Correlation of Fabrication Methods and Enhanced Wear Performance in Nanoporous Anodic Aluminum Oxide with Incorporated Molybdenum Disulfide (MoS2) Nanomaterials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

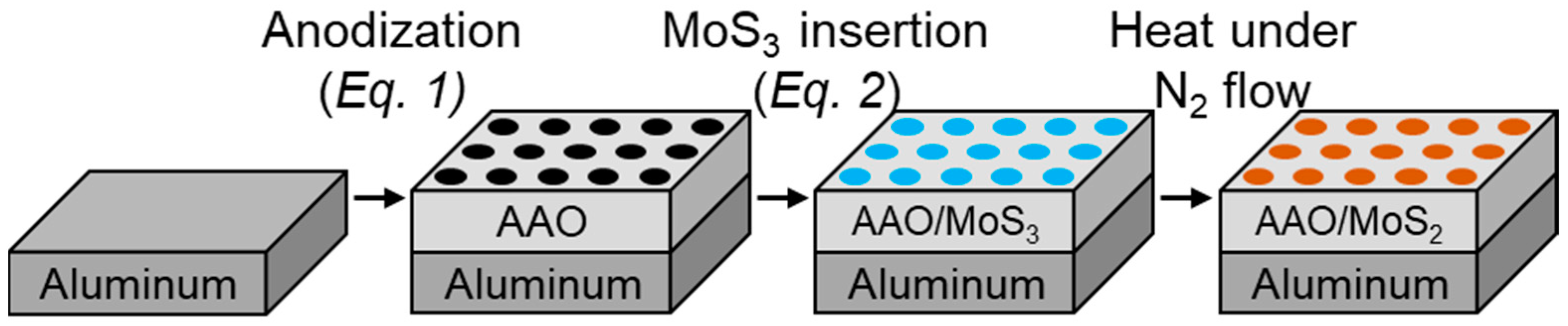

2.2. Anodization Procedure

2.3. Sample Analysis

3. Results and Discussion

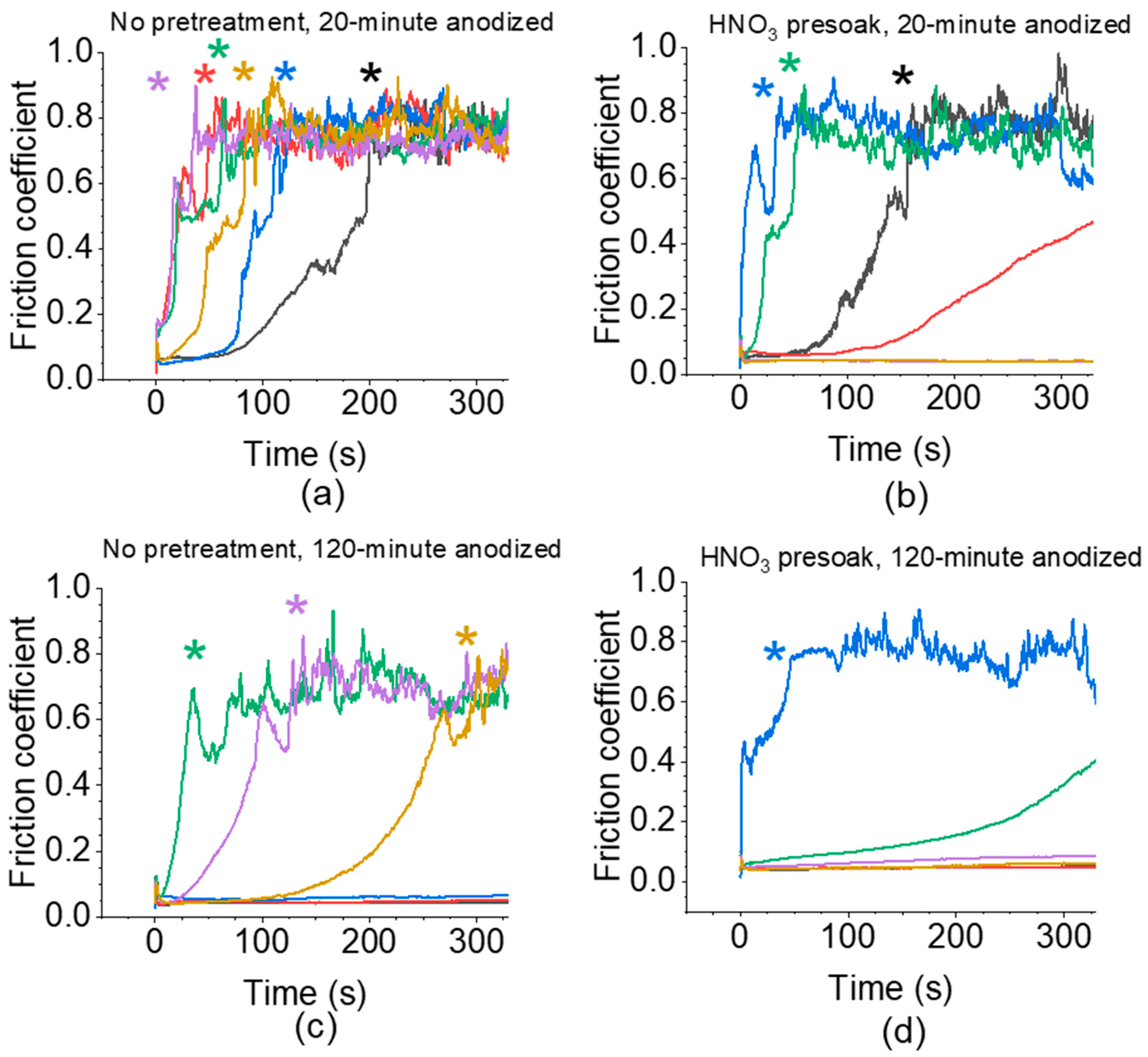

