Self-Powered Dual-Band Electrochromic Supercapacitor Devices for Smart Window Based on Ternary Dielectric Triboelectric Nanogenerator

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of TWO Film

2.3. Assembly of TDR-TENG

2.4. Assembly of SP-DESCD

2.5. Characterization and Measurement

3. Results and Discussion

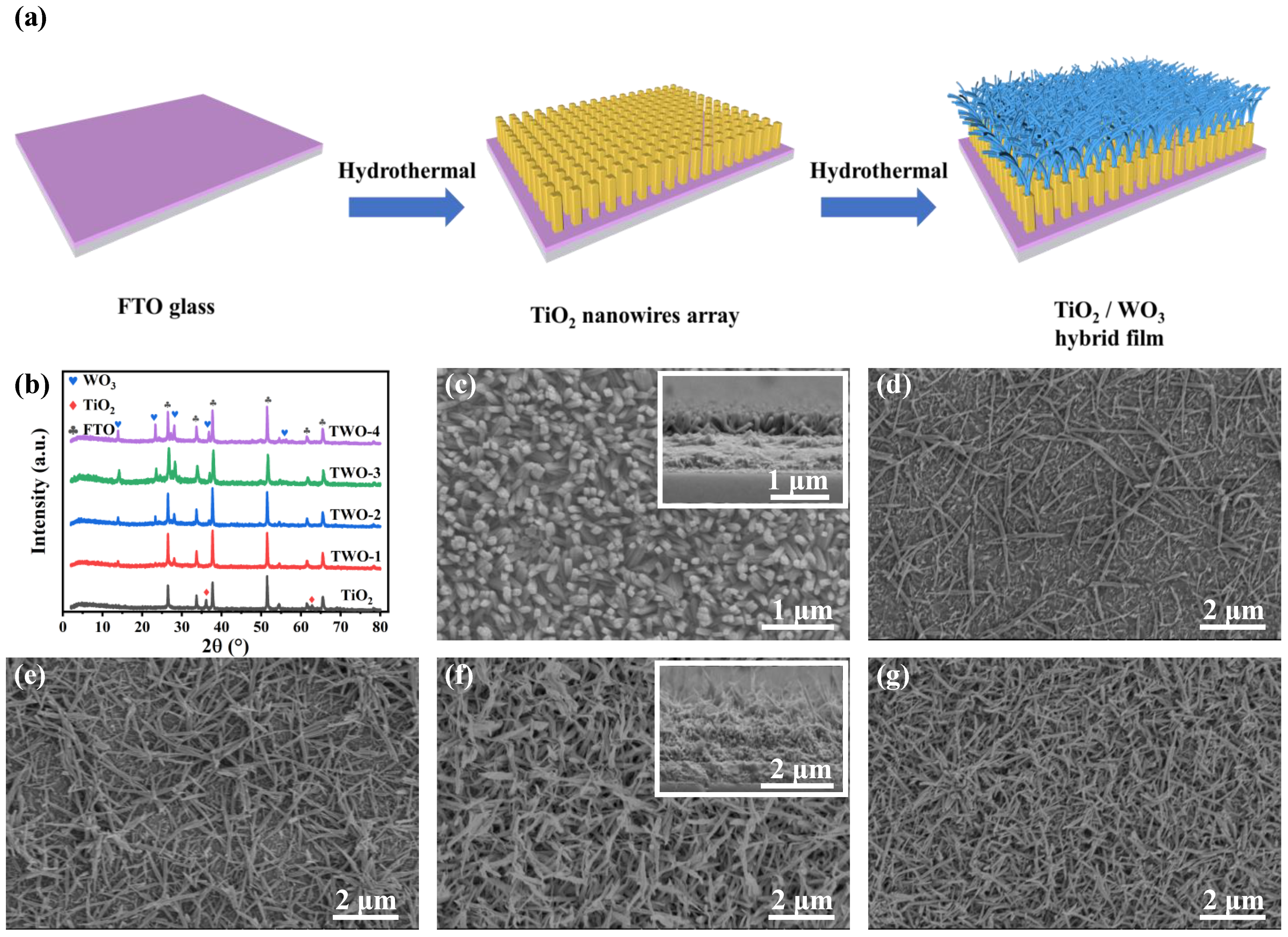

3.1. Fabrication of the TWO Composition Materials

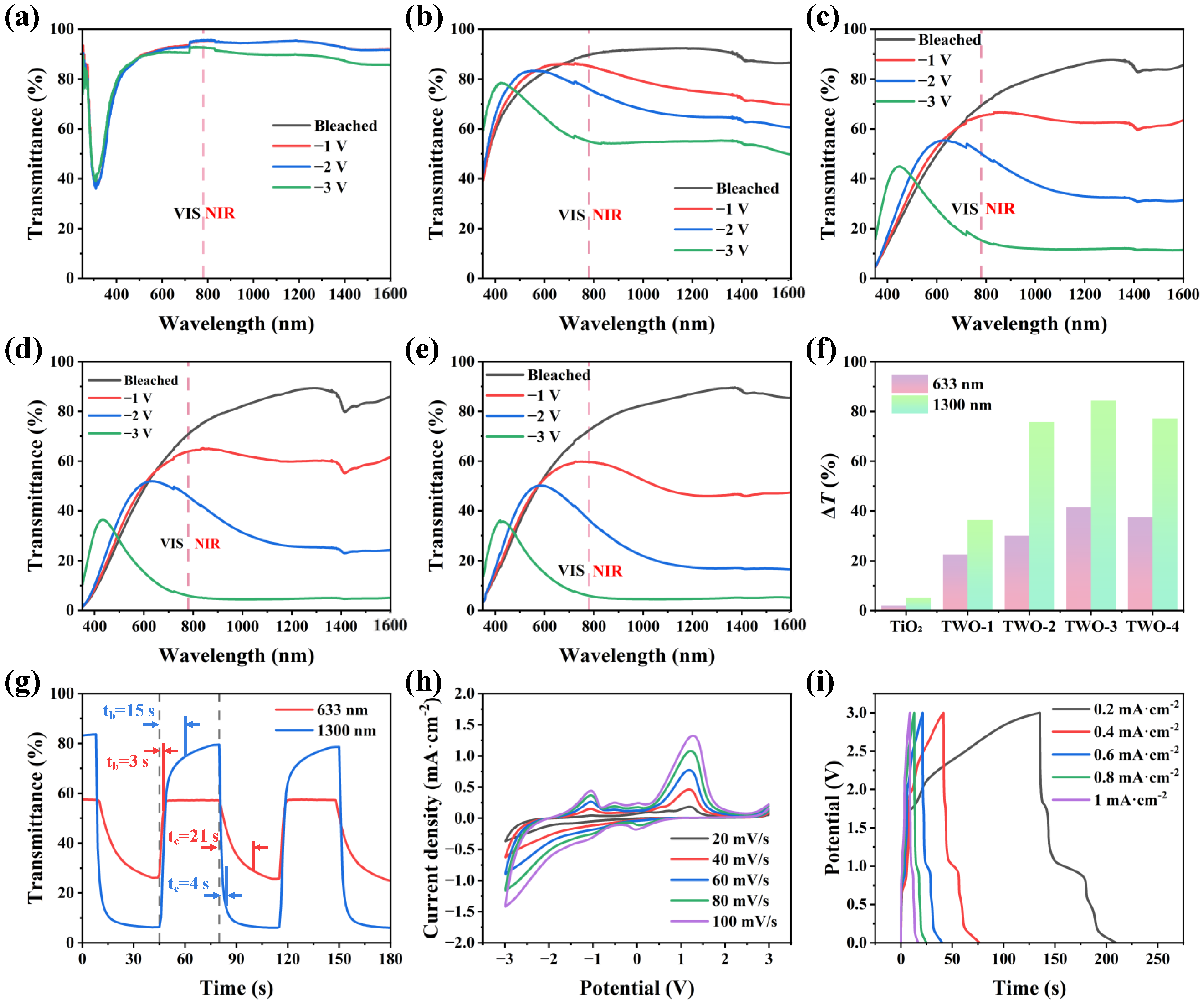

3.2. Electrochromic and Electrochemical Properties of TWO Film

3.3. Structure and Working Principle of TDR-TENG

3.4. Performance Optimization of TDR-TENG

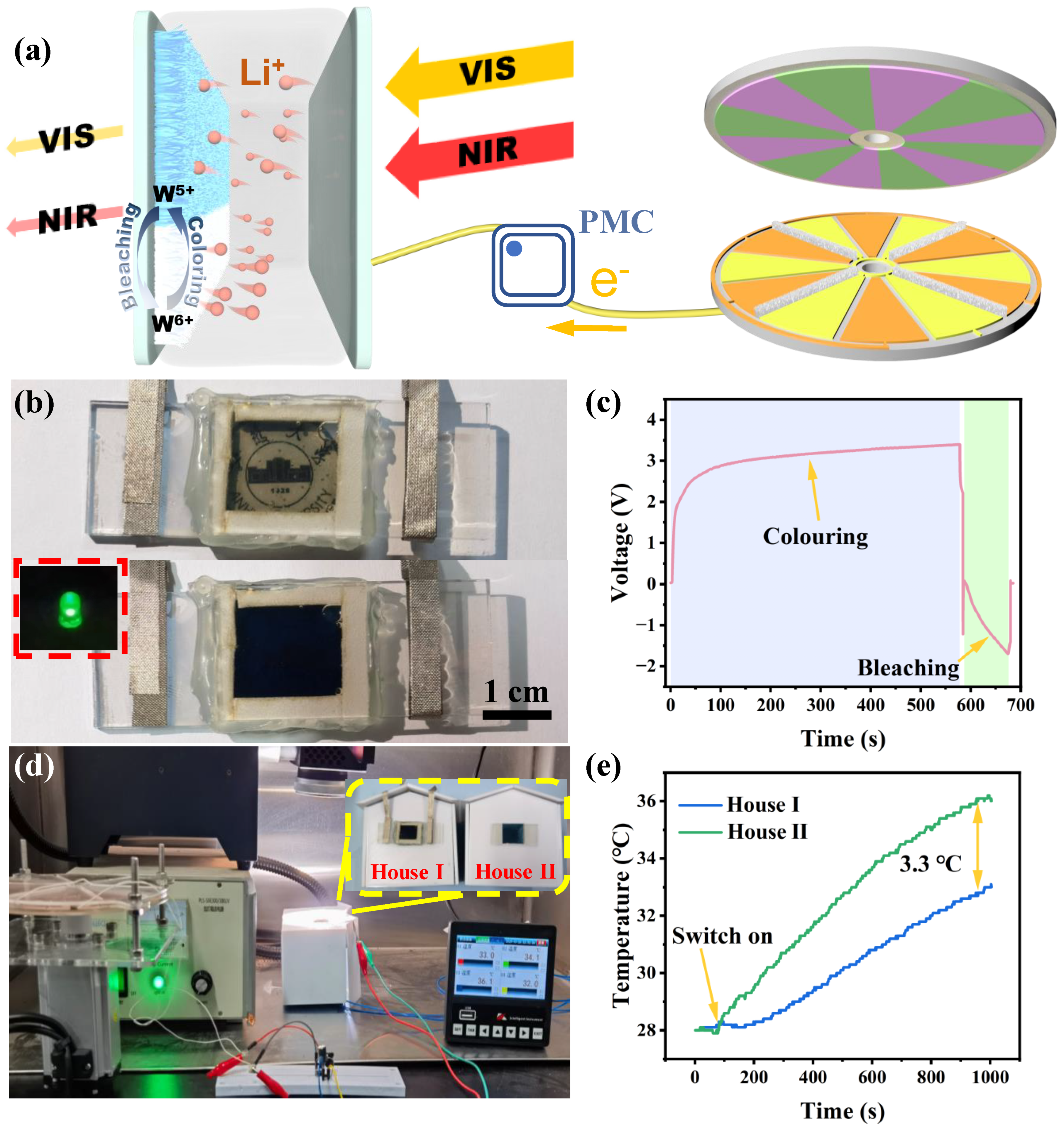

3.5. Self-Powered System Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meng, Q.; Cao, S.; Guo, J.; Wang, Q.; Wang, K.; Yang, T.; Zeng, R.; Zhao, J.; Zou, B. Sol-gel-based porous Ti-doped tungsten oxide films for high-performance dual-band electrochromic smart windows. J. Energy Chem. 2023, 77, 137–143. [Google Scholar] [CrossRef]

