Controlling GaN-Based Laser Diode Performance by Variation of the Al Content of an Inserted AlGaN Electron Blocking Layer

Abstract

1. Introduction

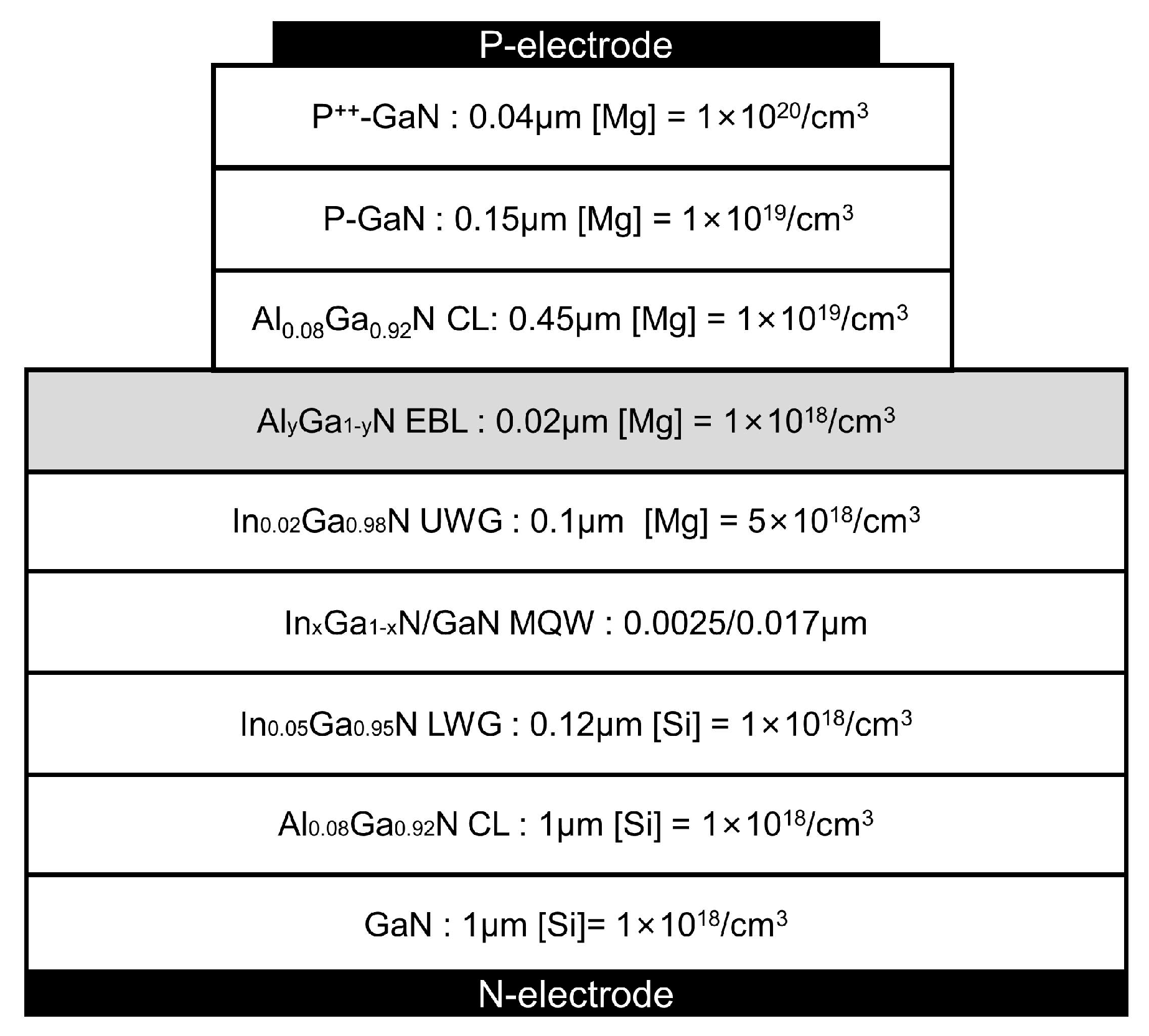

2. Laser Structure and Simulation Parameters

3. Results and Discussion

3.1. Violet and Green LDs

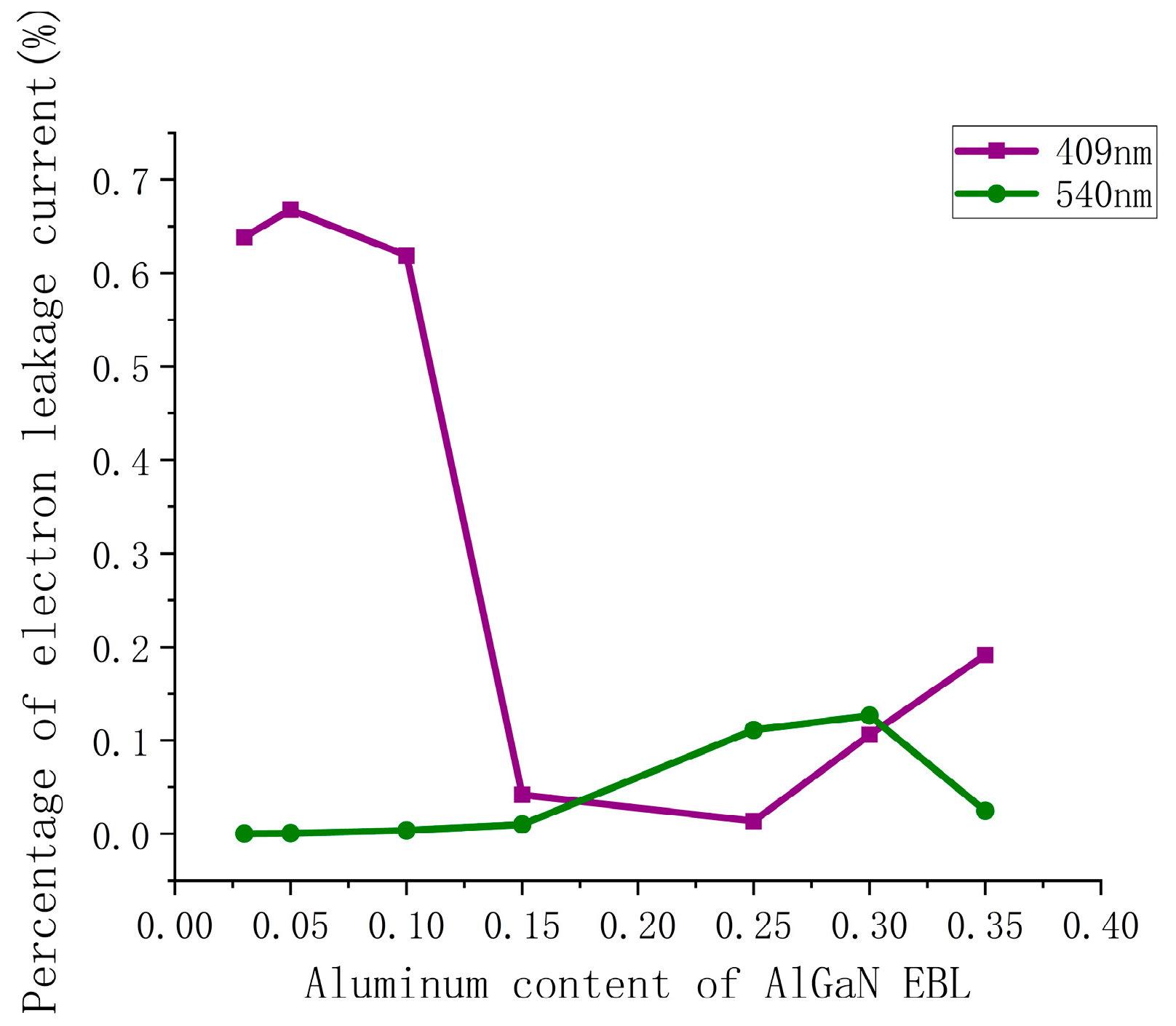

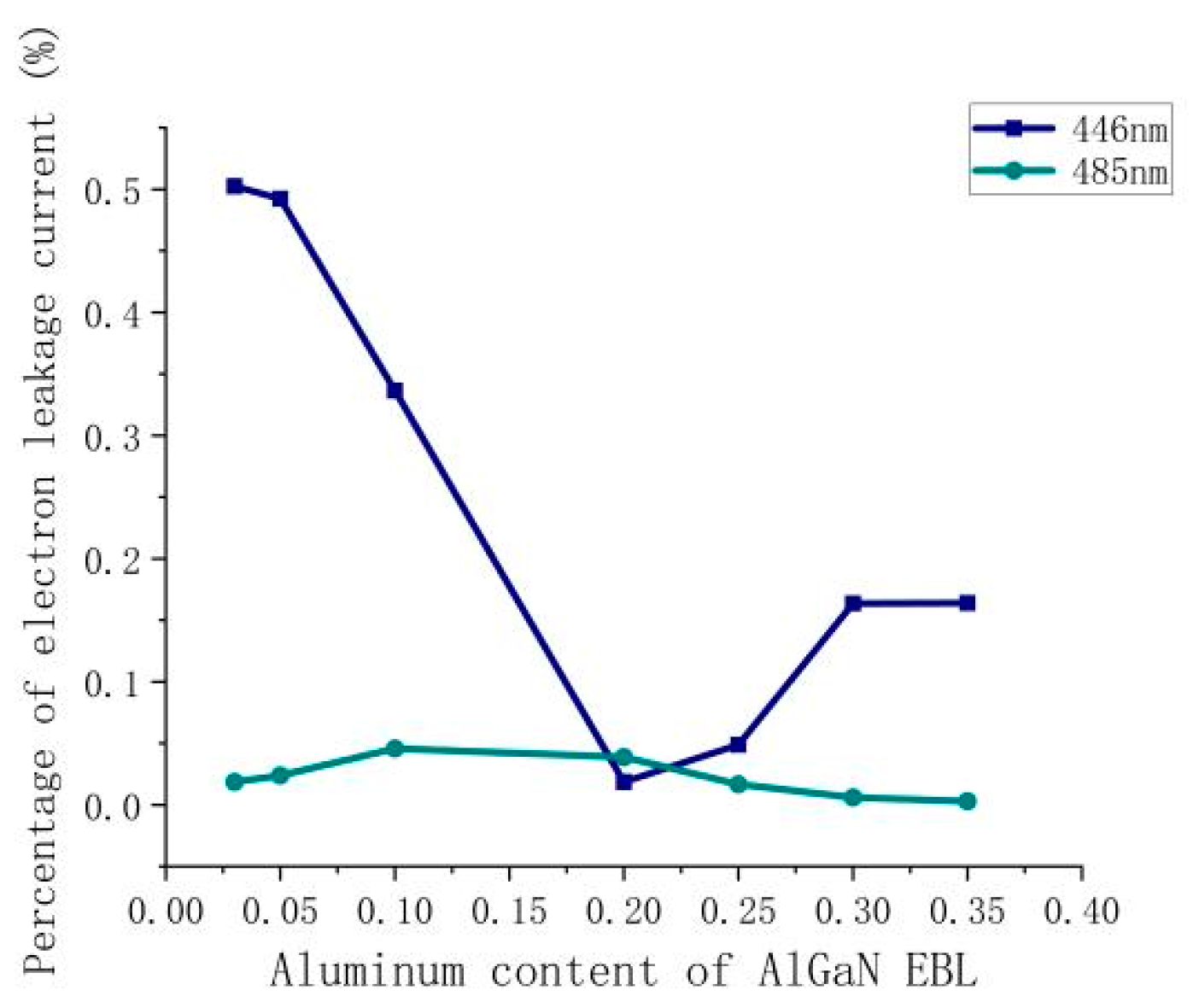

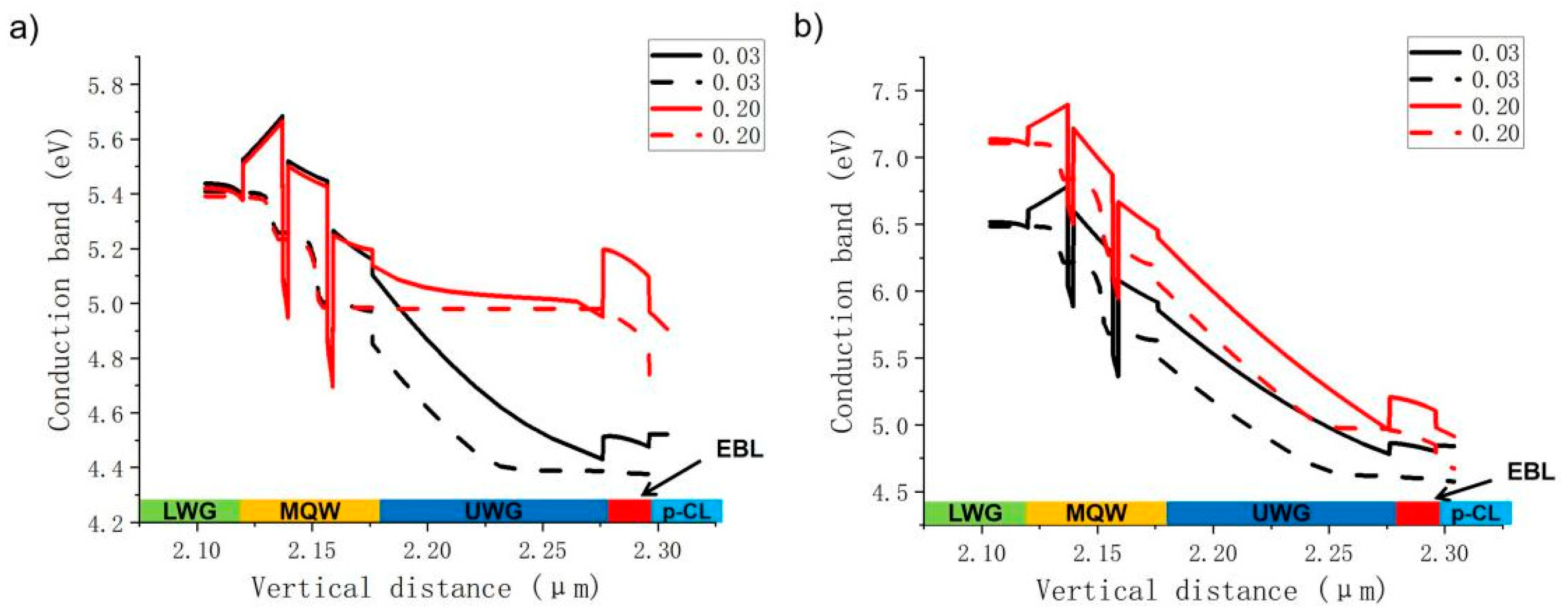

3.1.1. Electron Leakage Current of Violet and Green LDs

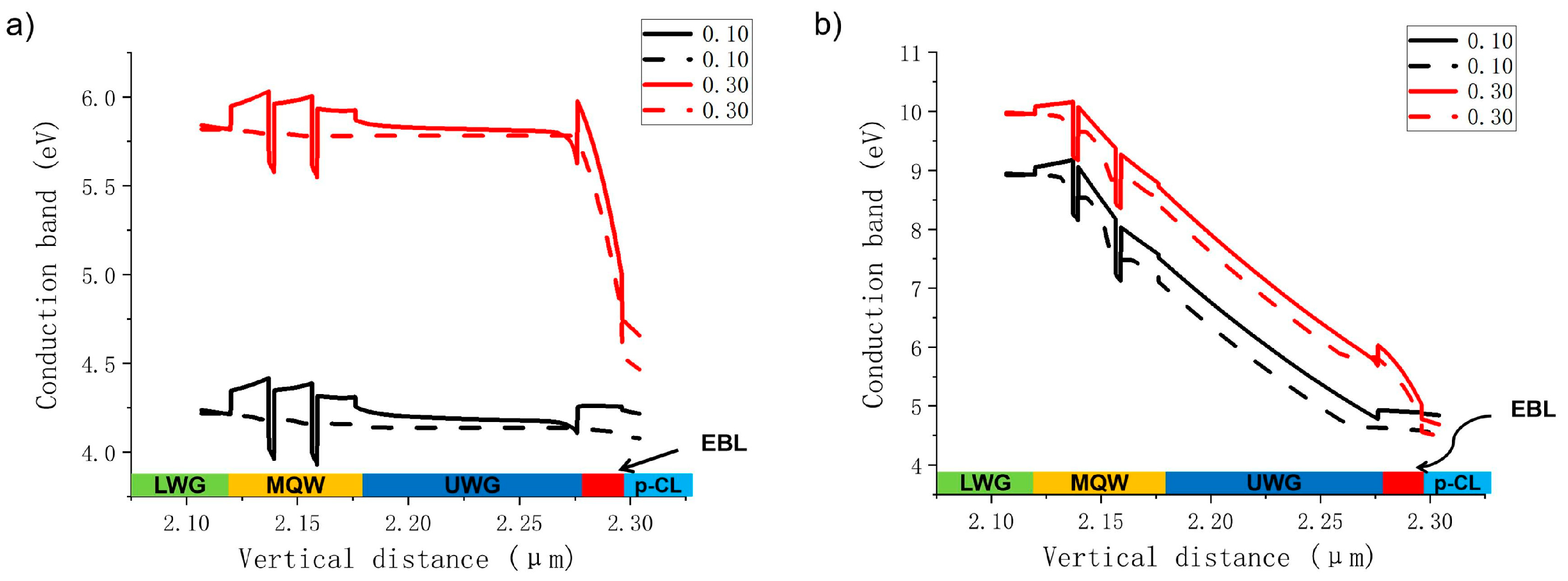

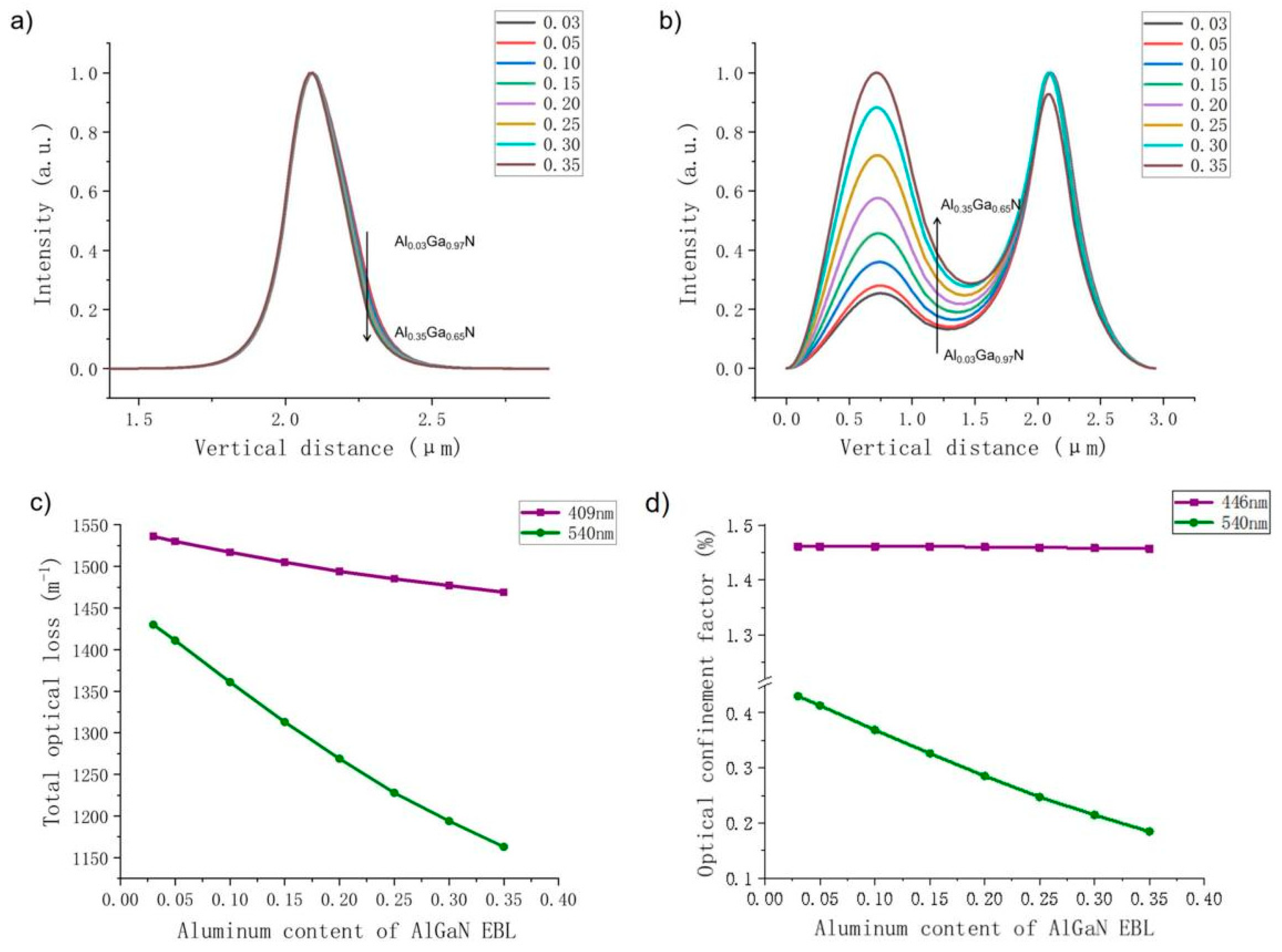

