Synergistic Effect of He for the Fabrication of Ne and Ar Gas-Charged Silicon Thin Films as Solid Targets for Spectroscopic Studies

Abstract

1. Introduction

2. Materials and Methods

2.1. Film Preparation

2.2. Films Characterization (Microstructure and Elemental Composition)

2.3. Films Characterization (Spectroscopic Studies)

3. Results and Discussion

3.1. Selection of Experimental Conditions for the Fabrication of Investigated Gas-Charged Silicon Films

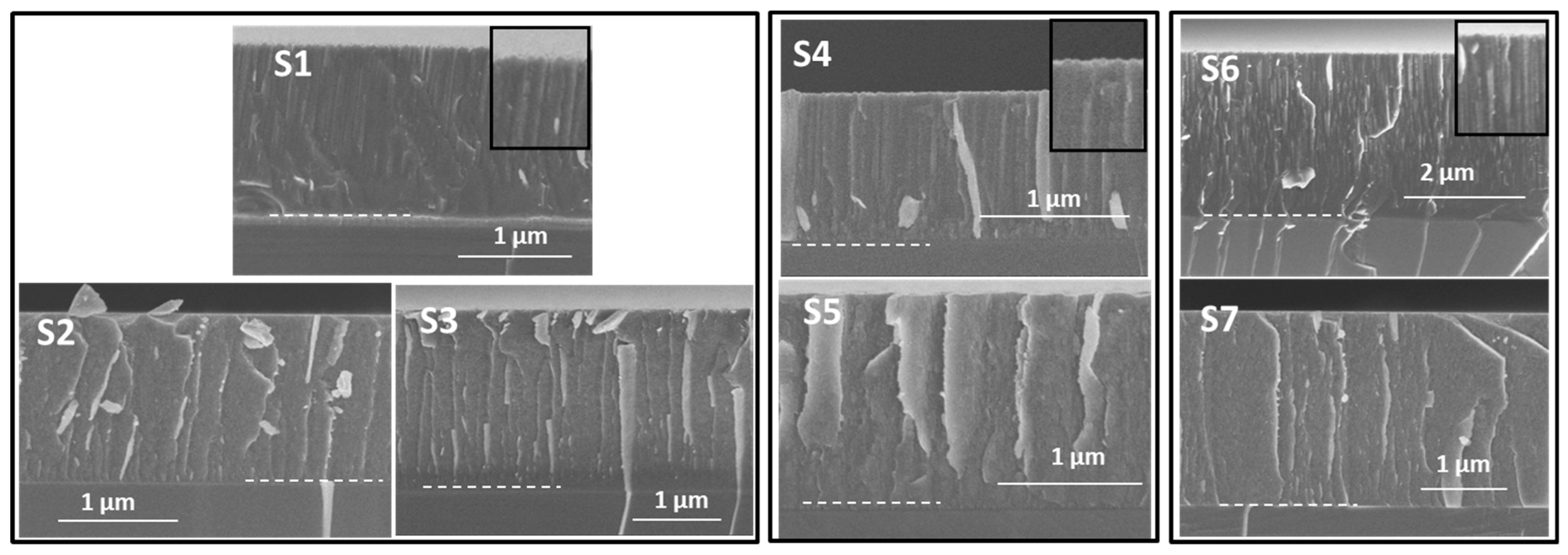

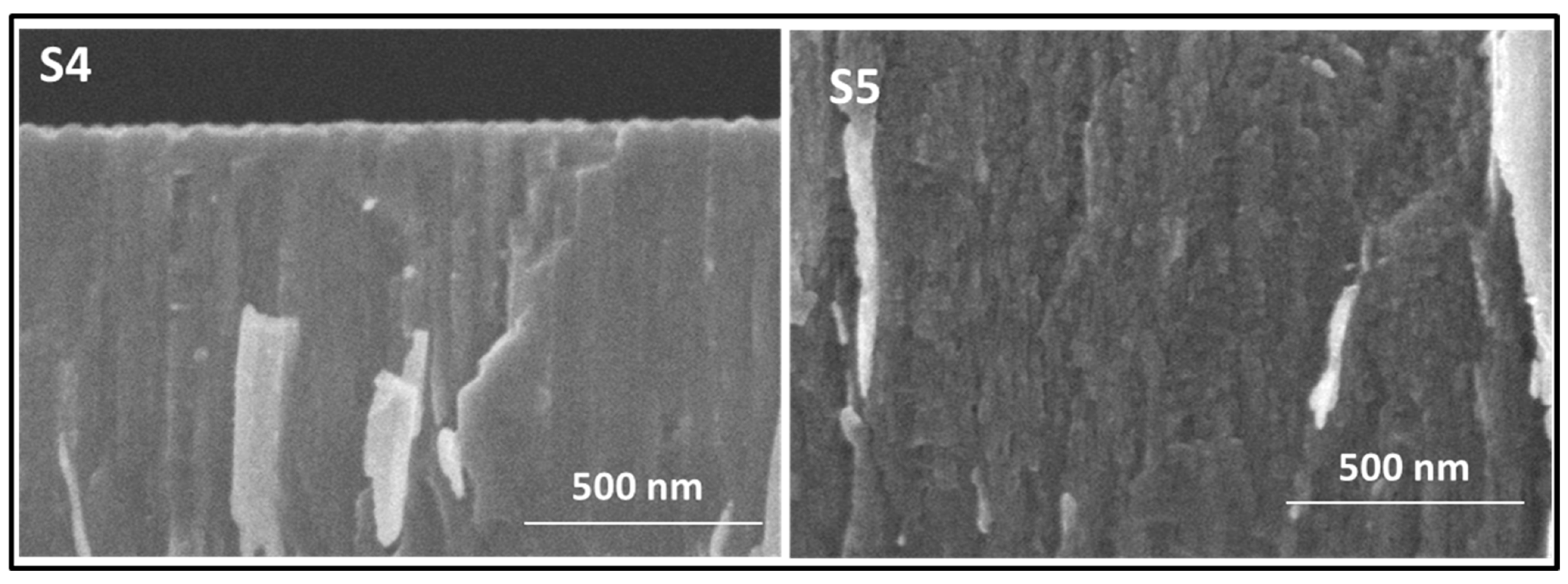

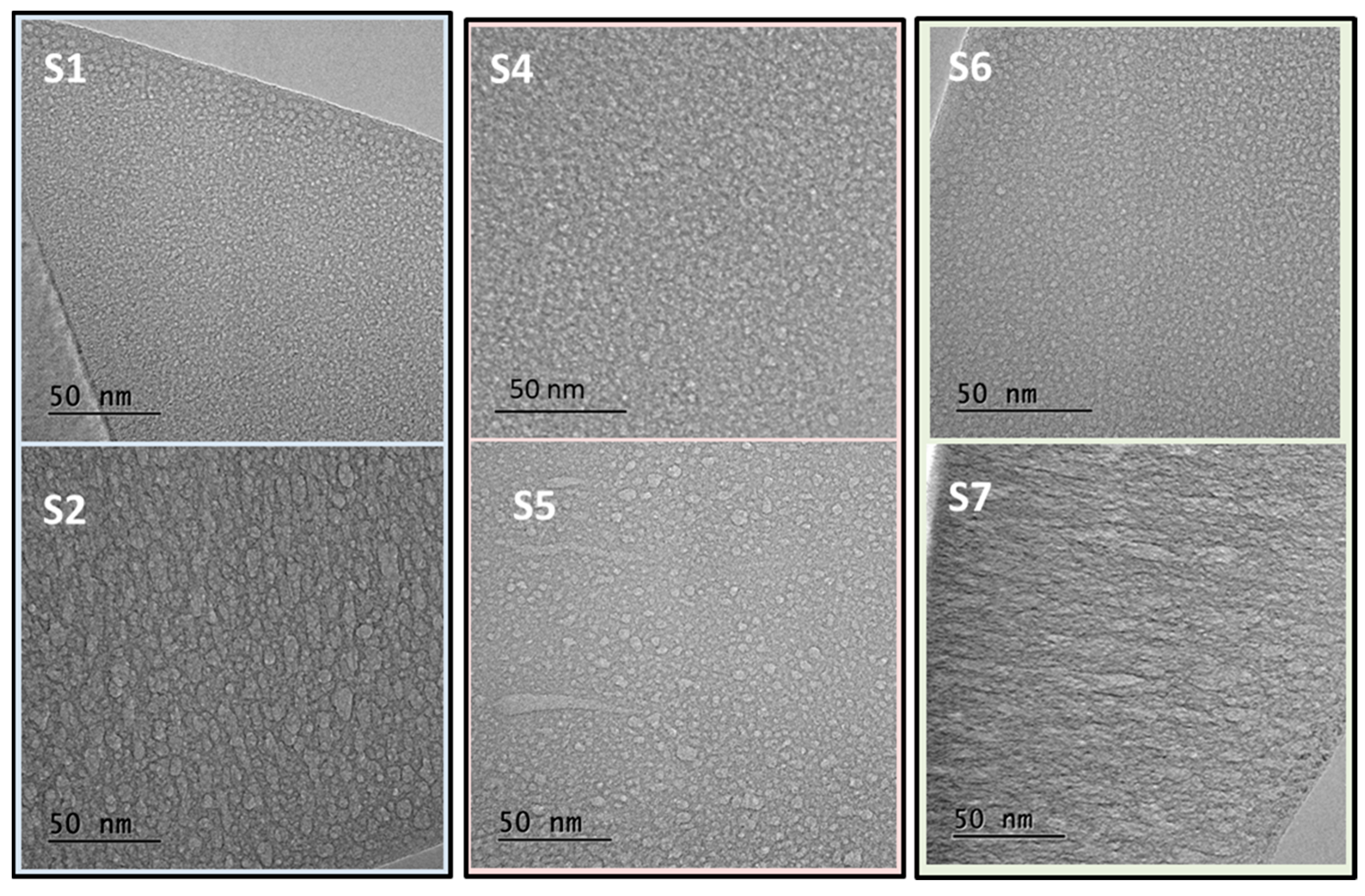

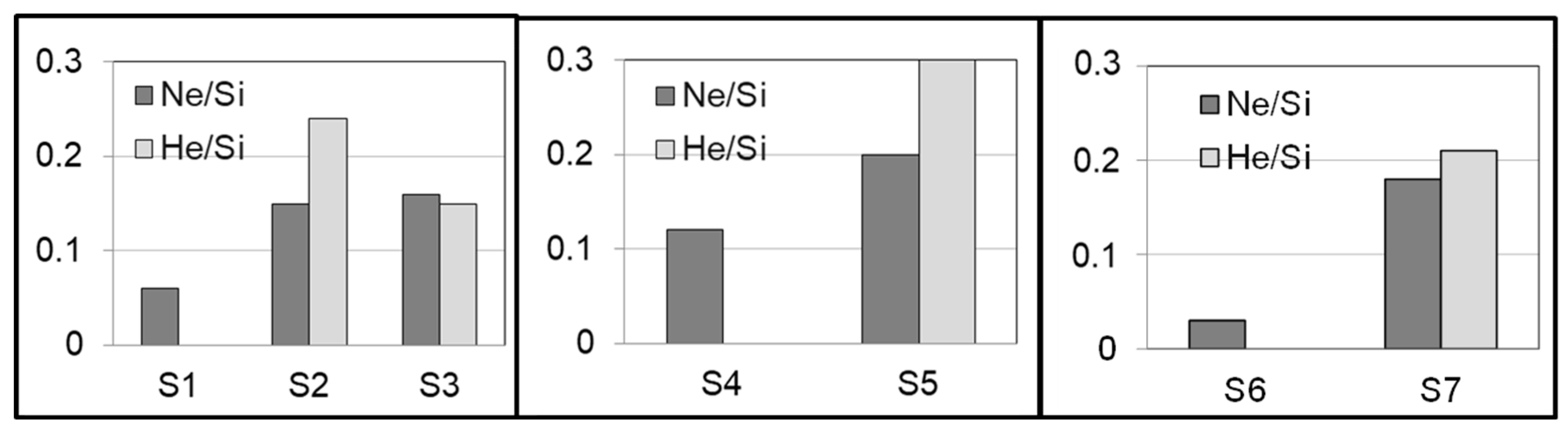

3.2. The Microstructure and Elemental Composition of Ne-Charged Silicon Thin Films