3.1. High-Acid Anodized Aluminum 5052

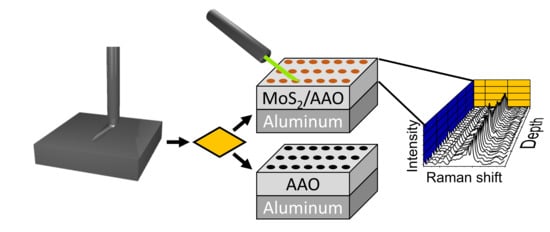

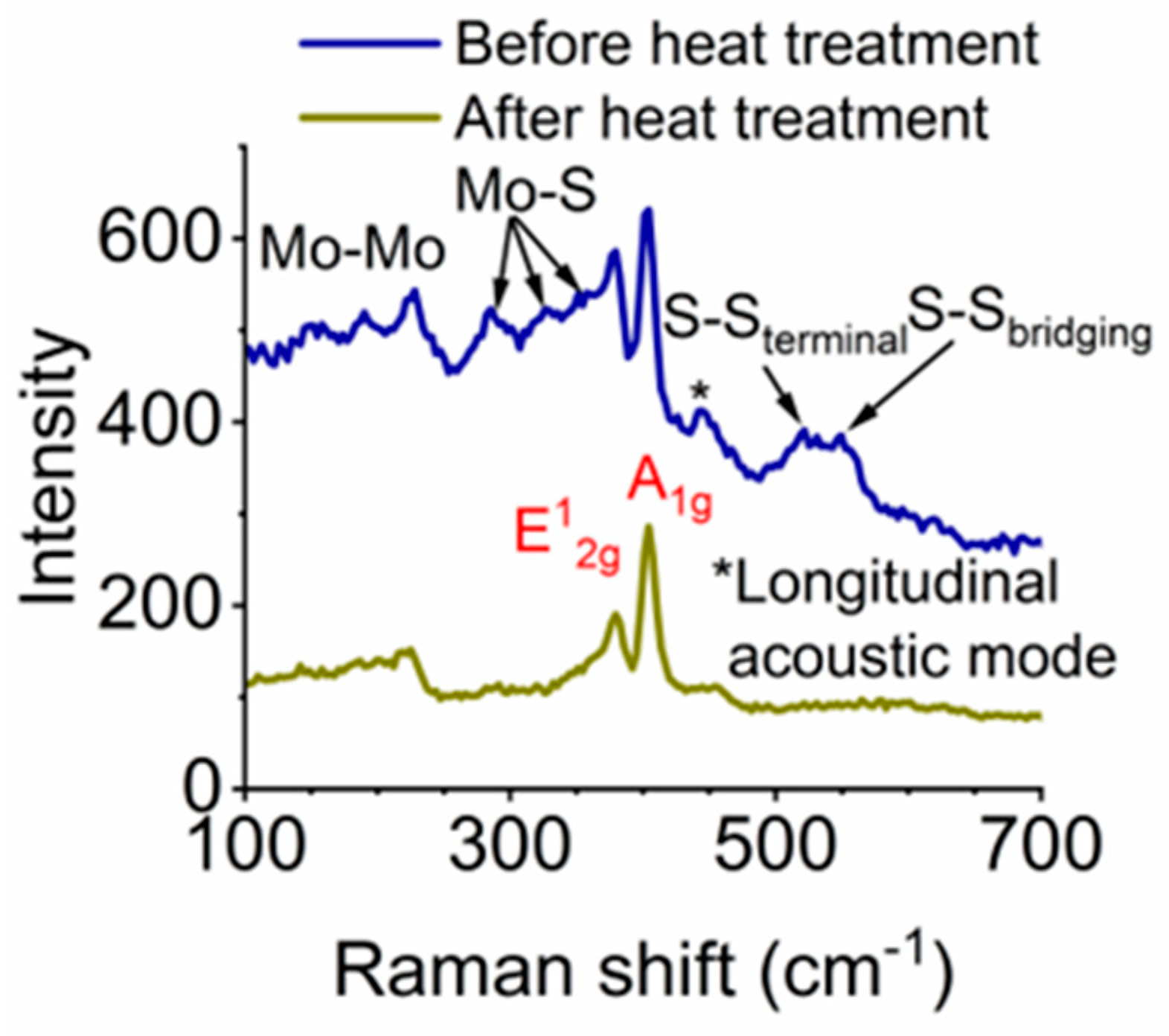

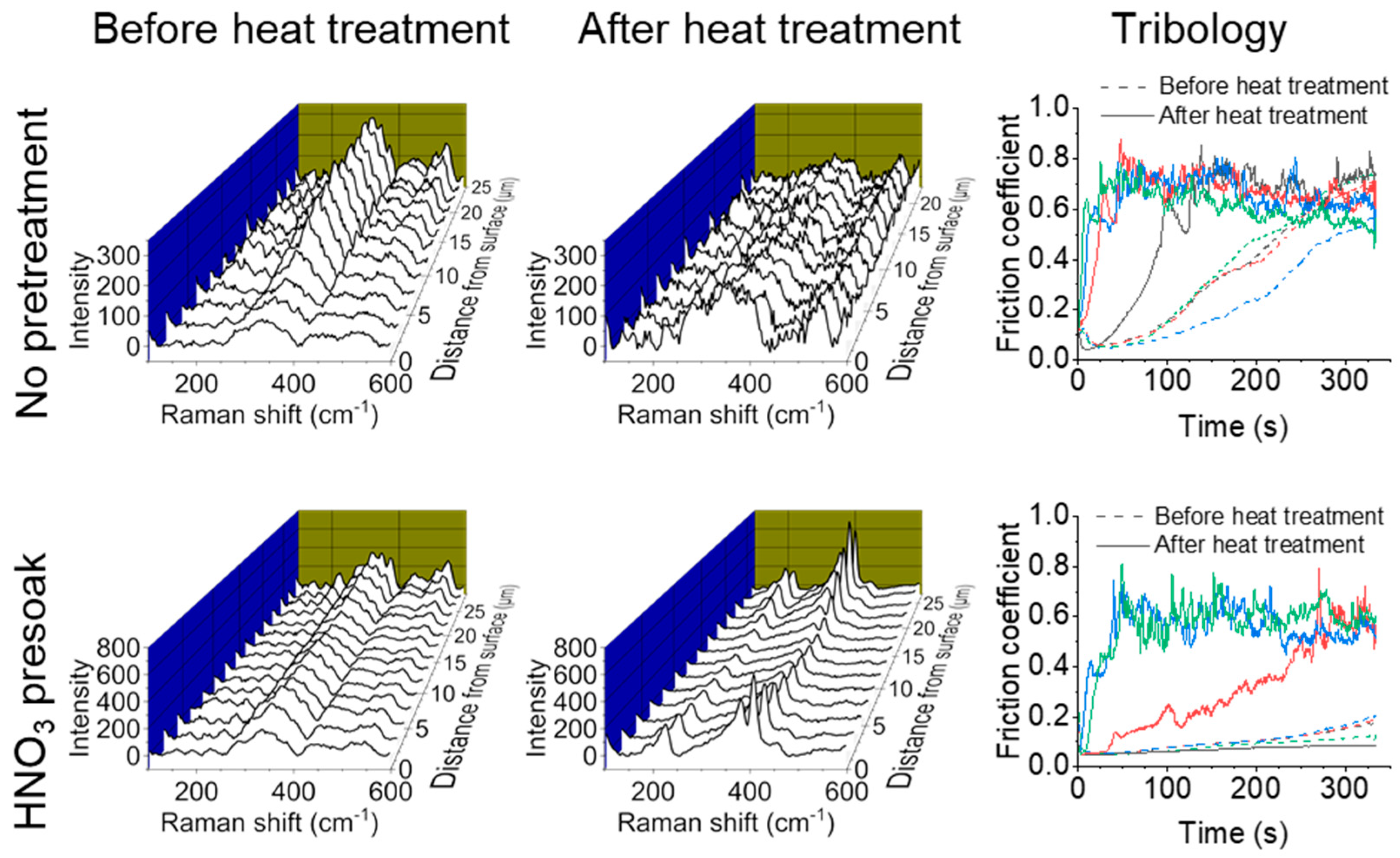

