Analysis of Carbon Nanoparticle Coatings via Wettability

Abstract

1. Introduction

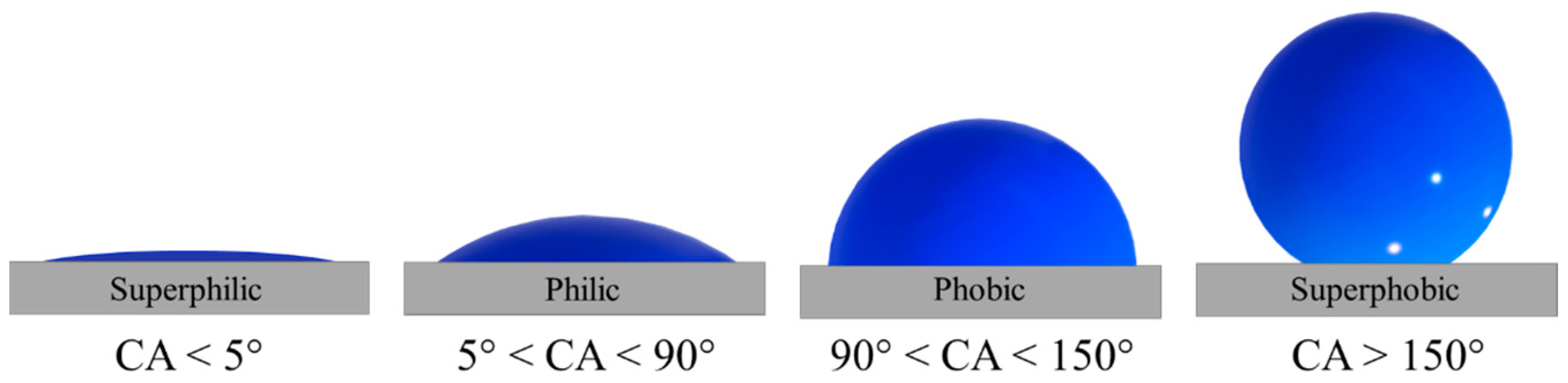

2. Wettability

3. Materials and Methods

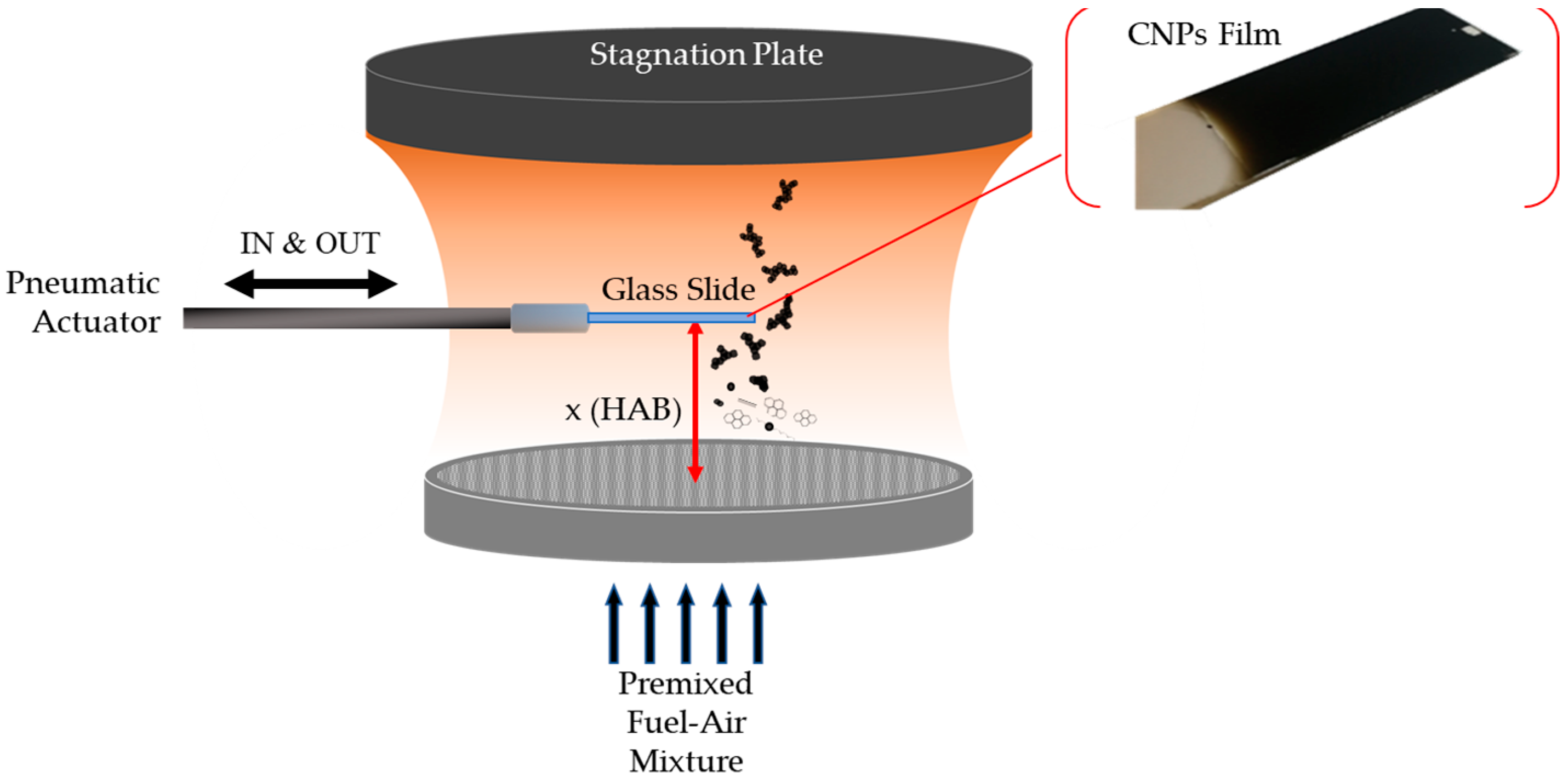