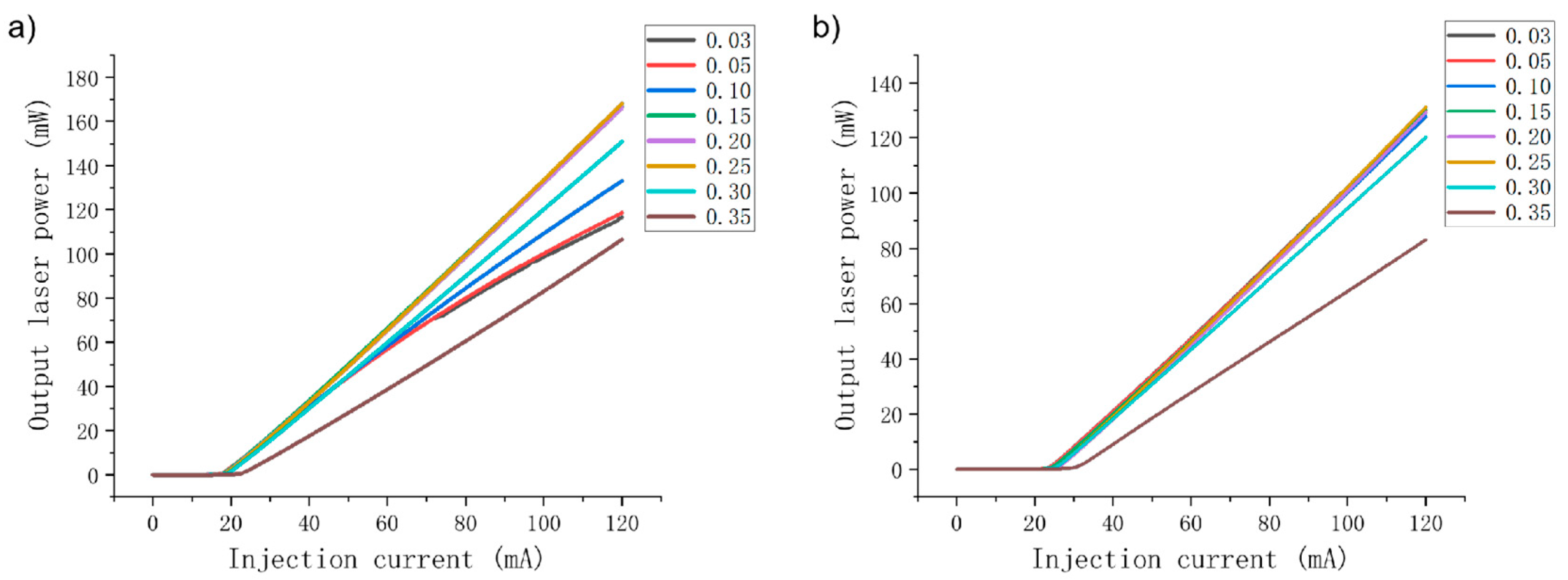

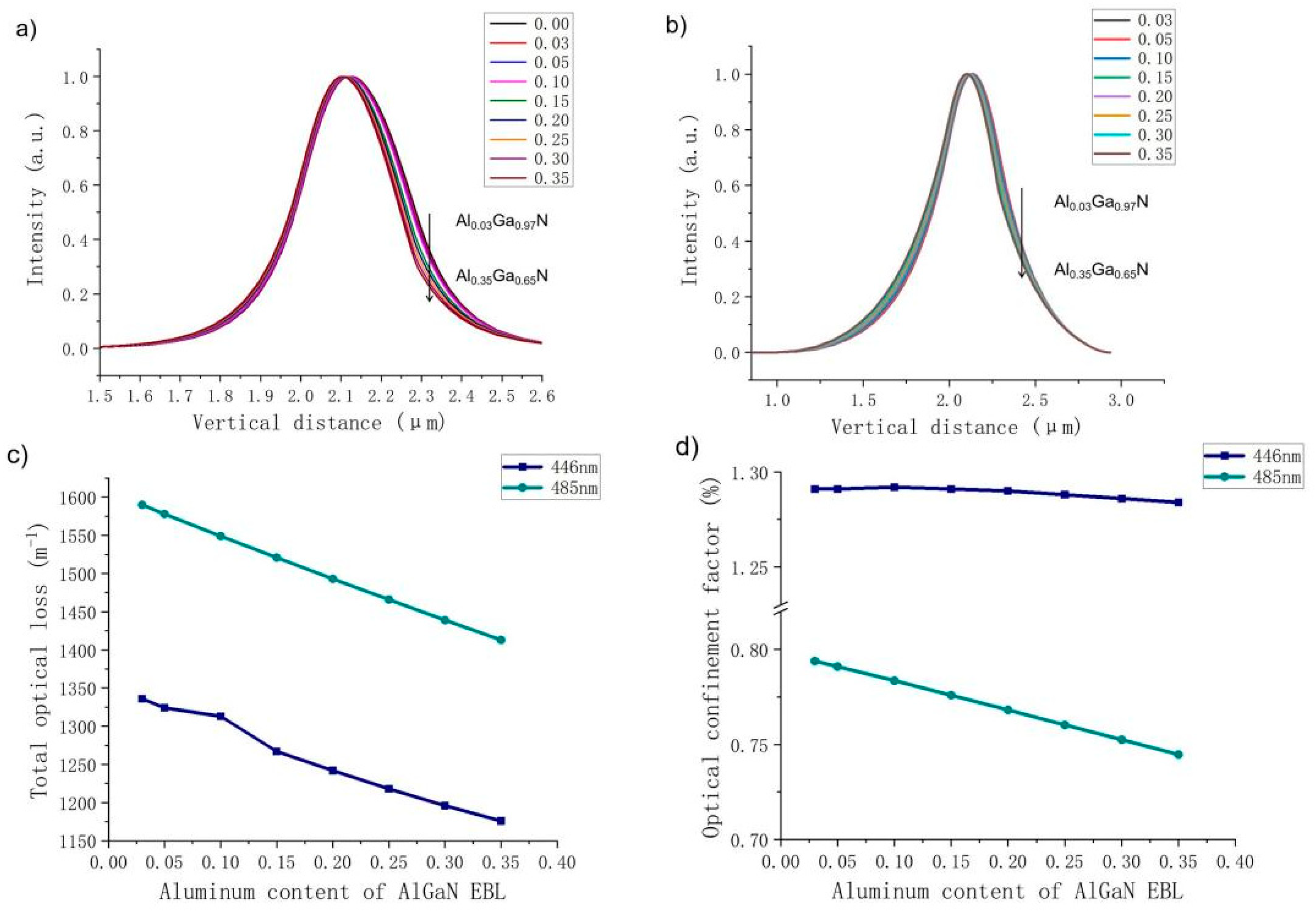

3.1.2. Effects of Al Content in the AlGaN EBL on Electrical and Optical Properties of LDs

3.2. Blue and Cyan LDs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Simon, J.; Protasenko, V.; Lian, C.; Xing, H.; Jena, D. Polarization-Induced Hole Doping in Wide-Band-Gap Uniaxial Semiconductor Heterostructures. Sci. New Ser. 2010, 327, 60–64. [Google Scholar] [CrossRef] [PubMed]

- Taniyasu, Y.; Kasu, M.; Makimoto, T. An Aluminium Nitride Light-Emitting Diode with a Wavelength of 210 Nanometres. Nature 2006, 441, 325–328. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Kao, T.-T.; Liu, J.; Lochner, Z.; Kim, S.-S.; Ryou, J.-H.; Dupuis, R.D.; Shen, S.-C. Effects of a Step-Graded AlxGa1−xN Electron Blocking Layer in InGaN-Based Laser Diodes. J. Appl. Phys. 2011, 109, 083115. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.-G.; Jiang, D.-S.; Liu, Z.-S.; Zhu, J.-J.; Chen, P.; Yang, J.; Liu, W.; Li, X.; Liu, S.-T.; et al. Different Influences of U-InGaN Upper Waveguide on the Performance of GaN-Based Blue and Green Laser Diodes. Chin. Phys. B 2017, 26, 114203. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.; Jiang, D.; Liu, Z.; Zhu, J.; Chen, P.; Yang, J.; Liu, W.; Li, X.; Liu, S.; et al. New Design of Upper Waveguide with Unintentionally Doped InGaN Layer for InGaN-Based Laser Diode. Opt. Laser Technol. 2017, 97, 284–289. [Google Scholar] [CrossRef]

- Xing, Y.; Zhao, D.G.; Jiang, D.S.; Li, X.; Liang, F.; Chen, P.; Zhu, J.J.; Liu, Z.S.; Yang, J.; Liu, W.; et al. Suppression of Hole Leakage by Adding a Hole Blocking Layer Prior to the First Quantum Barrier in GaN-Based near-Ultraviolet Laser Diodes: Suppression of Hole