The Effect of Infiltration Temperature on the Microstructure and Magnetic Levitation Force of Single-Domain YBa2Cu3O7-x Bulk Superconductors Grown by a Modified Y+011 IG Method

Abstract

1. Introduction

2. Experimental Sections

2.1. Preparation of Precursor Powders

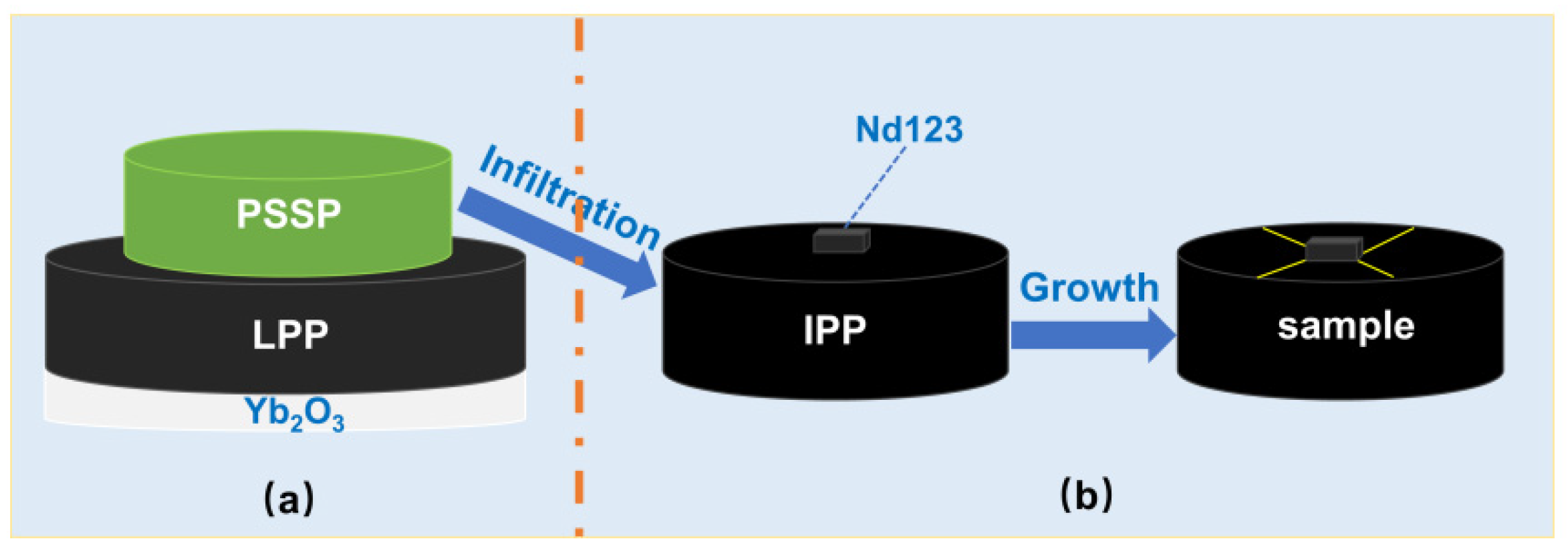

2.2. Fabrication of S-D Y-123 Bulks

2.3. Measurements

3. Results and Discussion

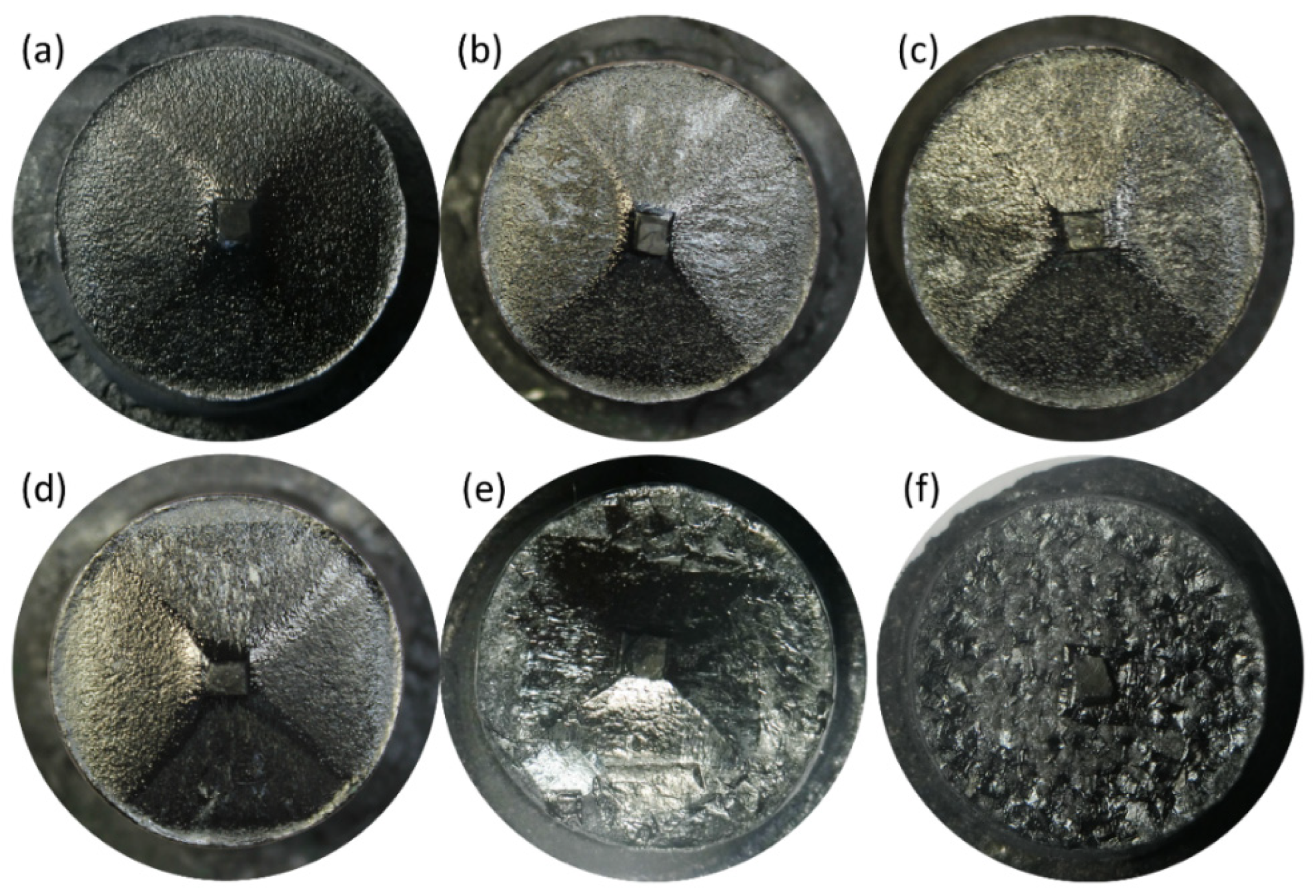

3.1. Surface Morphology of the IP Pellet

3.2. Surface Morphology of the S-D Y-123

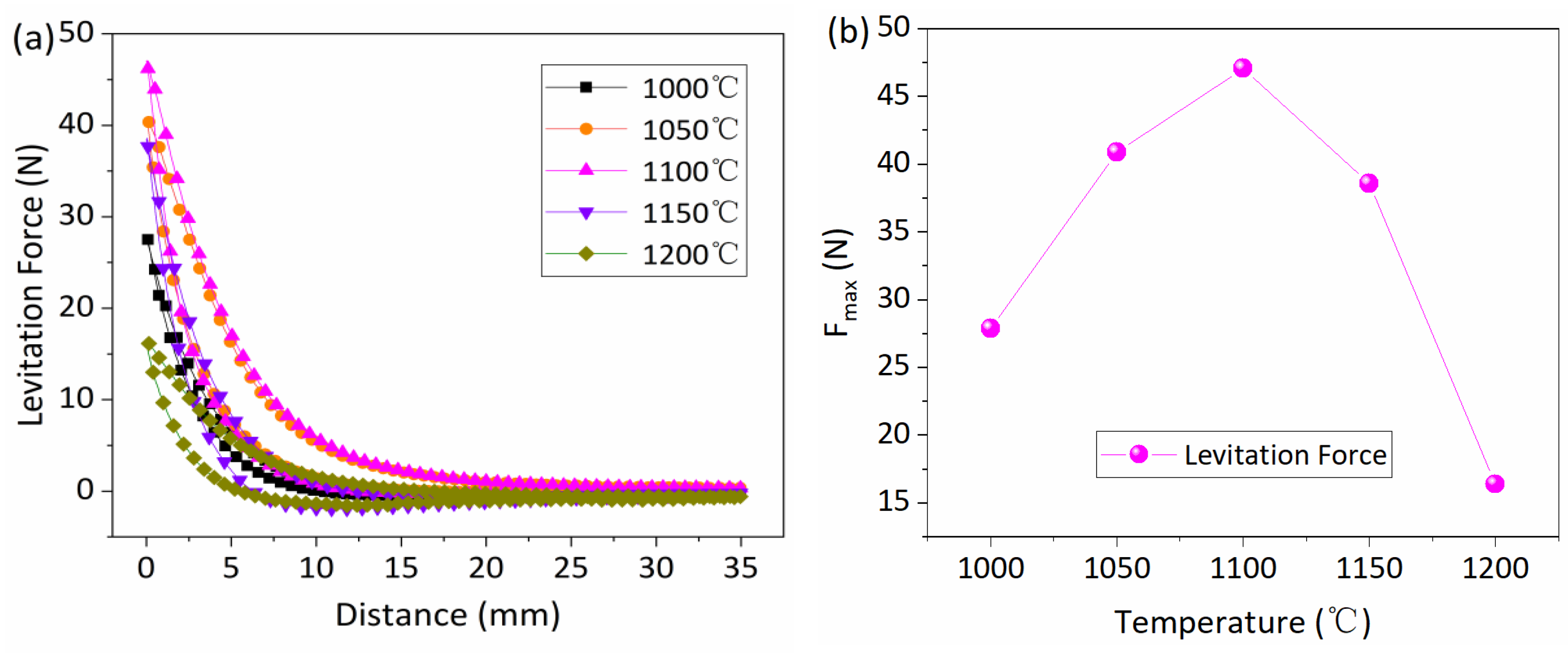

3.3. Levitation Force