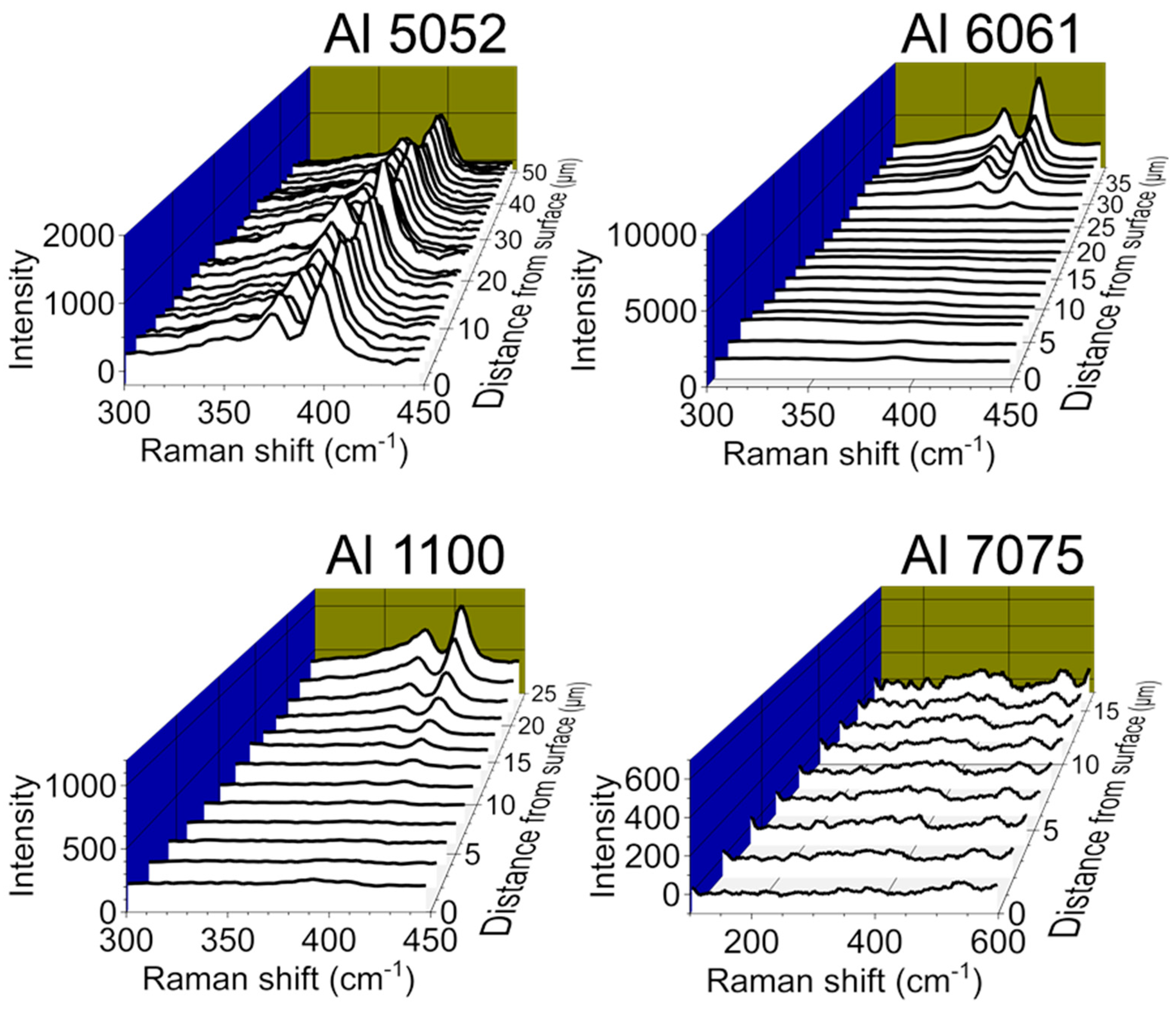

3.2. Raman Spectroscopy and Cross-Sectional Analysis

3.3. Heat Treatment Effects

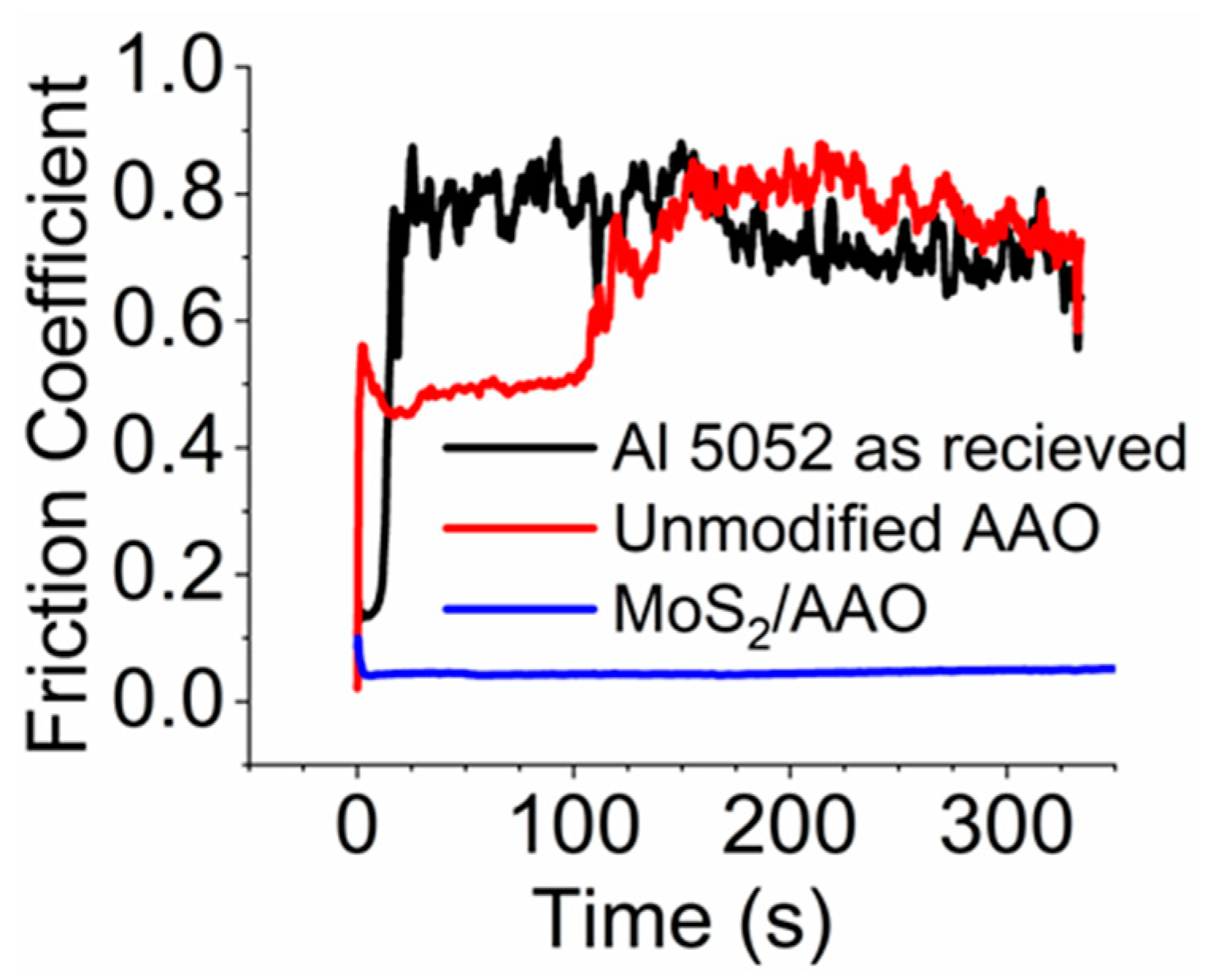

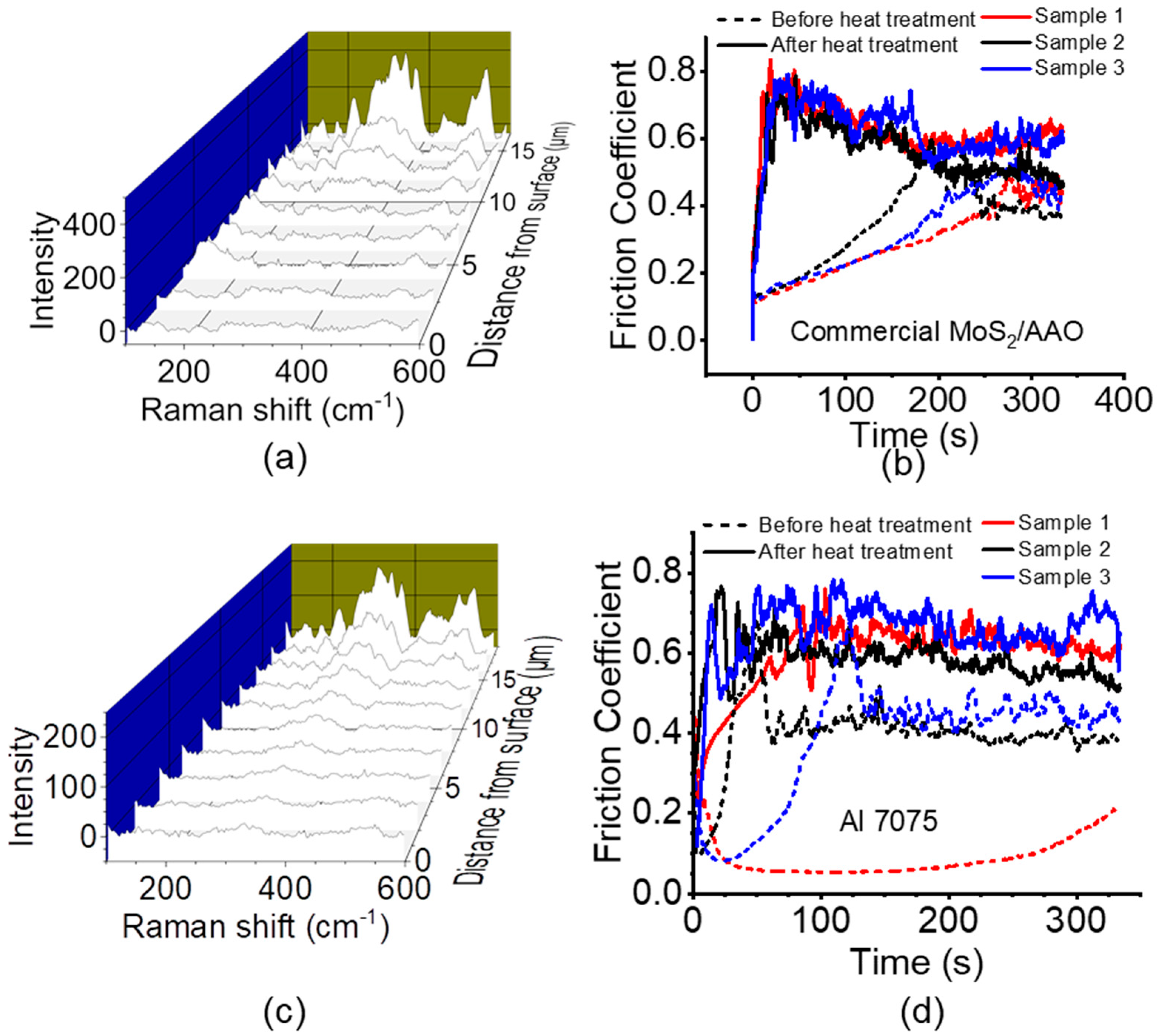