- Sun, W.; Liang, H.; Zhang, F.; Li, B. Theoretical study of the electroactive bistable actuator and regulation methods. Int. J. Smart Nano Mater. 2023, 14, 36–56. [Google Scholar] [CrossRef]

- Wei, J.; Li, L.; Li, R.; Liu, Q.; Yan, Z.; Chen, T. Dual-imaging-mode smart hydrogel information platform for illumination-independent covert decryption and read. Int. J. Smart Nano Mater. 2022, 13, 612–625. [Google Scholar] [CrossRef]

- Wu, J.; Yi, S.; Wang, Y.; Yao, J.; Gao, W. Polymer-based TiO2 nanocomposite membrane: Synthesis and organic pollutant removal. Int. J. Smart Nano Mater. 2021, 12, 129–145. [Google Scholar]

- Matko, V.; Brezovec, B. Improved Data Center Energy Efficiency and Availability with Multilayer Node Event Processing. Energies 2018, 11, 2478. [Google Scholar]

- Zhai, Y.; Li, J.; Shen, S.; Zhu, Z.; Mao, S.; Xiao, X.; Zhu, C.; Tang, J.; Lu, X.; Chen, J. Recent Advances on Dual-Band Electrochromic Materials and Devices. Adv. Funct. Mater. 2022, 32, 2109848. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Liu, L.; He, L.; Cao, X.; Wang, J.; Wang, Z.L. Recent Advances in Self-Powered Electrochemical Systems. Research 2021, 2021, 4673028. [Google Scholar] [CrossRef]

- Barawi, M.; De Trizio, L.; Giannuzzi, R.; Veramonti, G.; Manna, L.; Manca, M. Dual Band Electrochromic Devices Based on Nb-Doped TiO2 Nanocrystalline Electrodes. ACS Nano 2017, 11, 3576–3584. [Google Scholar]

- Barawi, M.; Veramonti, G.; Epifani, M.; Giannuzzi, R.; Sibillano, T.; Giannini, C.; Rougier, A.; Manca, M. A dual band electrochromic device switchable across four distinct optical modes. J. Mater. Chem. A 2018, 6, 10201–10205. [Google Scholar]

- Cao, S.; Zhang, S.; Zhang, T.; Yao, Q.; Lee, J.Y. A Visible Light-Near-Infrared Dual-Band Smart Window with Internal Energy Storage. Joule 2019, 3, 1152–1162. [Google Scholar]

- Liu, R.; Ren, Y.; Wang, J.; Wang, Y.; Jia, J.; Zhao, G. Preparation of Nb-doped TiO2 films by sol-gel method and their dual-band electrochromic properties. Ceram. Int. 2021, 47, 31834–31842. [Google Scholar] [CrossRef]

- Zhao, Z.; Xia, K.; Hou, Y.; Zhang, Q.; Ye, Z.; Lu, J. Designing flexible, smart and self-sustainable supercapacitors for portable/wearable electronics: From conductive polymers. Chem. Soc. Rev. 2021, 50, 12702–12743. [Google Scholar] [CrossRef]

- Huo, X.; Li, R.; Wang, J.; Zhang, M.; Guo, M. Repairable electrochromic energy storage devices: A durable material with balanced performance based on titanium dioxide/tungsten trioxide nanorod array composite structure. Chem. Eng. J. 2022, 430, 132821. [Google Scholar] [CrossRef]