3.4. Microstructure

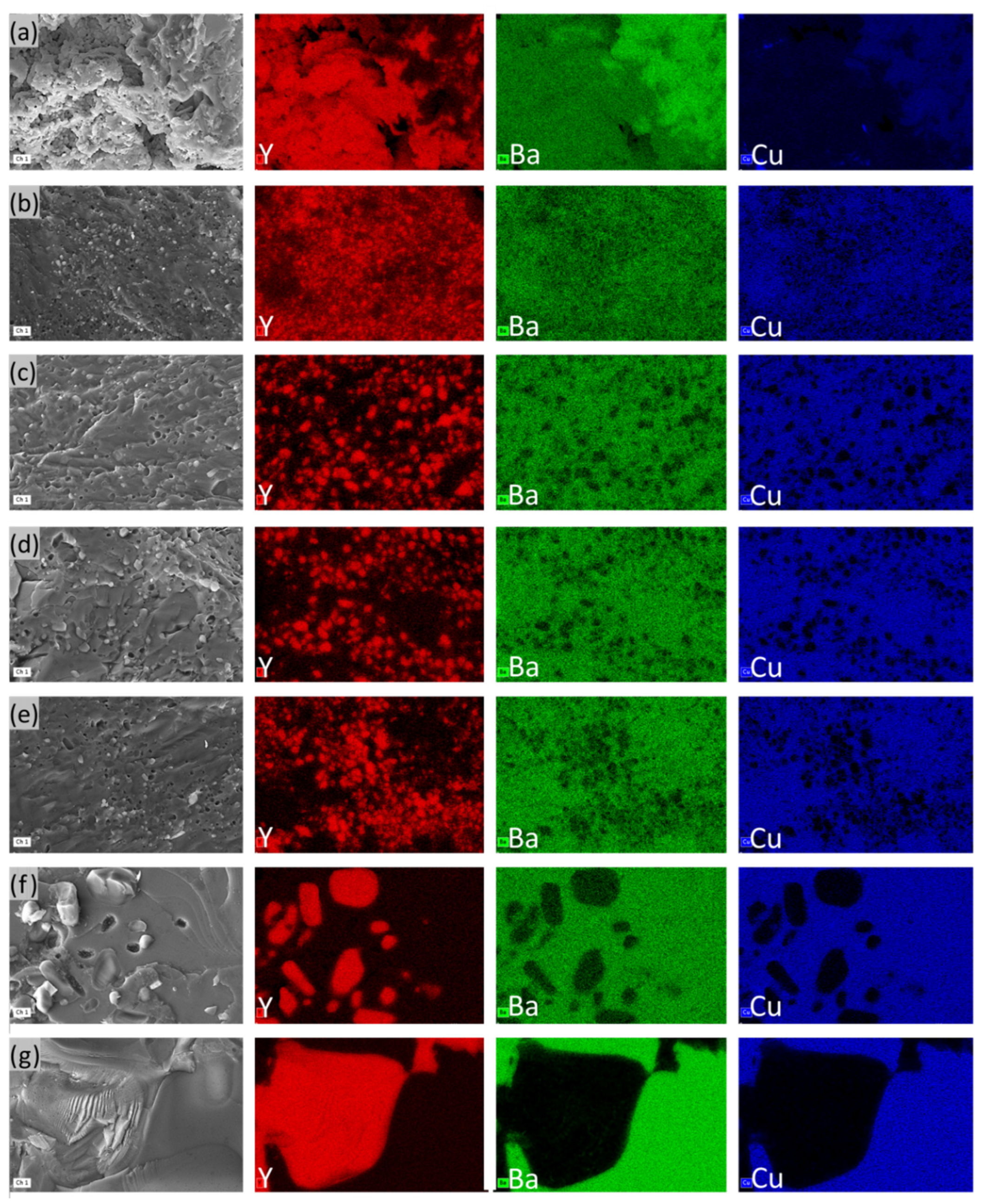

3.4.1. SEM–EDS Mapping of IP Pellet

3.4.2. Y-211 Particle Distribution of Final Sample

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Durrell, J.H.; Dennis, A.R.; Jaroszynski, J.; Ainslie, M.D.; Palmer, K.G.B.; Shi, Y.H.; Campbell, A.M.; Hull, J.; Strasik, M.; Hellstrom, E.E.; et al. A trapped field of 17.6 T in melt-processed, bulk Gd-Ba-Cu-O reinforced with shrink-fit steel. Supercond. Sci. Technol. 2014, 27, 082001. [Google Scholar] [CrossRef]