3.4. Commercial MoS2/AAO Film Comparison

3.5. Low-Acid Anodized Aluminum 5052

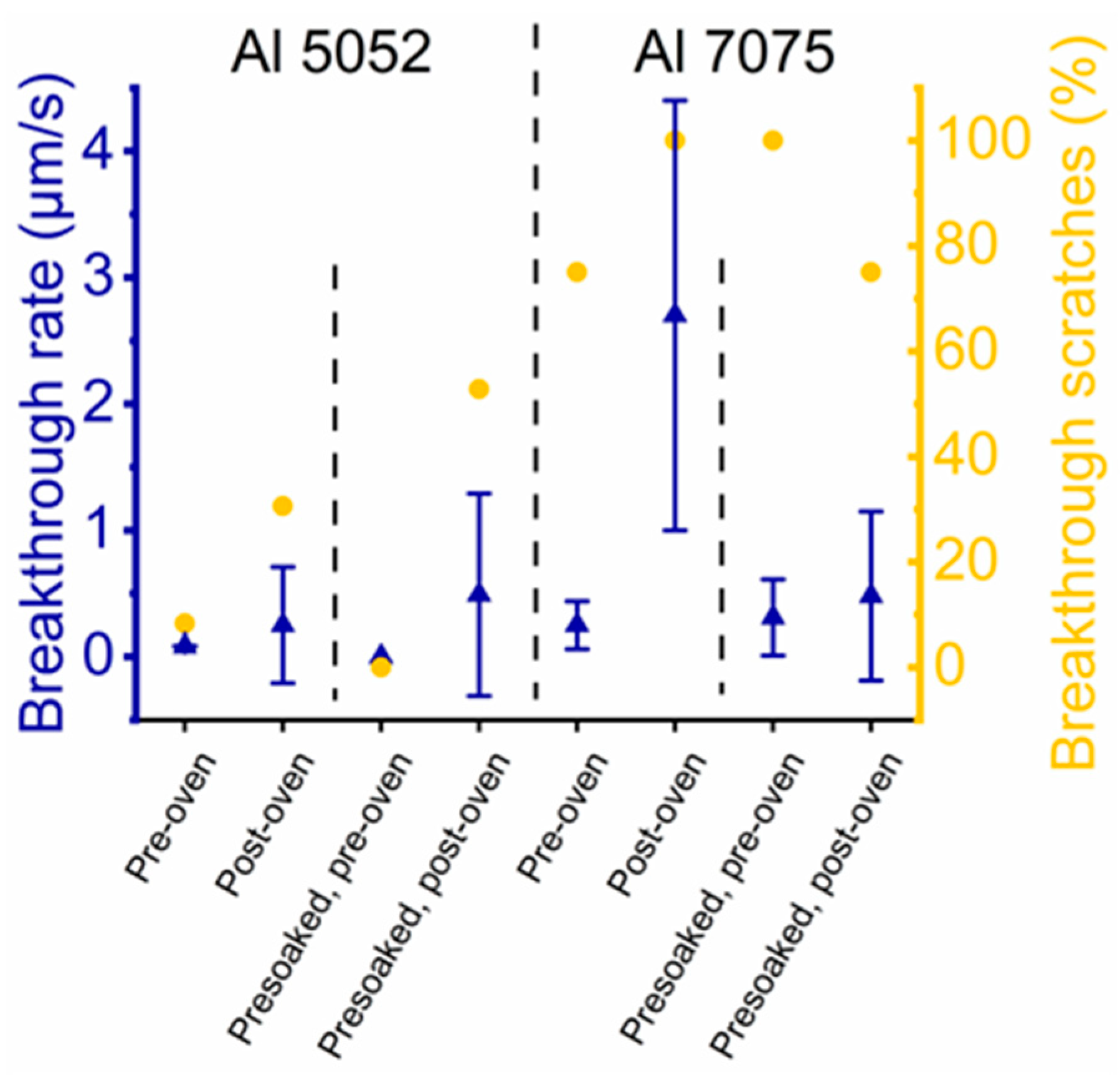

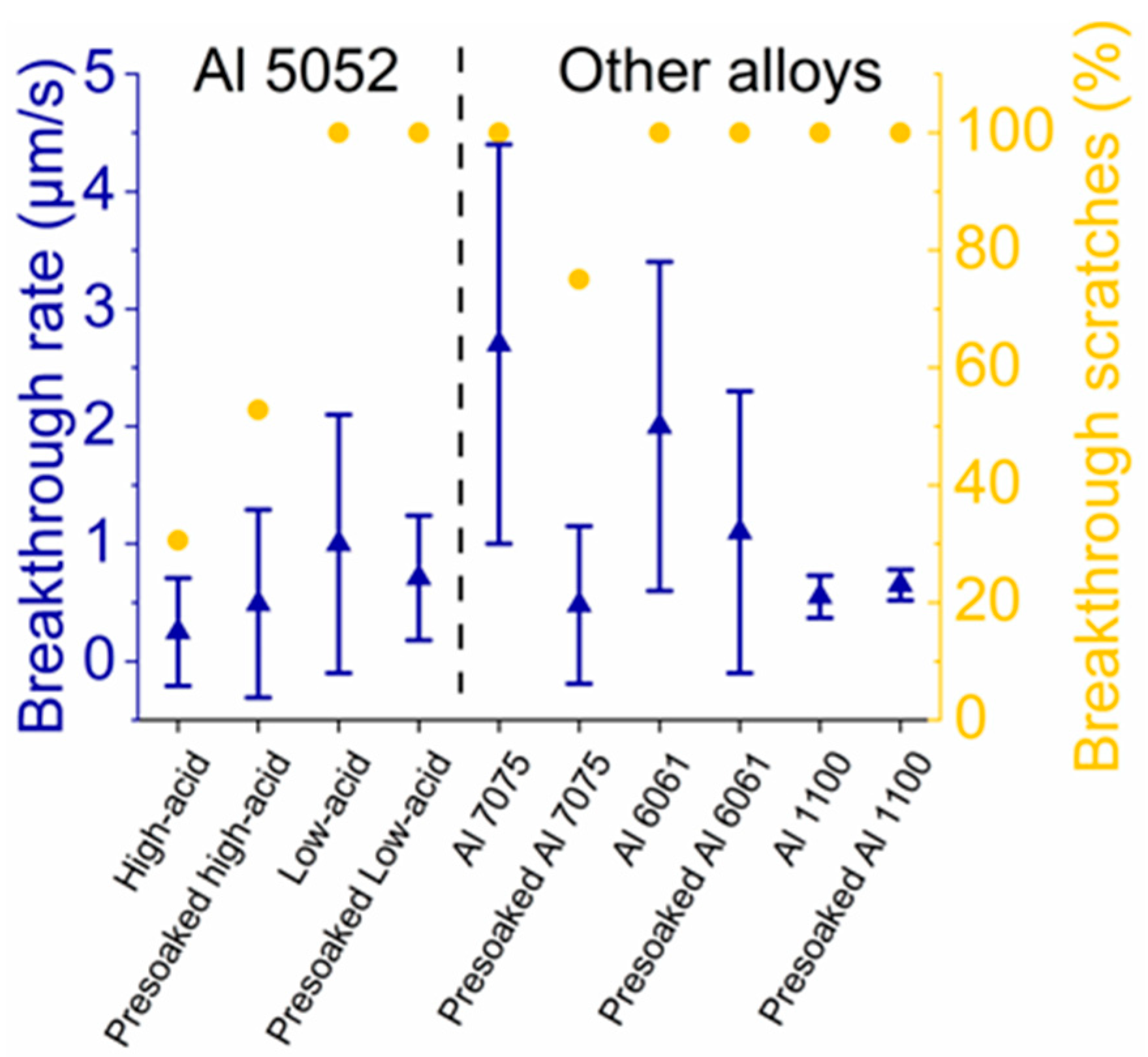

3.6. Aluminum Alloy Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Donahue, C.J.; Exline, J.A. Anodizing and Coloring Aluminum Alloys. J. Chem. Educ. 2014, 91, 711–715. [Google Scholar] [CrossRef]