3.1. Fabrication of the CNP Film

3.2. Contact Angle Measurement

4. Results

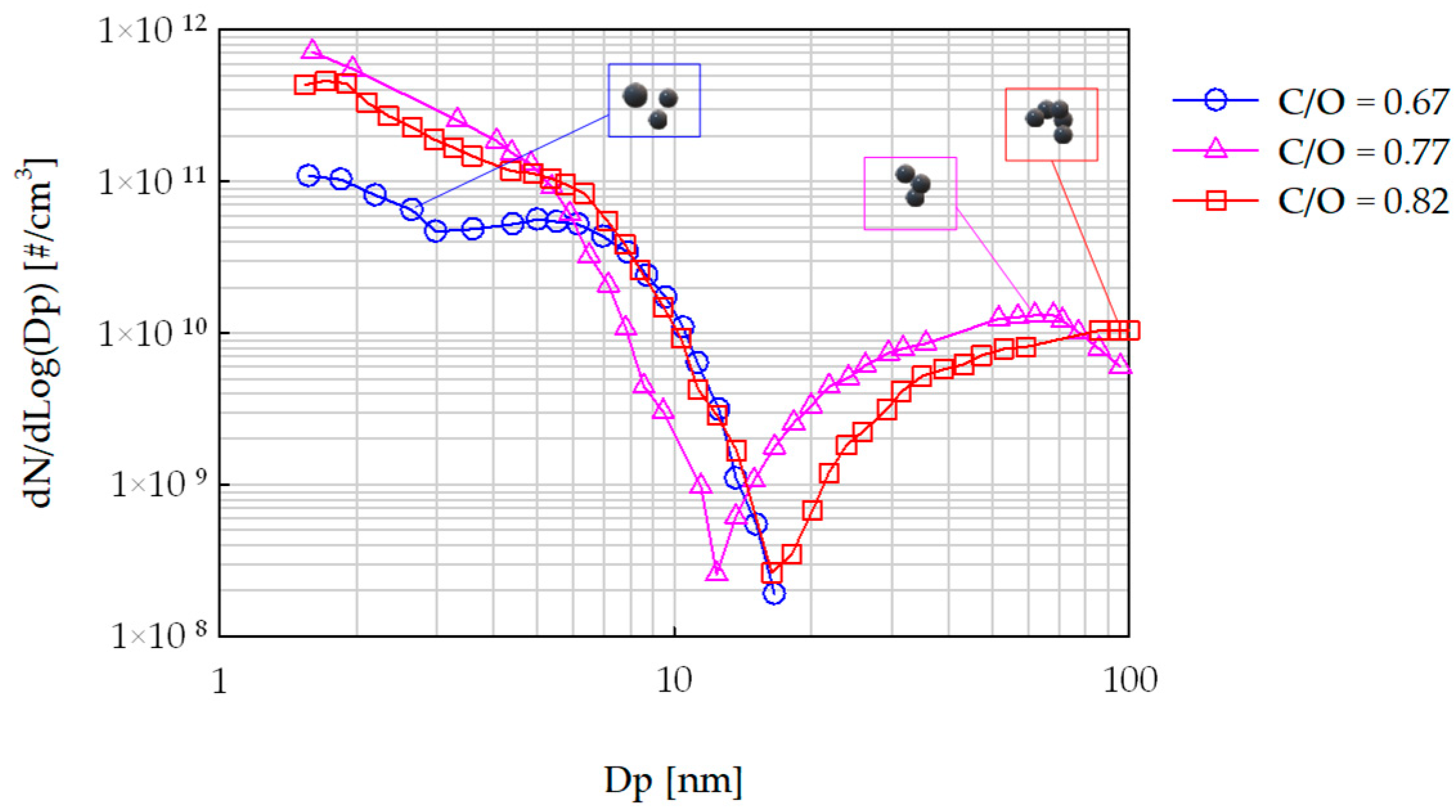

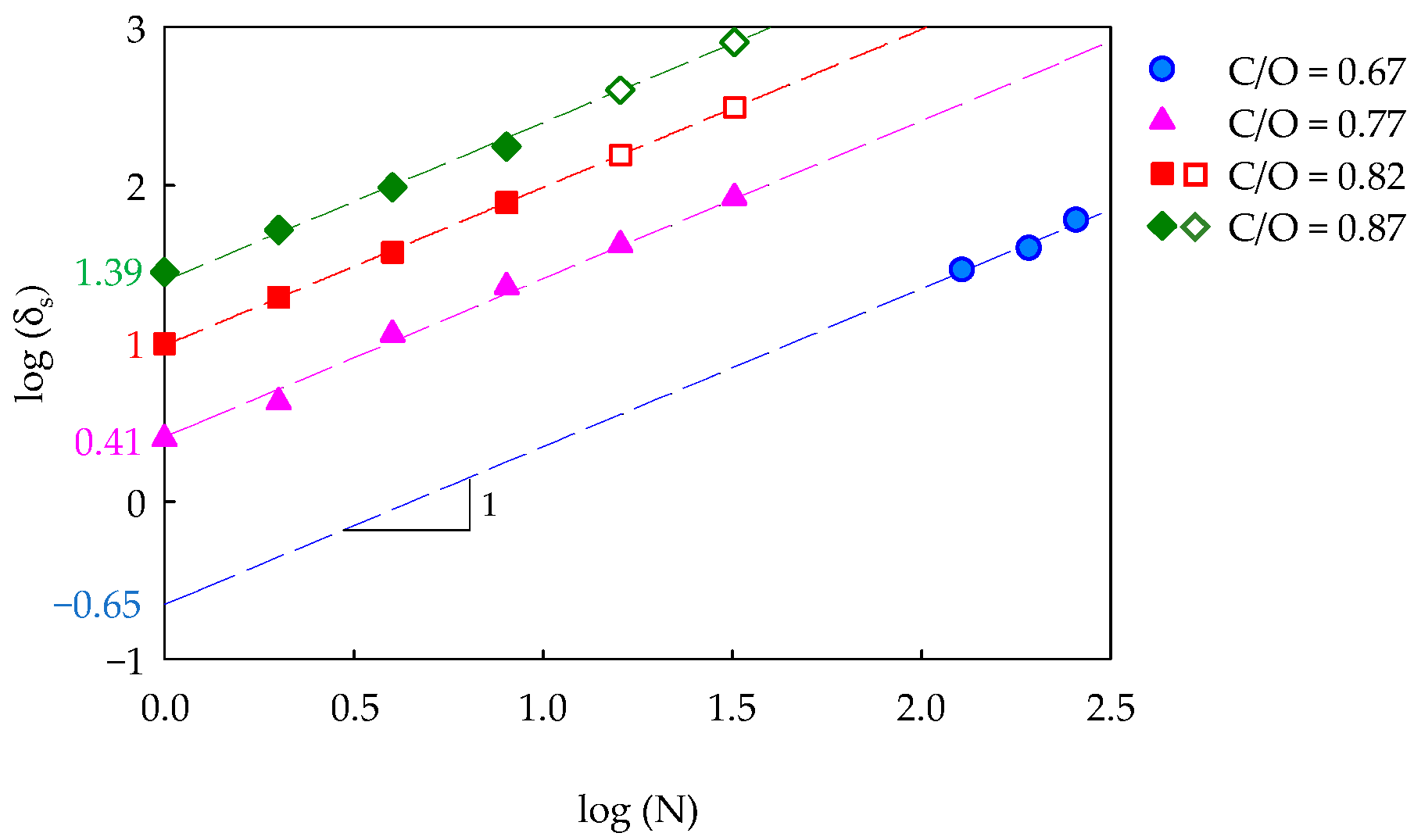

4.1. Properties of CNP Films

4.2. Wettability with Distilled Water