- Tomita, M.; Murakami, M. High-temperature superconductor bulk magnets that can trap magnetic fields of over 17 tesla at 29 K. Nature 2003, 421, 517–520. [Google Scholar] [CrossRef]

- Miyazaki, Y.; Mizuno, K.; Yamashita, T.; Ogata, M.; Hasegawa, H.; Nagashima, K.; Mukoyama, S.; Matsuoka, T.; Nakao, K.; Horiuch, S.; et al. Development of superconducting magnetic bearing for flywheel energy storage system. Cryogenics 2016, 80, 234–237. [Google Scholar] [CrossRef]

- Gawalek, W.; Habisreuther, T.; Zeisberger, M.; Litzkendorf, D.; Surzhenko, O.; Kracunovska, S.; Prikhna, T.A.; Oswald, B.; Kovalev, L.K.; Canders, W. Batch-processed melt-textured YBCO with improved quality for motor and bearing applications. Supercond. Sci. Technol. 2004, 17, 1185–1188. [Google Scholar] [CrossRef]

- Strasik, M.; Hull, J.R.; Mittleider, J.A.; Gonder, J.F.; Johnson, P.E.; McCrary, K.E.; McIver, C.R. An overview of Boeing flywheel energy storage systems with high-temperature superconducting bearings. Supercond. Sci. Technol. 2010, 23, 034021. [Google Scholar] [CrossRef]

- Arnaud, J.; Fernandes, J.F.P.; Branco, P.J.C. Use of Bulk Superconductors in the Excitation System of Low-Speed Synchronous Generators. IEEE Trans. Appl. Supercond. 2021, 31, 5. [Google Scholar] [CrossRef]