- Dervishi, E.; McBride, M.; Edwards, R.; Gutierrez, M.; Li, N.; Buntyn, R.; Hooks, D.E. Mechanical and Tribological Properties of Anodic Al Coatings as a Function of Anodizing Conditions. Surf. Coat. Technol. 2022, 444, 128652. [Google Scholar] [CrossRef]

- Alshujery, M.K.; Al-Saadie, K.A.S. Anodizing of Aluminum 6061 Alloy with Incorporated Nanoparticles to Inhibits the Aluminum Corrosion. Int. J. Health Sci. 2022, 6, 930–940. [Google Scholar] [CrossRef]

- Ku, C.-A.; Yu, C.-Y.; Hung, C.-W.; Chung, C.-K. Advances in the Fabrication of Nanoporous Anodic Aluminum Oxide and its Applications to Sensors: A Review. Nanomaterials 2023, 13, 2853. [Google Scholar] [CrossRef]

- Vandekerkhove, A.; Negahdar, L.; Glas, D.; Stassen, I.; Matveev, S.; Meeldijk, J.D.; Meirer, F.; De Vos, D.E.; Weckhuysen, B.M. Synthesis and Characterization of Ru-loaded Anodized Aluminum Oxide for Hydrogenation Catalysis. ChemistryOpen 2019, 8, 532–538. [Google Scholar] [CrossRef] [PubMed]

- Jensen, J.D.; Krüger, U.; Winkler, G. Method for Introducing Nanoparticles into an Anodized Aluminum Surface. DE Patent WO2008152077A2, 18 December 2008. [Google Scholar]

- Wu, D.; Zhang, D.; Ye, Y.; Ma, L.; Minhas, B.; Liu, B.; Terryn, H.A.; Mol, J.M.C.; Li, X. Durable Lubricant-infused Anodic Aluminum Oxide Surfaces with High-aspect-ratio Nanochannels. Chem. Eng. J. 2019, 369, 138–147. [Google Scholar] [CrossRef]

- Sarraf, M.; Nasiri-Tabrizi, B.; Dabbagh, A.; Basirun, W.J.; Sukiman, N.L. Optimized Nanoporous Aluminum Coating on AA3003-H14 Aluminum Alloy with Enhanced Tribo-corrosion Performance in Palm Oil. Ceram. Int. 2020, 46, 7306–7323. [Google Scholar] [CrossRef]

- Lansdown, A.R. Molybdenum Disulphide Lubrication; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Joseph, J.S.D.; Kumaragurubaran, B.; Sathish, S. Effect of MoS2 on the Wear Behavior of Aluminium (AlMg0.5Si) Composite. Silicon 2019, 12, 1481–1489. [Google Scholar] [CrossRef]

- Torres, H.; Caykara, T.; Rojacz, H.; Prakash, B.; Ripoll, M.R. The tribology of Ag/MoS2-based self-lubricating laser claddings for high temperature forming of aluminium alloys. Wear 2019, 442–443, 203110. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, C.; Cao, X. The Effect of MoS2 and MWCNTs Nanomicro Lubrication on the Process of 7050 Aluminum Alloy. Processes 2024, 12, 68. [Google Scholar] [CrossRef]

- Yücel, A.; Yıldırım, Ç.V.; Sarıkaya, M.; Şirin, Ş.; Kıvak, T.; Gupta, M.K.; Tomaz, Í.V. Influence of MoS2 based nanofluid-MQL on tribological and machining characteristics in turning of AA 2024 T3 aluminum alloy. J. Mater. Res. Technol. 2021, 15, 1688–1704. [Google Scholar] [CrossRef]

- Dhyani, R.; Zindal, A.; Singh, V.K.; Chauhan, S. Tuning of MoS2 Particle in Al-Based Composite for Self-Lubrication. JOM 2023, 75, 2949–2961. [Google Scholar] [CrossRef]

- Liu, W.; Qiao, X.; Liu, S.; Chen, P. A Review of Nanomaterials with Different Dimensions as Lubricant Additives. Nanomaterials 2022, 12, 3780. [Google Scholar] [CrossRef] [PubMed]

- Agbe, H.; Sarkar, D.K.; Chen, X.G. Electrochemically synthesized silver phosphate coating on anodized aluminum with superior antibacterial properties. Surf. Coat. Technol. 2021, 428, 127892. [Google Scholar] [CrossRef]

- Han, D.; Wang, Y.; Li, Y.; Li, X.; Zhu, Z.; Shi, X.; Qiu, S. Formation and Tribological Properties of MoS2 Self-lubricating Porous Anodic Alumina Thin Films. Int. J. Mod. Phys. B 2020, 34, 2040021. [Google Scholar] [CrossRef]

- Hu, L.; Chen, P.-C. Hot-injection for Synthesizing Ammonium Thiosulfate Precursor of Molybdenum Disulfide Thin Film Coated on Nano-porous Aluminum Oxide for Surface Strengthening. J. Alloys Compd 2020, 848, 156262. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Liu, T.; Ye, Z.; He, R.; Sankaran, R.M. Synthesis of Large-area MoS2 Films by Plasma-enhanced Chemical Film Conversion of Solution-processed Ammonium Tetrathiomolybdate. J. Vac. Sci. Technol. A 2020, 38, 063006. [Google Scholar] [CrossRef]

- Tao, X.; Jianmin, C.; Jiazheng, Z.; Hongxin, D. The Pore-enlargement and Self-lubrication Treatment of Anodic Oxide Film of Aluminum. Wear 1996, 196, 214–218. [Google Scholar] [CrossRef]