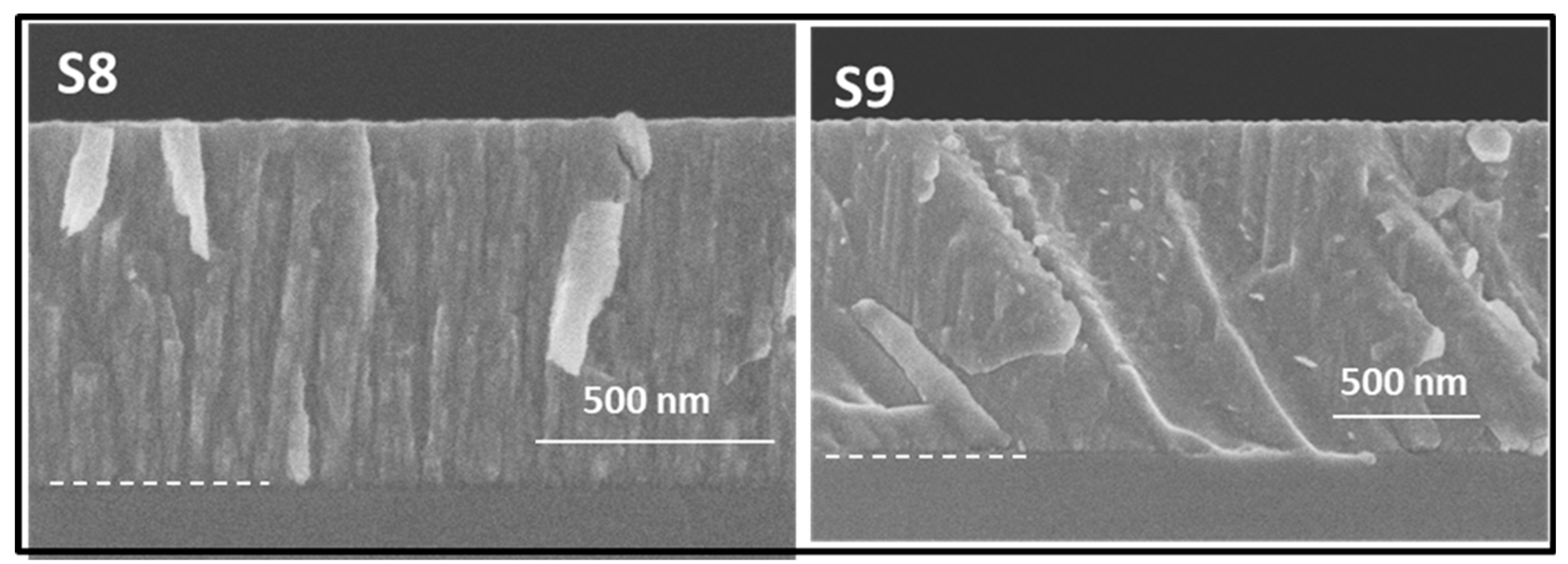

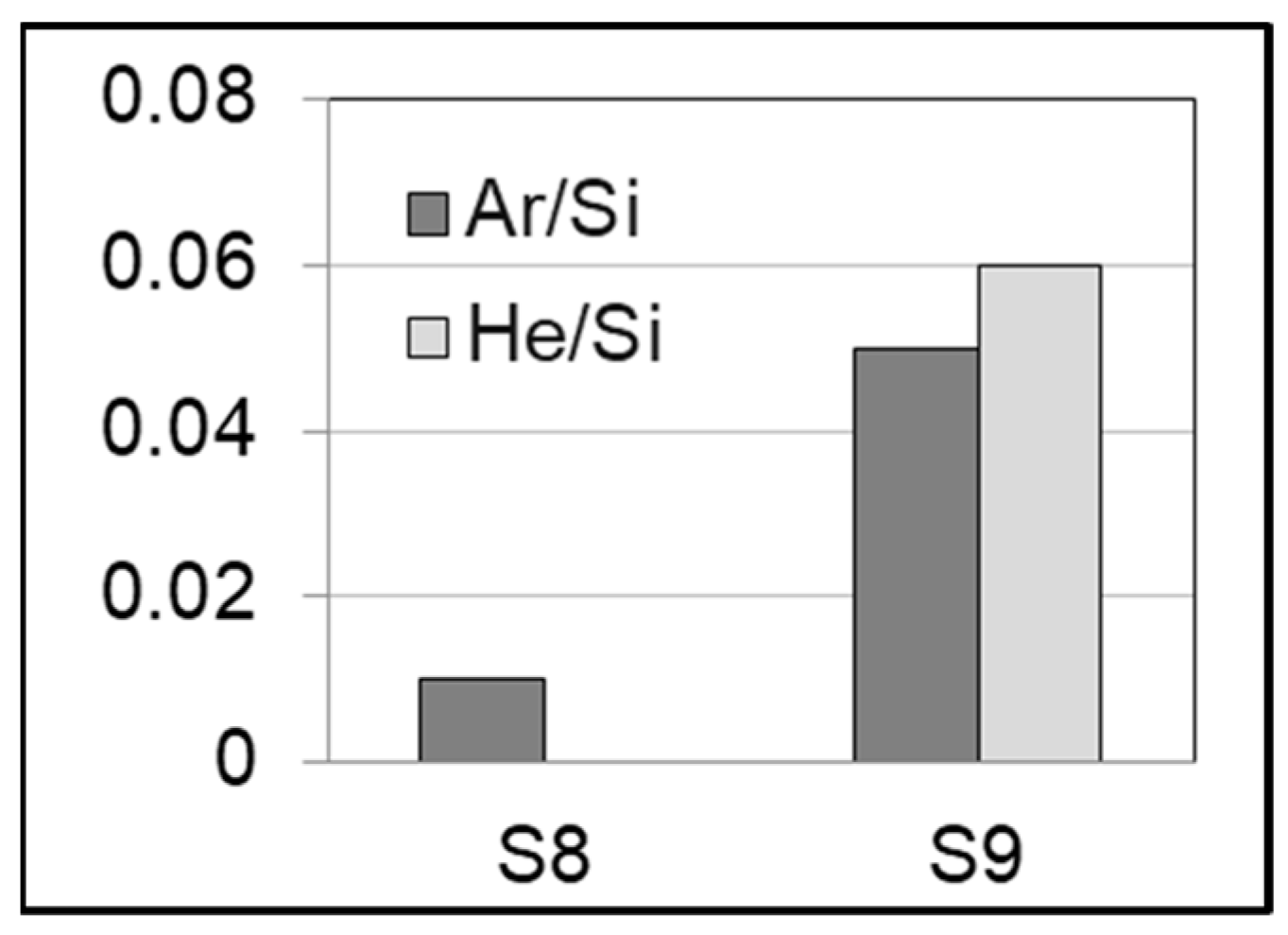

3.3. The Microstructure and Elemental Composition of Ar-Charged Silicon Thin Films

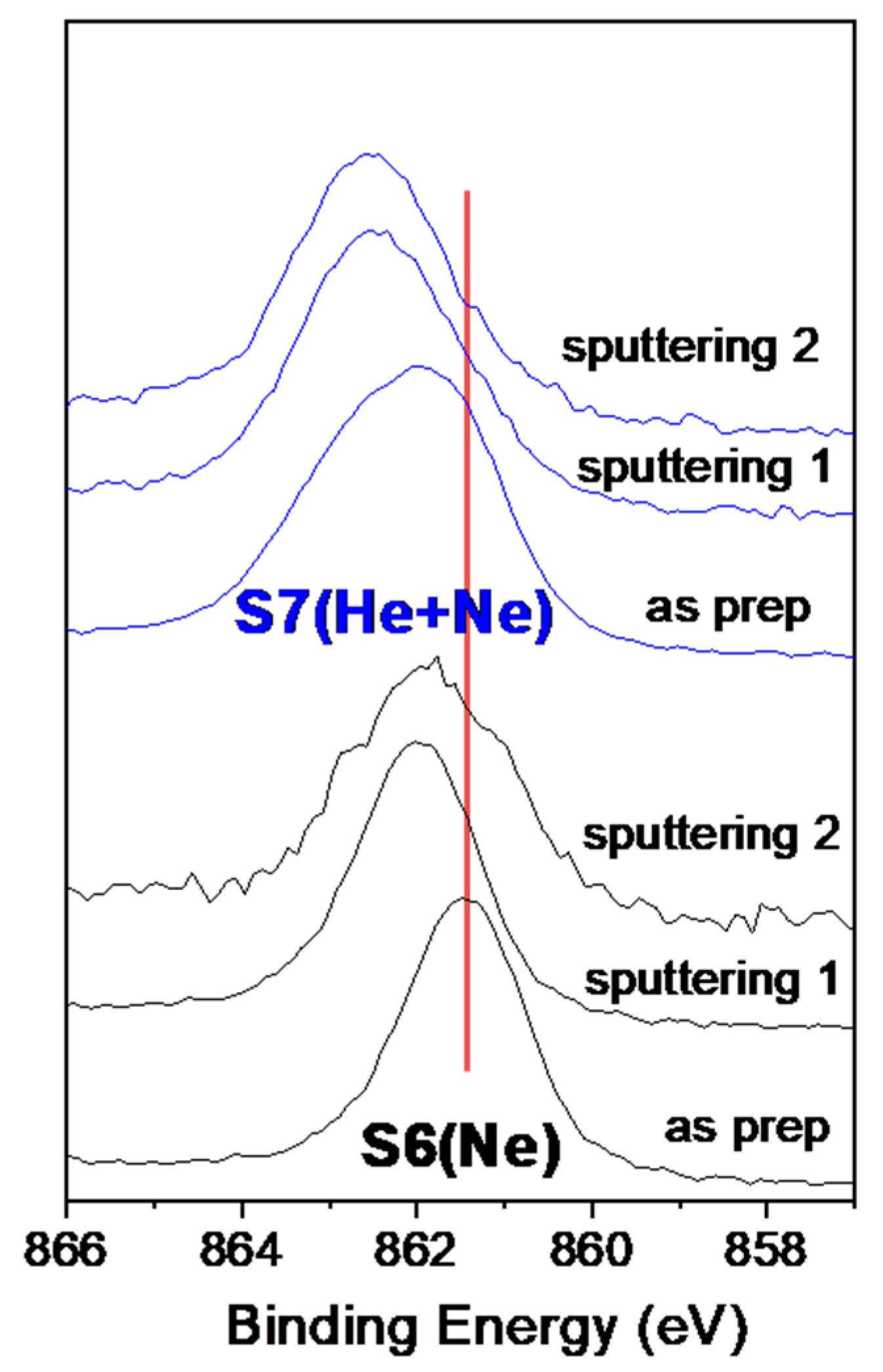

3.4. Spectroscopic Study of the Ne1s Binding Energy of Ne-Charged Si Films by XPS

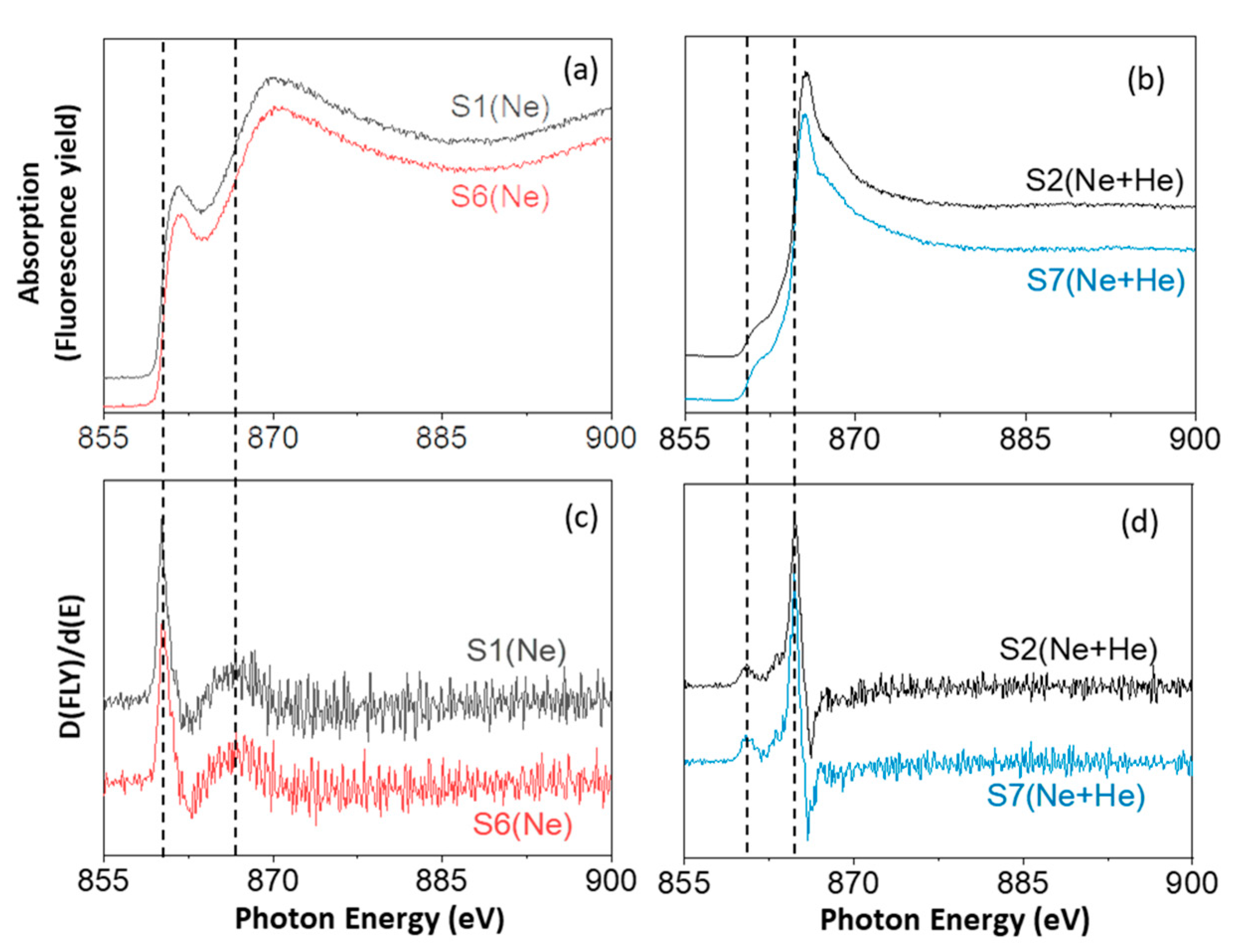

3.5. Spectroscopic Study of the Ne-Kedge Absorption Spectra of Ne-Charged Si Films by XAS

4. Conclusions and Perspectives

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ullmaier, H. The influence of helium on the bulk properties of fusion reactor structural materials. Nucl. Fusion 1984, 24, 1039. [Google Scholar] [CrossRef]