- Ezhilmaran, B.; Bhat, S.V. Rationally designed bilayer heterojunction electrode to realize multivalent ion intercalation in bifunctional devices: Efficient aqueous aluminum electrochromic supercapacitor with transparent nanostructured TiO2/MoO3. Chem. Eng. J. 2022, 446, 136924. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, B.; Bai, X.; Han, Y.; Zhang, W.; Zhou, C.; Meng, H.; Chen, F.; Wu, X.; Jiang, Q.; et al. 3D Pine-Needle-Like W18O49/TiO2 Heterostructures as Dual-Band Electrochromic Materials with Ultrafast Response and Excellent Stability. Adv. Opt. Mater. 2022, 10, 2102399. [Google Scholar]

- Fan, K.; Chen, C.; Zhang, B.; Li, X.; Wang, Z.; Cheng, T.; Lin Wang, Z. Robust triboelectric-electromagnetic hybrid nanogenerator with maglev-enabled automatic mode transition for exploiting breeze energy. Appl. Energy 2022, 328, 120218. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, Z.; Chang, W.; Sun, J.; He, W.; Zeng, Q.; Guo, H.; Hu, C. Interface Static Friction Enabled Ultra-Durable and High Output Sliding Mode Triboelectric Nanogenerator. Adv. Funct. Mater. 2022, 32, 2202055. [Google Scholar] [CrossRef]

- Liu, H.; Guo, Z.H.; Xu, F.; Jia, L.; Pan, C.; Wang, Z.L.; Pu, X. Triboelectric-optical responsive cholesteric liquid crystals for self-powered smart window, E-paper display and optical switch. Sci. Bull. 2021, 66, 1986–1993. [Google Scholar]

- Rui, P.; Zhang, W.; Zhong, Y.; Wei, X.; Guo, Y.; Shi, S.; Liao, Y.; Cheng, J.; Wang, P. High-performance cylindrical pendulum shaped triboelectric nanogenerators driven by water wave energy for full-automatic and self-powered wireless hydrological monitoring system. Nano Energy 2020, 74, 104937. [Google Scholar] [CrossRef]

- Wang, C.; Guo, H.; Wang, P.; Li, J.; Sun, Y.; Zhang, D. An Advanced Strategy to Enhance TENG Output: Reducing Triboelectric Charge Decay. Adv. Mater. 2023, 35, e2209895. [Google Scholar]

- Choi, D.; Lee, Y.; Lin, Z.H.; Cho, S.; Kim, M.; Ao, C.K.; Soh, S.; Sohn, C.; Jeong, C.K.; Lee, J.; et al. Recent Advances in Triboelectric Nanogenerators: From Technological Progress to Commercial Applications. ACS Nano 2023, 17, 11087–11219. [Google Scholar] [CrossRef] [PubMed]

- Rui, P.; Zhang, W.; Wang, P. Super-Durable and Highly Efficient Electrostatic Induced Nanogenerator Circulation Network Initially Charged by a Triboelectric Nanogenerator for Harvesting Environmental Energy. ACS Nano 2021, 15, 6949–6960. [Google Scholar] [CrossRef] [PubMed]

- Song, W.-Z.; Qiu, H.-J.; Zhang, J.; Yu, M.; Ramakrishna, S.; Wang, Z.L.; Long, Y.-Z. Sliding mode direct current triboelectric nanogenerators. Nano Energy 2021, 90, 106531. [Google Scholar] [CrossRef]

- Cao, B.; Wang, P.; Rui, P.; Wei, X.; Wang, Z.; Yang, Y.; Tu, X.; Chen, C.; Wang, Z.; Yang, Z.; et al. Broadband and Output-Controllable Triboelectric Nanogenerator Enabled by Coupling Swing-Rotation Switching Mechanism with Potential Energy Storage/Release Strategy for Low-Frequency Mechanical Energy Harvesting. Adv. Energy Mater. 2022, 12, 2202627. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, Y.H.; Kim, J.W.; Lee, H.; Jung, G.; Ha, J.S. A stretchable array of high-performance electrochromic devices for displaying skin-attached multi-sensor signals. Chem. Eng. J. 2022, 429, 132289. [Google Scholar] [CrossRef]

- Qiu, W.; Feng, Y.; Luo, N.; Chen, S.; Wang, D. Sandwich-like sound-driven triboelectric nanogenerator for energy harvesting and electrochromic based on Cu foam. Nano Energy 2020, 70, 104543. [Google Scholar] [CrossRef]