- Yang, P.-T.; Yang, W.-M.; Wang, M.; Li, J.-W.; Guo, Y.-X. Effective method to control the levitation force and levitation height in a superconducting maglev system. Chin. Phys. B 2015, 24, 117403. [Google Scholar] [CrossRef]

- Muralidhar, M.; Sakai, N.; Jirsa, M.; Murakami, M.; Hirabayashi, I. Record flux pinning in melt-textured NEG-123 doped by Mo and Nb nanoparticles. Appl. Phys. Lett. 2008, 92, 162512–162513. [Google Scholar] [CrossRef]

- Muralidhar, M.; Sakai, N.; Chikumoto, N.; Jirsa, M.; Machi, T.; Nishiyama, M.; Wu, Y.; Murakami, M. New type of vortex pinning structure effective at very high magnetic fields. Phys. Rev. Lett. 2002, 89, 237001. [Google Scholar] [CrossRef] [PubMed]

- Li, H.-C.; Fan, W.-S.; Peng, B.-n.; Wang, W.; Zhuang, Y.-F.; Guo, L.-S.; Yao, X.; Ikuta, H. Seed-Size Effect on the Growth and Superconducting Performance of YBCO Single-Grain Bulks. Cryst. Growth Des. 2015, 15, 1740–1744. [Google Scholar] [CrossRef]

- Baumann, J.; Shi, Y.; Weerakonda, D.; Durrell, J.H.; Cardwell, D.A. Understanding the porosity and its effects on the superconducting properties of YBCO single grains. J. Eur. Ceram. Soc. 2023, 43, 1542–1547. [Google Scholar] [CrossRef]

- Namburi, D.K.; Shi, Y.; Palmer, K.G.; Dennis, A.R.; Durrell, J.H.; Cardwell, D.A. Control of Y-211 content in bulk YBCO superconductors fabricated by a buffer-aided, top seeded infiltration and growth melt process. Supercond. Sci. Technol. 2016, 29, 034007. [Google Scholar] [CrossRef]

- Agarwal, A.G.; Miryala, M. Advancing processing of the ternary (Sm,Eu,Gd)Ba2Cu3O7-y superconductor via top-seeded infiltration growth. Ceram. Int. 2024, 50, 31559–31566. [Google Scholar] [CrossRef]

- Agarwal, A.G.; Miryala, M. Enhanced trapped magnetic field in bulk (Gd, Y, Er) Ba2Cu3O7-y via varied liquid sources in top-seeded infiltration growth process. Mater. Chem. Phys. 2024, 318, 129254. [Google Scholar] [CrossRef]

- Diko, P. Microstructural limits of TSMG REBCO bulk superconductors. Phys. C Supercond. Its Appl. 2006, 445–448, 323–329. [Google Scholar] [CrossRef]

- Naik, S.P.K.; Muralidhar, M.; Murakami, M. Influence of Processing Conditions on the Microstructure and Physical Properties in Infiltration Growth Processed Mixed REBCO Bulk Superconductors. IEEE Trans. Appl. Supercond. 2019, 29, 3. [Google Scholar] [CrossRef]

- Diko, P.; Antal, V.; Zmorayová, K.; Šefčiková, M.; Chaud, X.; Kováč, J.; Yao, X.; Chen, I.; Eisterer, M.; Weber, H.W. The influence of post-growth thermal treatments on the critical current density of TSMG YBCO bulk superconductors. Supercond. Sci. Technol. 2010, 23, 124002. [Google Scholar] [CrossRef]

- Muralidhar, M.; Sunsanee, P. Mapping spatial superconducting property variations in IG-processed bulk ternary (Gd0.33Y0.13Er0.53)Ba2Cu3Oy. J. Alloys Compd. 2024, 997, 174745. [Google Scholar] [CrossRef]

- Cloots, R.; Koutzarova, T.; Mathieu, J.P.; Ausloos, M. From RE-211 to RE-123. How to control the final microstructure of superconducting single-domains. Supercond. Sci. Technol. 2005, 18, R9–R23. [Google Scholar] [CrossRef]

- Li, G.-Z.; Wang, M. Influence of preforming pressure on the morphology and properties of single-grain Y–Ba–Cu–O superconductors by the 011-type infiltration growth technique. Mater. Today Commun. 2021, 29, 102771. [Google Scholar] [CrossRef]