- Lucas, A.A. Helium in metals. Physica B+C 1984, 127, 225–239. [Google Scholar] [CrossRef]

- Sun, X.; Chen, F.; Huang, H.; Lin, J.; Tang, X. Effects of interfaces on the helium bubble formation and radiation hardening of an austenitic stainless steel achieved by additive manufacturing. Appl. Surf. Sci. 2019, 467–468, 1134–1139. [Google Scholar] [CrossRef]

- Donnelly, S.E.; Evans, J.H. (Eds.) Fundamental Aspects of Inert Gases in Solids; Plenum Press: New York, NY, USA, 1991. [Google Scholar] [CrossRef]

- Gai, X.; Smith, R.; Kenny, S.D. Inert gas bubbles in bcc Fe. J. Nucl. Mater. 2016, 470, 84–89. [Google Scholar] [CrossRef]

- Fleischer, E.L.; Norton, M.G. Noble gas inclusions in materials. Heterog. Chem. Rev. 1996, 3, 171–201. [Google Scholar] [CrossRef]

- Nishijima, D.; Ye, M.Y.; Ohno, N.; Takamura, S. Formation mechanism of bubbles and holes on tungsten surface with low-energy and high-flux helium plasma irradiation in NAGDIS-II. J. Nucl. Mater. 2004, 329–333, 1029–1033. [Google Scholar] [CrossRef]

- Pentecoste, L.; Brault, P.; Thomann, A.-L.; Desgardin, P.; Lecas, T.; Belhabib, T.; Barthe, M.-F.; Sauvage, T. Low energy and low fluence helium implantations in tungsten: Molecular dynamics simulations and experiments. J. Nucl. Mater. 2016, 470, 44–54. [Google Scholar] [CrossRef]

- Oliviero, E.; Peripolli, S.; Fichtner, P.F.P.; Amaral, L. Characterization of neon implantation damage in silicon. Mater. Sci. Eng. B 2004, 112, 111–115. [Google Scholar] [CrossRef]

- Biswas, C.; Shukla, A.K.; Banik, S.; Barman, S.R. Argon Nanobubbles in Al(111): A Photoemission Study. Phys. Rev. Lett. 2004, 92, 115506. [Google Scholar] [CrossRef]

- Cummings, R.B.; Blackmur, M.S.; Grunwald, M.; Minty, A.; Styman, P.; MacLaren, I. Xenon bubbles formed by ion implantation in zirconium alloy films. J. Nucl. Mater. 2022, 560, 153497. [Google Scholar] [CrossRef]

- Eriksson, L.; Davies, J.A.; Mayer, J.W. Ion implantation studies in silicon. Science 1969, 163, 627–633. [Google Scholar] [CrossRef] [PubMed]

- Nastasi, M.; Meyer, J.W. Ion Implantation and Synthesis of Materials; Springer: Berlin/Heilderberg, Germany, 2006. [Google Scholar] [CrossRef]

- Sahu, B.B.; Kim, S.I.; Lee, M.W.; Han, J.G. Effect of helium incorporation on plasma parameters and characteristic properties of hydrogen free carbon films deposited using DC magnetron sputtering. J. Appl. Phys. 2020, 127, 014901. [Google Scholar] [CrossRef]

- Ibrahim, S.; Zahrae Lahboub, F.; Brault, P.; Petit, A.; Caillard, A.; Millon, E.; Sauvage, T.; Fernández, A.; Thoman, A.-L. Influence of helium incorporation on growth process and properties of aluminum thin films deposited by DC magnetron sputtering. Surf. Coat. Technol. 2021, 426, 127808. [Google Scholar] [CrossRef]

- Shi, L.Q.; Liu, C.Z.; Xu, S.L.; Zhou, Z.Y. Helium-charged titanium films deposited by direct current magnetron sputtering. Thin Solid. Films 2005, 479, 52–58. [Google Scholar] [CrossRef]

- Godinho, V.; Caballero-Hernández, J.; Jamon, D.; Rojas, T.C.; Schierholz, R.; García-López, J.; Ferrer, F.J.; Fernández, A. A new bottom-up methodology to produce silicon layers with a closed porosity nanostructure and reduced refractive index. Nanotechnology 2013, 24, 275604. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.Z.; Shi, L.Q.; Zhou, Z.Y.; Hao, X.P.; Wang, B.Y.; Liu, S.; Wang, L.B. Investigations of helium incorporated into a film deposited by magnetron sputtering. J. Phys. D Appl. Phys. 2007, 40, 2150–2156. [Google Scholar] [CrossRef]

- Caballero-Hernández, J.; Godinho, V.; Lacroix, B.; Jiménez de Haro, M.C.; Jamon, D.; Fernández, A. Fabrication of Optical Multilayer Devices from Porous Silicon Coatings with Closed Porosity by Magnetron Sputtering. ACS Appl. Mater. Interfaces 2015, 7, 13889–13897. [Google Scholar] [CrossRef] [PubMed]

- Sakabe, J.; Ohta, N.; Ohnishi, T.; Mitsuishi, K.; Takada, K. Porous amorphous silicon film anodes for high capacity and stable all-solid-state lithium batteries. Commun. Chem. 2018, 1, 24. [Google Scholar] [CrossRef]

- Uchida, G.; Nagai, K.; Habu, Y.; Hayashi, J.; Ikebe, Y.; Hiramatsu, M.; Narishige, R.; Itagaki, N.; Shiratani, M.; Setsuhara, Y. Nanostructured Ge and GeSn films by high-pressure He plasma sputtering for high-capacity Li ion battery anodes. Sci. Rep. 2022, 12, 1742. [Google Scholar] [CrossRef]

- Ovejero, J.G.; Godinho, V.; Lacroix, B.; García, M.A.; Hernando, A.; Fernández, A. Exchange bias and two steps magnetization reversal in porous Co/CoO layers. Mater. Des. 2019, 171, 107691. [Google Scholar] [CrossRef]

- Giarratano, F.; Arzac, G.M.; Godinho, V.; Hufschmidt, D.; Jiménez de Haro, M.C.; Montes, O.; Fernández, A. Nanoporous Pt-based catalysts prepared by chemical dealloying of magnetron-sputtered Pt-Cu thin films for the catalytic combustion of hydrogen. Appl. Catal. B Environ. 2018, 235, 168–176. [Google Scholar] [CrossRef]

- Schierholz, R.; Lacroix, B.; Godinho, V.; Caballero-Hernández, J.; Duchamp, M.; Fernández, A. STEM–EELS analysis reveals stable high density He in nanopores of amorphous silicon coatings deposited by magnetron sputtering. Nanotechnology 2015, 26, 075703. [Google Scholar] [CrossRef] [PubMed]