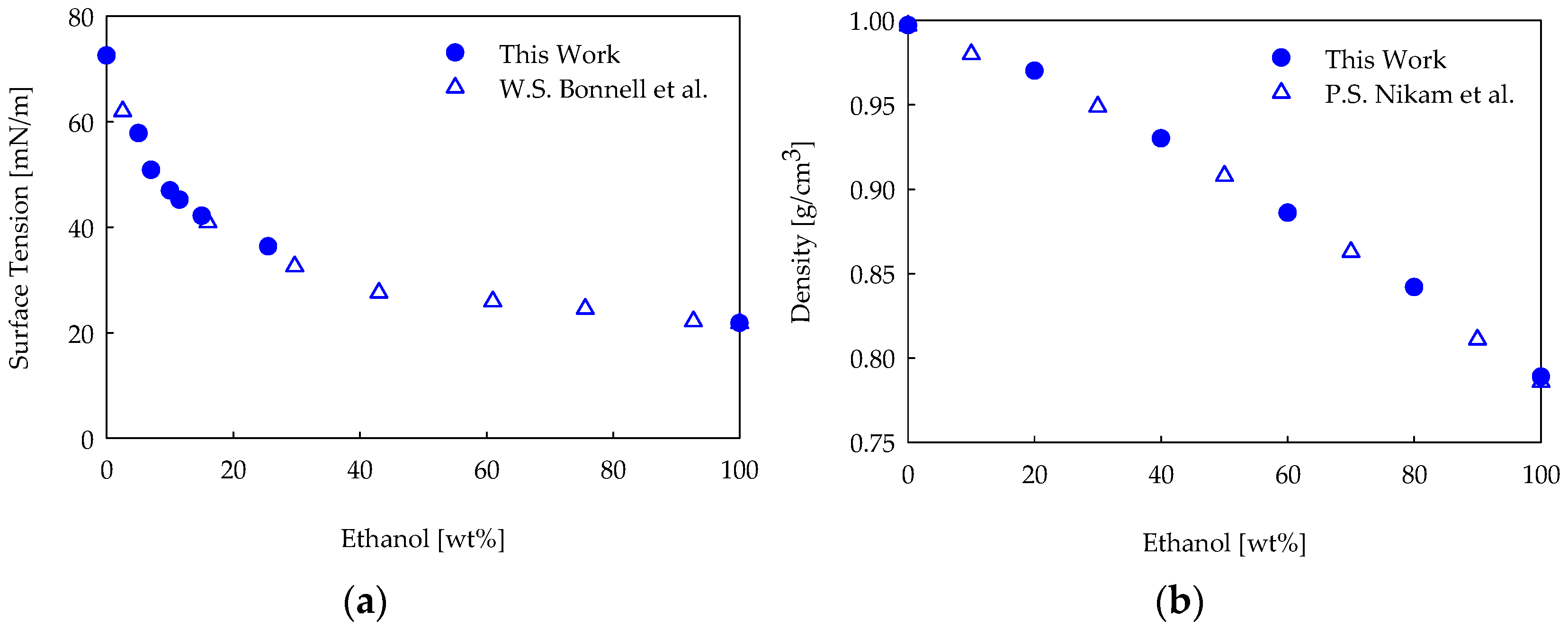

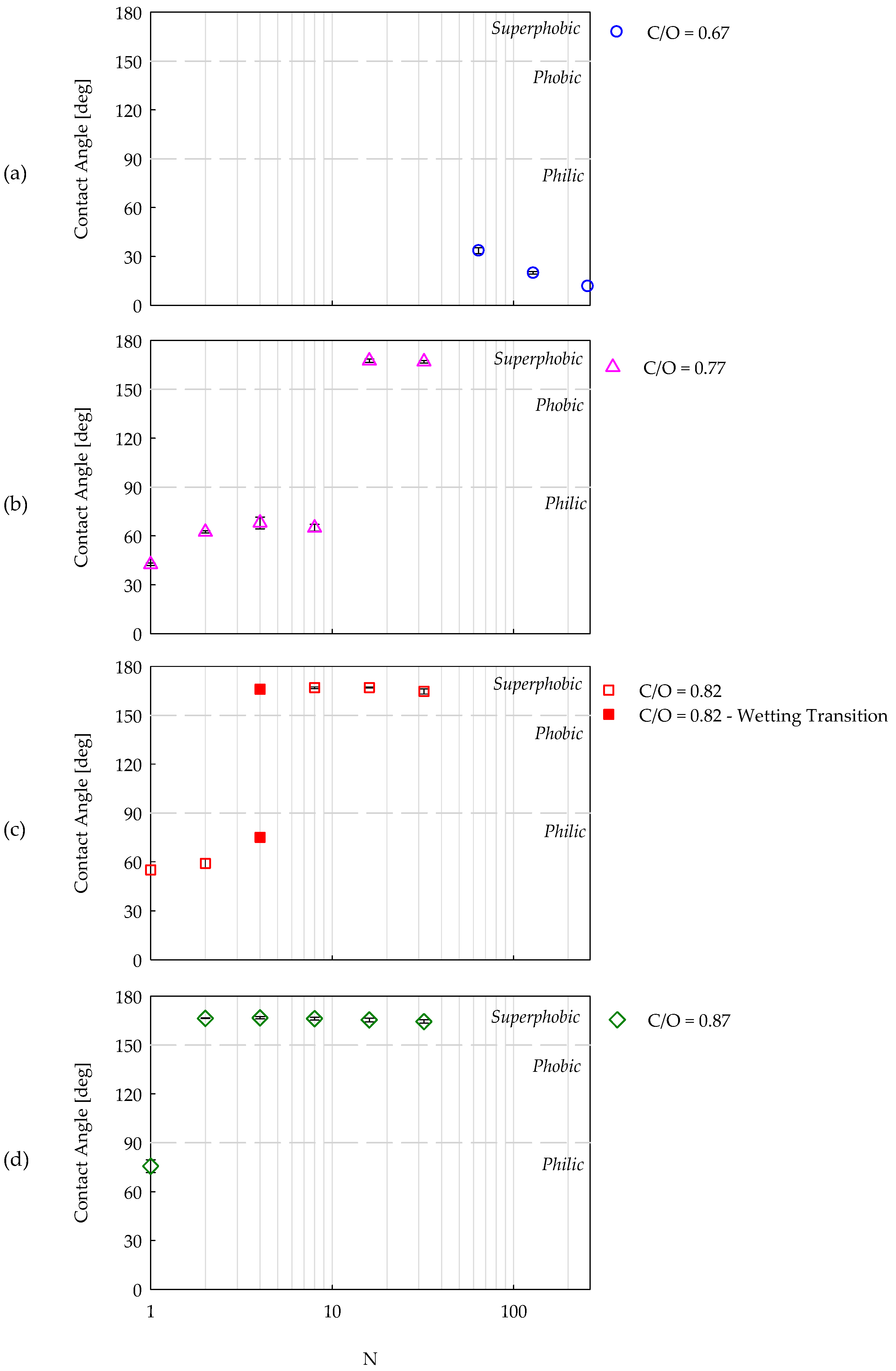

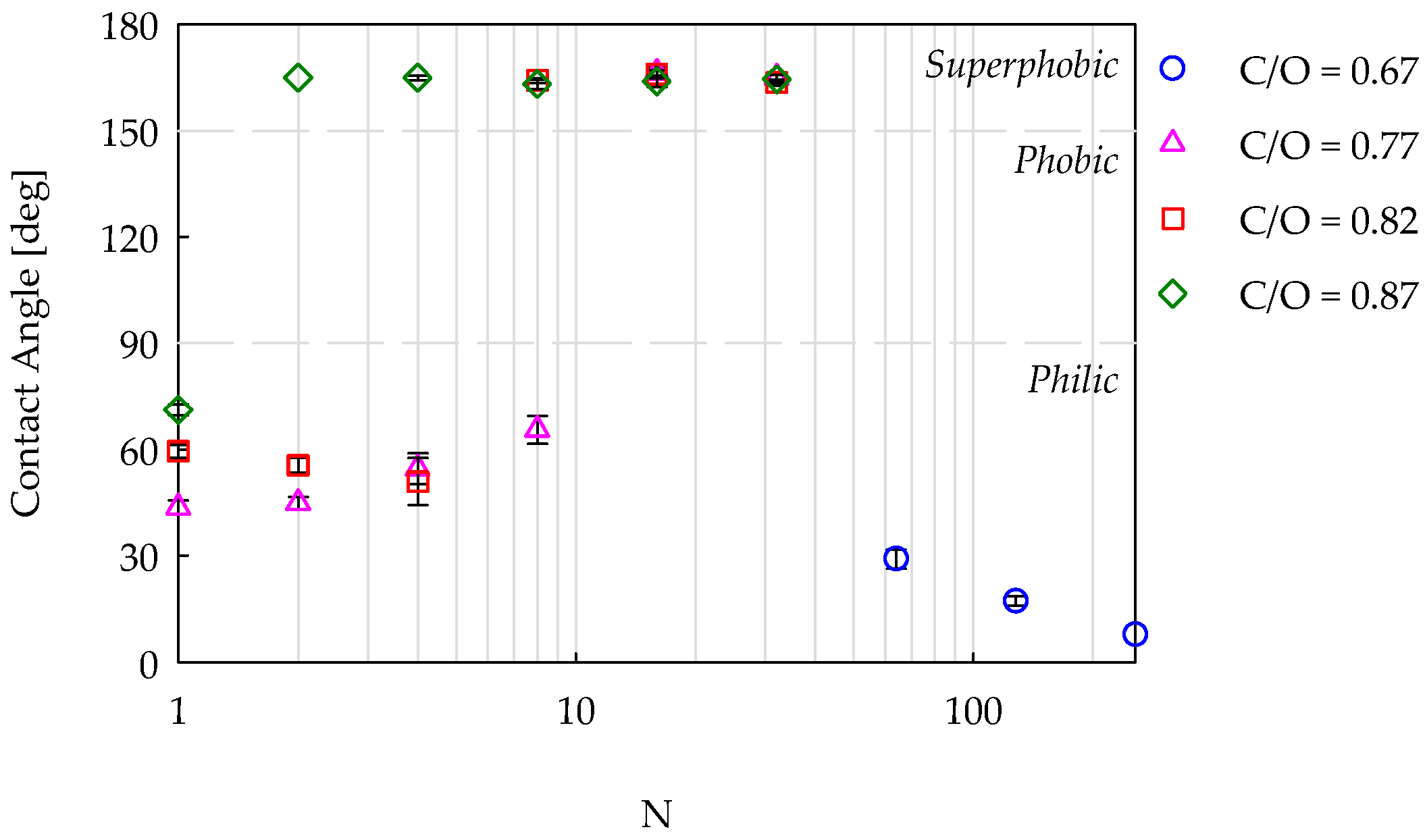

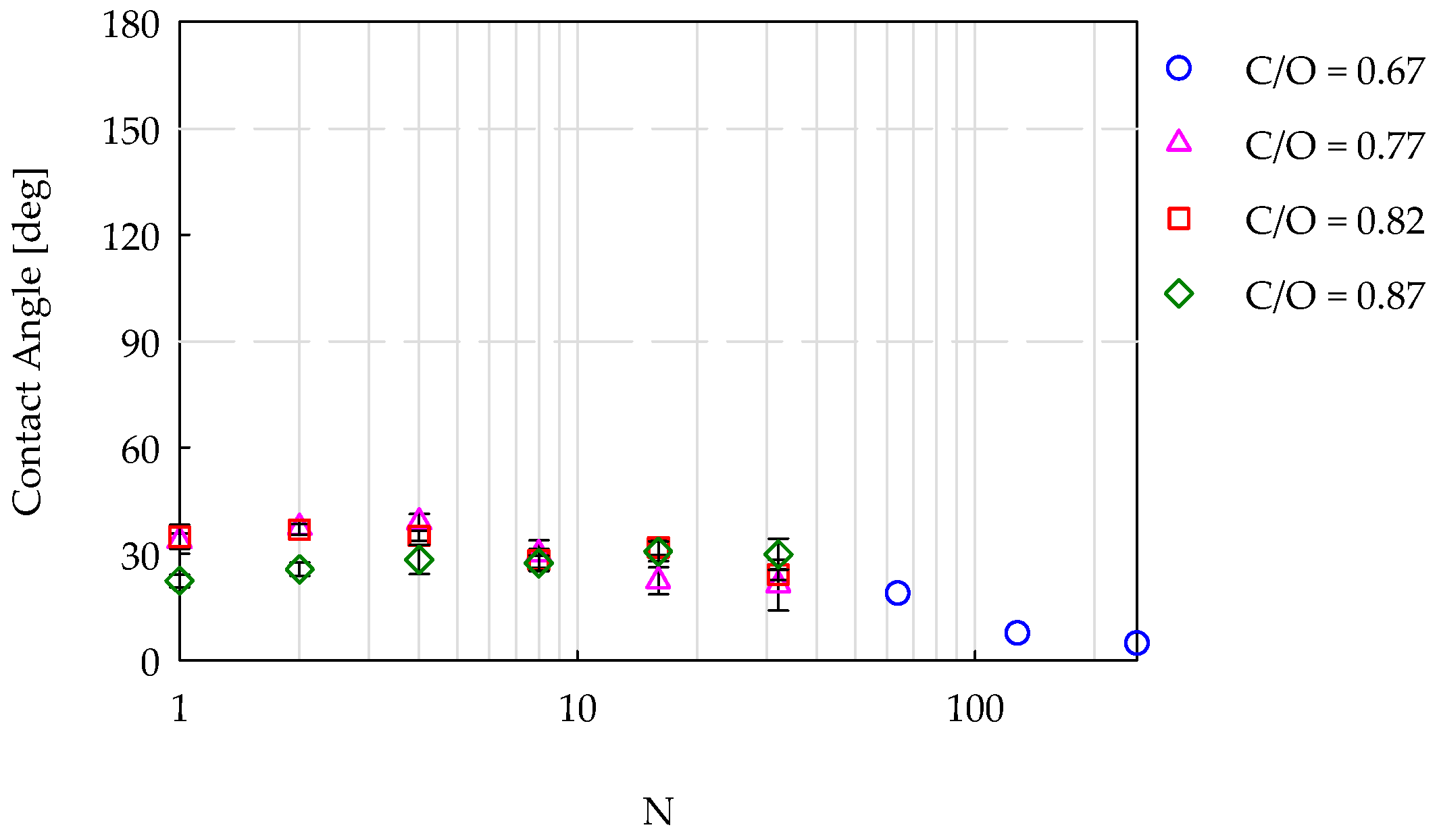

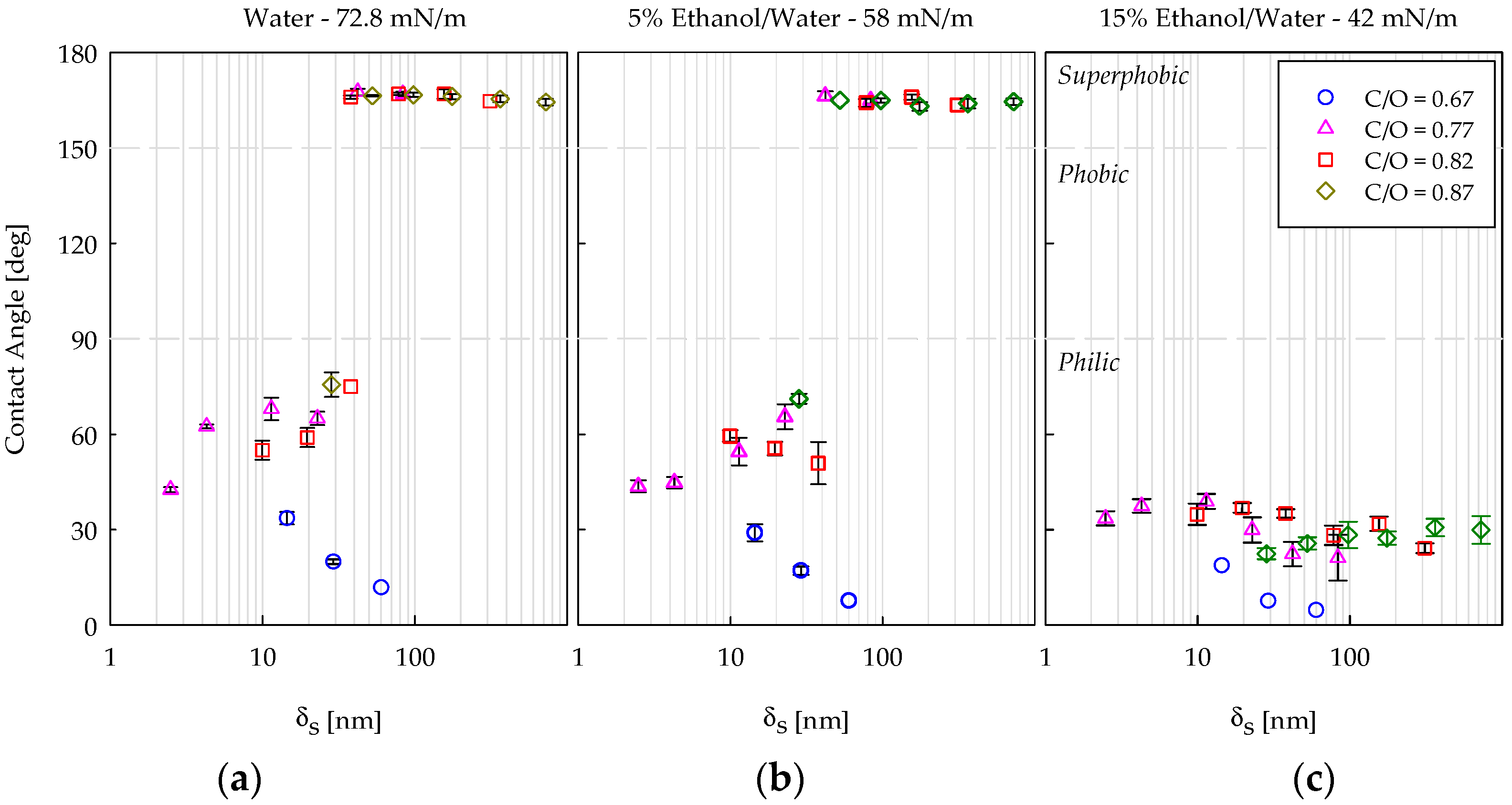