- Mahmood, A.; Jun, B.H.; Park, H.W.; Kim, C.J. Pre-sintering effects on the critical current density of YBCO bulk prepared by infiltration method. Phys. C Supercond. 2008, 468, 1350–1354. [Google Scholar] [CrossRef]

- Namburi, D.K.; Shi, Y.; Palmer, K.G.; Dennis, A.R.; Durrell, J.H.; Cardwell, D.A. A novel, two-step top seeded infiltration and growth process for the fabrication of single grain, bulk (RE)BCO superconductors. Supercond. Sci. Technol. 2016, 29, 095010. [Google Scholar] [CrossRef]

- Abulaiti, A.; Yang, W.-M.; Wu, T.-T.; Cui, Y.-L. The effect of pre-sintering and high-temperature infiltration on the properties of single-domain YBCO bulk superconductors by the Y + 011 top-seeded infiltration growth process. Supercond. Sci. Technol. 2022, 36, 025005. [Google Scholar] [CrossRef]

- Wu, T.; Yang, W.; Chen, L. The Effect of the Pre-Infiltration Temperature on the Liquid-Phase Infiltration Characteristics and the Magnetic Properties of Single-Domain GdBCO Bulk Superconductors. Crystals 2024, 14, 842. [Google Scholar] [CrossRef]

- Yang, W.M.; Chen, L.P.; Wang, X.J. A new RE + 011 TSIG method for the fabrication of high quality and large size single domain YBCO bulk superconductors. Supercond. Sci. Technol. 2016, 29, 024004. [Google Scholar] [CrossRef]

- Li, G.-Z.; Yang, W.-M.; Cheng, X.-F.; Fan, J.; Guo, X.-D. A modified TSIG technique for simplifying the fabrication process of single-domain GdBCO bulks with a new kind of liquid source. J. Mater. Sci. 2009, 44, 6423–6426. [Google Scholar] [CrossRef]

- Namburi, D.K.; Shi, Y.; Palmer, K.G.; Dennis, A.R.; Durrell, J.H.; Cardwell, D.A. An improved top seeded infiltration growth method for the fabrication of Y–Ba–Cu–O bulk superconductors. J. Eur. Ceram. Soc. 2016, 36, 615–624. [Google Scholar] [CrossRef]

- Yang, W.M.; Chao, X.X.; Shu, Z.B.; Zhu, S.H.; Wu, X.L.; Bian, X.B.; Liu, P. A levitation force and magnetic field distribution measurement system in three dimensions. Phys. C Supercond. Its Appl. 2006, 445–448, 347–352. [Google Scholar] [CrossRef]

- Yang, W.M.; Chao, X.X.; Bian, X.B.; Liu, P.; Feng, Y.; Zhang, P.X.; Zhou, L. The effect of magnet size on the levitation force and attractive force of single-domain YBCO bulk superconductors. Supercond. Sci. Technol. 2003, 16, 789–792. [Google Scholar] [CrossRef]

- Antončík, F.; Jiříčková, A.; Sedmidubský, D.; Hlásek, T.; Lojka, M.; Jankovský, O. Heat capacity and thermal stability of Y2BaCuO5. AIP Conf. Proc. 2019, 2170, 020002. [Google Scholar] [CrossRef]

- Yuan, X.; Yang, W. Effects of Gd211 Particles Characteristic in the Precursor Pellets on the Levitation Force of Single-Domain GdBCO Bulks Prepared by the Gd + 011 TSIG Method. Adv. Mater. Sci. Eng. 2018, 2018, 1. [Google Scholar] [CrossRef]

- Chao, X.X.; Yang, W.M.; Wan, F.; Guo, F.X.; Li, J.W.; Chen, S.L. The effect of Y2Ba4CuWOy addition on the properties of single domain YBCO superconductors by TSIG technique. Phys. C Supercond. 2013, 493, 49–51. [Google Scholar] [CrossRef]

- Feng, Z.L.; Yang, W.M.; Li, J.W.; Zheng, S.K.; Zhang, C.H.; Hassan, Q.U. A Facile Infiltration Growth Technique for Fabricating a NdBCO Seed Crystal and High-Performance Single-Domain GdBCO Bulk Superconductor Using One Precursor Powder: BaCuO2. J. Supercond. Nov. Magn. 2019, 32, 2283–2288. [Google Scholar] [CrossRef]