- Fernández, A.; Sauvage, T.; Diallo, B.; Hufschmidt, D.; Jiménez de Haro, M.C.; Montes, O.; Martínez-Blanes, J.M.; Caballero, J.; Godinho, V.; Ferrer, F.J.; et al. Microstructural characterization and thermal stability of He charged amorphous silicon films prepared by magnetron sputtering in helium. Mater. Chem. Phys. 2023, 301, 127674. [Google Scholar] [CrossRef]

- Lacroix, B.; Godinho, V.; Fernández, A. The nanostructure of porous cobalt coatings deposited by magnetron sputtering in helium atmosphere. Micron 2018, 108, 49–54. [Google Scholar] [CrossRef] [PubMed]

- Pyper, N.C.; Thom, A.J.W.; Whelan, C.T. The density and pressure of helium nano-bubbles encapsulated in silicon. Proc. R. Soc. A 2023, 479, 2023.0081. [Google Scholar] [CrossRef]

- Godinho, V.; Ferrer, F.J.; Fernández, B.; Caballero-Hernández, J.; Gómez-Camacho, J.; Fernández, A. Characterization and Validation of a-Si Magnetron-Sputtered Thin Films as Solid He Targets with High Stability for Nuclear Reactions. ACS Omega 2016, 1, 1229–1238. [Google Scholar] [CrossRef]

- Carozzi, G.; Valiente-Dobón, J.J.; Gadea, A.; Siciliano, M.; Mengoni, D.; Fernández, A.; Godinho, V.; Hufschmidt, D.; Di Nitto, A. Test of a 3He target for transfer reactions in inverse kinematics. Il Nuovo Cimento C 2019, 42, 94. [Google Scholar] [CrossRef]

- Fernández, A.; Hufschmidt, D.; Colaux, J.L.; Valiente-Dobón, J.J.; Godinho, V.; Jiménez de Haro, M.C.; Feria, D.; Gadea, A.; Lucas, S. Low gas consumption fabrication of 3He solid targets for nuclear reactions. Mater. Des. 2020, 186, 108337. [Google Scholar] [CrossRef]

- Fernández, A.; Hufschmidt, D.; Godinho, V.; Jiménez de Haro, M.C. Procedimiento de obtención de un material sólido con agregados gaseosos mediante pulverización catódica por magnetrón en condiciones estáticas o cuasiestáticas para reducir el consumo de gas. Spain Patent ES2761148A1, 15 November 2018. [Google Scholar]

- Ferrer, F.J.; Fernández, B.; Fernández-García, J.P.; Barba, F.G.; Fernández, A.; Galaviz, D.; Godinho, V.; Gómez-Camacho, J.; Sánchez-Benítez, A.M. Novel solid 4He targets for experimental studies on nuclear reactions: 6Li+4He differential cross-section measurement at incident energy of 5.5 MeV. Eur. Phys. J. Plus 2020, 135, 465. [Google Scholar] [CrossRef]

- Angus, C.; Williams, M.; Andreyev, A.; Bhattacharjee, S.; Buck, S.; Chakraborty, S.; Davids, B.; Diget, C.; Garnsworthy, A.; Griffin, C.; et al. Measurement of the 86Kr(α,n)89Sr cross section at energies relevant for the weak r-process. EPJ Web Conf. 2023, 279, 11003. [Google Scholar] [CrossRef]

- Depla, D.; Mahieu, S.; Greene, J.E. Chapter 5: Sputter Deposition Processes. In Handbook of Deposition Technologies for Films and Coatings, 3rd ed.; William Andrew Publishers: Norwich, NY, USA, 2010; pp. 253–296. [Google Scholar] [CrossRef]

- Jacobsohn, L.G.; Averitt, R.D.; Nastasi, M. The role of trapped Ar atoms in the mechanical properties of boron carbide films deposited by dc-magnetron sputtering. J. Vac. Sci. Technol. A 2003, 21, 1639–1643. [Google Scholar] [CrossRef]

- Sagara, R.; Kawamura, M.; Kiba, T.; Abe, Y.; Kim, K.H. Characteristics of Ag thin films sputter deposited using Ar or Kr gas under different pressure. Surf. Coat. Technol. 2020, 388, 125616. [Google Scholar] [CrossRef]

- Hatton, P.; Abbas, A.; Kaminski, P.; Yilmaz, S.; Watts, M.; Walls, M.; Goddard, P.; Smith, R. Inert gas bubble formation in magnetron sputtered thin-film CdTe solar cells. Proc. R. Soc. A 2020, 476, 2020.0056. [Google Scholar] [CrossRef] [PubMed]

- Godinho, V.; Moskovkin, P.; Álvarez, R.; Caballero-Hernández, J.; Schierholz, R.; Bera, B.; Demarche, J.; Palmero, A.; Fernández, A.; Lucas, S. On the formation of the porous structure in nanostructured a-Si coatings deposited by dc magnetron sputtering at oblique angles. Nanotechnology 2014, 25, 355705. [Google Scholar] [CrossRef]

- Petrov, I.; Ivanov, I.; Orlinov, V. Comparison of magnetron sputtering deposition conditions in neon, argon, krypton, and xenon discharges. J. Vac. Sci. Technol. A 1993, 11, 2733–2741. [Google Scholar] [CrossRef]

- Wicher, B.; Chodun, R.; Greczynski, G.; Lackowski, A.; Trzcinski, M.; Pshyk, A.V.; Król, K.; Kulikowski, K.; Skowronski, L.; Zdunek, K. Carbon ion self–sputtering attained by sublimation of hot graphite target and controlled by pulse injection of a neon–helium gas mixture. Appl. Surf. Sci. 2023, 620, 156708. [Google Scholar] [CrossRef]

- Aijaz, A.; Sarakinos, K.; Lundin, D.; Brenning, N.; Helmersson, U. A strategy for increased carbon ionization in magnetron sputtering discharges. Diam. Relat. Mater 2012, 23, 1–4. [Google Scholar] [CrossRef]

- Tiron, V.; Bulai, G.; Costin, C.; Velicu, I.-L.; Dincă, P.; Iancu, D.; Burducea, I. Growth and characterization of W thin films with controlled Ne and Ar contents deposited by bipolar HiPIMS. Nucl. Mater. Energy 2021, 29, 101091. [Google Scholar] [CrossRef]

- Dhaka, R.S.; Barman, S.R. Bimodal distribution of neon nanobubbles in aluminum. Phys. Rev. B 2009, 79, 125409. [Google Scholar] [CrossRef]

- Lucas, A.A.; Vigneron, J.P.; Donnelly, S.E.; Rife, J.C. Theoretical interpretation of the vacuum ultraviolet reflectance of liquid helium and of the absorption spectra of helium microbubbles in aluminium. Phys. Rev. B 1983, 28, 2485–2496. [Google Scholar] [CrossRef]

