023, 19, 014018. [Google Scholar] [CrossRef]

- Cao, D.; Cheng, X.; Xie, Y.H.; Zheng, L.; Wang, Z.; Yu, X.; Wang, J.; Shen, D.; Yu, Y. Effects of rapid thermal annealing on the properties of AlN films deposited by PEALD on AlGaN/GaN heterostructures. RSC Adv. 2015, 5, 37881–37886. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).