- Sun, J.; Pu, X.; Jiang, C.; Du, C.; Liu, M.; Zhang, Y.; Liu, Z.; Zhai, J.; Hu, W.; Wang, Z.L. Self-powered electrochromic devices with tunable infrared intensity. Sci. Bull. 2018, 63, 795–801. [Google Scholar] [CrossRef]

- Qin, S.; Zhang, Q.; Yang, X.; Liu, M.; Sun, Q.; Wang, Z.L. Hybrid Piezo/Triboelectric-Driven Self-Charging Electrochromic Supercapacitor Power Package. Adv. Energy Mater. 2018, 8, 1800069. [Google Scholar] [CrossRef]

- Guo, W.; Cong, Z.; Guo, Z.H.; Zhang, P.; Chen, Y.; Hu, W.; Wang, Z.L.; Pu, X. Multifunctional Self-Charging Electrochromic Supercapacitors Driven by Direct-Current Triboelectric Nanogenerators. Adv. Funct. Mater. 2021, 31, 2104348. [Google Scholar]

- Huang, J.; Ren, Z.; Zhang, Y.; Fong, P.W.K.; Chandran, H.T.; Liang, Q.; Yao, K.; Tang, H.; Xia, H.; Zhang, H.; et al. Tandem Self-Powered Flexible Electrochromic Energy Supplier for Sustainable All-Day Operations. Adv. Energy Mater. 2022, 22, 2201042. [Google Scholar]

- Li, Q.; Liu, W.; Yang, H.; He, W.; Long, L.; Wu, M.; Zhang, X.; Xi, Y.; Hu, C.; Wang, Z.L. Ultra-stability high-voltage triboelectric nanogenerator designed by ternary dielectric triboelectrification with partial soft-contact and non-contact mode. Nano Energy 2021, 90, 106585. [Google Scholar] [CrossRef]

- Li, Q.; Hu, Y.; Yang, Q.; Li, X.; Zhang, X.; Yang, H.; Ji, P.; Xi, Y.; Wang, Z.L. A Robust Constant–Voltage DC Triboelectric Nanogenerator Using the Ternary Dielectric Triboelectrification Effect. Adv. Energy Mater. 2022, 13, 2202921. [Google Scholar] [CrossRef]

- Su, E.; Li, H.; Zhang, J.; Xu, Z.; Chen, B.; Cao, L.N.Y.; Wang, Z.L. Rationally Designed Anti-Glare Panel Arrays as Highway Wind Energy Harvester. Adv. Funct. Mater. 2023, 33, 2214934. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, T.; Zhang, H.; Chen, C.; Tu, X.; Fang, L.; Zhang, M.; He, W.; Wang, P. Self-Powered Dual-Band Electrochromic Supercapacitor Devices for Smart Window Based on Ternary Dielectric Triboelectric Nanogenerator. Nanomaterials 2024, 14, 229. https://doi.org/10.3390/nano14020229

Zheng T, Zhang H, Chen C, Tu X, Fang L, Zhang M, He W, Wang P. Self-Powered Dual-Band Electrochromic Supercapacitor Devices for Smart Window Based on Ternary Dielectric Triboelectric Nanogenerator. Nanomaterials. 2024; 14(2):229. https://doi.org/10.3390/nano14020229

Chicago/Turabian StyleZheng, Tianxiang, Haonan Zhang, Chen Chen, Xinbo Tu, Lin Fang, Mingjie Zhang, Wen He, and Peihong Wang. 2024. "Self-Powered Dual-Band Electrochromic Supercapacitor Devices for Smart Window Based on Ternary Dielectric Triboelectric Nanogenerator" Nanomaterials 14, no. 2: 229. https://doi.org/10.3390/nano14020229

APA StyleZheng, T., Zhang, H., Chen, C., Tu, X., Fang, L., Zhang, M., He, W., & Wang, P. (2024). Self-Powered Dual-Band Electrochromic Supercapacitor Devices for Smart Window Based on Ternary Dielectric Triboelectric Nanogenerator. Nanomaterials, 14(2), 229. https://doi.org/10.3390/nano14020229