4.3. Wettability with Ethanol/Water Mixtures

4.4. Wettability vs. Film Thickness

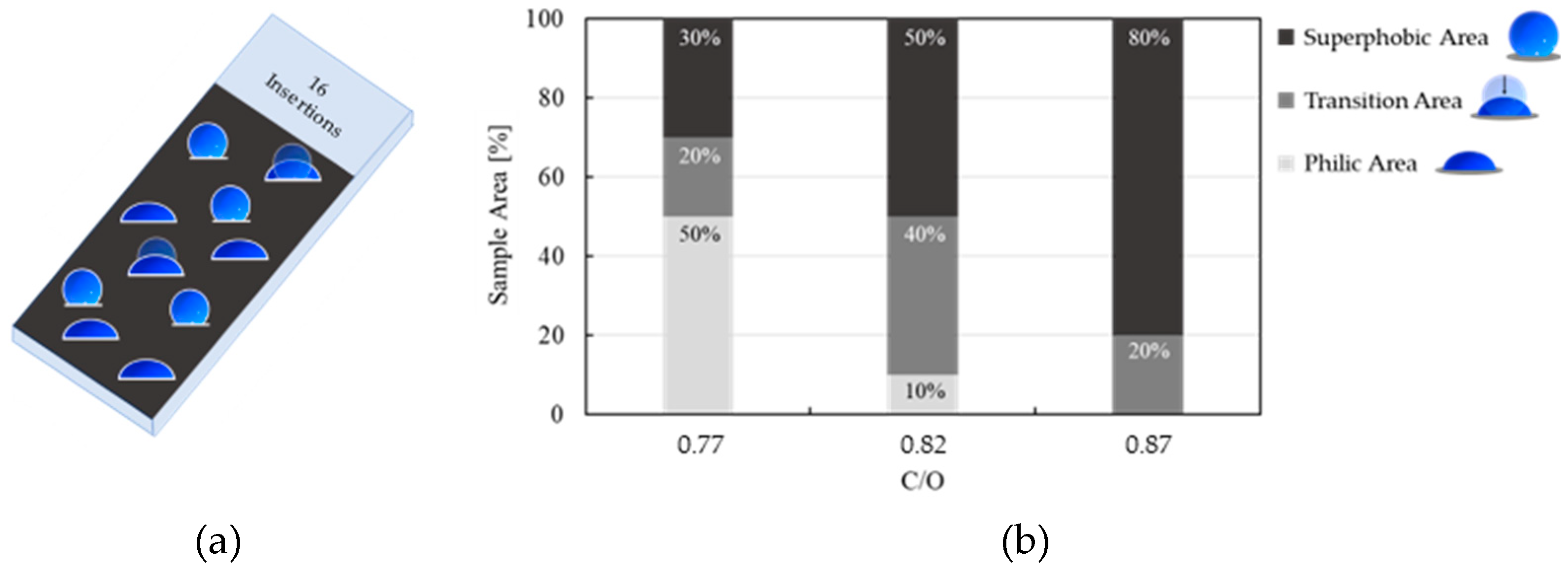

4.5. Wettability Transitions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kung, C.H.; Sow, P.K.; Zahiri, B.; Mérida, W. Assessment and interpretation of surface wettability based on sessile droplet contact angle measurement: Challenges and opportunities. Adv. Mater. Interfaces 2019, 6, 1900839. [Google Scholar] [CrossRef]