Leakage by Adding a Hole Blocking Layer. Phys. Status Solidi A 2017, 214, 1700320. [Google Scholar] [CrossRef]

- Sfuncia, G.; Nicotra, G.; Giannazzo, F.; Pécz, B.; Gueorguiev, G.K.; Kakanakova-Georgieva, A. 2D Graphitic-like Gallium Nitride and Other Structural Selectivity in Confinement at the Graphene/SiC Interface. CrystEngComm 2023, 25, 5810–5817. [Google Scholar] [CrossRef]

- Alves Machado Filho, M.; Hsiao, C.-L.; Dos Santos, R.B.; Hultman, L.; Birch, J.; Gueorguiev, G.K. Self-Induced Core–Shell InAlN Nanorods: Formation and Stability Unraveled by Ab Initio Simulations. ACS Nanosci. Au 2023, 3, 84–93. [Google Scholar] [CrossRef]

- Kuo, Y.-K.; Chang, Y.-A. Effects of Electronic Current Overflow and Inhomogeneous Carrier Distribution on InGaN Quantum-Well Laser Performance. IEEE J. Quantum Electron. 2004, 40, 437–444. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Yamada, T.; Matsushita, T.; Hiroyuki Kiyoku, H.K.; Yasunobu Sugimoto, Y.S. InGaN-Based Multi-Quantum-Well-Structure Laser Diodes. Jpn. J. Appl. Phys. 1996, 35, L74. [Google Scholar] [CrossRef]

- Kuo, Y.-K.; Chang, J.-Y.; Chen, M.-L. Role of Electron Blocking Layer in III-Nitride Laser Diodes and Light-Emitting Diodes. In Proceedings of the Physics and Simulation of Optoelectronic Devices XVIII, San Francisco, CA, USA, 25–28 January 2010; Volume 7597, p. 759720. [Google Scholar] [CrossRef]

- Le, L.; Zhao, D.; Jiang, D.; Chen, P.; Liu, Z.; Zhu, J.; Yang, J.; Li, X.; He, X.; Liu, J.; et al. Utilization of Polarization-Inverted AlInGaN or Relatively Thinner AlGaN Electron Blocking Layer in InGaN-Based Blue–Violet Laser Diodes. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2015, 33, 011209. [Google Scholar] [CrossRef]