- Fréchard, S.; Walls, M.; Kociak, M.; Chevalier, J.P.; Henry, J.; Gorse, D. Study by EELS of helium bubbles in a martensitic steel. J. Nucl. Mater. 2009, 393, 102–107. [Google Scholar] [CrossRef]

- Romberg, R.; Kassühlke, B.; Wiethoff, P.; Menzel, D.; Feulner, P. Condensation effects in K-shell excitation and de-excitation of solid neon. Chem. Phys. 2003, 289, 69–79. [Google Scholar] [CrossRef]

- Arms, D.A.; Graber, T.J.; Macrander, A.T.; Simmons, R.O.; Schwoerer-Böhning, M.; Zhong, Y. Excitons in bulk liquid 4He. Phys. Rev. B 2005, 71, 233107. [Google Scholar] [CrossRef]

- Rasband, W.S. U. S. National Institutes of Health, Bethesda, Maryland, USA. ImageJ. Available online: https://imagej.nih.gov/ij/ (accessed on 5 June 2017).

- Mayer, M. SIMNRA, a Simulation Program for the Analysis of NRA, RBS and ERDA. AIP Conf. Proc. 1999, 475, 541–544. [Google Scholar] [CrossRef]

- Colaux, J.L.; Terwagne, G.; Jeynes, C. On the traceably accurate voltage calibration of electrostatic accelerators. Nucl. Instrum. Methods Phys. Res. B 2015, 349, 173–183. [Google Scholar] [CrossRef]

- Gurbich, A.F.; Bogdanović Radović, I.; Siketić, Z.; Jakšić, M. Measurements and evaluation of the cross-section for helium elastic scattering from nitrogen. Nucl. Instrum. Methods Phys. Res. B 2011, 269, 40–44. [Google Scholar] [CrossRef]

- Gai, E.V.; Gurbich, A.F. Evaluated 12C(4He,4He)12C cross-section and its uncertainty. Nucl. Instrum. Methods Phys. Res. B 2013, 296, 87–91. [Google Scholar] [CrossRef]

- Barradas, N.P.; Jeynes, C.; Webb, R.P. Simulated annealing analysis of Rutherford backscattering data. Appl. Phys. Lett. 1997, 71, 291–293. [Google Scholar] [CrossRef]

- Gurbich, A.F. SigmaCalc recent development and present status of the evaluated cross-sections for IBA. Nucl. Instrum. Methods Phys. Res. B 2016, 371, 27–32. [Google Scholar] [CrossRef]

- Avila, J.; Razado-Colambo, I.; Lorcy, S.; Lagarde, B.; Giorgetta, J.-L.; Polack, F.; Asensio, M.C. ANTARES, a scanning photoemission microscopy beamline at SOLEIL. J. Phys. Conf. Ser. 2013, 425, 192023. [Google Scholar] [CrossRef]

- Dhaka, R.S.; Biswas, C.; Shukla, A.K.; Barman, S.R.; Chakrabarti, A. Xe and Ar nanobubbles in Al studied by photoemission spectroscopy. Phys. Rev. B 2008, 77, 104119. [Google Scholar] [CrossRef]

- Donnelly, S.E.; Rife, J.C.; Gilles, J.M.; Lucas, A.A. Optical measurements of the density of helium in small bubbles in aluminium films. J. Nucl. Matter 1980, 93–94, 767–772. [Google Scholar] [CrossRef]

- Jäger, W.; Manzke, R.; Trinkhaus, H.; Crecelius, G.; Zeller, R.; Fink, J.; Bay, H.L. Density and pressure of helium in small bubbles in metals. J. Nucl. Matter 1982, 111–112, 674–680. [Google Scholar] [CrossRef]

- Pyper, N.C.; Naginey, T.C.; Nellist, P.N.; Whelan, C.T. Excited helium under high pressures in the bulk and in nanobubbles. Phil. Mag. Lett. 2017, 97, 295–303. [Google Scholar] [CrossRef]

- Pyper, N.C.; Naginey, T.C.; Whelan, C.T. Environmental modifications of atomic properties: The ground and 1s2p excited states of compressed helium. J. Chem. Phys. 2021, 155, 214301. [Google Scholar] [CrossRef] [PubMed]

- David, M.-L.; Pailloux, F.; Mauchamp, V.; Pizzagalli, L. In situ probing of helium desorption from individual nanobubbles under electron irradiation. Appl. Phys. Lett. 2011, 98, 171903. [Google Scholar] [CrossRef]

- Hitchcock, A.P.; Brion, C.E. Neon K-shell excitation by electron energy-loss spectroscopy. J. Phys. B Atom. Molec. Phys. 1980, 113, 3269–3273. [Google Scholar] [CrossRef]

- Brault, P.; Thomann, A.-L.; Cavarroc, M. Theory and molecular simulations of plasma sputtering, transport and deposition processes. Eur. Phys. J. D. 2023, 77, 19. [Google Scholar] [CrossRef]

- Cheng, J.; Li, M.; Peng, Y.; Li, J.; Xiao, X.; Shi, M.; Yang, J.; Peng, P.; Liu, F.; Xiao, J.; et al. Improving the accuracy of ion implantation simulations through the use of DFT-MD methodology. Phys. B Condens. Matter 2024, 675, 415616. [Google Scholar] [CrossRef]

- Mikoushkin, V.M.; Makarevskaya, E.A.; Brzhezinskaya, M. Effect of ion irradiation on GaAs core-level electron binding energies and band structure. Appl. Surf. Sci. 2021, 539, 148273. [Google Scholar] [CrossRef]

| Sample nr. Description | Deposition Time (h) | Sputtering Gas and Pressure (Pa) | Power (dc or rf) (W) | V (V) | I (A) | Deposition Rate * (nm/min) |

|---|---|---|---|---|---|---|

| S1: Si-Ne/150dc/2Ne | 2 | Ne(2) | 150 (dc) | 430 | 0.35 | 12.6 ± 0.4 |

| S2: Si-Ne(He)/150dc/2Ne + 2He | 2 | Ne(2) + He(2) | 150 (dc) | 350 | 0.42 | 12.1 ± 0.3 |

| S3: Si-Ne(He)/150dc/1Ne + 1He | 3 | Ne(1) + He(1) | 150 (dc) | 410 | 0.37 | 11.9 ± 0.3 |

| S4: Si-Ne/150rf/2Ne | 2 | Ne(2) | 150 (rf) | 425 ** | 8.6 ± 0.2 | |

| S5: Si-Ne(He)/150rf/2Ne + 2He | 3.5 | Ne(2) + He(2) | 150 (rf) | 310 ** | 7.0 ± 0.1 | |