- Tran, N.G.; Chun, D.-M. Green manufacturing of extreme wettability contrast surfaces with superhydrophilic and superhydrophobic patterns on aluminum. J. Mater. Process. Technol. 2021, 297, 117245. [Google Scholar] [CrossRef]

- Song, W.; Veiga, D.D.; Custódio, C.A.; Mano, J.F. Bioinspired degradable substrates with extreme wettability properties. Adv. Mater. 2009, 21, 1830–1834. [Google Scholar] [CrossRef]

- Liu, X.; Liang, Y.; Zhou, F.; Liu, W. Extreme wettability and tunable adhesion: Biomimicking beyond nature? Soft Matter 2012, 8, 2070–2086. [Google Scholar] [CrossRef]

- Drelich, J.; Chibowski, E. Superhydrophilic and superwetting surfaces: Definition and mechanisms of control. Langmuir 2010, 26, 18621–18623. [Google Scholar] [CrossRef]

- Tettey, K.E.; Dafinone, M.I.; Lee, D. Progress in superhydrophilic surface development. Mater. Express 2011, 1, 89–104. [Google Scholar] [CrossRef]

- Ahmad, D.; Van Den Boogaert, I.; Miller, J.; Presswell, R.; Jouhara, H. Hydrophilic and hydrophobic materials and their applications. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 2686–2725. [Google Scholar] [CrossRef]

- Parvate, S.; Dixit, P.; Chattopadhyay, S. Superhydrophobic surfaces: Insights from theory and experiment. J. Phys. Chem. B 2020, 124, 1323–1360. [Google Scholar] [CrossRef]

- Walzak, M.; Davidson, R.; Biesinger, M. The use of XPS, FTIR, SEM/EDX, contact angle, and AFM in the characterization of coatings. J. Mater. Eng. Perform. 1998, 7, 317–323. [Google Scholar] [CrossRef]

- Tkadletz, M.; Schalk, N.; Daniel, R.; Keckes, J.; Czettl, C.; Mitterer, C. Advanced characterization methods for wear resistant hard coatings: A review on recent progress. Surf. Coat. Technol. 2016, 285, 31–46. [Google Scholar] [CrossRef]

- Nguyen-Tri, P.; Nguyen, T.A.; Carriere, P.; Ngo Xuan, C. Nanocomposite coatings: Preparation, characterization, properties, and applications. Int. J. Corros. 2018, 2018, 4749501. [Google Scholar] [CrossRef]

- Baer, D.R.; Thevuthasan, S. Characterization of thin films and coatings. In Handbook of Deposition Technologies for Films and Coatings; Elsevier: Amsterdam, The Netherlands, 2010; pp. 749–864. [Google Scholar]

- Oke, J.A.; Jen, T.-C. Atomic layer deposition and other thin film deposition techniques: From principles to film properties. J. Mater. Res. Technol. 2022, 21, 2238–7854. [Google Scholar] [CrossRef]

- Stoian, M.; Maurer, T.; Lamri, S.; Fechete, I. Techniques of Preparation of Thin Films: Catalytic Combustion. Catalysts 2021, 11, 1530. [Google Scholar] [CrossRef]

- Rietveld, I.B.; Kobayashi, K.; Yamada, H.; Matsushige, K. Electrospray deposition, model, and experiment: Toward general control of film morphology. J. Phys. Chem. B 2006, 110, 23351–23364. [Google Scholar] [CrossRef]

- Pfaff, G. Carbon black pigments. Phys. Sci. Rev. 2021, 7, 109–125. [Google Scholar]

- Hu, J.; Zhong, S.; Yan, T. Using carbon black to facilitate fast charging in lithium-ion batteries. J. Power Sources 2021, 508, 230342. [Google Scholar] [CrossRef]

- Li, Z.H.; Liu, Y.Q.; Xia, P.; Ma, L. Experimental Research on Carbon Black Flowing in Pneumatic Conveying System. Adv. Mater. Res. 2010, 87, 256–262. [Google Scholar] [CrossRef]

- Gholami, F.; Pircheraghi, G.; Sarafpour, A. Long-term mechanical performance of polyethylene pipe materials in presence of carbon black masterbatch with different carriers. Polym. Test. 2020, 91, 106857. [Google Scholar] [CrossRef]

- Hu, J.; Yu, J.; Li, Y.; Liao, X.; Yan, X.; Li, L. Nano carbon black-based high performance wearable pressure sensors. Nanomaterials 2020, 10, 664. [Google Scholar] [CrossRef]

- Verma, A.; Baurai, K.; Sanjay, M.; Siengchin, S. Mechanical, microstructural, and thermal characterization insights of pyrolyzed carbon black from waste tires reinforced epoxy nanocomposites for coating application. Polym. Compos. 2020, 41, 338–349. [Google Scholar] [CrossRef]

- Peng, H.; Liu, X.; Liu, X.; Li, T.; Jin, J.; Ma, X.; Shi, T.; Li, L. A facile and cost-effective fabrication of robust carbon black-based superhydrophobic coatings on aluminum alloy. Surf. Interfaces 2023, 41, 103317. [Google Scholar] [CrossRef]

- Richard, E.; Aruna, S. Facile Fabrication of Stable Superhydrophobic and Conductive Carbon Black Coating. In Recent Trends in Electrochemical Science and Technology: Proceedings of Papers Presented at NSEST-2020 and ECSIRM-2020; Springer: Berlin/Heidelberg, Germany, 2022; pp. 207–219. [Google Scholar]

- Liu, S.-L.; Shen, Q. Formation and characterization of superhydrophilic carbon black via layer-by-layer electro-assembly. Inorg. Chem. Commun. 2020, 118, 108020. [Google Scholar] [CrossRef]

- Hajmohammadi, Z.; Fattahi, R.; Zarei-Behjani, Z.; Hosseinzadeh, S. Carbon nanoparticles for medicine: Current and future. Bull. Mater. Sci. 2022, 45, 1–19. [Google Scholar] [CrossRef]

- Bouchear, S.; Bellel, N.; Chetibi, L. Elaboration and Characterization of Carbon Dots for Hydrogen Storage. Acta Phys. Pol. A 2021, 139, 717–721. [Google Scholar] [CrossRef]

- Zammataro, A.; Sfrazzetto, G.T. Carbon dots as catalysts: A new class of nanozymes. Curr. Organocatalysis 2020, 7, 3–6. [Google Scholar] [CrossRef]

- Shpilevsky, E.; Penyazkov, O.; Filatov, S.; Shilagardi, G.; Tuvshintur, P.; Timur-Bаtor, D.; Ulam-Orgikh, D. Modification of materials by carbon nanoparticles. Solid. State Phenom. 2018, 271, 70–75. [Google Scholar] [CrossRef]

- Li, Y.; Zuo, Z.; Li, Y. Handbook of Carbon-Based Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Michelsen, H.A.; Colket, M.B.; Bengtsson, P.-E.; D’anna, A.; Desgroux, P.; Haynes, B.S.; Miller, J.H.; Nathan, G.J.; Pitsch, H.; Wang, H. A review of terminology used to describe soot formation and evolution under combustion and pyrolytic conditions. ACS Nano 2020, 14, 12470–12490. [Google Scholar] [CrossRef] [PubMed]

- Griffo, R.; Di Natale, F.; Parisi, A.; De Falco, G.; Sirignano, M.; Dondè, R.; Migliorini, F.; De Iuliis, S.; Carotenuto, C. Wettability of CNP Nanofilm Obtained with Different Harvesting Process. In Proceedings of the Joint Meeting of the Belgian and Italian Sections of The Combustion Institute: Combustion for Energy Transition and Sustainable Mobility, Florence, Italy, 28–31 May 2023; Available online: https://www.combustion-institute.it/proceedings/XXXXV-ASICI/papers/45proci2023.II4.pdf (accessed on 28 January 2024).