- Yu, D.; Feng, Y.; Zhu, Y.; Zhang, X.; Li, B.; Liu, H. Template Synthesis and Characterization of Molybdenum Disulfide Nanotubules. Mater. Res. Bull. 2011, 46, 1504–1509. [Google Scholar] [CrossRef]

- Saruwatari, K.; Isawa, K.; Maejima, M.; Suzuki, T. Method for Surface Treatment of Anodic Oxide Film. US Patent 4230539, 28 October 1980. [Google Scholar]

- Skeldon, P.; Wang, H.W.; Thompson, G.E. Formation and Characterization of Self-lubricating MoS2 Precursor Films on Anodized Aluminium. Wear 1997, 206, 187–196. [Google Scholar] [CrossRef]

- Wang, H.W.; Skeldon, P.; Thompson, G.E. Tribological Enhancement of Aluminum by Porous Anodic Films Containing Solid Lubricants of MoS2 Precursors. Tribol. Trans. 1999, 42, 202–209. [Google Scholar] [CrossRef]

- Maejima, M.; Saruwatari, K.; Takaya, M. Friction Behaviour of Anodic Oxide Film on Aluminum Impregnated with Molybdenum Sulfide Compounds. Surf. Coat. Technol. 2000, 132, 105–110. [Google Scholar] [CrossRef]

- Cochran, W.C. Anodizing. In Aluminum: Fabrication and Finishing; Horn, K.R.V., Ed.; American Society for Metals: Materials Park, OH, USA, 1967; Volume 3, pp. 641–684. [Google Scholar]

- Li, Y.; Nakamura, R. Structural Change of Molybdenum Sulfide Facilitates the Electrocatalytic Hydrogen Evolution Reaction at Neutral pH as Revealed by in situ Raman Spectroscopy. Chin. J. Catal. 2018, 39, 401–406. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.; Han, S.; Ryu, G.H.; Lee, Z.; Cheong, H. Raman Signatures of Polytypism in Molbdenum Disulfide. ACS Nano 2016, 10, 1948–1953. [Google Scholar] [CrossRef] [PubMed]

- Davis, J.R. Aluminum and Aluminum Alloys. In Alloying: Understanding the Basics; ASM International: Materials Park, OH, USA, 2001; p. 356. [Google Scholar]

| Sample Treatment | AAO/MoS2 Thickness (mm) |

|---|---|

| No pretreatment, 20 min. anodization | 14 ± 4 |

| HNO3 presoak, 20 min. anodization | 15 ± 2 |

| No pretreatment, 120 min. anodization | 38 ± 12 |

| HNO3 presoak, 120 min. anodization | 47 ± 18 |

| Sample Identification | Breakthrough Rate (mm/s) | Breakthrough Scratches (%) |

|---|---|---|

| No pretreatment, 20 min. anodization, | 0.28 ± 0.20 | 83 |

| HNO3 presoak, 20 min. anodization | 0.22 ± 0.19 | 63 |

| No pretreatment, 120 min. anodization, | 0.25 ± 0.46 | 31 |

| HNO3 presoak, 120 min. anodization | 0.49 ± 0.8 | 53 |

| No MoS2, 120 min. anodization | 0.12 ± 0.02 | 100 |

| Heat treated, No MoS2, 120 min. anodization | 0.7 ± 0.5 | 100 |

| Alloy | Al | Mg | Si | Cu | Fe | Cr | Zn | Friction Coefficient |

|---|---|---|---|---|---|---|---|---|

| 5052 | 97.2 | 2.5 | - | - | - | 0.25 | - | 0.73 ± 0.03 |

| 7075 | 90 | 2.5 | - | 1.6 | - | 0.23 | 5.6 | 0.43 ± 0.01 |

| 6061 | 97.9 | 1.0 | 0.6 | 0.28 | - | 0.2 | - | 0.59 ± 0.01 |

| 1100 | 99.2 | - | 0.2 | 0.1 | 0.5 | - | - | 0.95 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hatfield, K.O.; Brown, N.; Dervishi, E.; Carpenter, B.; Janusz, J.N.; Hooks, D.E. Correlation of Fabrication Methods and Enhanced Wear Performance in Nanoporous Anodic Aluminum Oxide with Incorporated Molybdenum Disulfide (MoS2) Nanomaterials. Nanomaterials 2024, 14, 451. https://doi.org/10.3390/nano14050451

Hatfield KO, Brown N, Dervishi E, Carpenter B, Janusz JN, Hooks DE. Correlation of Fabrication Methods and Enhanced Wear Performance in Nanoporous Anodic Aluminum Oxide with Incorporated Molybdenum Disulfide (MoS2) Nanomaterials. Nanomaterials. 2024; 14(5):451. https://doi.org/10.3390/nano14050451

Chicago/Turabian StyleHatfield, Kendrich O’Donaghue, Nathan Brown, Enkeleda Dervishi, Bradley Carpenter, Jordyn N. Janusz, and Daniel E. Hooks. 2024. "Correlation of Fabrication Methods and Enhanced Wear Performance in Nanoporous Anodic Aluminum Oxide with Incorporated Molybdenum Disulfide (MoS2) Nanomaterials" Nanomaterials 14, no. 5: 451. https://doi.org/10.3390/nano14050451

APA StyleHatfield, K. O., Brown, N., Dervishi, E., Carpenter, B., Janusz, J. N., & Hooks, D. E. (2024). Correlation of Fabrication Methods and Enhanced Wear Performance in Nanoporous Anodic Aluminum Oxide with Incorporated Molybdenum Disulfide (MoS2) Nanomaterials. Nanomaterials, 14(5), 451. https://doi.org/10.3390/nano14050451