| S6: Si-Ne/300dc/2Ne | 1.5 | Ne(2) | 300 (dc) | 450 | 0.65 | 31.5 ± 0.5 |

| S7: Si-Ne(He)/300dc/2Ne + 2He | 1.5 | Ne(2) + He(2) | 300 (dc) | 380 | 0.81 | 24.6 ± 0.4 |

| S8: Si-Ar/150dc/2Ar | 0.75 | Ar(2) | 150 (dc) | 417 | 0.36 | 16.2 ± 0.5 |

| S9: Si-Ar(He)/150dc/1Ar + 1He | 1.25 | Ar(1) + He(1) | 150 (dc) | 384 | 0.39 | 15.1 ± 0.3 |

| Sample nr. Description | Thickness (SEM) (µm) | Column Size Range (SEM) (nm) | Mean Column Size (SEM) (nm) | Pore Size Range (TEM) (nm) | Mean Pore Size (TEM) (nm) | Mean Aspect Ratio (TEM) |

|---|---|---|---|---|---|---|

| S1: Si-Ne/150dc/2Ne | 1.51 ± 0.02 | 1–5 | 2.5 ± 0.9 | 0.6 ± 0.2 | ||

| S2: Si-Ne(He)/150dc/2Ne + 2He | 1.45 ± 0.01 | 1–12 | 5.5 ± 2.3 | 0.6 ± 0.2 | ||

| S3: Si-Ne(He)/150dc/1Ne + 1He | 2.14 ± 0.01 | |||||

| S4: Si-Ne/150rf/2Ne | 1.03 ± 0.01 | 1–5 | 1.7 ± 0.6 | 0.6 ± 0.2 | ||

| S5: Si-Ne(He)/150rf/2Ne + 2He | 1.47 ± 0.01 | 1–20 | 3.8 ± 1.8 | 0.6 ± 0.2 | ||

| S6: Si-Ne/300dc/2Ne | 2.84 ± 0.02 | 0.5–5 | 2.7 ± 0.8 | 0.7 ± 0.2 | ||

| S7: Si-Ne(He)/300dc/2Ne + 2He | 2.22 ± 0.01 | 1–14 | 5.2 ± 2.7 | 0.5 ± 0.2 | ||

| S8: Si-Ar/150dc/2Ar | 0.73 ± 0.01 | 20–90 | 38 ± 20 | |||

| S9: Si-Ar(He)/150dc/1Ar + 1He | 1.13 ± 0.01 | 20–100 | 49 ± 26 |

| Sample nr. Description | at% Si | at% Ne | at% Ar | at% He | Atomic Ratio Ne/Si or Ar/Si | Atomic Ratio He/Si |

|---|---|---|---|---|---|---|

| S1: Si-Ne/150dc/2Ne | 94.1 ± 2.3 | 5.90 ± 0.25 | 0.063 ± 0.004 | |||

| S2: Si-Ne(He)/150dc/2Ne + 2He | 71.8 ± 1.8 | 10.95 ± 0.50 | 17.24 ± 0.90 | 0.15 ± 0.01 | 0.24 ± 0.02 | |

| S3: Si-Ne(He)/150dc/1Ne + 1He | 76.3 ± 2.3 | 12.10 ± 0.61 | 11.62 ± 0.58 | 0.16 ± 0.01 | 0.15 ± 0.01 | |

| S4: Si-Ne/150rf/2Ne | 89.5 ± 2.7 | 10.5 ± 0.53 | 0.12 ± 0.01 | |||

| S5: Si-Ne(He)/150rf/2Ne + 2He | 66.9 ± 2.0 | 13.0 ± 0.65 | 20.1 ± 1.0 | 0.19 ± 0.01 | 0.30 ± 0.02 | |

| S6: Si-Ne/300dc/2Ne | 97.0 ± 2.9 | 3.0 ± 0.30 | 0.031 ± 0.004 | |||

| S7: Si-Ne(He)/300dc/2Ne + 2He | 71.6 ± 2.1 | 13.0 ± 0.65 | 15.36 ± 0.77 | 0.18 ± 0.01 | 0.21 ± 0.02 | |

| S8: Si-Ar/150dc/2Ar | 99 ± 1 | 1.00 ± 0.15 | 0.010 ± 0.001 | |||

| S9: Si-Ar(He)/150dc/1Ar + 1He | 89 ± 10 | 4.8 ± 0.3 | 5.7 ± 0.5 | 0.05 ± 0.01 | 0.06 ± 0.01 |

| Sample nr. Description | at% C | at% O | at% H |

|---|---|---|---|

| S1: Si-Ne/150dc/2Ne | 1.30 ± 0.07 | 1.55 ± 0.29 | 2.10 ± 0.11 |

| S2: Si-Ne(He)/150dc/2Ne + 2He | 1.22 ± 0.08 | 2.85 ± 0.38 | 2.74 ± 0.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, A.; Godinho, V.; Ávila, J.; Jiménez de Haro, M.C.; Hufschmidt, D.; López-Viejobueno, J.; Almanza-Vergara, G.E.; Ferrer, F.J.; Colaux, J.L.; Lucas, S.; et al. Synergistic Effect of He for the Fabrication of Ne and Ar Gas-Charged Silicon Thin Films as Solid Targets for Spectroscopic Studies. Nanomaterials 2024, 14, 727. https://doi.org/10.3390/nano14080727

Fernández A, Godinho V, Ávila J, Jiménez de Haro MC, Hufschmidt D, López-Viejobueno J, Almanza-Vergara GE, Ferrer FJ, Colaux JL, Lucas S, et al. Synergistic Effect of He for the Fabrication of Ne and Ar Gas-Charged Silicon Thin Films as Solid Targets for Spectroscopic Studies. Nanomaterials. 2024; 14(8):727. https://doi.org/10.3390/nano14080727

Chicago/Turabian StyleFernández, Asunción, Vanda Godinho, José Ávila, M. Carmen Jiménez de Haro, Dirk Hufschmidt, Jennifer López-Viejobueno, G. Eduardo Almanza-Vergara, F. Javier Ferrer, Julien L. Colaux, Stephane Lucas, and et al. 2024. "Synergistic Effect of He for the Fabrication of Ne and Ar Gas-Charged Silicon Thin Films as Solid Targets for Spectroscopic Studies" Nanomaterials 14, no. 8: 727. https://doi.org/10.3390/nano14080727

APA StyleFernández, A., Godinho, V., Ávila, J., Jiménez de Haro, M. C., Hufschmidt, D., López-Viejobueno, J., Almanza-Vergara, G. E., Ferrer, F. J., Colaux, J. L., Lucas, S., & Asensio, M. C. (2024). Synergistic Effect of He for the Fabrication of Ne and Ar Gas-Charged Silicon Thin Films as Solid Targets for Spectroscopic Studies. Nanomaterials, 14(8), 727. https://doi.org/10.3390/nano14080727