- Parisi, A.; De Falco, G.; Sirignano, M.; Minutolo, P.; Commodo, M.; Carotenuto, C.; Di Natale, F. Modelling the electrophoretically-enhanced in-flame deposition of carbon nanoparticles. J. Aerosol Sci. 2023, 172, 106193. [Google Scholar] [CrossRef]

- Shen, Q.; Jiang, L.H. Enhancement of the wettability of carbon blacks by electrocapillary rise wetting. ChemistrySelect 2016, 1, 3132–3135. [Google Scholar] [CrossRef]

- Anderson, W. Wettability literature survey-part 2: Wettability measurement. J. Pet. Technol. 1986, 38, 1246–1262. [Google Scholar] [CrossRef]

- Abdallah, W.; Buckley, J.S.; Carnegie, A.; Edwards, J.; Herold, B.; Fordham, E.; Graue, A.; Habashy, T.; Seleznev, N.; Signer, C. Fundamentals of wettability. Technology 1986, 38, 268. [Google Scholar]

- Wang, Z.; Elimelech, M.; Lin, S. Environmental applications of interfacial materials with special wettability. Environ. Sci. Technol. 2016, 50, 2132–2150. [Google Scholar] [CrossRef]

- Good, R.J. Contact angles and the surface free energy of solids. In Surface and Colloid Science: Volume 11: Experimental Methods; Springer: Berlin/Heidelberg, Germany, 1979; pp. 1–29. [Google Scholar]

- Young, T., III. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar]

- Marmur, A. Thermodynamic aspects of contact angle hysteresis. Adv. Colloid. Interface Sci. 1994, 50, 121–141. [Google Scholar] [CrossRef]

- Akbari, R.; Antonini, C. Contact angle measurements: From existing methods to an open-source tool. Adv. Colloid. Interface Sci. 2021, 294, 102470. [Google Scholar] [CrossRef]

- Nishino, T.; Meguro, M.; Nakamae, K.; Matsushita, M.; Ueda, Y. The lowest surface free energy based on− CF3 alignment. Langmuir 1999, 15, 4321–4323. [Google Scholar] [CrossRef]

- Wenzel, R.N. Surface roughness and contact angle. J. Phys. Chem. 1949, 53, 1466–1467. [Google Scholar] [CrossRef]

- Cassie, A.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Sigmund, W.M.; Hsu, S.-H. Cassie–Baxter Model. In Encyclopedia of Membranes; Springer: Berlin/Heidelberg, Germany, 2016; pp. 310–311. [Google Scholar]

- Drelich, J.W.; Boinovich, L.; Chibowski, E.; Della Volpe, C.; Hołysz, L.; Marmur, A.; Siboni, S. Contact angles: History of over 200 years of open questions. Surf. Innov. 2019, 8, 3–27. [Google Scholar] [CrossRef]

- Wang, X.; Fu, C.; Zhang, C.; Qiu, Z.; Wang, B. A comprehensive review of wetting transition mechanism on the surfaces of microstructures from theory and testing methods. Materials 2022, 15, 4747. [Google Scholar] [CrossRef]

- Whyman, G.; Bormashenko, E. Wetting transitions on rough substrates: General considerations. J. Adhes. Sci. Technol. 2012, 26, 207–220. [Google Scholar] [CrossRef]

- Bormashenko, E. Progress in understanding wetting transitions on rough surfaces. Adv. Colloid. Interface Sci. 2015, 222, 92–103. [Google Scholar] [CrossRef]

- Barbieri, L.; Wagner, E.; Hoffmann, P. Water wetting transition parameters of perfluorinated substrates with periodically distributed flat-top microscale obstacles. Langmuir 2007, 23, 1723–1734. [Google Scholar] [CrossRef] [PubMed]

- Minutolo, P.; De Falco, G.; Commodo, M.; Aloisio, A.; D’Anna, A. Temperature Sensing with Thin Films of Flame-Formed Carbon Nanoparticles. Appl. Sci. 2022, 12, 7714. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, M.; He, Q.; You, X. Experimental investigation on the size-dependent maturity of soot particles in laminar premixed ethylene burner-stabilized stagnation flames. Proc. Combust. Inst. 2023, 39, 1147–1155. [Google Scholar] [CrossRef]

- Commodo, M.; Sgro, L.A.; Minutolo, P.; D’Anna, A. Characterization of combustion-generated carbonaceous nanoparticles by size-dependent ultraviolet laser photoionization. J. Phys. Chem. A 2013, 117, 3980–3989. [Google Scholar] [CrossRef] [PubMed]

- Commodo, M.; De Falco, G.; Minutolo, P.; D’Anna, A. Structure and size of soot nanoparticles in laminar premixed flames at different equivalence ratios. Fuel 2018, 216, 456–462. [Google Scholar]

- De Falco, G.; Commodo, M.; Bonavolontà, C.; Pepe, G.P.; Minutolo, P.; D’Anna, A. Optical and electrical characterization of carbon nanoparticles produced in laminar premixed flames. Combust. Flame 2014, 161, 3201–3210. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, M.; You, X. Measurements of sooting limits in laminar premixed burner-stabilized stagnation ethylene, propane, and ethylene/toluene flames. Fuel 2019, 235, 178–184. [Google Scholar] [CrossRef]

- Ho, K.J. Soot Measurement and Species Simulation in Laminar Premixed Flames; University of Adelaide: Adelaide, Australia, 2010. [Google Scholar]

- Russo, C.; D’Anna, A.; Ciajolo, A.; Sirignano, M. The effect of butanol isomers on the formation of carbon particulate matter in fuel-rich premixed ethylene flames. Combust. Flame 2019, 199, 122–130. [Google Scholar] [CrossRef]

- Schenk, M.; Lieb, S.; Vieker, H.; Beyer, A.; Gölzhäuser, A.; Wang, H.; Kohse-Höinghaus, K. Morphology of nascent soot in ethylene flames. Proc. Combust. Inst. 2015, 35, 1879–1886. [Google Scholar] [CrossRef]

- Lai, F.; Friedlander, S.; Pich, J.; Hidy, G. The self-preserving particle size distribution for Brownian coagulation in the free-molecule regime. J. Colloid. Interface Sci. 1972, 39, 395–405. [Google Scholar] [CrossRef]

- Kholghy, M.R.; Kelesidis, G.A. Surface growth, coagulation and oxidation of soot by a monodisperse population balance model. Combust. Flame 2021, 227, 456–463. [Google Scholar] [CrossRef]