- Kuo, Y.-K.; Chang, J.-Y.; Tsai, M.-C.; Yen, S.-H. Advantages of Blue InGaN Multiple-Quantum Well Light-Emitting Diodes with InGaN Barriers. Appl. Phys. Lett. 2009, 95, 011116. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, J.; Tian, A.; Cheng, Y.; Li, Z.; Zhang, L.; Zhang, S.; Li, D.; Ikeda, M.; Yang, H. GaN-Based Green Laser Diodes. J. Semicond. 2016, 37, 111001. [Google Scholar] [CrossRef]

- Meyaard, D.S.; Lin, G.B.; Shan, Q.; Cho, J.; Fred Schubert, E.; Shim, H.; Kim, M.-H.; Sone, C. Asymmetry of carrier transport leading to efficiency droop in GaInN based light-emitting diodes. Appl. Phys. Lett. 2011, 99, 251115. [Google Scholar] [CrossRef]

- Hou, Y.; Zhao, D.; Liang, F.; Yang, J.; Chen, P.; Liu, Z. Characteristics of InGaN-Based Green Laser Diodes with Additional InGaN Hole Reservoir Layer. Vacuum 2021, 186, 110049. [Google Scholar] [CrossRef]

- Xing, Y.; Zhao, D.-G.; Jiang, D.-S.; Li, X.; Liu, Z.-S.; Zhu, J.-J.; Chen, P.; Yang, J.; Liu, W.; Liang, F.; et al. Suppression of Electron and Hole Overflow in GaN-Based near-Ultraviolet Laser Diodes. Chin. Phys. B 2018, 27, 028101. [Google Scholar] [CrossRef]

- Alahyarizadeh, G.; Amirhoseiny, M.; Hassan, Z. Effect of Different EBL Structures on Deep Violet InGaN Laser Diodes Performance. Opt. Laser Technol. 2016, 76, 106–112. [Google Scholar] [CrossRef]

- Paliwal, A.; Singh, K.; Mathew, M. Effects of Electron Blocking Layer Configuration on the Dynamics of Laser Diodes Emitting at 450 Nm. Laser Phys. 2020, 30, 016210. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.; Jiang, D.; Liu, Z.; Zhu, J.; Chen, P.; Yang, J.; Liu, S.; Xing, Y.; Zhang, L. Suppression of Optical Field Leakage in GaN-Based Green Laser Diode Using Graded-Indium n-InxGa1-xN Lower Waveguide. Superlattices Microstruct. 2019, 132, 106153. [Google Scholar] [CrossRef]

- Li, X.; Zhao, D. Effectiveness of Inserting an InGaN Interlayer to Improve the Performances of InGaN-Based Blue-Violet Laser Diodes. Chin. Opt. Lett. 2016, 14, 062502–062506. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for Nonlinear Macroscopic Polarization in III–V Nitride Alloy Heterostructures. Appl. Phys. Lett. 2002, 80, 1204–1206. [Google Scholar] [CrossRef]

- Ben, Y.; Liang, F.; Zhao, D.; Jiang, D.; Liu, Z.; Zhu, J.; Chen, P.; Yang, J.; Xing, Y.; Liu, S. Different Influence of InGaN Lower Waveguide Layer on the Performance of GaN-Based Violet and Ultraviolet Laser Diodes. Superlattices Microstruct. 2019, 133, 106208. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Jiang, D.; Zeng, C.; Xu, C.; Sun, H.; Hou, Y.; Zhou, M. Controlling GaN-Based Laser Diode Performance by Variation of the Al Content of an Inserted AlGaN Electron Blocking Layer. Nanomaterials 2024, 14, 449. https://doi.org/10.3390/nano14050449

Chen Y, Jiang D, Zeng C, Xu C, Sun H, Hou Y, Zhou M. Controlling GaN-Based Laser Diode Performance by Variation of the Al Content of an Inserted AlGaN Electron Blocking Layer. Nanomaterials. 2024; 14(5):449. https://doi.org/10.3390/nano14050449

Chicago/Turabian StyleChen, Yuhui, Daiyi Jiang, Chunmiao Zeng, Chuanxiong Xu, Haoran Sun, Yufei Hou, and Mei Zhou. 2024. "Controlling GaN-Based Laser Diode Performance by Variation of the Al Content of an Inserted AlGaN Electron Blocking Layer" Nanomaterials 14, no. 5: 449. https://doi.org/10.3390/nano14050449

APA StyleChen, Y., Jiang, D., Zeng, C., Xu, C., Sun, H., Hou, Y., & Zhou, M. (2024). Controlling GaN-Based Laser Diode Performance by Variation of the Al Content of an Inserted AlGaN Electron Blocking Layer. Nanomaterials, 14(5), 449. https://doi.org/10.3390/nano14050449