- Zhai, W.; Shi, Y.; Durrell, J.H.; Dennis, A.R.; Cardwell, D.A. The Influence of Y-211 Content on the Growth Rate and Y-211 Distribution in Y–Ba–Cu–O Single Grains Fabricated by Top Seeded Melt Growth. Cryst. Growth Des. 2014, 14, 6367–6375. [Google Scholar] [CrossRef]

- Zhu, Y.; Yin, Y.; Huang, S.; Zhou, D.; Kucharova, V.; Zmorayova, K.; Diko, P.; Yao, X. Enhancing the superconducting performance of YBa2Cu3O7−δ bulks with nano-sized and well distributed Y2BaCuO5 particles. CrystEngComm 2020, 22, 4116–4123. [Google Scholar] [CrossRef]

- Ouerghi, A.; Moutalbi, N.; Noudem, J.G.; M’Chirgui, A. The influence of slow cooling on Y211 size and content in single-grain YBCO bulk superconductor through the infiltration-growth process. Phys. C Supercond. Its Appl. 2017, 534, 37–44. [Google Scholar] [CrossRef]

- Koblischka-Veneva, A.; Koblischka, M.R.; Mücklich, F.; Ogasawara, K.; Murakami, M. Interactions of Y2BaCuO5particles and the YBCO matrix within melt-textured YBCO samples studied by means of electron backscatter diffraction. Supercond. Sci. Technol. 2005, 18, S158–S163. [Google Scholar] [CrossRef]

- Murakami, M.; Fujimoto, H.; Yamaguchi, K.; Nakamura, N.; Koshizuka, N.; Tanaka, S. Flux pinning sites in melt-processed YBaCuO superconductors. Phase Transit. 1993, 41, 69–78. [Google Scholar] [CrossRef]

- Nariki, S.; Sakai, N.; Murakami, M.; Hirabayashi, I. Effect of RE2BaCuO5 refinement on the critical current density and trapped field of melt-textured (Gd, Y)–Ba–Cu–O bulk superconductors. Phys. C Supercond. 2006, 439, 62–66. [Google Scholar] [CrossRef]

| Final Sample | Infiltration Temp. | Vf of Y-211 | AVG of Y-211 |

|---|---|---|---|

| S1 | 1000 °C | 40.8% | 1.16 µm |

| S2 | 1050 °C | 37.2% | 1.35 µm |

| S3 | 1100 °C | 32.7% | 1.11 µm |

| S4 | 1150 °C | 30.5% | 1.67 µm |

| S5 | 1200 °C | 46.4% | 2.09 µm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maimaiti, N.; Abulaiti, A.; Yang, W. The Effect of Infiltration Temperature on the Microstructure and Magnetic Levitation Force of Single-Domain YBa2Cu3O7-x Bulk Superconductors Grown by a Modified Y+011 IG Method. Nanomaterials 2025, 15, 21. https://doi.org/10.3390/nano15010021

Maimaiti N, Abulaiti A, Yang W. The Effect of Infiltration Temperature on the Microstructure and Magnetic Levitation Force of Single-Domain YBa2Cu3O7-x Bulk Superconductors Grown by a Modified Y+011 IG Method. Nanomaterials. 2025; 15(1):21. https://doi.org/10.3390/nano15010021

Chicago/Turabian StyleMaimaiti, Nuerseman, Abulizi Abulaiti, and Wanmin Yang. 2025. "The Effect of Infiltration Temperature on the Microstructure and Magnetic Levitation Force of Single-Domain YBa2Cu3O7-x Bulk Superconductors Grown by a Modified Y+011 IG Method" Nanomaterials 15, no. 1: 21. https://doi.org/10.3390/nano15010021

APA StyleMaimaiti, N., Abulaiti, A., & Yang, W. (2025). The Effect of Infiltration Temperature on the Microstructure and Magnetic Levitation Force of Single-Domain YBa2Cu3O7-x Bulk Superconductors Grown by a Modified Y+011 IG Method. Nanomaterials, 15(1), 21. https://doi.org/10.3390/nano15010021