- Köylü, Ü.Ö.; McEnally, C.S.; Rosner, D.E.; Pfefferle, L.D. Simultaneous measurements of soot volume fraction and particle size/microstructure in flames using a thermophoretic sampling technique. Combust. Flame 1997, 110, 494–507. [Google Scholar] [CrossRef]

- De Falco, G.; Commodo, M.; Barra, M.; Chiarella, F.; D’Anna, A.; Aloisio, A.; Cassinese, A.; Minutolo, P. Electrical characterization of flame-soot nanoparticle thin films. Synth. Met. 2017, 229, 89–99. [Google Scholar] [CrossRef]

- Tissue, B.M. Ultraviolet and visible absorption spectroscopy. In Characterization of Materials; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar]

- Smyth, K.C.; Shaddix, C.R. The elusive history of m∼= 1.57–0.56 i for the refractive index of soot. Combust. Flame 1996, 107, 314–320. [Google Scholar] [CrossRef]

- Bonnell, W.; Byman, L.; Keyes, D. Surface tension of ethyl alcohol-water mixtures. Ind. Eng. Chem. 1940, 32, 532–534. [Google Scholar] [CrossRef]

- Berry, J.D.; Neeson, M.J.; Dagastine, R.R.; Chan, D.Y.; Tabor, R.F. Measurement of surface and interfacial tension using pendant drop tensiometry. J. Colloid. Interface Sci. 2015, 454, 226–237. [Google Scholar] [CrossRef] [PubMed]

- Drelich, J. Guidelines to measurements of reproducible contact angles using a sessile-drop technique. Surf. Innov. 2013, 1, 248–254. [Google Scholar] [CrossRef]

- Council, N.R. International Critical Tables of Numerical Data, Physics, Chemistry and Technology; The National Academies Press: Washington, DC, USA, 1930; p. 49. [Google Scholar]

- Nikam, P.; Hasan, M.; Pawar, T.; Sawant, A. Ultrasonic velocity and allied parameters of symmetrical tetraalkyl ammonium bromides in aqueous ethanol at 298.15 K. Indian. J. Pure Appl. Phys. 2004, 42, 172–178. [Google Scholar]

- Al-Milaji, K.N. Fabricating Superhydrophobic and Superoleophobic Surfaces with Multiscale Roughness Using Airbrush and Electrospray; Virginia Commonwealth University: Richmond, VA, USA, 2016. [Google Scholar]

- Liu, T.L.; Kim, C.-J.C. Contact angle measurement of small capillary length liquid in super-repelled state. Sci. Rep. 2017, 7, 740. [Google Scholar] [CrossRef]

- Ponomar, M.; Krasnyuk, E.; Butylskii, D.; Nikonenko, V.; Wang, Y.; Jiang, C.; Xu, T.; Pismenskaya, N. Sessile drop method: Critical analysis and optimization for measuring the contact angle of an ion-exchange membrane surface. Membranes 2022, 12, 765. [Google Scholar] [CrossRef]

- Ibáñez-Ibáñez, P.F.; Ruiz-Cabello, F.J.M.; Cabrerizo-Vílchez, M.A.; Rodríguez-Valverde, M.A. Contact line relaxation of sessile drops on PDMS surfaces: A methodological perspective. J. Colloid. Interface Sci. 2021, 589, 166–172. [Google Scholar] [CrossRef]

- Chibowski, E. On some relations between advancing, receding and Young’s contact angles. Adv. Colloid. Interface Sci. 2007, 133, 51–59. [Google Scholar] [CrossRef]

- Xu, F.; Sunderland, P.; Faeth, G. Soot formation in laminar premixed ethylene/air flames at atmospheric pressure. Combust. Flame 1997, 108, 471–493. [Google Scholar] [CrossRef]

- Bonn, D. Wetting transitions. Curr. Opin. Colloid Interface Sci. 2001, 6, 22–27. [Google Scholar] [CrossRef]

- Lafuma, A.; Quéré, D. Superhydrophobic states. Nat. Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef]

- Ubuo, E.E.; Udoetok, I.A.; Tyowua, A.T.; Ekwere, I.O.; Al-Shehri, H.S. The direct cause of amplified wettability: Roughness or surface chemistry? J. Compos. Sci. 2021, 5, 213. [Google Scholar] [CrossRef]

- Kubiak, K.; Wilson, M.; Mathia, T.; Carval, P. Wettability versus roughness of engineering surfaces. Wear 2011, 271, 523–528. [Google Scholar] [CrossRef]

- De Falco, G.; Picca, F.; Commodo, M.; Minutolo, P. Probing soot structure and electronic properties by optical spectroscopy. Fuel 2020, 259, 116244. [Google Scholar] [CrossRef]

- Martin, J.W.; Pascazio, L.; Menon, A.; Akroyd, J.; Kaiser, K.; Schulz, F.; Commodo, M.; D’Anna, A.; Gross, L.; Kraft, M. π-Diradical aromatic soot precursors in flames. J. Am. Chem. Soc. 2021, 143, 12212–12219. [Google Scholar] [CrossRef] [PubMed]

- Ghazi, R.; Tjong, H.; Soewono, A.; Rogak, S.N.; Olfert, J.S. Mass, mobility, volatility, and morphology of soot particles generated by a McKenna and inverted burner. Aerosol Sci. Technol. 2013, 47, 395–405. [Google Scholar] [CrossRef]

- Eremin, A.; Gurentsov, E.; Kolotushkin, R.; Mikheyeva, E.Y. Dependence of soot primary particle size on the height above a burner in target ethylene/air premixed flame. Combust. Sci. Technol. 2022, 194, 2847–2863. [Google Scholar] [CrossRef]

| Insertion Number in the Burner | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 4 | 8 | 16 | 32 | 64 | 128 | 256 | ||

| C/O | 0.67 |  |  |  | ||||||

| 0.77 |  |  |  |  |  |  | ||||

| 0.82 |  |  |  |  |  |  | ||||

| 0.87 |  |  |  |  |  |  | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Griffo, R.; Di Natale, F.; Minale, M.; Sirignano, M.; Parisi, A.; Carotenuto, C. Analysis of Carbon Nanoparticle Coatings via Wettability. Nanomaterials 2024, 14, 301. https://doi.org/10.3390/nano14030301

Griffo R, Di Natale F, Minale M, Sirignano M, Parisi A, Carotenuto C. Analysis of Carbon Nanoparticle Coatings via Wettability. Nanomaterials. 2024; 14(3):301. https://doi.org/10.3390/nano14030301

Chicago/Turabian StyleGriffo, Raffaella, Francesco Di Natale, Mario Minale, Mariano Sirignano, Arianna Parisi, and Claudia Carotenuto. 2024. "Analysis of Carbon Nanoparticle Coatings via Wettability" Nanomaterials 14, no. 3: 301. https://doi.org/10.3390/nano14030301

APA StyleGriffo, R., Di Natale, F., Minale, M., Sirignano, M., Parisi, A., & Carotenuto, C. (2024). Analysis of Carbon Nanoparticle Coatings via Wettability. Nanomaterials, 14(3), 301. https://doi.org/10.3390/nano14030301